#Solidworks Electrical

Explore tagged Tumblr posts

Text

Discover how SOLIDWORKS Electrical revolutionizes electrical system design with real-time collaboration, automated tools, and intelligent synchronization between 2D schematics and 3D models. Minimize errors, shorten design cycles, and reduce costs while optimizing wire routing and BOM generation. Whether for manufacturing or embedded systems, SOLIDWORKS Electrical provides the tools needed to enhance accuracy and efficiency. Learn more about how to improve your electrical design process with SOLIDWORKS Electrical at MSD Facilitators.

0 notes

Text

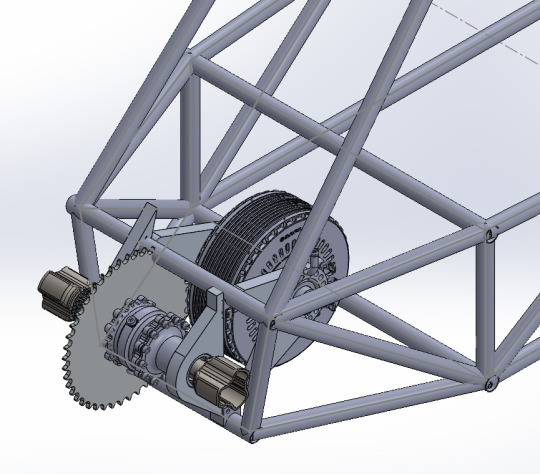

Transmission Progress 2.0

Keeping this post brief-

What I accomplished on the podcast last night:

created weld tabs that can be shared by the differential and motor mounts

updated dimensions on the rotor and stator motor mounts

researched the basics of dimensioning spline connectors

modeled a very rough small sprocket with internal splines for mounting

decreased number of teeth on small sprocket to 11 which will help decrease large sprocket diameter while keeping a high gear ratio

What's on the to-do list:

move the transmission assembly into the chassis with curved rear bars

model a large sprocket with 39 teeth to see how outer diameter fits in chassis

further investigate weld tab designs to save weight and allow for dual motor/differential mounting

estimate overall transmission system mass based on current CAD assembly

#solidworks#mechanical engineering#formula 1#formula e#formula one#cars#engineering#differential#motor#electric cars#electric vehicles

0 notes

Text

Engineering Empowerment: Testimonials Illustrating SolidWorksAssignmentHelp.com's Role

Who Can Do My Solidworks Electrical Assignment? This question echoed in my mind as I found myself grappling with complex electrical engineering concepts in my academic journey. Faced with a daunting SolidWorks Electrical assignment, I turned to SolidWorksAssignmentHelp.com for assistance. Little did I know that this decision would not only alleviate my academic stress but also pave the way for a transformative learning experience.

As a student pursuing electrical engineering, I understand the intricate challenges that come with mastering SolidWorks Electrical. From schematic design to electrical system documentation, every aspect demands meticulous attention to detail. However, amidst the myriad of assignments and projects, I found myself struggling to grasp certain concepts and execute them effectively.

That's when I stumbled upon SolidWorksAssignmentHelp.com, a beacon of hope in my academic journey. From the moment I reached out to them, I was greeted with professionalism and expertise. Their team of experienced engineers and academic experts not only possessed in-depth knowledge of SolidWorks Electrical but also understood the nuances of academic requirements.

My first interaction with SolidWorksAssignmentHelp.com was enlightening. They patiently listened to my concerns and tailored a customized solution to address my specific needs. Whether it was clarifying doubts, guiding me through complex topics, or providing hands-on assistance with my assignment, their support was invaluable.

One aspect that truly stood out was their commitment to excellence. Unlike generic assignment help services, SolidWorksAssignmentHelp.com took the time to delve deep into the intricacies of SolidWorks Electrical. Their solutions were not just about meeting deadlines but about fostering a deeper understanding of the subject matter.

With their assistance, I was able to navigate through challenging topics with ease. Whether it was creating schematic diagrams, generating reports, or simulating electrical systems, SolidWorksAssignmentHelp.com equipped me with the tools and knowledge needed to excel in my assignments.

Moreover, their approach was not just about providing quick fixes but about nurturing long-term growth. Through interactive sessions and comprehensive explanations, they empowered me to become a better engineer. Concepts that once seemed daunting now felt within reach, thanks to their guidance and support.

One of the most significant benefits of working with SolidWorksAssignmentHelp.com was the flexibility they offered. As a student juggling multiple responsibilities, having the option to schedule sessions according to my convenience was invaluable. Whether it was early morning brainstorming sessions or late-night assignment revisions, they were always there to lend a helping hand.

