#Subsea Networks

Explore tagged Tumblr posts

Text

#Under sea Cables#Telecommunication Infrastructure#Global Connectivity#Fiber OpticCables#Subsea Networks#Coherent Market Insights

1 note

·

View note

Text

🌍 1) Largest country in Africa by land mass - Algeria 🇩🇿

2) Largest country in Africa by population - Nigeria 🇳🇬

3) Largest movie industry in Africa - Nigeria 🇳🇬

4) Largest democracy in Africa - Nigeria 🇳🇬

5) Richest Black man - Nigerian 🇳🇬

6) Richest African woman - Nigerian 🇳🇬

7) largest single solar power plant in Africa - Morocco 🇲🇦

8) Largest Museum in Africa - Egypt 🇪🇬

9) Tallest building in Africa - Egypt 🇪🇬

10) Largest rice mill in Africa - Nigeria 🇳🇬

11) Largest fertilizer plant in Africa - Nigeria 🇳🇬

12) largest oil refinery in Africa - Nigeria 🇳🇬

13) largest fish farm in Africa - Egypt 🇪🇬

14) largest cement plant in Africa - Nigeria 🇳🇬

15) largest tea farm in Africa - Kenya 🇰🇪

16) largest music industry in Africa - Nigeria 🇳🇬

17) largest stadium in Africa - South Africa 🇿🇦

18) Fastest train in Africa - Nigeria 🇳🇬

19) longest subsea gas pipeline in Africa - Nigeria 🇳🇬

20) largest city by population - Nigeria 🇳🇬

21) Largest news network in Africa - Nigeria 🇳🇬

22) largest car race arena in Africa - South Africa 🇿🇦

23) largest pharmaceutical industry in Africa - Nigeria 🇳🇬

24) Fastest woman in Africa - Nigerian 🇳🇬

25) Fastest man in Africa - Kenyan 🇰🇪

26) largest stock exchange by market capitalization in Africa - South Africa 🇿🇦

27) largest stock exchange by number of listings - south Africa 🇿🇦

28) longest concrete road in Africa - Nigeria 🇳🇬

29) largest airline in Africa - Ethiopia 🇪🇹

30) most streamed musicians in Africa - Nigeria 🇳🇬

31) most awarded artist in Africa - Nigerian 🇳🇬

32) largest mall in Africa by structure - Morocco 🇲🇦

33) most valuable tech startup in Africa - Nigeria 🇳🇬

34) most valuable company in Africa - South Africa 🇿🇦

35) largest economy in Africa - Nigeria 🇳🇬

36) Most tribes in Africa - Nigeria 🇳🇬

37) most languages in Africa - Nigeria 🇳🇬

39) largest seaport In Africa by size - Morocco 🇲🇦

40) largest university in Africa by area - Nigeria 🇳🇬

62 notes

·

View notes

Text

Sweden is investigating a series of suspected sabotage incidents involving more than 30 telecom towers, raising alarms over infrastructure vulnerability amid ongoing geopolitical tensions in Europe.

The affected infrastructure spans locations along Sweden's E22 highway, where cables were severed and technical equipment damaged at multiple sites, according to local media and Data Center Dynamics.

Why It Matters

Sweden, which joined NATO in March 2024, is among several member states seeing increased focus on critical infrastructure protection, particularly in the context of the Baltic region's elevated security posture following Russia's war in Ukraine.

Though the motive and perpetrator remain unknown, the nature of the damage has heightened concerns within Sweden's security community.

"This stands out and is more than usual," Roger Gustafsson, head of security at Sweden's Post and Telecom Authority (PTS), told the national broadcaster SVT Nyheter.

What To Know

The incidents started during Easter weekend at more than 30 locations and led to outages on mobile networks in some cases but nothing major.

The E22, also known as the European Road, is part of a road network that stretches for more than 3,300 miles, connecting the U.K. in the west to Russia in the east.

Detective Superintendent Håkan Wessung, head of serious crime in Kalmar, said investigators "don't rule anything out," including the possibility of deliberate attacks, according to The Economic Times.

Previous incidents in Sweden include a 2016 case in which a 300-meter mast was deliberately taken down, affecting tens of thousands of households.

Meanwhile, concerns about infrastructure security have extended to undersea cables.

In February, a fiber-optic cable between Finland and Germany was damaged in Swedish waters near Gotland. Swedish authorities opened a sabotage investigation, although the Finnish operator reported no service disruption.

"These incidents must be viewed in the context of the existing serious security situation," Swedish Prime Minister Ulf Kristersson wrote on X, formerly Twitter, at the time.

Similar sabotage acts previously affected NATO member states, including Sweden, such as the cutting of key underwater communications cables in the Baltic, arson attacks on logistics facilities in Germany, and cyberattacks targeting defense firms.

What People Are Saying

Swedish prosecutor Michelle Stein, who is leading the police investigation, told SVT: "There are circumstances that make everything seem to be connected, but it is something that the investigation will have to show."

Multiple European telecommunications firms, in an open letter to the European Union, U.K. and NATO In April: "At this crucial time for Europe's security and resilience, we commend your efforts to strengthen collective defence and protect critical infrastructure. Subsea cables play a vital role in Europe's connectivity, competitiveness, defence readiness, and economic stability. We recommend the EU/EEA and UK authorities as well as NATO renew their collaboration to address this situation effectively, together with the industry stakeholders from the EU and from the UK.

"With the rise in hybrid threats, including incidents affecting subsea cables in the Baltic and North Sea, we emphasize the importance of enhanced, coordinated action to safeguard Europe's cross-border networks. The EU Action Plan on Cable Security provides a clear approach to further increase the resilience and security of subsea cables."

What Happens Next

Swedish authorities continue to investigate the tower incidents, with assistance from security services and technical experts. They have not announced arrests or released findings confirming sabotage.

In the meantime, national and regional coordination on critical infrastructure protection is expected to intensify.

The developments have pushed telecommunications and energy security higher on Sweden's national agenda as European nations adapt to a security environment reshaped by war and technological vulnerability.

4 notes

·

View notes

Text

Why MSERW Pipes Are Ideal for Oil & Gas Pipelines

In the complex and high-stakes world of oil and gas transportation, the infrastructure must be built on a foundation of safety, durability, and cost-efficiency. Among the critical components of this infrastructure are the pipelines that transport crude oil, natural gas, and refined petroleum products over long distances and under harsh conditions. One of the most reliable materials used in such pipeline systems today is the MSERW pipe, short for Mild Steel Electric Resistance Welded pipe. Known for its strength and cost-effectiveness, MSERW pipes are increasingly becoming the preferred choice for oil and gas projects across India, particularly in industrial hubs like Gujarat.

In this blog, we explore why MSERW pipes are ideal for oil and gas pipelines, their technical advantages, and why choosing the right supplier—like a trusted MSERW Pipe Supplier in Gujarat is essential for long-term project success.

What Are MSERW Pipes?

MSERW (Mild Steel Electric Resistance Welded) pipes are made using a high-frequency electric resistance welding process. Mild steel plates or coils are rolled into cylindrical shapes and welded longitudinally without the use of any filler material. This method ensures consistent weld strength, smooth internal surfaces, and precise dimensional control.

Due to their favorable mechanical and chemical properties, MSERW pipes are suitable for a wide range of applications, particularly in the oil and gas industry where reliability is non-negotiable.

Key Benefits of MSERW Pipes for Oil & Gas Pipelines

1. High Strength and Durability:

Oil and gas pipelines often traverse difficult terrain and are exposed to high pressure, corrosive environments, and temperature fluctuations. MSERW pipes offer excellent tensile strength and toughness, making them ideal for handling such challenging conditions.

The electric resistance welding process enhances the pipe's structural integrity, ensuring long service life with minimal maintenance—an essential requirement in pipeline projects that demand continuous operation over decades.

