#Tantalum Sheets & Plates Exporters

Explore tagged Tumblr posts

Text

Tantalum Sheets & Plates Exporters

All the material used for manufacturing of fittings are tested for chemical & mechanical properties.

1. Overview of Tantalum and the Industry

Tantalum is a highly corrosion-resistant metal widely used in various industries, including electronics, aerospace, medical, and chemical processing, due to its excellent conductivity and durability. Tantalum sheets and plates are essential components in the manufacturing of capacitors, reactors, heat exchangers, and other high-performance equipment.

India has emerged as a significant player in tantalum products manufacturing, with companies like Navneet Metal Corporation standing out as leading suppliers of tantalum sheets and plates. Navneet Metal Corporation offers high-quality tantalum products to meet the increasing global demand across multiple sectors. The company’s commitment to precision, quality, and customer service has allowed it to solidify its position as one of the top manufacturers in this niche market.

2. Current Trends in Tantalum Sheets & Plates Manufacturing

The demand for tantalum sheets and plates is rising, driven by the following trends:

Increased Use in Electronics: Tantalum capacitors are critical for the electronics sector, particularly in smartphones, computers, and medical devices. The growing electronics market is boosting the demand for tantalum products.

Adoption in Aerospace and Defense: Tantalum’s ability to withstand extreme temperatures makes it a preferred material for aerospace and defense applications, contributing to an increase in demand for tantalum sheets and plates.

Advancements in Manufacturing Technology: Companies like Navneet Metal Corporation are adopting advanced production techniques, including precision rolling and heat treatment, to ensure the highest quality in tantalum sheets and plates. This enhances their durability, consistency, and performance in critical applications.

Focus on Sustainable and Ethical Sourcing: Given the ethical concerns around tantalum mining, many manufacturers, including Navneet Metal Corporation, are focusing on sustainable and responsible sourcing to meet global standards for ethical trade.

3. Impact on the Industry

The increased demand for tantalum sheets and plates is significantly impacting industries such as electronics, medical devices, chemical processing, and aerospace. Navneet Metal Corporation’s high-quality products support critical manufacturing processes in these industries, driving innovation and ensuring reliability.

Electronics Sector: As one of the primary consumers of tantalum, the electronics industry benefits from high-performance capacitors that enhance device efficiency.

Chemical Processing: Tantalum's corrosion resistance is critical in chemical processing plants, where equipment must withstand harsh environments.

Medical Technology: Tantalum’s biocompatibility makes it an essential material for surgical implants and devices, improving the reliability and longevity of life-saving equipment.

Aerospace & Defense: The aerospace sector values tantalum for its strength and heat resistance in high-performance applications, improving safety and efficiency in aviation technologies.

4. Implications and Future Prospects

Growth in High-Tech Sectors: As industries like 5G, electric vehicles (EVs), and medical technology expand, the demand for tantalum sheets and plates is expected to grow. Navneet Metal Corporation is well-positioned to cater to these emerging markets with its quality products.

Rising Importance of Sustainable Practices: As global awareness of ethical mining and environmental concerns increases, manufacturers like Navneet Metal Corporation will need to further emphasize transparency and sustainability in their supply chains.

Innovation in Materials Science: Continued advancements in materials science may lead to the development of new tantalum-based alloys with enhanced properties, increasing the range of applications for tantalum sheets and plates in high-performance sectors.

5. Summary & Recommendations

Navneet Metal Corporation has established itself as a key player in India’s tantalum sheets and plates manufacturing industry. Their commitment to quality, innovation, and sustainability positions them to meet the growing global demand across various sectors such as electronics, aerospace, and chemical processing.

Recommendations for Navneet Metal Corporation:

Expand R&D Capabilities: To stay ahead of competitors, invest in research and development to innovate new tantalum alloys and improve production techniques.

Focus on Ethical Sourcing: Continue prioritizing sustainable and ethical sourcing practices to align with global industry standards and maintain customer trust.

Global Market Expansion: With growing demand worldwide, consider expanding operations to international markets to capitalize on the increasing demand for tantalum products.

Strengthen Partnerships: Building strong partnerships with key players in high-demand sectors such as electronics and aerospace will ensure a steady growth trajectory for the company.

Navneet Metal Corporation’s strong foundation in manufacturing, paired with a strategic focus on innovation and sustainability, ensures a promising future in the tantalum industry.

#Pipes & Tubes#Sheet & Plate#Round Bars#Pipe Fittings#Flanges#Fasteners#Wires#Tantalum Sheets & Plates#Tantalum Sheets & Plates Manufacturers#Tantalum Sheets & Plates Suppliers#Tantalum Sheets & Plates Stockists#Tantalum Sheets & Plates Exporters#Tantalum Sheets & Plates In India#Tantalum Sheets & Plates Manufacturers In India#Tantalum Sheets & Plates Suppliers In India#Tantalum Sheets & Plates Stockists In India#Tantalum Sheets & Plates Exporters In India

0 notes

Text

Comparing Titanium and Tantalum Alloys: Key Distinctions Unveiled

Tantalum and Titanium alloys rank as ambitious material contenders, every with residences tailored to unique commercial enterprise programs. Jay Steel Corporation stands proud as a leading Titanium and Tantalum alloy product Manufacturer. Renowned for excellence, our Titanium and Tantalum alloys, which incorporates round bars, plates, and sheets, cater to particular industrial packages. As a famous provider, stockist, and exporter, we provide a whole kind of merchandise tailored to satisfy the suitable specs of severa industries. Whether you're searching out a Titanium alloy round bar issuer, Titanium alloy plates exporters, Titanium alloy sheets exporters, or a Tantalum round bar supplier, our numerous offerings, which includes cord mesh, strips, tube & pipes, fittings, flanges, welding rods, and fasteners, exhibit unique houses.

This blog publish goals to get to the bottom of the key distinctions among Titanium and Tantalum alloys, shedding light on their respective strengths, weaknesses, and best use cases.

Titanium Alloys Products:

Titanium alloys are well-known for their fantastic electricity-to-weight ratio, corrosion resistance, and biocompatibility. Composed in particular of Titanium with small additions of various factors like aluminum and vanadium, those alloys discover first-rate packages in aerospace, clinical implants, and high-commonplace overall performance engineering. Our Titanium alloy services embody Grade 2 (GR.2), Grade 5, Grade 7 (GR.7), and Grade 12 (GR.12). Each grade is carefully crafted to meet particular corporation goals, offering extremely good energy and reliability. Our huge Titanium alloy product line consists of Wire Mesh, Round Bar, Strips, Sheets & Plates, Tube & Pipes, Fittings, Flanges, Welding Rods, and Fasteners.

