#Static Mixer market size

Explore tagged Tumblr posts

Text

Static Mixer Market - Forecast(2024 - 2030)

Static Mixer Market Overview:

The static mixers are market has been growing rapidly mainly due to used extensively for extensively use of static mixer in the process of homogenization various hominization process in various the industrial operations such as food processing, heat transfer, chemical reactions, polymer blending, and cosmetics and pharmaceutics, but also for in water treatment of waste water. The global Static Mixer Market size is estimated to grow at a CAGR of 5.1% during the forecast period i.e. 2018—-2023. The APAC region is estimated calculated to be as the largest segment for market for Static Mixers, with holding a share of 35.28% of the overall market in by 2023, and itsthe value is estimated to grow toreach $965.28mM by 2023. The rising market in China and India, particularly for disposable static mixers will drive the market.

Request Sample

Static Mixer Market Outlook:

The static mixer is also known as a motionless mixer, this device is basically inserted into housing or pipelines with the objective to handle or control the fluid streams. Insertion of a static mixer significantly accelerates inline mixing or reaction. This market includes the technique essentially desirable for inexpensive, fast and continuous operation. According to IndustryARC findings, iIndustrial static mixers will hold the largest market share during the forecast period. In the industrial static mixer, there is a very broad range of applications are incorporated in fluid processing industries such as Chemical Industry, Oil, Gas & Petrochemicals, Plastics Injection Molding & Extrusion, Polymer Production, and other industries. The Industrial segment of the static mixer market was valued at $459.28m in 2017 and by type is estimated to reach $581.29m by 2023, M growing at a CAGR of 4.5% during the forecast period of 2018—-2023 by 2023 from $459.28m M in 2017 and is forecast to grow at a CAGR of 4.5% during the forecast period of 2018-2023.

The average selling price of disposable static mixer was estimated to be $0.75 per unit in 2017 and is anticipated to reach $0.59 per unit. This decline in ASP is more compared to non-disposable static mixer due to the decline in the plastic prices and the increasing number of Chinese players in disposable static mixer market that provides the less priced products.The decline in average selling price of disposable static mixers is higher as compared tothan that of non-disposable static mixers because of the increasing number of Chinese players in the disposable static mixer market offering that offer low-cost products; and also, due to the drop in plastic prices.

Static Mixer Market Growth Drivers:

According to the Organisation for Economic Co-operation and DevelopmentOrganization For Corporation and Development (OECD), in manufacturing sector, countries such as Estonia, Lithuania, the Czech Republic, Brazil, and Slovenia are anticipated to witness a have significant increase of SMEs in the manufacturing sectorin SME’s. The growing number of SMEs coupled with the growing demand for the static mixers in various end- user industries such as water treatment, oil & gas, pulp and paper, and food & beverage for mixing, blending, dispersion, heat transfer, mass transfer, solids suspension, dosing, emulsion formation, dissolution, pH adjustment, and dilution is expected to strengthen the static mixers market growth. The rising market for disposable static mixers in China and India, particularly for disposable static mixers will also act as a growth driver.drive the market.

Inquiry Before Buying

Static Mixer Market Challenges:

Though the helical static mixers market has continued to be in matured over stage the since past 15 recent years, . The customers are still viewing the helical static mixers as a commodity, and are ignoring the difference between the offerings andor performance. This view of customers towards helical static mixers is anticipated to give rise provide prospects to the new entrants in the market offeringthat offer which offers the helical static mixers for at huge price variations. This price variation is anticipated to further result in decreased margins for major players and lessen the number of distribution channels, thereby affecting the overall profitability of the manufacturers of helical static mixers. Thus, the increasing number of new players in the manufacturing of helical static mixers with huge price variation is anticipated to hampering the revenue growth of helical static mixers;, which in turn and consequently, affectings the entire Sstatic Mmixer market growth.

Number of SMEs and Large Enterprises in Brazil, 2012—-2017

Schedule a Call

Static Mixer Market Research Scope:

The base year of the study is 2017, with forecast done up to 2023. The study presents a thorough analysis of the competitive landscape, taking into account the market shares of the leading companies. It also provides information on unit shipments. These provide the key market participants with the necessary business intelligence and help them understand the future of the plastics in electric vehicleStatic Mixer market. The assessment includes the forecast, an overview of the competitive structure, the market shares of the competitors, as well as the market trends, market demands, market drivers, market challenges, and product analysis. The market drivers and restraints have been assessed to fathom their impact over the forecast period. This report further identifies the key opportunities for growth while also detailing the key challenges and possible threats. The key areas of focus include the types of static mixer market, and itstheir specific applications in different end user industries in different types of vehicles.

Static Mixer Market Report: Industry Coverage

Types of Static Mixer Market — By Type: Industrial, Laboratory

Structure of Static Mixer Market — By Structure: Helical, Square, Plate

Usage of Static Mixer Market — By Usages: Disposable, Non Disposable

Flow of Static Mixer Market — By Flow: Laminar flow, Turbulent flow, Transitional fFlow

End Users of Static Mixer Market — By End Users: Water Treatment, Oil & Gas, Pulp and Paper, Food and Bbeverages, Pharmaceuticals, Construction, Chemicals, HealthCare and Cosmetics, Mining and Metal, Transportation, and Power Generation.

The Static Mixer market report also analyzes the major geographic regions for the market as well as the major countries for the market in these regions. The regions and countries covered in the study include:

North America: The U.S., Canada, Mexico

South America: Brazil, Chile, Argentina, Ecuador, Peru, Colombia, Costa Rica

Europe: The U.K., Germany, Italy, France, The Netherlands, Belgium, Spain, Denmark

APAC: China, Japan, Australia, South Korea, India, Taiwan, Malaysia, Hong Kong

Middle East and Africa: Israel, South Africa, Saudi Arabia

Static Mixer Market Key Players Perspective:

Nordson Xaloy, SPX Corporation, and Sulzer Ltd. were analyzed to be the dominant players ofin the Static Mixer market in 2017, with a share of 12.7%, 11.4% and 8.8% respectively. EThe extensive product portfolio, along with well- diversified sales and distribution network, provides avail significant exposure and visibility to these players in the market.

Some of the other key players mentioned in this report are DuPont, BASF SE, Solvay SA, Covestro (Bayer), DSM NV, Toray Industries, Celanese Corporation, RTP Company, and Mitsui Chemicals America among others.

Buy Now

Static Mixer Market Trends:

The U.A.E. has planned to establish a comprehensive hub for international pharmaceutical companies, and the country is planning to double its drug manufacturing factories by 2021. As of now, the country has 54 pharmaceutical firms in the region. These i The iIncreasinge in the number of pharmaceutical firms coupled with the deployment of static mixers for various applications such as penicillin production, syrup dilution, and others is anticipated to provide offer prospects for the Static Mixer market.

