#Subsurface Defects

Explore tagged Tumblr posts

Text

Magnetic Particle Test: Techniques and Principles Explained

Magnetic Particle Test (MPT) is a widely used non-destructive testing (NDT) method. It detects surface and near-surface discontinuities in ferromagnetic materials, such as iron, nickel, cobalt, and their alloys. This technique is renowned for its speed, cost-effectiveness, and relative ease of application, making it a preferred choice across various industries, including aerospace, automotive,…

#Defect Detection#Engineering Testing#Flaw Detection#Industrial Testing#Infrastructure Testing#Magnetic Field Testing#Magnetic Inspection#Magnetic Particle Inspection#Magnetic Particle Test#Magnetic Particles#Magnetic Testing#Manufacturing Quality#Material Testing#Metal Testing#MPT#MPT Procedure#NDT#NDT Methods#NDT Technology#Non-Destructive Testing#Pipeline Inspection#Quality Inspection#Safety Inspection#Structural Integrity#Subsurface Defects#Surface Defects#Testing Equipment#Weld Inspection#Welding Defects

0 notes

Text

Ensuring Weld Quality: Advanced Ultrasonic Testing Methods

In the world of welding, ensuring the quality and integrity of welds is crucial. One of the most effective ways to inspect welds is through ultrasonic testing, which uses high-frequency sound waves to detect imperfections. This blog explores advanced ultrasonic testing methods for welding inspection, highlighting their benefits and applications in the UK.

Introduction to Ultrasonic Testing

Ultrasonic testing for welding involves high-frequency sound waves to detect flaws in welds. This non-destructive testing (NDT) method effectively identifies internal and surface defects without damaging the material.

Why Ultrasonic Testing for Welding?

Accuracy: Provides precise detection of internal flaws.

Non-Destructive: Does not damage the material being inspected.

Versatility: Suitable for a wide range of materials and thicknesses.

Advanced Ultrasonic Testing Techniques

Advanced ultrasonic testing techniques have revolutionised the NDT industry, providing unprecedented levels of accuracy and efficiency. Below are some of the most advanced testing techniques used in the industry:

1. Phased Array Ultrasonic Testing (PAUT)

PAUT is an advanced technique that uses different ultrasonic elements and electronic time delays to create a sweeping beam. This method provides a detailed image of the weld, allowing for precise identification of defects.

Benefits:

High-resolution and detailed images

Faster inspection times

Improved defect characterisation

2. Time-of-Flight Diffraction (TOFD)

TOFD is another complex ultrasonic testing method that uses the time taken by sound waves to travel and diffract around defects to detect and size flaws accurately.

Benefits:

High accuracy in defect sizing

Effective for detecting both surface and subsurface defects

Reduced operator dependency

3. Automated Ultrasonic Testing (AUT)

AUT involves automated systems that perform ultrasonic inspections. This method enhances the consistency and repeatability of inspections, making it ideal for large-scale projects.

Benefits:

Consistent and repeatable results

Increased inspection speed

Reduced human error

Applications of Ultrasonic Testing in the UK

Ultrasonic testing is widely used in the UK across different industries to provide safety and integrity to critical infrastructure. Here are some key applications of ultrasonic testing in the UK.

1. Oil and Gas Industry

In the UK, the oil and gas industry rely heavily on ultrasonic testing for welding to ensure the integrity of pipelines and other critical infrastructure. PAUT and TOFD are commonly used to inspect welds in pipelines, ensuring they are free from defects that could lead to failures.

2. Aerospace Industry

The aerospace industry requires the highest levels of safety and reliability. Ultrasonic testing methods are used extensively to inspect welds in aircraft components, ensuring they meet strict safety standards.

3. Construction and Infrastructure

Ultrasonic testing plays a crucial role in the construction industry, particularly for inspecting welds in bridges, buildings, and other structures.

Advantages of Advanced Ultrasonic Testing Methods

Check out the advantages of advanced ultrasonic testing methods over traditional approaches.

1. Enhanced Accuracy

Advanced ultrasonic testing methods provide higher accuracy in detecting and sizing defects than traditional methods.

2. Increased Efficiency

Automated and advanced techniques like PAUT and AUT significantly reduce inspection times while maintaining high levels of accuracy.

3. Comprehensive Reporting

These methods offer detailed and comprehensive reporting, providing clear images and data that can be used for further analysis and decision-making.

Conclusion

Adopting advanced ultrasonic testing for welding is essential for industries aiming to maintain high quality and safety standards.

Investing in these advanced techniques enhances inspection reliability and ensures compliance with stringent safety regulations. By leveraging the benefits of advanced ultrasonic testing, industries can achieve greater efficiency, accuracy, and overall project success.

9 notes

·

View notes

Text

Defective lotus info (in english) 1 out of 2

Irk

The birth planet of the Irken race was once, in prehistoric times, a living planet filled with all kinds of ecosystems and many types of fauna and flora. Now, it's nothing more than a gigantic metal ball.

Irk, as the name suggests, is the habitat of the Irken species, a reptilian, insectoid, semi-amphibian intelligent species that currently could be considered a race of cyborgs, as they use bioengineering to live.

Over the years, Irk went from being a wandering planet in the Nova Irkarus 720 solar system to a fixed planet in said system because, at some point, it was drawn into the gravitational field of the sun, nicknamed Alpha Ikarus star.

Irk has around 3 moons called Pendora, Ignis, and Mortem, the main one being Ignis, shining with a powerful pink glow, Mortem the second shining with a strong purple, and Pendora with a faint blue, being the smallest moon.

There isn't much recorded history of ancient Irk, so it's often not considered much when summarizing the planet's history.

Meanwhile, modern Irk is somewhat complicated.

Over the years, the planet has undergone many changes, from the force fields surrounding it, to using its core as an energy source in addition to electricity.

Irk can be divided into three rings: the surface, the subsurface, and the incinerator. The latter is somewhat self-explanatory but is essentially what precedes the core, where all of Irk's waste is thrown to feed the planet's core and keep it running.

The subsurface, or the main smelting area, is where the entire process of incubation and basic academic education for all Irkens happens.

It's equipped with thousands of machines including incubators, teaching machines, as well as other machines maintaining order like the sentinels. There are also departments serving as provisional homes for the smeets and their flesh-and-bone tutors.

Some families with smeets stay here until the smeets turn 10 and can go to their current surface homes, while in other cases, smeets are left here until that age.

That's the case for non-mutant smeets, as mutant smeets are of little importance and can surface as long as they are with an adult Irken from the subsurface.

Mostly, however, they stay underground until they turn 10.

The surface is where the majority of the population resides, both Irkens and other races allowed to live there, having lost their planets or having a population of fewer than 50, or being a labor force.

These races include the 3 branches of the Artifex, the Couwlek, Sraigo, Polum, who reside along with mutants in the southern area of Irk known as the slums or the never-dawning zone, as it's mostly in semi-darkness.

Due to the mix of species, there's a culture amalgamated from various cultures and a common language known as Joik, besides Irken and other languages, leading to a unique southern accent, sometimes hard to follow (akin to merging Scottish and Chilean accents).

