#Sulfone Polymer Market

Explore tagged Tumblr posts

Text

Sulfone Polymer Market: Impact Analysis of COVID-19 on the Market

Sulfone Polymers: A Versatile Class of Thermoplastics Sulfone polymers are a class of high-performance engineering thermoplastics known for their exceptional heat resistance, chemical resistance and electrical properties. They have been used in diverse applications ranging from electrical and electronic components to medical devices. In this article, we will discuss the key characteristics of sulfone polymers along with their various uses and future potential. Chemical Structure and Properties

Sulfone polymers are characterized by the sulfone group (O=S=O) in their main chain. The most common commercial sulfone polymer is polysulfone (PSU) which was first developed by Union Carbide in the late 1960s. PSU has an aromatic backbone containing bisphenol units linked together by sulfone groups. This linear structure gives PSU its robust thermomechanical properties. PSU exhibits excellent thermal stability with a glass transition temperature around 185°C and a continuous use limit of 125-150°C. It also demonstrates outstanding chemical resistance to acids, alkalis and aliphatic hydrocarbons. Sulfone polymers are highly resistant to oxidation, hydrolysis and radiation damage as well. Their dimensional stability, rigidity and melting point of around 270°C makes them useful for high-temperature applications. In addition, sulfone polymers also have good dielectric properties with a dielectric constant of around 3.0 and very low dielectric losses. Uses in Electrical & Electronics industries

Due to their superior electrical properties, sulfone polymers find major use in electrical and electronics applications. PSU is commonly used to produce printed circuit boards (PCBs), capacitors, connectors and switches as insulating materials that can handle high voltages and temperatures. Its ability to survive lead-free soldering processes further adds to its attractiveness for printed electronics. Sulfone polymer are also used to manufacture housings and parts for industrial equipment operating in harsh conditions like metering devices, semiconductor fabrication equipment, high voltage switchgears etc. Their resistance to corona discharge and hydrolysis makes them well-suited for outdoor insulators. New derivatives of sulfone polymers are being evaluated as gate insulators in photovoltaics and thin film devices owing to their favorable insulating properties. Medical Applications

In the medical industry, sulfone polymers find extensive applications owing to their biocompatibility and processing versatility. PSU is commonly used to make blood dialysis equipment including hemodialyzers, blood lines and dialysis cartridges. It provides an excellent thromboresistant surface and can be steam sterilized repeatedly. Sulfone polymers are also gaining popularity for manufacturing contact lenses as they can be easily fabricated into thin structures and impart significant oxygen permeability to the cornea. Their moldable nature allows producing complex contact lens geometries for orthokeratology and vision correction. Other medical uses include catheter tubing, drug delivery components, implantable devices and cartridges for insulin pens or syringes. New Developments

Continuous research efforts are being made to develop sulfone polymers with advanced properties. Copolymerization with other stabilizing units has enabled engineering higher glass transition temperatures over 250°C in new sulfone polymers. Grafting with siloxane side chains has also produced modified sulfone polymers with better hydrolytic stability and microporosity. Combining sulfone groups with biphenyl groups led to the development of polymers with extremely high modulus and strength, making them potential candidates for ballistic shielding and armor applications. New sulfone polymers based on polyamides, polyimides and polysulfides have also emerged with enhanced properties such as permeation resistance and bioerodibility. Future Outlook

Going forward, sulfone polymers are expected to gain further acceptance in niche applications that demand robust performance under extreme conditions of heat, chemicals and high voltages. New advanced materials from this family can facilitate greater penetration in developing technologies like water purification membranes, fuel cells, electrical energy storage, implantable medical devices and aerospace structural components. Continuous innovations in polymer chemistry are likely to birth novel sulfone polymers catering to emerging application spaces. Conclusion In conclusion, with their excellent thermal and chemical stability along with good processability, sulfone polymers have established themselves as premium engineering thermoplastics. They fulfill critical requirements in strategic industries from electronics and electrical equipment to medical technologies. Constant advancement in sulfone polymer chemistry is further expanding their application potential. Undoubtedly, sulfone polymers have a bright future ahead as high-performance materials for demanding environments.

0 notes

Text

Sulfone Polymer Market Transformation: Reshaping Industries with Advanced Materials

The sulfone polymer market size is expected to reach US$ 2.6 Mn by 2030, from US$ 1.4 Mn in 2023, at a CAGR of 9.3% during the forecast period. Sulfone polymers such as polysulfone, polyethersulfone, and polyphenylsulfone are high performance thermoplastics offering exceptional thermal, mechanical, and electrical properties. They find major applications in electronics, automotive components, and water treatment membranes owing to attributes like heat resistance, hydrolytic stability, and structural integrity. Key drivers are increasing use in consumer electronics and automobile production, along with water treatment investments globally.

The sulfone polymer market is segmented by product type , application, and region. By product, the market is segmented into polysulfone, polyethersulfone, polyphenylsulfone keton and others. Polysulfone is the largest segment and is expected to grow steadily due to its wide use in electrical, healthcare, and food processing equipment, which require repeated steam sterilization for durability.

0 notes

Text

Chlorosulphonic Acid in Agrochemical Production

When it comes to industrial chemicals, Chlorosulfonic acid stand out for their remarkable versatility and importance in various sectors. At Maruti Fine Chemicals, we specialize in providing high-quality chemical solutions that meet the diverse needs of industries worldwide.

Chlorosulphonic Acid

This acid is a highly reactive compound with the chemical formula ClSO₃H. This colorless to slightly yellow fuming liquid is a chlorinated derivative of sulfuric acid, known for its strong acidity and reactivity. It is a critical intermediate in the production of numerous industrial and consumer products.

