#Stainless Steel 347/347H Flanges Manufacturers in India

Text

Stainless Steel 347 Flanges Exporters in India

One of the fundamental suppliers and the maker of the SS 347/347H spines is the Technolloy Inc. SS 347/347H is a combination that is settled by columbium and tantalum. The pieces of this grade have a mind blowing proclivity for carbon than chromium. As a result of the extraordinary substance of the carbon, this grade is proper for use in the different present day applications. We make the tempered steel spines for different endeavors and have some mastery in achieving this work for a really long time.

We make the spines in the standard specifics or re-tried subtleties relying upon the circumstance by the clients. A part of the properties of SS 347/347 H spines is that they show further creates insurance from utilization as well as have high killjoy obstacle features. These spines are best for use in the application where there is consistent warming is normal in the extent of the 800-1650F.

Moreover, this grade shows supportive mechanical part at raised temperature. These ribs are used in the plane exhaust stacks, augmentations joints, treating box, authority ring, etc. We on a very basic level produce SS 347/347H spines in the construction makes ribs, connection weld ribs, welding neck rib, long weld neck rib, reduced rib, etc.

The kind of rib you get is a level face, ring type and raised face spine. These spines we produce are extraordinarily strong since we perform various tests to take a gander at the thing quality as a matter of fact. The test we perform on the thing is basically hardening, manageable test, engineered assessment, PMI, IGC test, smaller than normal and full scale test. The attempted material is furthermore surveyed by particularly capable gathering of specialists.

The test supports are conveyed with things like raw substance, 100% radiography test validation, test reports and assessment reports. These confirmations and records are proposed to the clients at whatever point referenced by them. The outcome is full to give prosperity while simultaneously conveying. The packaging material we use major areas of strength for is environment agreeable. We transport the thing to different countries inside a short period of time in sensible conditions.

We guarantee the client gets definitively careful thing they truly demands for. Thusly, the thing is made to satisfy all of the necessities of various applications in different endeavors.

0 notes

Text

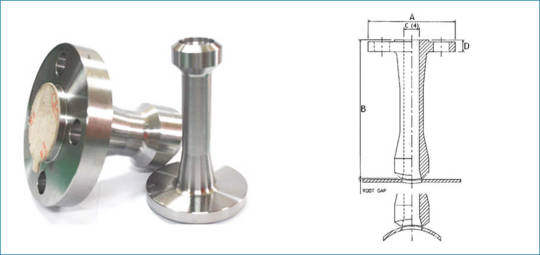

Nipo Flanges

Class 300 Nipo Flanges, Carb

on Steel Nipo Flange, Nickel Alloy Nipo Flanges, ASME B16.5 Raised Face Nipo Flange, ANSI B16.5 Nipo Flanges, Best Deals on Raised Face Nipo Flanges, ASME / ANSI B16.5 Nipo Flanges, Stainless Steel Nipo Flange dealer in India.

NIPO FLANGES MATERIAL & GRADES

Stainless Steel Nipo FlangesASTM A182 F 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904LCarbon Steel Nipo FlangesASTM A105, ASTM A694 Gr. F42, 46, 52, 56, 60, 65, 70Alloy Steel Nipo FlangesASTM A182, F1, F5, F9, F11, F22, F91Duplex Steel Nipo FlangesASTM A182, F44, F45, F51, F53, F55, F60, F61Super Duplex Nipo FlangesASTM A182, F44, F45, F51, F53, F55, F60, F61Low Temperature Carbon Steel Nipo FlangesASTM A350, LF2, LF3

ASME B16.5 NIPO FLANGES SPECIFICATION

BS

BS4504 , BS4504, BS1560, BS10

FLANGE FACE TYPE

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

2 notes

·

View notes

Text

Supplier of Stainless Steel Angle in Bihar

Arisa Impex is a leading Manufacturer, Exporter, and Supplier of Stainless Steel Angle in Bihar.

Arisa Impex offers stainless steel products, including stainless steel round bars, wires, rods, sheets, coils, pipes, flat bars, square bars, hexagonal bars, angles, flanges, and alloy steel.

Our Manufacturer Unit is in Ahmedabad, Gujarat, India.

We are selling high-grade quality series such as 200, 300, and 400.

Stainless steel angle is a type of metal profile with a 90-degree angle, commonly used in various construction and manufacturing applications.

It is characterized by its durability, corrosion resistance, and versatility, making it an ideal choice for both structural and decorative purposes.

Stainless steel angles can be easily cut, welded, and fabricated to meet the needs of various projects.

Proper techniques should be employed to ensure clean cuts and strong welds, maximizing the material’s properties.

Resistant to wear and tear, stainless steel maintains its integrity over time, ensuring long-lasting performance.

You can customize stainless steel angles in various sizes, grades, and finishes to meet specific project requirements.

Specification:

Stainless Steel Angle Grades: 201, 202, 301, 304, 304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H, etc.

Size: 20mm x 20mm to 150 x 150 mm

Thickness: 3.0mm – 120mm

Length: 3MTR, 4MTR, 5MTR, 6MTR, or Custom Cut Sizes

Finish: Hot Rolled Annealed Pickled (HRAP), Shot Blasted, Polished

Specifications: ASTM A276 / ASME SA276

Usage in

Petrochemical Industries

Oil and Gas Industries

Pulp and Paper Industries

Chemical Industries

Food Processing Industries

Instrumentation Industries

Automobile Industries

Fluid Piping Industries and many more

Arisa Impex is a Supplier of Stainless Steel Angle in Bihar including locations like Patna, Gaya, Muzaffarpur, Darbhanga, Bhagalpur, Katihar, Purnia, Buxar, Bettiah, Chapra, Bihar Sharif, Siwan,

Arrah, Sasaram, Begusarai, Munger, Saharsa, Kasba, Habibpur, Nalanda, Danapur, Nawada,

Sitamarhi, Madhubani, Jamui, Bagaha, Kishanganj, Madhubani.