The northern zone, known as the affluent districts or the eternal day zone, is exclusively inhabited by non-mutated Irkens or Irkens with low-importance mutations like Linea Linea and Alis Alis variants, without any other race present.

Only Irken is spoken here, with varying pronunciations based on the region, but it remains Irken overall and doesn't usually have a pronounced accent like the southern one.

Then there's the center or the privileged zone where high-ranking Irkens, elites, or celebrities, irrespective of faction (north or south), reside. It's also where significant events, such as the arrival of the highest authorities, take place.

Irk has a peculiar climate, mainly characterized by technically no wind, or at least no strong winds, but frequent rain—around 60% of the time. When it's not raining, it's cloudy or there's a dry but scarce wind blowing.

Temperatures are generally warm but can get hot, with longer periods of cold causing snowfall due to excessive moisture.

Fauna and flora are almost nonexistent in this concrete and metal jungle, with very few living specimens preserved, protected, or kept as pets.

Clear examples include Tei Tei hounds, Qiwed birds (resembling a mix of falcon and vulture), and large Xquima felines, along with the recurring Rod-Ei rodents, as part of the fauna.

Regarding flora, some tree and plant species are still conserved, like the Angel's Calla Lily flowers or Angelis flowers, which usually bloom if someone in the household where the plant is located dies.

There are also indigenous fruit and vegetable species cultivated on the Pendora moon, as it's most suitable for growing these crops, supplying a significant portion of the planet.

There are livestock species like Kiba, a mix of pig, cow, goat, and sheep, providing all that these four animals offer in one, and Fei Fam, a mix of turkey, goose, and chicken providing eggs, both raised in Mortem.

Lastly, there's a species akin to eel and a mix of salmon and tuna called Rifem, also bred in Mortem for consumption. These products are exported and sold in markets or shops.

Ignis, on the other hand, is a moon used entirely for industrial purposes, essentially housing thousands of factories and warehouses, including the first still-functional quarantine station.

Most technology, from ships, weapons, and armors to simple household appliances, is manufactured in Ignis. There's also a small PAK factory operating 24/7.

Irk is surrounded by two strong force fields keeping it safe, projected by a gigantic artificial metal ring, creating a second exosphere and a second stratosphere. The second field is the stronger one between the two shields.

These shields allow entry and exit of ships only if they have a special seal allowing passage. The shields have detectors preventing anything without the seal from entering.

the months and the passing of time

the time passing on irk is certainly a slow process,with a day of aproximately 30 hours of wich 15 are day and the other 15 are night,tho during certain periods of time theres only 7 hours of day while the other 23 lefth are night or vice versa.

with 12 months of 40 days and weekends of 10 days each,a year of aproximetly of 480 days wich are divided in 120 days for each seasson,the time period on irk is certainly long.

in fact tho for irkens and the other races living in irk the time passege is like this while on irk outside of the planet the time is different as an example for humans an irken year is the equivalent of around 12 human years,since each irkean month is a year for humans.

the irken months are called of the following way,premerc the first month of the year,loter,shiofer,doika,okaltek,muna,kuna,irter,lunaria,soikot,jurtia and ultum the last month of the year.

Seasons

The seasons on Irk, like on Earth, are four, but they're not entirely the same since there isn't exactly spring or autumn, rather something akin to winter and summer.

The snowy season, also known as Crystel, is characterized as Irk's winter equivalent. During this season, snow falls heavily, occasionally accompanied by hail. Temperatures drop, and the typically absent wind blows as a freezing breeze that penetrates to the bone.

The Artifex are among the races most prepared for this season as they are highly resistant to the cold and harsh environment. They're the only creatures on Irk capable of 'swimming' effortlessly through the snow and ice.

Upon the arrival of this season, Irkens tend to feel more drowsy, move much slower, and their usually high body temperatures rise. Many theorize that if Irkens were a more peaceful race, they would likely hibernate during this period.

Irkens alter their sleep patterns, sleeping many more hours during this time. Additionally, Irkens with fur develop denser coats against the cold. Those with more insectoid wings, not of the moth or butterfly type, shed them as they don't withstand the cold well.

Mutated Irkens lacking the mentioned characteristics don't usually fare well during winter, especially those with reptilian, amphibian, or insectoid features without fur, as mutants seem more susceptible to the cold.

The next season is the rainy season called Lacrimus. As implied, it rains incessantly throughout this season, sometimes causing floods. The air is humid with fog, surprisingly, this is the only season with strong winds alongside continuous lightning.

During this time, blackouts are common, so all Irkens and underlying races have emergency generators, especially in the southern zone, where there are high risks of floods as it's technically a basin where water collects.

Often, Irkens are allowed to stay home and not work due to the risks posed by this extreme rainy season, mainly because of the sudden water surges that sometimes occur, lightning strikes, or the inability to leave homes due to flooding.

Mutants with aquatic traits and the Polum are better adapted for this season due to their aquatic adaptations, experiencing fewer difficulties throughout the period.

This is generally the most disliked season by Irkens and other races due to the numerous problems it brings, being one of the most challenging seasons to endure.

The following season is the opposite of the wet season, known as Fercius, the equivalent of summer. It's characterized by intense drought, with only a 10% chance of rain during the three months and scorching temperatures.

Mutated Irkens with reptilian and insectoid characteristics, as well as the Couwlek race, fare well during this time as they're prepared to handle the heat.

Meanwhile, normal Irkens and other mutations struggle a bit as they're not built for intense heat and the almost non-existent but devastatingly hot breeze and intense sun during this period.

It's not uncommon to see people using umbrellas and hats against the sun or individuals fainting in the middle of the road due to the incredibly hot temperatures of these periods.

Contrarily, nights, like a desert, are cold and cool but very brief. This is the time when a day lasts 23 hours, and the night only 7.

Lastly, the fourth and final season, Nocturnia, also known as the eternal night season because here, unlike Fercius, the night lasts 23 hours and the day 7, hence its name, emphasizing its main characteristic.

During this season, Irk is almost entirely in penumbra, barely illuminated by the sun. Irkens prevail thanks to their night vision and the intense neon lights of the gigantic metropolis.

This season is the only one on Irk that doesn't feature extreme changes like rain, cold, or heat. It's mild with the normal percentage of rainfall in Irk, technically Irk's spring, but without plants and allergies.

Mutant Irkens, having developed in some cases glowing marks in the dark, technically have it easier than average Irkens during this season, similarly, Sraigo with their bioluminescence.

Throughout this season, there are constant meteor showers illuminating the almost perpetually nocturnal Irken sky, rendering it a vibrant pink color akin to Irk's daytime sky.

During Nocturnia's duration, a phenomenon similar to the aurora borealis occurs every few nights, along with the always-awaited triple lunar eclipse, turning Pendora yellow, Mortem red-orange, and Ignis green for one night.

---

Thanks to @stingerking for helping ne on the traduction

#defective lotus au#iz au#four for the price of one au#invader zim au#a tale of blood petals au#a promising future au

2 notes

·

View notes

Text

Eddy Current Testing Machine and Automatic Systems - Magkraftndt

The Eddy Current Testing Machines are apparatuses for detecting any surface or subsurface defect found in a material through electromagnetic induction. Progress in automation, however, has not been left behind because the systems support the testing process to yield speedy and accurate results in quality control for different industries.