Environmental Impact and Sustainability

While this acid is a vital industrial chemical, its use must be balanced with environmental considerations. We are committed to sustainability by promoting the responsible use and disposal of chemicals. Our production processes are designed to minimize waste and reduce environmental footprints.

Future Trends in the Use of Acid

The demand for Chlorosulfonic acid is expected to grow with advancements in the chemical, pharmaceutical, and agricultural sectors. Innovations in sustainable practices and improved manufacturing techniques are likely to enhance its applications while reducing environmental concerns.

Emerging Trends and Future Outlook

The demand for Chlorosulphonic Acid is projected to grow with advancements in chemical manufacturing, pharmaceuticals, and agriculture. Industries are continually finding new applications for this versatile chemical while focusing on sustainable production practices. Maruti Fine Chemicals is at the forefront of these innovations, ensuring that its customers stay ahead in their respective markets.

Applications

It plays a pivotal role in numerous industries. Here are some of its prominent applications:

1. Detergent and Surfactant Manufacturing

One of the most common uses of this acid is in the production of detergents and surfactants. It acts as a sulfonating agent, introducing sulfonic acid groups into organic compounds, which are then used to manufacture cleaning agents with excellent emulsifying properties.

2. Pharmaceutical Industry

In the pharmaceutical sector, this acid is employed as a reagent in the synthesis of various drugs and active pharmaceutical ingredients (APIs). Its ability to introduce functional groups makes it indispensable for creating complex chemical structures.

3. Dye and Pigment Production

The dye industry relies on Chlorosulfonic Acid to sulfonate aromatic compounds, enabling the production of vibrant and long-lasting dyes. This process enhances the solubility and binding capacity of dyes to fabrics and surfaces.

4. Pesticides and Agrochemicals

The agrochemical industry uses Chlorosulphonic Acid in the synthesis of pesticides and herbicides. Its reactivity ensures the efficient production of compounds that protect crops from pests and diseases.

5. Polymer and Resin Manufacturing

Chlorosulphonic Acid serves as a catalyst in the production of specialty polymers and resins. It helps modify polymer structures, enhancing their durability and performance in various applications.

6. Electronics Industry

In the electronics sector, this compound is utilized in the etching of semiconductor materials and the preparation of advanced chemical solutions for microfabrication.

Why Choose Us?

1.Quality Assurance: We adhere to strict quality control measures to ensure that our products meet industry standards.

2.Custom Solutions: Our team works closely with clients to provide customized chemical solutions for specific applications.

3.Safe Packaging: We prioritize safe and secure packaging to maintain the integrity of our products during transit.

4.Technical Support: Our experts are always available to provide guidance on the proper use and handling of acid.

FAQs

Q1: What industries use Chlorosulfonic acid the most? A1: The pharmaceutical, dye, detergent, and chemical industries are the primary users of Chlorosulfonic acid.

Q2: How should Chlorosulfonic acid be stored? A2: It should be stored in airtight containers, away from moisture, heat, and incompatible substances.

Q3: What makes us a reliable supplier? A3: We offers high-purity products, reliable delivery, and excellent technical support.

Q4: Is there a difference between Chlorosulphonic Acid and Chlorosulfonic Acid? A4: No, both terms refer to the same chemical compound.

Q5: Can Chlorosulphonic Acid be used in agriculture? A5: Yes, it is used in the production of agrochemicals such as herbicides and pesticides.

Conclusion

Chlorosulphonic Acid, or Chlorosulfonic acid is a cornerstone of modern chemical manufacturing. Its versatility and effectiveness in diverse applications make it an indispensable compound for industries ranging from detergents to electronics. At Maruti Fine Chemicals, we ensure that our clients receive the highest-quality chemicals coupled with expert support and safe practices. For your industrial needs, trust us as your reliable partner in chemical solutions.

0 notes

Text

0 notes

Text

Sulfone Polymers Market In-Depth Research Analysis, Dynamics Opportunities, and Challenges, and Future Outlook

The Sulfone Polymers Market is Valued at USD 1.42 billion in 2024 and is projected to reach USD 2.2 billion by 2032, growing at a CAGR of 5.00% During the Forecast period of 2024–2032.

Introduction: Sulfone polymers are high-performance thermoplastics known for their exceptional thermal stability, mechanical strength, and chemical resistance. These polymers are widely utilized in various industries, including automotive, aerospace, medical, and electronics, due to their ability to maintain performance under extreme conditions. The sulfone polymers market has witnessed significant growth in recent years, driven by increasing demand for lightweight and durable materials across these sectors.

Download a Free Sample Copy of the Report: https://www.marketdigits.com/request/sample/3429

Major Players In Sulfone Polymers Market Include: ↬ Mitsubishi Chemicals Holdings Corporation, ↬ Sumitomo Chemical Co., Ltd., ↬ Solvay SA, ↬ Saudi Basic Industries Corporation (SABIC), ↬ Sino Polymer, ↬ BASF SE, ↬ UJU New Materials Co Ltd., ↬ Shandong Horan, ↬ RTP Company, ↬ Westlake Plastics Company, Inc, ↬ LATI Industria Termoplastici SpA, ↬ Centroplast Engineering Plastics GmbH, ↬ Ovation Polymers, Inc., ↬ Aquapharm Chemicals Pvt., Ltd., ↬ Jinmen Youju New Materials Co., ↬ GEHR GmbH, ↬ Evonik Industries AG, ↬ PolyOne Corporation, ↬ Americhem Engineered Compounds, ↬ Youju New Materials Co., Ltd ↬ and others.

Why Should Access This Report? Accessing this comprehensive report on the sulfone polymers market is crucial for industry stakeholders, investors, and decision-makers looking to stay ahead in a competitive landscape. The report provides detailed insights into market trends, key drivers, and potential opportunities, helping businesses make informed decisions. By understanding the market dynamics and future outlook, stakeholders can strategize effectively to maximize their market presence and profitability.