Key Characteristics of Titanium Alloys:

Lightweight Strength:

Titanium alloys are celebrated for being as strong as metallic but with most effective 60% of its density. This makes them critical in aerospace engineering, in which mild-weight but long lasting materials are critical.

Corrosion Resistance:

The corrosion resistance of Titanium alloys is remarkable, especially in competitive environments at the side of seawater or chemical processing. This quality extends the lifespan of components and decreases renovation costs.

Biocompatibility:

Titanium's biocompatibility makes it a remarkable choice for clinical implants, which incorporates dental implants and joint replacements. The frame actually accepts Titanium, minimizing the chance of rejection.

On The Other Hand Tantalum Alloys

Tantalum alloys, however, show off precise characteristics that make them precious in unique packages, specifically within the electronics and chemical industries. As a main supplier, we convey to you Tantalum alloy products designed to excel in electronic components and chemical processing applications.

Key Characteristics of Tantalum Alloys:

High Melting Point:

Tantalum boasts an exceptionally high melting factor, making it suitable for programs concerning excessive temperatures. This property is leveraged inside the manufacturing of digital additives and superalloys.

Chemical Inertness:

Tantalum alloys are fantastically inert to chemical reactions, making them resistant to corrosion. This exceptional is exploited inside the production of chemical processing device, in which exposure to corrosive materials is commonplace.

Excellent Capacitance:

Tantalum capacitors are broadly utilized in electronics because of their excessive capacitance in keeping with quantity. This makes them valuable in compact electronic devices where space is at a premium.

Comparing Titanium and Tantalum Alloys:

While both Titanium and Tantalum alloys show off super residences, their applications range extensively based on the particular necessities of industries.

Titanium alloys shine in aerospace and medical programs, due to their light-weight strength and biocompatibility.

Tantalum alloys locate their niche in digital components and chemical processing equipment, excelling in excessive-temperature and chemically competitive environments.

Final Words!

When deciding between Titanium and Tantalum Alloys for your challenge, it is vital to keep in mind the precise necessities. At Jay Steel Corporation, as a outstanding Titanium alloy product supplier, Titanium alloy round bar supplier, Titanium alloy plates exporters, and Titanium alloy sheets exporters, we take satisfaction in providing a numerous and tremendous range. We also are a good Tantalum round bar supplier and Tantalum product supplier. Our dedication to excellence guarantees that clients can make informed selections tailored to their specific needs. Reach out to us nowadays at [email protected] or [email protected] to explore our sizable product portfolio. Experience firsthand the distinction of our alloys in movement, as we are committed to offering exceptional solutions in your unique requirements.

#Titanium Alloy Product Supplier#Titanium Alloy Plates Exporters#Tantalum Round Bar Supplier#Tantalum Sheets Exporters

0 notes

Text

Tantalum Sheets & Plates Supplier and Exporter in India | Reliable Overseas

Discover high-quality tantalum sheets and plates from Reliable Overseas, India's leading supplier and exporter. We provide durable, corrosion-resistant tantalum products for diverse industries. Contact us today for competitive pricing and reliable service.

0 notes

Text

🌟 Elevate Your Projects with Quality Tantalum Sheets! 🌟

Looking for top-notch tantalum sheets for your industrial needs? Look no further! ✨ Ozair Trade Link ✨ is your trusted stockiest for premium tantalum sheets that guarantee excellence in performance.

🔍 Why Choose Ozair Trade Link? ✅ Unmatched Quality: Our tantalum sheets meet the highest industry standards, ensuring durability and reliability for your projects. ✅ Extensive Inventory: Explore a wide range of sizes and thicknesses to find the perfect match for your specific requirements. ✅ Competitive Prices: Enjoy cost-effective solutions without compromising on quality. We believe in providing value for your investment.

🚀 Key Features: 🛠️ High Heat Resistance: Ideal for applications in extreme temperature environments. 🌐 Corrosion Resistance: Ensure longevity and stability in corrosive conditions. 💼 Versatile Applications: From aerospace to electronics, our tantalum sheets excel in various industries.

🌈 Experience the Ozair Difference: Our commitment to excellence and customer satisfaction sets us apart. Join countless satisfied clients who trust Ozair Trade Link for their tantalum sheet needs.

📞 Contact us today to discuss your requirements and place your order. Your success is our priority! 💼✨

1 note

·

View note

Link

Get the best-quality Tantalum R05240 Sheet & Plate made by assuring all quality standards from Indias most trusted Tantalum products stockist, suppliers, and exporter. Visit our website or call on +91 9619440863 to know more.

0 notes

Link

We offer our customers the top of the line solid items and administrations with the most elevated level of specialized aptitude and business benefit amid generation and after deals. In the middle of this, we lay solid accentuation on the quality confirmation, ecological insurance, monetary development, and human regard as they are the crucial keys to progress. All these have helped us to make and supply top of the line items, for example, Titanium Pipes, Titanium Pipe Suppliers, Titanium Suppliers, Titanium Sheets, Titanium Plates, Titanium Round Bars, Stainless Steel Pipes and Tubes, SS Pipes and Tubes, Stainless Steel Sheets and Plates, Carbon Steel, Carbon Steel Pipes and Tubes, Alloy Steel Pipes, Alloy Steel Pipes and Tubes, Mild Steel Pipes and Tubes, Monel Round Bars, Inconel Pipes, Hastelloy Pipes, Incoloy Pipes, Tantalum Sheet, Tantalum Rods, Super Duplex Steel Pipes, Super Duplex Steel Sheets, Titanium Alloy Tubes, Titanium Alloy Plates, Pipe Fittings, SS Flanges, MS Flanges, Exporters in India.

0 notes

Text

Tantalum Sheets & Plates In India

Navneet Metal Corporation Tantalum Alloy Sheets are adaptable materials with many purposes in business. They are routinely used in flying, auto, and clinical applications, thinking about their fortitude, strength, and stalling block. Tantalum plates are delivered utilising pure tantalum metal, which is a change metal from the periodic table. It has a high combining point and is remarkably insusceptible to oxidation. Its low warm conductivity makes it suitable for use in radiator linings, heat exchangers, electrochemical cells, and astounding blends.

Tantalum sheets are unpretentious, level pieces of tantalum metal that are dependably used in applications that require phenomenal disintegrating obstruction, high-temperature strength, and astounding mechanical properties. Tantalum is a fascinating, thick, and versatile metal that is astoundingly impenetrable to disintegration and can conquer ludicrous temperatures.

