#Synthetic Yarn Suppliers

Explore tagged Tumblr posts

Text

Global Synthetic Yarn Market Dynamics: End-Use Industry Trends and Regional Forecast to 2029

The synthetic yarn market is projected to grow from USD 234.1 billion in 2024 to USD 300.5 billion by 2029, at a CAGR of 5.1% during the forecast period. Synthetic yarn has a wide range of applications such as clothing, home textiles, aerospace components, automotive parts and other applications. The growing demand from apparels & home furnishings is driving the growth of synthetic yarn market…

#Synthetic Yarn Market Opportunities#Synthetic Yarn Market Trends#Synthetic Yarn Producers#Synthetic Yarn Suppliers

0 notes

Text

Understanding the Different Grades of PP Multifilament Yarn

Polypropylene (PP) multifilament yarn is a versatile and widely used material across various industries, including textiles, packaging, and agricultural applications. As a synthetic fiber derived from the polymerization of propylene, PP yarn is known for its durability, lightweight properties, and resistance to moisture and chemicals. Understanding the different grades of PP multifilament yarn is crucial for manufacturers, suppliers, and end-users to make informed choices that suit their specific requirements.

The Basics of PP Multifilament Yarn

PP filament yarn consists of numerous filaments twisted together to form a single strand. The multifilament structure enhances the yarn's strength and elasticity while maintaining its flexibility. These yarns are available in a range of grades, each tailored for specific applications and industries. The quality and characteristics of PP multifilament yarn can vary significantly based on the production process, raw materials used, and intended end use.

Common Applications of PP Multifilament Yarn

PP multifilament yarns find applications in various fields due to their unique properties:

Textiles: In the textile industry, Multifilament yarns in India are used to produce fabrics for garments, upholstery, and industrial textiles. Their resistance to moisture makes them ideal for outdoor fabrics and sportswear.

Ropes and Twines: The strength and durability of PP multifilament yarns make them suitable for manufacturing ropes and twines used in fishing, agriculture, and construction.

Geotextiles: These yarns are used in geotextiles for soil stabilization, erosion control, and drainage applications, helping to improve the longevity and stability of structures.

Packaging: In the packaging industry, PP multifilament yarns are utilized to create strong and lightweight bags, nets, and containers, enhancing the protection of products during transportation and storage.

Grades of PP Multifilament Yarn

PP multifilament yarns can be categorized into different grades based on several factors, including denier, tensile strength, elongation, and specific applications. Understanding these grades helps manufacturers and end-users select the most appropriate yarn for their needs.

1. Low-Denier vs. High-Denier

Denier is a unit of measurement that expresses the thickness of the yarn. Low-denier yarns (typically below 300 denier) are finer and more suitable for lightweight applications, such as textiles and delicate fabrics. They offer a softer feel and better drape, making them ideal for clothing and interior fabrics.

High-denier yarns (above 300 denier) are thicker and more robust, making them suitable for heavy-duty applications. These yarns are commonly used in manufacturing ropes, tarpaulins, and industrial fabrics that require enhanced strength and durability.

2. Tensile Strength

Tensile strength refers to the maximum amount of tensile (pulling) stress that a material can withstand without breaking. Different grades of PP multifilament yarns exhibit varying tensile strengths based on their production processes and raw material quality.

High tensile strength yarns are essential for applications requiring durability and resistance to wear and tear, such as in the production of ropes and nets. PP multifilament yarn manufacturer often specify tensile strength in their product descriptions, allowing users to select the appropriate grade for their specific applications.

3. Elongation at Break

Elongation at break measures how much a yarn can stretch before breaking. This property is vital for applications where flexibility and stretchability are essential. Different grades of PP multifilament yarns have varying elongation characteristics, with some being designed for high elasticity while others prioritize strength over stretch.

In industries like textiles, where garments need to accommodate movement, a higher elongation at break is desirable. Conversely, applications like ropes may benefit from lower elongation, ensuring the material retains its shape and does not stretch excessively under load.

Factors Influencing the Selection of PP Multifilament Yarn

When selecting the right grade of PP multifilament yarn, several factors come into play. Here are some essential considerations:

End Use: Understanding the intended application is crucial. For example, if the yarn is intended for clothing, a low-denier, softer yarn with good draping qualities would be ideal. In contrast, heavy-duty applications require high-denier, high-strength yarns.

Environmental Conditions: The environment in which the yarn will be used can also influence the choice of grade. For instance, if the yarn will be exposed to harsh chemicals or UV radiation, selecting a grade with enhanced resistance to these conditions is critical.

Cost Considerations: While high-quality yarns may come at a premium, it’s essential to balance cost with performance. Identifying the most suitable grade that meets performance requirements without overspending is a key consideration for manufacturers and buyers.

The Role of Manufacturers of PP Multifilament Yarn

In India, the demand for PP multifilament yarn is on the rise, driven by the growing textile and packaging industries. Various PP multifilament yarn manufacturers in India are working to meet this demand by offering a wide range of grades and specifications. These manufacturers often invest in advanced technologies and quality control processes to ensure their products meet international standards.

Working closely with manufacturers allows businesses to customize yarns according to specific needs. For instance, a manufacturer may produce specialized yarn grades that cater to unique requirements in industrial textiles or custom rope production. Additionally, reputable manufacturers often provide technical support and guidance to help clients select the best grade for their applications.

Conclusion

Understanding the different grades of PP multifilament yarn is essential for anyone involved in industries that utilize this versatile material. By grasping the significance of denier, tensile strength, elongation, and specific applications, manufacturers and end-users can make informed decisions when selecting the appropriate yarn for their needs.

As the demand for PP filament yarn continues to grow, particularly in India, it is crucial to partner with reliable PP multifilament yarn manufacturers who can provide high-quality products tailored to specific applications. With the right knowledge and resources, businesses can harness the unique properties of PP multifilament yarn to enhance their products and meet the demands of an ever-evolving market. Frequently Asked Questions (FAQs)

How is the quality of PP multifilament yarn determined? The quality of PP multifilament yarn is determined by factors such as tensile strength, elongation, denier, and resistance to environmental factors like UV light and moisture. Manufacturers often conduct tests to ensure the yarn meets industry standards.

Is PP multifilament yarn suitable for outdoor use? Yes, many grades of PP multifilament yarn are suitable for outdoor use, especially those treated for UV resistance. These yarns are commonly used in products like tarpaulins, outdoor furniture, and awnings.

What are the common applications of PP multifilament yarn? Common applications include textiles for clothing and upholstery, industrial fabrics, ropes, nets, and agricultural products. Its versatility allows it to be used in a wide range of products across various industries.

0 notes

Text

Exploring TexPro's Export-Import Data & Trade Analysis Capabilities

In today’s globalized textile and apparel industry, staying competitive requires businesses to have access to accurate and up-to-date trade data. Export-import activities are at the core of global supply chains, and understanding the dynamics of trade flows can help businesses make informed decisions about sourcing, procurement, and market expansion.

TexPro, a leading market intelligence tool, offers an in-depth look into global trade activities, helping textile and apparel businesses gain a competitive edge. With its robust export-import data and trade analysis capabilities, TexPro empowers businesses to analyze trade flows, monitor international markets, and make data-driven decisions for long-term success.

1. Comprehensive Export-Import Data for Textile and Apparel Markets

TexPro provides businesses with access to extensive export-import data for over 100 reporting countries and 150 partnering countries, covering a wide range of commodities and products in the textile and apparel sector. By utilizing detailed trade data, businesses can understand the movement of goods, identify new sourcing opportunities, and monitor their competitors’ activities.

Key Features of TexPro’s Export-Import Data:

Global coverage: Access export-import data for key textile markets such as China, India, the U.S., the EU, and emerging markets.

Product-specific insights: Analyze trade flows by specific commodities, such as cotton, yarn, synthetic fibres, and finished apparel, providing tailored insights into your area of interest.

HS code tracking: Monitor trade data at the HS code level, covering over 1,000 product categories relevant to the textile and apparel industry.

Country-to-country analysis: Understand bilateral trade flows between countries, helping you make informed sourcing and market expansion decisions.