The manufacturers of static mixers are actively investing in R&D, research and the development of static mixers. These increasing the chances of investments in R&D is primarily responsible for the launching of new products with advanced technology. One such instance is was the launch of PerfectPeak™ 3D Printed Static Mixer by Motto Corp. This product has incorporated incorporates 3D printing technology to reduce the baseline noise significantly. Thus, the increasing investments in R&D is anticipated to provide ample amount of opportunities for Static Mixer market in near future

Water is a critical global resource now and for the future. With the world population expected to reach 9.8 bBillion by 2050 coupled with extensive industrial growth, there is tremendous a pressing need for recycling and reusing of the water. Growing industrialization coupled with erratic rain fall patterns due to climate change in developing countries has resulted in lowering and depletion of water resources. At this juncture, governments around the world have started focusing on setting upthe water treatment plants. This is set to drive the market for the Static Mixers.

DThe dental implants, where the static mixers have direct applications, is one market that is set to witness tremendous growth in the future due to the increased increasing number of dental clinics in developed countries and the growing awareness about dental hygiene in emerging economies. The rising demand for better oral hygiene services coupled with the growing disposable incomes is set to boost the market for dental services.

#static mixer market#static mixer market size#static mixer market shape#static mixer market forecast#static mixer market analysis#static mixer market report#static mixer market growth#motionless mixer#food processing#Water And Wastewater Treatment Technologies#chemical reactions#polymer blending

0 notes

Text

Static Mixer Market - Forecast(2023 - 2028)

Types of Static Mixer Market — By Type: Industrial, Laboratory

Structure of Static Mixer Market — By Structure: Helical, Square, Plate

Usage of Static Mixer Market — By Usages: Disposable, Non Disposable

Flow of Static Mixer Market — By Flow: Laminar flow, Turbulent flow, Transitional fFlow

End Users of Static Mixer Market — By End Users: Water Treatment, Oil & Gas, Pulp and Paper, Food and Bbeverages, Pharmaceuticals, Construction, Chemicals, HealthCare and Cosmetics, Mining and Metal, Transportation, and Power Generation.

#Static Mixer market share#Static Mixer market size#Static Mixer market value#Static Mixer market place#Static Mixer price#Static Mixer

0 notes

Link

Static Mixer Market Size

According to a new report by EMR titled, 'Static Mixer Market Size, Share, Industry, Analysis, Report & Forecast 2020-2025', the global industry is expected to witness a healthy growth in the forecast period of 2020-2025.

#Static Mixer Market Size#Static Mixer Market Share#Static Mixer Market Indsutry#Static Mixer Market Analysis#Static Mixer Market#Static Mixer Market Forecast#Static Mixer Market Outlook#Static Mixer Market Report

0 notes

Text

Global Food and Beverage Mechanical Seals Market – Industry Trends and Forecast to 2028

The food and beverage mechanical seals market will hit an approximate size of USD 1.69 billion by 2028, with growth of 5.80% for the forecast period from 2021 to 2028. The market report on food and beverage mechanical seals analyses the growth that is currently rising due to the increasing demand for milk, beverages, poultry, and confectionery products.

Global Food and Beverage Mechanical Seals Market Scope and Market Size

Food and beverage mechanical seals market is segmented on the basis of type, design, product, application. The growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate different strategies to help identify core application areas and the difference in your target markets.

On the basis of type, the food and beverage mechanical seals market is segmented into metals, face materials, elastomers, and other type.

Food and beverage mechanical seals market is segmented in terms of market value, volume, market opportunities, and niches into multiple applications. The application segment for food and beverage mechanical seals market includes bakery and confectionary; meat, poultry, and seafood; dairy products; alcoholic beverages; non-alcoholic beverages; and others.

Based on design, the food and beverage mechanical seals market is segmented into balanced and unbalanced mechanical seals, single spring and multiple spring mechanical sheets, pusher and non- pusher type mechanical sheets.

On the basis of product, food and beverage mechanical seals market is segmented into axial seal, bi-directional seal, diaphragm, dynamic seal, excluder, gasket, hydrodynamic seal, O-ring, radial seal, rotary seal, and static seal.

Food and Beverage Mechanical Seals Market Country Level Analysis

Food and beverage mechanical seals market is analysed and market size, volume information is provided by country, type, design, product, and application as referenced above.

The countries covered in the food and beverage mechanical seals market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, Israel, Egypt, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

Europe dominates the food and beverage mechanical seals market due to the prevalence of stringent regulations regarding the usage of seals in food and beverages applications along with increasing food production in the region. Asia-Pacific region is expected to hold the largest growth rate due to the rapid industrialization along with expansion of wastewater industries in the region.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as consumption volumes, production sites and volumes, import export analysis, price trend analysis, cost of raw materials, down-stream and upstream value chain analysis are some of the major pointers used to forecast the market scenario for individual countries. Also, presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Get the sample copy of the report here:

Market Analysis and Insights: Global Food and Beverage Mechanical Seals Market

Mechanical seals are classified as leakage control devices found on rotating devices, such as pumps and mixers, to prevent liquids and gases from leaking. The mechanical seals help seal the shaft's revolving part against the pump housing's stationary part. Mechanical seals are commonly used in various industries, such as oil and gas, chemicals, and others.

The growing preferences towards the consumption of processed and convenience foods, prevalence of stringent standards and regulations, adoption of advanced technology, growth of the food and beverages industry across the globe are some of the major as well as impactful factors which will likely to augment the growth of the food and beverage mechanical seals market in the projected timeframe of 2021-2028. On the other hand, increasing demand for advanced seals from wastewater industry along with increasing investment in pipelines and refineries which will further contribute by generating immense opportunities that will led to the growth of the food and beverage mechanical seals market in the above mentioned projected timeframe.

Volatility in the prices of raw material along with prevalence of seal less equipment which will likely to act as market restraints for the growth of the food and beverage mechanical seals in the above mentioned projected timeframe. Increasing demand of fresh and organic food products which will become the biggest and foremost challenge for the growth of the market.

This food and beverage mechanical seals market report provides details of new recent developments, trade regulations, import export analysis, production analysis, value chain optimization, market share, impact of domestic and localised market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographical expansions, technological innovations in the market. To gain more info on food and beverage mechanical seals market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Food and Beverage Mechanical Seals Market Country Level Analysis

Food and beverage mechanical seals market is analyzed and market size, volume information is provided by country, type, design, product, and application as referenced above.