Tantalum Sheets can be used in different applications, including flying parts, for instance, fuel tanks, engine parts, valves, and radiators; vehicle parts like chambers and smoke structures; clinical supplements like pacemakers; stream equipment like syphons and blowers; substance overseeing gear, for instance, evaporators and sanitizers; buyer things like kitchenware and contraptions; devices including workstations, phones, tablets, and game control neighbourhoods; making applications like rings or pendants; and, incredibly, military contraptions like assistance plating or cautious shields. We also make Tantalum nuts, Tantalum round bars, etc.

One of the essential benefits of using Tantalum Turns over various materials is its coarseness-to-weight degree, which moves beyond high temperatures without sabotaging its reliability, which is light yet adequate. Additionally, it has astounding disintegrating resistance, so it won't rust or separate when familiar with moistness or planned substances, making Tantalum R05200 Sheets ideal for use in present-day cycles, including undesirable liquids or gases like hydrochloric horrible or sulfuric heartbreaking. It's also non-enchanting, so it won't restrain fragile electronic stuff or connect with fields used in clinical diagnostics machines like X-point support scanners. It has amazing electrical conductivity, which makes Tantalum HR Sheets ideal for use in electrical parts where a stream needs to stream straightforwardly without checking or impedance from various materials in the plan. Different kinds of things are available, similar to SS 15-5 PH washers, Hastelloy C2000 Pipes, etc.

Tantalum sheets appear in a few evident plans. The all-around saw type is tempered tantalum sheet-free by heat treatment. This sheet type is rarely used because of its adaptability and ability to be welded easily. There is nearly a new moved tantalum sheet, which is more touchy in any event and passes forward through higher temperatures than set sheets. Moreover, misleadingly cut tantalum sheets have been treated with materials produced to make unique models or anticipate a shallow level. An electro-cleaned tantalum sheet has been cleaned using expertise to ensure smooth fulfilment.

For more information

Visit our website: https://www.navneetcorp.com/

Call us on: 8369128023

Email us: [email protected]

#Tantalum Sheets & Plates#Tantalum Sheets & Plates Manufacturers#Tantalum Sheets & Plates Suppliers#Tantalum Sheets & Plates Stockists#Tantalum Sheets & Plates Exporters

0 notes

Text

All you need to know about Tantalum and its applications

Are you curious about the metal that powers modern technology? Look no further than Tantalum, a crucial element with unique properties that make it essential for many applications.

In this blog post, we will closely understand each and everything of Tantalum along with its uses (Applications) in various Industries!

What is Tantalum, and what are its uses?

Tantalum is a rare and hard metal that has a variety of applications in different industries. It is highly resistant to corrosion, heat, and wear, making it an ideal material for high-performance equipment. Tantalum is also known for its biocompatibility, which makes it useful in medical implants and devices. It is commonly used in the electronic, aerospace, medical, and chemical industries.

Characteristics of Tantalum Round Bars

Tantalum round bars are a popular choice for many applications due to their unique characteristics. Some of the main characteristics of Tantalum round bars include:

High melting point: Tantalum has one of the highest melting points of all metals, making it ideal for use in high-temperature applications.

High density: Tantalum has a high density, which provides excellent strength and durability.

Corrosion resistance: Tantalum is highly resistant to corrosion, making it suitable for use in harsh chemical environments.

Biocompatibility: Tantalum is biocompatible and non-toxic, making it suitable for use in medical implants and devices.

Excellent conductivity: Tantalum has excellent electrical conductivity, making it useful in electronic applications.

Ductility: Tantalum is a ductile metal, which means it can be easily formed into different shapes and sizes.

Low thermal expansion: Tantalum has a low coefficient of thermal expansion, which means it can withstand changes in temperature without warping or cracking.

Overall, Tantalum round bars are an excellent choice for applications that require strength, durability, and corrosion resistance in harsh environments. At Jay Steel Corporation, we offer Tantalum round bars in various sizes and lengths to meet your specific needs.

Tantalum Element Facts

Tantalum element facts are it is known for its high melting point, which is approximately 3,017 degrees Celsius. It has a density of 16.6 grams per cubic centimeter and is highly ductile, meaning it can be drawn into a thin wire without breaking. Tantalum is also non-toxic, making it ideal for medical applications.

Tantalum is Available in various forms with Jay Steel Corporation!

Tantalum Round Bars

Tantalum Square Bars

Tantalum Flat Bar

Hex Bar

Rectangular Bar

Forged Bar

Chemical Properties of Tantalum

Tantalum is a transition metal with the atomic number 73. It has a high resistance to corrosion, making it suitable for use in harsh chemical environments. Tantalum can also withstand high temperatures, making it useful in high-temperature applications.

At Jay Steel Corporation, we offer a wide range of Tantalum products, including a Tantalum round bars, Tantalum sheets and plates, and Tantalum tubes and pipes. Our products are manufactured using the highest quality materials and state-of-the-art technology to ensure their durability and reliability. Moreover, we also do export these Tantalum Round bars to various countries such as the united arab emirates, Kuwait, the united states of America, Egypt, Qatar, the kingdom of Saudi Arabia, Jordan, Africa, Malaysia, Europe, Australia, Iran, and Iraq.

Standards and Specifications of Tantalum Round Bars!

Specifications: ASTM B365, ASME SB365

Dimensions: EN, DIN, JIS, ASTM, BS, ASME, AISI

Round Bar Size: 3mm ~ 800mm

Square Bar Size: 4mm * 4mm ~ 100mm * 100mm

Flat Bar Size: 2mm ~ 100mm

Hex Bar Size: 2mm ~ 100mm

Thickness: 50 mm to 6000 mm Long

Length: 1 To 6 Meters, Custom Cut Length

Grade: R05200, R05240, R05252, R05255, R05400

Applications Uses of Tantalum Round Bars

Tantalum has a variety of uses in different industries. Here are some of the most common applications of Tantalum:

Electronics: Tantalum is a critical component of electronic devices, such as capacitors and high-power resistors. Tantalum capacitors are widely used in smartphones, tablets, computers, and other electronic devices due to their high capacitance and reliability.

Aerospace: Tantalum is used in jet engine components, such as turbine blades, because of its high strength, durability, and resistance to heat. It is also used in rocket nozzles, heat exchangers, and other aerospace equipment.

Medical: Tantalum's biocompatibility and corrosion resistance make it an ideal material for medical implants, such as dental implants, joint replacements, and pacemaker leads.

Chemical Processing: Tantalum's resistance to corrosion and high temperatures make it useful in chemical processing equipment, such as reactors, heat exchangers, and pipes.

Tantalum Round Bars Offered by Jay Steel Corporation;

At Jay Steel Corporation, we offer a wide range of Tantalum products to meet your business needs. Here are some of the products we offer:

Tantalum Round Bar: Our Tantalum round bars are available in different diameters and lengths to meet your specific requirements. They are used in various applications, such as chemical processing, aerospace, and electronics.

