#Sulfone Polymers future market

Explore tagged Tumblr posts

Text

Chlorosulphonic Acid in Agrochemical Production

When it comes to industrial chemicals, Chlorosulfonic acid stand out for their remarkable versatility and importance in various sectors. At Maruti Fine Chemicals, we specialize in providing high-quality chemical solutions that meet the diverse needs of industries worldwide.

Chlorosulphonic Acid

This acid is a highly reactive compound with the chemical formula ClSO₃H. This colorless to slightly yellow fuming liquid is a chlorinated derivative of sulfuric acid, known for its strong acidity and reactivity. It is a critical intermediate in the production of numerous industrial and consumer products.

Environmental Impact and Sustainability

While this acid is a vital industrial chemical, its use must be balanced with environmental considerations. We are committed to sustainability by promoting the responsible use and disposal of chemicals. Our production processes are designed to minimize waste and reduce environmental footprints.

Future Trends in the Use of Acid

The demand for Chlorosulfonic acid is expected to grow with advancements in the chemical, pharmaceutical, and agricultural sectors. Innovations in sustainable practices and improved manufacturing techniques are likely to enhance its applications while reducing environmental concerns.

Emerging Trends and Future Outlook

The demand for Chlorosulphonic Acid is projected to grow with advancements in chemical manufacturing, pharmaceuticals, and agriculture. Industries are continually finding new applications for this versatile chemical while focusing on sustainable production practices. Maruti Fine Chemicals is at the forefront of these innovations, ensuring that its customers stay ahead in their respective markets.

Applications

It plays a pivotal role in numerous industries. Here are some of its prominent applications:

1. Detergent and Surfactant Manufacturing

One of the most common uses of this acid is in the production of detergents and surfactants. It acts as a sulfonating agent, introducing sulfonic acid groups into organic compounds, which are then used to manufacture cleaning agents with excellent emulsifying properties.

2. Pharmaceutical Industry

In the pharmaceutical sector, this acid is employed as a reagent in the synthesis of various drugs and active pharmaceutical ingredients (APIs). Its ability to introduce functional groups makes it indispensable for creating complex chemical structures.

3. Dye and Pigment Production

The dye industry relies on Chlorosulfonic Acid to sulfonate aromatic compounds, enabling the production of vibrant and long-lasting dyes. This process enhances the solubility and binding capacity of dyes to fabrics and surfaces.

4. Pesticides and Agrochemicals

The agrochemical industry uses Chlorosulphonic Acid in the synthesis of pesticides and herbicides. Its reactivity ensures the efficient production of compounds that protect crops from pests and diseases.

5. Polymer and Resin Manufacturing

Chlorosulphonic Acid serves as a catalyst in the production of specialty polymers and resins. It helps modify polymer structures, enhancing their durability and performance in various applications.

6. Electronics Industry

In the electronics sector, this compound is utilized in the etching of semiconductor materials and the preparation of advanced chemical solutions for microfabrication.

Why Choose Us?

1.Quality Assurance: We adhere to strict quality control measures to ensure that our products meet industry standards.

2.Custom Solutions: Our team works closely with clients to provide customized chemical solutions for specific applications.

3.Safe Packaging: We prioritize safe and secure packaging to maintain the integrity of our products during transit.

4.Technical Support: Our experts are always available to provide guidance on the proper use and handling of acid.

FAQs

Q1: What industries use Chlorosulfonic acid the most? A1: The pharmaceutical, dye, detergent, and chemical industries are the primary users of Chlorosulfonic acid.

Q2: How should Chlorosulfonic acid be stored? A2: It should be stored in airtight containers, away from moisture, heat, and incompatible substances.

Q3: What makes us a reliable supplier? A3: We offers high-purity products, reliable delivery, and excellent technical support.

Q4: Is there a difference between Chlorosulphonic Acid and Chlorosulfonic Acid? A4: No, both terms refer to the same chemical compound.

Q5: Can Chlorosulphonic Acid be used in agriculture? A5: Yes, it is used in the production of agrochemicals such as herbicides and pesticides.

Conclusion

Chlorosulphonic Acid, or Chlorosulfonic acid is a cornerstone of modern chemical manufacturing. Its versatility and effectiveness in diverse applications make it an indispensable compound for industries ranging from detergents to electronics. At Maruti Fine Chemicals, we ensure that our clients receive the highest-quality chemicals coupled with expert support and safe practices. For your industrial needs, trust us as your reliable partner in chemical solutions.

0 notes

Text

0 notes

Text

Sulfone Polymers Market In-Depth Research Analysis, Dynamics Opportunities, and Challenges, and Future Outlook

The Sulfone Polymers Market is Valued at USD 1.42 billion in 2024 and is projected to reach USD 2.2 billion by 2032, growing at a CAGR of 5.00% During the Forecast period of 2024–2032.

Introduction: Sulfone polymers are high-performance thermoplastics known for their exceptional thermal stability, mechanical strength, and chemical resistance. These polymers are widely utilized in various industries, including automotive, aerospace, medical, and electronics, due to their ability to maintain performance under extreme conditions. The sulfone polymers market has witnessed significant growth in recent years, driven by increasing demand for lightweight and durable materials across these sectors.