The countries covered in the food and beverage mechanical seals market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, Israel, Egypt, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

Food and Beverage Mechanical Seals Market Share Analysis

Food and beverage mechanical seals market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies’ focus related to food and beverage mechanical seals market.

Major players covered in the food and beverage mechanical seals market

The major players covered in the food and beverage mechanical seals market report are SKF; Flowserve Corporation; Smiths Group plc; Trelleborg Group; GARLOCK FAMILY OF COMPANIES; Waukesha Bearings.; ERIKS Seals and Plastics, Inc.; Freudenberg SE; Tenneco Inc.; Hallite Seals; AESSEAL plc; A.W. Chesterton Company; EagleBurgmann; Flexaseal Engineered Seals and Systems, LLC.; Avon Seals Pvt. Ltd.; TREM Engineering SC; PPC Mechanical Seals; Meccanotecnica Umbra S.p.A.; THE TIMKEN COMPANY; Bal Seal Engineering; among other domestic and global players. Market share data is available for global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South America separately. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately.

Get Full Access of Report @

MAJOR TOC OF THE REPORT

Chapter One: Introduction

Chapter Two: Market Segmentation

Chapter Three: Market Overview

Chapter Four: Executive Summary

Chapter Five: Premium Insights

Chapter Six: food and beverage mechanical seals market

Get TOC Details

Browse Related Reports@

Global Methylene Chloride Market – Industry Trends and Forecast to 2029

Asia-Pacific Oil Refining Catalyst Market is Expected to grow at 9.1% in the Forecast Period of 2020 to 2027

The Global Auto Catalyst Market is Projected to Grow at A CAGR of 4.20% During the Forecast Period

Global Oil Refining Catalyst Market is Expected to Grow at 5.1% in the Forecast Period of 2021 to 2028

The Global Polyolefin Catalyst Market is Projected to Grow at a CAGR of 5.00% During the Forecast Period

The Global Syngas Catalyst Market is Projected to Grow at a CAGR of 8.00% During the Forecast Period

Global Refinery Catalyst Market – Industry Trends and Forecast to 2028

Global Polypropylene Catalyst Market – Industry Trends and Forecast to 2029

Global Automotive Catalyst Market – Industry Trends and Forecast to 2028

Global Platinum Automotive Catalyst Market – Industry Trends and Forecast to 2028

Global Phase Transfer Catalyst Market – Industry Trends and Forecast to 2028

Global Industrial Catalyst Market - Industry Trends and Forecast to 2029

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

#Food and Beverage Mechanical Seals Market#Food and Beverage Mechanical Seals Market scope#Food and Beverage Mechanical Seals Marketshare#Food and Beverage Mechanical Seals Marketsize#Food and Beverage Mechanical Seals Market demand#Food and Beverage Mechanical Seals Marketforecast#Food and Beverage Mechanical Seals Marketfuture#Food and Beverage Mechanical Seals Market invest

0 notes

Text

Polyurea Coatings Market Size Forecast to Reach $1,477.89 Million by 2025

Polyurea Coatings Market size is forecast to reach $1,477.89 million by 2025, after growing at a CAGR of 10.80% during 2020-2025. Polyurea coatings are derived from the reaction of isocyanate components and resin-blend. isocyanate components can be aromatic, aliphatic, polymer, or monomer. Products from the polyurea coatings have wide ranging applications as these Coatings are solvent-free and non-toxic. Their unique qualities such as temperature stability, favorable adhesion strength, high elongation, and water resistance are highly useful for crack bridging. Polyurea coatings have wide acceptability as they are environment-friendly and compliant with norms related to VOCs.

Polyurea Coatings Market Segment Analysis - By Raw Material

Aromatic segment held a significant share in polyurea coatings market in 2019. These coatings have good physical properties and easy process ability. Hence, aromatic systems are coated with aliphatic topcoats for desired color stability on exposure to UV light. The aromatic polyurea coatings also have high ability to retain their elastomeric physical properties which is likely to propel its demand over the forecast period. The aliphatic isocyanate-based polyurea coatings are likely to witness fastest growth over the forecast period on account of rapid technological advancement, superior physical properties as compared to aromatic polyurea coatings. These coatings are manufactured using aliphatic compounds such as isophorone diisocyanate (IPDI) and hexamethylene diisocyanate (HDI). Aliphatic compounds are light stable; however, they are more difficult to process and retail at a higher price as opposed to their counterparts. High demand across numerous application areas including wind energy, transportation, and mining industries is expected to drive the aliphatic compounds demand.

Request for Sample of the Report @ https://www.industryarc.com/pdfdownload.php?id=16550

Report Price: $ 4500 (Single User License)

Polyurea Coatings Market Segment Analysis - By Type

Pure polyurea segment held a significant share in polyurea coatings market in 2019. Pure polyurea is derived from the chemical reaction of isocyanates and amine-terminated resins. Pure polyurea plays a vital role in determining the properties of the final coated surface. It has zero VOC content and is used widely due to its excellent performance properties, such as fast curing time, long pot life, outstanding chemical resistance, and moisture resistance. The pure polyurea coatings market is highly dependent on the growth of the end-use industries. The main applications of pure polyurea include roof coat, floor coat, and bonded area, among others.

Hybrid polyurea coatings are produced through two different chemical processes. They are produced through the chemical reaction of isocyanates, amine-terminated resins, and a hydroxyl functionality cross-linker or chain extender. Additionally, they are also produced through the chemical reaction of isocyanates, hydroxyl functional resins, and an amine-functional cross-linker or chain extender. Hybrid polyurea coatings are moisture and temperature-sensitive due to the catalyst used in their formation. They have excellent abrasion resistance and adhesion to metal and concrete body or structure. Polyurea hybrid coatings are cheaper than pure polyurea coatings and are typically used in the building & construction, industrial, and other applications.

Polyurea Coatings Market Segment Analysis - By Technology

Pouring segment held a significant share in polyurea coatings market in 2019. Pouring (used for many floors and roof coatings) is an emerging technology for polyurea coatings. Two components: isocyanates and resin blend are poured with the help of a pouring gun. The pouring gun helps in the accurate mixing of ingredients that are mixed with a static mixer. The increasing residential and home remodeling/reconstruction/ renovation activities in the building & construction end-use industry are expected to drive the polyurea coatings market in this segment.

The spraying technology segment holds the maximum percentage of the polyurea coatings market. In this technology, the two components—isocyanates and resin blend, are pumped through storage drums/barrels into the spraying machine. With the help of this machine, the two components are brought to the required processing parameters at the accurate mix ratio of 1:1. This mixture is then sprayed onto the surface. Spraying is the most widely used coating technology as it can be applied quickly and accurately on to the surface.