Inquire Before Buying at — https://www.marketdigits.com/request/enquiry-before-buying/3429

Major Segmentataions:

By Product Type

Polysulfone Polymers (PSU)

Polyethersulfone Polymers (PESU)

Polyphenylsulfone Polymers (PPSU)

By Application

Orthopedic Devices

Coatings

Consumer Electronics

Aircraft Interiors

Composites

Fittings & Manifolds

Others

By End-use

Automotive & Transportation

Healthcare

Electrical & Electronics

Consumer Products

Industrial Processing

Aerospace

Others

The Report Offers: ➤ Market Overview: Comprehensive overview of the sulfone polymers market, including market size, growth trends, and key segments. ➤ Competitive Landscape: Analysis of key players in the market, their market share, strategies, and recent developments. ➤ Market Drivers and Challenges: Identification of major factors driving market growth and potential challenges faced by industry players. ➤ Opportunities and Forecast: Insights into emerging opportunities, market forecasts, and growth prospects over the next five years. ➤ Regional Analysis: Detailed analysis of the market across different regions, highlighting key markets and regional trends. ➤ Application Insights: Examination of various applications of sulfone polymers in different industries and their market potential.

Click to Request Free 10% Customization on this Report @ https://www.marketdigits.com/request/customization/3429

Mostly Asked Questions: ➲What are sulfone polymers, and what makes them unique compared to other thermoplastics? ➲ What are the primary applications of sulfone polymers in various industries? ➲ What factors are driving the growth of the sulfone polymers market? ➲ Who are the key players in the sulfone polymers market, and what are their strategies? ➲ What are the challenges faced by the sulfone polymers industry, and how can they be addressed?

Conclusion: The sulfone polymers market is poised for significant growth, driven by the increasing demand for high-performance materials in various industries. This comprehensive report provides valuable insights into the market dynamics, competitive landscape, and future prospects, making it an essential resource for industry stakeholders and decision-makers. By leveraging the information in this report, businesses can effectively navigate the market and capitalize on emerging opportunities.

0 notes

Text

Battery Grade Propanesulfolactone, Global Market Size Forecast, Top 10 Companies Rank and Market Share

Battery Grade Propanesulfolactone Market Summary

Battery grade propanesulfolactone, also known as propanesultone, is a chemical compound that is sometimes used as an electrolyte additive in lithium-ion batteries. It is a cyclic sulfonic ester with the molecular formula C3H6O3S. Propanesulfolactone is a colorless liquid with a slightly sweet odor.

According to the new market research report “Global Battery Grade Propanesulfolactone Market Report 2024-2030”, published by QYResearch, the global Battery Grade Propanesulfolactone market size is projected to reach USD 0.04 billion by 2030, at a CAGR of 6.9% during the forecast period.

Figure. Global Battery Grade Propanesulfolactone Market Size (US$ Million), 2019-2030

Figure. Global Battery Grade Propanesulfolactone Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

According to QYResearch Top Players Research Center, the global key manufacturers of Battery Grade Propanesulfolactone include Jiangsu Hicomer New Material, Changshu Juhe Chemical, etc. In 2023, the global top three players had a share approximately 45.0% in terms of revenue.

About The Authors

Yunmei Sun---Lead Author

Email: [email protected]

Sun Yunmei has 2 years of industry research experience, focusing on research in the chemical industry chain related fields, including medical grade reagents, high-purity reagents for semiconductors, and chemical laboratory equipment.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

0 notes

Text

https://www.custommarketinsights.com/report/sulfone-polymers-market/

0 notes

Text

0 notes

Text

Sulfone Polymer Market: Innovations and Advancements in Electronic Components

Sulfone polymer, also known as polysulfone, is a highly temperature resistant material used for its strength, durability and resistance to chemicals. It is commonly used to produce medical devices such as dialyzers, blood filters and artificial organs owing to its bio-compatibility. Sulfone polymers do not leach any toxic chemicals and can withstand high temperatures, making them ideal for uses in the medical industry.

The global sulfone polymer market is estimated to be valued at US$ 2.65 Bn in 2023 and is expected to exhibit a CAGR of 9.3% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights. Market Opportunity: Increasing Demand from Medical Industry The key market opportunity for sulfone polymer market lies in the increasing demand from the medical industry. Sulfone polymers are widely used in medical devices such as dialyzers, syringes, blood oxygenators, contact lenses and surgical instruments owing to their bio-compatibility and chemical resistance. Growing elderly population and increasing healthcare expenditure is expected to boost the demand for various medical devices. As sulfone polymers are an integral part of manufacturing these devices, increasing demand from the medical industry will have a positive impact on the growth of the sulfone polymer market over the forecast period. Advantages of sulfone polymers such as non-toxicity, chemical resistance and heat stability make them suitable for critical medical applications. Porter’s Analysis

Threat of new entrants: The threat of new entrants in the sulfone polymer market is moderate. High capital requirements and established brand value of existing players creates barriers for new players.

Bargaining power of buyers: The bargaining power of buyers is high due to availability of substitutes. Buyers can negotiate on price and demand customized products.

Bargaining power of suppliers: The bargaining power of suppliers is moderate. Suppliers of raw materials like bisphenol-A and PBT have moderate switching costs.

Threat of new substitutes: The threat of substitutes is high due to availability of alternative polymers like polyetherketone, polyetherimide and polyphenylene sulfide in the market.

Competitive rivalry: The competitive rivalry is high among the key players to gain major market share. SWOT Analysis

Strength: High heat and chemical resistance properties make sulfone polymers suitable for use in automotive, electronics and healthcare industries. Excellent dimensional stability and low moisture absorption characteristics provides durability.