SolidWorksAssignmentHelp.com not only helped me achieve academic success but also instilled in me a newfound confidence in my abilities as an engineer. With their guidance, I not only completed my SolidWorks Electrical assignment but also gained invaluable insights that will stay with me throughout my career.

Conclusion: In conclusion, my journey with SolidWorksAssignmentHelp.com has been nothing short of transformative. From struggling with my SolidWorks Electrical assignment to emerging with newfound confidence and competence, their role in my academic journey cannot be overstated. Through their expertise, dedication, and unwavering support, SolidWorksAssignmentHelp.com has empowered me to overcome challenges and embrace the opportunities that lie ahead in my engineering career. For anyone wondering, "Who Can Do My Solidworks Electrical Assignment?" - SolidWorksAssignmentHelp.com is the answer.

0 notes

Text

They wanna start modeling wire harnesses. This is do-able but implementing this would be painful for everyone. But I've learned my lesson. Standing up and saying "Here is why this is a bad idea." just gets me volunteered bc it demonstrates that I know too much.

This time around? I have no fuckin' clue what all this is about. Wires? I've never seen a wire in my goddamn life.

#ooc#I'm the only guy here who can use the solidworks electrical routing addon but it's best nobody knows that

1 note

·

View note

Video

youtube

(via Elonroad: The Future of Electric Vehicle Charging)

Electric Road System: A Revolution in Transportation

1 note

·

View note

Text

sorry for not posting Oops

i may have gotten attached to the DJMM bot and in a glorious derailing of the original intent to pull a Clavier and make him have an existential crisis about death, i made the swagmaster, a totally tubular dude whose whole thing is that he travels around the world to compete against presidents in smash bros and a game of their choice. somehow djmm fell for this guy

i may have struck a nerve with him earlier though

other than that there is this!

Comet can control the speaker on his back and is able to produce electricity and while physics may be a problem in letting a lightshow like this being possible, its still Cool as Shit

there's also these that i got to work on as part of a mural. there's a lot of mistakes in the first one but i still Thoroughly Enjoy

what else

.

oh right DJMM solidworks model YAHOO

16 notes

·

View notes

Text

We helping in

1. ICA ,assignment, project,Lab Report

2. Civil Engineering

3. AutoCAD

4.mechanical,Solidworks

5.Solid works

6. Electronic

7.mathematics

8. Electrical

9. Sketchup pro and many more subjects

2 notes

·

View notes

Text

SOLIDWORKS Electrical empowers engineers to seamlessly integrate electrical designs into 3D models, ensuring real-time collaboration and error reduction. With features like automated wire routing, bi-directional updates between 2D and 3D, and extensive symbol libraries, this tool simplifies complex electrical projects. Shorten design cycles, improve accuracy, and reduce costs with the powerful features of SOLIDWORKS Electrical.

Streamline your electrical designs with SOLIDWORKS Electrical from MSD Facilitators.

0 notes

Text

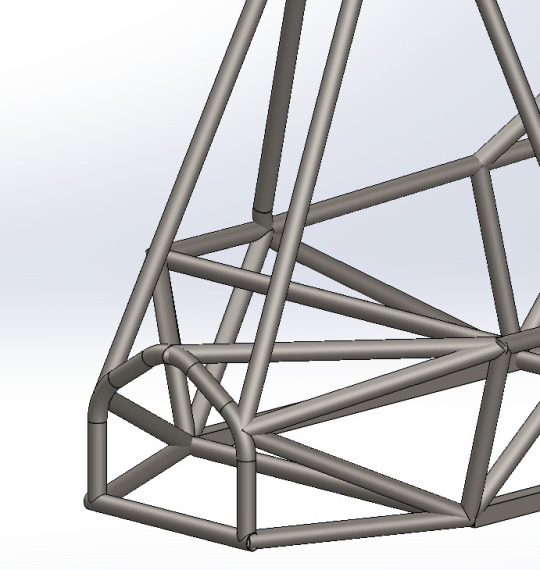

Transmission Packaging

Today I worked on updating our transmission project concepting in SOLIDWORKS. As we are still in the preliminary stages of the design phase, there is emphasis on ensuring that all projects will integrate with one another on the car. This is especially critical for this car design because we are moving the differential to be mounted outside the chassis enclosure in order to reduce chassis weight.

I have been discussing with our chassis lead and head of handling to determine the exact positioning of the differential which drives all the rest of the transmission layout.