Download a Free Sample Copy of the Report: https://www.marketdigits.com/request/sample/3429

Major Players In Sulfone Polymers Market Include: ↬ Mitsubishi Chemicals Holdings Corporation, ↬ Sumitomo Chemical Co., Ltd., ↬ Solvay SA, ↬ Saudi Basic Industries Corporation (SABIC), ↬ Sino Polymer, ↬ BASF SE, ↬ UJU New Materials Co Ltd., ↬ Shandong Horan, ↬ RTP Company, ↬ Westlake Plastics Company, Inc, ↬ LATI Industria Termoplastici SpA, ↬ Centroplast Engineering Plastics GmbH, ↬ Ovation Polymers, Inc., ↬ Aquapharm Chemicals Pvt., Ltd., ↬ Jinmen Youju New Materials Co., ↬ GEHR GmbH, ↬ Evonik Industries AG, ↬ PolyOne Corporation, ↬ Americhem Engineered Compounds, ↬ Youju New Materials Co., Ltd ↬ and others.

Why Should Access This Report? Accessing this comprehensive report on the sulfone polymers market is crucial for industry stakeholders, investors, and decision-makers looking to stay ahead in a competitive landscape. The report provides detailed insights into market trends, key drivers, and potential opportunities, helping businesses make informed decisions. By understanding the market dynamics and future outlook, stakeholders can strategize effectively to maximize their market presence and profitability.

Inquire Before Buying at — https://www.marketdigits.com/request/enquiry-before-buying/3429

Major Segmentataions:

By Product Type

Polysulfone Polymers (PSU)

Polyethersulfone Polymers (PESU)

Polyphenylsulfone Polymers (PPSU)

By Application

Orthopedic Devices

Coatings

Consumer Electronics

Aircraft Interiors

Composites

Fittings & Manifolds

Others

By End-use

Automotive & Transportation

Healthcare

Electrical & Electronics

Consumer Products

Industrial Processing

Aerospace

Others

The Report Offers: ➤ Market Overview: Comprehensive overview of the sulfone polymers market, including market size, growth trends, and key segments. ➤ Competitive Landscape: Analysis of key players in the market, their market share, strategies, and recent developments. ➤ Market Drivers and Challenges: Identification of major factors driving market growth and potential challenges faced by industry players. ➤ Opportunities and Forecast: Insights into emerging opportunities, market forecasts, and growth prospects over the next five years. ➤ Regional Analysis: Detailed analysis of the market across different regions, highlighting key markets and regional trends. ➤ Application Insights: Examination of various applications of sulfone polymers in different industries and their market potential.

Click to Request Free 10% Customization on this Report @ https://www.marketdigits.com/request/customization/3429

Mostly Asked Questions: ➲What are sulfone polymers, and what makes them unique compared to other thermoplastics? ➲ What are the primary applications of sulfone polymers in various industries? ➲ What factors are driving the growth of the sulfone polymers market? ➲ Who are the key players in the sulfone polymers market, and what are their strategies? ➲ What are the challenges faced by the sulfone polymers industry, and how can they be addressed?

Conclusion: The sulfone polymers market is poised for significant growth, driven by the increasing demand for high-performance materials in various industries. This comprehensive report provides valuable insights into the market dynamics, competitive landscape, and future prospects, making it an essential resource for industry stakeholders and decision-makers. By leveraging the information in this report, businesses can effectively navigate the market and capitalize on emerging opportunities.

0 notes

Text

Battery Grade Propanesulfolactone, Global Market Size Forecast, Top 10 Companies Rank and Market Share

Battery Grade Propanesulfolactone Market Summary

Battery grade propanesulfolactone, also known as propanesultone, is a chemical compound that is sometimes used as an electrolyte additive in lithium-ion batteries. It is a cyclic sulfonic ester with the molecular formula C3H6O3S. Propanesulfolactone is a colorless liquid with a slightly sweet odor.

According to the new market research report “Global Battery Grade Propanesulfolactone Market Report 2024-2030”, published by QYResearch, the global Battery Grade Propanesulfolactone market size is projected to reach USD 0.04 billion by 2030, at a CAGR of 6.9% during the forecast period.

Figure. Global Battery Grade Propanesulfolactone Market Size (US$ Million), 2019-2030

Figure. Global Battery Grade Propanesulfolactone Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

According to QYResearch Top Players Research Center, the global key manufacturers of Battery Grade Propanesulfolactone include Jiangsu Hicomer New Material, Changshu Juhe Chemical, etc. In 2023, the global top three players had a share approximately 45.0% in terms of revenue.