Weakness: High production cost of sulfone polymers compared to alternatives limits its use in price sensitive applications. Complex production process poses challenge for mass production.

Opportunity: Growing demand for lightweight and durable polymers from automotive and aerospace industries due to stringent regulations creates market opportunity. Increasing R&D on polymer blends can help utilize properties efficiently.

Threats: Volatility in price of crude oil poses threat to raw material supply and price fluctuations. Stringent environmental regulations regarding production waste disposal can increase compliance cost. Key Takeaways

The global sulfone polymer market is expected to witness high growth during the forecast period of 2023-2030. The market is expected to reach a value of US$ 4.45 Bn by 2030 expanding at a CAGR of 9.3% from 2023 to 2030.

The Asia Pacific region dominates the global sulfone polymer market with over 35% share in 2023 in terms of value. China leads the Asia Pacific sulfone polymer market due to presence of large automotive and electronics industry. Key players operating in the sulfone polymer market are Solvay, BASF, Sumitomo, Evonik, Sabic, Ensinger GmbH, PolyOne Corporation, RTP Company, Mitsubishi Chemical, and Omnia Plastica SPA. Solvay and BASF capture over 35% of the global sulfone polymer market share. Solvay offers a wide range of sulfone polymers under the name Udel P-1700, Udel P-1750, Udel P-1800 for automotive, medical and electronics applications.

0 notes

Text

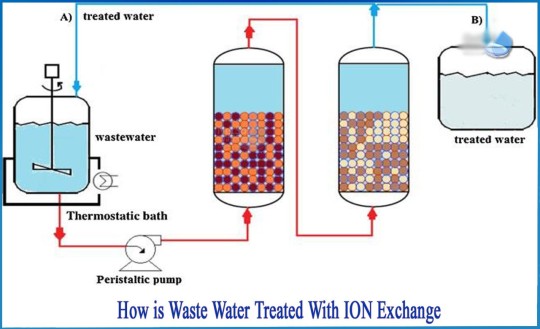

Ion Exchange Resins Market Growth - Global Industry In Depth Study And Huge Demand In Future 2023-2030

Ion exchange resins are a type of solid polymer material that can selectively exchange ions with a surrounding solution. They are widely used in various industrial and scientific applications, including water treatment, chemical processing, pharmaceuticals, food and beverage production, and more. Ion exchange resins are typically composed of small beads or particles made of a cross-linked polymer matrix, which provides a porous structure with a large surface area for ion exchange to occur. The polymer matrix is usually functionalized with specific chemical groups that determine the type of ions that can be exchanged. Common functional groups include sulfonic acid (-SO3H) for cation exchange resins that exchange positively charged ions (cations), and quaternary ammonium (-NR4+) for anion exchange resins that exchange negatively charged ions (anions).

The ion exchange process occurs when ions in a solution come into contact with the resin beads. The ions that have a higher affinity for the resin's functional groups will replace the ions originally attached to the resin, resulting in an exchange of ions between the resin and the solution. This allows for selective removal or recovery of specific ions from a solution.

The global ion exchange resins market is a growing industry that is driven by various factors, including increasing demand for clean water, growing awareness about water pollution and the need for water treatment, and the expanding industrial and manufacturing sectors. The ion exchange resins market is also influenced by factors such as regulatory requirements for water quality, advancements in technology, and increasing applications in diverse industries.

The market for ion exchange resins is segmented based on type, application, end-use industry, and geography. The most common types of ion exchange resins include cation exchange resins, anion exchange resins, and mixed bed resins. Cation exchange resins are used for cation exchange processes, anion exchange resins are used for anion exchange processes, and mixed bed resins are used for both cation and anion exchange processes.

Ion exchange resins find applications in various industries, including water treatment, chemical processing, pharmaceuticals, food and beverages, power generation, and others. In the water treatment industry, ion exchange resins are used for water softening, demineralization, dealkalization, and removal of heavy metals and other contaminants. In the chemical processing industry, they are used for purification, separation, and recovery of chemicals and compounds. In pharmaceuticals, they are used for drug purification and formulation. In food and beverages, they are used for juice and wine clarification, sugar decolorization, and other applications. In power generation, they are used for water treatment in boilers and condensers to prevent scale formation.

Geographically, the ion exchange resins market is segmented into regions such as North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Asia-Pacific is expected to be the fastest-growing region due to increasing industrialization, urbanization, and growing awareness about water pollution and the need for water treatment. North America and Europe are also significant markets for ion exchange resins due to strict water quality regulations and increasing demand for clean water.

Major players operating in the global ion exchange resins market include The Dow Chemical Company, Lanxess Ag, Purolite Corporation, Thermax Limited, Ion Exchange India Ltd., Samyang Holdings Corporation, Mitsubishi Chemical Holdings Corporation, Sunresin New Materials Co. Ltd., ResinTech Inc., Novasep Holding, Samyang Corporation, Bio-Rad Laboratories Inc. and Jiangsu Suqing Water Treatment Engineering Group Co., Ltd

Ion exchange resins find diverse applications across various industries due to their ability to selectively remove ions from solutions based on their functional groups. Some of the common applications of ion exchange resins are:

➢ Water treatment and purification: Ion exchange resins are widely used in water treatment and purification processes to remove contaminants such as dissolved salts, heavy metals, nitrates, and other pollutants from drinking water, industrial process water, and wastewater. These resins are used in both municipal and industrial water treatment plants to improve water quality, meet regulatory standards, and ensure safe and clean water supply.

➢ Chemical processing: Ion exchange resins are used in the chemical industry for various applications, such as purification of process streams, recovery of valuable compounds, and removal of impurities. They are used in processes such as demineralization, decolorization, deionization, and catalysis in chemical reactions, contributing to the production of high-quality chemicals and intermediates.