Tantalum Sheet and Plate: We offer Tantalum sheets and plates in different thicknesses and sizes to meet your needs. They are commonly used in chemical processing equipment, heat exchangers, and medical implants.

Tantalum Tubes and Pipes: Our Tantalum tubes and pipes are available in different sizes and lengths to meet your requirements. They are commonly used in chemical processing equipment, heat exchangers, and aerospace applications.

Conclusion

Tantalum is a rare and hard metal with unique properties that make it crucial in modern technology. At Jay Steel Corporation, we are proud to be the leading Tantalum products manufacturers, suppliers, stockists, and exporters in Mumbai, India. With our high-quality products and commitment to customer satisfaction, we are dedicated to providing the best solutions to our customers' needs. Whether you are in the electronics, aerospace, medical, or chemical processing industry, we have the Tantalum products you need to succeed.

#Nuts and Bolts manufacturers#Fasteners Manufacturers#SS Fasteners#Stainless Steel Products#pressure vessel manufacturer#Steel Product manufacturers in India#Flanges Types#Pipe and tube manufacturers#Nickel alloy products#Titanium alloy products

0 notes

Text

Tantalum sheets Importers, stockiest and suppliers in India

We are offering a comprehensive range of Tantalum Sheet.

Features:

Purity ≥99.95% or 99.99%

High durability

Reliability

Purity:

99.95 min or 99.99 min conformity with ASTM B 708 98

Size:

Thickness (mm), Width (mm), Length (mm)

Foil 0.03-0.07 30-200>50

Sheet 0.07-0.5 30- 700 30-2000

Board 0.5-1050-1000 50-3000

1 note

·

View note

Link

We offer our customers the top of the line solid items and administrations with the most elevated level of specialized aptitude and business benefit amid generation and after deals. In the middle of this, we lay solid accentuation on the quality confirmation, ecological insurance, monetary development, and human regard as they are the crucial keys to progress. All these have helped us to make and supply top of the line items, for example, Titanium Pipes, Titanium Pipe Suppliers, Titanium Suppliers, Titanium Sheets, Titanium Plates, Titanium Round Bars, Stainless Steel Pipes and Tubes, SS Pipes and Tubes, Stainless Steel Sheets and Plates, Carbon Steel, Carbon Steel Pipes and Tubes, Alloy Steel Pipes, Alloy Steel Pipes and Tubes, Mild Steel Pipes and Tubes, Monel Round Bars, Inconel Pipes, Hastelloy Pipes, Incoloy Pipes, Tantalum Sheet, Tantalum Rods, Super Duplex Steel Pipes, Super Duplex Steel Sheets, Titanium Alloy Tubes, Titanium Alloy Plates, Pipe Fittings, SS Flanges, MS Flanges, Exporters in India.

0 notes

Text

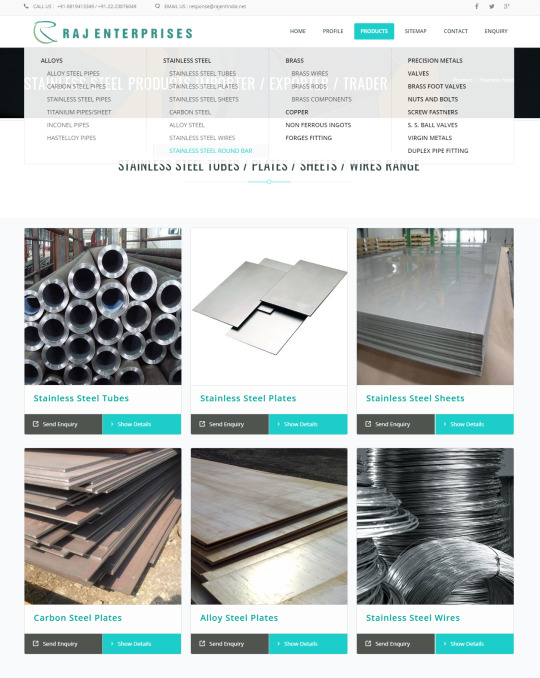

Stainless Steel Plates, Stainless Steel Tubes, Stainless Steel Wires, Mumbai, India

Raj Enterprises, Mumbai, Are a Renowned Importer, Exporter, Trader And Stockist of Mumbai, India.

Importing, Exporting And Stocking Of Stainless Steel Products, Nickel Alloys, SS Pipes, MS Pipes, Alloys, Alloy Steel Pipes, Carbon Steel Pipes, Stainless Steel Pipes, Titanium Pipes, Titanium Sheet, Inconel Pipes, Hastelloy Pipes, Stainless Steel, Stainless Steel Tubes, Stainless Steel Plates, Stainless Steel Sheets, Carbon Steel Plates, Alloy Steel Plates, Stainless Steel Wires, Stainless Steel Round Bar, Steel Coils, 316 Stainless Steel CR Coils, 304 Stainless Steel CR Sheets, 316 Flat Bars, Stainless Steel Designer Sheets, 316 SS Designer Sheets, SS Designer Sheets, Stainless Steel Checkered Sheet, SS Gold Mirror Sheet, Non Ferrous Metals, Chequered Plate, Duplex Steel Sheets, 316 Stainless Steel Slitting Coil, Slitting Coil, Duplex Sheet, Seamless SS Tubes, Brass, Brass Wires, Brass Rods, Brass Round Bar, Brass Soft Wire, Brass Components, Copper, Copper Wire, Air Conditioning Copper Tubes, Earthing Copper Rods, Copper Strips Bus Bars, Copper Plates, Copper Circle, Copper Alloys Products, Copper Tubes, Copper Strips, Copper Earthing Plates, Copper Coils, Copper Flats, Copper Rods, Copper Nickle Rod, Non Ferrous Ingots, Non Ferrous Alloy Ingots, Antimony Ingot 99.65, Antimony Ingot, Nickel Inco, Backed Bismuth Ingots, Tin Ingots, Forges Fitting, Weld Neck Flange, Slip On Forged Flanges, Ring Joint Flange, Forged Flanges, Virgin Metals, Precision Metals, Valves, Manifold Valves, Gauge Valves, Stainless Steel 316 Needle Valves, Diaphragm Valve Cast Iron, Gate Valve Bronze, Heavy Brass Gate Valve, Swing Check Valve Brass, Check Valve (Spring) Brass, 3 Way Port Ball Valve Brass, Mini Ball Valve Brass, Root Valves, Brass Foot Valves, Nuts And Bolts, Screw Fastners, S.S.Ball Valves, Duplex Pipe Fitting, Stainless Steel Duplex Butt Weld Fitting, Duplex Steel Buttweld Fittings, Alloy Pipe, Beryllium Copper Alloy Products, Tantalum Plates, Tantalum Strip, Tantalum Tubes, Nimonic Alloy 90, Molybdenum Bolts, Hex Bolts, Tungsten Bolts, Nuts Fasteners, Mumbai, Maharashtra, India

0 notes

Text

Tarnum Plate - Company Overview

Tarnum Plate - Company Overview

The Annual Summary Report of Industry Sales of Tantalum, Inc. is prepared by KPMG, a global management consulting firm that regularly conducts industry research surveys. The Annual Summary Report provides an up-to-date summary of sales and revenues collected throughout the year. The report provides a region- wise analysis such as revenues, current, growth, profit, and forecasted trends, study of emerging consumer markets, and global expansion opportunities. The company conducted its first survey in 1996 and has been conducting surveys since then.