For example, if a business is looking to source cotton from India, TexPro’s export-import data can reveal the volume of cotton exported to different countries, allowing businesses to identify reliable suppliers and assess pricing trends.

Explore TexPro’s export-import data for real-time trade insights. Request a Free Demo.

2. Analyzing Trade Flow Patterns and Trends

Understanding trade flow patterns is crucial for optimizing supply chains, forecasting demand, and identifying new market opportunities. TexPro’s trade analysis capabilities enable businesses to track trade flows across global markets, providing insights into the volume, value, and direction of goods being traded.

How TexPro Helps Analyze Trade Flows:

Volume and value tracking: Monitor the quantity and monetary value of goods being traded, giving you a clear picture of global demand and supply trends.

Historical data: Access historical trade data to analyze long-term trends and predict future market movements.

Trade route analysis: Identify the most efficient trade routes for exporting and importing goods, helping you optimize logistics and reduce transportation costs.

For instance, if the demand for synthetic fibres is increasing in a particular region, TexPro’s trade analysis can help businesses identify growth opportunities and develop strategies for entering or expanding in that market.

3. Identifying Emerging Markets and New Opportunities

TexPro’s trade analysis capabilities go beyond tracking existing trade flows; they also help businesses identify emerging markets and new opportunities. By analyzing trade data across different regions and product categories, businesses can pinpoint high-growth markets and adapt their strategies to capitalize on these opportunities.

Emerging Market Insights with TexPro:

Growth indicators: Use TexPro to track year-on-year growth rates in specific countries or regions, allowing you to identify markets with increasing demand for textile products.

Market entry strategies: Analyze import data to identify regions with growing demand for specific textiles or apparel, helping you formulate an effective market entry strategy.

Competitor analysis: Monitor your competitors’ trade activities to understand their market positioning and identify gaps where your business can gain an advantage.

For example, if TexPro reveals that the demand for technical textiles is rapidly growing in Southeast Asia, your business can explore partnerships, suppliers, or distribution channels in that region to expand its market reach.

Take advantage of TexPro’s trade analysis to discover new markets. Explore TexPro Now.

4. Tariff and Non-Tariff Barriers: Navigating Global Trade Challenges

One of the challenges businesses face when trading globally is navigating the complex web of tariffs, duties, and non-tariff barriers. These factors can significantly impact the cost and feasibility of importing and exporting goods. TexPro offers in-depth insights into tariff structures, non-tariff barriers, and trade agreements, helping businesses minimize risks and maximize profitability.

TexPro’s Trade Barriers Analysis:

Tariff rate tracking: Stay informed about changes in tariff rates for over 80 reporting countries, covering a wide range of textile and apparel products.

Non-tariff barriers: Monitor non-tariff barriers such as quotas, licensing requirements, and trade restrictions that can affect your business’s ability to trade in certain markets.

Trade agreement insights: Analyze the impact of regional trade agreements, such as NAFTA, TPP, or EU free trade agreements, on your business operations.

For instance, if a new trade agreement reduces tariffs on textiles imported from a particular country, TexPro can provide real-time insights into how these changes will affect sourcing costs, enabling businesses to adjust their strategies accordingly.

Stay ahead of trade challenges with TexPro’s tariff and trade barrier insights. Explore the Market Intelligence Tool.

5. Customized Reports and Export-Import Analysis

TexPro’s export-import data and trade analysis tools are highly customizable, allowing businesses to generate tailored reports based on their unique needs. Whether you are a manufacturer looking to optimize your supply chain or a retailer exploring new markets, TexPro’s customized reports provide actionable insights to guide your decision-making process.

Benefits of TexPro’s Customized Reports:

Product-specific analysis: Focus your analysis on specific products or raw materials that are critical to your business, ensuring that you have the most relevant data.

Region-specific reports: Generate reports based on specific regions or countries, providing localized insights into trade dynamics.

Competitive benchmarking: Compare your company’s export-import activities with those of your competitors, helping you stay ahead of the competition.

With TexPro’s customizable features, businesses can gain a deeper understanding of trade dynamics in the textile industry, enabling them to make more strategic decisions when it comes to sourcing, procurement, and market expansion.

6. Strategic Decision-Making with TexPro’s Trade Insights

The ability to make strategic decisions based on reliable data is key to success in the textile and apparel industry. TexPro’s export-import data and trade analysis capabilities empower businesses to make informed choices regarding their supply chains, market entries, and competitive positioning.

How TexPro Drives Strategic Decision-Making:

Supply chain optimization: Use export-import data to optimize your supply chain by identifying cost-effective sourcing regions, monitoring trade flows, and predicting market demand.

Pricing strategies: Analyze global trade data to understand market pricing trends and set competitive prices for your products.

Risk management: Stay informed about changes in trade regulations, tariffs, and trade barriers, allowing you to manage risks and adapt to new market conditions.

By leveraging TexPro’s comprehensive trade analysis tools, textile and apparel businesses can navigate the complexities of international trade and make strategic decisions that enhance profitability and growth.

Conclusion: TexPro as a Game-Changer for Export-Import Analysis

TexPro’s export-import data and trade analysis capabilities provide textile and apparel businesses with the insights they need to navigate the global market effectively. Whether you are looking to optimize your supply chain, explore new markets, or stay ahead of competitors, TexPro’s in-depth trade data offers the actionable intelligence necessary for success.

By leveraging TexPro’s powerful tools, businesses can identify new opportunities, mitigate risks, and gain a competitive edge in the dynamic and ever-changing textile industry.

0 notes

Text

The Benefits of Learning to Spin Your Own Yarn

In the world of crafting, few skills are as rewarding as learning to spin your own yarn. Not only does it deepen your connection to your projects, but it also opens up a realm of creative possibilities. In this post, we’ll explore the benefits of spinning your own yarn, with a focus on technical yarn, and discuss how materials like polyester cotton knitted yarns can enhance your creations. We’ll also touch on resources from SD Polytech for those looking to dive deeper into yarn spinning.

1. Enhanced Creativity

Spinning your own yarn allows you to experiment with various fibers, textures, and colors. Whether you prefer the softness of wool or the sleekness of polyester cotton knitted yarns, you can create unique blends that reflect your personal style. By controlling the spin and ply, you can achieve the exact look and feel you desire for your projects.

2. Quality Control

When you spin your own yarn, you have complete control over the quality of the fibers you use. This is particularly beneficial when working with technical yarns, as you can select high-quality materials that suit your specific needs. Using materials from trusted suppliers, such as those offered by SD Polytech, ensures you have access to top-notch fibers designed for durability and performance.

3. Sustainability

Creating your own yarn can be a more sustainable practice compared to purchasing commercially produced options. By sourcing natural fibers or upcycling old materials, you can reduce waste and make eco-friendly choices. Even when working with synthetic options like polyester cotton, understanding the production process allows you to make informed decisions that benefit the environment.

4. Personal Connection to Your Craft

Spinning yarn is an art that fosters a deep connection to the crafting process. The act of spinning can be meditative and relaxing, providing a sense of accomplishment as you transform raw fibers into a usable product. This personal touch adds value to your projects, making them not just items but pieces of your journey.

5. Skill Development

Learning to spin yarn improves your overall crafting skills. It requires practice and patience, enhancing your dexterity and understanding of yarn properties. As you become more skilled, you’ll gain insights into how different fibers behave, which is invaluable when selecting the right yarn for your projects.

6. Community Engagement

The spinning community is vibrant and welcoming. By learning to spin your own yarn, you’ll have the opportunity to connect with fellow crafters, attend workshops, and participate in local spinning groups. These interactions can lead to lasting friendships and collaborative projects, enriching your crafting experience.

7. Versatility in Projects

Spinning your own yarn means you can create yarn tailored to specific projects. Whether you’re knitting, crocheting, or weaving, having a customized yarn allows you to push your creative boundaries. You can create textured yarns for blankets or smooth, fine yarns for delicate garments—all suited to your style and needs.