➢ Pharmaceuticals: Ion exchange resins are used in the pharmaceutical industry for purification of Active Pharmaceutical Ingredients (APIs) and other chemicals, as well as for drug formulation and drug delivery systems. These resins help in removing impurities, such as salts, organic compounds, and heavy metals, from pharmaceutical products to ensure their quality, safety, and efficacy.

➢ Food and beverages: Ion exchange resins are used in the food and beverage industry for water purification, as well as for removal of impurities, such as color, taste, and odor, from process streams. These resins help in improving the quality of drinking water, soft drinks, fruit juices, brewing water, and other food and beverage products.

➢ Power generation: Ion exchange resins are used in the power generation industry for water treatment in steam generation systems, such as boilers and condensers. These resins help in removing impurities from water, such as dissolved salts and heavy metals, to prevent scaling, corrosion, and fouling in the steam generation equipment, which can improve their efficiency and extend their lifespan.

➢ Electronics: Ion exchange resins are used in the electronics industry for purification of ultrapure water used in semiconductor manufacturing processes. These resins help in removing trace impurities from water, such as ions, organic compounds, and particulate matter, which can impact the quality and reliability of electronic devices.

➢ Mining and metallurgy: Ion exchange resins are used in the mining and metallurgy industry for recovery of valuable metals, such as gold, silver, uranium, and rare earth elements, from process streams and waste streams. These resins help in selectively adsorbing and recovering specific metal ions from complex mixtures, providing an efficient and cost-effective method for metal recovery.

➢ Environmental remediation: Ion exchange resins are used in environmental remediation processes for removal of contaminants from soil, groundwater, and other environmental matrices. These resins can selectively adsorb contaminants, such as heavy metals, radioactive ions, and organic pollutants, from environmental media, contributing to the cleanup of contaminated sites and protection of the environment.

➢ Other applications: Ion exchange resins are also used in various other applications, such as sugar refining, biotechnology, cosmetics, and personal care products, where purification, separation, and recovery of specific ions or compounds are required.

The ion exchange resins market offers several benefits, which contribute to its growing demand across various industries. Some of the key benefits of ion exchange resins are:

✦ Water purification ✦ Selective ion removal ✦ Process efficiency ✦ Wide range of applications ✦ Compliance with environmental regulations ✦ Improved product quality ✦ Cost-effective solution

In summary, the benefits of ion exchange resins include water purification, selective ion removal, process efficiency, wide range of applications, compliance with environmental regulations, improved product quality, and cost-effective solutions, which contribute to their growing demand in the market.

0 notes

Text

The Purity Paradigm: Exploring High-Quality Chlorosulfonic Acid

Chlorosulfonic acid, a powerful and versatile chemical compound, is a key ingredient in various industrial processes. Whether you're in the chemical, pharmaceutical, or research sector, finding a reliable source for high-quality chlorosulfonic acid is crucial. In this comprehensive blog, we will introduce you to Maruti Fine Chemicals, a trusted supplier that offers the convenience of buy chlorosulfonic acid online. You will also learn about the benefits of choosing Maruti Fine Chemicals for all your chemical needs.

Chlorosulfonic Acid: A Brief Overview

Chlorosulfonic acid, chemically represented as HSO3Cl, is a strong, colorless, and highly corrosive liquid. It is primarily used as a sulfonating agent, meaning it introduces sulfonic acid groups (SO3H) into organic compounds. These sulfonated compounds have various applications across industries, including:

Dyes and Pigments:

Chlorosulfonic acid is essential in the production of dyes and pigments, allowing for the coloration of textiles, plastics, and other materials.

Pharmaceuticals:

It is used in the synthesis of certain pharmaceuticals and intermediates, playing a vital role in the development of drugs.

Agrochemicals:

Chlorosulfonic acid is used in the production of herbicides, insecticides, and other agricultural chemicals.

Polymers and Plastics:

It is employed to modify the properties of polymers and plastics, enhancing their chemical and physical characteristics.

Chemical Intermediates:

Chlorosulfonic acid serves as a critical intermediate in the production of various chemicals, including surfactants, detergents, and specialty chemicals.

Given its significance across multiple industries, securing a reliable source of high-quality chlorosulfonic acid is essential for businesses and research institutions.

Why Choose Maruti Fine Chemicals?

Now that we understand the importance of buy chlorosulfonic acid online, let's delve into why Maruti Fine Chemicals is the ideal choice for procuring this chemical online:

1. Quality Assurance

Maruti Fine Chemicals takes pride in delivering high-quality chlorosulfonic acid. Their products meet stringent quality standards, ensuring consistency and reliability in your applications. Quality control measures are implemented at every stage of the manufacturing process, from raw material sourcing to final product delivery.

2. Variety of Packaging Options

Maruti Fine Chemicals offers a range of packaging options to suit your specific requirements. Whether you need small quantities for laboratory use or bulk quantities for industrial processes, they have you covered. Common packaging options include glass bottles, plastic containers, and drums.

3. Competitive Pricing

One of the significant advantages of buying from Maruti Fine Chemicals is their competitive pricing. They understand the importance of cost-effectiveness in today's competitive market, and they strive to provide you with cost-efficient solutions without compromising on quality.

4. Online Convenience

In today's digital age, convenience is paramount. Maruti Fine Chemicals offers a user-friendly online platform where you can browse their product catalog, place orders, and track shipments with ease. This online convenience saves you time and streamlines the procurement process.

5. Global Reach

Maruti Fine Chemicals caters to a global clientele. Whether you are located locally or internationally, they can deliver chlorosulfonic acid to your doorstep. Their extensive logistics network ensures timely and secure deliveries.

6. Technical Support

Understanding the complexities of chemical processes is essential. Maruti Fine Chemicals provides technical support and assistance to help you make informed decisions regarding the use of chlorosulfonic acid in your applications. Their team of experts is readily available to address your queries and provide guidance.