About The Authors

Yunmei Sun---Lead Author

Email: [email protected]

Sun Yunmei has 2 years of industry research experience, focusing on research in the chemical industry chain related fields, including medical grade reagents, high-purity reagents for semiconductors, and chemical laboratory equipment.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

0 notes

Text

Sulfone Polymer Market: Impact Analysis of COVID-19 on the Market

Sulfone Polymers: A Versatile Class of Thermoplastics Sulfone polymers are a class of high-performance engineering thermoplastics known for their exceptional heat resistance, chemical resistance and electrical properties. They have been used in diverse applications ranging from electrical and electronic components to medical devices. In this article, we will discuss the key characteristics of sulfone polymers along with their various uses and future potential. Chemical Structure and Properties

Sulfone polymers are characterized by the sulfone group (O=S=O) in their main chain. The most common commercial sulfone polymer is polysulfone (PSU) which was first developed by Union Carbide in the late 1960s. PSU has an aromatic backbone containing bisphenol units linked together by sulfone groups. This linear structure gives PSU its robust thermomechanical properties. PSU exhibits excellent thermal stability with a glass transition temperature around 185°C and a continuous use limit of 125-150°C. It also demonstrates outstanding chemical resistance to acids, alkalis and aliphatic hydrocarbons. Sulfone polymers are highly resistant to oxidation, hydrolysis and radiation damage as well. Their dimensional stability, rigidity and melting point of around 270°C makes them useful for high-temperature applications. In addition, sulfone polymers also have good dielectric properties with a dielectric constant of around 3.0 and very low dielectric losses. Uses in Electrical & Electronics industries

Due to their superior electrical properties, sulfone polymers find major use in electrical and electronics applications. PSU is commonly used to produce printed circuit boards (PCBs), capacitors, connectors and switches as insulating materials that can handle high voltages and temperatures. Its ability to survive lead-free soldering processes further adds to its attractiveness for printed electronics. Sulfone polymer are also used to manufacture housings and parts for industrial equipment operating in harsh conditions like metering devices, semiconductor fabrication equipment, high voltage switchgears etc. Their resistance to corona discharge and hydrolysis makes them well-suited for outdoor insulators. New derivatives of sulfone polymers are being evaluated as gate insulators in photovoltaics and thin film devices owing to their favorable insulating properties. Medical Applications

In the medical industry, sulfone polymers find extensive applications owing to their biocompatibility and processing versatility. PSU is commonly used to make blood dialysis equipment including hemodialyzers, blood lines and dialysis cartridges. It provides an excellent thromboresistant surface and can be steam sterilized repeatedly. Sulfone polymers are also gaining popularity for manufacturing contact lenses as they can be easily fabricated into thin structures and impart significant oxygen permeability to the cornea. Their moldable nature allows producing complex contact lens geometries for orthokeratology and vision correction. Other medical uses include catheter tubing, drug delivery components, implantable devices and cartridges for insulin pens or syringes. New Developments

Continuous research efforts are being made to develop sulfone polymers with advanced properties. Copolymerization with other stabilizing units has enabled engineering higher glass transition temperatures over 250°C in new sulfone polymers. Grafting with siloxane side chains has also produced modified sulfone polymers with better hydrolytic stability and microporosity. Combining sulfone groups with biphenyl groups led to the development of polymers with extremely high modulus and strength, making them potential candidates for ballistic shielding and armor applications. New sulfone polymers based on polyamides, polyimides and polysulfides have also emerged with enhanced properties such as permeation resistance and bioerodibility. Future Outlook

Going forward, sulfone polymers are expected to gain further acceptance in niche applications that demand robust performance under extreme conditions of heat, chemicals and high voltages. New advanced materials from this family can facilitate greater penetration in developing technologies like water purification membranes, fuel cells, electrical energy storage, implantable medical devices and aerospace structural components. Continuous innovations in polymer chemistry are likely to birth novel sulfone polymers catering to emerging application spaces. Conclusion In conclusion, with their excellent thermal and chemical stability along with good processability, sulfone polymers have established themselves as premium engineering thermoplastics. They fulfill critical requirements in strategic industries from electronics and electrical equipment to medical technologies. Constant advancement in sulfone polymer chemistry is further expanding their application potential. Undoubtedly, sulfone polymers have a bright future ahead as high-performance materials for demanding environments.

0 notes

Text

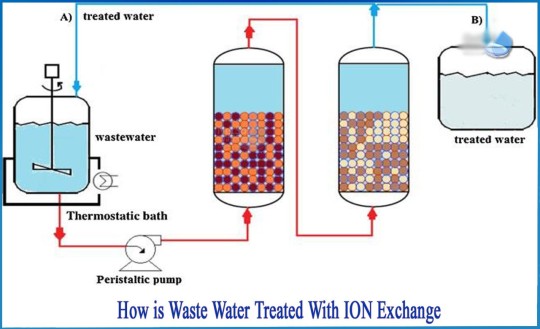

Ion Exchange Resins Market Growth - Global Industry In Depth Study And Huge Demand In Future 2023-2030

Ion exchange resins are a type of solid polymer material that can selectively exchange ions with a surrounding solution. They are widely used in various industrial and scientific applications, including water treatment, chemical processing, pharmaceuticals, food and beverage production, and more. Ion exchange resins are typically composed of small beads or particles made of a cross-linked polymer matrix, which provides a porous structure with a large surface area for ion exchange to occur. The polymer matrix is usually functionalized with specific chemical groups that determine the type of ions that can be exchanged. Common functional groups include sulfonic acid (-SO3H) for cation exchange resins that exchange positively charged ions (cations), and quaternary ammonium (-NR4+) for anion exchange resins that exchange negatively charged ions (anions).