Polyurea Coatings Market Segment Analysis - By End User Industry

Building & Construction segment held a significant share in polyurea coatings market in 2019 growing at a CAGR of 10.97% during the forecast period. Polyurea coatings are used in a variety of substrates such as concrete, metals, and wood across a range of temperature and humidity environments, and are ideal for use in many waterproofing, corrosion control, immersion, and lining applications. These coatings are exclusively used for residential and commercial applications which are expected to have a positive impact on demand over the next eight years. High humidity resistance of the product increases its application scope in roofing, membranes, containment liners, decks, car parking, bridges, and offshores, thereby augmenting demand.

The prevailing pandemic situation has led to weakened demand for paints and coatings in Automotive, construction, electronics, and white goods. The path to recovery of growth for the industry is highly dependent on the duration of restrictions imposed and their influence on economic activity across the globe. Contrary to the trend prevalent in the industry in general, certain segments of the market such as antimicrobial coatings are witnessing a surge in demand in healthcare and food industries.

Polyurea Coatings Market Segment Analysis - Geography

Asia Pacific dominated the polyurea coatings market with a share of more than 41%, followed by North America and Europe. The growth is mainly attributed to high economic growth, and substantial investment in industries, such as automotive, marine, building & construction, and manufacturing. APAC is an emerging economy with many rapidly developing countries. Various industry players are willing to invest in this region. Most of the leading players in North America and Europe are planning to shift their manufacturing base to APAC as it offers inexpensive raw materials, low cost of production, and the ability to serve the local emerging market in a better way. The APAC region is experiencing increased demand for premium and high-quality products due to the increasing disposable income of the middle-class population. This has led to an increased demand for polyurea coatings in the APAC market.

Polyurea Coatings Market Drivers

Growing use in end user industries

Polyurea coatings are primarily used for waterproofing and corrosion-protection purposes. Polyurea coatings are used for the waterproofing of roofs, walls, and floors in the building and construction industry. Polyurea coatings are also used as bridge coatings for corrosion protection as well as waterproofing. Therefore, the growing building and construction industry and increasing infrastructural development, especially in developing nations, are expected to drive the growth of the polyurea coatings market.

The demand for polyurea coatings across the landscape industry has increased significantly in the recent past. The applications include aquariums, pools, water parks, theme parks, reservoirs, facades, and bathtub & cabins, among others. Polyurea coatings protect against moisture damage and resistance to chemicals, abrasion, and corrosion to landscape structures. These coatings are expected to replace paint and fiberglass due to their beneficial properties, such as fast cure and the ability to reduce maintenance cycles.

Talk to one of our sales representative about the full report by providing your details in the link below:

https://www.industryarc.com/support.php?id=16550

Polyurea Coatings Market Challenges

Health effects

Polyurea coatings application process involves high health risks and requires skilled labour. The health risks associated with spraying and toxicity arising due to vapours of amines substrates and exposure to high pressure equipment is estimated to offer restraints to the growth of global polyurea coatings market. Additionally, construction industry faces problems with intercoat adhesion. These are often related to low quality of raw materials, manufacturing, and spray equipment. Innovations in the machine-based coatings are proving to be effective in solving these challenges.

Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the polyurea coatings market. In 2019, the market of polyurea coatings has been consolidated by the top five players accounting for xx% of the share. Major players in the polyurea coatings market are Huntsman Corporation, Albemarle Corporation, PPG Industries Inc., Nukote Coating Systems International, Covestra AG, BASF SE, and The Sherwin-Williams Company among others.

Investment/ Acquisition

In February 2019, PPG invested USD 10 million in a new 82,000-square-feet facility and Class A paint line at its South Carolina coatings services facility. This initiative was taken to meet the increasing demand for Class A coatings from automotive and large truck markets.

In October 2017, PPG acquired The Crown Group, a US-based coatings application service provider, from Charter Oak Capital Partners and High Road Capital Partners. The Crown Group caters to customers in the automotive, agriculture, construction, heavy truck, and alternative energy industries, which are the key areas of interest for PPG. This acquisition has helped PPG enhance its services to OEM customers.

Key Takeaways

Growing consumer awareness regarding utilization of superior quality waterproofing coating in residential buildings is expected to propel growth over the forecast period.

Increasing requirements for improving performance, durability, and ease-of-use of products are the key factors contributing to the growth of the polyurea coatings market.

Asia Pacific dominated the polyurea coatings market.

Related Reports :

A. Polyurethane Coating Market

https://www.industryarc.com/Research/Polyurethane-Coating-Market-Research-500192

B. Industrial Coatings Market

https://www.industryarc.com/Report/11724/industrial-coatings-market.html

About IndustryARC: IndustryARC primarily focuses on Cutting Edge Technologies and Newer Applications market research. Our Custom Research Services are designed to provide insights on the constant flux in the global supply-demand gap of markets. Our strong team of analysts enables us to meet the client research needs at a rapid speed, with a variety of options for your business. Any other custom requirements can be discussed with our team, drop an e-mail to [email protected] to discuss more about our consulting services.

0 notes

Text

Inside the facility where Kodak brings film back to life

Inside the facility where Kodak brings film back to life Here’s a look at how thin strips of acetate become tiny blank canvases.

Paul Simon never wrote a song about Kodak Ektachrome, so you’ve probably never heard of it. But you have seen pictures shot on the film: The astronauts brought it to the moon in 1969, and National Geographic photographers have carried it around the globe.

Launched in 1946, Ektachrome evolved from a slightly finicky stock prone to issues with fading into a go-to medium valued for its vibrant colors. Hues skew toward the blue end of the spectrum, creating more-realistic images than the warmer Kodachrome of Simon fame. Both are slide films—meaning they produce full-color pictures right on the film rather than white-is-black/black-is-white negatives. But Ektachrome is easier to handle: While Kodachrome gets its color from dyes in the developing process, Ektachrome contains its own pigments, so developing is less labor-intensive.

But the film favorite nearly didn’t survive a tumultuous decade. As digital cameras and smartphones axed analog photography’s market by 80 percent, Kodak ended Ektachrome’s run in 2012. The sunset, however, did not last long. Since 2015, a growing enthusiast market and a goose from cinematic heavies such as directors J.J. Abrams and Christopher Nolan have helped 35-millimeter-film sales rebound. The trend spurred Kodak to revive Ektachrome.

Over the past 18 months, the Rochester, New York, company has worked to fine-tune the chemical mix that made the iconic film. Kodak will have it back in the hands of photographers later in 2018. Here’s a look at how thin strips of acetate become tiny blank canvases.

A tall tale.

Stan Horaczek

The Eastman Business Park in Rochester spans 1,200 acres and has its own power plant, private railroad, and fire station. This smokestacked building, which Kodak sold in 2013, sits just outside one of the company’s only remaining facilities for analog-film production, where Ektachrome takes form.