#magkraftndt#eddycurrenttestingmachine#automaticsystems#advancetechnology#automation#testingmachines#eddycurrentmachinemanufacturer

0 notes

Text

Non-destructive Testing Market Innovation and Technological Advancements to 2033

Introduction

Non-destructive testing (NDT) is a critical inspection method used across various industries to evaluate the properties of a material, component, or structure without causing damage. The NDT market has experienced significant growth in recent years due to increasing demand for quality assurance, safety regulations, and advancements in inspection technologies. This article explores the current trends, key drivers, market segmentation, challenges, and future outlook of the NDT market.

Market Overview

The global non-destructive testing market is poised for robust growth, driven by the rising adoption of automated NDT solutions, stringent government regulations, and the growing need for maintenance and inspection in industries such as aerospace, oil & gas, automotive, and construction. According to market research reports, the NDT market size was valued at approximately USD XX billion in 2023 and is expected to grow at a CAGR of over XX% from 2024 to 2030.

Download a Free Sample Report:-https://tinyurl.com/289zdknc

Key Drivers of Market Growth

Stringent Quality and Safety Regulations Governments and regulatory bodies worldwide impose strict safety regulations on industries such as aerospace, automotive, and construction to prevent failures and accidents. NDT techniques ensure compliance with these standards without compromising structural integrity.

Advancements in NDT Technologies The emergence of advanced technologies, such as artificial intelligence (AI), machine learning, and robotics, has enhanced the accuracy and efficiency of NDT methods. Automated ultrasonic testing, eddy current testing, and phased array ultrasonic testing (PAUT) are some of the advanced techniques gaining traction.

Growth in Infrastructure and Manufacturing Sectors Rapid urbanization and industrialization are fueling the need for NDT services in construction and manufacturing. Regular inspections help identify defects early, thereby reducing maintenance costs and increasing the lifespan of structures and equipment.

Aging Infrastructure and Asset Management Many industries, particularly in developed countries, have aging infrastructure that requires continuous monitoring to ensure structural safety and efficiency. NDT plays a crucial role in predictive maintenance strategies.

Increasing Use in Aerospace and Defense The aerospace and defense sectors rely heavily on NDT for inspecting aircraft components, engines, and critical parts. With increasing air travel and defense budgets, the demand for NDT solutions is set to rise.

Market Segmentation

The NDT market is segmented based on testing techniques, end-use industries, and geographic regions.

By Testing Technique

Ultrasonic Testing (UT) – Used extensively in pipeline inspection, aerospace, and automotive sectors.

Radiographic Testing (RT) – Commonly used in detecting internal flaws in castings and welds.

Magnetic Particle Testing (MPT) – Effective in identifying surface and subsurface defects in ferrous materials.

Eddy Current Testing (ECT) – Used in aerospace and power generation for inspecting conductive materials.

Visual Testing (VT) – The most basic yet crucial technique in quality control.

Liquid Penetrant Testing (LPT) – Ideal for detecting surface discontinuities in non-porous materials.

By End-use Industry

Aerospace & Defense – Ensuring safety and reliability of aircraft components.

Oil & Gas – Pipeline and storage tank inspections to prevent leaks and failures.

Automotive – Quality assurance in manufacturing and assembly processes.

Construction & Infrastructure – Structural health monitoring of buildings and bridges.

Power Generation – Inspection of nuclear and renewable energy plants.

By Region

North America – Leading market due to stringent safety regulations and advanced technological adoption.

Europe – Strong presence of aerospace and automotive industries driving demand.

Asia-Pacific – Rapid industrialization and infrastructure development boosting NDT adoption.

Middle East & Africa – Growth fueled by the oil & gas sector.

Challenges in the NDT Market

Despite its growth prospects, the NDT market faces several challenges:

High Initial Investment Costs Advanced NDT equipment and software require substantial upfront investment, limiting adoption among small and medium-sized enterprises.

Shortage of Skilled Workforce The industry faces a shortage of certified and experienced NDT professionals, impacting efficiency and quality of inspections.

Complex Regulatory Compliance Different countries have varying safety and inspection standards, making it difficult for NDT service providers to operate seamlessly across regions.

Limitations in Testing Certain Materials Some NDT techniques have limitations in detecting defects in composite materials and complex geometries.

Future Trends and Opportunities

The future of the NDT market is expected to witness several transformative trends:

Integration of AI and Automation AI-powered NDT systems are improving defect detection capabilities and reducing human error. Automated drones and robots are being deployed for inspections in hazardous environments.

Adoption of IoT and Digital Twins The integration of IoT with NDT enables real-time monitoring and predictive maintenance. Digital twins allow for virtual simulations to detect potential failures before they occur.

3D Imaging and Augmented Reality (AR) Applications 3D imaging technology enhances visualization of defects, while AR assists technicians in performing precise inspections.

Sustainability and Green Energy Inspections The growing focus on renewable energy is increasing the demand for NDT in wind turbines, solar panels, and hydrogen storage systems.

Conclusion

The non-destructive testing market is poised for significant expansion, driven by technological advancements, regulatory compliance, and increasing industrial applications. While challenges such as high costs and skill shortages persist, innovations in AI, automation, and IoT are expected to reshape the industry landscape. As industries continue to prioritize safety and efficiency, the demand for reliable and advanced NDT solutions will remain strong, paving the way for a robust and sustainable market growth in the coming years.Read Full Report:-https://www.uniprismmarketresearch.com/verticals/semiconductor-electronics/non-destructive-testing.html

0 notes

Text

Phased Array Ultrasonic Testing: Benefits and Applications

Phased Array Ultrasonic Testing (PAUT) is an advanced non-destructive testing (NDT) technique that utilizes multiple ultrasonic elements and electronic time delays to create a focused beam of sound waves. This innovative technology allows for precise control over the angle, focal point, and depth of the inspection, resulting in highly detailed images. Such precision is crucial for identifying defects like cracks, voids, and inclusions within materials, ensuring the integrity and safety of critical components.

Comprehensive Inspection Capabilities

Phased Array Ultrasonic Testing excels in inspecting complex geometries and materials, making it invaluable in industries such as aerospace, oil and gas, and power generation. It is commonly employed for weld inspections, corrosion mapping, and flaw detection in metals and composites. The ability to generate real-time images enables inspectors to make immediate assessments, enhancing the efficiency of the inspection process.

Original Source: https://www.rvsglobe.com/phased-array-ultrasonic-testing-see-beyond-the-surface-benefits-and-applications-120

Integration with Other NDT Methods

For optimal results, PAUT is often integrated with other NDT methods. Combining PAUT with Time of Flight Diffraction (TOFD), for instance, offers a more comprehensive evaluation of material integrity. This integrated approach provides a robust framework for detecting and sizing defects, ensuring the highest standards of safety and reliability.

Cost-Effectiveness and Efficiency

While the initial setup cost for Phased Array Ultrasonic Testing equipment may be higher than traditional methods, the long-term benefits make it a cost-effective solution. The ability to perform thorough inspections quickly reduces downtime, which is crucial for industries where time is of the essence. Moreover, the detailed imaging capabilities minimize the need for multiple inspections, saving both time and resources. The efficiency of PAUT makes it an attractive option for industries looking to optimize their maintenance schedules and extend the lifespan of their assets.