The ion exchange process occurs when ions in a solution come into contact with the resin beads. The ions that have a higher affinity for the resin's functional groups will replace the ions originally attached to the resin, resulting in an exchange of ions between the resin and the solution. This allows for selective removal or recovery of specific ions from a solution.

The global ion exchange resins market is a growing industry that is driven by various factors, including increasing demand for clean water, growing awareness about water pollution and the need for water treatment, and the expanding industrial and manufacturing sectors. The ion exchange resins market is also influenced by factors such as regulatory requirements for water quality, advancements in technology, and increasing applications in diverse industries.

The market for ion exchange resins is segmented based on type, application, end-use industry, and geography. The most common types of ion exchange resins include cation exchange resins, anion exchange resins, and mixed bed resins. Cation exchange resins are used for cation exchange processes, anion exchange resins are used for anion exchange processes, and mixed bed resins are used for both cation and anion exchange processes.

Ion exchange resins find applications in various industries, including water treatment, chemical processing, pharmaceuticals, food and beverages, power generation, and others. In the water treatment industry, ion exchange resins are used for water softening, demineralization, dealkalization, and removal of heavy metals and other contaminants. In the chemical processing industry, they are used for purification, separation, and recovery of chemicals and compounds. In pharmaceuticals, they are used for drug purification and formulation. In food and beverages, they are used for juice and wine clarification, sugar decolorization, and other applications. In power generation, they are used for water treatment in boilers and condensers to prevent scale formation.

Geographically, the ion exchange resins market is segmented into regions such as North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Asia-Pacific is expected to be the fastest-growing region due to increasing industrialization, urbanization, and growing awareness about water pollution and the need for water treatment. North America and Europe are also significant markets for ion exchange resins due to strict water quality regulations and increasing demand for clean water.

Major players operating in the global ion exchange resins market include The Dow Chemical Company, Lanxess Ag, Purolite Corporation, Thermax Limited, Ion Exchange India Ltd., Samyang Holdings Corporation, Mitsubishi Chemical Holdings Corporation, Sunresin New Materials Co. Ltd., ResinTech Inc., Novasep Holding, Samyang Corporation, Bio-Rad Laboratories Inc. and Jiangsu Suqing Water Treatment Engineering Group Co., Ltd

Ion exchange resins find diverse applications across various industries due to their ability to selectively remove ions from solutions based on their functional groups. Some of the common applications of ion exchange resins are:

➢ Water treatment and purification: Ion exchange resins are widely used in water treatment and purification processes to remove contaminants such as dissolved salts, heavy metals, nitrates, and other pollutants from drinking water, industrial process water, and wastewater. These resins are used in both municipal and industrial water treatment plants to improve water quality, meet regulatory standards, and ensure safe and clean water supply.

➢ Chemical processing: Ion exchange resins are used in the chemical industry for various applications, such as purification of process streams, recovery of valuable compounds, and removal of impurities. They are used in processes such as demineralization, decolorization, deionization, and catalysis in chemical reactions, contributing to the production of high-quality chemicals and intermediates.

➢ Pharmaceuticals: Ion exchange resins are used in the pharmaceutical industry for purification of Active Pharmaceutical Ingredients (APIs) and other chemicals, as well as for drug formulation and drug delivery systems. These resins help in removing impurities, such as salts, organic compounds, and heavy metals, from pharmaceutical products to ensure their quality, safety, and efficacy.

➢ Food and beverages: Ion exchange resins are used in the food and beverage industry for water purification, as well as for removal of impurities, such as color, taste, and odor, from process streams. These resins help in improving the quality of drinking water, soft drinks, fruit juices, brewing water, and other food and beverage products.

➢ Power generation: Ion exchange resins are used in the power generation industry for water treatment in steam generation systems, such as boilers and condensers. These resins help in removing impurities from water, such as dissolved salts and heavy metals, to prevent scaling, corrosion, and fouling in the steam generation equipment, which can improve their efficiency and extend their lifespan.

➢ Electronics: Ion exchange resins are used in the electronics industry for purification of ultrapure water used in semiconductor manufacturing processes. These resins help in removing trace impurities from water, such as ions, organic compounds, and particulate matter, which can impact the quality and reliability of electronic devices.

➢ Mining and metallurgy: Ion exchange resins are used in the mining and metallurgy industry for recovery of valuable metals, such as gold, silver, uranium, and rare earth elements, from process streams and waste streams. These resins help in selectively adsorbing and recovering specific metal ions from complex mixtures, providing an efficient and cost-effective method for metal recovery.

➢ Environmental remediation: Ion exchange resins are used in environmental remediation processes for removal of contaminants from soil, groundwater, and other environmental matrices. These resins can selectively adsorb contaminants, such as heavy metals, radioactive ions, and organic pollutants, from environmental media, contributing to the cleanup of contaminated sites and protection of the environment.