For more information and inquiries, feel free to contact us.

View Product: Click Here

Read the full article

#AlloySteel#Angles#ArisaImpex#Arrah#Bagaha#Begusarai#Bettiah#Bhagalpur#Bihar#BiharSharif#Buxar#Chapra#Coils#Danapur#Darbhanga#Exporter#Flanges#FlatBars#Gaya#Habibpur#HexagonalBars#Jamui#Kasba#Katihar#Kishanganj#Madhubani#Manufacturer#Munger#Muzaffarpur#Nalanda

0 notes

Text

Stainless Steel 316 Flanges Exporters in India

Introduction

Stainless Steel 316 Flanges, renowned for their exceptional resistance to corrosion and high temperatures, are a cornerstone in various industrial applications. These flanges are particularly favored in environments where superior resistance to chlorides and acids is required, making them indispensable in industries such as chemical processing, petrochemical, and marine engineering. At Universe Metal & Alloys, we pride ourselves on being leading Manufacturers, Suppliers, Stockists, and Exporters of top-quality Stainless Steel 316L Flanges, ensuring that our clients receive only the best in durability and performance.

Description

Universe Metal & Alloys specializes in manufacturing stainless steel 316 flanges, designed to meet the rigorous demands of industries such as petrochemical, oil and gas, power generation, and more. Stainless steel 316 is a highly sought-after material due to its superior corrosion resistance, strength, and durability. These flanges are produced using state-of-the-art technology and adhere to stringent international standards to ensure optimal performance and reliability.

The flanges are available in various types, including slip-on, weld neck, blind, socket weld, and threaded, catering to the diverse needs of different applications. Each flange is meticulously crafted to ensure a perfect fit and seal, providing long-lasting and leak-free connections in piping systems.

Benefits

Choosing stainless steel 316 flanges from Universe Metal & Alloys comes with a multitude of benefits:

Excellent Corrosion Resistance: Stainless steel 316 flanges offer superior resistance to corrosion, especially in harsh environments and chemical exposure, ensuring longevity and reliability.

High Strength and Durability: The mechanical properties of stainless steel 316 make these flanges exceptionally strong and durable, capable of withstanding high pressure and temperature conditions.

Versatility: Available in various types and sizes, these flanges can be used in a wide range of applications, from industrial piping systems to specialized equipment.

Hygiene and Cleanliness: The smooth surface finish of stainless steel 316 ensures easy cleaning and maintenance, making these flanges ideal for applications in the food and pharmaceutical industries.

Compliance with Standards: Universe Metal & Alloys ensures that all its products meet international standards and certifications, providing customers with confidence in the quality and safety of their products.

Specification

Stainless Steel 316L Flanges Specification:

Stainless Steel 316 Flange Specification

ASTM A182 / ASME SA182

Stainless Steel 316 Flange Manufacturing Process

Hot Forging / Rolling / Machining

Stainless Steel 316 Flange Other Grades

202 / 304 / 304L / 304H / 309S / 310S / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L etc.

UNS No. - UNS S30400, UNS S30403, UNS S31008, UNS S31620, UNS S31603, UNS S31603, UNS S31635, UNS S31703, UNS S32100, UNS S34700, UNS S34709, UNS S8904

EN No. - 1.4301, 1.4307, 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539

Stainless Steel 316 Flange and Flanges Pipe Fittings Outer Diameter

1/2" NB TO 64" NB

Stainless Steel 316 Flange Pressure Class

Class 150#, Class 300#, Class 400#, Class 600#, Class 900#, Class 1500#, Class 2500# or As Per Custom Requirement

PN 6, PN 10, PN 16, PN 25 and PN 40 etc

Stainless Steel 316 Flange Schedule

Sch 10s TO Sch XXS or As Per Custom Requirement

Stainless Steel 316 Flange Facing

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Stainless Steel 316 Flange Dimension

ASME B16.5, ASME B16.47 SERIES A, ASME B16.47 SERIES B, ASME B16.36, BS10, EN1092-1:2013, MSS SP44, ASA, API-605, ISO 7005, ISO 15590-3, DIN 2631--2638, DIN 2573-2576, DIN 2527, DIn 2641-2642, DIN 2565-2566, DIN2502, AWWA, AS2129 TABLE C, D, E, F, J etc..

Stainless Steel 316 Flange Other Testing

NACE MR0175, Ultrasoung TEST, IGC TEST, Intergranular Corrrosion Test as per ASTM A262 Practice E, Charpy Impact Test, Macro, Grain Size, Hardness, HIC, SSC, Sour Service etc.

Stainless Steel 316 Flange Value Added Services

Rolling, Drill, Punch, CNC Machining, Sand Blasting, Shot Blasting, Heat Treatment, Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized

Stainless Steel 316 Flange Packaging

Loose / Carrate / Wooden Pallet / Wooden Box / Plastic Cloth Wraps

Stainless Steel 316 Flange Shipment & Transportation

By Road - Truck / Train Partial Load, Full Load, By Sea - Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air - Freighter Civil Passenger and Cargo Planes

Stainless Steel 316 Flange Material Test Certificate

Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS, Bureau of Indian Standards BIS Approved ETC

Conclusion

Universe Metal & Alloys has established itself as a leading manufacturer of stainless steel 316 flanges in India, thanks to its unwavering commitment to quality, innovation, and customer satisfaction. Their products are trusted by industries worldwide for their superior performance, durability, and compliance with stringent standards.

For more information or to place an order, contact Universe Metal & Alloys at [email protected] or call +91-22-66363360 / 66393788. Experience the excellence of working with a premier manufacturer of stainless steel 316 flanges.