Applications Across Various Industries

The applications of PAUT are vast and varied, extending across multiple industries. In the oil and gas sector, PAUT is utilized to assess the condition of pipelines and pressure vessels, ensuring their safe operation. The aerospace industry employs PAUT for the inspection of aircraft components, where even the smallest defect can have significant consequences. Additionally, the power generation industry uses PAUT to monitor the condition of turbines and other critical equipment, preventing catastrophic failures.

Enhanced Accuracy and Versatility

Phased Array Ultrasonic Testing stands out for its exceptional accuracy and versatility. Unlike conventional ultrasonic testing, PAUT uses multiple ultrasonic elements and electronic time delays to create a focused beam of sound waves. This method allows for precise control over the angle, focal point, and depth of the inspection, resulting in highly detailed images. This level of precision is crucial for identifying defects that might be missed by other testing methods, such as cracks, voids, and inclusions within a material.

Complementary NDT Techniques

In addition to PAUT, various complementary NDT services provide a holistic approach to material inspection. For instance, Infrared Thermography Services are used to detect surface and subsurface anomalies by measuring temperature variations. This non-contact method is particularly useful for identifying electrical and mechanical issues in a wide range of applications. When combined with PAUT, infrared thermography provides a comprehensive understanding of material integrity, ensuring the highest level of safety and performance.

Conclusion

Phased Array Ultrasonic Testing is a powerful tool in the field of non-destructive testing, offering unparalleled accuracy and versatility. The ability to inspect complex geometries and integrate with other NDT methods makes PAUT an essential technique for various industries. By adopting advanced inspection technologies like PAUT, industries can maintain high standards of quality and safety, ensuring the longevity and reliability of their critical assets.

0 notes

Text

The Power of Ground Penetrating Radar: What You Need to Know

When it comes to construction, renovations, or any other project that involves working underground, understanding what lies beneath the surface is essential. Ground Penetrating Radar (GPR) has revolutionized the way professionals approach such tasks. Whether it’s finding hidden utilities, mapping structures, or ensuring safety, GPR scanning is an indispensable tool in the industry. At Safe Scanners, we specialize in providing cutting-edge GPR services to help you make informed decisions and avoid costly mistakes. Here’s everything you need to know about the power of GPR.

What is Ground Penetrating Radar (GPR)?

Ground Penetrating Radar (GPR) is a non-destructive technology used to scan and map subsurface structures. It works by emitting high-frequency radio waves into the ground, which then reflect back when they encounter materials of different densities. These reflected waves are captured and used to create a detailed image of what's below the surface. It’s one of the safest and most effective ways to visualize what’s hidden without digging or drilling.

How Does GPR Work?

The GPR system uses a transmitter and receiver. The transmitter sends high-frequency radio waves into the ground. These waves travel through various materials like soil, concrete, rock, or asphalt. When the waves hit a boundary, such as an underground utility or a structural element, they bounce back toward the receiver, providing data that is processed into an image or map.

This real-time imaging allows users to detect:

Buried utilities: Gas lines, water pipes, electrical cables

Structural elements: Rebar, post-tension cables, and other embedded materials

Void detection: Air pockets or gaps that could compromise structural integrity

Cracks and defects: In concrete and other materials

Key Applications of GPR Scanning

GPR scanning is incredibly versatile, making it suitable for various industries. Here are some of the most common applications of GPR:

1. Concrete Scanning

One of the most common uses of GPR is concrete scanning. When working with concrete, whether it’s cutting, drilling, or coring, knowing the location of embedded elements like rebar or post-tension cables is critical. Using GPR scanning, Safe Scanners can help you map these elements before work begins, preventing costly mistakes and improving safety. Concrete scanning also allows you to identify cracks, voids, or areas of deteriorating concrete.

2. Concrete X-Ray Services

Similar to traditional X-rays used in the medical field, Concrete X-Ray Services use GPR technology to visualize what's embedded within concrete structures. This non-invasive method allows for a safer, faster alternative to traditional radiographic testing, providing clear images of rebar, post-tension cables, and other embedded objects without the risk of radiation exposure. With this service, you can plan your projects with greater accuracy and avoid accidental damage to existing structures.

3. Scanning Utility Locating

One of the most significant risks when excavating or performing construction work is hitting a hidden utility line. Scanning utility locating is a vital service that allows for the precise identification of underground utilities, such as water pipes, gas lines, or electrical cables. By using GPR scanning, Safe Scanners can help you map out these utilities before any work begins, ensuring that your project proceeds without incident.

4. Mapping Subsurface Structures

GPR scanning is also used to map out subsurface structures. This is particularly useful for engineers and construction teams who need to know what’s below ground before starting large-scale projects, such as roads, bridges, or foundation work. GPR can identify old foundations, buried walls, and other man-made structures that might otherwise go unnoticed.

Benefits of GPR Scanning

The power of GPR scanning comes with numerous benefits that make it an invaluable tool in modern construction and engineering projects. Here’s why GPR is the go-to technology for professionals:

1. Non-Destructive Testing

Unlike traditional methods of digging or drilling to locate utilities or inspect concrete, GPR scanning is non-destructive. This means you can gather critical data without causing harm to the area being scanned. Whether you're working in a residential home or on a commercial site, GPR allows for the safe exploration of subsurface materials without disrupting the environment or structure.

2. Improved Safety

By using GPR scanning, you can detect potential hazards before they become a problem. Whether it's buried utilities or cracks in concrete, knowing what's below the surface reduces the chances of accidents. Avoid hitting a gas line, damaging electrical cables, or cutting through a critical structural element. Safety is always a priority, and GPR helps mitigate many risks.

3. Cost-Effective

Performing excavation or demolition work to locate underground utilities can be costly and time-consuming. GPR scanning helps prevent unnecessary digging by accurately identifying underground structures. This reduces labor costs, minimizes delays, and helps avoid costly repairs or fines for damaging utilities.

4. Real-Time Results

GPR provides real-time imaging, allowing you to immediately assess what’s beneath the surface. This instant feedback helps guide your decisions and can be integrated into the planning phase of any project, reducing project timelines and ensuring a more efficient workflow.

5. Versatility

GPR scanning is highly versatile and can be used in a wide variety of applications, from concrete scanning to utility locating to environmental studies. Whether you’re working in a construction site, at a landfill, or in a geological investigation, GPR can be adapted to meet your needs.

Why Choose Safe Scanners for GPR Services?

At Safe Scanners, we provide the most advanced GPR services available. Our team of experts is highly trained and experienced in conducting detailed scans and providing actionable insights. Whether you need concrete scanning, concrete X-ray services, or utility locating, we have the right tools and expertise to help you.

Conclusion

The power of Ground Penetrating Radar (GPR) cannot be overstated. It’s a safe, efficient, and cost-effective solution for uncovering what’s hidden beneath the surface. With the ability to map underground utilities, structural elements, and potential hazards, GPR is a crucial tool for anyone involved in construction or renovation. At Safe Scanners, we’re committed to providing you with the best GPR services, ensuring that your projects are completed with precision and safety in mind.