The left side of this image is from a modern digital camera (a Canon 5D Mark III); the right side is an Ektachrome exposure. We retouched the Ektachrome frame to better match the stock’s original color (rich blues). Our original shot was on an expired roll from the secondary market and so had a pinkish tint—though you could still see some of the characteristic blue in the shadows.

Into the light.

Stan Horaczek

The elevators in Building 30, where Kodak blends film chemicals, help workers’ eyes get used to the conditions that light-sensitive compounds demand. From street level, they enter cars lit green, a hue that encourages their peepers to adjust to the dim, film-safe red tones upstairs. The crimson light won’t react with the more than 1,200 chemicals Kodak keeps and catalogs here. Staff maintain the building at 75 degrees and 50 percent humidity, conditions that help stabilize setting agents such as gelatin and cut down static electricity, which can expose film.

Wet ingredients.

Stan Horaczek

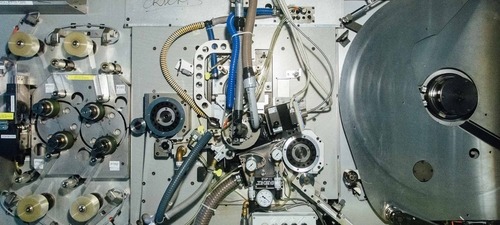

All film has two main components: a substrate and layers of photosensitive chemicals—the stuff that makes pictures happen. Ektachrome requires 106 components distributed across 15 layers. Workers load raw materials into the industrial mixers seen here to create blends that, among other functions, resist fog and balance the acidity of the film.

Color seal.

Stan Horaczek

Down the hall in the precipitation room, chemists mix the compounds that make the film sensitive to light. Pumps push raw materials such as silver, bromide, dyes, and salts into the kettle (center) in densities measured out to five decimal places. The result is silver halide crystals tuned for different colors; those dyed yellow will grab blue light, magentas capture green, and cyans snag red.

Blend tech.

Stan Horaczek

At the bottom of this 475-gallon mixing kettle, a planar emulsion precipitation apparatus (or PEPA), which vaguely resembles a perforated plastic watermelon, spins at up to 5,000 rpm. The speed helps evenly distribute the silver halide crystals in liquefied gelatin to create an emulsion. Learning to work with the fussy animal-derived material is what spurred Kodak founder George Eastman to create the film giant’s research arm in the late 1800s.

Connect the pots.

Stan Horaczek

Once blended, chemicals travel in barcoded containers across “The Bridge,” a conveyor-belt system that connects Building 30 to a coating facility in Building 38. Once the substances cross this expanse, an automated process takes over, reducing the risk of spills or mix-ups. The light-sensitive emulsions occupy matte black boxes, while other elements await their fate in bottles.

Hot pot.

Stan Horaczek

Here in the melting room, machines called dumpers move silver halide emulsions and other chemicals into massive kettles. This row of 26 mixers re-melt gelatin and marry disparate compounds into film coatings. This room is typically blackout dark when mixing is in process.

Shake it off.

Stan Horaczek

Coatings get cleaned up in this, the “hot room,” on their way to meet their acetate base. The tubes running across the room’s frame deliver materials to filters (not shown) that catch any undissolved gelatin. Meanwhile, ultrasonic vibrations shake out bubbles that could leave voids on the film. The space stays above 100 degrees to keep everything flowing freely.

Master control.

Stan Horaczek

The coating process happens in perfect darkness, but it’s controlled from this 1980s masterpiece. Two rooms away, machines paint each of Ektachrome’s 15 layers onto acetate. The 52-inch-wide film rolls pass through a coating waterfall, a cooler, and a dryer. Once they reach the other side, the direction switches, and the film circuits through the whole process again. If laid end to end, the trip would stretch nearly a mile. The facility sits on a steel-reinforced concrete slab that reaches 100 feet below the ground, all the way to bedrock, negating any ambient vibration that could cause coating inconsistencies.

Drum line.

Stan Horaczek

Once the film is finished and the coatings hardened, workers seal it in light-tight wooden containers and truck it down the street. Each case holds a roll of sensitized stock as long as 12,000 feet—Ektachrome runs will be 6,000 feet. Kodak paints the airtight containers flat black on the inside, and seals them with collars to ensure no light can seep in and prematurely expose the film.

Cut, cut, cut.

Stan Horaczek

This moving-truck-size machine, known as the slitter, slices the 52-inch rolls into 38 individual strips of 35mm Ektachrome. The apparatus is similar to what food packagers would use to trim Doritos bags but with some special Kodak modifications, such as custom blades. Normally, this room is pitch-black; only strips of green glow-in-the-dark tape help workers find their way around the behemoth.

Punch a bunch.

Stan Horaczek

This device, which Kodak calls “the heart,” punches holes in the edges of the film so sprockets inside a camera can crank through exposures. Film travels from the reel at the right through the rotary perforator in the center at a rate of 3,000 feet per minute. The corrugated tubes that extend like arteries (hence the cardiovascular name) on the top and bottom of the machine are vacuum lines that suck away the chads. Each roll of 36 pictures will have roughly 700 holes.

GADGETS

You should buy an instant film camera—here’s how

Instant prints make smart phone photography seem boring.

You have lots of options for instant film cameras. Here’s how to pick the best one for you.

Quality control.

Stan Horaczek

Engineers test sections of film in a developing lab. They spot-check for imperfections including incomplete chemical coating or crinkles from the machinery. During production, Kodak uses night-vision cameras to monitor the film for irregularities such as uneven application or breaks. If the machines sense that something is wrong, they mark that spot on the roll so testers can then cut out that piece and diagnose the mishap.

Wrap it up.

Stan Horaczek

The final film goes on to the packaging area, where a machine wraps it around plastic spools like these. Each batch of Ektachrome nets out to nearly 3 million feet of film—or more than 600,000 individual rolls. How much of it the company makes will depend on sales; film has a finite shelf life—even if you store it in the fridge.

June 13, 2018 at 08:39AM via Digg https://ift.tt/2t2TMnJ

More from our dtla photo studio in downtown los angeles at www.theroomdowntown.com

The post Inside the facility where Kodak brings film back to life appeared first on The Room Downtown.

from WordPress https://theroomdowntown.com/index.php/2018/06/19/inside-the-facility-where-kodak-brings-film-back-to-life/ photo, video, los angeles, dtla, photostudio, studio, photography, downtown, light, cinematography, film, fashion, portrait, camera, www.theroomdowntown.com

1 note

·

View note

Link

Static Mixer Market Size

According to a new report by EMR titled, 'Static Mixer Market Size, Share, Industry, Analysis, Report & Forecast 2020-2025', the global industry is expected to witness a healthy growth in the forecast period of 2020-2025.