0 notes

Text

Welded Flanges Exporters in India

We are broadly known for manufacturing and supplying an extensive variety of high quality of Welded Flanges. These flanges are welded to the end of pipe so that the pipe can be bolted to another pipe with a same flanges. Complying with the characterized parameters of the business, these offered welded flanges hold a few properties, such as,Epoxy Coating, Longer service life, Hot Dip Galvanizing, Resistance against corrosion, Dimensions stability, Compressive strength.SPECIFICATION

Size:

1/2" NB TO 60"NB.

Class:

150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS DIN Standard ND-6,10, 16, 25, 40 Etc.

Nickel Alloy Socket Weld Flange:

ASTM / ASME SB 564 / 160 / 472.

UNS 10276 -HASTELLOY C 276 Socket Weld Flange

UNS 2200 -NICKEL 200 Socket Weld Flange

UNS 2201 -NICKEL 201 Socket Weld Flange

UNS 4400 -MONEL 400 Socket Weld Flange

UNS 8020 -ALLOY 20 Socket Weld Flange

UNS 8825 -INCONEL 825 Socket Weld Flange

UNS 6600 -INCONEL 600 Socket Weld Flange

UNS 6601 -INCONEL 601 Socket Weld Flange

UNS 6625 -INCONEL 625 Socket Weld Flange

Copper Alloy Socket Weld Flange:

ASTM / ASME SB 61 / 62 / 151 / 152.

C 70600 (CU -NI- 90/10)/Cupro Nickel Socket Weld Flange

C 71500 (CU -NI- 70/30)/Copper Nickel Socket Weld Flange

UNS NO. C 92200, UNS NO. C 83600, UNS NO. UNS NO C 10100,

C 10200, C 10300, C 10800, C 12000, C 12200

Duplex Steel Socket Weld Flange:

ASTM / ASME A/SA 182 UNS F 44, F 45, F51, F 53, F 55, F 60, F 61.

Stainless Steel Socket Weld Flange/SS SWRF Flange:

ASTM A182 Grade : F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L.

Alloy Steel Socket Weld Flange/AS SWRF Flange:

ASTM SA 182 F1/F5/F9/F11/F22/F91

Carbon Steel Socket Weld Flange/CS SWRF Flange:

ASTMA 105 Gr. F42/46/52/56/60/65/70

Low Temperature Carbon Steel Socket Weld Flange/LTCS SWRF Flange:

A350 LF2/A350 LF3, Value Added Services, Hot Dip Galvanizing, Epoxy Coating,, Test Certificate, Mill Test Certificate as per EN 10204 / 3.1Bc

0 notes

Text

Stainless Steel Blind Flanges Exporters in India

ANSI B 16.5, ASME B 16.47 Stainless Steel Blind Flange, of ASTM A182 Stainless Steel 347/347H Blind Flanges, Exporter of Stainless Steel 304/304L Raised Face Blind Flanges, MSS SP44 Stainless Steel BLRF Flanges Stockist.

of Stainless Steel 304/304L Blind Flange, Stainless Steel 310/310S Blind Flange Supplier, Stainless Steel 317/317L Blind Flanges Exporter, Stainless Steel 316/316H Blind Pipe Flanges in India.

B16.5 ASTM A182 Blind Flange, Fusion Bonded Epoxy Coating, EN 1092-2 PN16 Blind Flange, ASME B16.5 Dual Stainless Steel Blind Flange, ANSI B16.5 Class 150 Flat Face Blind Flange, Stainless Steel Reducing Blind Flange Stockiest.

A Blind Flange is a plate for covering or closing the end of a pipe. A flange joint is a connection of pipes, where the connecting pieces have flanges by which the parts are bolted together.

Stainless Steel Blind Flanges are manufactured without a bore and used to blank off the ends of piping, Valves and pressure vessel openings. From the standpoint of internal pressure and bolt loading, blind flanges, particularly in the larger sizes, are the most highly stressed flange types. A Blind flange is round plate which has all of the relevant boltholes but no center hole, and because of this feature this flange is used to close off the ends of a piping systems and pressure vessel openings. It also permits easy access to the interior of a line or vessel once it has been sealed and must be reopened.

However, most of these stresses are bending types near the center, and since there is no standard inside diameter, these flanges are suitable for higher pressure temperature applications.

Stainless Steel Blind Flanges are used for testing the flow of gas or liquid through a pipeline or vessel. It helps to close the end of piping systems or vessel openings. It allows easy access to the pipeline when there is a requirement to work done inside the line. They are used in high pressure applications available in all grades, materials, size and specifications. Blind pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for blind pipe flanges, the standard height is 1/16" for blind pipe flanges under 400 ( 2.4360)#. For blind pipe flanges of 400 ( 2.4360)# and up, the standard blind pipe flange raised face height is 1/4".

Standards Specification:

Size : 1/2" to 48"

Specifications : ASTM A182

Rating: 150#, 300#, 600 (2.4640)#, 900#, 1500#, 2500#

For more details :

Website - http://kobsindia.in/

Phone No. - 9819523999

Email - [email protected]

#Stainless Steel Blind Flanges in India#Stainless Steel Blind Flanges Manufacturers in India#Stainless Steel Blind Flanges Suppliers in India#Stainless Steel Blind Flanges Exporters in India#Stainless Steel Blind Flanges Stockists in India.

0 notes

Text

Stainless Steel 347, 347H Flanges

0 notes

Text

What are prefabricated piping spools - MetalforgeIndia

What are prefabricated piping spools?

When it comes to the oil and gas industry, piping spools play a crucial role in the transportation of fluids and gasses. These components are used to connect pipes together, allowing for the safe and efficient transfer of materials. At Metal Forge India, we are the leading manufacturers, suppliers, and exporters of piping spools in India.

In this blog post, we'll be discussing everything you need to know about prefabricated piping spools, including their benefits, applications, and how to choose the right supplier.