2. Smooth Internal Surface:

One of the less-discussed yet important features of MSERW pipes is their smooth internal bore, which reduces friction during fluid transmission. This translates into improved flow efficiency and reduced pumping costs, which can add up significantly over time in oil and gas transportation networks.

3. Dimensional Accuracy:

Precision is crucial in pipeline design. MSERW pipes are known for their accurate diameters and consistent wall thickness, which allows for better joint fitting, easier welding, and reduced chances of leakage or pressure drops. This dimensional accuracy makes MSERW pipes a reliable choice in critical applications.

4. Corrosion Resistance:

Oil and gas pipelines often carry chemically reactive substances. MSERW pipes can be coated with anti-corrosive layers like epoxy or zinc, enhancing their resistance to harsh environmental and chemical exposure. A reliable MSERW Pipe Provider in Gujarat will often offer customization options like internal and external coatings to match specific project needs.

5. Cost-Effective Solution:

Compared to other pipe types such as seamless or spiral welded pipes, MSERW pipes are more economical while still delivering excellent performance. Their relatively lower manufacturing costs and ease of installation contribute to reduced overall project expenses—without compromising on quality or safety.

Applications of MSERW Pipes in the Oil & Gas Industry

Due to their versatility, MSERW pipes are used across several oil and gas infrastructure components, such as:

Oil transmission pipelines:

Natural gas distribution lines:

Petroleum refining pipelines:

Subsea risers and flowlines:

Tank farm pipelines:

Offshore platform connections:

Whether it's a massive cross-country crude oil pipeline or a localized gas distribution system in Gujarat, MSERW pipes meet the performance criteria required in each scenario.

Why Choose a Trusted MSERW Pipe Supplier in Gujarat?

When it comes to industrial products like pipelines, choosing the right supplier can make or break the success of your project. Gujarat, being a key industrial state, is home to many steel and pipe manufacturers. However, not all suppliers offer the same level of product quality, customization, or after-sales support.

A reliable MSERW Pipe Supplier in Gujarat will provide:

Test-certified products meeting IS, API, or ASTM standards

Custom sizes, thicknesses, and coatings

Timely delivery for project timelines

Technical support for design and installation

Competitive pricing for bulk orders

Whether your project is located in Jamnagar, Ahmedabad, Vadodara, or the coastal industrial belt, sourcing from a reputed MSERW Pipe Provider in Gujarat ensures you receive consistent quality and service.

Sustainability and Environmental Compliance:

Sustainability is increasingly becoming a core concern in infrastructure development. MSERW pipes are eco-friendly due to their efficient manufacturing process and recyclability. Modern MSERW manufacturing facilities in Gujarat follow environmental norms that align with international standards.

Additionally, the energy-efficient flow facilitated by the smooth internal surface of MSERW pipes reduces the carbon footprint associated with fuel transportation. By selecting a reputed MSERW Pipe Provider in Gujarat, you're also contributing to environmentally responsible construction practices.

Conclusion: A Pipe You Can Trust:

In conclusion, MSERW pipes offer a powerful combination of strength, durability, cost-effectiveness, and precision—making them a go-to solution for oil and gas pipelines. Their performance in both onshore and offshore environments has been proven across numerous large-scale projects.

If you’re looking for a reliable and quality-driven supplier for your next project, partnering with a reputed MSERW Pipe Supplier in Gujarat is the right move. Not only will you gain access to high-quality products, but you'll also benefit from industry expertise, logistical support, and tailored solutions that match your pipeline requirements.

Make the smart choice—invest in MSERW pipes and work with a professional MSERW Pipe Provider in Gujarat to ensure your oil and gas infrastructure is built to last.

6 notes

·

View notes

Text

How Meta (Facebook) is Building Its Metaverse Infrastructure

Introduction

When Mark Zuckerberg announced Facebook's rebrand to Meta in late 2021, he wasn't just changing a company name he was signaling a massive shift in digital infrastructure investment. The tech giant's ambitious vision for the metaverse represents one of the largest infrastructure projects in tech history, requiring revolutionary advancements in hardware, networking, and computing power. Let's explore how Meta is creating the foundation for its virtual universe and what it means for the future of digital interaction.

The Backbone: Computing Power and Data Centers

Meta's metaverse dreams begin with raw computing muscle. The company has dramatically expanded its data center footprint, investing billions in specialized facilities designed specifically for the computational demands of immersive 3D worlds.

Unlike traditional web services, metaverse environments require real-time rendering, physics simulations, and support for thousands of simultaneous users—all while maintaining low latency. To meet these demands, Meta has been upgrading its data centers with specialized AI processors and graphics hardware optimized for spatial computing.

The company recently unveiled its AI Research SuperCluster (RSC), which it claims is among the world's fastest AI supercomputers. This computing powerhouse isn't just for current AI tasks—it's being positioned as critical infrastructure for metaverse development, capable of training the massive models that will power everything from realistic avatars to intelligent virtual assistants.

Solving the Latency Challenge: Edge Computing and Network Infrastructure

For the metaverse to feel real, interactions must be nearly instantaneous. Even small delays between user actions and visual feedback can break immersion and cause physical discomfort. This creates a massive technical challenge that Meta is addressing through strategic investments in edge computing and network architecture.

The company has been quietly building out edge computing nodes closer to users, reducing the physical distance data must travel. Additionally, Meta has invested in subsea cable projects like 2Africa and Echo, expanding global internet backbone capacity to support the massive data transfers the metaverse will require.

Perhaps most interesting is Meta's work on "Project Aria," which explores how distributed computing between devices and the cloud can reduce latency. By splitting computational tasks—performing some calculations on headsets while offloading more intensive processes to nearby servers—Meta aims to deliver responsive experiences even with limited on-device processing power.

Creating the Interface: Hardware Development

While software and servers form the metaverse's foundation, hardware is where users will actually experience it. Meta's acquisition of Oculus in 2014 (for $2 billion) now seems prescient, giving the company a significant head start in VR hardware development.

The Quest headset line has evolved to become increasingly powerful while remaining affordable and wireless—crucial factors for mass adoption. But Meta's hardware ambitions extend far beyond current VR headsets. The company's Reality Labs division is working on multiple next-generation interfaces:

Lightweight AR glasses that overlay digital information on the physical world

Haptic gloves that let users "feel" virtual objects

Neural interfaces that can detect subtle muscle movements for more natural control

Spatial audio systems that create convincing 3D soundscapes

Project Cambria (now released as the Quest Pro) represented Meta's push toward higher-end mixed reality, incorporating eye tracking, face tracking, and improved passthrough technology—all essential components for creating presence in virtual environments.

Building the Digital Foundation: Software Infrastructure

Underpinning Meta's metaverse is a complex software ecosystem designed to handle everything from avatar creation to virtual economies. The company has developed several key platform components:

Horizon Worlds serves as Meta's social VR platform where users can create and explore virtual spaces. While still developing, it represents the company's vision of user-generated content driving metaverse growth.

Presence Platform provides developers with tools to blend virtual and physical reality, including scene understanding, spatial anchors, and interaction SDKs.

Avatar system allows persistent digital identities across Meta's apps, with increasingly realistic appearances and expressions.

Meta has also been acquiring companies with specialized metaverse technology, such as Within (VR fitness), Supernatural (VR fitness), and BigBox VR (social VR gaming)—integrating their innovations into the broader infrastructure.

The Interoperability Challenge

Despite investing billions in proprietary technology, Meta has publicly committed to metaverse interoperability—the idea that virtual worlds should connect rather than exist as isolated islands. The company joined the Metaverse Standards Forum alongside competitors like Microsoft, helping establish protocols for identity, payments, and virtual assets.

This approach recognizes a crucial reality: no single company can build the entire metaverse alone. By establishing open standards while maintaining ownership of key infrastructure components, Meta aims to influence the metaverse's direction while ensuring its central role in its development.