The focus of this report is on the tantalum plate project. The project encompasses a broad range of activities related to the development and growth of the Company. This includes both the planning and the implementation phases of the project as well as the activities related to financing and working capital requirements. The overall aim of the project is to develop cost-effective production methods, enhance productivity and efficiency of the Company and reduce costs, all of which will have a positive impact on the Company's bottom line.

Many companies in the tantalum plate industry operate through joint ventures with other companies in the United States and Canada. In the last few years many large corporations and businesses in the semiconductor processing sector have established strategic alliances with semiconductor producers in the united states and Canada. These collaborations provide substantial cost savings, increased market exposure, and the sharing of resources between the Company and the associated players. The emergence of these joint ventures has contributed to the overall competitiveness of the Company in the China and tantalum plate markets.

As with all major announcements regarding the Company's business strategy, timing is of the essence. For the Company to emerge successfully from the tantalum plate market it must have a competitive landscape that is in sync with its core business processes and business models. To do this, the Company must develop a winning team that will help to execute its plan of attack and build a strong customer base.

In this Q2 Fiscal Year 2011 annual tantalum plate research report issued by The Conference Board of the Chemical Industry (CCI), the Company released its Strategic Planning Study detailing its plans for the next five years and beyond. Included in the report were a three-part strategic overview, two part performance reporting and one part management strategy planning. The first strategic overview identified three areas of focus for the Company. These areas focused on the growth of the Company, its future product portfolio, and the personnel who will manage those products and the overall business leadership. The second area of focus detailed how the Company will reduce costs, make an investment in its personnel, enhance productivity, improve its quality, increase its market share, strengthen its partnerships, and create new financial opportunities.

In the Performance Reporting segment, the Company provided its full year and half year completed cost performance and earnings results and a summary of its strategic and operational strategies. This Q2 fiscal year 2011 quarterly report provided an overview of its Executive Management team and the changes that have occurred over the last three years. The company also outlined its current drug development activities and the pipeline of its future drug development activities. Finally, the company reviewed its financial performance and provided a comment on its credit risk.

The research team projects that the Tantalum Plate market size will grow from XXX in 2020 to XXX by 2027, at an estimated CAGR of XX. The base year considered for the study is 2020, and the market size is projected from 2020 to 2027.

The prime objective of this report is to help the user understand the market in terms of its definition, segmentation, market potential, influential trends, and the challenges that the market is facing with 10 major regions and 50 major countries. Deep researches and analysis were done during the preparation of the report. The readers will find this report very helpful in understanding the market in depth. The data and the information regarding the market are taken from reliable sources such as websites, annual reports of the companies, journals, and others and were checked and validated by the industry experts. The facts and data are represented in the report using diagrams, graphs, pie charts, and other pictorial representations. This enhances the visual representation and also helps in understanding the facts much better.

By Market Players: H.C. Starck Western Metal Fangda Group ATI Metal Global Advanced Metals Alcoa Ningxia Orient Baoji Zhongpu Stanford Advanced Materials Zhuzhou Jiabang Plansee Group

By Type Foil Sheet Board

By Application Machinery Chemical Industry Aerospace & Military Industry Other

By Regions/Countries: North America United States Canada Mexico

East Asia China Japan South Korea

Europe Germany United Kingdom France Italy Russia Spain Netherlands Switzerland Poland

South Asia India Pakistan Bangladesh

Southeast Asia Indonesia Thailand Singapore Malaysia Philippines Vietnam Myanmar

Middle East Turkey Saudi Arabia Iran United Arab Emirates Israel Iraq Qatar Kuwait Oman

Africa Nigeria South Africa Egypt Algeria Morocoo

Oceania Australia New Zealand

South America Brazil Argentina Colombia Chile Venezuela Peru Puerto Rico Ecuador

Rest of the World Kazakhstan

Points Covered in The Report The points that are discussed within the report are the major market players that are involved in the market such as market players, raw material suppliers, equipment suppliers, end users, traders, distributors and etc. The complete profile of the companies is mentioned. And the capacity, production, price, revenue, cost, gross, gross margin, sales volume, sales revenue, consumption, growth rate, import, export, supply, future strategies, and the technological developments that they are making are also included within the report. This report analyzed 12 years data history and forecast. The growth factors of the market is discussed in detail wherein the different end users of the market are explained in detail. Data and information by market player, by region, by type, by application and etc, and custom research can be added according to specific requirements. The report contains the SWOT analysis of the market. Finally, the report contains the conclusion part where the opinions of the industrial experts are included.

Key Reasons to Purchase To gain insightful analyses of the market and have comprehensive understanding of the global market and its commercial landscape. Assess the production processes, major issues, and solutions to mitigate the development risk. To understand the most affecting driving and restraining forces in the market and its impact in the global market. Learn about the market strategies that are being adopted by leading respective organizations. To understand the future outlook and prospects for the market. Besides the standard structure reports, we also provide custom research according to specific requirements.

The report focuses on Global, Top 10 Regions and Top 50 Countries Market Size of Tantalum Plate 2016-2021, and development forecast 2022-2027 including industries, major players/suppliers worldwide and market share by regions, with company and product introduction, position in the market including their market status and development trend by types and applications which will provide its price and profit status, and marketing status & market growth drivers and challenges, with base year as 2020.

Key Indicators Analysed Market Players & Competitor Analysis: The report covers the key players of the industry including Company Profile, Product Specifications, Production Capacity/Sales, Revenue, Price and Gross Margin 2016-2021 & Sales by Product Types. Global and Regional Market Analysis: The report includes Global & Regional market status and outlook 2022-2027. Further the report provides break down details about each region & countries covered in the report. Identifying its production, consumption, import & export, sales volume & revenue forecast. Market Analysis by Product Type: The report covers majority Product Types in the Tantalum Plate Industry, including its product specifcations by each key player, volume, sales by Volume and Value (M USD). Markat Analysis by Application Type: Based on the Tantalum Plate Industry and its applications, the market is further sub-segmented into several major Application of its industry. It provides you with the market size, CAGR & forecast by each industry applications. Market Trends: Market key trends which include Increased Competition and Continuous Innovations. Opportunities and Drivers: Identifying the Growing Demands and New Technology Porters Five Force Analysis: The report will provide with the state of competition in industry depending on five basic forces: threat of new entrants, bargaining power of suppliers, bargaining power of buyers, threat of substitute products or services, and existing industry rivalry.