Prefabricated piping spools are prefabricated sections of pipe that come with flanges, fittings, and valves. These sections are custom-designed and manufactured off-site to exact specifications. Once on-site, these sections can be easily connected together to form the complete pipeline. Piping spools are designed to make the installation process faster and more efficient.

Types of Piping Spools

There are several types of piping spools available, including:

Welded Piping Spools: These spools are fabricated by welding the pipes together. They are ideal for applications where high pressure and temperature are involved.

Threaded Piping Spools: In these spools, the pipes are threaded together. They are suitable for low-pressure applications.

Grooved Piping Spools: Grooved spools have grooves on the ends of the pipes, which are connected using couplings. They are ideal for applications where quick installation is required.

Flanged Piping Spools: Flanged spools have flanges on the ends of the pipes, which are bolted together. They are ideal for applications where frequent disassembly is required.

Benefits of Using Prefabricated Piping Spools

Prefabricated piping spools have become increasingly popular in recent years due to the many benefits they offer. Some of these benefits include:

Time and cost-saving benefits: Prefabricated spools are manufactured off-site, which reduces the time and cost involved in on-site fabrication and assembly.

Improved quality control: Prefabricated spools are manufactured under controlled conditions, ensuring consistent quality and reducing the risk of errors and defects.

Increased efficiency: Prefabricated spools are designed and fabricated to exact specifications, which ensures a high level of accuracy and reduces the need for on-site adjustments.

Reducing the risk of on-site errors: Prefabricated spools are delivered to the site ready for installation, reducing the risk of errors and delays caused by on-site fabrication and assembly.

Why Choose Metal Forge India for Your Piping Spools Needs

If you're looking for a reliable and high-quality piping spools supplier, Metal Forge India is the top choice. As one of the top pipes spools manufacturers, Metal Forge India offers a wide range of options, including Inconel Pipe Spools.

Some of the reasons to choose Metal Forge India:

Quality materials and fabrication processes: We use only the highest quality materials and follow strict fabrication processes to ensure consistent quality and performance.

Wide range of pipe spool options: we do also offer a wide range of options to choose from, including different types of spools, sizes, and materials.

Pipe Spools are available in various materials and grades including;

Materials

Grade

Stainless Steel

ASTM A403 WP Gr. 304, 304L, 304H, 309, 310, 316, 316L, 316Ti, 317L, 321, 347, 347H, 904L

Carbon Steel

ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70

Low-Temperature Carbon Steel

ASTM A420 WPL3, A420 WPL 6

Alloy Steel

ASTM / ASME A / SA 234 Gr. WP1, WP5, WP9, WP11, WP12, WP22, WP 91

Duplex Steel

ASTM A815, ASME SA 815 UNS S31803, UNS S32205 (Dual Certified)

The Process of Manufacturing Prefabricated Piping Spools

The process of manufacturing prefabricated piping spools typically involves four stages:

Design and Engineering: The design and engineering stage involves creating detailed drawings and specifications for the spools.

Material Selection: The appropriate materials are selected based on the design and the application requirements.

Fabrication and Assembly: The pipes are cut, bent, and welded together to create the spools.

Quality Control: The finished spools are inspected and tested to ensure they meet the required specifications and standards.

Pipe Spools Size Ranges Available

Construction

Grade

Size Range

Min Thickness

(MM)

Max Thickness (MM)

Seamless Fabricated

CS

0.5” to 30”

10s/3 mm

XXS/85 mm

Seamless Fabricated

AS

0.5” to 30”

10s/3 mm

XXS/85 mm

Seamless Fabricated

SS

0.5” to 24”

10s/3 mm

XXS/70 mm

Welded Fabricated

CS

0.5” to 96”

10s/8 mm

XXS/85 mm

Welded Fabricated

AS

0.5” to 48”

10s/8 mm

XXS/85 mm

Welded Fabricated

SS

0.5” to 74”

10s/6 mm

XXS/70 mm

Applications of Prefabricated Pipe Spools

Prefabricated pipe spools are widely used in various industries, including

Refineries

Off-Shore Oil Drilling Companies

Pulp & Paper Industry

Pharmaceutical Equipment

Power Generation

Sea Water Equipment

Speciality Chemical

Gas Processing

Heat Exchangers

Petrochemicals

Condensers and so on.

Choosing the Right Supplier for Your Piping Spools

When choosing a supplier for your piping spools, it's important to consider the following factors:

Experience and expertise: Look for a supplier with extensive experience and expertise in manufacturing piping spools.

Quality control processes: Choose a supplier who follows strict quality control processes to ensure consistent quality and performance.

Range of options: Look for a supplier who offers a wide range of options to choose from, including different types of spools, sizes, and materials.

Customer service: Choose a supplier who provides excellent customer service and support throughout the entire process, from design to installation.

Conclusion

Prefabricated piping spools are an essential component in various industries, offering numerous benefits over traditional on-site fabrication and assembly. When choosing a supplier for your piping spools needs, it's important to consider factors such as experience, quality control processes, range of options, and customer service. With Metal Forge India as your supplier, you can be assured of high-quality products, excellent service, and a wide range of options to choose from.

As we specialize in manufacturing piping spools in a wide range of materials, including stainless steel, carbon steel, Inconel, and other alloys. Our state-of-the-art manufacturing facility is equipped with the latest technology and equipment, allowing us to produce piping spools that meet the highest standards of quality and performance.

Explore the High-Quality Pipe Spools & material ranges that will fulfill all your upcoming project requirements!

0 notes

Text

What are Flanges and their types?

Flanges are an essential component of any piping system, as they provide a secure and leak-free connection between two pipes or valves. As the leading Flanges manufacturers, suppliers, and exporters in India, Bullion Pipes & Tubes LLP understands the importance of choosing the right type of flange for your application.

In this blog post, we will cover everything you need to know about flanges, including their types, materials, and applications.

Before we dive into the details, let's start with the basics!