Ethical Infrastructure and Trust & Safety

Building metaverse infrastructure isn't just about technology—it's also about creating systems to ensure safety, privacy, and responsible use. Meta has established a $50 million XR Programs and Research Fund partly focused on developing ethical guidelines and safety features.

The company is developing tools like personal boundaries to prevent harassment in virtual spaces and content moderation systems designed specifically for 3D environments. These "trust and safety" elements represent critical but often overlooked infrastructure components.

The Economic Foundation: Payments and Commerce

A self-sustaining metaverse requires robust economic systems. Meta has been building financial infrastructure through several initiatives:

Horizon Marketplace enables creators to sell virtual items

Meta Pay (formerly Facebook Pay) provides payment processing

Digital collectible support allows for NFT displays on Instagram and Facebook

While Meta's cryptocurrency efforts (formerly Libra/Diem) faced regulatory challenges and ultimately shut down, the company continues exploring digital payment solutions that could power metaverse economies.

Conclusion

Meta's metaverse infrastructure represents one of the most ambitious digital projects in history, spanning hardware, networking, computing, and platform development. While significant technical, ethical, and business challenges remain, the company has demonstrated its commitment through unprecedented investment—reportedly over $10 billion annually.

The success of this massive infrastructure project remains uncertain. Questions about user adoption, regulatory oversight, and competition from other tech giants loom large. However, what's clear is that Meta isn't just talking about the metaverse—it's building the foundations it believes will support the next generation of digital experiences.

Whether Meta's vision of the metaverse becomes reality or evolves into something different, the infrastructure investments being made today will likely shape digital interaction for decades to come.

#mobile game development#gaming#multiplayer games#nft#metaverse#game#vr games#blockchain#unity game development

1 note

·

View note

Text

ASX All Ordinaries: Telstra Group (ASX:TLS) Expands Network Capabilities Across Australia

Highlights:

Telstra Group drives national connectivity through advanced mobile and broadband infrastructure.

Strategic initiatives reinforce Telstra’s presence across regional, urban, and enterprise markets.

The company is aligned with the ASX 200 and also tracks among stocks in the ASX All Ordinaries.

Telecommunication Sector Overview and ASX All Ordinaries Placement Telstra Group (ASX:TLS) operates in the telecommunications sector, delivering voice, mobile, fixed broadband, and enterprise services. As part of the ASX 200 and also included in the ASX All Ordinaries, the company maintains a central role in Australia's digital infrastructure landscape. The ASX All Ordinaries tracks a wide range of companies from diverse sectors, providing a comprehensive view of Australia's publicly listed firms.

Telstra’s presence in these indices reflects its established operations, national coverage, and continuing evolution in next-generation connectivity. Through a combination of fibre infrastructure, mobile spectrum access, and cloud-aligned services, the company serves a broad base of residential, business, and government clients. Its ongoing investment in 5G networks and international subsea cable systems strengthens its footprint across Asia-Pacific markets.

5G Rollout and Digital Network Expansion Telstra has significantly scaled its fifth-generation mobile network footprint. The expansion includes regional deployments and metro-area upgrades, offering improved data speeds and enhanced device support. The company’s deployment strategy centres around spectrum acquisition and smart antenna design to support capacity and reduce latency.

Telstra’s mobile network now incorporates technology enhancements such as carrier aggregation and multi-access edge computing. These capabilities enable the delivery of real-time applications including remote healthcare, industrial automation, and smart city infrastructure. The company also collaborates with technology vendors to ensure integration across network layers, core systems, and customer devices.

Enterprise Solutions and Cloud Connectivity Through its enterprise services division, Telstra provides communication and digital transformation solutions to corporate clients. Offerings include software-defined networking, cybersecurity, data centre access, and managed cloud connectivity. These solutions are tailored to sectors such as finance, logistics, mining, and education.

Enterprise clients benefit from Telstra’s reach across Australian and international data corridors. The company manages subsea cables linking Australia to Asia, North America, and Europe, enabling secure, low-latency access for global applications. Edge services and data integration platforms allow seamless cross-network application delivery for hybrid business environments.

Regional Connectivity and Community Access Telstra continues to enhance its regional and remote area coverage through infrastructure investment and government partnerships. The company’s regional strategy includes the installation of mobile base stations, microwave towers, and satellite gateways to reach underserved locations. Network improvements support emergency communications, education delivery, and telehealth services across rural regions.

In partnership with government programs, Telstra has co-developed connectivity infrastructure aimed at boosting regional economic activity. Rural businesses, agricultural facilities, and Indigenous communities now access digital tools supported by Telstra’s upgraded mobile and fixed wireless networks. The company also offers community tech hubs and customer assistance centres in regional towns.

Dividend Track Record and Market Indices Telstra Group's standing in ASX dividend yield rankings reflects its longstanding capital return program. The company’s dividend history aligns with cash flows generated from mobile, broadband, and wholesale services. Telstra maintains financial strategies aimed at supporting sustainable distributions to shareholders over time.

As a constituent of the ASX 200 and the broader ASX All Ordinaries, Telstra is regularly reviewed for inclusion in yield-tracking indices and sector-based benchmarks. These indices monitor pricing behaviour, sector performance, and broader economic themes. Telstra’s alignment with such benchmarks underlines its role as a major telecommunications provider within the Australian capital market framework.

0 notes

Text

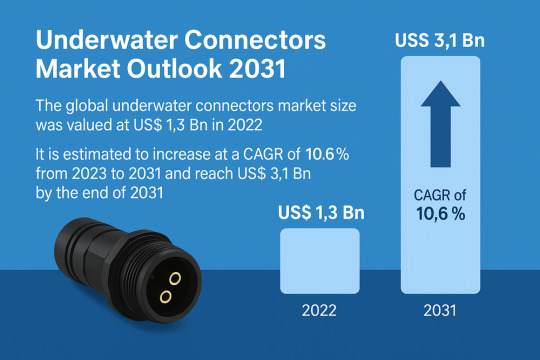

Underwater Connectors Market Gears Up for 10.6% Annual Growth

The global underwater connectors market is poised for significant growth, with industry analysts projecting a robust CAGR of 10.6% from 2023 to 2031. Valued at US$ 1.3 Bn in 2022, the market is expected to cross US$ 3.1 Bn by the end of 2031. A confluence of technological innovation, expanding maritime activity, and growing demand for autonomous and remotely operated underwater vehicles is fueling this expansion.

Market Overview: Underwater connectors play a vital role in ensuring power transmission, signal transfer, and data communication in submerged environments. These connectors are integral to applications across oil & gas exploration, defense, marine science, and renewable offshore energy. Wet-mateable and dry-mateable connectors continue to evolve to meet deep-sea operational challenges, with innovations in materials and design further driving their adoption.

Market Drivers & Trends

The surge in global data consumption has led to rapid expansion in subsea fiber optic cable networks, creating a sustained demand for reliable and high-performance underwater connectors. These systems support internet backbone infrastructure and intercontinental connectivity, relying on connectors to manage complex transmission needs over long oceanic distances.

Additionally, increased deployment of autonomous underwater vehicles (AUVs) and remotely operated vehicles (ROVs) across commercial and defense sectors has propelled the need for high-quality, wet-mateable connectors that enable real-time control, data relay, and power distribution.

The growing emphasis on oceanographic research, renewable energy (especially offshore wind farms), and undersea exploration has created new avenues for underwater connectors across global waters.

Recent Developments

CRE expanded its Aberdeen facility with a custom connector manufacturing cell to meet growing demand for metal shell connectors.

Fischer Connectors enhanced its UltiMate series with new ultra-rugged models suitable for harsh environments.

Hydro Group introduced advanced rubber-molded subsea connectors under its Hydro Rubber Moulded (HRM) series.