7. Safety and Compliance

Working with chlorosulfonic acid requires strict adherence to safety protocols and regulatory compliance. Maruti Fine Chemicals places a strong emphasis on safety and ensures that all products are shipped, handled, and stored following industry standards and regulations.

Applications of Chlorosulfonic Acid

Chlorosulfonic acid finds its applications in various industries, as mentioned earlier. Let's explore some of these applications in greater detail:

1. Dyes and Pigments

The vibrant colors in textiles, plastics, and paints owe their existence to . It is used to introduce sulfonic acid groups into aromatic compounds, enhancing their solubility and colorfastness. This process is crucial for producing a wide range of dyes and pigments used in the textile and automotive industries, among others.

2. Pharmaceuticals

In the pharmaceutical industry, chlorosulfonic acid plays a critical role in the synthesis of various drugs and intermediates. It is used to introduce sulfonic acid groups into specific molecules, altering their chemical properties and enhancing their pharmacological effects.

3. Agrochemicals

Chlorosulfonic acid is a key ingredient in the production of herbicides, insecticides, and other agrochemicals. Its sulfonation capabilities are harnessed to modify the chemical structure of active ingredients, making them more effective in controlling pests and weeds.

4. Polymers and Plastics

In the realm of polymers and plastics, chlorosulfonic acid is employed to modify the properties of these materials. It can be used to introduce sulfonic acid groups into polymers, enhancing their chemical resistance, heat stability, and overall performance. This is particularly valuable in the production of specialty plastics and films.

5. Chemical Intermediates

Chlorosulfonic acid serves as a versatile intermediate in the synthesis of various chemicals, including surfactants, detergents, buy chlorosulfonic acid online and specialty chemicals. Its sulfonation capabilities make it a valuable tool for chemists in designing and producing a wide range of chemical products.

Chlorosulfonic acid, a powerful and versatile chemical compound, is a key ingredient in various industrial processes. Whether you're in the chemical, pharmaceutical, or research sector, finding a reliable source for high-quality chlorosulfonic acid is crucial. In this comprehensive blog, we will introduce you to Maruti Fine Chemicals, a trusted supplier that offers the convenience of purchasing chlorosulfonic acid online. You will also learn about the benefits of choosing Maruti Fine Chemicals for all your chemical needs.

Chlorosulfonic Acid: A Brief Overview

Chlorosulfonic acid, chemically represented as HSO3Cl, is a strong, colorless, and highly corrosive liquid. It is primarily used as a sulfonating agent, meaning it introduces sulfonic acid groups (SO3H) into organic compounds. These sulfonated compounds have various applications across industries, including:

Dyes and Pigments:

Chlorosulfonic acid is essential in the production of dyes and pigments, allowing for the coloration of textiles, plastics, and other materials.

Chemical Intermediates:

Chlorosulfonic acid serves as a critical intermediate in the production of various chemicals, including surfactants, detergents, and specialty chemicals.

Given its significance across multiple industries, securing a reliable source of high-quality chlorosulfonic acid is essential for businesses and research institutions.

Why Choose Maruti Fine Chemicals?

Now that we understand the importance of chlorosulfonic acid, let's delve into why Maruti Fine Chemicals is the ideal choice for procuring this chemical online:

1. Quality Assurance

Maruti Fine Chemicals takes pride in delivering high-quality chlorosulfonic acid. Their products meet stringent quality standards, ensuring consistency and reliability in your applications. Quality control measures are implemented at every stage of the manufacturing process, from raw material sourcing to final product delivery.

2. Variety of Packaging Options

Maruti Fine Chemicals offers a range of packaging options to suit your specific requirements. Whether you need small quantities for laboratory use or bulk quantities for industrial processes, they have you covered. Common packaging options include glass bottles, plastic containers, and drums.

3. Competitive Pricing

One of the significant advantages of buying from Maruti Fine Chemicals is their competitive pricing. They understand the importance of cost-effectiveness in today's competitive market, and they strive to provide you with cost-efficient solutions without compromising on quality.

4. Online Convenience

In today's digital age, convenience is paramount. Maruti Fine Chemicals offers a user-friendly online platform where you can browse their product catalog, place orders, and track shipments with ease. This online convenience saves you time and streamlines the procurement process.

5. Global Reach

Maruti Fine Chemicals caters to a global clientele. Whether you are located locally or internationally, they can deliver chlorosulfonic acid to your doorstep. Their extensive logistics network ensures timely and secure deliveries.

6. Technical Support

Understanding the complexities of chemical processes is essential. Maruti Fine Chemicals provides technical support and assistance to help you make informed decisions regarding the use of chlorosulfonic acid in your applications. Their team of experts is readily available to address your queries and provide guidance.

7. Safety and Compliance

Working with chlorosulfonic acid requires strict adherence to safety protocols and regulatory compliance. Maruti Fine Chemicals places a strong emphasis on safety and ensures that all products are shipped, handled, and stored following industry standards and regulations.

Applications of Chlorosulfonic Acid

Chlorosulfonic acid finds its applications in various industries, as mentioned earlier. Let's explore some of these applications in greater detail:

1. Dyes and Pigments

The vibrant colors in textiles, plastics, and paints owe their existence to chlorosulfonic acid. It is used to introduce sulfonic acid groups into aromatic compounds, enhancing their solubility and colorfastness. This process is crucial for producing a wide range of dyes and pigments used in the textile and automotive industries, among others.

2. Pharmaceuticals

In the pharmaceutical industry, chlorosulfonic acid plays a critical role in the synthesis of various drugs and intermediates. It is used to introduce sulfonic acid groups into specific molecules, altering their chemical properties and enhancing their pharmacological effects.