Introduction

Flanges are mechanical connectors used to join two pipes or valves. They are usually made of steel, and their main purpose is to provide a tight and leak-free seal between the two parts. Flanges come in various types and sizes, and choosing the right type of flange is essential for the safety and efficiency of your piping system.

Types of Flanges?

Flanges come in several types, including weld neck, slip-on, socket weld, lap joint, threaded, and blind flanges. Each type has its unique characteristics and applications, and selecting the right one will depend on several factors, such as pressure ratings, temperature ratings, size, material compatibility, and cost.

● Weld Neck Flanges

Weld neck flanges are the most common type of flange, known for their high durability and strength. They are welded to the pipe or valve, making them ideal for high-pressure and high-temperature applications.

● Slip-On Flanges

Slip-on flanges are easy to install and remove, making them ideal for applications that require frequent maintenance. They slide over the pipe or valve and are then welded or bolted in place.

● Socket Weld Flanges

Socket weld flanges are similar to slip-on flanges, but they are welded only on the outer side of the flange, leaving the inner side free of welding marks. They are ideal for smaller-sized pipes and low-pressure applications.

● Lap Joint Flanges

Lap joint flanges are used when a piping system requires dismantling frequently. They are also ideal for applications that require easy access to the pipe or valve.

● Threaded Flanges

Threaded flanges are designed to be screwed onto the pipe or valve, making them ideal for applications that require easy installation and removal. They are commonly used in low-pressure applications.

● Blind Flanges

Blind flanges are used to seal the end of a pipe or valve. They are commonly used for pressure testing and maintenance purposes.

Materials & Grades Available In Flanges with Bullion Pipes & Tubes LLP

Flanges can be made of various materials & Grades, such as,

●

Stainless Steel - 904L Flanges, 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347H, 446 Flanges

● Hastelloy Flanges - C22, B2 Flanges, C276 Flanges

● Carbon Steel Flanges - ASTM A350 15LF1, LF2 CL1/CL2, LF3 CL1/CL2 Carbon Steel Flanges

● Nickel Alloy - 200/201

● Duplex Steel Flanges - Duplex UNS S32205/31803 Flanges

● Alloy Steel Flanges - P5, P9, P11, P12, P22, P91 Flanges

● Super Duplex Steel - UNS S32750/S32760 Flanges

● Titanium Alloys - Gr 2 Flanges, Gr 5 Flanges, Gr 7 Flanges

● Aluminium Flanges - 5052 Reducing Flanges, 5082 Flanges, 5082 Flanges, 6063 SORF Flanges, 6082 Blind Flanges, 2024 Aluminum Weld Neck Flanges, and 5052 Threaded Flanges.

● Tantalum Flanges - ASTM B521 Tantalum Flanges, Spectacle Blind Flanges, Orifice Flange, Ta-10W Flanges, Tantalum UNS R05200 Flanges, ASTM B365 Ta2.5W Flanges

● Monel Flanges - Monel K500 Flanges, Monel 400 Flanges

● Alloy 20 Flanges - Alloy 20 RTJ Flange, Alloy 20 WNRF Flanges, Alloy UNS N08020 Pipe Flanges, Alloy 20 Weld Neck Flange, Alloy 20 Nipo Flanges, ASTM B462 Alloy Threaded Flanges, Alloy 20 Spectacle Blind Flanges, Alloy 20 Industrial Flanges, and UNS N08020 Alloy 20 Forged Flanges

● SMO 254 Flanges

● Inconel Flanges - Inconel 718, 600, 601 and 625 Flanges

● Incoloy Flanges - 825, 800/800H/800HT Flanges

Choosing the right material for your flange will depend on several factors, such as the application's temperature, pressure, and corrosion resistance requirements.

Factors to Consider When Selecting Flanges

Selecting the right flange for your application can be challenging, as there are several factors to consider, such as pressure ratings, temperature ratings, size, material compatibility, and cost. At Bullion Pipes & Tubes LLP, we can help you choose the right flange for your application, ensuring safety and efficiency.

Flange Standard Ratings

Flanges come in various standard ratings, such as ANSI, API, DIN, and JIS. These ratings determine the flange's pressure-temperature rating and its compatibility with other components in the piping system.

Flange Installation

Proper flange installation is essential for the safety and efficiency of your piping system. It involves several steps, such as preparation of the piping system, installation of the flanges, flange tightening process, flange alignment, and testing and inspection.

Maintenance and Repair of Flanges

Maintaining and repairing flanges is critical for the longevity and safety of your piping system. Regular inspections, leak checks, and maintenance can help detect any potential issues before they become a more significant problem.

Applications of Flanges

Flanges have a wide range of applications in various industries, including:

● Oil and Gas Industry

● Petrochemical Industry

● Chemical Industry

● Power Generation Industry

● Water Treatment Industry

They are used in various applications, including HVAC systems, plumbing, and firefighting systems.

Why Choose Bullion Pipes & Tubes LLP for Flanges?

As the leading Flanges manufacturers, suppliers, and exporters in India, Bullion Pipes & Tubes LLP offers a wide range of flanges made from high-quality materials. We provide customized solutions to meet our customers' specific needs, and our flanges are available in various sizes, ratings, and materials.

We have been providing high-quality flanges to various countries, such as Ukraine, Australia, Syria, Iraq, Iran, Kazakhstan, Russia, Brazil, Armenia, Azerbaijan, Egypt, South Africa, Qatar, Turkey, Oman, Bahrain, and Germany, and our products are known for their durability, reliability, and safety.

Conclusion

Flanges are a critical component of any piping system, and selecting the right type of flange for your application is essential for safety and efficiency. Choosing a reliable and trustworthy supplier like Bullion Pipes & Tubes LLP can ensure that you get high-quality flanges that meet your specific requirements.