COVID-19 Impact Report covers Impact of Coronavirus COVID-19: Since the COVID-19 virus outbreak in December 2019, the disease has spread to almost every country around the globe with the World Health Organization declaring it a public health emergency. The global impacts of the coronavirus disease 2019 (COVID-19) are already starting to be felt, and will significantly affect the Tantalum Plate market in 2021. The outbreak of COVID-19 has brought effects on many aspects, like flight cancellations; travel bans and quarantines; restaurants closed; all indoor/outdoor events restricted; over forty countries state of emergency declared; massive slowing of the supply chain; stock market volatility; falling business confidence, growing panic among the population, and uncertainty about future.

For more details contact as https://www.reportmines.com/contact-us.php

0 notes

Text

Inconel 625 Price, UNS N06625, Alloy 625 Price, Incoloy 625 Suppliers

Inconel 625 Suppliers is utilized both for its high quality and extraordinary fluid consumption opposition. The quality of Inconel 625 is essentially a strong arrangement impact from molybdenum and columbium. Nickel Alloy 625 has fantastic weldability. The coordinating filler metals are regularly utilized for disparate metal joining and to weld the watery erosion composite AL-6XN®. Inconel 625 UAE, Bahrain, Italy, Indonesia, Malaysia, USA, Singapore, Philippines, Mexico, China, Brazil, Peru, Nigeria, Kuwait, Jordan, Oman, Muscat, Dubai, Thailand, Venezuela, Iran, Germany, UK, Canada, Russia, Turkey, Australia, New Zealand, Sri Lanka, Vietnam, South Africa, India.

Material Notes:

Niobium content above incorporates tantalum. A nickel-chromium-molybdenum amalgam with an expansion of niobium that demonstrations with the molybdenum to solidify the compound's framework and along these lines give high quality without a fortifying warmth treatment. The composite opposes a wide scope of seriously destructive conditions and is particularly impervious to setting and cleft erosion. Utilized in substance handling, aviation and marine building, contamination control hardware, and atomic reactors. Standard item structures are round, pads, producing stock, expelled segment, pipe, tube, plate, sheet, strip, and wire.

Inconel 625! is a nickel-chromium-molybdenum amalgam that is utilized for its high quality, high strength, and superb consumption opposition. The quality of compound 625 is gotten from the solidifying impact of molybdenum and niobium on its nickel-chromium framework. In spite of the fact that the amalgam was produced for high-temperature quality, its exceptionally alloyed organization likewise gives a critical degree of general erosion opposition.

Enterprises and Applications

Inconel 625 is utilized in an assortment of businesses, including car, marine, aviation, oil and gas, concoction handling and atomic. Regular end-use applications incorporate warmth exchangers, howls, extension joints, exhaust frameworks, latches, speedy associated fittings and numerous different applications requiring quality and opposition against forceful destructive situations.

#Protection of Inconel 625 Price

Compound 625 has great protection from oxidation and scaling at high temperatures. At 1800°F, scaling obstruction turns into a critical factor in administration. It is better than numerous other high-temperature composites under cyclic warming and cooling conditions. The blend of the alloyed components in composite Inconel 625 empowers it to withstand a wide assortment of extreme destructive situations. There is no assault in mellow situations, for example, new and seawater, unbiased pH conditions, and soluble media. The chromium substance of these composite outcomes in better obstruction than oxidizing conditions. The high molybdenum substance makes amalgam 625 exceptionally impervious to setting and cleft consumption.

Inconel 625 is a nickel-base compound utilized both for its high quality and exceptional fluid consumption obstruction. The quality of amalgam 625 is principally a strong arrangement impact from molybdenum and columbium. Inconel 625! has superb weldability and is much of the time used to weld AL-6XN® combination. Coordinating filler metals are likewise used to join disparate metals.

Stock

625 Plate, 625 Round Bar, 625 Sheet, 625 Weld Wire Suppliers

Normal Trade Names

Inconel® 625, Alloy 625, Nickel 625

Particulars

AMS 5599, AMS 5666, AMS 5837, ASME SB 443 Gr 1, ASME SB 446 Gr 1, ASTM B 443 Gr 1, ASTM B 446 Gr 1, EN 2.4856, ISO 15156-3, NACE MR0175-3, UNS N06625, Werkstoff 2.4856

Highlights

High jerk crack quality

Oxidation impervious to 1800°F

Great weariness obstruction

Astounding weldability

Exceptional protection from chloride setting and hole consumption

Resistant to chloride particle stress erosion breaking

Impervious to seawater under both streaming and stale conditions and under fouling

Applications

Airship ducting frameworks

Stream motor fumes frameworks

Motor push reverser frameworks

Roars and extension joints

Turbine cover rings

Flare stacks

Seawater segments

Difference Between Inconel 625 and 718

Difference Between Inconel 600 and 625

#Difference Between (INCONEL 625 vs 718)

Inconel!

625 (ALLOY 625 UNS N06625)

Basic Trade Names :

Inconel 625, Chronin® 625, Altemp® 625, Haynes® 625, Nickelvac® 625, Nicrofer® 6020

Inconel ® 625 is a nonmagnetic, consumption and oxidation safe, nickel-base combination. Composite 625 has high quality and durability in the temperature go cryogenic to 2000°F (1093°C) which is gotten generally from the strong arrangement impacts of the headstrong metals, columbium, and molybdenum, in a nickel-chromium framework. Amalgam 625 has astounding exhaustion quality and stress - consumption breaking protection from chloride particles.

INCONEL® 625 LCF is a variation of INCONEL® 625. LCF represents Low Cycle Fatigue. This implies the amalgam has improved cycle weakness properties and better warm exhaustion opposition. In different viewpoints, for example, substance structure and other mechanical properties the composite is like INCONEL® 625. The composite is for example utilized for roars, air ship depletes and development joints.