Factors that need to be considered:

angle of axles from differential to wheels in vertical plane

angle of axles from differential to wheels from top-down view

clearance between chassis bars for large sprocket and chain

method of mounting differential and motor to chassis

1

When the driver is sitting in the car, the axles should be parallel to the ground to optimize the performance of the tripod bearings on each end of the axles. Since the axles connect the differential to the wheels, the vertical position of the differential is critical.

Our head of handling estimates that the shocks will compress 0.27 inches when the driver is in the car, so I have positioned the differential to be 0.27 inches above the center plane of the wheels.

2

Similarly, when looking at a top-down view of the car, the axles should be as close to horizontal as possible. Again, this is to keep the tripod bearings in an optimal position. In this case, the position of the differential longitudinally within the car is critical.

Currently, I have the differential positioned such that the axles are at a 9 degree angle with respect to horizontal. I would like this angle to stay below 10 degrees for the final design although the position of the differential also depends on the two following points.

3

As mentioned above, we are removing nonessential chassis bars by mounting the differential externally on the rear of the car. This means that the large sprocket (mounted to the differential) will also extend outside the chassis enclosure and require the chain to pass into the chassis where it meets the small sprocket on the motor. So, the vertical distance between the rear-most chassis bars must be tall enough to accommodate the large sprocket and chain moving between.

I am estimating that we need the vertical distance between those bars to be 9-10 inches; however, this creates an added challenge because the suspension project also has specific requirements for these bars. The control arms for suspension must mount to the nodes created by those two bars that the differential also mounts to. Based on suspension geometry, our handing team wants the two bars to be only 6 inches apart.

This integration issue will need further discussion between transmission, suspension, and chassis leads.

4

We will have to determine exactly how the differential and motor mount to the chassis. In the past we made small, steel weld tabs that welded directly to the chassis and then bolted on larger steel mounts to hold the differential and motor. In hopes to save weight we hope to make the large mounts out of aluminum this year. To mount to the chassis we can use steel weld tabs again or drill holes in the chassis bars and mount directly to the chassis.

Our transmission and chassis leads are investigating which of these mounting options is better based on rules compliance and structural integrity.

0 notes

Text

Diesel Engines: Powering the World with Efficiency and Reliability

Established in 1979, Engines, Inc. is a fourth-generation, family-owned business with roots tracing back to 1935 in the John Deere implement sector. Specializing in diesel and spark-ignited power products, we proudly serve the OEM, Marine, Agriculture, and Industrial markets. Our commitment to quality is reflected in our partnerships with top-tier brands such as John Deere, Yanmar, Kohler, and Ford.

Our Facilities

Our main production facility in Jonesboro, Arkansas, spans 117,000 square feet of climate-controlled space dedicated to parts, shipping, receiving, production, and offices. Complementing this is our 54,000-square-foot ei Technology Center, where our engineering team designs, tests, and prototypes engine packages. Additionally, we maintain a 120,000-square-foot warehouse housing our extensive engine inventory.

Our Products

At Engines, Inc., we offer a comprehensive range of products tailored to meet diverse power needs:

Industrial Diesel Engines: We provide engines with varying levels of efficiency, capability, and affordability to suit your specific applications. Engines, Inc.

DriveTrain Components: Our John Deere and Funk™ drivetrain components are designed with a modular approach, ensuring versatility and prompt delivery. Engines, Inc.

Generator Drive Engines: Our engines deliver both prime and standby power, catering to a wide array of critical applications. Engines, Inc.

Marine Engines: We offer marine propulsion systems, generators, and auxiliary engines renowned for their endurance and performance, tailored to fit your operations. Engines, Inc.

Agricultural Power Solutions: Our solutions are designed to keep your agricultural operations running smoothly, even during peak times. Engines, Inc.

Repower Options: Choosing a repower engine is an excellent way to extend the lifespan of your equipment without overextending your budget. Engines, Inc.

Export Solutions: We offer engines compliant with Tier 1, 2, and 3 emissions standards for Marine, Agriculture, Generator, and Industrial industries, providing power solutions beyond U.S. borders. Engines, Inc.

Rental Options: Our rental fleet comprises compact yet powerful units, ready to provide reliable power wherever you need it. Engines, Inc.

Our Services

Customer service is at the core of Engines, Inc. We offer an extensive support system, including a 24-hour support line and a vast global network, to ensure your operations run smoothly.

ei Technologies

Our ei Technology Center is equipped with the latest software and technology, enabling our engineers to customize engines specifically for your operations. Our services include:

Designing & Prototyping: Utilizing Solidworks software, we facilitate rapid and efficient design and inspection of complex packages, reducing costs and enhancing quality. Operating in a 3D design environment allows for better visualization of the end product. Engines, Inc.