Northrop Grumman signed a non-exclusive agreement to manufacture NiobiCon niobium-based connectors, specially designed for challenging underwater environments.

Key Players and Industry Leaders

The underwater connectors landscape is marked by innovation-driven competition. Key companies leading the charge include:

AMETEK Inc.

Amphenol Corporation

Fischer Connectors SA

GISMA Steckverbinder GmbH

Hydro Group

TE Connectivity

Teledyne Technologies Inc.

MacArtney A/S

OTAQ Group

Eaton

Siemens AG

Amissiontech Co., Ltd.

These firms are heavily investing in R&D, leveraging materials like stainless steel, Inconel, and titanium to develop ruggedized connectors tailored to meet the demands of both shallow and deep-sea operations.

Latest Market Trends

Customization and Modularity: Manufacturers are responding to market needs with customizable connector designs that suit application-specific parameters.

Material Innovation: Adoption of corrosion-resistant materials such as niobium and titanium to ensure durability and safety in high-pressure underwater environments.

Hybrid Connection Technologies: The market is seeing a growing demand for connectors that can simultaneously handle electrical, optical, and fluidic signals.

Increased Use of Wet-Mateable Connectors: Their ability to be connected and disconnected underwater has made them vital in oil & gas and offshore energy applications.

Market Opportunities

Expansion of Offshore Wind Farms: As countries prioritize renewable energy, underwater connectors are critical components for energy transmission from ocean-based turbines to onshore facilities.

Defense Modernization Programs: Increasing investments in unmanned maritime surveillance and combat platforms are opening up significant opportunities in the defense sector.

Scientific Exploration and Monitoring: Deep-sea observatories and underwater communication infrastructures require robust connectivity solutions, presenting new use cases for undersea connectors.

Emerging Markets in Asia and Africa: Rapid industrialization and offshore resource exploration in these regions are fueling demand for underwater infrastructure, including connectors.

Explore the highlights and essential data from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=38582

Future Outlook

Analysts predict steady growth in underwater connectors market share across defense, scientific research, oil & gas, and renewable energy sectors. Key to this outlook is the anticipated rise in remote operations via AUVs and ROVs, increased data demand via undersea fiber networks, and development of robust subsea communication infrastructure.

North America, particularly the U.S., is expected to dominate the market through 2031 due to its established oil & gas sector and naval modernization programs. Europe and Asia Pacific will also exhibit high growth, driven by technological advancements, renewable energy initiatives, and increased maritime research activities.

Market Segmentation

By Type:

Dry-Mateable Connectors

Wet-Mateable Connectors

Others

By Sealing Technology:

Rubber-molded

Rigid shell

Fluid-filled

Inductive Couplings

By Connection Type:

Electrical

Optical

Hybrid

By Material:

Stainless Steel

Inconel

Titanium

By Application:

Oil & Gas Exploration Equipment

Offshore Wind Energy

Submarine Systems

ROV/AUV

Underwater Communication Infrastructure

Underwater Observatories

Others

By End-use Industry:

Oil & Gas

Renewable Energy

Military & Defense

Scientific Research

Telecommunications

Regional Insights

North America: Leads the market, fueled by oil & gas exploration, military investments, and a robust scientific ecosystem.

Europe: Advanced defense activities and presence of leading electronics manufacturers position it as a high-growth region.

Asia Pacific: Rapidly developing infrastructure in China, Japan, South Korea, and ASEAN countries offers significant future potential.

Middle East & Africa: Offshore oil activities and increasing fiber optic connectivity offer promising growth.

South America: Brazil’s deepwater oil reserves are driving demand for subsea infrastructure, including connectors.

Why Buy This Report?

Comprehensive Market Insights: Understand key trends, growth drivers, and challenges shaping the underwater connectors market.

Strategic Forecasting: Get reliable projections up to 2031, including quantitative and qualitative assessments.

Competitive Landscape Analysis: Evaluate the positioning, capabilities, and strategies of leading market players.

Regional Breakdown: Gain insight into regional performance and emerging geographic opportunities.

Technology Trends: Track the evolution of materials, design innovations, and connector technology advancements.

Investment Insights: Identify high-opportunity segments, application areas, and potential investment avenues.

0 notes

Text

Carbon Steel Flanges ADNOC Approved Stockiest in Ajman

When it comes to high-pressure and high-stress pipeline systems, especially in oil and gas transmission, ASTM A694 F65 Flanges have emerged as a reliable and high-performance solution. These flanges are manufactured from high-yield carbon steel and are specifically designed for severe service conditions, including high-pressure fluid transmission and sour service environments.

This article explores the key characteristics, types, applications, and advantages of ASTM A694 F65 Carbon Steel Flanges, providing insights into their role in modern industrial systems.

What is ASTM A694 F65?

ASTM A694 is a standard specification established by ASTM International for forged or rolled carbon and alloy steel flanges, fittings, valves, and parts intended for high-pressure transmission service. The F65 grade indicates a minimum yield strength of 65,000 psi (450 MPa), ensuring the flange can withstand high stress and pressure conditions without deformation or failure.

Key Features of ASTM A694 F65 Flanges

Material: Forged high-strength carbon steel (Grade F65)

Yield Strength: ≥ 65,000 psi (450 MPa)

Tensile Strength: ≥ 77,000 psi (531 MPa)

Service Environment: Suitable for sour gas (H2S), high pressure, and high-temperature applications

Heat Treatment: Normalized, quenched and tempered, or normalized and tempered

Types of ASTM A694 F65 Carbon Steel Flanges

These flanges are available in various configurations to support different system requirements:

Weld Neck Flanges (WN)

Ideal for high-pressure pipelines and critical stress environments.

Slip-On Flanges (SO)

Economical and suitable for moderate pressure applications.

Blind Flanges (BL)

Used to seal piping ends or pressure vessels for inspection or closure.

Socket Weld Flanges (SW)

Used for small-diameter, high-pressure pipework.

Threaded Flanges (TH)

Used in systems where welding is not feasible or preferred.

Lap Joint Flanges (LJ)

Ideal for systems requiring frequent assembly and disassembly.

Ring Type Joint Flanges (RTJ)

High-performance sealing in high-pressure and high-temperature systems.

Standards and Classifications

Specifications: ASTM A694 / ASME SA694

Size Range: ½″ to 60″ Nominal Bore (NB)

Pressure Ratings: ANSI Class 150 to 2500

Design Standards: ASME B16.5, ASME B16.47 (Series A & B), MSS-SP-44

Face Types: Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ)

Sour Service Compatibility: Available upon request as per NACE MR0175 / ISO 15156

Applications of ASTM A694 F65 Flanges

Thanks to their high strength and pressure-handling capabilities, ASTM A694 F65 carbon steel flanges are extensively used in:

Oil & Gas Pipelines

Petrochemical Refineries

Natural Gas Distribution Networks

LNG Plants and Terminals

Offshore Drilling and Subsea Equipment

High-Pressure Steam and Water Lines

Power Generation Facilities

These flanges are ideal for severe service conditions, including high flow rates, corrosive fluids, and extreme pressure differentials.

Advantages of ASTM A694 F65 Flanges

✅ High Yield Strength: Supports high-pressure fluid transport ✅ Superior Durability: Withstands mechanical stress and temperature fluctuations ✅ Good Weldability: Easy to fabricate and assemble on-site ✅ Cost-Effective Performance: Offers strength and reliability without resorting to exotic alloys ✅ Sour Service Compatibility: Can be customized for H2S resistance with proper testing and certification

Testing and Quality Assurance

To ensure optimal performance, ASTM A694 F65 flanges undergo rigorous quality control procedures, including:

Chemical Composition Verification

Tensile and Yield Strength Testing

Charpy V-Notch Impact Testing (for low-temp or sour service)

Hardness Testing

Non-Destructive Testing (NDT): Ultrasonic, Magnetic Particle, Radiographic (as required)

Hydrostatic Pressure Testing

Conclusion

ASTM A694 F65 Carbon Steel Flanges are built for excellence in strength, toughness, and pressure resistance. In industries where reliability under high-pressure, high-stress, and corrosive conditions is non-negotiable, these flanges deliver consistent and safe performance. Their widespread adoption in the global energy and processing sectors underscores their importance in critical infrastructure and pipeline engineering.