0 notes

Text

Nipo Flanges

Class 300 Nipo Flanges, Carb

on Steel Nipo Flange, Nickel Alloy Nipo Flanges, ASME B16.5 Raised Face Nipo Flange, ANSI B16.5 Nipo Flanges, Best Deals on Raised Face Nipo Flanges, ASME / ANSI B16.5 Nipo Flanges, Stainless Steel Nipo Flange dealer in India.

NIPO FLANGES MATERIAL & GRADES

Stainless Steel Nipo FlangesASTM A182 F 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904LCarbon Steel Nipo FlangesASTM A105, ASTM A694 Gr. F42, 46, 52, 56, 60, 65, 70Alloy Steel Nipo FlangesASTM A182, F1, F5, F9, F11, F22, F91Duplex Steel Nipo FlangesASTM A182, F44, F45, F51, F53, F55, F60, F61Super Duplex Nipo FlangesASTM A182, F44, F45, F51, F53, F55, F60, F61Low Temperature Carbon Steel Nipo FlangesASTM A350, LF2, LF3

ASME B16.5 NIPO FLANGES SPECIFICATION

BS

BS4504 , BS4504, BS1560, BS10

FLANGE FACE TYPE

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

2 notes

·

View notes

Text

Supplier of Stainless Steel Square Bar in Gujarat

Arisa Impex is a Supplier of a Stainless Steel Square Bar in Gujarat.

Our Manufacturer Unit is in Ahmedabad, Gujarat, India.

Arisa Impex is a Manufacturer, Exporter, and Supplier of Stainless Steel Products, including Stainless Steel Round Bars, Wires, Rods, Sheets, Coils, Pipes, Flat Bars, Square Bars, Hexagonal Bars, Angles, Flanges, and Alloy Steel.

We are selling high-grade quality series such as 200, 300, and 400.

Our stainless steel square bars are available in various grades and sizes to accommodate different specifications and requirements.

Manufactured using advanced techniques and quality raw materials, our products ensure superior performance and reliability.

Why Choose Us?

Experience and Expertise: With years of experience in manufacturing stainless steel products, we have honed our skills to deliver exceptional quality.

Customer-Centric Approach: We prioritize our customers’ needs and work closely with them to provide tailored solutions.

Timely Delivery: Our efficient production process ensures that we meet deadlines without compromising quality.

Competitive Pricing: We offer high-quality stainless steel square bars at competitive prices, providing excellent value.

Specification:

Stainless Steel Square Bar Grades: 202, 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L, ASTM A276, ASTM A484

Size: 3mm to 800mm

Length: Long Bars: 15-20 Random Lengths

Tolerances: H8, H13, H11, H10, H9, K9, H12, K11, K12, K10

Length: 12 Random Lengths

Long Bars: 15-20 Random Lengths

Arisa Impex is a Supplier of Stainless Steel Square Bar in Gujarat including locations like Ahmedabad, Amreli, Bharuch, Bhavnagar, Bhuj, Dwarka, Gandhinagar, Godhra, Jamnagar, Junagadh, Kandla,

Khambhat, Kheda, Mahesana, Morbi, Nadiad, Navsari, Okha, Palanpur, Patan, Porbandar, Rajkot,

Surat, Surendranagar, Valsad, Veraval, and more.

For more information about our product catalog, please feel free to reach out to us through the provided contact details.

View Product: Click Here

Read the full article

0 notes

Text

Stainless Steel 347/347H Flanges Exporters in India

INTRODUCTION

Universe Metal & Alloys, a distinguished name in the realm of industrial solutions, presents an exemplary offering: Stainless Steel 347/347H Flanges. With a commitment to excellence and a focus on meeting diverse industrial needs, we stand as premier manufacturers, suppliers, stockists, and exporters of these flanges worldwide.

DESCRIPTION

Stainless Steel 347/347H Flanges, a testament to meticulous craftsmanship and superior quality, are crafted with precision to meet stringent industry standards. These flanges boast a composition stabilized by columbium and tantalum, setting them apart in terms of performance and durability. Their higher affinity for carbon over chromium makes them ideal for various industrial applications, ensuring unparalleled resilience and longevity.

BENEFITS

The inherent properties of Stainless Steel 347/347H Flanges make them highly desirable in demanding environments. Their superior resistance to corrosion and exceptional creep resistance make them excel in applications requiring sustained exposure to elevated temperatures, ranging from 800-1650°F. Additionally, their robust mechanical properties ensure reliable performance in critical settings such as aeroplane exhaust stacks, expansion joints, annealing boxes, and collector rings.

SPECIFICATION

Stainless Steel Flanges Specification: ASTM A182 / ASME SA182

Dimension Standard: ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc.

Size Range: 1/2" (15 NB) to 48" (1200NB)

Class / Pressure: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64, etc.

Flange Face Type: Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

DIN Flanges: DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673.

JIS Flanges: JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K

BS Flanges: BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

PRODUCT OVERVIEW

Universe Metal & Alloys offers an extensive range of Stainless Steel 347/347H Flanges, including forged flanges, socket weld flanges, welding neck flanges, long weld neck flanges, and reduced flanges, among others. Whether it's a flat face, ring type, or raised face flange, we ensure precision engineering and superior craftsmanship in every product. Our commitment to quality assurance is unwavering, as evidenced by the rigorous testing processes each product undergoes.

CONCLUSION

In conclusion, Stainless Steel 347/347H Flanges from Universe Metal & Alloys epitomize excellence in industrial solutions. With a steadfast focus on quality, reliability, and customer-centricity, we provide unmatched products and services to meet the diverse needs of industries worldwide. Choose Universe Metal & Alloys for impeccable quality, reliability, and service in Stainless Steel 347/347H Flanges. For inquiries and orders, contact us at [email protected] or call us at +91-22-66363360 / 66393788.