➢ Other applications: Ion exchange resins are also used in various other applications, such as sugar refining, biotechnology, cosmetics, and personal care products, where purification, separation, and recovery of specific ions or compounds are required.

The ion exchange resins market offers several benefits, which contribute to its growing demand across various industries. Some of the key benefits of ion exchange resins are:

✦ Water purification ✦ Selective ion removal ✦ Process efficiency ✦ Wide range of applications ✦ Compliance with environmental regulations ✦ Improved product quality ✦ Cost-effective solution

In summary, the benefits of ion exchange resins include water purification, selective ion removal, process efficiency, wide range of applications, compliance with environmental regulations, improved product quality, and cost-effective solutions, which contribute to their growing demand in the market.

0 notes

Photo

Global Sulfone Polymers Industry 2019 Market Research Report Key Trends, Size, Shares, Forecast and Opportunities Sulfone Polymers Market Report The report offers an overview of the Sulfone Polymers with the help of application segments and geographical regions (United States, Europe, China, Japan, Southeast Asia, India, Central & South America, ROW) that govern the market currently.

0 notes

Text

Sulfone Polymers Market Global Industry Overview and Competitive Landscape till 2030

The sulfone polymer market is expanding due to the increase in demand for amorphous thermoplastics with higher strength and hydrolytic stability. A recent study by Future Market Insights (FMI) states that the global sulfone polymer market is expected to grow at 5.0% CAGR through 2030.

According to the report, the surge in demand from the healthcare and consumer products segments will propel the growth of the sulfone polymer market throughout the forecast period between 2022 and 2030. Sulfone polymer is increasingly used in electrical and electronics industry for miniaturization of electronics.

Demand for sulfone polymer from the electrical and electronics industry is anticipated to be worth US$ 354 Mn by 2030. This in turn is expected to bolster the growth of sulfone polymer market. FMI offers a holistic overview of the sulfone polymer market along with the detailed insights into growth drivers, restraints, and potential.

Key Companies Profiled:

BASF SE

Mitsubishi Chemicals Holdings Corporation

Sumitomo Chemical Co., Ltd.

Solvay SA

SABIC

Sino Polymer

UJU New Materials Co Ltd.

Shandong Horan

RTP Company

Who is Winning?

The global sulfone polymer market is highly competitive. In order to sustain in the positions, the key players in the market are started with launching of better quality products which target diverse end users.

For instance, SABIC has launched their new extensive range of sulfone polymers such as SUPER™ Metallocene Linear Low Density Polyethylene (mLLDPE), COHERE™ Metallocene Polyolefin Plastomer (POP), and others in the current year.

Sino Polymer has launched their new range of eco-friendly sulfone polymer such as BISPHENOL-A EPOXY VE, BROMINATED FR VE, NOVOLAC VE, and others in the recent year.

Get a Sample Copy of the Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-12871

Sulfone Polymers Markey by Category

By Product Type :

Polysulfone

Polyethersulfone

Polyphenylsulfone

By End Use :

Automotive & Transportation

Healthcare

Electrical & Electronics

Consumer Products

Industrial Processing

Others

More Valuable Insights on Sulfone Polymer Market

In the latest report by Future Market Insights, we offer an unbiased analysis of the global sulfone polymer market, providing historical data for the period of 2015-2021 and forecast statistics for the period of 2022-2030.

In order to understand the global market potential, its growth and scopes, the market is segmented on the basis of end use (automotive & transportation, consumer products, electrical & electronics, healthcare, industrial processing, others), product type (polyethersulfone, polyphenylsulfone, polysulfone), across six major regions (North America, Latin America, Europe, South Asia, East Asia, Oceania, MEA).

Browse latest Market Reports@ https://www.futuremarketinsights.com/category/chemicals-and-materials

0 notes

Text

Global 4 4-Dichlorodiphenyl Sulfone (DCDPS) Market - Industry Trends and Forecast to 2028

Global 4 4-Dichlorodiphenyl Sulfone (DCDPS) Market was valued at USD 325.2 million in 2021 and is expected to reach USD 518.8 million by the year 2028, at a CAGR of 6.9%.

4,4-Dichlorodiphenyl Sulfone (DCDPS), is a monomer utilized for the production of polysulfones (PES) through various polymerization methods. 4,4-Dichlorodiphenyl Sulfone (DCDPS) derived polysulfones have unique characteristics such as high transparency and high-temperature performance which makes them suitable replacements for glass and metals in a wide range of automotive, aerospace, medical, and consumer products. Moreover, DCDPS, or 4,4-Dichlorodiphenyl Sulfone (DCDPS), is a solid organic compound having molecular formula (C12H8Cl2O2S) and is in crystal or powder form. In addition, it is white. The rapid urbanization and the growing usage of electrical equipment, medical devices, and automobiles have compelled manufacturers to adopt polysulfones to decrease the stress on the natural sources of metals. 4,4-dichloro diphenyl sulfone (DCDPS) is essential as a starting material required for the production of polysulfones and polyethersulfones. Polysulfones and polyethersulfones are a family of thermoplastics called engineering plastics and are utilized in applications operating at high temperatures.