#ASTM A694 F65 Flanges Manufacturers in UAE#ASTM A694 F65 Flanges Suppliers in UAE#ASTM A694 F65 Flanges Stcokists in UAE#ASTM A694 F65 Flanges Exporters in UAE#carbon steel flanges stockist in uae#carbon steel flanges in uae#wmass carbon steel flanges manufacturers in uae#cs flanges in uae

0 notes

Text

How Offshore Drilling Services Drive Energy Infrastructure Growth

As the global demand for reliable energy sources intensifies, offshore drilling services play a foundational role in expanding and strengthening the world’s energy infrastructure. From discovering new reserves to supporting long-term production, offshore drilling operations are essential in enabling economic growth, industrial development, and energy security.

At SCOFI, we are proud to provide cutting-edge offshore drilling solutions that not only fuel the world—but also build the infrastructure that keeps it running.

Offshore Drilling: The Engine Behind Energy Development

Offshore reserves account for a significant portion of the world’s oil and gas supply. These operations do more than extract hydrocarbons—they catalyze infrastructure investment in pipelines, ports, storage terminals, refineries, and shipping lanes.

SCOFI’s comprehensive offshore drilling services are a critical first step in this development chain, supporting:

Exploration and appraisal of offshore reserves

Establishment of long-term production platforms

Integration of marine logistics and transport systems

Expansion of onshore support infrastructure

By enabling access to energy beneath the ocean floor, we help lay the foundation for regional and national infrastructure expansion.

Building a Connected Energy Ecosystem

Offshore drilling doesn’t operate in isolation. It directly contributes to the growth of interconnected infrastructure, such as:

Subsea pipelines and flowlines to transport oil and gas from offshore rigs to processing facilities

Floating production units (FPSOs) and platform infrastructure that serve as offshore energy hubs

Onshore facilities including terminals, processing plants, and export depots

Workforce housing, ports, and roads built to support offshore operations

With each drilling project SCOFI undertakes, we not only unlock energy—but also help create the physical infrastructure needed to sustain long-term energy production and delivery.

SCOFI’s Role in Infrastructure-Driven Growth

As a trusted offshore services provider, SCOFI is uniquely positioned to support the complete offshore development lifecycle—from exploration to infrastructure integration. Our services include:

✅ Deepwater and shallow water drilling

✅ Well intervention, coiled tubing, and completion

✅ Engineering and project management consulting

✅ Offshore logistics and marine support

✅ HSE compliance and environmental risk mitigation

By combining drilling expertise with strategic logistics and operational foresight, we help clients scale infrastructure faster and more efficiently.

Advancing Sustainability Through Smart Development

Modern offshore projects must also align with environmental and social sustainability goals. SCOFI supports this through:

Low-impact drilling and emissions-reduction technologies

Real-time environmental monitoring systems

Safe decommissioning and site restoration practices

Supporting local workforce development and infrastructure investment

In this way, SCOFI’s offshore drilling services not only grow infrastructure—they help build responsible, future-ready energy systems.

Conclusion

Offshore drilling is more than a method of extraction—it’s a catalyst for infrastructure growth, energy access, and global economic development. Through innovative, reliable offshore drilling services, SCOFI helps shape the energy networks that power nations and industries.

0 notes

Text

Distributed Buoyancy Module Market Set to Double by 2034: Key Growth Drivers

The global distributed buoyancy module market, valued at US$ 80.9 million in 2023, is poised for significant growth over the next decade. Projected to expand at a compound annual growth rate (CAGR) of 6.5%, the market is expected to reach approximately US$ 161.5 million by 2034. This upward trajectory is primarily driven by the increasing adoption of floating solar farms and the rising demand for clean, renewable energy sources worldwide.

Understanding Distributed Buoyancy Modules

Distributed buoyancy modules (DBMs) play a critical role in the stability and efficiency of floating and offshore renewable energy installations. These modules provide buoyancy and support to floating structures, such as solar farms and offshore pipelines, ensuring weight is evenly distributed and the platforms remain secure against water-induced damage.

DBMs consist of two main components: the assembly, which is firmly attached to the riser or structure using clamps, and the buoyancy portion, which is strapped circumferentially and mechanically locked around the assembly. This design enables precise elevation and location control of floating systems across various water bodies.

Market Drivers: Floating Solar Farms and Renewable Energy Demand

One of the most significant drivers of the distributed buoyancy module market is the rapid rise of floating photovoltaic (PV) solar farms. Unlike conventional land-based solar panels, floating solar farms are installed on water bodies such as lakes, reservoirs, and basins. These installations maximize space utilization, reduce land use conflicts, and improve solar panel efficiency due to the cooling effect of water.

To maintain stability, floating solar panels are mounted on platforms constructed from buoyant materials like high-density polyethylene, anchored securely to prevent drifting. Distributed buoyancy modules are integral to these platforms, helping distribute weight evenly and protecting the structures from water damage.

The increasing global focus on renewable energy, driven by climate change concerns and a push to reduce carbon emissions, is accelerating the deployment of such innovative energy solutions. Governments, industries, and consumers are investing heavily in cleaner energy infrastructure, which directly benefits the DBM market. For example, in 2022, Huaneng Power International completed the world’s largest floating PV project—a 320 MW facility in Dezhou, China—highlighting the scale and potential of floating solar technology.

Applications Beyond Solar Farms

Besides floating solar installations, distributed buoyancy modules find applications in offshore renewable energy plants such as wave energy converters, building energy management systems, and water distribution networks. They also provide critical support for offshore pipelines and subsea infrastructure, particularly in deep-water areas where fixed installations are impractical.

Offshore pipe buoyancy modules ensure the stability and safety of pipelines in maritime and gas field operations, further expanding the DBM market’s relevance. Leading companies in the industry are innovating subsea floatation devices with enhanced features to meet growing market demands.

Regional Market Insights

Europe currently dominates the global distributed buoyancy module market, driven by robust adoption of green energy policies, increasing urbanization, and modernization initiatives. The continent’s commitment to sustainability and the environment fuels investment in floating solar and offshore energy infrastructure, positioning it as a key market for DBMs.

North America is also expected to witness significant growth, supported by rising environmental awareness, expanding industrial projects, and government investments in power generation infrastructure. Canada’s substantial investments in hydroelectricity and renewable energy infrastructure highlight the region’s potential to become a major market for distributed buoyancy modules.

Competitive Landscape and Key Players

The distributed buoyancy module market features several prominent players including Trelleborg Group, AIS, Matrix Composites & Engineering, Balmoral Comtec Ltd, DeepWater Buoyancy, Inc., Koil Energy Solutions, and Shinyang Tech CO., Ltd. These companies are advancing their product portfolios through innovations in underwater floatation and subsea modules.

Recent key developments such as AIS CRP Subsea’s contract to supply buoyancy modules for a large gas field off Western Australia and Trelleborg Group’s distribution agreement with VIKING Life-Saving Equipment demonstrate ongoing market momentum and strategic collaborations.

Future Outlook

With the global shift towards sustainable and renewable energy sources, the demand for distributed buoyancy modules is expected to grow steadily. Technological advancements, increasing offshore renewable projects, and expanding applications beyond solar farms will continue to propel the market forward.

Investors and industry stakeholders should monitor regional developments, key player strategies, and emerging technologies to capitalize on opportunities in this evolving market landscape.