Testing & Validation: With three Taylor dynamometers and two load banks, we validate every custom power unit package and generator, accurately testing horsepower from 17 to 1500 and eKW up to 1250. Engines, Inc.

Service & Rebuild Department: Our skilled team services engines from all manufacturers we represent, whether at our location or yours. We offer complete engine rebuilds, overhauls, equipment refurbishment, and maintenance contracts to minimize downtime. Engines, Inc.

Diesel engines have been a cornerstone of industrial and commercial applications for over a century, offering unparalleled efficiency, durability, and power. From powering heavy machinery in construction and agriculture to propelling marine vessels and generating electricity, diesel engines are integral to various sectors. This comprehensive article delves into the intricacies of diesel engines, their applications, advantages, and the innovative solutions provided by industry leaders like Engines, Inc.

Understanding Diesel Engines

A diesel engine is an internal combustion engine in which fuel ignition occurs due to the high temperature of air compressed in the cylinder, a process known as compression ignition. This contrasts with petrol engines, which use spark plugs for ignition. The efficiency of diesel engines stems from their high compression ratios and lean air-fuel mixtures, leading to better fuel economy and torque characteristics.

Key Components and Operation

Cylinder Block and Head: The main structure housing the cylinders where combustion occurs.

Pistons and Crankshaft: Convert the energy from combustion into mechanical motion.

Fuel Injection System: Precisely injects fuel into the combustion chamber at high pressure.

Turbocharger: Many modern diesel engines are equipped with turbochargers to increase air intake, enhancing power and efficiency.

Exhaust Aftertreatment Systems: Components like Diesel Particulate Filters (DPF) and Selective Catalytic Reduction (SCR) systems reduce emissions to meet environmental standards.

Advantages of Diesel Engines

Fuel Efficiency: Diesel engines typically offer higher fuel efficiency compared to petrol engines, making them cost-effective for long-term use.

Durability and Longevity: Built to withstand high compression, diesel engines often have longer lifespans.

High Torque Output: Diesel engines provide substantial torque at low RPMs, ideal for heavy-duty applications.

Safety: Diesel fuel is less flammable than petrol, reducing the risk of fire hazards.

Applications of Diesel Engines

Diesel engines are versatile and find applications across various industries:

Automotive: Used in trucks, buses, and some passenger vehicles for their fuel efficiency and torque.

Industrial Machinery: Powering equipment like excavators, loaders, and cranes.

Agriculture: Driving tractors, harvesters, and irrigation pumps.

Marine: Propelling ships, boats, and submarines.

Power Generation: Serving as generators for electricity in remote locations or as backup power sources.

Engines, Inc.: A Leader in Diesel Engine Solutions

Established in 1979, Engines, Inc. is a fourth-generation, family-owned business with a rich history dating back to 1935 in the John Deere implement sector. Specializing in diesel and spark-ignited power products, Engines, Inc. serves the OEM, Marine, Agriculture, and Industrial markets. Their commitment to quality is reflected in partnerships with top-tier brands such as John Deere, Yanmar, Kohler, and Ford.

Product Offerings

Engines, Inc. provides a comprehensive range of products tailored to meet diverse power needs:

Industrial Diesel Engines: Offering engines with varying levels of efficiency, capability, and affordability to suit specific applications.

DriveTrain Components: John Deere and Funk™ drivetrain components designed with a modular approach, ensuring versatility and prompt delivery.

Generator Drive Engines: Engines that provide prime and standby power for a wide variety of critical applications.

Marine Engines: Marine propulsion systems, generators, and auxiliary engines with unmatched endurance and performance to fit various operations.

Agricultural Power Solutions: Solutions designed to keep agricultural operations running smoothly, even during peak times.

Repower Options: Reliable repower options to extend the lifespan of equipment without overextending budgets.

Export Solutions: Engines compliant with Tier 1, 2, and 3 emissions standards for Marine, Agriculture, Generator, and Industrial industries, providing power solutions beyond U.S. borders.

Rental Options: A rental fleet comprising compact yet powerful units, ready to provide reliable power wherever needed.

Services and Support

Customer service is at the core of Engines, Inc. They offer an extensive support system, including a 24-hour support line and a vast global network, to ensure operations run smoothly.

#diesel engine solutions#diesel engine services in odessa#diesel parts#diesel engine solution#diesel engine#kohler engine#new orleans#baton rouge#san antonio tx#Diesel engine houston TX#Diesel engine dallas TX#Diesel engine odessa TX

0 notes

Text

What is a CAD Workstation?