The global 4 4-Dichlorodiphenyl Sulfone (DCDPS) market research investigates the market in-depth and offers a comprehensive analysis of the major growth determinants, 4 4-Dichlorodiphenyl Sulfone (DCDPS) market share, current trends, key players, and their future predictions. In addition, market demand and supply, each geographical region's growth rate, and market potential are all included in the 4 4-Dichlorodiphenyl Sulfone (DCDPS) Market study. Raw materials, marketing channels, client surveys, industry trends and proposals, CAGR status, product scope, 4 4-Dichlorodiphenyl Sulfone (DCDPS) market trends, major leading countries/regions, market risk, and market driving force are all included in the market research. The market prediction was based on a thorough market investigation completed by several industry experts.

To learn more about this report, request a free sample copy:

https://introspectivemarketresearch.com/request/6061

Key Industry Players in 4 4-Dichlorodiphenyl Sulfone (DCDPS) Market:

· Aarti Industries Ltd. (India)

· Atul Ltd (India)

· Banchem Intermediates (India)

· Jiujiang Zhongxing Medicine Chemical Co. Ltd.

· Solvay S.A (Belgium)

· TCI Chemicals Private Limited (India)

· Nantong VolantChem Corp. (China)

· Huai'an Shengli Materials Co. Ltd. (China)

· Vertellus Holdings Inc. (US)

· BASF SE (Germany)

· Jiangmen Youju (China)

· Sino Polymer (China) and Others major players.

Demand for 4,4-dichlorodiphenyl sulfone (DCDPS) is predominantly increasing in the pharmaceutical and life sciences industry. It is the precursor for the development of equipment used in critical life science applications such as hemodialysis. Heavy investment to strengthen the medical infrastructure is the main driving factor for the growth of the DCDPS market.

Segmentation Analysis Includes,

By Grade:

· Industry

· Pharma

By Application:

· Engineered Plastics

· Pharmaceutical Drug

· Others

By Region:

· North America (U.S., Canada, Mexico)

· Europe (Germany, U.K., France, Italy, Russia, Spain, Rest of Europe)

· Asia-Pacific (China, India, Japan, Singapore, Australia, New Zealand, Rest of APAC)

· Middle East & Africa (Turkey, Saudi Arabia, Iran, UAE, Africa, Rest of MEA)

· South America (Brazil, Argentina, Rest of SA)

Will you have any doubt about this report? Please contact us on:

https://introspectivemarketresearch.com/inquiry/6061

Reasons to Purchase this Report:

· Qualitative and quantitative analysis of the market based on segmentation involving both economic as well as non-economic factors

· Provision of market value (USD Billion) data for each segment and sub-segment

· Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market

· Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region

· Competitive landscape which incorporates the market ranking of the major players, along with new service/product launches, partnerships, business expansions, and acquisitions in the past five years of companies profiled

This report offers useful peakthroughs that influence the growth of the 4, 4-dichlorodiphenyl sulfone market positively. It also focuses on various parameters such as key trends, competitive structure, regional assessment, etc. The segmental study enables an individual to thoroughly understand the different growth aspects of the 4, 4-dichlorodiphenyl sulfone market in a well-ordered manner.

Purchase This Report: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=6061

The pharmaceutical industry is set to grow at a faster rate going forward owing to its unique role in developing new medicines and vaccines to improve the lives of patients worldwide. DCDPS is considered to be a very important component, especially for the development of polymers used in critical medical procedures. Government initiatives for the production of pharma grade 4,4-dicholordiphenyl sulfone are an enticing opportunity for market players to enhance their production capacity as well as the quality of the substrate being produced.

Related Report: -

https://introspectivemarketresearch.com/reports/phenyl-tribromomethyl-sulfonephotoinitiator-bmps-market/

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyze extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1047

Linkedin| Twitter| Facebook

Email: [email protected]

0 notes

Text

High temperature Thermoplastics Market to Witness Astonishing Growth by 2027

Stratview Research delivers key insights on the global High temperature Thermoplastics Market. According to Stratview Research, the market is estimated to grow at a decent CAGR of 5.1% during the forecast period to reach a value of US$ 310 Million in 2027.

Get a free sample report here:

The present report can be of high utility for the key decision-makers and growth strategists in terms of precise market insights, forthcoming growth opportunities, and key success factors. Especially, the report also analyses and mentions the possible impact of COVID-19 on the market dynamics. This will not only help in mitigating the uncertain business environment, but also help in rearranging the strategies and future- decisions in a fruitful manner.

Key Players

The following are some of the key players in the High temperature Thermoplastics Market:

Solvey S.A

BASF

Evonik Industries

Dupont

Celanese Corporation

Arkema

SABIC

Toray

Royal DSM

Victrex.