Compound Analysis of ALLOY 625 (UNS N06625)

Basic Names: Inconel 625®, Chronin® 625, Altemp® 625, Haynes® 625, Nickelvac® 625, Nicrofer® 6020

#INCONEL 718 (UNS N07718)

Inconel Alloy 718 is austenitic nickel-based superalloy. Inconel 718 is assigned as UNS N07718 and Werkstoff Number 2.4668. Inconel 718 is otherwise called Nicrofer 5219, Superimphy 718, Haynes 718, Pyromet 718, Superman 718. also, Udimet 718. Inconel 718 Chemistry is Nickel 52%, Chromium 19%, Iron, 18%, Columbium 5%, Molybdenum 3%, Titanium 1%. Combination 718 is for the most part utilized in Gas turbine motors channels, cryogenic tanks, springs and clasp, and engine segments. For most applications, Alloy 718/Inconel 718 is determined as arrangement tempered and precipitation solidified. Inconel Alloy 718 is solidified by the precipitation of auxiliary stages.

Inconel 625 Price Per Kg

#Inconel 625 PriceOriginPrice in INR

(per kg)Price in USD

(per kg)Price in Euro

(per kg)

#Inconel 625 Price in IndiaIndianRs 3200/-$46€39

#Inconel 625 Price in JapanJapaneseRs 3500/-$51€43

#Inconel 625 Price in UK / EuropeEuropeanRs 3600/-$52€44

#Inconel 625 Price in USAUSARs 3800/-$55€47

Individuals likewise scan for:

Inconel 625 and 718, machining Inconel 625 and 718, Inconel 625 718 examination, Inconel 625 versus 718 machinability, contrast between Inconel 625 and 718, distinction between Inconel 625 and Inconel 718, Inconel 625 or 718, what is the distinction between Inconel 625 and 718, Inconel 625 versus 718, combination 625 versus 718

#Difference Between Inconel 600 and 625

You might be acquainted with the Inconel® group of high-nickel compounds. This arrangement of composites is outstanding for its presentation in extraordinary warmth conditions—which makes each Inconel® variation phenomenally well known for use in heater applications, for example, heat-treating or toughening steel.

Be that as it may, what contrasts exist between the different definitions of Inconel®? This is an inquiry that Marlin's specialists are posed much of the time.

To help answer this inquiry, here's a speedy correlation of these three high-heat claims to fame metals:

#Difference Between (INCONEL 600 vs 625)

When considering Inconel 625 versus Inconel 600, there are a serious number of contrasts that can be seen. For example, Inconel 625 has a nickel content between the scope of at least 58% and this implies it subsequently falls in the 330 and 600 compounds. Then again, Alloy 600, has a nickel substance of at least 72%.

Understanding Inconel 625 versus Inconel 600, Grade 600 is very well known and at high temperatures, it displays radiant protection from oxidation. It additionally shows five-star protection from carburization, it has great elasticity, it offers generally excellent warm stun opposition and it likewise appears better than expected protection from oxidation. On the off chance that UNS N06600 is pressure assuaged, it indicates magnificent protection from chloride stress consumption splitting. UNS N06625 has generally excellent hole erosion opposition, it shows sublime downer burst quality, it has superb chloride setting obstruction and it likewise displays amazing weakness obstruction. As contrasted and different composites of Inconel, Grade 625 is entirely simple to weld.

#Difference Between (UNS N06600 vs UNS N06625) Grade

Incoloy 600 is utilized, all things considered, for warmth treating plate and bushels, as heater parts and in the warmth treating industry it is utilized for suppressing. Incoloy 625 is utilized in seawater hardware, flare stacks, stream motor depletes and in light of the fact that it is impervious to high temperatures and different synthetic concoctions, it is additionally utilized in compound plant gear.

Whatever the reasons that you may look at Inconel 625 versus Inconel 600, one thing you can make sure of is that we are driving exporters, providers, stockists, and producers of Inconel 625 cylinders, just as Inconel 600 cylinders. We produce our Grade 625 and 600 funnels from the best crude materials. To guarantee that our Inconel 600 funnels fulfill worldwide guidelines, we run them through intense quality tests, for example, Hardness Test, Flaring Test, Micro and MacroTest, Tensile of Area Test, Flattening Test, Spectro Analysis, Pitting Resistance Test, Intergranular Corrosion Test, Positive Material Identification Testing, and so on. It is simply after our Inconel 625 pipes and cylinders have passed these inflexible quality tests, do we at that point dispatch them to our customers, everywhere throughout the globe.

#(UNS N06625 and Also UNS N06852) and (UNS N06219) Pipe and TubeSummary

UNS N06625 along with UNS N06852 nickel-chromium-molybdenum-columbium metals and UNS N06219 nickel-chromium-molybdenum-silicon metal in the kind of cold-worked seamless tube and pipe. UNS N06625 services and products have been supplied in annealed Grade inch and also remedy annealed Grade two whereas UNS N06219 and also UNS N06852 have been in option annealed state just. The chemical screening will likely be executed on every kind of substance and will adapt to the chemical makeup constraints given such as carbon monoxide, manganese, chromium, potassium and phosphorus, chromium, tantalum, columbium, cobalt, molybdenum, iron, and aluminum, and titanium, aluminum, and nickel. The substance will experience Atomic testing and also will adjust to the essential area temperature electrical components such as tensile strength, yield strength, and elongation based upon heat therapy utilized and for example, little diameter and also light-walled tube. Each tube or pipe will experience hydrostatic screening and also will adapt to this allowable fiber pressure and also be analyzed using a non-destructive electric evaluation as approved.

Inch. Scope

1.1 This specification2 handles nickel-chromium-molybdenum-columbium metals ( UNS N06852 and also UNS N06852) along with nickel-chromium-molybdenum-silicon metal (UNS N06219)3 at the kind of cold-worked seamless tube and pipe. The typical conditions for tube and pipe are all insured by Specification B829.

1.1.1 UNS N06625 goods have been supplied in just two ranges of distinct heat-treated requirements:

1.1.1.1 Grade inch (annealed)--Substance is commonly used in service temperatures as much as 1100°F (593°C).

1.1.1.2 Grade two (alternative annealed)--Substance is commonly used in service temperatures over the 1100°F (593°C) if an immunity to creep and rust is demanded.

NOTE inch: Hot-working or even reannealing can change qualities somewhat, based upon working temperatures and history.

1.1.2 Alloys UNS N06219 and also UNS N06852 are provided at the solution annealed state just.

1.2 The values mentioned in inch-pound components should be considered ordinary. The values supplied in parentheses are mathematical conversions to SI models which can be supplied for information only and aren't thought ordinary.

1.3 The next precautionary caveat pertains solely into the evaluation methods section, Section 9, with the specification: This standard doesn't purport to tackle all the security issues, if any, connected with its usage. It's the obligation of an individual with this benchmark to get acquainted with hazards including those diagnosed from the right Safety Data Sheet (SDS) with this particular product/material provided by the producer, to set proper protection, overall health, and ecological factors, and also decide the applicability of regulatory limitations before usage.