A CAD workstation is a high-performance computer specifically designed and optimized for running Computer-Aided Design (CAD) software and other resource-intensive applications. These workstations are commonly used by professionals in fields such as engineering, architecture, product design, and 3D modeling, where precision, speed, and reliability are critical.

Key Features of a CAD Workstation

High-Performance Processors (CPUs):

CAD applications rely heavily on single-core performance, so CAD workstations often feature CPUs with high clock speeds.

Multithreaded workflows (e.g., rendering) may require multi-core processors.

Professional Graphics Cards (GPUs):

Workstations are equipped with GPUs optimized for CAD software, such as NVIDIA Quadro or AMD Radeon Pro series, which provide enhanced stability and certified drivers.

Large Memory (RAM):

CAD workstations typically include 16 GB or more of RAM to handle large models and datasets efficiently.

High-Speed Storage:

Solid State Drives (SSDs) are commonly used to reduce loading times and improve overall system performance.

Expandability and Customization:

Workstations allow for additional memory, storage, or expansion cards, making them adaptable to evolving project needs.

Certified Software Compatibility:

CAD workstations are often tested and certified by software vendors (e.g., AutoDesk, SolidWorks) to ensure compatibility and reliability.

Robust Build Quality:

Designed to operate reliably under heavy loads for extended periods, with enhanced cooling systems and durable components.

Why Use a CAD Workstation?

Performance: Superior speed and reliability for rendering, simulation, and modeling.

Stability: Certified hardware and drivers reduce crashes and ensure software runs as intended.

Efficiency: Handles large files and complex operations smoothly, minimizing downtime.

Common Applications for CAD Workstations

Architectural and building design (AutoCAD, Revit)

Mechanical engineering (SolidWorks, CATIA)

Electrical engineering (Altium Designer)

3D modeling and animation (Maya, Blender)

Investing in a CAD workstation ensures that professionals can work efficiently and produce high-quality designs without the limitations of standard consumer-grade computers.

0 notes

Text

learning goals for the year

framework web dev via next.js. I really wanted to learn svelte and sveltekit, but with the release of svelte5 a lot of the prime learning resources are either half-useful or not at all, so I'm going to focus more on next.js. Sessions and auth are finally becoming clearer. I've recently gotten into sanity but would really like a self-hosted solution.

solidworks I need to become more fluent with solidworks' specific CAD features and make the leap to more complicated assemblies. there's a few concepts that trip me up, particularly using extruded geometry as a reference?

3d printing custom designs Kinda goes with the solidworks one. I want to be able to design and print more complicated assemblies. after I figure out why my x1c is having trouble z-homing oh and I want to try 3-d printed silicone molds!

electrical engineering I have a farfetched goal of being able to design PCBs one day, but I need more experience. I have come a long way in the past year. I converted an npn sensor to pnp the other day! Alright that's not super impressive but I'm learning

low-level digital comm this is such a big scary category I should just stick to serial emulation with VISA. It's easy and PCs are cheap (for automation). I would like to try out pyvisa though

guitar I have an electric guitar and amp but I've been severely neglecting them. I've gotten as far as playing the intro to Vinushka poorly! and my strumming is whack, but I just need to practice

#personal#goals#engineering#if you could snort new technologies like coke I would#I kind of already do

0 notes

Text

Automobile Courses in Kerala: Driving Careers Toward Success

The automobile industry is one of the fastest-growing sectors in the world, creating exciting opportunities for individuals with technical skills and passion for innovation. In Kerala, the demand for skilled professionals in automobile engineering, design, and project management has led to the rise of specialized courses that equip students with the knowledge and hands-on experience required for a successful career.

Kerala has become a hub for professional education, offering state-of-the-art training programs to aspiring engineers and designers. Among the premier training institutes, Sree CADD stands out as a leading AutoCAD training center in Trivandrum and Nagercoil. With industry-integrated courses, Sree CADD helps students enhance their careers in Engineering Design, Architecture, Interior Design, and Project Management, offering specialized training in software that is essential for success in these fields.

This blog explores the importance of automobile courses, the skills they provide, and how leading training centers like Sree CADD are shaping the future of engineering and design professionals in Kerala.

Why Choose Automobile Courses in Kerala?

The automobile sector is evolving rapidly, with advancements in electric vehicles (EVs), autonomous technology, and sustainable engineering reshaping the industry. This shift demands professionals who are not only skilled in traditional engineering practices but also adept in modern software tools and design technologies.

Automobile courses in Kerala cater to this growing demand by providing:

Practical Knowledge: Courses integrate hands-on training with real-world applications.