0 notes

Text

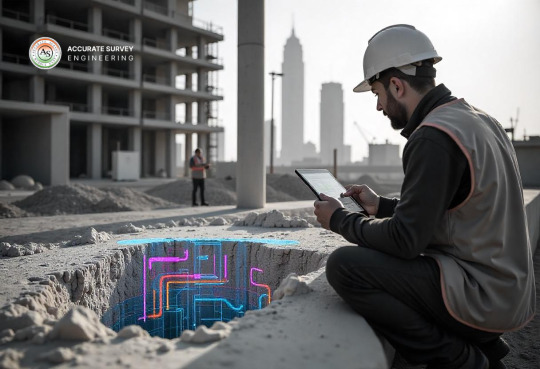

Building Smarter: How Concrete Imaging is Revolutionizing UAE’s Construction Industry

The construction industry in the UAE is advancing at an unprecedented pace, with towering skyscrapers, massive infrastructure projects, and state-of-the-art developments shaping the landscape. However, with rapid urbanization comes the need for precision, efficiency, and safety. One of the most significant technological advancements transforming construction processes today is concrete imaging. This revolutionary technique ensures that construction professionals make informed decisions, minimize risks, and maintain structural integrity.

Concrete imaging, often carried out by Concrete Scanning and Imaging Companies in UAE, plays a crucial role in modern construction. By using cutting-edge technology such as Ground Penetrating Radar (GPR) and X-ray scanning, professionals can detect hidden objects within concrete structures before drilling or cutting. This reduces costly damages, improves safety, and enhances the efficiency of construction projects.

The Importance of Concrete Imaging in the UAE’s Construction Sector

The UAE's construction industry is known for its ambitious projects, making precision and risk mitigation essential. Concrete imaging has become a necessity for contractors, engineers, and project managers for the following reasons:

Avoiding Structural Damage: Hidden reinforcements, electrical conduits, and plumbing lines can be damaged during drilling or cutting. Concrete scanning helps prevent such incidents, saving time and money.

Enhancing Safety Standards: Accidents due to undetected obstructions in concrete structures can be hazardous. With proper scanning, risks to workers and project delays are minimized.

Compliance with Regulations: Many UAE construction regulations require thorough scanning before any modification to existing structures.

Cost Savings: Repairing damaged structural elements can be expensive. Scanning before cutting eliminates unnecessary expenses by ensuring a clear understanding of the internal layout.

Increasing Project Efficiency: Concrete imaging streamlines workflow by reducing guesswork, making construction and renovation projects more efficient.

How Concrete Imaging Works

Concrete imaging involves various advanced scanning techniques that provide real-time insights into a structure’s composition. The most commonly used methods by Top Concrete Scanning and Imaging Companies in UAE include:

Ground Penetrating Radar (GPR):

Uses electromagnetic waves to create detailed images of subsurface materials.

Identifies rebar, post-tension cables, voids, and embedded utilities.

Provides non-destructive and fast results.

Concrete X-Ray Scanning:

Offers high-resolution images for deeper insights into structural components.

Used in complex scanning requirements where GPR alone is insufficient.

Requires proper safety precautions due to radiation exposure.

Ultrasonic Testing (UT):

Uses sound waves to detect cracks, voids, and internal defects.

Ideal for assessing structural integrity before major renovations or modifications.

Electromagnetic Induction Scanning:

Helps identify embedded metallic components like rebar and conduit pipes.

Useful for ensuring reinforcement placement aligns with design specifications.

Each of these methods provides detailed insights, allowing engineers to plan construction activities with precision.

Benefits of Concrete Imaging for Construction Projects

Modern construction requires a data-driven approach, and Concrete Scanning and Imaging Companies in UAE offer valuable services that significantly improve project outcomes. Some key benefits include:

Prevention of Accidental Utility Strikes: Construction teams can avoid damaging electrical cables and water pipelines embedded within concrete structures.

Non-Destructive Inspection: Traditional methods of assessing concrete integrity often involve destructive techniques. Imaging ensures a non-invasive, damage-free assessment.

Better Resource Management: By knowing the exact composition of a structure, project managers can allocate resources efficiently, reducing waste and increasing productivity.

Supporting Renovation and Retrofitting Projects: Older buildings require careful modification, and concrete imaging ensures safe and precise alterations without compromising structural stability.

Enhancing Quality Control: Scanning helps verify if concrete slabs have been poured correctly and whether reinforcement is in place as per design specifications.

Choosing the Right Concrete Imaging Provider in the UAE

Selecting the right Concrete Scanning and Imaging Company in UAE is crucial to ensure accurate and reliable results. Here are some factors to consider:

Advanced Technology: Ensure the company uses state-of-the-art scanning tools like GPR, X-ray, and ultrasonic testing.

Experienced Professionals: Trained and certified technicians provide more accurate assessments.

Compliance with Safety Standards: The company should adhere to UAE construction safety regulations and guidelines.

Comprehensive Reporting: Look for a provider that delivers detailed and easy-to-understand reports.

Proven Track Record: Experience in handling large-scale projects demonstrates the company’s reliability.

As the UAE continues its journey toward architectural excellence, concrete imaging remains a fundamental aspect of safe and efficient construction. By employing advanced scanning techniques, construction professionals can minimize risks, prevent costly damages, and ensure seamless project execution.

For those looking for a trusted provider, Accurate Survey stands out as one of the top Concrete Scanning and Imaging Companies in UAE. Our expertise in non-destructive testing ensures precise results, making construction projects safer and more efficient.

Investing in concrete imaging is not just a technological advancement, it’s a necessity for smarter and more sustainable construction in the UAE.

0 notes

Text

A Comprehensive Guide to Conducting Periodic Structural Inspections in Singapore

Ensuring the safety and longevity of buildings is paramount in a city-state like Singapore, where urban density and stringent building standards demand meticulous care. Periodic structural inspections (PSIs) are crucial to identifying potential risks, addressing maintenance needs, and complying with regulatory requirements. This guide outlines the systematic steps in conducting these inspections effectively, ensuring that buildings meet safety and sustainability benchmarks.

Understanding Singapore’s Regulatory Framework

Singapore’s robust legal framework underpins the necessity of structural inspections. The Building Control Act and the Building Maintenance and Strata Management Act (BMSMA) outline specific inspection requirements to ensure buildings remain safe for use:

Periodic Structural Inspections (PSIs): Required for buildings older than 10 years, excluding low-rise residential buildings with fewer than two stories.

Facade Inspections are mandatory for buildings taller than 13 meters and over 20 years old.

Familiarity with these regulations ensures compliance and helps define the scope of an inspection, setting the foundation for a successful evaluation process.

Step 1: Engaging a Qualified Professional

Singapore’s regulations stipulate that only certified Professional Engineers (PEs) specializing in civil or structural engineering are authorized to conduct periodic structural inspections. Building owners must carefully select a PE to guarantee the highest assessment standards.

Tips for Choosing the Right Engineer:

Verify credentials and professional certifications.

Ensure the engineer’s experience aligns with the building type and complexity.