Growth drivers and Market Value:

This report, from Stratview Research, studies the High Temperature Thermoplastics Market value and growth drivers over the trend period of 2022-27. According to the report -

High Temperature Thermoplastics market is likely to witness a CAGR of 8.8% during the forecast period. The prime factors that are driving the high temperature thermoplastics market is its superior thermal conductivity property leading to its wide usage in a wide array of industries.

Segment Analysis:

Based on Type:

Based on the type, the market is segmented as high temperature fluoropolymers, high performance polyamide (HPPA), polyphenylene sulfide (PPS), sulfone polymers (SP), liquid crystal polymers (LCP), aromatic ketone polymers (AKP), and polyimide (PI). The high temperature fluoropolymers segment dominated the market in 2021, and is expected to maintain its position during the forecast period. Sulfone polymers (SP) are expected to witness the highest growth during the forecast period owing to increasing penetration in various end-use industries such as electricals & electronics and industrial.

Based on Region:

In terms of regions, Asia-Pacific is estimated to be the largest market for high temperature thermoplastics during the forecast period. China, Japan, South Korea, Taiwan, and India are the largest consumer of high temperature thermoplastics in the region. Significant economic development in the region is paving the path of transportation, electricals & electronics, medical, and industrial sectors, leading to a higher demand for high temperature thermoplastics in the region. North America and Europe are also expected to witness a healthy demand for high temperature thermoplastics during the forecast period.

Know more about the report, click here

FREQUENTLY ASKED QUESTIONS

The report answers several questions related to the market. The user can get to know the answers to the following questions…

What is the global demand for High temperature Thermoplastics Market in terms of revenue?

Which are the prominent players in the market?

At what CAGR is the market projected to grow within the forecast period?

What are the driving factors fuelling the growth of the market?

Which region accounted for the largest share in the market?

How did the Covid19 impacted the market?

How long will it take to recover from the Covid impact?

Why Stratview Research?

Exhaustive qualitative and quantitative data

Uninterrupted post-sales support

Appropriate market trend and forecast analysis.

All-inclusive report

Decent price-performance ratio

Reliable data

Attractive market segments and associated growth opportunities.

Customised report services

About Us –

Stratview Research is a leading global market research firm providing expert research solutions, trusted by clients worldwide. To keep our clients ahead of the curve, we provide data backed by extensive market research and in-depth industry knowledge. The broad spectrum of integrated insights is referred to, and cited by press releases, interview with key players, white papers, journals, etc. Stratview research also offers custom research services across the sectors. In case of any custom research requirement related to market assessment, competitive benchmarking, sourcing and procurement, target screening, and others, please connect with our team.

Get in touch with us for more details –

Call: +1-313-307-4176

Or Mail Us: [email protected]

0 notes

Text

Industry analysis provides a company with an understanding of its position relative to other companies in the industry. This can help them identify opportunities and potential threats, so they can prepare for the present and future. MRI Research helps organizations to figure out whats happening in a given industry, including demand and supply statistics, degree of competition, state of competition with other emerging industries, future prospects considering technological changes, and external factors on the industry.

0 notes

Photo

The global high-performance thermoplastics market size is estimated to reach USD 65.6 billion by 2026 according to a new report by Polaris Market Research. The report “High Performance Thermoplastics Market Size, Share & Industry Report By Product Type (Polyamides, Polyphenylsufone, Sulfone Polymers, Liquid Crystal Polymers, Aromatic Polyketones, Polyethersulfone), By Application (Electrical & Electronics, Automotive, Aircraft, Industrial), By Regions, & Segment Forecast, 2019 – 2026” provides competent analysis of current market position and portrays future market trends.

0 notes

Text

High Performance Plastics Market Analysis Research Report to 2027

The report provides a detailed analysis of the main dynamics affecting both positively and negatively the High Performance Plastics Market . The study included drivers, opportunities and industry challenges. It helps you understand the main factors that affect market developments and therefore develop your business strategy. The report contains forecast information for the near future. In this way, you will learn how the market has worked in the past and how it will work in the following years. The historical and forecast analysis therefore includes global market sales and revenue data.

COVID-19 Impact Analysis

The report showed how the COVID-19 pandemic affected the High Performance Plastics Marketfollowing the analysis of the entire market. All the parameters cover the overall market value, market share, and market growth impact of COVID -19 and how these changes are applied by major players in the particular market. This will help you understand how the coronavirus pandemic has overall optimistic, pessimistic and neutral effects on the market.

Get a sample of report @ https://www.intelligencemarketreport.com/report-sample/97480

Key players for the report:

Dupont Sabic Solvay Daikin DSM 3M Kaneka Arkema Dongyue Evonik Celanese Ube Industries Sumitomo Sichuan Chenguang AGC Toray Polyplastics Saint-Gobain Kureha DIC Gujarat Fluorochemicals Juhua Group BASF HaloPolymer Shin-Etsu RTP Company Ueno Fine Chemicals Flontech Nylacast Prochase Enterprise

Market Segmentation

The latest report on the High Performance Plastics Market includes detailed segmentation of the market based on product types, application, end-use, and regions. In this section, the report covers in-depth analysis for each segment and sub-segment of the market. This information is crucial for market players to understand the direction of the market development.