Cutting-Edge Software Training: Programs focus on tools like AutoCAD, CATIA, SolidWorks, and other design software widely used in the industry.

Career Enhancement: Students gain specialized skills that improve their job prospects and enable them to thrive in competitive markets.

Industry-Relevant Curriculum: The courses are designed in collaboration with industry leaders, ensuring students are job-ready.

Whether you aspire to become an automobile designer, mechanical engineer, or project manager, Kerala’s training centers provide you with the skills and certifications to make a mark in the industry.

Sree CADD: Leading the Way in Engineering and Design Courses

When it comes to industry-oriented courses in Kerala, Sree CADD has established itself as a leading AutoCAD training center in Trivandrum and Nagercoil. Known for its commitment to quality education and career enhancement, Sree CADD offers industry-integrated courses that bridge the gap between academic knowledge and real-world application.

What Makes Sree CADD Stand Out?

Comprehensive Curriculum: Sree CADD provides specialized training in software relevant to Engineering Design, Architectural Design, Interior Design, and Project Management. These courses focus on equipping students with hands-on experience in tools like AutoCAD, which is critical for automobile engineering and design projects.

Expert Faculty: The institute boasts experienced instructors who are well-versed in both the software and its applications in the industry. Students benefit from personalized mentorship and practical insights that prepare them for professional challenges.

Industry Integration: Sree CADD ensures its programs are aligned with industry standards, making its students highly employable. The courses emphasize real-world projects, case studies, and simulations to give participants practical exposure.

Modern Training Facilities: With state-of-the-art training labs and access to the latest software, students receive a world-class learning experience. Sree CADD creates an environment that encourages innovation and creativity in design and engineering.

Flexible Learning: The courses are tailored to suit the needs of students, working professionals, and aspiring engineers. Whether you are starting your career or looking to upskill, Sree CADD has the right program for you.

Popular Courses Offered for Automobile Enthusiasts

1. AutoCAD for Engineering Design

AutoCAD is a fundamental tool for engineers, designers, and project managers in the automobile industry. Sree CADD’s AutoCAD course focuses on teaching the essentials of 2D and 3D design, drafting, and modeling. Students learn to create technical drawings, analyze designs, and produce accurate blueprints for manufacturing processes.

2. SolidWorks for Mechanical Design

SolidWorks is widely used in the automobile sector for mechanical design and simulation. The course at Sree CADD covers 3D modeling, product design, assembly techniques, and performance simulations. Students gain hands-on experience in developing automobile components and systems using this powerful software.

3. CATIA for Advanced Product Design

For those aspiring to work on high-end automobile design projects, CATIA training is essential. Sree CADD offers a comprehensive CATIA course that teaches advanced surface modeling, automotive design, and simulation. This program is ideal for students who want to specialize in automotive product development.

4. Project Management with Design Tools

In addition to design courses, Sree CADD offers training in project management tools that integrate with engineering software. Learning project management skills enables participants to manage complex automobile design and production projects efficiently, ensuring timely delivery and quality results.

Why Sree CADD is the Best Choice for Automobile Courses in Kerala

Choosing the right training center can make a significant difference in your career growth. Sree CADD is the preferred choice for students and professionals in Kerala because of its industry-oriented curriculum, expert faculty, and advanced training facilities. The institute not only focuses on software proficiency but also helps participants develop problem-solving skills, design-thinking abilities, and real-world expertise.

Whether you want to become a mechanical engineer, CAD designer, or project manager in the automobile industry, Sree CADD’s courses will give you the edge you need to succeed. With locations in Trivandrum and Nagercoil, the institute makes it convenient for students across Kerala to access high-quality training.

Conclusion: Accelerate Your Career with Sree CADD

The automobile industry offers endless possibilities for innovation and career growth. By enrolling in specialized automobile courses in Kerala, you can acquire the skills and knowledge needed to thrive in this competitive sector.

Sree CADD, a leading AutoCAD training center in Trivandrum and Nagercoil, provides industry-integrated courses that focus on Engineering Design, Architectural Design, Interior Design, and Project Management. With expert faculty, state-of-the-art facilities, and a commitment to excellence, Sree CADD empowers students to build successful careers in engineering and design.

If you are passionate about automobiles and want to excel in this dynamic industry, enroll at Sree CADD today and take the first step toward a bright and rewarding future.