Review past projects and client testimonials for a comprehensive evaluation of their expertise.

Step 2: Preparing for the Inspection

Effective preparation is key to a seamless inspection process. This stage involves gathering essential documentation, notifying relevant parties, and organizing inspection tools.

Reviewing Building Records:

Collect architectural plans, structural drawings, and historical inspection reports.

Understand the building’s history, including prior modifications or repairs.

Coordinating with Stakeholders:

Inform tenants, building occupants, and management about the inspection timeline.

Ensure access to restricted or high-risk areas like rooftops, basements, and mechanical rooms.

Assembling Necessary Equipment:

Arrange for tools such as measuring devices, drones for aerial inspections, and personal protective equipment (PPE) for safety compliance.

Step 3: Conducting the Visual Inspection

A visual inspection is the first step in evaluating a building’s structural integrity. Engineers examine visible elements during this stage for signs of wear, damage, or deterioration. Key areas of focus include:

Foundations: Look for cracks, signs of settlement, or water infiltration.

Columns and Beams: Check for spalling concrete, rusted reinforcements, or deformation.

Walls and Facades: Identify cracks, water seepage, or peeling paint.

Roof and Ceiling: Examine for leaks, sagging structures, or damaged tiles.

Staircases and Railings: Ensure they are structurally sound and comply with safety regulations.

Advanced tools such as infrared thermography may be employed to detect hidden defects that are not visible to the naked eye.

Step 4: Employing Non-Destructive Testing (NDT)

Non-destructive testing (NDT) techniques provide critical insights into a building’s condition without causing damage. These methods enhance the accuracy of inspections and help identify underlying issues:

Ultrasonic Testing: Detects internal flaws in concrete and steel elements.

Rebound Hammer Test: Evaluates the surface strength of concrete.

Ground Penetrating Radar (GPR): Identifies subsurface issues such as voids or improper rebar placement.

Carbonation Testing: Measures the depth of carbonation in concrete to assess the risk of corrosion.

By combining visual assessments with NDT results, engineers can create a comprehensive picture of the structure’s health.

Step 5: Documenting Findings and Assessing Risks

Post-inspection, engineers compile a detailed report summarizing their findings and recommendations. The report typically includes:

A summary of observed defects and their severity.

Results from non-destructive tests and their implications.

Photographic evidence documenting key issues.

Suggested remedial actions and timelines.

The report categorizes risks by severity, helping building owners prioritize repairs and allocate resources effectively.

Step 6: Planning and Executing Repairs

If the inspection identifies defects, addressing them promptly is essential to maintaining safety and compliance. This phase involves:

Developing a Repair Strategy:

Prioritize critical repairs that impact structural safety.

Specify materials and techniques for remedial work.

Engaging Competent Contractors:

Select contractors with experience in structural repairs.

Ensure adherence to the Building and Construction Authority’s (BCA) standards.

Supervising the Repairs:

The PE should oversee repair work to ensure it meets specified requirements.

Step 7: Submitting the Inspection Report

Upon completing the inspection and repairs, the final report must be submitted to the BCA within the stipulated timeframe. A complete submission includes:

Detailed inspection findings.

Photographs of identified issues.

Results of NDT methods.

Recommended repairs and completion timelines.

This step ensures transparency, regulatory compliance, and proper documentation of the inspection process.

Step 8: Scheduling Future Inspections

Periodic inspections are not a one-time activity but an ongoing commitment to building safety. Depending on the structure’s age and condition, the BCA may require subsequent inspections within specific intervals. Building owners should:

Maintain an updated maintenance schedule.

Address minor issues proactively to prevent major defects.

Stay informed about changes to inspection guidelines and requirements.

Best Practices for Effective Structural Inspections

To maximize the efficiency and reliability of inspections, consider adopting these best practices:

Proactive Maintenance:

Regularly monitor and address minor issues to prevent them from escalating into significant problems.

Leverage Technology:

Utilize drones to inspect hard-to-reach areas, particularly the facades of high-rise buildings.

Implement digital platforms for tracking inspection data and maintenance schedules.

Engage Stakeholders:

Collaborate with tenants, management, and contractors to create a culture of safety and vigilance.

Continuous Education:

Stay updated on technological advancements and regulatory changes to enhance inspection practices.

Conclusion

Periodic structural inspections are vital for maintaining the integrity, safety, and longevity of buildings in Singapore. By adhering to a systematic approach and leveraging modern technologies, building owners can ensure compliance with stringent regulations while fostering a safe environment for occupants. As Singapore continues to develop, prioritizing structural inspections will remain essential to sustainable urban growth. By engaging qualified professionals, planning effectively, and addressing issues promptly, stakeholders can uphold the city’s reputation for safety and excellence in urban management.

0 notes

Text

Magnetic Particle Inspection Machine - Magkraftndt

Machine for the Magnetic Particle Inspection detects surface or subsurface defects in metal objects using magnetic fields together with iron particles to expose cracks with a view to control quality and safety in various sectors.

#magkraftndt#mptmachine#advancedtechnology#inspectionmachine#magneticparticletestingmachine#demagnetizermachine#eddycurrenttestingmachine#magnafluxmachine#mpimachinemanufacturer

0 notes

Text

Looking for advanced, reliable, and non-destructive testing methods? Phased Array Ultrasonic Testing is here to offer you:

✔️ Increased Efficiency: PAUT allows for fast, accurate inspection of materials without the need for direct contact. ✔️ Enhanced Accuracy: Multiple angles and frequencies for precise imaging of flaws. ✔️ Comprehensive Results: Ideal for complex geometries, detecting surface and subsurface defects with ease.

🔗 Learn more about PAUT and how it can benefit your business: https://www.bestndtinspection.com/

#NDT#PhasedArrayUltrasonicTesting#QualityControl#NonDestructiveTesting#InspectionServices#BestNDTInspection#PAUT#EngineeringExcellence#SafetyFirst

0 notes

Text

Defect Detection in Manufacturing

Defect detection in manufacturing ensures product quality by identifying flaws during production. Advanced technologies like optical metrology and automated systems detect surface, dimensional, and subsurface defects with precision. By leveraging tools such as CMMs and laser scanners, manufacturers reduce waste, improve efficiency, and maintain high standards across diverse industries.

Read more in our latest blog! https://viewmm.com/en/defect-detection-in-manufacturing/

0 notes

Text

The Power of Drone Surveys | Epitome Geo Technical Services

The geotechnical industry has seen tremendous advancements in recent years, and one of the most transformative technologies is drone surveying. Drone surveys have revolutionized how geotechnical data is collected, analyzed, and utilized, leading to enhanced accuracy, efficiency, and cost-effectiveness. At Epitome GeoTechnical Services, we leverage cutting-edge drone technology to provide unparalleled geospatial solutions for various industries. This blog explores the power of drone surveys and how they are reshaping geotechnical services. What Are Drone Surveys? Drone surveys involve using Unmanned Aerial Vehicles (UAVs) equipped with high-resolution cameras, LiDAR sensors, and GPS technology to capture aerial imagery and topographical data. These surveys provide real-time, precise data, allowing geotechnical engineers to assess terrain, soil conditions, and structural integrity with unprecedented accuracy. Benefits of Drone Surveys in Geotechnical Services

Enhanced Data Accuracy Traditional surveying methods rely on ground-based equipment and manual measurements, which can be time-consuming and prone to human error. Drones equipped with high-resolution cameras and LiDAR sensors capture detailed topographical data with millimeter-level accuracy, improving decision-making and project outcomes.