#Static Mixer Market Size#Static Mixer Market Share#Static Mixer Market Industry#Static Mixer Market Analysis#Static Mixer Market Price#Static Mixer Market Trends#Static Mixer Market Growth#Static Mixer Market Forecast#Static Mixer Market Outlook#Static Mixer Market Report

0 notes

Link

0 notes

Text

Report on Truck Mounted Concrete Pump Market Research 2026 - Value Market Research

Truck Mounted Concrete Pump Market report published by Value Market Research delivers a comprehensive market analysis covering of market size, share, value, growth and trends for the forecast period of 2020-2026. The report includes data regarding market attractiveness analysis by segments, company share analysis and recent developments by key players. Moreover, this market report also covers regional and country market analysis in detail.

The report also covers detailed competitive landscape including company profiles of key players operating in the global market. The key players in the truck mounted concrete pump market includes Alliance Concrete Pumps Inc., Anhui Hualing Automobile Group Co, Ltd, Concord Concrete Pumps, Fangyuan Group Inc., KCP Heavy Industries, LIEBHERR, PUTZMEISTER, Sany Group, SCHWING, Shantui Construction Machinery Co., Ltd., XCMG Co., Ltd., and Zoomlion Heavy Machinery Co, Ltd. An in-depth view of the competitive outlook includes future capacities, key mergers & acquisitions, financial overview, partnerships, collaborations, new product launches, new product developments and other developments with information in terms of H.Q.

Get more information on "Global Truck Mounted Concrete Pump Market Research Report" by requesting FREE Sample Copy at https://www.valuemarketresearch.com/contact/truck-mounted-concrete-pump-market/download-sample

Market Dynamics

Growing construction activities along with the advancement in construction materials are serving as a key driver to the market growth. Rising refurbishment of residential and commercial infrastructure and increasing usage of the precast structure across construction site is further augmenting market demand. Increasing funding by the government for the development of infrastructure projects coupled with the rising demand for fast construction material is also expected to favor market growth. Whereas, global political and economic conditions may restraint market growth. This detailed market study is centered on the data obtained from multiple sources and is analyzed using numerous tools including porter’s five forces analysis, market attractiveness analysis and value chain analysis. These tools are employed to gain insights of the potential value of the market facilitating the business strategists with the latest growth opportunities. Additionally, these tools also provide a detailed analysis of each application/product segment in the global market of truck mounted concrete pump.

Browse Global Truck Mounted Concrete Pump Market Research Report with detailed TOC at https://www.valuemarketresearch.com/report/truck-mounted-concrete-pump-market

Market Segmentation

The broad truck mounted concrete pump market has been sub-grouped into product type and end-use. The report studies these subsets with respect to the geographical segmentation. The strategists can gain a detailed insight and devise appropriate strategies to target specific market. This detail will lead to a focused approach leading to identification of better opportunities. By Product Type

Truck Mounted Mobile Pump

Truck Mounted Static Pump

Truck Mixer Concrete Pump

By End-Use

Industrial

Residential

Commercial

Regional Analysis

This section covers regional segmentation which accentuates on current and future demand for aerosol valve market across North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Further, the report focuses on demand for individual application segment across all the prominent regions.

Purchase Complete Global Truck Mounted Concrete Pump Market Research Report at https://www.valuemarketresearch.com/contact/truck-mounted-concrete-pump-market/buy-now

About Us:

Value Market Research was established with the vision to ease decision making and empower the strategists by providing them with holistic market information.

We facilitate clients with syndicate research reports and customized research reports on 25+ industries with global as well as regional coverage.

Contact:

Value Market Research

401/402, TFM, Nagras Road, Aundh, Pune-7.

Maharashtra, INDIA.

Tel: +1-888-294-1147

Email: [email protected]

Website: https://www.valuemarketresearch.com

#TruckMountedConcretePumpMarketSize#TruckMountedConcretePumpMarketShare#TruckMountedConcretePumpIndustryReport#TruckMountedConcrete PumpReport#TruckMountedConcrete Pump#TruckMountedConcretePumpMarket

0 notes

Text

Tools Required for Starting a Podcast

Want to get started with the basics of podcast recording to build up further? Follow this article to the end. With the help of this article, you will know what all essentials you need to start a podcast. There is not much that you require to start a podcast. You only need a PC, headphones, a microphone, and recording software so that you can reach out to listeners. You already are having some of the equipment which is needed for a podcast setup creation. Let’s talk about them in detail below.

Microphones

You will need a microphone to let your voice get your voice into your computer for recording. It is not recommended not to spend a lot of money on a microphone if the quality is not what you want, but make sure the better your podcast’s audio quality, the more professional it will sound. No one will listen to your podcasts if the audio is inferior. You can opt for the USB microphones. They are easy to handle and work efficiently. They can handle a one-person podcast.

Once you have spent a reasonable amount of time podcasting, you can go for a higher-end microphone. You can opt for microphones with XLR connections. These microphones need a mixer or an audio interface or a mixer, which provides you a more significant amount of control over your recording.

Some microphones offer both the USB as well as XLR connections. We recommend you start your journey with the USB connection, and then after some time, you can add a mixer or audio interface for use alongside the XLR capabilities. In general, there are two types of microphones: Dynamic and Condenser. Dynamic microphones are less expensive than condenser microphones. They provide good audio results alongside less feedback. On the other hand, Condenser microphones are more expensive and sensitive with a higher dynamic range.

Microphones come with an individual sound pickup pattern that is either omnidirectional, bidirectional, or cardioid. If you are not in a soundproof studio, you will require a cardioid microphone. In case you want to share your microphone with your co-host, you can go for the bidirectional microphone.

Mixers

You will need a mixer; in case you choose an XLR microphone. Mixers come in various price ranges along with various channels. You will need a specific channel for every microphone you will use with the mixer. You can check for the mixers from Mackie mixers, Focusrite Scarlett series mixer, or Behringer.

Headphones

Headphones help in monitoring the recorded sound. Don’t go for the soft-shell headphones as they lack in suppressing sound. This may cause feedback. We recommend using a hard-shell headphone, which has a sturdy plastic or rubber outside. These kinds of headphones can easily trap the sound. You don’t need to spend a lot on headphones, but obviously, if you want good results, you will have to spend a decent amount on it.

Computer

If you have recently purchased a PC within some years, it can easily handle your podcast’s recording sessions. You don’t need to buy a new PC right away. You can still work efficiently with the one you already have. In case it doesn’t work correctly, then you can surely go for a new one with more memory and faster processing speed. But if it works fine, then there is no need to waste your money.