0 notes

Text

Affordable Electrical BIM Outsourcing Services Provider in Tennessee, USA under $49

CAD Outsourcing Consultants has a wide range of Electrical BIM Outsourcing Services that covers every facet of Electrical Structure, Designing and Engineering that is sorted with the aid of Electrical Building Information Modeling. Within the Electrical BIM, we also offer BIM Engineering, BIM Drafting, BIM Design Solution, BIM Outsourcing and Electrical Building Model.

CAD Outsourcing provides the following Electrical BIM Services:

· Modeling of Power, Data & Communication Systems

· Modeling of Fire Alarm Systems

· Modeling of Cable Trays and Conduits as per the given layout

· BOQ of Electrical Equipment

· Preparation of Lighting & Power Circuit Drawings

· Scheduling panel and circuit board

· Electrical Lighting Fixtures Modeling

· Walk-through of Electrical BIM Model

· Rendering of BIM Model with Lights

· Generator room and electrical room BIM Modeling

We offer our Electrical BIM Services Tennessee and covered other cities: Nashville, Atlanta, Charlotte, South Carolina, Indiana, North Carolina, Virginia, San Antonia and New Mexico.

Visit Us

https://www.cadoutsourcing.net/building-information-modelling/tennessee-cad-bim-services.html

License User

AutoDesk AutoCAD, Revit, Tekla, STAAD.Pro, SOLIDWORKS, ZWCAD, AutoDesk Navisworks, 3Ds Max, Inventor, Showcase, ReCap, Infraworks 360, Civil 3D.

Connect with us today to get quotations for the CAD Services. For More Details Website: https://www.cadoutsourcing.net/building-information-modelling/electrical-bim-services.html

#ElectricalBIMServices#ElectricalEngineeringServices#ElectricalServices#BIMServices#B1M#CadOutsourcing#CadOutsourcingCompany#CADServices#CAD#CADD#CADDrafting#CADDrawings#Engineering#AutoDesk#AutoCAD#SolidWorks#USA

2 notes

·

View notes

Text

Solidworks Assignment Help with a Holiday Twist: Save Big This Christmas!

The holiday season is here, and it's time to take a break from the grind and enjoy the festivities with your loved ones. But if you’re a SolidWorks student, you may be feeling the stress of looming assignments and deadlines, wondering how you'll fit everything in. Don't worry – we’ve got your back! This Christmas, you can relax and let us handle all your SolidWorks assignments while you enjoy the holiday season.

At SolidworksAssignmentHelp.com, we’re not just about providing expert assistance with SolidWorks; we’re about giving you peace of mind so you can truly enjoy this special time of year. And this year, we’re making it even easier with a special offer that includes a 100% refund guarantee on all our services.

Why Choose SolidWorks Assignment Help During the Holidays?

The holiday season should be a time for joy, family, and relaxation. But for students, it's often a stressful period of balancing holiday fun and academic responsibilities. SolidWorks assignments can be tough – they require precision, time, and attention to detail. Whether it's product design, motion analysis, or advanced simulation, these tasks can be overwhelming during the holidays.

This is where SolidWorks Assignment Help comes in. We offer expert help with all SolidWorks assignments, making sure you get the grades you deserve without compromising your holiday plans. Let us take care of the technicalities, while you focus on what matters most: family, friends, and some well-deserved relaxation.

The Benefits of Choosing Us for Your SolidWorks Assignments

When you choose us, you’re not just getting expert help – you’re getting peace of mind. Here’s why:

Expert Assistance: Our team of SolidWorks experts has years of experience solving assignments across various modules. No matter how challenging your task may seem, we have the skills to handle it.

100% Refund Guarantee: We stand behind the quality of our work. If you’re not completely satisfied with the outcome, we offer a full refund – no questions asked. That’s how confident we are in delivering the best results for your assignments.

On-Time Delivery: Deadlines can be tight during the holidays, but don’t worry – we’ll deliver your assignments on time, every time. You can trust us to get your work done so you don’t miss out on any holiday fun.

Affordable Prices: We understand that students have a budget, especially during the holiday season. That’s why we offer affordable pricing without compromising on quality. Plus, we have special discounts for the holiday season, so you can save big!

Custom Solutions: We tailor our solutions to meet the specific requirements of your assignment. Whether you need help with SolidWorks Electrical, Sheet Metal Design, or Motion Analysis, we provide personalized support that fits your needs.

Plagiarism-Free Work: All our assignments are original and crafted specifically for you. We guarantee that your work will be free from plagiarism, ensuring that you get a unique solution every time.

24/7 Customer Support: Got a question? Need to check on your assignment’s progress? Our friendly support team is available 24/7 via chat, email, or WhatsApp. We’re always here to help.