Time and Cost Efficiency Drone surveys significantly reduce the time required to conduct site assessments. A survey that might take days or weeks using traditional methods can be completed in just a few hours. This efficiency translates to lower labor costs, reduced project timelines, and minimized disruptions to ongoing construction or exploration activities.

Improved Safety Many geotechnical sites involve hazardous or hard-to-reach areas, such as steep slopes, unstable terrains, or contaminated zones. Drone surveys eliminate the need for personnel to physically access these areas, mitigating the risk of accidents and injuries while ensuring comprehensive site evaluations.

Comprehensive Data Collection Drones can capture vast amounts of data in a single flight, providing detailed 3D models, elevation maps, and geospatial analytics. This holistic view enables geotechnical engineers to identify potential issues such as erosion, subsidence, or structural weaknesses before they escalate.

Versatility Across Industries Drone surveys are not limited to geotechnical applications. They are extensively used in construction, mining, agriculture, environmental monitoring, and disaster management. Their ability to provide real-time aerial insights makes them invaluable across multiple sectors. How Epitome Geo Technical Services Utilizes Drone Surveys At Epitome Geo Technical Services, we incorporate drone surveys into our geotechnical investigations to ensure high-quality, data-driven results. Our team of experts uses state-of-the-art UAV technology to provide:

Site Assessment and Mapping We conduct aerial surveys to generate high-resolution topographic maps, contour maps, and digital terrain models (DTMs). These outputs help in understanding site conditions, planning construction projects, and assessing land suitability.

Soil and Terrain Analysis Using LiDAR-equipped drones, we analyze soil composition, detect subsurface anomalies, and evaluate ground stability. This information is crucial for infrastructure development, road construction, and foundation design.

Monitoring and Risk Assessment Our drone surveys provide ongoing monitoring of construction sites, mining operations, and environmental projects. We assess risks such as landslides, erosion, and groundwater movement, ensuring proactive mitigation strategies.

Structural Inspections Drones enable us to inspect bridges, dams, towers, and other structures with high precision. By identifying cracks, deformations, or other defects early, we help clients maintain structural integrity and avoid costly repairs.

Environmental Impact Studies We use drone surveys for environmental assessments, monitoring deforestation, tracking changes in vegetation, and analyzing pollution effects. These insights aid in sustainable development and conservation efforts. Future of Drone Surveys in Geotechnical Services The adoption of drone technology in geotechnical services is expected to grow exponentially in the coming years. Advancements in artificial intelligence (AI) and machine learning (ML) will further enhance data analysis, enabling predictive modeling and automation. Additionally, the integration of drones with Geographic Information Systems (GIS) will provide even more detailed and interactive geospatial insights. Regulatory frameworks are also evolving to accommodate drone operations, making it easier for geotechnical firms to deploy UAVs for large-scale projects. As technology advances, drone surveys will continue to redefine the industry, offering faster, safer, and more cost-effective solutions. Conclusion Drone surveys have become an indispensable tool in geotechnical services, offering unparalleled accuracy, efficiency, and safety. At Epitome GeoTechnical Services, we are committed to leveraging the latest UAV technology to deliver precise geospatial solutions for our clients. Whether it’s site assessment, structural inspections, or environmental monitoring, our drone surveys provide the critical data needed to make informed decisions. If you’re looking for cutting-edge geotechnical solutions, contact Epitome GeoTechnical Services today and experience the power of drone surveys in transforming your projects.

#GIS Mapping Survey in India#GIS Mapping Survey#GIS Mapping Company in India#Drone Survey#aerial photography survey#aerial survey

1 note

·

View note

Text

Understanding Eddy Current Testing Equipment: Tools, Probes, and Techniques

Eddy Current Testing (ECT) is a non-destructive testing (NDT) method that leverages electromagnetic induction to detect flaws in conductive materials. Its widespread use spans various industries, including aerospace, automotive, and power generation, due to its ability to quickly and accurately identify defects without causing damage. Central to the effectiveness of ECT are the tools, probes, and techniques used during inspections. This article provides an in-depth look at the key components and considerations involved in eddy current testing.

Core Components of Eddy Current Testing Equipment

Eddy Current Instruments The primary component of ECT is the eddy current instrument or tester, which generates an alternating current to produce a magnetic field in the probe coil. When this probe is placed near a conductive surface, it induces eddy currents within the material. The instrument measures changes in these currents, which can indicate the presence of defects, material thickness variations, or conductivity changes.

Modern ECT instruments range from portable handheld devices to sophisticated desktop systems with advanced data analysis capabilities. Features such as multi-frequency testing, real-time data visualization, and automated defect analysis enhance their versatility and accuracy in various applications.

Probes and Coils Probes are critical for effective eddy current testing. They come in various shapes and configurations, tailored to specific testing requirements and material properties. Selecting the right probe is crucial for achieving accurate results. Here’s a breakdown of common probe types:

Pencil Probes: These are versatile probes ideal for testing small, localized areas such as cracks in welds or holes. Pencil probes offer high precision but require a steady hand during inspections.

Surface Probes: These probes are used for inspecting larger, flat surfaces and can detect surface cracks, corrosion, and thickness variations. Surface probes often feature multiple coils for greater sensitivity and faster scanning.

Encircling Coils: As the name suggests, these coils encircle the test piece, making them suitable for cylindrical components such as pipes and rods. They’re commonly used for testing for defects like cracks, seams, and material inconsistencies.

Differential Probes: These probes compare signals from two adjacent points, providing high sensitivity to small changes. They are effective for detecting localized flaws and are commonly used for detecting cracks in tubing and thin materials.

Data Acquisition and Analysis Software Data acquisition software plays a vital role in modern ECT systems, allowing inspectors to visualize, interpret, and analyze the data collected during testing. Advanced software can generate C-scans, B-scans, and impedance planes, offering a detailed view of subsurface defects and material properties. Automated defect detection algorithms enhance the efficiency and accuracy of inspections, reducing the reliance on manual interpretation.

Techniques and Configurations for Eddy Current Testing

Single-Frequency Testing This is the simplest and most commonly used technique, in which the eddy current probe operates at a single frequency. It’s suitable for applications that require the detection of surface or near-surface defects. However, it may have limitations in detecting deeper flaws or defects in complex geometries.

Multi-Frequency Testing Multi-frequency testing involves the simultaneous use of multiple frequencies to inspect a material. This technique improves the ability to detect defects at different depths and helps differentiate between various flaw types and material properties. It is particularly useful for complex inspections, such as those involving layered materials.

Conductivity and Thickness Testing In addition to flaw detection, ECT can be used to measure the conductivity and thickness of materials. Conductivity testing is valuable for sorting alloys and assessing heat treatment effects, while thickness testing is used for non-destructive coating thickness measurements and material thickness verification.