Conclusion

Learning to spin your own yarn is a fulfilling and enriching experience that enhances your crafting journey. From fostering creativity to ensuring quality, the benefits are numerous. Whether you choose to work with traditional fibers or innovative options like polyester cotton knitted yarns, resources from SD Polytech can guide you in your spinning endeavors. Embrace this skill and discover a new world of possibilities in your yarn crafts!

Also Read:

The Importance of Quality Control in Cotton Yarn Manufacturing

The Role of Traditional Techniques in Modern Cotton Yarn Production

Originally published at https://sdpolytech.blogspot.com

0 notes

Text

Discovering Quality: Organic Cotton Yarn Wholesale and Polyester Yarn Manufacturers in India

The textile industry is undergoing a significant transformation, with sustainability and quality at the forefront of consumer choices. Among the growing trends, organic cotton yarn and polyester yarn have gained considerable attention. This article delves into the wholesale market for organic cotton yarn and highlights some of the leading polyester yarn manufacturers in India.

Understanding Organic Cotton Yarn

Organic cotton yarn is made from cotton grown without synthetic pesticides, herbicides, or fertilizers, adhering to environmentally sustainable practices. This type of yarn has become increasingly popular among consumers seeking eco-friendly options for their projects.

Benefits of Organic Cotton Yarn:

Eco-Friendly: Grown using sustainable farming practices, organic cotton yarn minimizes environmental impact.

Chemical-Free: It’s free from harmful chemicals, making it a safer choice for sensitive skin and health-conscious consumers.

Superior Quality: Organic cotton yarn is often softer and more durable than conventional cotton yarn, providing better texture and longevity in finished products.

Wholesale Options for Organic Cotton Yarn

When looking for organic cotton yarn wholesale, various manufacturers in India specialize in providing quality products at competitive prices. These wholesalers cater to businesses, artisans, and hobbyists, ensuring a steady supply of organic cotton yarn in different weights and colors.

Leading Manufacturers of Polyester Yarn in India

Polyester yarn is widely used in the textile industry due to its strength, durability, and versatility. Several manufacturers in India specialize in producing high-quality polyester yarn that meets various industrial standards.

Key Features of Top Polyester Yarn Manufacturers:

Diverse Product Range: Manufacturers offer various types of polyester yarn, including filament, textured, and specialty yarns.

Innovative Technologies: Many manufacturers employ advanced spinning techniques and technology to produce high-quality yarns that cater to the evolving needs of the textile market.

Sustainability Initiatives: With increasing awareness about environmental issues, many polyester yarn manufacturers are incorporating recycled materials into their production processes.

Why Choose Polyester Yarn?

Durability: Polyester yarn is known for its strength and resilience, making it suitable for a wide range of applications, from clothing to home textiles.

Color Retention: It retains color well after washing, making it an ideal choice for vibrant and long-lasting fabric.

Cost-Effectiveness: Generally more affordable than natural fibers, polyester yarn offers an economical option for manufacturers and consumers alike.

Finding Reliable Suppliers

When searching for organic cotton yarn or polyester yarn in India, it's essential to choose reliable suppliers who maintain high quality and ethical manufacturing practices. Here are a few tips for sourcing yarn:

Research Manufacturers: Look for manufacturers with a solid reputation in the market. Online directories, trade shows, and industry reviews can be helpful.

Request Samples: Before making a bulk purchase, request samples to assess the quality of the yarn.

Check Certifications: For organic cotton yarn, ensure that the supplier has relevant certifications proving the yarn's organic status.

Evaluate Pricing: Compare prices from different suppliers to ensure you’re getting a competitive rate without compromising quality.

Conclusion

The demand for organic cotton yarn and high-quality polyester yarn is on the rise as consumers prioritize sustainability and quality in their textile choices. With a variety of manufacturers and wholesalers available in India, sourcing these materials has never been easier. By embracing organic cotton yarn for eco-friendly projects and choosing reputable polyester yarn manufacturers, businesses and consumers can contribute to a more sustainable textile industry while ensuring high-quality products. Whether you’re a manufacturer, designer, or hobbyist, there’s a world of possibilities waiting in the yarn market.

+919999561776 [email protected] Shiv Nagar, Krishanpura, Gohana Road, Panipat - 132103 https://guptafibres.com/

#fiber weaving products#best quality dyed yarns#cotton fiber yarn#cheapest place to buy yarn#best polyester yarn companies in india#cotton weaving yarn#recycled cotton yarn#buy sustainable yarn online in india#buy weaving yarn online in india#weaving yarn

0 notes

Text

PP Fibrillated Yarn: Enhancing Durability in Woven Fabrics

In the world of textiles, the quest for durability and resilience has led to the emergence of innovative materials that enhance the longevity of products. One such material making waves in the industry is PP (Polypropylene) fibrillated yarn. Renowned for its strength and versatility, PP Fibrillated Yarn Price is revolutionizing the way woven fabrics are manufactured, providing a myriad of benefits for various applications. In this blog, we will explore what PP fibrillated yarn is, its unique properties, its applications, and how it enhances the durability of woven fabrics.

Understanding PP Fibrillated Yarn

PP fibrillated yarn is a type of synthetic yarn produced from polypropylene, a thermoplastic polymer that is widely used in various industries. The term "fibrillated" refers to the process of creating numerous thin fibers from a single strand of yarn. This process results in a network of interconnected fibers that provide enhanced strength and durability.

The unique structure of fibrillated yarn gives it a larger surface area compared to traditional yarns, allowing for PP Fibrillated Yarn Suppliers with other materials. This characteristic is particularly advantageous in woven fabrics, where the integrity and strength of the weave are crucial for performance.

Properties of PP Fibrillated Yarn

PP fibrillated yarn possesses several properties that contribute to its effectiveness in enhancing the durability of woven fabrics:

1. High Tensile Strength

One of the standout features of PP fibrillated yarn is its high tensile strength. This property allows it to withstand significant stress and strain, making it ideal for applications that require durable materials. Woven fabrics made with PP fibrillated yarn can endure heavy loads without compromising their structural integrity.

2. Moisture Resistance

PP fibrillated yarn is naturally resistant to moisture, which prevents mold and mildew growth in textiles. This moisture resistance is crucial for maintaining the quality and longevity of woven fabrics, especially in outdoor applications where exposure to the elements is common.

3. UV Stability

Exposure to sunlight can degrade many synthetic materials over time. However, PP fibrillated yarn has good UV stability, allowing it to maintain its strength and color even when subjected to prolonged sun exposure. This makes it an excellent choice for outdoor textiles, such as tarps and canopies.

4. Lightweight

Despite its strength, PP fibrillated yarn is lightweight, which is an essential characteristic for many textile applications. This property enables the creation of durable yet manageable fabrics, reducing the overall weight of the final product without sacrificing performance.

5. Flexibility and Softness

PP fibrillated yarn retains a degree of flexibility and softness, making it suitable for applications where comfort is essential. This balance between durability and softness allows manufacturers to create woven fabrics that are not only tough but also pleasant to the touch.

Applications of PP Fibrillated Yarn

The versatility of PP fibrillated yarn allows it to be used in a variety of applications across different industries:

1. Agricultural Textiles

In the agricultural sector, PP fibrillated yarn is commonly used to produce netting, shade cloths, and ground covers. The strength and durability of the yarn ensure that these products can withstand harsh environmental conditions while protecting crops and promoting healthy growth.

2. Geotextiles

PP fibrillated yarn is also used in geotextiles, which are fabrics used in civil engineering and landscaping projects. These textiles provide soil stabilization, erosion control, and drainage solutions. The high tensile strength and moisture resistance of PP fibrillated yarn enhance the durability and effectiveness of geotextiles in various applications.

3. Industrial Fabrics

In industrial settings, PP fibrillated yarn is employed to create durable fabrics for products such as tarps, bags, and containers. The ability to withstand heavy loads and environmental stresses makes it a preferred choice for manufacturers seeking reliable and long-lasting materials.

4. Furniture and Upholstery

PP fibrillated yarn is also making its way into the furniture and upholstery markets. Its combination of strength, softness, and resistance to wear makes it an excellent choice for producing durable fabrics that can withstand daily use while maintaining their aesthetic appeal.