How to Enjoy a Stress-Free Christmas

With SolidWorks Assignment Help, you don’t have to choose between your assignments and enjoying the holiday season. Here’s how you can make the most of this time:

Delegate Your Work: Leave the technical work to us! We can handle everything from the most basic assignments to the most complex tasks, so you can enjoy your Christmas celebrations without the stress of looming deadlines.

Focus on What Matters: Christmas is about family, friends, and relaxation. Take this time to catch up with loved ones, enjoy the festive atmosphere, and recharge for the new year ahead.

Stay On Top of Your Grades: While you’re unwinding, we’ll be working behind the scenes to make sure your SolidWorks assignments are top-notch. Our experts ensure that every task is completed to perfection, helping you achieve the grades you deserve without lifting a finger.

Get Peace of Mind: Our 100% refund guarantee means you can rest easy knowing that your assignments are in good hands. If you're not satisfied with the final result, we’ll make it right or refund your money – no stress, no worries.

Save Big: Christmas isn’t just about presents – it’s about getting great deals too! This holiday season, we’re offering special discounts on our services. Save money while ensuring top-quality work for your SolidWorks assignments.

What’s Included in Our Holiday Offer?

Expert Help on All SolidWorks Assignments: From 3D Modeling to Sheet Metal Design, we’ve got you covered.

100% Refund Guarantee: If you’re not satisfied, we’ll refund your payment – simple as that!

Holiday Discounts: Save money with our special holiday pricing, and refer a friend to save even more.

Quick Turnaround: Don’t worry about last-minute assignments – we deliver quality work on time.

Affordable Rates: Get high-quality work at student-friendly prices.

Don’t Wait – Let Us Handle Your SolidWorks Assignments Today!

Why stress over your SolidWorks assignments this Christmas when you can enjoy the holiday season stress-free? Let SolidWorks Assignment Help be your trusted partner in academic success. We’ll handle your assignments so you can focus on the things that truly matter.

Contact us today to get started on your assignments, and take advantage of our exclusive holiday offer. The best part? If you’re not satisfied with the work, you get your money back – that’s our promise!

Ready to Enjoy Your Christmas Break?

Leave your SolidWorks assignments to the experts and enjoy a well-deserved break this holiday season. Whether it's a complex simulation task or a design project, we’ve got you covered. Reach out to us now, and let’s make this Christmas truly stress-free.

Contact Us Today!

WHATSAPP: +13155576473 Email: [email protected] Website: https://www.solidworksassignmenthelp.com/

#SolidworksAssignmentHelp#ChristmasBreak#StressFreeChristmas#HolidaySeason#StudentHelp#SolidworksExperts#AssignmentHelp#ChristmasRelaxation#100PercentRefund#HolidayDiscounts#SolidworksStudents#AssignmentsMadeEasy#RelaxThisChristmas#SolidworksSupport#ChristmasStressFree#AssignmentSolutions#HolidaySavings#EnjoyChristmas#ChristmasOffer#SolidworksAssignments#PerfectGrades#AcademicSuccess

0 notes

Text

SOLIDWORKS Electrical: Revolutionizing Electrical System Design

SOLIDWORKS Electrical, offered by MSD Facilitators, provides cutting-edge solutions for designing complex electrical systems. The software enables seamless collaboration between electrical and mechanical engineers, with real-time updates between 2D schematics and 3D models. It simplifies tasks such as component placement, wire routing, and generating accurate bills of materials (BOMs). Whether you're using single-line schematics or advanced 3D models, SOLIDWORKS Electrical enhances efficiency, reduces design errors, and optimizes the design process.

Why Choose SOLIDWORKS Electrical?

Real-Time Synchronization: Ensures bi-directional updates between 2D schematics and 3D models, streamlining workflows across disciplines.

Collaboration & Multi-User Environment: Enables multiple engineers to work together on the same project, improving communication and design accuracy.

Extensive Libraries: Pre-built libraries of symbols and manufacturer parts save time and help design reuse.

Automated Design Tools: Automate complex tasks like PLC and terminal block assignments, reducing repetitive tasks.

Key Benefits:

Error Reduction: Minimize errors by integrating electrical design into the mechanical design process.

Shortened Design Cycles: Real-time collaboration and intelligent routing help reduce development time.

Cost Efficiency: Optimize wire lengths and ensure accurate BOMs to control production costs.

SOLIDWORKS Electrical makes it easy to design robust electrical systems with less effort and more accuracy. Whether you're an equipment manufacturer or working on embedded systems, SOLIDWORKS Electrical provides the tools you need to succeed. Learn more about SOLIDWORKS Electrical at MSD Facilitators.

0 notes