Practical Considerations for Effective ECT

Calibration and Reference Standards: To ensure accurate measurements, eddy current instruments must be properly calibrated using known reference standards. These standards replicate the material properties and defects that inspectors may encounter, allowing for precise and consistent results.

Surface Preparation: Surface condition significantly impacts the accuracy of eddy current testing. Inspectors must ensure that surfaces are clean and free from debris, coatings, or rust that could interfere with signal generation and interpretation.

Operator Training and Expertise: Effective ECT requires skilled operators with a deep understanding of electromagnetic theory, probe selection, and data interpretation. Training and certification ensure that inspections are performed correctly, reducing the risk of false positives or undetected defects.

Conclusion

Eddy current testing is a powerful non-destructive testing method that relies on specialized tools, probes, and techniques to detect defects and assess material properties. By understanding the key components of ECT equipment and the various techniques used, inspectors can achieve accurate and reliable results. As technology advances, ECT systems continue to improve in versatility, accuracy, and efficiency, solidifying their importance in industries where safety and precision are paramount.

0 notes

Text

The Pros and Cons of Different Bridge Inspection Technologies

Bridge inspections are critical to ensuring that some of our country’s most crucial infrastructure elements stay structurally sound and safe.

Bridge inspection technology is key to ensuring that these inspections are as accurate and undisruptive as possible.

The technology used to inspect bridges has rapidly increased in sophistication over the past 20 years.

What was once done with chains and boots-on-the-ground is now possible with airplanes and infrared technology. Although there is still a place for older methods of bridge inspection.

In this article, we’ll walk you through some of the different forms of bridge inspection and outline what scenarios each method is ideal for.

Visual Inspection

Visual inspection remains a fundamental aspect of bridge assessment, serving as a starting point for identifying obvious defects.

This method is cost-effective and requires minimal equipment, allowing inspectors to detect surface-level issues like cracks, spalling, and corrosion.

It also enables immediate identification of urgent repairs, which can be crucial for maintaining public safety.

However, visual inspection has its limitations. It's restricted to surface-level defects and can be highly subjective, depending on the inspector's expertise.

Visual inspections can be time-consuming for large structures and may miss subsurface issues that could compromise the bridge's integrity.

Visual inspections are usually paired with other auditory and tactile techniques.

Acoustic Techniques

Bridge inspectors can detect damage to bridges using acoustic methods, such as chain dragging and hammer sounding.

The different sounds that are made when applying chains or hammers to the bridge’s surface indicate whether there are fractures, or delaminations, within the bridge’s structure.

These techniques are relatively inexpensive and easy to implement, requiring minimal training for inspectors.

However, acoustic techniques are not without drawbacks. They are labor-intensive and time-consuming, especially for large bridge decks.

The results are subject to human error and interpretation, which can lead to inconsistencies in assessments. Additionally, these methods are not effective on bridges with asphalt overlays and have a limited depth of detection.

They also require bridges to be shut down to traffic, which can frustrate the public.

Thermal Infrared (TIR) Inspection

Thermal Infrared (TIR) technology is a scientific tool for bridge inspections that is more accurate and hands-off than traditional techniques.

Here’s how it works: TIR tech detects temperature differences within a bridge’s structure, which indicate issues such as delamination

However, several different ways are available to collect TIR data, and some are less disruptive than others.

TIR With Mobile, Ground-Based Vehicles

Mobile, ground-based vehicles equipped with TIR cameras offer a practical solution for bridge deck inspections.

These vehicles can cover large areas quickly, minimizing traffic disruption and allowing for consistent data collection at highway speeds.

This approach is particularly useful for assessing long bridge spans or multiple bridges in a single session.

However, ground-based TIR inspections are limited to deck surfaces accessible by vehicle, which may exclude some bridge components.

In some cases, lane closures may be necessary, causing temporary traffic inconveniences.

Additionally, this method is less effective for inspecting the undersides of bridges, which can be critical areas for detecting structural issues.

TIR With Fixed-Wing Aircrafts

Fixed-wing aircraft equipped with TIR cameras offer a comprehensive solution for bridge inspection technology.

This method can survey multiple bridges in a single flight, providing a wide-area perspective that is particularly efficient for large-scale infrastructure assessments.

Aircraft-based TIR inspections cause minimal traffic disruption and can capture both deck and underside imagery, offering a more complete view of the bridge's condition.

However, this approach has higher initial costs compared to ground-based methods. It's also weather-dependent, which can lead to scheduling challenges.

Special permits may be required for low-altitude flights, adding to the logistical complexity.

While aircraft-based TIR provides excellent coverage, it may offer less detail than close-range inspections.

TIR With Unmanned Aerial Vehicles (UAVs) or Drones

UAVs or drones equipped with TIR cameras have gained popularity in bridge inspection due to their versatility. These devices are highly maneuverable, allowing access to difficult areas that might be challenging or dangerous for human inspectors.

They can capture high-resolution imagery and are cost-effective for individual bridge inspections, causing minimal traffic disruption.

However, drones have limitations in flight time and range, which can be problematic for large bridges or extensive surveys. They are also susceptible to wind and weather conditions, potentially affecting data quality or preventing inspections altogether.

Operating drones requires skilled pilots and compliance with aviation regulations, which adds to the complexity of this method.

Other Non-TIR Bridge Inspection Technologies

While thermal infrared solutions offer significant advantages, other bridge inspection technologies also play important roles in comprehensive assessments.

Ground Penetrating Radar (GPR)

Ground Penetrating Radar is a non-destructive testing method that uses electromagnetic pulses to detect subsurface defects and rebar corrosion in bridge structures.

It has the advantage of working through asphalt overlays and providing depth information, which is crucial for assessing the internal condition of bridge decks.

However, GPR requires specialized equipment and expertise to operate effectively. Data interpretation can be complex, requiring trained professionals to analyze the results accurately.

While GPR is excellent for detecting certain types of defects, it is less effective than TIR technology in identifying delaminations.

Final Thoughts

As bridge inspection technology continues to evolve, engineers and inspectors have an array of tools at their disposal.

Thermal infrared solutions, particularly those deployed via fixed-wing aircraft, offer a compelling combination of efficiency and effectiveness for large-scale bridge assessments.

However, less sophisticated bridge inspection techniques still have their place in infrastructure assessment.

When selecting bridge inspection technology, factors such as bridge type, size, location, and specific inspection goals should be considered. By leveraging the strengths of different inspection methods, agencies can develop more effective maintenance strategies, ultimately ensuring the safety and longevity of our critical infrastructure.

The future of bridge inspection lies in the intelligent integration of these diverse technologies, which would create a more robust and efficient system for maintaining our vital transportation networks.

0 notes

Text

Magnetic Particle Testing: Enhancing Crane Safety with Cossack Inspections in Perth

Crane safety is critical to industrial operations, especially in sectors like construction, mining, and heavy manufacturing. A crane failure can lead to catastrophic damage, injury, or loss of life, making regular inspection a vital part of safety protocols. One of the most effective non-destructive testing (NDT) methods for identifying surface and subsurface defects in crane components is Magnetic Particle Testing (MT). In Perth, Cossack Inspections provides specialised MT services, ensuring the safety and reliability of cranes used in high-stakes environments.

0 notes