Recording & Mixing Software

Recording and mixing tools play a significant role in a podcast. You can record and mix your audio statically or straightforwardly in real-time. Mixing your audio in real-time needs the right tactics and reliable software. You should mix your audio in the form of a static project as it will allow you a more significant amount of time to make your finished product professional and more polished.

To start a podcast, you must have software. Many software related to mixing and recording is available in the market, both paid and free. You can start with a low at cost or free software. Once your podcast starts well, you can upgrade your software.

Internet Access

You will require a robust internet connection to upload your finished outcome when it is all set to be heard. Podcasts are large-sized files, so it is recommended that you should have a good internet connection.

So, you need a computer, a pair of headphones, a microphone, and a recording and mixing software f to start your podcast.

Emily Johnson is a Microsoft product expert and has been working in the technology industry since 2002. As a technical expert, Emily has written technical blogs, manuals, white papers, and reviews for many websites such as office.com/setup.

Source: Tools Required for Starting a Podcast

0 notes

Text

Global Static Mixer Market 2019-2023| Use of Static Mixer as Catalysts to Boost Growth| Technavio

The global static mixer market is expected to post a CAGR of over 5% during the period 2019-2023, according to the latest market research report by Technavio.

A key factor driving the market is the growth of end-user industries. Process industries such as chemical and petrochemical, food and beverage, as well as water and wastewater are among the major end-user industries in the global static mixer market. Thus, capacity additions in these industries are increasing the demand for static mixers. For instance, the food and beverage industry uses static mixers to mix flavoring agents, coloring agents, and additives of fruits. Apart from this, static mixers are used for the blending of fruit juices, the production of drinking yogurt and the mixing of edible oils. Thus, the growth of the end-user industries is expected to augment the global static mixers market during the forecast period.

As per Technavio, the use of static mixer as catalysts will have a positive impact on the market and contribute to its growth significantly over the forecast period. This global static mixer market 2019-2023 research report also analyzes other important trends and market drivers that will affect market growth over 2019-2023.

Global static mixer market: Use of static mixer as catalysts

Static mixers are mainly used for blending and equalizing differences in physical parameters, such as the viscosity or temperature of the gases that are mixed. However, some research and development (R&D) organizations have developed static mixers for catalyzing processes. For instance, in January 2017, the Commonwealth Scientific and Industrial Research Organization (CSIRO) developed a catalyst-coated static mixer for continuous flow reactors. The catalyst-coated static mixer can cause more churning and mixing in a continuous flow reactor. This improves the efficiency of a continuous flow manufacturing process. Since various processes in industries such as chemical and petrochemical use catalysts, the vendors are expected to commercially launch catalyst-coated static mixers, thereby driving market growth during the forecast period.

“Apart from the use of static mixer as catalysts, the introduction of 3D printed static mixers and the introduction of static mixers in automatic dispensing systems are considered to be two other factors that will boost market growth,” says a senior analyst at Technavio.

Global static mixer market: Segmentation analysis

This market research report segments the global static mixer market by application (laminar flow and turbulent flow), by end-user (oil and gas; chemical and petrochemical; food and beverage; water and wastewater; and others) and geographical regions (APAC, North America, Europe, South America, and MEA).

The APAC region led the market in 2018, followed by North America, Europe, South America, and MEA respectively. During the forecast period, the APAC region is expected to maintain its dominance over the global market and register the highest incremental growth due to growing investments in various end-user industries in the region.

Looking for more information on this market? Request a free sample report

Technavio’s sample reports are free of charge and contain multiple sections of the report such as the market size and forecast, drivers, challenges, trends, and more.

0 notes

Text

What Are The Types Of Game Engine Used By Game Development Companies In USA

While showing no sign of stopping, gaming has been a big business for decades. By 2021, the gaming market is expected to be worth over 138 billion USD. When it comes to choosing the right game engine platform, game development organizations must make the right decision despite a large number of solutions are available today.

When it comes to game development companies in USA, they always make the right call. But it is necessary to know first what is a game engine?

What Is Game Engine

While bringing and supporting several core areas, a game engine is a framework for game development. You have the option of importing 2D and 3D from other software, including the assets and art. All the assets are then assembled into environments and scenes.

For your target audience, you need to include special effects, audio, lighting, animation, and physics. Apart from that, you need to include the gameplay logic, interactivity, edit and at the same time optimize and debug the content.

What The Game Engine Will Provide You

It is necessary that whatever game engines you are choosing should tackle multiple issues. Hence it is necessary to understand the basic elements of the game engine. The basic elements are as follows.

Physics-

For the end-users, the in-game immersions should be a precise balance between computing power limitations and simulation quality.

Input -

In cross-platform development, the input is an extremely common issue. Your game engine must need to solve multiple problems related to the game.

Visual Assets Processing -

When you are using the game engines, it is necessary to do texture mapping, shading, and lighting. There is less programming effort with the depth of field.

You must choose the game engine, where there will be less coding effort. To deliver the special and unique user experience, it assists the design team to design the games and gives enough time to develop the game fruitfully.

Unreal

One of the key technologies used for game development is the unreal engine. It is considered as one of the wide and popular game engines. For the game of all sizes, you need to use the multi-platform engine for game development.

While initially being released in the year 1998, the unreal game engine is still very popular after 22 years. For providing unique experiences, the unreal game can modify the games in a new way. The game should be developed by skill developers with vast experience.

The unreal engine users can use Quixel’s Megascans library assets and Quixel bundled tools ( such as Mixer and Bridge).

Strengths Of The Unreal Game

Wealthy Customization Capacities

Scalability

Can be used for 2D and 3D games

Multiple features

Unity

To create the 3D content with ease, Unity is a multi-platform game engine. Due to the high-quality content, excellent functionality and capacity to be used in any type of game, the Unity game engine is the perfect choice for most of the game developers. The game engine can support 2D and 3D content.

This game engine can develop games for Linux, Mac, Windows, Android, Xbox, Tizen, and other platforms since it has all in one editor. While minimizing the requirement for training, the user-friendly game engine makes the development of the game easy.

While the content is created daily, the Unity game engine has a vast collection of tools.

Strength

When it comes to unity, it provides multi-platform support

Often the free version is available

When it comes to the unity it can develop games, which are good for teams of all sizes.

Cocos 2D

For building games and other cross-platform interactive programs, Cocos2D is an open-source framework. There are many forms of Cocos2d and they are Cocos2D XNA, Cocos2D - HTML, Cocos2D -x and Cocos 2D obj.

There are some of the independent editors in the Cocos2D community that can contribute in the areas of particle editing, sprite sheet editing, Tilemap editing, and font editing.