5. Sports and Outdoor Gear

In the world of sports and outdoor equipment, PP fibrillated yarn is used to create strong, lightweight fabrics for items such as tents, backpacks, and outdoor gear. The moisture resistance and UV stability of the yarn ensure that these products remain functional and visually appealing, even with frequent exposure to the elements.

Enhancing Durability in Woven Fabrics

The integration of PP fibrillated yarn into woven fabrics significantly enhances their durability through several mechanisms:

1. Improved Bonding

The fibrillated structure of the yarn increases the surface area available for bonding during the weaving process. This leads to stronger inter-fiber connections, resulting in woven fabrics that can withstand higher levels of stress and strain.

2. Resistance to Wear and Tear

Woven fabrics made with PP fibrillated yarn exhibit superior resistance to abrasion and wear. This characteristic is particularly important for products subjected to constant movement or friction, ensuring that they maintain their integrity over time.

3. Longevity of Outdoor Textiles

The moisture and UV resistance of PP fibrillated yarn contribute to the longevity of outdoor woven fabrics. These properties prevent deterioration from environmental factors, allowing products to retain their functionality and appearance for extended periods.

4. Versatility in Design

The flexibility and softness of PP fibrillated yarn allow for creative designs in woven fabrics. Manufacturers can create products that are not only durable but also visually appealing, meeting consumer demands for both performance and aesthetics.

Conclusion

PP fibrillated yarn is a game-changer in the textile industry, offering a unique combination of strength, moisture resistance, and versatility. Its ability to enhance the durability of woven fabrics makes it an invaluable material for a wide range of applications, from agriculture to outdoor gear.

As the demand for durable and reliable textiles continues to grow, the adoption of PP fibrillated yarn is likely to expand. Fibrillated Polypropylene Yarn who embrace this innovative material can create products that meet the evolving needs of consumers while contributing to sustainability and performance.

In a world where durability is paramount, PP fibrillated yarn stands out as a solution that not only enhances the longevity of woven fabrics but also opens the door to new possibilities in design and application. Whether for outdoor use, industrial products, or agricultural needs, the advantages of PP fibrillated yarn make it a compelling choice for manufacturers and consumers alike.

Frequently Asked Questions (FAQs):

What advantages does Singhal Industries' PP fibrillated yarn offer for woven fabrics? Singhal Industries' PP fibrillated yarn provides exceptional tensile strength, moisture resistance, and UV stability, making it ideal for enhancing the durability of woven fabrics. This yarn ensures that the products maintain their integrity even in harsh conditions, making it a preferred choice for various applications in agriculture, outdoor gear, and industrial textiles.

How does Singhal Industries ensure the quality of its PP fibrillated yarn? At Singhal Industries, quality control is paramount. The company employs advanced manufacturing processes and rigorous testing standards to ensure that its PP fibrillated yarn meets high-performance criteria. This dedication to quality guarantees that the yarn delivers superior durability and reliability in all applications.

In which industries can I find Singhal Industries' PP fibrillated yarn being used? Singhal Industries' PP fibrillated yarn is versatile and can be found in various industries, including agriculture, civil engineering, industrial textiles, and outdoor gear manufacturing. Its strength and durability make it suitable for a wide range of applications, from geotextiles to sports equipment and furniture upholstery.

0 notes

Text

PP Fibrillated Yarn: Revolutionizing Textile and Industrial Applications

In the ever-evolving world of textiles and industrial materials, PP Fibrillated Yarn has emerged as a game-changer, offering a unique combination of strength, versatility, and cost-effectiveness. As leading PP Fibrillated Yarn Suppliers, we at Singhal Global understand the critical role this innovative material plays in various sectors. Let's delve into the world of Fibrillated Polypropylene Yarn and explore its myriad applications and benefits.

Understanding PP Fibrillated Yarn

Polypropylene (PP) Fibrillated Yarn is a synthetic fiber produced through a specialized extrusion process. The term "fibrillated" refers to the splitting of the yarn into numerous fine fibrils, resulting in a unique structure that enhances its properties. This process significantly increases the surface area of the yarn, leading to improved strength, durability, and versatility.

Key Properties and Advantages

High Strength-to-Weight Ratio: PP Fibrillated Yarn boasts an impressive strength-to-weight ratio, making it ideal for applications where lightweight yet robust materials are required.

Chemical Resistance: The yarn exhibits excellent resistance to a wide range of chemicals, acids, and alkalis, ensuring longevity in harsh environments.

Moisture Resistance: Unlike natural fibers, PP Fibrillated Yarn does not absorb moisture, making it perfect for outdoor and marine applications.

UV Stability: Many variants of PP Fibrillated Yarn are UV-stabilized, offering protection against degradation from sunlight exposure.

Eco-Friendly: Polypropylene is recyclable, contributing to sustainable manufacturing practices.

Cost-Effective: The PP Fibrillated Yarn price is often competitive compared to alternative materials, offering excellent value for money.

Applications Across Industries

Geotextiles and Construction

In the construction industry, PP Fibrillated Yarn is widely used in geotextiles for soil stabilization, erosion control, and drainage systems. Its high tensile strength and resistance to degradation make it an excellent choice for long-term ground reinforcement projects.

Rope and Cordage

The marine and shipping industries benefit greatly from ropes and cords made with PP Fibrillated Yarn. Its lightweight nature, combined with high strength and water resistance, makes it ideal for mooring lines, fishing nets, and general-purpose ropes.

Artificial Grass and Sports Surfaces

Fibrillated Polypropylene Yarn is extensively used in the production of artificial turf for sports fields and landscaping. Its durability, UV resistance, and ability to maintain its appearance make it a preferred choice for long-lasting, low-maintenance surfaces.

Packaging and Industrial Applications

In the packaging industry, PP Fibrillated Yarn finds use in woven sacks and bags, offering strength and moisture resistance for storing and transporting goods. It's also used in filtration systems, demonstrating its versatility in industrial applications.

Textiles and Apparel

While not as common in everyday clothing, PP Fibrillated Yarn is used in specialized textiles such as high-performance sportswear, where its moisture-wicking properties and durability are advantageous.

Innovation and Future Trends

As PP Fibrillated Yarn Suppliers, we're constantly exploring new ways to enhance the properties and applications of this versatile material:

Improved Dyeing Techniques: Developing new methods to improve color fastness and expand the range of achievable colors.

Enhanced Biodegradability: Research into additives that can make PP Fibrillated Yarn more environmentally friendly without compromising its performance.

Smart Textiles Integration: Exploring ways to incorporate conductive properties or sensors into PP Fibrillated Yarn for use in smart textiles and wearable technology.

Nanotechnology Applications: Investigating the use of nanoparticles to further enhance the yarn's properties, such as antimicrobial capabilities or increased strength.

Market Dynamics Understanding the Factors

The global market for PP Fibrillated Yarn continues to grow, driven by increasing demand from various end-use industries. The PP Fibrillated Yarn price remains competitive, especially when considering its long-term durability and performance benefits. Factors influencing the price include:

Raw material costs (primarily polypropylene resin)

Energy prices affecting production costs

Technological advancements in manufacturing processes

Global supply and demand dynamics

As PP Fibrillated Yarn Suppliers, we strive to offer competitive pricing while maintaining the highest quality standards. The cost-effectiveness of PP Fibrillated Yarn, coupled with its superior properties, makes it an attractive option for many industries looking to optimize their material choices.

Sustainability Considerations

In an era where environmental concerns are paramount, the recyclability of PP Fibrillated Yarn is a significant advantage. Many Fibrillated Polypropylene Yarn products can be recycled at the end of their lifecycle, contributing to circular economy initiatives. Additionally, the long lifespan of products made with PP Fibrillated Yarn reduces the need for frequent replacements, further minimizing environmental impact.

Conclusion

PP Fibrillated Yarn has proven itself to be a versatile, durable, and cost-effective material across a wide range of applications. From construction and marine use to sports surfaces and packaging, its unique properties continue to drive innovation and efficiency in various industries.