0 notes

Text

Subsea Mateable Connector Market 2025-2032

MARKET INSIGHTS

The global Subsea Mateable Connector Market size was valued at US$ 189 million in 2024 and is projected to reach US$ 267 million by 2032, at a CAGR of 4.9% during the forecast period 2025-2032.

Subsea mateable connectors are specialized underwater electrical or optical connectors designed for reliable operation in harsh marine environments. These critical components enable power transmission, data communication, and signal transfer between subsea equipment while maintaining watertight integrity at extreme depths. The market includes both dry mate (assembled above water) and wet mate (connectable underwater) variants, with applications spanning oil & gas, military, telecommunications, and renewable energy sectors.

While increasing offshore energy exploration drives demand, the market faces challenges from high R&D costs and stringent quality requirements. However, technological advancements in materials science and connector design are creating new opportunities. Major players like SEACON and Teledyne Marine continue to expand their portfolios, with recent developments including high-voltage connectors for offshore wind farms. The oil & gas sector currently dominates applications, accounting for over 45% of 2024 market share, though renewable energy applications are growing at 9.2% CAGR as underwater power transmission networks expand.

Access Your Free Sample Report Now-https://semiconductorinsight.com/download-sample-report/?product_id=97882

Key Industry Players

Technological Innovations and Strategic Expansions Define Market Competition

The global subsea mateable connector market features a dynamic competitive environment with established players dominating revenue share while emerging companies focus on specialization. SEACON leads the market, holding approximately 18% revenue share in 2024, attributed to its comprehensive product range spanning both dry mate and wet mate connectors for extreme underwater environments.

Similarly, Teledyne Marine and Amphenol have cemented their positions through continuous R&D investments, accounting for 15% and 12% market share respectively. Their growth stems from patented pressure-compensated connector technologies that outperform industry standards in deep-sea applications beyond 3,000 meters.

These leaders differentiate themselves through vertically integrated manufacturing capabilities and active participation in subsea industry consortiums that establish global technical standards. Recent developments include SEACON’s launch of its NextGen MX Series connectors featuring enhanced EMI shielding—a critical requirement for offshore windfarm applications.

Meanwhile, mid-tier players like Hydro Group and MacArtney are gaining traction by focusing on customized solutions for defense applications. Their strategy involves forming technology partnerships with naval contractors, exemplified by Hydro Group’s recently announced collaboration with BAE Systems for specialized submarine connectors.

List of Key Subsea Mateable Connector Companies Profiled

SEACON (U.S.) – Market leader in deepwater connector systems

Teledyne Marine (U.S.) – Specialists in high-pressure optical-electric hybrids

Amphenol (U.S.) – Dominant in offshore oil & gas applications

Hydro Group (UK) – Defense sector specialists

Eaton (Ireland) – Focused on renewable energy applications

Glenair (U.S.) – Leading in miniaturized connector solutions

MacArtney (Denmark) – Innovators in modular connection systems

BIRNS (U.S.) – Pioneers in high-voltage underwater connectors

Marshall Underwater Industries (U.S.) – Specialized in rapid-deployment solutions

The competitive intensity is expected to increase as companies address emerging requirements from floating offshore wind projects and subsea data centers. Industry experts note that partnerships between connector manufacturers and renewable energy developers will become a key differentiator, particularly in markets like Europe where underwater grid infrastructure spending is projected to grow by 22% annually through 2030.

Segment Analysis:

By Type

Wet Mate Connector Segment Leads Owing to Rising Subsea Infrastructure Deployments

The market is segmented based on type into:

Dry Mate Connector

Subtypes: Electrical, fiber optic, and hybrid variants

Wet Mate Connector

By Application

Oil and Gas Sector Dominates With Expanding Offshore Exploration Activities

The market is segmented based on application into:

Oil and Gas

Military and Defense

Telecommunication

Power Industry

Others

By Water Depth

Shallow Water Segment Holds Significant Share Due to Cost-Effectiveness

The market is segmented based on water depth into:

Shallow Water (Up to 500 meters)

Deepwater (500-1,500 meters)

Ultra-Deepwater (Beyond 1,500 meters)

By Installation Method

ROV-Installed Connectors Gaining Traction for Underwater Operations

The market is segmented based on installation method into:

ROV-Installed

Diver-Installed

Pre-installed

Download Your Complimentary Sample Report-https://semiconductorinsight.com/download-sample-report/?product_id=97882

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global Subsea Mateable Connector Market?

-> The global Subsea Mateable Connector size was valued at US$ 189 million in 2024 and is projected to reach US$ 267 million by 2032, at a CAGR of 4.9% during the forecast period 2025-2032.

Which key companies operate in Global Subsea Mateable Connector Market?

-> Key players include SEACON, Eaton, Teledyne Marine, Hydro Group, Glenair, Amphenol, MacArtney, BIRNS, Marshall Underwater Industries, and others.

What are the key growth drivers?

-> Key growth drivers include increasing offshore oil & gas exploration, growing defense budgets, expansion of underwater communication networks, and renewable energy projects.

Which region dominates the market?

-> North America currently leads the market, while Asia-Pacific is expected to witness the highest growth rate during the forecast period.

What are the emerging trends?

-> Emerging trends include development of high-pressure resistant connectors, integration of smart monitoring capabilities, and adoption of advanced materials for deep-sea applications.

About Semiconductor Insight:

Established in 2016, Semiconductor Insight specializes in providing comprehensive semiconductor industry research and analysis to support businesses in making well-informed decisions within this dynamic and fast-paced sector. From the beginning, we have been committed to delivering in-depth semiconductor market research, identifying key trends, opportunities, and challenges shaping the global semiconductor industry.

CONTACT US:

City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014

[+91 8087992013]

Related Url-

0 notes

Text

Europe Hydrographic Survey Equipment Market Trends and Forecast: Size, Demand, Innovation & Competitive Analysis

"Executive Summary Europe Hydrographic Survey Equipment Market : Europe hydrographic survey equipment market size was valued at USD 658.34 million in 2024 and is projected to reach USD 973.37 million by 2032, with a CAGR of 5.2% during the forecast period of 2025 to 2032.

This Europe Hydrographic Survey Equipment Market research report takes into account several industry verticals such as company profile, contact details of manufacturer, product specifications, geographical scope, production value, market structures, recent developments, revenue analysis, market shares and possible sales volume of the company. Businesses can gain current as well as upcoming technical and financial details of the industry to 2025 with this Europe Hydrographic Survey Equipment Market report. Europe Hydrographic Survey Equipment Market report has been mainly designed by keeping in mind the customer requirements which will ultimately assist them in boosting their return on investment (ROI).

The company profiles of all the top market players and brands with moves like product launches, joint ventures, mergers and acquisitions which in turn is affecting the sales, import, export, revenue and CAGR values are revealed in this Europe Hydrographic Survey Equipment Market industry report. With this market report, it becomes easy to get an in-depth market analysis and thrive in this competitive environment. The report will surely aid in growing your sales and improve return on investment (ROI). Europe Hydrographic Survey Equipment Market research report makes available wide-ranging analysis of the market structure along with evaluations of the various segments and sub-segments of the market.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive Europe Hydrographic Survey Equipment Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/europe-hydrographic-survey-equipment-market

Europe Hydrographic Survey Equipment Market Overview

**Segments**

- **Product Type**: The Europe hydrographic survey equipment market can be segmented based on product type into acoustic sensors, echo sounders, sonar systems, positioning systems, and others. The echo sounders segment is expected to witness significant growth due to the increasing demand for precise depth measurement in underwater survey applications.

- **Application**: In terms of application, the market can be segmented into hydrographic charting, offshore oil & gas, coastal engineering, port & harbor management, dredging, and others. The hydrographic charting segment is expected to dominate the market owing to the rising demand for accurate mapping of water bodies for navigation and resource exploration purposes.