0 notes

Text

Blind Flanges Exporters in India

These level face steel blind flanges are utilized to clear off pipelines, valves and pumps, it can likewise be utilized as a review spread. Blind flanges is some of the time alluded to as a blanking flanges. Experienced experts are engaged with us who fabricate these flanges with great accuracy. We are recognized blind flanges manufacturer.

Standards:

ANSI B 16.5 Class 150

ANSI B 16.5 Class 300

ANSI B 16.5 Class 600

ANSI B 16.5 Class 900

ANSI B 16.5 Class 1500

ANSI B 16.5 Class 2500

Stainless Steel :

ASTM A 182, A 240

Grade:

F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L, Duplex stainless steel UNS S31803, 2205, Super Duplex stainless steel UNS S32750

Carbon Steel:

ASTM A 105, ASTM A 181

Alloy Steel:

ASTM A 182, GR F1, F11, F22, F5, F9, F91

Nickel Alloys:

Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy C22,C276

Copper Alloys:

Copper, Brass & Gunmetal

Size:

1/8" NB TO 48"NB.

Class:

150#, 300#,400 #,600#,900#, 1500# & 2500 #.

ANSI:

ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

DIN:

DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673

B.S:

BS4504 , BS4504, BS1560, BS10

0 notes

Text

We Royal Steel India, are one of the leading Manufacturer, Exporter & Supplier of Welding Flanges.

Our offered Welding Flanges are widely applicable in petrochemical and heavy engineering industries. These flanges are designed using high grade material sourced from trusted dealers across the country under the supervision of the team of experts and are highly acclaimed by the clients for its durability and long life. The valued clients are served at industry leading prices.

Grade

F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L, Duplex stainless steel UNS S31803, 2205, Super Duplex stainless steel UNS S32750

Features

High strength

Durable

Dimensional accuracy

Corrosion resistance

Excellent finish

Materials of Construction

Mild Steel

Carboon Steel

Stainless Steel

0 notes

Text

Top 5 Grades of Round Bars

Stainless Steel Round Bar Manufacturer, Supplier, & Exporter in India – Petromet Flange Inc

Stainless Steel Round Bar

Petromet Flange Inc is one of the top most reliable sources of Stainless Steel Round Bar Manufacturers in India. We have been a prominent part of the growth of the Indian market and quality exports. Our company Manufactures Stainless Steel Industrial Round Bar in different shapes, sizes and with different specifications as per the customers’ requirements. Stainless Steel Forged Round Bar is designed and developed in accordance with international quality standards. We have ready stock available for shipment to most parts of the country. These Stainless Steel Round Bar are manufactured from high-grade corrosion-resistant metal alloy.

Stainless Steel Round Bar Specification

Dimensions: EN, DIN, JIS, ASTM, BS, ASME, AISI

Standard : ASTM A276, ASTM A479

Material Grade: 304, 304L, 304H, 308, (308)/F45, 309, 309S, 310S, 310H, 312, 314, 316, 316L 316H, 316Ti, 317L, 321, 347, 347H,904L

Stainless Steel Round Bar: Outside Diameter in the range of 4mm to 500mm

Stainless Steel Bright Bar: Outside Diameter in the range of 4mm to 100mm

Stainless Steel Hex Bar: 18mm – 57mm (11/16″ to 2-3/4″)

Stainless Steel Square Bar: 18mm – 47mm (11/16″ to 1-3/4″)

Stainless Steel Flats: 1/2” to 10” in a thickness range of 2 mm to 150mm, Custom Size Stainless Steel Flats available

Length: 1 to 6 Meters, Custom Cut Lengths

Form: Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Finish: Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

2. Carbon Steel Round Bar Manufacturer in India

Petromet Flange Inc is one of the top most reliable sources of Carbon Steel Round Bars Manufacturers in India. We have been a prominent part of the growth of the Indian market and quality exports. Our company Manufactures Carbon Steel Black Bars in different shapes, sizes and with different specifications as per the customers’ requirements. Carbon Steel Industrial Round Bars are designed and developed in accordance with international quality standards. We have ready stock available for shipment to most parts of the country. These Carbon Steel Round Bars are manufactured from high-grade corrosion-resistant metal alloy.

3. Alloy Steel Round Bars Manufacturer, Supplier, & Exporter in India – Petromet Flange Inc

Petromet Flange Inc is one of the top most reliable sources of Alloy Steel Round Bars Manufacturers in India. We have been a prominent part of the growth of the Indian market and quality exports. Our company Manufactures Alloy Steel Bright Bar in different shapes, sizes and with different specifications as per the customers’ requirements. Alloy Steel Forged Bars are designed and developed in accordance with international quality standards. We have ready stock available for shipment to most parts of the country. These Alloy Steel Round Bars are manufactured from high-grade corrosion-resistant metal alloy.

4. Copper Round Bar Manufacturer in India

Copper Round Bar Manufacturer, Supplier, & Stockist in India – Petromet Flange Inc

Petromet Flange Inc is one of the top most reliable sources of Stainless Steel Copper Round Bar Manufacturers, in India. We have been a prominent part of the growth of the Indian market and quality exports. Our company Manufactures Copper Round Bar in different shapes, sizes, and specifications as per the customers’ requirements. ASTM B62 Copper Round Bar is designed and developed under international quality standards. We have ready stock available for shipment to most parts of the country. These Stainless Steel Copper Round bars are manufactured from high-grade corrosion-resistant metal alloy.

5. Copper Alloy Round Bar Manufacturer in India

Petromet Flange Inc is one of the top most reliable sources of Copper Alloy Round Bars Manufacturers, in India. We have been a prominent part of the growth of the Indian market and quality exports. Our company Manufactures Copper Alloy Round Bar in different shapes, sizes, and specifications as per the customers’ requirements. ASTM B133 Copper Alloy Round Bars are designed and developed under international quality standards. We have ready stock available for shipment to most parts of the country. These Copper Alloy Round Bars are manufactured from high-grade corrosion-resistant metal alloy.