1.4 This Global benchmark Was Designed according to internationally recognized principles about standardization based from the Decision on Rules to the Growth of International Standards, Guides, and also advice issued from the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Paperwork

Expectations

B829 Specification for Common Requirements for Nickel and Nickel Alloys Seamless Pipe and Tube

B880 Specification to Basic Requirements for Chemical Check Always Investigation Restrictions for Nickel, Nickel Alloys and Cobalt Alloys

E112 Check Techniques for Determining Average Grain Size

G-28 Exam Strategies for Detecting Susceptibility to Intergranular Corrosion in Wrought, Nickel-Rich, Chromium-Bearing Alloys

G-48 Exam Strategies for Pitting and Crevice Corrosion Resistance of Stainless Steels and Related Alloys with Usage of Ferric Chloride Solution

Software UNS N06625:

UNS N06625 can be really a nickel-chromium-molybdenum metal with niobium additional. This allows high durability devoid of strengthening heating therapy. The metal features a broad selection of seriously polluted surroundings and can be resistant to pitting and crevice corrosion. Found in compound processing, aerospace and maritime technology, pollution-control gear, and atomic reactors.

Keywords and Phrases

Annealing - Fixing - Nickel-Chromium-Molybdenum Alloys - Fixing Pipes And Tubes

ICS Code

ICS Variety Code 77.150.40 (Nickel and chromium goods )

UNSPSC Code

UNSPSC Code 11101711(Non-ferrous metal )

0 notes

Link

We offer our customers the top of the line solid items and administrations with the most elevated level of specialized aptitude and business benefit amid generation and after deals. In the middle of this, we lay solid accentuation on the quality confirmation, ecological insurance, monetary development, and human regard as they are the crucial keys to progress. All these have helped us to make and supply top of the line items, for example, Titanium Pipes, Titanium Pipe Suppliers, Titanium Suppliers, Titanium Sheets, Titanium Plates, Titanium Round Bars, Stainless Steel Pipes and Tubes, SS Pipes and Tubes, Stainless Steel Sheets and Plates, Carbon Steel, Carbon Steel Pipes and Tubes, Alloy Steel Pipes, Alloy Steel Pipes and Tubes, Mild Steel Pipes and Tubes, Monel Round Bars, Inconel Pipes, Hastelloy Pipes, Incoloy Pipes, Tantalum Sheet, Tantalum Rods, Super Duplex Steel Pipes, Super Duplex Steel Sheets, Titanium Alloy Tubes, Titanium Alloy Plates, Pipe Fittings, SS Flanges, MS Flanges, Exporters in India.

0 notes

Link

We offer our customers the top of the line solid items and administrations with the most elevated level of specialized aptitude and business benefit amid generation and after deals. In the middle of this, we lay solid accentuation on the quality confirmation, ecological insurance, monetary development, and human regard as they are the crucial keys to progress. All these have helped us to make and supply top of the line items, for example, Titanium Pipes, Titanium Pipe Suppliers, Titanium Suppliers, Titanium Sheets, Titanium Plates, Titanium Round Bars, Stainless Steel Pipes and Tubes, SS Pipes and Tubes, Stainless Steel Sheets and Plates, Carbon Steel, Carbon Steel Pipes and Tubes, Alloy Steel Pipes, Alloy Steel Pipes and Tubes, Mild Steel Pipes and Tubes, Monel Round Bars, Inconel Pipes, Hastelloy Pipes, Incoloy Pipes, Tantalum Sheet, Tantalum Rods, Super Duplex Steel Pipes, Super Duplex Steel Sheets, Titanium Alloy Tubes, Titanium Alloy Plates, Pipe Fittings, SS Flanges, MS Flanges, Exporters in India.

0 notes

Text

Alloy Steel, Seamless Alloy Steel Pipe, Alloy Steel Tee, Alloy Steel Concentric Reducer, Mumbai, India

Raj Enterprises, Mumbai, Are a Renowned Importer, Exporter, Trader And Stockist of Mumbai, India

http://www.rajentindia.net/alloy-steel.html

Importing, Exporting And Stocking Of Stainless Steel Products, Nickel Alloys, SS Pipes, MS Pipes, Alloys, Alloy Steel Pipes, Carbon Steel Pipes, Stainless Steel Pipes, Titanium Pipes, Titanium Sheet, Inconel Pipes, Hastelloy Pipes, Stainless Steel, Stainless Steel Tubes, Stainless Steel Plates, Stainless Steel Sheets, Carbon Steel Plates, Alloy Steel Plates, Stainless Steel Wires, Stainless Steel Round Bar, Steel Coils, 316 Stainless Steel CR Coils, 304 Stainless Steel CR Sheets, 316 Flat Bars, Stainless Steel Designer Sheets, 316 SS Designer Sheets, SS Designer Sheets, Stainless Steel Checkered Sheet, SS Gold Mirror Sheet, Non Ferrous Metals, Chequered Plate, Duplex Steel Sheets, 316 Stainless Steel Slitting Coil, Slitting Coil, Duplex Sheet, Seamless SS Tubes, Brass, Brass Wires, Brass Rods, Brass Round Bar, Brass Soft Wire, Brass Components, Copper, Copper Wire, Air Conditioning Copper Tubes, Earthing Copper Rods, Copper Strips Bus Bars, Copper Plates, Copper Circle, Copper Alloys Products, Copper Tubes, Copper Strips, Copper Earthing Plates, Copper Coils, Copper Flats, Copper Rods, Copper Nickle Rod, Non Ferrous Ingots, Non Ferrous Alloy Ingots, Antimony Ingot 99.65, Antimony Ingot, Nickel Inco, Backed Bismuth Ingots, Tin Ingots, Forges Fitting, Weld Neck Flange, Slip On Forged Flanges, Ring Joint Flange, Forged Flanges, Virgin Metals, Precision Metals, Valves, Manifold Valves, Gauge Valves, Stainless Steel 316 Needle Valves, Diaphragm Valve Cast Iron, Gate Valve Bronze, Heavy Brass Gate Valve, Swing Check Valve Brass, Check Valve (Spring) Brass, 3 Way Port Ball Valve Brass, Mini Ball Valve Brass, Root Valves, Brass Foot Valves, Nuts And Bolts, Screw Fastners, S.S.Ball Valves, Duplex Pipe Fitting, Stainless Steel Duplex Butt Weld Fitting, Duplex Steel Buttweld Fittings, Alloy Pipe, Beryllium Copper Alloy Products, Tantalum Plates, Tantalum Strip, Tantalum Tubes, Nimonic Alloy 90, Molybdenum Bolts, Hex Bolts, Tungsten Bolts, Nuts Fasteners, Mumbai, Maharashtra, India

0 notes