Phaser

For making HTML5 games for mobile and desktop, the Phaser is a free software 2D game framework. While it can automatically switch between the WebGL and Canvas based on browser support, Phaser uses both javascript and element.

Across the mobile and desktop, it permits fast rendering. Through 3rd party tools like Phonegap and Apache Cordova, games can be compiled to native desktop, IOS, and Android. There are some of the elements available for the Phaser. These are

Physics Of The Game- There is the inclusion of three main physics engines in Phaser.

There is enough input control.

There are static and dynamic images, and the sprite sheets and tweens are used to animate them.

Benefits Of Using Accelerated Game Engines

There will be little wait time for the time-consuming execution, and concurrent, as the accelerated game engine will speed up the process of game design and development. Game development company often uses the accelerated game engines for the benefit.

There is a possibility of achieving better quality graphics when the accelerated game engine is running faster. The artist can try different experiments and variations, instead of settling for mediocre quality output for games.

The accelerated game engine assists in detecting errors, executions, bottlenecks and dependencies in real-time.

Conclusion- You need to consider the expectations, capacity and other features of the game engine when you are developing the game for a particular platform. While it is a tough decision, but if you choose the above-said game engines then the game development should be really good and users will seriously enjoy playing the game.

0 notes

Text

All About Sealing in Mechanical Industry

Summary

Mechanical sealing is a method of containing fluid within a vessel typically pumps, mixers, etc. Where a rotating shaft passes through a stationary housing, where the housing rotates around the shaft.

There are several types and arrangement of the mechanical seals used for the centrifugal pumps. Some of the commonly used ones are described below.

Picture courtesy: JDJones

1) Pusher Type of Mechanical Seals: The pusher type of seals moves axially along the rotating shaft or the sleeve to maintain the contact with the faces of the seal. This feature helps compensate for the wearing that may occur at the seal face and wobbling due to misalignment. This type of mechanical seals are used commonly, are less expensive and are easily available in the market in a wide range of sizes and designs.

2) Unbalanced Type of Mechanical Seals: The unbalanced types of seals are used under drastic conditions where there are vibrations, misalignment of the shaft, and the problem of the cavitation of the fluid. These mechanical seals are inexpensive, allow lesser leakage and are highly stable. However, these seals can be operated only under low-pressure and if the force of the fluid exceeds certain limits the lubricating film between the faces squeezes out and the seal fails.

3) Non-pusher Type of Mechanical Seals: As the name suggests, the non-pusher or bellow type of seals don’t have to be moved axially to maintain their contact with the faces. These mechanical seals can work under low temperature and high pressure applications. The bellows used in these seals should be upgraded so that they can work under the corrosive environments.

4) Balanced Mechanical seals: The balanced seals have the ability to sustain higher pressures across the faces and tgenerate lesser heat thus those are suitable for handling liquids that have low lubricating capacity and hydrocarbons that have high vapor pressure.

5) Cartridge Mechanical Seals: The major advantage of the cartridge mechanical seals is that they don’t require complicated setting during the installation as required by the conventional seal. This helps reducing errors associated with the meachnical seal setting and eventually also reduces the maintenance required.

Mechanical seals are devices that can accept some shaft movement at high speeds. Higher rotating shaft speed should always linked to minimal shaft movement to achieve the best seal life. This provides a good static sealing surface for the next mechanical seal installation.

Conclusion Today, Mechanical seals has touched nearly every aspect of industrialised society. Wherever a rotating shaft moves fluid, mechanical seals play a key role in sealing process fluids in, keeping contaminants out, or both. Mechanical seals are used with many process fluids. Each fluid has different lubrication qualities, but remember a thin, lubricating film at the sealing interface is always needed.

0 notes

Link

Static Mixer Market Size

According to a new report by EMR titled, 'Static Mixer Market Size, Share, Industry, Analysis & Report 2020-2025', the global market is estimated to grow at a CAGR of 6% in the forecast period of 2020-2025.

#Static Mixer Market Size#Static Mixer Market Share#Static Mixer Market Industry#Static Mixer Market Analysis#Static Mixer Market Price#Static Mixer Market Trends#Static Mixer Market Growth#Static Mixer Market Forecast#Static Mixer Market Outlook#Static Mixer Market Report

0 notes

Link

0 notes

Text

Static Mixer Market Global Driving Factors & Technology Advancements Forecast 2024

Market.Biz focuses on providing the users or readers with a descriptive assessment of the industry and the valuable analyzed information of several markets. The latest research report on the global Static Mixer market is completely concentrated on satisfying the requirements of the users by offering them with all insights into the industry. The Entire data Structured in the report is collected by Professional researchers and experts.

Market Scope of the Static Mixer report:

Each segment included in the research report is detailed and well-examined based on various crucial factors such as market share, revenue, Production, Region, Usage of the Static Mixer, Regional overview, Types, and Manufacturer. The report on Static Mixer market supports the competitors to focus on key regions of the Industry. It also provides an independent assessment of each segment as per future opportunities.

"Global Static Mixer Market 2019 Sample Pdf"

The Competitive Manufacturers of the Static Mixer Market:

Lenntech Fluitec Sulzer Noritake Chemineer SPX Nordson Xaloy Charles Ross & Son Company StaMixCo Koflo Verdermix Komax Philadelphia Mixing Solutions Admix Statiflo International

Some Advantages of the Global Static Mixer Market Report:

1. This Report is a precise document that provides basic guidance to the User of the Static Mixer market.

2. The information collected in the Report is derived for true sources such as Press releases, Personal Interviews, Industry expert reviews, Government documents, Financial Reports, and investor information.

3. The Evolution of market dynamics, market trends and also the changing supply and demand conditions are framed in the report.

4. It Quantifies market opportunities and threats with the help of market sizing and market forecasting.

5. Competitive insights included in this report helps in Tracking current trends which leads to a forecast of upcoming changes in current business ideas.

Key Type of Static Mixer:

Channel Mixers Pipe Mixers Gas Dispersion Systems

Main Applications of Static Mixer:

Water and Wastewater Treatment Oil Gas and Petrochemical Industries Food and Pharmaceutical Pulp and Paper

Global Static Mixer Market Key Geographical Segments:

North America Europe China Japan The Middle East & Africa India South America

"Ask Your Query Here"

In Addition, the Static Mixer Market report gives a strong Foundation for gathering a bunch of insights that potential customers can refer to reduce costs and enhance the revenues. The Report is the outcome of various analyses such as Pestle analysis and Porter's 5 force analysis etc. The reference and facts in the report are put forth to give the reader a clear thought of the market.

Also, Visit this Interesting Article:

Global Gate Drivers Industry Market Research Report

0 notes