3. Agrochemicals

Chlorosulfonic acid is a key ingredient in the production of herbicides, insecticides, and other agrochemicals. Its sulfonation capabilities are harnessed to modify the chemical structure of active ingredients, making them more effective in controlling pests and weeds.

4. Polymers and Plastics

In the realm of polymers and plastics, high-quality chlorosulfonic acid is employed to modify the properties of these materials. It can be used to introduce sulfonic acid groups into polymers, enhancing their chemical resistance, heat stability, and overall performance. This is particularly valuable in the production of specialty plastics and films.

5. Chemical Intermediates

Chlorosulfonic acid serves as a versatile intermediate in the synthesis of various chemicals, including surfactants, detergents, and specialty chemicals. Its sulfonation capabilities make it a valuable tool for chemists in designing and producing a wide range of chemical products.

Safety Precautions

While chlorosulfonic acid is a valuable chemical reagent, it is crucial to handle it with care due to its corrosive nature. Here are some essential safety precautions when working with chlorosulfonic acid:

Personal Protective Equipment (PPE): Always wear appropriate PPE, including chemical-resistant gloves, safety goggles or a face shield, a lab coat, and closed-toe shoes.

Ventilation: Work in a well-ventilated area or under a fume hood to minimize exposure to fumes and vapors.

Storage: Store chlorosulfonic acid in a cool, dry place, away from incompatible materials and sources of heat or ignition.

Emergency Equipment: Ensure access to emergency eyewash stations, safety showers, and spill containment materials.

Training: Only trained personnel should handle chlorosulfonic acid, and they should be familiar with its properties, hazards, and safe handling procedures.

Here are some key points to understand about chemical intermediates:

Temporary Species: Chemical intermediates are temporary species that exist during the progression of a chemical reaction. They are neither the starting materials (reactants) nor the final products. Instead, they are formed as intermediate steps in a reaction pathway.

Multiple Reaction Steps: Complex chemical reactions often involve multiple steps. Chemical intermediates are formed in one step and subsequently consumed or transformed in subsequent steps until the final product is obtained. Each intermediate serves as a stepping stone in the overall reaction mechanism.

Reactive Nature: Intermediates are typically more reactive than the starting materials but less reactive than the final products. This reactivity is what allows them to participate in the chemical transformation, facilitating the conversion of reactants into products.

Stability: While intermediates are transient in nature, they may have varying degrees of stability. Some intermediates are highly reactive and short-lived, while others may be relatively stable and can be isolated or stored for further use.

Examples: Common examples of chemical intermediates include free radicals, carbocations, carbanions, and various reactive species like nitrenes and carbenes. These species are often involved in organic chemistry reactions.

Role in Organic Synthesis: In organic synthesis, chemical intermediates are critical for building complex molecules. For example, in the synthesis of pharmaceuticals, intermediates are used to introduce functional groups or structural modifications into organic compounds.

Purification and Isolation: In some cases, chemical intermediates are isolated and purified to be used as starting materials for subsequent reactions. This isolation process can be challenging due to the often unstable or reactive nature of intermediates.

Control of Reaction Pathways: Chemists often manipulate reaction conditions and reagents to control the formation and fate of chemical intermediates. This control allows them to direct reactions toward specific products.

Safety Considerations: Handling certain chemical intermediates can be hazardous due to their reactivity. Proper safety precautions, such as using appropriate protective equipment and working in controlled environments, are essential when dealing with reactive intermediates.

Conclusion

In conclusion, chlorosulfonic acid is a valuable chemical reagent with diverse applications across multiple industries. When you're in need of high-quality chlorosulfonic acid, Maruti Fine Chemicals stands out as a reliable and convenient supplier. Their commitment to quality, competitive pricing, and global reach make them an excellent choice for all your chlorosulfonic acid requirements. However, always prioritize safety and adhere to best practices when handling this powerful chemical. By choosing Maruti Fine Chemicals, you can confidently access top-notch chlor

0 notes

Text

Increasing Application of Plastomers to Modify Polymers

What are Alpha Olefins?

Alpha-olefins are organic compounds. They are alkene in nature with a chemical formula CₓH₂ₓ. It is identified by a double at alpha or primary position. The double bond improves the compound's reactivity and makes it suitable for various applications.

Alpha-olefins serve as building blocks for various industrial chemicals. A major part of long-chain or medium derivatives is converted into plasticizers and detergents. It first involves hydroformylation, later in the next step, the resulting aldehydes are hydrogenated. Oligomerization of long-chain alpha-olefins is required to provide medium molecular weight oils that are used as lubricants.

Benzene alkylation with alpha-olefines after ring-sulfonation results in linear alkylbenzene sulfonates. These are biodegradable in nature. The petroleum-derived products such as fatty acids derivatives, including fatty amines, and fatty alcohols often compete with linear alkylbenzene sulfonates.

The alpha olefins with low-weight molecules such as butenes and hexenes are used as comonomers. These are incorporated into polyethylene.

Lubricants based on poly-alpha-olefin provide higher oxidative stability with a greater viscosity index compared to mineral oils. Such benefits, result in the rising usage of alpha-olefin in lubricant production.

To receive free sample pages of this report@ https://www.psmarketresearch.com/market-analysis/alpha-olefins-market/report-sample

1-Hexene is a transparent water-like mobile liquid. Ziegler ethylene chain growth technology is used to produce it. 1-Hexene can be utilized in polyolefin comonomer as well as an intermediate in various compounds such as hexyl mercaptans, oxo alcohols, organic aluminum, and synthetic fatty acids.

Numerous end uses of alpha olefins include synthetic lubricants, lubricant additives, synthetic drilling fluids base oil, and polyethylene comonomers. It is 99% or more olefinic in nature.