As one of the leading PP Fibrillated Yarn Suppliers, we at Singhal Global are committed to providing high-quality products that meet the evolving needs of our clients. We understand that the choice of material can significantly impact the success of a project or product line. That's why we offer not just superior Fibrillated Polypropylene Yarn, but also the expertise and support to help our customers make the most of this remarkable material.

Whether you're in need of geotextiles for a large-scale construction project, seeking durable materials for marine applications, or looking to innovate in the field of technical textiles, PP Fibrillated Yarn offers a solution that combines performance, durability, and value. As we look to the future, we're excited about the potential for further innovations in PP Fibrillated Yarn technology and its ability to meet the challenges of tomorrow's industries.

Frequently Asked Questions (FAQs)

Q: What is PP Fibrillated Yarn? A: PP Fibrillated Yarn is a synthetic fiber made from polypropylene that undergoes a special extrusion process, resulting in a yarn with numerous fine fibrils. This structure enhances its strength, durability, and versatility.

Q: What are the main advantages of using PP Fibrillated Yarn? A: The main advantages include high strength-to-weight ratio, chemical and moisture resistance, UV stability, eco-friendliness, and cost-effectiveness.

Q: How does the PP Fibrillated Yarn price compare to alternative materials? A: Generally, PP Fibrillated Yarn offers competitive pricing, especially when considering its long-term durability and performance benefits. The exact price can vary based on factors like raw material costs and market demand.

Q: Who are the main PP Fibrillated Yarn Suppliers? A: There are several global suppliers of PP Fibrillated Yarn, including Singhal Global. It's best to research and compare suppliers based on your specific needs and location.

Q: What industries use Fibrillated Polypropylene Yarn? A: Major industries include geotextiles and construction, rope and cordage manufacturing, artificial grass and sports surfaces, packaging, and specialized textiles.

0 notes

Text

Interview — Yogesh Dutt Tiwari, RSWM Melange Yarn Business

RSWM Limited, one of the flagship company under the LNJ Bhilwara Group, is a prominent player in India’s textile industry, specializing in the manufacturing and export of synthetic, cotton, and blended spun yarn. RSWM-led by Riju Jhunjhunwala, chairman and managing director, the company boasts 12 manufacturing plants equipped with 6.25 lakh spindles, 172 looms, and 95 circular and flat knitting machines.

With an annual production capacity of 1,21,000 metric tonne (MT) Greige Yarn, 24,000 MT Melange yarn, 32,000 MT Dyed yarn, 32 M Meters Denim Fabric, 9000+ MT Knits Fabric, and 43,000 MT Green Fibre, RSWM caters to markets in over 70 countries.

Textiles South Asia caught up with Yogesh Tiwari, Business Head and Chief Executive, Melange Yarn Business of RSWM Limited, at Yarnex 2024, New Delhi, to discuss the company’s offerings and future plans.

Yarnex, a key platform in India for discovering the latest in fibres and yarns, brought together manufacturers and suppliers from major textile hubs like Ludhiana, Mumbai, and Tirupur. Held last month in Delhi, the heart of India, the event attracted both local and international participants, drawing a footfall of around 15,000 people and offering opportunities to explore trends and connect with industry leaders.

Sadhna Mishra, correspondent of Textiles South Asia: Could you elaborate on RSWM’s core business and its distinct offerings?

Yogesh Dutt Tiwari: RSWM is primarily recognized for its textile products, particularly synthetics. However, our melange yarn business, which commenced in 1993, has been a significant focus for the past 25 years. Apart from yarn, we also specialize in knitting and denim, with the latter being a separate vertical. The textile segment alone contributes to a turnover of Rs 6000 crores, while the overall company turnover exceeds Rs 10,000 crores.

Textiles South Asia: What is the theme of your new collection, and what inspired it?

Yogesh Dutt Tiwari: Our Yarn-X collection is centered around autumn/winter 25/26 and features a color palette inspired by the global scenario, particularly the ongoing war. We’ve chosen colors that symbolize peace and harmony. The collection showcases various color combinations that convey a message of tranquility.

Textiles South Asia: Could you elaborate on Milan Yarn and its distinguishing features?

Yogesh Dutt Tiwari: Milan yarn is a high-value product that differs from traditional yarns in its unique blend of fibers and shades. Unlike conventional yarns that are dyed either as raw white or after fiber dyeing, Milan yarn involves a meticulous process of mixing shades and fibers to create distinct textures.

Textiles South Asia: Which fibers are currently in high demand for Milan yarn, and how is RSWM addressing this trend?

Yogesh Dutt Tiwari: Milan yarn is consistently in trend, with approximately 20% of demand attributed to this category. The key to Milan yarn lies in experimentation with fibers, shades, and effects. We focus on innovation to meet the evolving preferences of the market.

Textiles South Asia: What are the primary applications of Milan yarn, and which end-use sectors benefit the most from its properties?

Yogesh Dutt Tiwari: Milan yarn enjoys widespread acceptance across various sectors. It is particularly popular in hosiery, including circular knit and flat knit products. Additionally, it finds application in woven fabrics like shirting.

Textiles South Asia: Does RSWM employ specialized machinery for Milan yarn production, or does it utilize the same equipment as for other yarn types?

Yogesh Dutt Tiwari: While the basic machinery is similar to that used for synthetic and cotton yarns, the production process for Milan yarn is distinct. It involves multiple stages, including sliver creation, dyeing, and texture development, requiring a higher level of expertise and innovation.

Textiles South Asia: What are the primary challenges and benefits of manufacturing Milan yarn?

Yogesh Dutt Tiwari: The production of Milan yarn demands a high degree of innovation and agility to meet tight lead time requirements. However, the potential for creating unique and high-value products makes it a rewarding endeavor.

Textiles South Asia: How is RSWM incorporating sustainable practices into Milan yarn production?

Yogesh Dutt Tiwari: Sustainability is a core focus for RSWM, and we have implemented comprehensive measures across the value chain. Our commitment includes using recycled polyester fiber, organic cotton, and eco-friendly dyes and chemicals. We have also adopted water recycling and renewable energy sources to minimize our environmental impact.

Textiles South Asia: Does RSWM export Milan yarn, and if so, to which markets? What are the prevailing trends in the global yarn market?

Yogesh Dutt Tiwari: Approximately 40% of our Milan yarn production is exported to various global markets, primarily through buying houses catering to international brands. The ongoing war and its impact on freight costs and economic conditions pose significant challenges to the industry.

Textiles South Asia: How do you envision the future of the Milan yarn industry, and what strategies is RSWM adopting to shape this future?

Yogesh Dutt Tiwari: We believe that Milan yarn will continue to be in demand, and RSWM is well-positioned to capitalize on this trend. By expanding our Milan yarn production capacity and focusing on innovation, we aim to strengthen our position in the global market.

0 notes

Text

A Comprehensive Guide to PP Yarn:

PP yarn, a crucial material in various industries, offers exceptional strength, durability, and versatility. This guide explores the key aspects of PP yarn manufacturers in India, PP yarn suppliers in Gujarat, and polypropylene yarn exporters in Ahmedabad.

What is PP Yarn?

PP yarn is made from polypropylene, a synthetic polymer renowned for its robustness. This yarn is used in a range of applications, from textiles to industrial products, due to its strength and resistance to wear and tear.

Advantages of PP Yarn

Strength: Known for its high tensile strength, PP yarn can handle heavy loads and strenuous conditions.

Durability: It resists abrasion and degradation, extending the lifespan of products made from it.

Lightweight: The yarn is lightweight, making it easy to handle and reducing transportation costs.

Chemical Resistance: PP yarn is resistant to chemicals, including acids and bases, which enhances its versatility.

Versatility: It is used in diverse applications such as ropes, sacks, textiles, and industrial fabrics.

Key Industry Players

PP Yarn Manufacturers in India: These manufacturers specialize in producing high-quality polypropylene yarns. They cater to various sectors, ensuring consistent quality and supply.

PP Yarn Supplier in Gujarat: Suppliers in Gujarat offer a range of PP yarns, making them accessible to different regions and industries. They play a vital role in ensuring the availability of yarns for local and regional needs.