- **End-User**: Based on end-user, the Europe hydrographic survey equipment market can be categorized into government, oil & gas industry, construction industry, mining industry, maritime archaeology, and others. The government segment is anticipated to hold a significant market share due to the increasing investments in marine infrastructure development and oceanographic research activities.

**Market Players**

- **Kongsberg Gruppen**: Kongsberg Gruppen is a key player in the Europe hydrographic survey equipment market, offering a wide range of products including multibeam echo sounders, sonar systems, and underwater positioning systems. The company's focus on technological advancements and strategic acquisitions has helped it maintain a strong market position.

- **Teledyne Technologies Incorporated**: Teledyne Technologies is another prominent player in the market, known for its innovative hydrographic survey equipment such as acoustic imaging systems, subsea navigation solutions, and marine sensors. The company's strong distribution network and emphasis on R&D activities have contributed to its market growth.

- **Trimble Inc.**: Trimble Inc. is a leading provider of positioning technology solutions for various industries, including hydrographic surveying. The company offers GNSS receivers, marine antennas, and software solutions for accurate data collection and analysis in marine environments.

- **Thales Group**: Thales Group specializes in providing advanced maritime solutions, including hydrographic survey equipment for defense and commercial applications. The company's expertise in navigation systems and maritime security technology has positioned it as a key player in the market.

The Europe hydrographic survey equipment market is characterized by intense competition among key players striving to enhance their product offerings and expand their market presence through collaborations, partnerships, and product innovations. The increasing emphasis on marine resource exploration, coastal infrastructure development, and maritime security measures is expected to drive market growth in the region.

The Europe hydrographic survey equipment market is poised for significant growth in the coming years, driven by various factors such as technological advancements, increasing demand for accurate mapping in underwater environments, and the rising investments in marine infrastructure development. One key trend shaping the market is the adoption of advanced acoustic sensors, echo sounders, sonar systems, and positioning systems for precise data collection in hydrographic survey applications. These high-tech solutions not only enhance the efficiency and accuracy of hydrographic charting but also cater to the evolving needs of industries such as offshore oil & gas, coastal engineering, dredging, and maritime archaeology.

Moreover, the market landscape is witnessing a surge in demand for hydrographic survey equipment from government entities, oil & gas companies, construction firms, mining industry players, and maritime archaeologists. Governments across Europe are increasingly investing in marine infrastructure projects and oceanographic research initiatives, thereby fueling the adoption of advanced surveying technologies. Similarly, the oil & gas industry relies heavily on hydrographic survey equipment for offshore exploration activities, pipeline routing, and environmental monitoring, further propelling market growth.

In terms of market players, key companies such as Kongsberg Gruppen, Teledyne Technologies Incorporated, Trimble Inc., and Thales Group are at the forefront of innovation and product development in the Europe hydrographic survey equipment market. These players leverage their expertise in multibeam echo sounders, acoustic imaging systems, GNSS receivers, and navigation solutions to cater to a diverse set of end-users and applications. Strategic collaborations, acquisitions, and R&D investments are key strategies adopted by these players to strengthen their market position and expand their product portfolios.

Looking ahead, the Europe hydrographic survey equipment market is poised for further expansion, driven by the continued focus on marine resource exploration, coastal infrastructure development, and maritime security measures. The integration of advanced technologies such as artificial intelligence, cloud computing, and autonomous surveying systems is expected to revolutionize the way hydrographic surveys are conducted, offering more efficient and cost-effective solutions to end-users. Overall, the market is set for dynamic growth and innovation, presenting lucrative opportunities for both established players and new entrants in the industry.The Europe hydrographic survey equipment market is witnessing significant growth driven by the increasing demand for precise mapping of water bodies for various applications such as navigation, resource exploration, and marine infrastructure development. The market segmentation based on product type highlights the importance of echo sounders in providing accurate depth measurements in underwater survey applications. This segment is expected to experience substantial growth as industries seek more precise data collection capabilities. Additionally, the emphasis on advanced acoustic sensors, sonar systems, and positioning systems underscores the trend towards adopting high-tech solutions for efficient hydrographic surveying.

In terms of applications, hydrographic charting is expected to dominate the market due to the need for accurate mapping of water bodies for navigation and resource exploration purposes. The offshore oil & gas segment is also a key driver of market growth, as the industry relies heavily on hydrographic survey equipment for exploration activities, pipeline routing, and environmental monitoring. The coastal engineering and dredging segments further contribute to the market expansion by requiring precise data collection and analysis for infrastructure development projects.

The end-user segmentation in the Europe hydrographic survey equipment market showcases the diverse set of industries leveraging this technology, with government entities, oil & gas companies, construction firms, mining industry players, and maritime archaeologists driving market demand. Governments' increasing investments in marine infrastructure projects and research initiatives, along with the oil & gas industry's reliance on surveying equipment for offshore activities, are key factors propelling market growth. The collaboration and partnerships among key market players such as Kongsberg Gruppen, Teledyne Technologies Incorporated, Trimble Inc., and Thales Group highlight the competitive landscape characterized by innovation, product development, and strategic initiatives focused on enhancing market presence and expanding product portfolios.

Looking ahead, the Europe hydrographic survey equipment market is poised for further expansion driven by the integration of advanced technologies like artificial intelligence, cloud computing, and autonomous surveying systems. These technological advancements are expected to revolutionize hydrographic surveys by offering more efficient and cost-effective solutions to end-users. Overall, the market presents lucrative opportunities for both established market players and new entrants, signaling a dynamic growth trajectory and ongoing innovation in the industry.

The Europe Hydrographic Survey Equipment Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/europe-hydrographic-survey-equipment-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

What insights readers can gather from the Europe Hydrographic Survey Equipment Market report?

Learn the behavior pattern of every Europe Hydrographic Survey Equipment Market -product launches, expansions, collaborations and acquisitions in the market currently.

Examine and study the progress outlook of the global Europe Hydrographic Survey Equipment Market landscape, which includes, revenue, production & consumption and historical & forecast.

Understand important drivers, restraints, opportunities and trends (DROT Analysis).

Important trends, such as carbon footprint, R&D developments, prototype technologies, and globalization.

Browse More Reports:

Global Thermosetting Aerospace Composites Market Middle East and Africa Lung Cancer Diagnostics Market Global Block Chain in Manufacturing Market Global Baselayer Compression Shirts Market Global Financial Analytics Market Global Co-polyester-Ether Elastomers (COPE) Market Global Payment Gateway Market Global Yeast Based Ingredients Market Global Vascular Graft Market Global Exterior Sheathing Market Europe Personal Care Ingredients Market North America Flight Data Recorder Market Global Special Effect Pigments Market Global Business To Business (B2b) Cartridge Filter Water Filtration Market Europe Xylose Market North America Weight Loss and Obesity Management Market Global Pulse Market Global Weight Loss and Obesity Management Market Global Opioids Market Global Thermal Imaging Cameras Market Global Flotation Reagents Market Middle East and Africa Dental Practice Management Software Market Global Veterinary Telehealth Market Global Automotive Open Differential Market Middle East and Africa Commercial Cleaning Equipment Market Global Demolition Robots Market Australia and New Zealand Concrete Admixture Market Middle East and Africa Infection Surveillance Solution Systems Market Global Chronic Kidney Disease Medication Market Global Video Surveillance as a Service Market Global Sailing Yatch Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]

Tag

"

0 notes

Text

ERW Pipes in Oil and Gas Industry: Key Roles and Market Trends

A stable and efficient infrastructure is crucial for the transportation of hydrocarbons in the oil and gas industry. Electric Resistance Welded (ERW) pipes are a critical component that assumes a central role in this system. The pipes in question are renowned for their multifunctionality, resilience, and economical nature, rendering them a widely favoured option for diverse applications within the oil and gas industry. The strength of seamless connectivity - Choose ERW Pipes offered by Tube Trading Co. – an excellent ERW Pipe Supplier in Gujarat for your critical applications.