Petromet Flange INC is reputed and well known across the globe for its reliability and quality. The ASTM B124 Copper Alloy Round Bars are well known for their dimensional accuracy and finest finish, and resistance against corrosion. Petromet Flange INC is recommended as Copper Alloy Round Bar applications manufacturer, Copper Alloy Round Bar exporter, copper alloy round bar manufacturer, and many more. We are also the dealers of Duplex Steel Round Bars, Leaded Bronze Round Bars & so on.

We also Provide Round Bar in UAE

Stainless Steel Round Bar

Carbon Steel Round Bar

Alloy Steel Round Bar

Copper Round Bar

Copper Alloy Round Bar

For more details Visit - Round Bars Manufacturer in India

0 notes

Photo

Galvanised Pipe Fitting Manufacturers, Galvanised Pipe Fitting Exporters, Galvanised Pipe Fitting Suppliers, Galvanised Pipe Fitting Importers.

Galvanised Pipe Fitting Manufacturers in India, Galvanised Pipe Fitting Exporters in India, Galvanised Pipe Fitting Suppliers in India, Galvanised Pipe Fitting Importers in India.

Galvanised Pipe Fitting Manufacturers in Mumbai, Galvanised Pipe Fitting Exporters in Mumbai, Galvanised Pipe Fitting Suppliers in Mumbai, Galvanised Pipe Fitting Importers in Mumbai.

A GI pipe fitting is utilized at the places where there is overwhelming presentation to dangerous powers of nature, for example, warmth, wind and water. These channels are covered with a uniform layer of zinc so as to keep the climate and common components from doing harm to the pipe. This procedure is called galvanization. GI pipe fittings are accessible in many shapes and sizes as they are consistently utilized and are sought after because of their quality. The GI channels are hued to evade disarray. Accessible in distance across of 8mm to even 100mm, these funnels are utilized all around. Consequently, the nearness of GI pipe fitting is basic. An appropriate fitting will guarantee that there is no loss of liquid contained inside.

PRODUCT DETAILS:

Size

1/2

Connection

Welded, Male, Female, Flange

Application

Structure Pipe, Gas Pipe, Hydraulic Pipe, Chemical Fertilizer Pipe

Surface

Hot Dipped Galvanized, Electro Galvanized, Insulated

These are three main types of GI pipes which include:

· Light - Class A is marked yellow color to recognize it.

· Medium - Class B is marked blue color to recognize it.

· Heavy - Class C is marked red color to recognize it.

The grading is done according to the thickness of the fittings.

MATERIALS

Stainless Steel Galvanized Pipe Fittings

· SS 304 Galvanized Pipe Fittings

· SS 304L Galvanized Pipe Fittings

· SS 304H Galvanized Pipe Fittings

· SS 316 Galvanized Pipe Fittings

· SS 316L Galvanized Pipe Fittings

· SS 316Ti Galvanized Pipe Fittings

· SS 310 Galvanized Pipe Fittings

· SS 310S Galvanized Pipe Fittings

· SS 321 Galvanized Pipe Fittings

· SS 321H Galvanized Pipe Fittings

· SS 317 Galvanized Pipe Fittings

· SS 347 Galvanized Pipe Fittings

· SS 347H Galvanized Pipe Fittings

· Copper Alloys Galvanized Pipe Fittings

· Aluminium Galvanized Pipe Fittings

· Copper Galvanized Pipe Fittings

· Brass Galvanized Pipe Fittings

· Alloy Steel Galvanized Pipe Fittings

· Nickel Alloys Galvanized Pipe Fittings

· Nickel 200 Galvanized Pipe Fittings

· Nickel 201 Galvanized Pipe Fittings

· Monel 400 Galvanized Pipe Fittings

· Monel 500 Galvanized Pipe Fittings

· Inconel 800 Galvanized Pipe Fittings

· Inconel 825 Galvanized Pipe Fittings

· Inconel 600 Galvanized Pipe Fittings

· Inconel 625 Galvanized Pipe Fittings

· Inconel 601 Galvanized Pipe Fittings

· Carbon Steel ASTM A 234 Galvanized Pipe Fittings

· Hastelloy C 276 Galvanized Pipe Fittings

· Alloy 20 Galvanized Pipe Fittings

· Titanium Galvanized Pipe Fittings

· Duplex Steel 2205 Galvanized Pipe Fittings

· Gunmetal Galvanized Pipe Fittings

OUR SUMMARY:

Reviewer

Dipti Metal Industries.

Review Date

6-06-2017

Reviewed Product

Galvanised Pipe Fitting

Author Rating

Domestic Area

Mumbai

Ahmedabad

Bhopal

Bikaner

Pune

Delhi

Chennai

Visakhapatnam

Mangalore

Nagpur

Bangalore

Kolkata

Siliguri

Assam

Indore

Hyderabad

Surat

Nashik

Cochin

Thane

Faridabad

Rajkot

Aurangabad

Bhavnagar

Ranchi

Coimbatore

Mysore

Salem

Tirupur

Bikaner

Raipur

Bhubaneswar

Bhilai

Ankleshwar

Bhiwandi

Our Export

Eastern Europe

Asia

North America

Western Europe

Mid East/Africa

Australasia

Central/South

UAE

America

Portugal

Spain

Indonesia

Italy

Angola

Poland

Brazil

Sri Lanka

Russia

Chile

Singapore

Oman

Venezuela

Costa Rica

USA

Qatar

Thailand

Canada

Saudi Arabia

Bahrain

Egypt

Malaysia

Turkey

Mexico

Chine

Peru

United States

Nigeria

Jordan

Kuwait

Dubai

Bangkok

Iran

Germany

UK

New Zealand

Vietnam

South Africa

Mexico

Kazakhstan

0 notes