Polypropylene Yarn Exporter in Ahmedabad: Exporters in Ahmedabad focus on distributing polypropylene yarns to international markets, providing global access to high-quality products.

Choosing the Right PP Yarn

When selecting PP yarn, consider the following factors:

Strength and Durability: Ensure the yarn meets the specific strength and durability requirements for your application.

Type of Yarn: Different types of PP yarns, such as multifilament and monofilament, cater to various needs. Choose based on your specific requirements.

Reputable Suppliers and Manufacturers: Evaluate PP yarn manufacturers in India, PP yarn suppliers in Gujarat, and polypropylene yarn exporters in Ahmedabad based on their reputation and reliability.

Pricing and Availability

The price of PP yarn can vary depending on factors such as type, quality, and supplier. Typically, prices range from ₹200 to ₹400 per kilogram. For the best value, compare quotes from various suppliers and manufacturers.

Conclusion

PP yarn is a versatile and cost-effective material used across many industries due to its strength, durability, and chemical resistance. By understanding the roles of PP yarn manufacturers in India, PP yarn suppliers in Gujarat, and polypropylene yarn exporters in Ahmedabad, you can make informed decisions and find the best yarn for your needs.

FAQs

What is PP yarn made of? PP yarn is made from polypropylene, a synthetic polymer known for its strength and durability.

What are the common applications of PP yarn? It is used in textiles, packaging materials, ropes, and industrial fabrics.

How can I find PP yarn manufacturers in India? Look for specialized PP yarn manufacturers in India who produce high-quality polypropylene yarns.

What should I consider when choosing a PP yarn supplier in Gujarat? Consider product quality, reliability, and the supplier’s ability to meet your specific needs.

What is the role of polypropylene yarn exporters in Ahmedabad?Polypropylene yarn exporters in Ahmedabad help distribute polypropylene yarns to international markets, making them available globally.

#pp yarn manufacturers in india#pp yarn Supplier in Gujarat#polypropylene yarn Exporter in Ahmedabad

0 notes

Text

Polypropylene Filament Yarn Prices Trend, Pricing, Database, News, Index, Chart, Forecast

Polypropylene Filament Yarn (PPFY) Prices have seen significant fluctuations in recent times, influenced by a multitude of factors within the global market. As a versatile material, polypropylene filament yarn is widely utilized in various industries such as textiles, automotive, packaging, and healthcare. Its demand is intricately tied to economic conditions, consumer preferences, and raw material costs.

The pricing dynamics of polypropylene filament yarn are primarily driven by the cost of raw materials, particularly propylene monomer. Since propylene is a byproduct of petroleum refining and natural gas processing, any fluctuations in crude oil prices directly impact its availability and cost. Moreover, geopolitical tensions and supply chain disruptions can further exacerbate price volatility, leading to unpredictable market conditions.

Additionally, the supply-demand balance plays a crucial role in determining PPFY prices. During periods of high demand, such as seasonal peaks in textile production or increased packaging requirements, prices tend to rise due to limited supply capacities. Conversely, during economic downturns or overproduction phases, prices may stabilize or decrease as manufacturers adjust their output levels to match reduced demand.

Get Real Time Prices of Polypropylene Filament Yarn (PPFY): https://www.chemanalyst.com/Pricing-data/polypropylene-filament-yarn-ppfy-1160

Global trade dynamics also influence PPFY prices significantly. Tariffs, trade agreements, and currency fluctuations can disrupt supply chains and alter pricing structures. For instance, changes in import/export policies between major producing countries like China, India, and the United States can have ripple effects on global PPFY prices.

Technological advancements and innovations in manufacturing processes also impact PPFY pricing. Improvements in production efficiency, recycling technologies, and sustainability initiatives can lead to cost reductions, making PPFY more competitive in the market. Conversely, regulatory changes aimed at environmental protection or labor practices may increase production costs, thereby affecting final product prices.

Environmental factors such as weather conditions can also influence polypropylene filament yarn prices. Natural disasters or extreme weather events can disrupt raw material supplies or manufacturing operations, leading to temporary shortages and subsequent price spikes.

Furthermore, consumer preferences for sustainable and eco-friendly products are increasingly shaping PPFY pricing strategies. As awareness grows regarding the environmental impact of synthetic materials, there is a rising demand for recycled or bio-based polypropylene filament yarns. Manufacturers responding to this trend by investing in green technologies may incur higher production costs initially but can potentially attract eco-conscious consumers willing to pay premium prices.

In conclusion, polypropylene filament yarn prices are subject to a complex interplay of factors encompassing raw material costs, supply-demand dynamics, global trade policies, technological advancements, environmental considerations, and consumer preferences. Market participants, including manufacturers, suppliers, and consumers, must remain vigilant and adaptable to navigate the ever-evolving landscape of PPFY pricing. Understanding these multifaceted influences is crucial for making informed decisions and effectively managing risks in the polypropylene filament yarn market.

Get Real Time Prices of Polypropylene Filament Yarn (PPFY): https://www.chemanalyst.com/Pricing-data/polypropylene-filament-yarn-ppfy-1160

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Polypropylene Filament Yarn#Polypropylene Filament Yarn Prices#PPFY Prices#PPFY Price#Polypropylene Filament Yarn Price

0 notes

Text

Innovative Crafting with PP Multifilament Yarn: Your Ultimate Guide

Introduction

What is PP Multifilament Yarn?

PP Multifilament Yarn, or Polypropylene Multifilament Yarn, is a durable and versatile synthetic fiber ideal for crafting. Made from polypropylene, it offers high strength, abrasion resistance, and moisture resistance. This lightweight yarn is perfect for intricate designs, outdoor projects, and comes in various colors and textures. It's eco-friendly, recyclable, and easy to dye, making it great for sustainable crafting. Explore the possibilities with this exceptional material and enhance your crafting projects.

Getting Started

Crafting with PP multifilament yarn is a delightful journey. Here's what you need to begin:

Essential Tools and Materials

PP Multifilament Yarn: Choose high-quality yarn for durability.

Scissors, Measuring Tape, Needles, Hooks, Glue: Essential for clean and precise work.

Work Surface: A comfortable space to spread out your materials.

Choosing the Right PP Multifilament Yarn

Consider:

Project Type: Thicker yarn for robust items, thinner yarn for intricate work.

Color and Finish: Match your project's aesthetic.

Supplier Reputation: Ensure quality and consistency.

Cost: Balance budget with quality.

With these essentials, you're ready to dive into the world of PP multifilament yarn crafting!

Basic Techniques

Crafting with PP multifilament yarn involves mastering several fundamental techniques:

Knotting and Weaving Knotting and weaving allow you to create intricate patterns and textures. Experiment with knots like the square knot and half-hitch knot, and explore weaving patterns such as the plain weave and twill weave.

Braiding and Twisting Braiding and twisting add depth and dimension to your projects. Try different braiding techniques like the traditional braid and fishtail braid, or incorporate twists like the rope twist for unique designs.

Creating Sturdy Edges Creating sturdy edges is vital for project durability. Seal edges with techniques like heat sealing or fray-check, and reinforce with stitching or binding to ensure longevity.

Conclusion

In conclusion, crafting with PP multifilament yarn offers a durable, eco-friendly, and versatile solution for a wide range of projects. Its high strength, abrasion resistance, and moisture resistance make it suitable for both indoor and outdoor applications. With endless possibilities for creativity, PP multifilament yarn is sure to elevate any crafting project. So, why wait? Dive into the world of PP multifilament yarn crafting today and unleash your imagination!

#Crafting#PPMultifilamentYarn#Polypropylene#SyntheticFiber#DIY#CraftingMaterials#TextileCrafts#Sustainability#EcoFriendly#CreativeProjects

0 notes

Text

Say Farewell To Unpleasant Odors: Strategies For Removing Dog Urine Smell From Synthetic Grass

Remove Dog Urine Smell From Synthetic Grass

There’s a number of methods to consider for removal of dog urine smells from synthetic grass, and they’re a lot simpler and better for the environment then you might’ve thought. The first solution is simply spraying the area down with water, flushing the urine into the soil beneath. Rain is sufficient for this task, so you’ll only really have to maintain the grass during warmer months. For extra protection, consider a Bio-Enzymatic Spray.