This blog examines the significant functions of ERW pipes within the industry and investigates the most recent market trends pertaining to these important components.

What are ERW Pipes?

ERW pipes are a variant of steel pipes that are manufactured through the application of a high-frequency electrical current along the edges of the steel strip or coil. The flow of electrical current produces thermal energy, resulting in the fusion of the adjacent edges and the creation of a connection without any visible seams. ERW pipes are extensively utilised in the oil and gas sector owing to their exceptional mechanical characteristics, rendering them appropriate for many applications in both onshore and offshore environments.

Key Roles of ERW Pipes in the Oil and Gas Industry:

Exploration and Production:

ERW pipes are widely employed in drilling activities within the upstream portion of the oil and gas industry. The primary function of these pipes is to act as protective casings for the wellbore, thereby preserving its structural integrity and mitigating the risk of collapse during the drilling process. ERW pipes are utilised in well-completion operations to enhance the effective extraction of hydrocarbons.

Transportation:

Transportation plays a crucial role in the hydrocarbon industry as it facilitates the movement of extracted hydrocarbons from wells to processing units or refineries. ERW pipes, known for their exceptional strength and weldability, serve as the fundamental component of pipelines utilised for the extensive transit of oil and gas. They facilitate the uninterrupted transportation of hydrocarbons from the point of extraction to the ultimate consumers.

Distribution and Storage:

Electric resistance welded (ERW) pipes are of significant importance in the midstream sector, since they are utilised for the purpose of distributing and storing refined fuels, including petrol, diesel and natural gas. The utilisation of these pipes is crucial to the establishment of distribution networks and terminals, facilitating the effective transportation of energy products to end-users.

Offshore Applications:

ERW pipes are commonly utilised in offshore drilling and production due to their notable resilience in challenging marine environments. These components find application in the construction of platforms, risers, and subsea pipelines, offering enhanced stability and dependability in demanding offshore environments.

Experience efficiency in every weld. Order precision-engineered ERW Pipes offered by Tube Trading Co. – a renowned ERW Pipe Provider in Gujarat!

Market Trends of ERW Pipes in the Oil and Gas Industry:

Increasing Demand:

The increasing global demand for electric resistance welded (ERW) pipes within the oil and gas sector is driven by the ongoing growth of exploration and production operations, with a particular emphasis on emerging economies. The consistent expansion in energy consumption and the imperative for novel infrastructure are significant factors that contribute to the heightened adoption of Electric Resistance Welded (ERW) pipes.

Technological Advancements:

Technological advancements in the field of ERW pipes are being pursued by manufacturers through ongoing investments in research and development, with the aim of improving their inherent qualities. The utilisation of advanced welding methodologies and enhanced steel compositions has resulted in the development of pipes exhibiting elevated levels of strength, corrosion resistance, and durability. Consequently, these pipes have emerged as highly suitable for deployment in demanding oil and gas applications.

Environmental Considerations:

The increasing focus of the industry on sustainability and environmental preservation has led to a transition towards more environmentally friendly practices. ERW pipes, due to their environmentally friendly nature and recyclability, are very compatible with these objectives, hence establishing themselves as a favoured option for enterprises that prioritise environmental consciousness.

Focus on Pipeline Safety:

The issue of pipeline safety has garnered significant attention due to worries surrounding leaks and ruptures, resulting in the implementation of more stringent regulations and standards. The superior weld quality and consistency of ERW pipes result in a decreased likelihood of failures, hence enhancing the safety of pipelines.

Market Consolidation:

The ERW pipe market is currently through a process of consolidation, wherein prominent industry participants are actively engaging in mergers and acquisitions to enhance their range of products and increase their market reach. The objective of this trend is to address the increasing demand and sustain a competitive advantage within the sector.

Final Thoughts:

ERW pipes are of significant importance within the oil and gas sector, as they fulfil crucial functions throughout a range of activities spanning from exploration to distribution. The indispensability of these components in the industry's infrastructure can be attributed to their versatility, durability, and cost-effectiveness.

The anticipated increase in the utilisation of ERW pipes is attributed to the escalating demand for energy and the heightened significance of environmental considerations. The continuous endeavours of manufacturers to innovate and enhance these pipes will inevitably result in the development of more effective and environmentally friendly solutions, thereby strengthening their significance as a crucial element within the ever-evolving realm of oil and gas transportation and distribution. Seamless solutions for your piping needs – Partner with Tube Trading Co. – the most reliable ERW Pipe Supplier in Gujarat today!

#ERW Pipe Supplier in Gujarat#ERW Pipe Provider in Gujarat#Business#Manufacturer#Steel industry#Steel company#Oil and gas industry#Oil companies#Agriculture industry

6 notes

·

View notes

Text

How Meta (Facebook) is Building Its Metaverse Infrastructure

Introduction

When Mark Zuckerberg announced Facebook's rebrand to Meta in late 2021, he wasn't just changing a company name he was signaling a massive shift in digital infrastructure investment. The tech giant's ambitious vision for the metaverse represents one of the largest infrastructure projects in tech history, requiring revolutionary advancements in hardware, networking, and computing power. Let's explore how Meta is creating the foundation for its virtual universe and what it means for the future of digital interaction.

The Backbone: Computing Power and Data Centers

Meta's metaverse dreams begin with raw computing muscle. The company has dramatically expanded its data center footprint, investing billions in specialized facilities designed specifically for the computational demands of immersive 3D worlds.

Unlike traditional web services, metaverse environments require real-time rendering, physics simulations, and support for thousands of simultaneous users—all while maintaining low latency. To meet these demands, Meta has been upgrading its data centers with specialized AI processors and graphics hardware optimized for spatial computing.

The company recently unveiled its AI Research SuperCluster (RSC), which it claims is among the world's fastest AI supercomputers. This computing powerhouse isn't just for current AI tasks—it's being positioned as critical infrastructure for metaverse development, capable of training the massive models that will power everything from realistic avatars to intelligent virtual assistants.

Solving the Latency Challenge: Edge Computing and Network Infrastructure

For the metaverse to feel real, interactions must be nearly instantaneous. Even small delays between user actions and visual feedback can break immersion and cause physical discomfort. This creates a massive technical challenge that Meta is addressing through strategic investments in edge computing and network architecture.

The company has been quietly building out edge computing nodes closer to users, reducing the physical distance data must travel. Additionally, Meta has invested in subsea cable projects like 2Africa and Echo, expanding global internet backbone capacity to support the massive data transfers the metaverse will require.

Perhaps most interesting is Meta's work on "Project Aria," which explores how distributed computing between devices and the cloud can reduce latency. By splitting computational tasks—performing some calculations on headsets while offloading more intensive processes to nearby servers—Meta aims to deliver responsive experiences even with limited on-device processing power.

Creating the Interface: Hardware Development

While software and servers form the metaverse's foundation, hardware is where users will actually experience it. Meta's acquisition of Oculus in 2014 (for $2 billion) now seems prescient, giving the company a significant head start in VR hardware development.

The Quest headset line has evolved to become increasingly powerful while remaining affordable and wireless—crucial factors for mass adoption. But Meta's hardware ambitions extend far beyond current VR headsets. The company's Reality Labs division is working on multiple next-generation interfaces:

Lightweight AR glasses that overlay digital information on the physical world

Haptic gloves that let users "feel" virtual objects

Neural interfaces that can detect subtle muscle movements for more natural control

Spatial audio systems that create convincing 3D soundscapes

Project Cambria (now released as the Quest Pro) represented Meta's push toward higher-end mixed reality, incorporating eye tracking, face tracking, and improved passthrough technology—all essential components for creating presence in virtual environments.

Building the Digital Foundation: Software Infrastructure