The major companies operating in the industry are, Royal Dutch Shell Plc., INEOS Group Holding S.A., Chevron Philips Chemical Company LLC, Saudi Basic Industries Corporation, Evonik Industries AG, and others.

The rising consumption of lubricants in various end use industries boosts the demand for alpha olefins.

#Alpha Olefins Market#Alpha Olefins Market Size#Alpha Olefins Market Share#Alpha Olefins Market Trends#Alpha Olefins Market Growth#Alpha Olefins Market Outlook

0 notes

Text

High Performance Plastics Market Size, Share and Forecast by 2029

The global high performance plastics market size was valued at USD 20.93 billion in 2021. The market is projected to grow from USD 22.71 billion in 2022 to USD 42.08 billion by 2029, exhibiting a CAGR of 9.2% during the forecast period.

Information Source- https://www.fortunebusinessinsights.com/high-performance-plastics-market-107109

Segments:

Fluoropolymers to Surge Demand due to their Dominant Use in End-use Industries

Based on type, the market is segmented into fluoropolymers, polyamides, polyphenylene sulfide (PPS), sulfone polymers (SP), liquid crystal polymers (LCP), and others.

The demand for fluoropolymers is comparatively high due to their massive performance in industries.

0 notes

Text

Poly(ether-Sulfone) Polymer Market Trends, Global Industry Research, Analysis, Production Demand Ratio, Suppliers and COVID-19 Pandemic Presenting Future Opportunities 2027

The recent report on “Global Poly(ether-Sulfone) Polymer Market Report 2021 by Key Players, Types, Applications, Countries, Market Size, Forecast to 2027” offered by Axel Reports, comprises of a comprehensive investigation into the geographical landscape, industry size along with the revenue estimation of the business. Additionally, the report also highlights the challenges impeding market growth and expansion strategies employed by leading companies in the “Poly(ether-Sulfone) Polymer Market”.

An exhaustive competition analysis that covers insightful data on industry leaders is intended to help potential market entrants and existing players in competition with the right direction to arrive at their decisions. Market structure analysis discusses in detail Poly(ether-Sulfone) Polymer companies with their profiles, revenue shares in market, comprehensive portfolio of their offerings, networking and distribution strategies, regional market footprints, and much more.

Download Sample PDF+ All Related Graphs & Charts (Including COVID19 Impact Analysis) @: https://axelreports.com/request-sample/78111

By Market Players: Solvay BASF Sumitomo Foshan Plolima JUSEP Jiangmen Youju Shandong Horan PSF New Materials By Type Powder Grade Granule Grade By Application Electronics and Electrical Auto Parts Food Industry Medical Industry Others

(Note: The sample of this report is updated with COVID-19 impact analysis before delivery)

Key Questions Covered in the Report :

What is the total market value of the Global Poly(ether-Sulfone) Polymer Market report?

What would be the forecast period in the market report?

What is the market value of the Global Poly(ether-Sulfone) Polymer Market in 2021?

What is the Key Industry Leader’s opinion for the Global Poly(ether-Sulfone) Polymer?

Which is the base year calculated in the Global Poly(ether-Sulfone) Polymer Market Report?

What are the key trends in the Global Poly(ether-Sulfone) Polymer Market Report?

What are the market values/growth % of emerging countries?

Which market holds the maximum market share of the Global Poly(ether-Sulfone) Polymer Market?

Some Point from Table of Content:

Market Overview: It includes six chapters, research scope, major manufacturers covered, market segments by type, Poly(ether-Sulfone) Polymer market segments by application, study objectives, and years considered.

Market Landscape: Here, the competition in the Worldwide Poly(ether-Sulfone) Polymer Market is analyzed, by price, revenue, sales, and market share by company, market rate, competitive situations Landscape, and latest trends, merger, expansion, acquisition, and market shares of top companies.

Profiles of Manufacturers: Here, leading players of the global Poly(ether-Sulfone) Polymer market are studied based on sales area, key products, gross margin, revenue, price, and production.

Market Status and Outlook by Region: In this section, the report discusses about gross margin, sales, revenue, production, market share, CAGR, and market size by region. Here, the global Poly(ether-Sulfone) Polymer Market is deeply analysed on the basis of regions and countries such as North America, Europe, China, India, Japan, and the MEA.

Application or End User: This section of the research study shows how different end-user/application segments contribute to the global Poly(ether-Sulfone) Polymer Market.

Market Forecast: Production Side: In this part of the report, the authors have focused on production and production value forecast, key producers forecast, and production and production value forecast by type.

Research Findings and Conclusion: This is one of the last sections of the report where the findings of the analysts and the conclusion of the research study are provided.

Do You Have Any Query Or Specific Requirement? Ask to Our Industry Expert @ https://axelreports.com/enquiry-before-buying/78111

Note: This content doesn’t contain all the Information of the Report please fill the form (via link) and get all interesting information just one click in PDF with the latest update with chart and Table of Content. Any special requirements about this report, please let us know and we can provide custom report.

ABOUT US:

Axel Reports has the most comprehensive collection of market research products and services available on the web. We deliver reports from virtually all major publications and refresh our list regularly to provide you with immediate online access to the world’s most extensive and up-to-date archive of professional insights into global markets, companies, goods, and patterns.

Contact: Axel Reports Akansha G (Knowledge Partner) Office No- B 201 Pune, Maharashtra 411060 Phone: US +18488639402 Web: https://axelreports.com/

0 notes

Photo

Global Sulfone Polymers Industry 2019 Market Research Report Key Trends, Size, Shares, Forecast and Opportunities Sulfone Polymers Market Report The report offers an overview of the Sulfone Polymers with the help of application segments and geographical regions (United States, Europe, China, Japan, Southeast Asia, India, Central & South America, ROW) that govern the market currently.

0 notes