Our second solution is a basic mixture of baking soda and vinegar, which effectively cleans away the urine and removes that lingering ammonia smell. We recommend flushing away the remnants with your hose to avoid a white residue on the lawn.

Lastly, there’s a range of products available in supermarkets that are designed specifically for removal dog urine smell from synthetic grass. Make sure you look for products that are marked as bio-degradable, non-toxic and suited specifically for fake lawns!

The Leading Suppliers In Pet-Friendly Turf Solutions

As the leading Australian specialists in artificial grass solutions, you can trust Titan Turf to keep you up to date with all the latest tips to keep on top of the removal dog urine smell from synthetic grass.

As the technology continues to advance, more people are learning that fake grass is actually a fantastic pet-friendly alternative to real grass—safe from the destruction of holes and unlikely to irritate sensitive skin.

Our yarns are even manufactured using Coolplus Technology, which effectively keeps temperatures at bay by reflecting UV rays, keeping our turf up to 20 – 25% cooler than traditional synthetic grass.

However, the main concern for a lot of people is how to keep their fake grass clean and free of lingering smells. So, we have some advice for all of the curious pet-owners that have been considering making the move to artificial grass. Keep reading to learn!

Products You Can Rely On

With products that are designed for easy maintenance and simple removal of dog urine smell from synthetic grass, you can rest assured that our lawns and products are suitable for any commercial or residential application.

Our range is manufactured right here in Australia, attaining the coveted ‘Australian Made’ seal of approval which gives us a distinguishable edge in the field. This means our products offer superior performance and maintain their aesthetic long-term, due to their high resistance against the fluctuating Australian climate.

To help you find your ideal solution, every option is given a rating for resistance against foot traffic, softness and natural look. Our products are also backed by an up to 15-year warranty for added peace of mind! Let the professionals at Titan Turf help you narrow down a selection that fits within the scope of your budget, followed by ongoing service with advice for removal dog urine smell from synthetic grass.

For More Information

Contact- (08) 8384 8604

Email- [email protected]

Address- Unit 1/10 Kitawah St, Lonsdale SA 5160, Australia

Website-https://titanturf.com.au/removal-dog-urine-smell-from-synthetic-grass/

0 notes

Text

Title: From Threads to Treasures: Exploring the World of Handmade Rug Craftsmanship

In the realm of interior design and décor, handmade rugs stand as timeless treasures, embodying both artistry and functionality. Each rug is not merely a floor covering but a manifestation of centuries-old craftsmanship, cultural heritage, and individual creativity. From the weaving techniques passed down through generations to the intricate designs that tell stories of distant lands, exploring the world of handmade rug craftsmanship is a journey into the heart of human ingenuity and tradition.

At the core of handmade rug craftsmanship lies the mastery of weaving techniques. Unlike mass-produced rugs churned out by machines, handmade rugs are meticulously crafted by skilled artisans who dedicate hours, days, and sometimes even months to create a single piece. The process begins with the selection of high-quality materials, typically wool, silk, or cotton, sourced from local or regional suppliers. These raw materials are then spun into yarns, dyed using natural or synthetic dyes, and prepared for the weaving loom.

The weaving loom serves as the artisan's canvas, where threads are meticulously intertwined to form intricate patterns and designs Buy Handmade Rugs Depending on the desired style and complexity of the rug, various weaving techniques such as knotting, flat weaving, or tufting are employed. Each knot or weave is carefully executed, requiring precision and patience to achieve the desired texture and density.

What distinguishes handmade rugs from their machine-made counterparts is the human touch infused into every step of the process. From the subtle variations in color to the imperfections that add character, each rug bears the mark of its creator, making it a truly unique work of art. Moreover, handmade rugs often incorporate traditional motifs and symbols that reflect the cultural heritage of the artisans and their communities. Whether it's the geometric patterns of Persian rugs or the tribal motifs of Moroccan rugs, these designs carry centuries of history and craftsmanship within their threads.

Beyond their aesthetic appeal, handmade rugs also possess practical benefits that contribute to their allure. Handmade carpets online The superior craftsmanship and quality materials used in their construction result in durability and longevity, ensuring that they can withstand the test of time and foot traffic. Additionally, the natural fibers used in many handmade rugs offer inherent qualities such as insulation, sound absorption, and hypoallergenic properties, making them not only beautiful but also functional additions to any space.

In today's fast-paced world dominated by mass production and disposable goods, handmade rugs serve as reminders of a slower, contemporary rug design more deliberate approach to craftsmanship. They are symbols of sustainability, ethical production practices, and the preservation of cultural heritage. By investing in handmade rugs, consumers not only acquire a piece of functional art but also support artisanal communities and traditional crafts that are in danger of being lost in the face of industrialization.

In conclusion, the world of handmade rug craftsmanship is a testament to human creativity, skill, and cultural heritage. From the humble threads spun into yarn to the intricate treasures that adorn floors around the world, handmade rugs embody the artistry and tradition of generations past. They are more than just decorative accents; they are symbols of craftsmanship, culture, and connection—a timeless legacy woven into every fiber.

0 notes

Text

Yarn Export Markets: Opportunities and Challenges

Introduction:

Yarn, the fundamental building block of textiles, plays a crucial role in the global textile industry. As one of the largest yarn producers, India has a significant presence in the global market. Exporting yarn presents numerous opportunities but also comes with challenges that must be navigated to achieve success. This article explores the key opportunities and challenges in the yarn export markets, providing insights for businesses looking to expand their reach.

Opportunities in Yarn Export Markets:

1. Growing Global Demand:

The global demand for yarn is steadily increasing, driven by the expanding textile and apparel industries. Countries with robust garment manufacturing sectors, such as China, Bangladesh, and Vietnam, rely heavily on imported yarns to meet their production needs. This growing demand presents substantial opportunities for yarn exporters to tap into these markets.

2. Diversification of Product Range:

Yarn manufacturers can diversify their product offerings to cater to various segments, including cotton, synthetic, blended, and specialty yarns. By offering a wide range of yarns, exporters can appeal to different market segments and fulfill the specific needs of diverse industries, such as fashion, home textiles, and technical textiles.

3. Advancements in Yarn Technology:

Technological advancements in yarn production, such as innovations in spinning and dyeing techniques, have led to the creation of high-performance and eco-friendly yarns. Exporters who invest in advanced technology can produce superior quality yarns that meet international standards, thereby enhancing their competitiveness in the global market.

4. Sustainability Trends:

There is a growing trend towards sustainability in the textile industry. Eco-friendly and sustainable yarns made from organic or recycled materials are in high demand. Exporters who focus on sustainable practices and certifications can attract environmentally conscious buyers and gain a competitive edge in the market.

5. Trade Agreements and Partnerships:

Trade agreements and partnerships between countries can facilitate smoother export processes and reduce tariffs and duties. Engaging in strategic partnerships with overseas buyers, distributors, and agents can help yarn exporters expand their market reach and establish a strong presence in international markets.

Challenges in Yarn Export Markets:

1. Intense Competition:

The global yarn market is highly competitive, with numerous suppliers vying for market share. Competing on price alone can be challenging, especially with low-cost producers in countries like China and Bangladesh. Exporters need to differentiate themselves through quality, innovation, and value-added services.

2. Quality Standards and Regulations:

Different countries have varying quality standards and regulations for imported yarns. Meeting these stringent requirements can be challenging for exporters. It is essential to stay updated on international standards and ensure that the products comply with the regulations of the target markets.

3. Logistics and Supply Chain Issues:

Efficient logistics and supply chain management are critical for successful yarn exports. Delays, disruptions, and high shipping costs can impact the competitiveness of yarn exporters. Investing in robust logistics solutions and establishing reliable supply chain networks can mitigate these challenges.