Segment by Type Fluoropolymers (FPS) High-performance Polyamides (HPPA) Polyphenylene Sulfide (PPS) Sulfone Polymers Liquid Crystal Polymers Other Segment by Application Transportation Medical Electrical and Electronics Industrial Others

Enquiry for the report @ https://www.intelligencemarketreport.com/send-an-enquiry/97480

Regional Overview

This report provides a comprehensive study of the country- and regional High Performance Plastics Market and analyses the industry trends from sales, turnover and consumption in each regions. It will help you understand which region dominates the market and is expected to grow substantially in the next few years. Regional analysis helps you to strategize business expansion.

Competitive Scenario

The market growth factors are discussed in detail, explaining in detail the various end customers of the market. Data and information can be added according to the specific requirements by market player, region, type, application and etc. The SWOT market analysis is contained in the report. Finally, the High Performance Plastics Market report includes the final part of the opinion of the industrial experts. To gain in-depth market analysis and understand the global market and its business landscape.

This helps you understand the competitiveness of the market and how other players performing within the market. This detailed competitive analysis can help you to strategize and keep you a step ahead of you. From the sales, revenues and price point of view, a quantitative and qualitative analysis of the main players in the market is introduced.

Complete analysis of the report @ https://www.intelligencemarketreport.com/market-report/high-performance-plastics-market

Contact US

Akash Anand

Head of Business Development & Strategy

Website: www.intelligencemarketreport.com

About US

Intelligence Market Report includes a comprehensive rundown of statistical surveying reports from many distributers around the world. We brag an information base traversing basically every market classification and a much more complete assortment of statistical surveying reports under these classifications and sub-classifications.

0 notes

Text

Global Top 7 Companies Accounted for 73% of total Alkyl Naphthalene Sulfonates market (QYResearch, 2021)

Alkyl naphthalene sulfonates are regarded as surface-active hydrotropes. They exhibit characteristics such as wetting,foaming, detergency and surface tension reduction. They have excellent rinseability, acid and base stability, hard-watertolerance and high-temperature stability.

According to the new market research report “Global Alkyl Naphthalene Sulfonates Market Report 2023-2029”, published by QYResearch, the global Alkyl Naphthalene Sulfonates market size is projected to reach USD 0.26 billion by 2029, at a CAGR of 4.5% during the forecast period.

Figure. Global Alkyl Naphthalene Sulfonates Market Size (US$ Million), 2018-2029

Figure. Global Alkyl Naphthalene Sulfonates Top 7 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Alkyl Naphthalene Sulfonates include Nouryon, Solvay, etc. In 2021, the global top three players had a share approximately 73.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Insights into the Global Sulfone Polymer Market: Trends, Growth Factors, and Future Outlook

Sulfone Polymer: Engineered for Outstanding Thermal and Chemical Resistance What are Sulfone Polymer? Sulfone macromolecules are a class of thermoplastic macromolecules characterized by a sulfone group (S=O2) present in the main macromolecule chain. Commonly used sulfone macromolecules include polysulfone (PSU), polyethersulfone (PES), and polyphenylsulfone (PPSU). These macromolecules exhibit outstanding thermal stability, chemical resistance, and mechanical strength, making them well-suited for applications across many industries. Thermal and Chemical Resistance One of the most notable properties of sulfone macromolecules is their high heat deflection temperature. PSU, PES, and PPSU can withstand continuous temperatures up to 150-180°C without significant loss of properties. Their unique sulfone group results in strong intermolecular forces that impart exceptional thermal stability. In addition to heat, sulfone macromolecules boast strong resistance to chemicals such as solvents, acids, bases, and disinfectants. The sulfone moiety is moderately polar but non-reactive, preventing dissolution or chemical attack. PSU, PES, and PPSU maintain their strength and functionality when exposed to chemicals where other plastics would degrade. This chemical inertness makes them preferred materials for applications involving harsh chemicals. Mechanical Strength and Rigidity While being thermally stable and chemically resistant, sulfone macromolecules also offer good mechanical properties. They have high tensile and flexural modulus similar to engineering thermoplastics like polycarbonate. PSU, PES, and PPSU components exhibit little creep under long-term loading and stress. The rigid backbone of sulfone macromolecules gives them high strength-to-density ratios. For instance, PSU and PES have tensile strengths over 80 MPa but densities of only 1.24 g/cm3. Their rigidity makes sulfone macromolecules dimensional stable during fabrication processes as well as in-use conditions.warping and material loss over time. Electrical Properties Sulfone macromolecules also display beneficial electrical properties. They have very high bulk resistivity (>1016 Ω-cm), rendering them suitable for electrical insulation applications. PSU, PES, and PPSF exhibit both high dielectric strength and excellent resistance to tracking and arcing. In addition, sulfone macromolecules demonstrate low dissipation factors and dielectric constants. PES in particular has one of the lowest dielectric constants of any thermoplastic at only 2.6. These electrical attributes open opportunities in applications requiring precise low-loss insulation, such as capacitors, cables, transformers, and connectors.

0 notes