4. Fluctuating Raw Material Prices:

The prices of raw materials used in yarn production, such as cotton and synthetic fibers, are subject to fluctuations. These price variations can affect the cost of production and pricing strategies. Exporters need to adopt flexible pricing mechanisms and hedging strategies to manage price volatility.

5. Currency Exchange Risks:

Currency exchange rate fluctuations can impact the profitability of yarn exports. Exporters must be vigilant about exchange rate movements and consider using financial instruments such as forward contracts and currency hedging to mitigate risks.

6. Market Entry Barriers:

Entering new markets often involves overcoming barriers such as import restrictions, tariffs, and local competition. Conducting thorough market research, understanding the regulatory environment, and building strong relationships with local partners can help navigate these barriers.

Conclusion:

The yarn export market offers significant opportunities for growth, driven by rising global demand, product diversification, technological advancements, and sustainability trends. However, exporters must also contend with challenges such as intense competition, quality standards, logistics issues, raw material price fluctuations, currency risks, and market entry barriers. By leveraging their strengths, staying abreast of market trends, and adopting strategic approaches, yarn exporters can successfully navigate these challenges and capitalize on the opportunities in the global market.

Ready to explore top-quality yarns for your business? Connect with trusted Yarn Suppliers at Fibre2Fashion and elevate your textile production with the finest materials available.

1 note

·

View note

Text

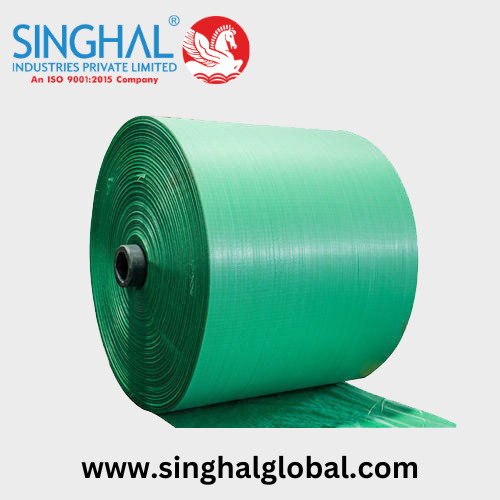

PP Woven Fabric: The Sustainable and Versatile Workhorse of Textiles

Introduction: In the vast landscape of textiles, one material stands out for its versatility, durability, and sustainability: PP (Polypropylene) woven fabric. Used across a myriad of industries, from agriculture to packaging, construction to geotextiles, PP woven fabric has become the workhorse of modern textiles. In this article, we delve into the characteristics, applications, and sustainability aspects of PP woven fabric, while also exploring the landscape of suppliers and manufacturers, particularly focusing on Ahmedabad, Gujarat, and India as a whole.

Understanding PP Woven Fabric: PP woven fabric is a type of synthetic fabric made from polypropylene polymer. Its construction involves weaving polypropylene tapes or flat yarns together to create a strong and durable fabric. This weaving process imparts exceptional tensile strength and tear resistance to the fabric, making it suitable for a wide range of applications.

Key Characteristics:

Strength and Durability: PP woven fabric is renowned for its high strength-to-weight ratio, making it ideal for applications requiring robustness and resilience. It can withstand heavy loads, punctures, and abrasion, ensuring long-lasting performance.

Lightweight: Regardless of its solidarity, PP woven texture is lightweight, which makes it simple to deal with and transport. This trademark is especially favorable in applications like bundling and transportation.

Water Resistance: PP woven fabric exhibits inherent water resistance, making it suitable for outdoor applications where exposure to moisture is a concern. It can be further enhanced with laminations or coatings for increased impermeability.

UV Stability: UV stability is another notable feature of PP woven fabric, allowing it to withstand prolonged exposure to sunlight without significant degradation. This makes it suitable for outdoor applications such as agricultural covers and geotextiles.

Applications of PP Woven Fabric: The versatility of PP woven fabric lends itself to a wide array of applications across various industries. Some of the key applications include:

Packaging: PP woven fabric is extensively used in packaging materials such as sacks, bags, and FIBCs (Flexible Intermediate Bulk Containers). Its strength and durability make it an ideal choice for transporting bulk goods such as grains, seeds, fertilizers, and cement.

Agriculture: In agriculture, PP woven fabric finds applications in crop protection, ground coverings, shade nets, and greenhouse films. Its UV stability and water resistance make it well-suited for protecting crops from adverse weather conditions and pests.

Construction: PP woven fabric is used in construction for purposes such as scaffolding nets, tarpaulins, and temporary enclosures. Its strength and durability make it an indispensable material for ensuring safety and protection on construction sites.

Geotextiles: In civil engineering and landscaping projects, PP woven fabric is employed as geotextiles for erosion control, soil stabilization, and drainage applications. Its permeability and strength contribute to the longevity and effectiveness of such infrastructure projects.

Sustainability Aspects: In addition to its functional attributes, PP woven fabric also offers significant sustainability benefits:

Recyclability: Polypropylene is a recyclable thermoplastic polymer, which means that PP woven fabric can be recycled and reused in various applications, reducing the demand for virgin materials and minimizing waste.

Energy Efficiency: The manufacturing process of PP woven fabric consumes relatively less energy compared to other materials such as paper or traditional textiles, contributing to lower carbon emissions and environmental impact.

Longevity: The durability of PP woven fabric ensures a longer lifespan compared to alternative materials, reducing the frequency of replacements and the associated resource consumption.

Resource Efficiency: PP woven fabric is produced using minimal water and natural resources, making it a more sustainable choice compared to materials that require extensive water and land resources for cultivation or extraction.

Suppliers and Manufacturers: Ahmedabad, Gujarat, and India as a whole boast a robust network of suppliers and manufacturers catering to the demand for PP woven fabric:

PP laminated woven fabric suppliers in Ahmedabad offer a diverse range of products tailored to specific applications, with options for customization and lamination to meet customer requirements.

PP woven fabric manufacturers in Gujarat leverage the state's industrial infrastructure and expertise in textile manufacturing to produce high-quality PP woven fabric at competitive prices.

PP woven fabric roll manufacturers in India cater to both domestic and international markets, supplying a wide range of industries with standard and customized fabric rolls to suit diverse applications.

Conclusion: PP woven fabric emerges as a sustainable and versatile solution for a multitude of applications, owing to its inherent strength, durability, and eco-friendly attributes. As industries continue to prioritize sustainability and efficiency, the demand for PP woven fabric is expected to rise, further driving innovation and advancements in its production and applications. With a strong network of suppliers and manufacturers in Ahmedabad, Gujarat, and across India, the future of PP woven fabric looks promising as it continues to establish itself as the workhorse of modern textiles.

Frequently Asked Questions about PP Woven Fabric

Is PP woven fabric eco-friendly? PP woven fabric's recyclability and durability contribute to its eco-friendly nature. However, the environmental impact depends on factors like production practices and end-of-life management.

Is PP woven fabric breathable? In its natural state, PP woven fabric exhibits limited breathability. However, breathable variations are available for specific applications.

How strong is PP woven fabric? PP woven fabric offers surprising strength and tear resistance, making it suitable for heavy-duty applications.

Can PP woven fabric be dyed? While dyeing PP woven fabric directly is challenging, it can be produced in various colors during manufacturing.

What are the limitations of PP woven fabric? PP woven fabric might not be the best choice for applications requiring high breathability or heat resistance.

#pp laminated woven fabric suppliers in Ahmedabad#pp woven fabric manufacturer in Gujarat#pp woven fabric roll manufacturers in india

0 notes

Text

Exploring Different Types of Yarn Produced in Delhi: From Natural to Synthetic

Introduction

Delhi, a bustling hub of creativity and innovation, is home to a diverse array of yarn manufacturers catering to both domestic and international markets. From natural fibers to synthetic blends, these manufacturers, including SD Polytech, one of the prominent spun polyester yarn producers in India, produce a wide range of yarn types to meet the demands of various industries and applications. Let's embark on a journey to explore the different types of yarn produced in Delhi, from natural to synthetic, and the contributions of manufacturers like SD Polytech in shaping the textile landscape.

1. Cotton Yarn: