#SolidWorks 3dexperience platform

Explore tagged Tumblr posts

Text

Deciding between SOLIDWORKS Desktop and 3DEXPERIENCE SOLIDWORKS can be challenging. This guide helps you understand the key differences, benefits, and use cases of each option, so you can make an informed decision that best fits your design and engineering needs. Whether you prioritize traditional software flexibility or cloud-based collaboration, in this blog we covered all the things.

1 note

·

View note

Text

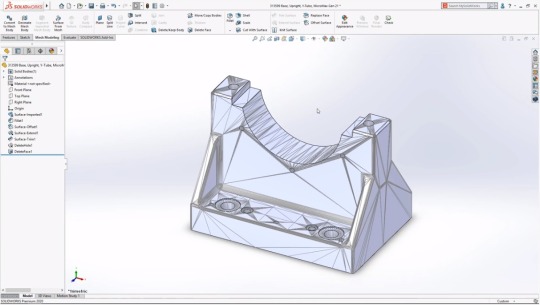

Staying Ahead in SolidWorks Assembly: Latest Trends and Tips for Students

As a student tackling SolidWorks assembly assignments, staying updated with the latest trends and advancements in the field is crucial. SolidWorks, a powerful computer-aided design (CAD) software, continues to evolve, offering new features and improvements that can significantly enhance your productivity and design capabilities. Whether you're seeking SolidWorks assembly assignment help or looking to refine your skills, understanding these trends will give you a competitive edge.

1. Enhanced Collaboration Tools

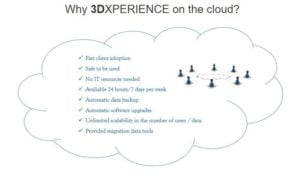

One of the most significant advancements in SolidWorks is the improved collaboration tools. The integration of SolidWorks with cloud-based platforms like 3DEXPERIENCE has revolutionized the way students and professionals work together on projects. These tools allow multiple users to collaborate in real-time, making it easier to share designs, provide feedback, and make necessary changes promptly. This feature is particularly beneficial for students working on group assignments, as it streamlines communication and ensures everyone is on the same page.

2. Increased Emphasis on Sustainability

Sustainability is becoming a key focus in engineering and design, and SolidWorks is at the forefront of this movement. The latest versions of SolidWorks include tools that help designers evaluate the environmental impact of their designs. Features such as the Sustainability module allow users to analyze the carbon footprint, energy consumption, and environmental impact of materials used in their assemblies. For students, this means an opportunity to create designs that are not only functional but also environmentally friendly, aligning with the global push towards sustainable engineering practices.

3. Integration with Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are transforming the CAD landscape, and SolidWorks is no exception. The integration of AI and ML into SolidWorks enhances the software's ability to predict design intent, suggest improvements, and automate repetitive tasks. For students, this means a significant reduction in the time spent on mundane tasks, allowing more focus on creativity and innovation. Tools like the Design Assistant leverage AI to provide intelligent design suggestions, which can be a great aid in completing complex assignments more efficiently.

4. Advancements in Simulation Capabilities

Simulation is a critical component of the design process, allowing students to test their assemblies under various conditions without physical prototypes. SolidWorks continues to enhance its simulation capabilities, making it easier to conduct complex analyses. The latest versions offer more robust finite element analysis (FEA) tools, improved computational fluid dynamics (CFD) simulations, and enhanced support for non-linear and dynamic simulations. These advancements help students validate their designs more accurately and make informed decisions to optimize performance.

5. Expanded Library of Standard Components

SolidWorks has significantly expanded its library of standard components, providing students with a vast array of pre-designed parts to incorporate into their assemblies. This expansion saves time and ensures that students use industry-standard components in their designs. The availability of these components in the library also means that students can focus on the custom and innovative aspects of their projects rather than spending excessive time designing standard parts from scratch.

6. Augmented Reality (AR) and Virtual Reality (VR) Integration

The integration of Augmented Reality (AR) and Virtual Reality (VR) into SolidWorks is opening up new dimensions in the design and visualization process. Students can now experience their designs in a virtual environment, providing a better understanding of scale, fit, and aesthetics. This immersive experience is invaluable for presentations and can help in identifying potential issues that might not be apparent in a traditional 2D or 3D view. The use of AR and VR also enhances collaboration, allowing team members and stakeholders to visualize and interact with the design in a more intuitive way.

7. Improved User Interface and Experience

SolidWorks continually updates its user interface to make it more intuitive and user-friendly. The latest versions feature a cleaner design, customizable toolbars, and improved command accessibility. These enhancements make the software easier to navigate, reducing the learning curve for new users and increasing efficiency for experienced ones. For students, this means less time spent figuring out how to use the software and more time dedicated to actual design and innovation.

8. Access to Comprehensive Learning Resources

Recognizing the importance of continuous learning, SolidWorks has expanded its range of educational resources. The SolidWorks website and community forums offer a plethora of tutorials, webinars, and certification programs designed to help students master the software. Additionally, platforms like MySolidWorks provide access to a vast library of instructional videos and training materials. Utilizing these resources can greatly enhance your understanding and proficiency in SolidWorks, making you more adept at tackling complex assembly assignments.

9. Customization and Automation with APIs

SolidWorks provides extensive API (Application Programming Interface) support, allowing users to customize and automate various aspects of the software. For students who are tech-savvy, learning to use APIs can open up new possibilities for automating repetitive tasks and creating custom tools tailored to specific project needs. This level of customization can significantly streamline your workflow and improve productivity, especially when dealing with large and complex assemblies.

10. Emphasis on Industry 4.0 Compatibility

Industry 4.0, characterized by smart manufacturing and automation, is reshaping the engineering landscape. SolidWorks is keeping pace with this trend by ensuring compatibility with Industry 4.0 standards and technologies. Features such as IoT (Internet of Things) integration and support for smart manufacturing processes are increasingly becoming part of the SolidWorks ecosystem. For students, understanding and leveraging these capabilities can provide a significant advantage in preparing for careers in the modern engineering and manufacturing industries.

Conclusion

As you navigate through your SolidWorks assembly assignments, staying abreast of the latest trends and advancements is essential. Whether you’re looking for SolidWorks assembly assignment help or aiming to enhance your skills, these developments can provide valuable insights and tools to improve your designs and workflows. Embrace the new features, leverage the enhanced capabilities, and utilize the extensive resources available to you. By doing so, you’ll not only excel in your assignments but also prepare yourself for a successful career in the ever-evolving field of engineering and design.

#solidworks#assignmenthelp#solidworks assignment help#solidworksassignmenthelp#studentassistance#academicsuccess#education#SolidWorks assembly assignment help

0 notes

Text

Catia vs SolidWorks | Choose the Right Software [2024]

In the world of Computer-Aided Design (CAD), two heavyweight contenders, Catia and SolidWorks, have long been at the forefront. Both software packages have loyal followings and are trusted by engineers, designers, and manufacturers worldwide. But when it comes to choosing the right software for your specific needs, how do you decide between Catia and SolidWorks? Let's delve into a comparative analysis of Catia vs Solidworks to help you make an informed decision.

Understanding Catia and SolidWorks

Before diving into the comparison, let's briefly understand what each software brings to the table.

Catia: Developed by Dassault Systèmes, Catia is an advanced multi-platform CAD/CAM/CAE software suite designed for product design and innovation. It's known for its robust capabilities in complex surface modeling, aerospace engineering, and automotive design.

SolidWorks: Created by Dassault Systèmes' subsidiary SolidWorks Corporation, SolidWorks is a 3D CAD software package renowned for its user-friendly interface, parametric design capabilities, and extensive support for product development workflows. It's widely used across various industries, including mechanical engineering, consumer products, and architecture.

Comparative Analysis

Complexity and Learning Curve: Catia: Catia is known for its steep learning curve, especially for beginners. Its extensive feature set and complex interface may require significant time and effort to master. SolidWorks: SolidWorks, on the other hand, offers a more intuitive and user-friendly interface, making it easier for beginners to get started. Its straightforward workflow and extensive online resources contribute to a shorter learning curve.

Feature Set and Capabilities: Catia: Catia excels in handling complex surface modeling, advanced assembly design, and large-scale engineering projects. It offers powerful tools for aerospace, automotive, and industrial design. SolidWorks: SolidWorks is renowned for its parametric modeling capabilities, allowing users to easily make changes and updates to their designs. It offers a comprehensive set of tools for 3D modeling, simulation, and documentation.

Industry Focus: Catia: Catia is widely used in industries such as aerospace, automotive, and manufacturing, where complex design requirements and large-scale projects are common. SolidWorks: SolidWorks caters to a broader range of industries, including consumer products, machinery, and electronics. Its versatility and ease of use make it suitable for small to medium-sized businesses and individual designers.

Collaboration and Integration: Catia: Catia offers robust collaboration features, allowing teams to work together seamlessly on complex projects. It integrates well with other Dassault Systèmes solutions, such as ENOVIA and 3DEXPERIENCE platform. SolidWorks: SolidWorks provides excellent collaboration tools through its PDM (Product Data Management) system, enabling teams to manage and share design data efficiently. It also integrates with various third-party software solutions for enhanced productivity.

Choosing the Right Software Between Catia and Solidworks

Ultimately, the choice between Catia and SolidWorks depends on your specific requirements, industry focus, and budget considerations. Here are some factors to consider:

Project Complexity: If you're working on complex surface modeling or large-scale engineering projects, Catia might be the better choice.

Ease of Use: For small to medium-sized businesses or individual designers seeking a user-friendly interface and shorter learning curve, SolidWorks could be the ideal option.

Industry Alignment: Consider which software aligns better with your industry requirements and standards. Catia is favored in aerospace and automotive sectors, while SolidWorks has a broader industry presence.

Collaboration Needs: Assess your collaboration requirements and compatibility with existing software ecosystems. Both Catia and SolidWorks offer robust collaboration features, but their integration capabilities may vary.

Conclusion

In conclusion, both Catia and SolidWorks are powerhouse CAD software packages with distinct strengths and capabilities. By evaluating your specific needs and priorities, you can choose the software that best fits your design and engineering workflows. Whether you opt for the advanced capabilities of Catia or the user-friendly interface of SolidWorks, rest assured that you're investing in a leading solution tailored to drive innovation and efficiency in your projects.

0 notes

Note

I remember you messing with cad a bit and i was wondering what software you use/recommend?

short version:

I use Solidworks. It's what we use at work, and it's what I personally own, but it's paid (and kind of expensive, and their cheaper "maker" license/3Dexperience platform majorly sucks ass IMO). But from like a "professional/business" angle it's one of the most popular CAD programs so that's the one I went out of my way to kinda-sorta-learn.

If you're just looking for personal use stuff though, Fusion360 is super popular. It has a free version and a paid version, although the free version seems perfectly fine. My understanding from other people who have used it is just that you can only have a certain number of "active" files, so you just need to take an extra step to activate and deactivate files as needed. But you don't lose any of them. iirc it's also cloud-based.

longer version:

I legally own a copy of Solidworks because I illegally downloaded it, fucked up and got caught when I connected some part of the program to the internet where it checked the license key, got a scary cease-and-desist letter and shockingly nice phone call which was a very weird tone switch from the letter, and as part of the deal I had to buy the license + that year's subscription to make it even. Which worked out to like $6- or $7000. I'm rounding here but I think the license itself (for the basic Standard tier, there are 3 tiers which are increasingly expensive) was roughly like $5500, and the subscription was $1500.

But I wanted to learn Solidworks specifically because it's what they were using at my dad's job and it's fairly popular for business use, and I desperately wanted an avenue out of being a cashier.

The good news is that Solidworks licenses are perpetual so like, I own the 2018 version outright and can use it as long as I want. But you're only entitled to upgrades if you're on the annual subscription, so I can't upgrade unless I go contact my local official Solidworks reseller and buy a subscription for a year. And it's still not clear to me if that permanently brings my license key up to 2022, or if it's still going to be a 2018 license when the subscription ends. I just sent them an email to ask because it's something I have been thinking about. I'm woefully behind and it's beginning to annoy me.

I haven't used Fusion360 but I know my dad has, and he did like using it. I think he still uses it for at-home stuff. And I have seen it recommended a lot in hobby/maker places. Even if the goal is to eventually do CAD stuff in a professional capacity you could totally start with the free copy of Fusion360. The general layout is gonna be different from Solidworks I think, and I think they do some overarching things a little differently, but the concepts are the same so it would totally be possible to translate any experience with Fusion360 over to Solidworks. The annoying part would probably be just re-learning the interface.

And because I never learn my lesson re: piracy, I have a bunch of videos I saved from LinkedIn Learning when I used the free 30 days, which goes over a whole bunch of Solidworks stuff from literal absolute beginner basics to some more intermediate stuff. If anyone wants access to those just lmk.

4 notes

·

View notes

Photo

Dassault Systèmes debuts SOLIDWORKS 2020 with new slicing features Dassault Systèmes, the French software company behind the 3DEXPERIENCE platform, has launched SOLIDWORKS 2020, the 28th edition of its portfolio of 3D design and engineering software. SOLIDWORKS 2020 features improved performance, streamlined workflows, and support for a connected design ecosystem in the cloud. This includes the new Detailing mode and graphics acceleration for drawings, the Make […] https://buff.ly/2NKN6EV

1 note

·

View note

Text

The 3DEXPERIENCE platform is your gateway to better cloud collaboration through 3DEXPERIENCE SOLIDWORKS. Contact our team to speak with an expert today!

0 notes

Text

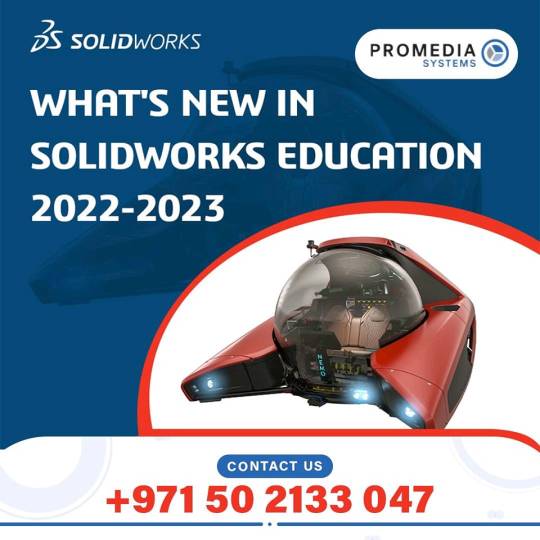

Improve Productivity with What’s New in SOLIDWORKS 2023

Learn more about the robust new features designed to increase your productivity by enabling you to work more quickly, more intelligently, and in tandem with market-leading product development tools.

Connect your design processes to the 3D EXPERIENCE platform to improve your 3D CAD capabilities and gain access to robust solutions for data management, collaboration, sophisticated simulation, manufacturing, and production throughout the full product development lifecycle.

SOLIDWORKS 2023 streamlines your product development process, allowing you to finish more work in less time, freely iterate and improve designs, and provide high-performing, high-quality designs that have been meticulously polished.

New Features for SOLIDWORKS 2023

Improve productivity with smarter and faster design tools. Break down barriers to collaboration. Learn here new top features of SOLIDWORKS 2023.

SOLIDWORKS 2023 - Sheet Metal and Structures

New improvements to SOLIDWORKS Structure Systems and Sheet Metal in 2023 allow for more efficient design-to-manufacturing processes and quicken time-consuming activities. By using a single command, Structure Systems can now find all identical corners in your structure and apply the same trimming criterion to them all. To save even more time in your production, connection pieces like gussets or base plates can also be designed to have comparable corners. The creation of sheet metal parts for production has never been simpler thanks to recent improvements that will appeal to all shop floor personnel. Identical uphill and downward bends are now easier than ever thanks to the ability to thicken sketched base flange portions symmetrically around the sketch.

Identical uphill and downward bends are now easier than ever thanks to the ability to thicken sketched base flange portions symmetrically around the sketch. There is also a completely new set of sheet metal sensors that will dynamically inform you if the bounding box for the flat pattern deviates from predetermined boundaries.

SOLIDWORKS 2023 - Cloud CAD with 3D Creator

The design, manufacturing, and collaboration features of xDesign are included in 3D Creator. From any connected device, you can develop production-ready parts and assemblies using robust browser-based parametric modelling tools. There is no need for emails when using the 3DEXPERIENCE platform to keep your team members informed of your progress. With 3D Creator, you can expand your digital toolkit and carry it with you everywhere you go.

SOLIDWORKS 2023 - Drawings

Improvements to Drawings' workflows and time-saving automation enable you to detail designs more quickly. Open an assembly drawing to reveal the sub-component drawings. Any Bill of Material cells that have been manually overridden should be highlighted and restored. When inserting auto balloons, show quantity callouts. In order to design unique BOM table layouts, apply filters. HLR designs with transparent elements can be seen through for better visualisation.

SOLIDWORKS 2023 - SOLIDWORKS Visualize

With SOLIDWORKS Visualize 2023, visualise your goods in high quality like never before. Streamlined import choices, more colour control features, and a brand-new rendering engine make it easier to produce outstanding pictures. See how these new capabilities can breathe fresh life into your static CAD model and create captivating visuals more quickly than before. Use Visualize 2023 to grab your audience's attention.

SOLIDWORKS 2023 – Assemblies

For SOLIDWORKS® 2023, new assembly design capabilities provide much-anticipated user improvements at your fingertips. A wide range of additional features are included in configurations, including instances to skip for the majority of pattern types, configuration-specific bill of materials ID management, and adjustable magnetic mates for speeding assembly layouts. Never before has replacing components been so simple. A new instances to replace option and a new preview window are both included in SOLIDWORKS 2023. You'll be thrilled with an automated method for fixing damaged friends that only requires one click. The ability to fully automate between resolved and lightweight modes will be available in SOLIDWORKS 2023, allowing SOLIDWORKS to choose the options that will result in the highest performance.

Conclusion

The outputs are consistent throughout, reducing the chance of costly errors and problems. SOLIDWORKS stays at the forefront of finding new ways to enhance the 3D drafting and design process. SOLIDWORKS product line is the way to take your CAD design experience to its next level.

INDOVANCE Inc with its exclusive delivery hub in India is a global CAD outsourcing partner serving the needs of the AEC industry since 2003. At INDOVANCE we focus on the unique need of each project or client and believe in addressing the real challenges and guarantee that the process will be well-coordinated, smooth, efficient, and hassle-free.

INDOVANCE Inc, has been providing all sorts of mechanical CAD drafting, modeling and analysis services to its clients for almost two decades. Our SOLIDWORKS 3D CAD design solutions offer easy extremely strong capabilities, reducing time for design development, cost reduction and quality improvement.

0 notes

Text

Best Upskilling Courses For Mechanical Engineers

We’re often being asked to list out some beneficial upskilling courses for mechanical engineers to help them in progressing their career. So here we go.

Upskilling is definitely the most important aspect of career development but what’s even more important is to select the right course for upskilling. There are a few pointers you should keep at the back of your head before opting for a course. We abbreviate it as RSVP (Relevance, Scope, Vitality, and Progressivism).

An upskilling course should be in-demand & relevant to your industry. It should have a significant scope in order to help you grow in your career. Vitality is important to sustain, grow, & develop in the future. And, most importantly progressivism to maintain appositeness with changing requirements.

Now, coming to the requested part - listing out the courses. Our top 3 suggested courses for mechanical engineers are the following:

CATIA

SOLIDWORKS

3DEXPERIENCE

The reason is that getting trained in this software has huge scope in various top industries around the globe. These courses are used widely & globally thus opening multi-industry opportunities.

As far as learning these software is concerned, we recommend checking out EDST e-learning. The platform is distinctively crafted to address skill requirements of future engineers. EDST e-learning plays a vital role in equipping you with industry-relevant skills and future-proofing your career. Some added advantages of learning with them also includes:

Their 25+ years of expertise in the industry.

Extensive study materials, case studies, practical application examples, webcasts, webinars.

They offer online skill assessments, certification, and necessary practical exposure.

Free demo and career counselling to guide you.

Subject-matter experts & highly-skilled trainers.

You can check out their website or connect with them to know more.

https://edstelearning.com

Tel: +91 (80) 49190333

Email: [email protected]

LEARN. LEVERAGE. LEAD.

0 notes

Photo

3DEXPERIENCE SOLIDWORKS for Education better prepares your students for the real-world with these benefits of the 3DEXPERIENCE platform, now directly integrated into the SOLIDWORKS interface: connected cloud storage, real-time Product Lifecycle Management (PLM), and collaborative task management.

0 notes

Text

3DEXPERIENCE Works

The 3DEXPERIENCE Works is a platform based on the cloud. It brings all your key stakeholders together on a single collaborative platform. The 3DEXPERIENCE Works portfolio unites your entire ecosystem, allowing you to connect the people, applications, and real-time data from every aspect of your business for improved productivity, increased collaboration, and accelerate innovation.

The 3DExperience Platform includes four main categories:

· Design Solution

· Simulation Solution

· Governance Solution

· Manufacturing Solution

The 3DEXPERIENCE Benefits:

· Cloud Based Storage

· Easy to use and collaborate

· Automatic Update for latest technologies

· Process Tracking and Visibility

MSDFacilitators is a SOLIDWORKS Authorized Reseller in North India. We appreciate your business needs and are set out to give the best solution as per your necessities. We offer venture consultancy organizations for item outline and Simulation through our SOLIDWORKS affirmed designers.

For More Information Contact US: MSDFacilitators

#SolidWorks Authorized Reseller#SolidWorks India#SolidWorks Professional 2022#Buy SolidWorks Delhi#SolidWorks India Reseller#SolidWorks Gurgaon#SolidWorks Reseller in India

0 notes

Text

3DEXPERIENCE’s Value Proposition In Your Company’s Product Life-Cycle

In our previous post, we talked about 3DEXPERIENCE’s value proposition. In your company’s product lifecycle, 3DEXPERIENCE Platform can especially contribute in following areas:

CAD/Document Management

CAD Management & Reuse

Concurrent Design

Design Change Management

Design Lifecycle Management

Engineering BOM Management

Global Engineering Management

Variant Management

Product Spec Management

Configuration Management

Enterprise BOM Management & Collaborative Business Processes

Digital Mockup

Program and Project Management

Materials Compliance

Traceable Requirements Management

Supplier Quality Management

Global Manufacturing Management

Program and Contract Management

Product Configuration

IP Protection

3DEXPERIENCE Platform’s intelligence allows automatic update of eBOM, with no manual effort or file exchanges, when a designer makes a change to the product structure.

When the Engineer updates the eBOM, that change is propagated to the standard product structure, allowing the designer to make revisions as needed.

3DEXPERIENCE manages all product-related data and information, including CAD data, through a single enterprise view. Securing all product data in one location provides a single source of truth for the enterprise.

SOLIDWORKS/CAD models and drawings are integrated directly into the desktop file system. Users can simply save their files to their desktop, much like they would in a non-managed environment. ENOVIA PLM software keeps track of which files are changed or out-of-date with the central server. Everyone in the organization is able to share and view SOLIDWORKS/CAD models in a single platform.

Functions, teams and locations are connected to drive collaborative innovation. Search capabilities enable you to uncover new information and data for improved designs.

With personalized dashboards you can collect, view and access your assigned tasks, issues, priorities and related CAD data.

You can create business dashboards to gain greater insight and analysis on industry, company, programs, or projects to make more informed and better decisions.

Real-time assessment of project status is possible with deliverables-based project management and invisible governance, whereby an update to a CAD part or related document is automatically reflected in the project dashboard.

Please let us know if you would like to know how 3DEXPERIENCE Platform can be valuable for your company. We would be happy to provide industry specific references and applications.

Contact Us:

1400 Broadfield Blvd #325 Houston, TX 77084 Phone: +1 (832) 301-0881 E-mail: [email protected]

0 notes

Link

In today's environment, it is critical to effectively communicate and collaborate with your entire team and extended development ecosystem - from R&D, Marketing and Sales, to external stakeholders - to stay competitive and foster innovation. 3DEXPERIENCE Works provides the ability to connect people, applications and information to allow ANY team to become an integral part of the innovation process and contribute to the company's bottom line.

This replay of SOLIDWORKS CEO Gian Paolo Bassi's presentation at 3DEXPERIENCE World explains how you can:

• Extend and improve what you do today with purpose-built tools • Connect disparate applications into a continuous loop without gaps in the product development process • Deploy task-focused applications when you need to evolve at your own pace • Leverage automation, powered by artificial intelligence and machine learning, to free up your time to explore and innovate • Turn your data into actionable information to make better, more informed decisions WATCH THE VIDEO to learn more about the benefits of the 3DEXPERIENCE WORKS portfolio.

About 3DEXPERIENCE Works Cloud Solutions

The 3DEXPERIENCE Works portfolio of cloud solutions bring all your key stakeholders together on a single collaborative platform, allowing you to seamlessly move from ideation through delivery for continuous development. Connecting the people, applications and real-time data from every aspect of your business helps you improve execution, increase productivity and accelerate innovation. Engineering Technique is the Largest SOLIDWORKS Authorized Reseller in Gujarat (India) providing comprehensive solutions for SOLIDWORKS Desktop & 3DEXPERIENCE Works Cloud Software products including 3D CAD, Product Data Management (PDM), Simulation, Plastics, Electrical, Visualize, eDrawings, 3D Sculptor, Collaborative Business Innovator, Social Business Analyst, Data & Product Lifecycle Management, 3DEXPERIENCE SOLIDWORKS, and DraftSight to industrial verticals including Industrial Equipment, Consumer Goods, Life Sciences, Manufacturing, Alternative Energy, Process & Plant, etc. Their clientele spans 600+ customers in design and manufacturing domains with 1850+ licenses in the state of Gujarat itself. For inquiry, please call us on +91 94276 11239 or email at [email protected]

0 notes

Text

Digital twins will lead to "a huge revolution" for designers says Anne Asensio of Dassault Systèmes

Promotion: Architecture and design are about to be revolutionised by digital twins – virtual representations of real-world products, buildings and even entire cities – according to Anne Asensio, vice president of design experience at Dassault Systèmes.

"We are at the very beginning of a huge change that may transform the way we design," said Asensio, who spoke to Dezeen as part of our Design for Life collaboration with Dassault Systèmes.

"It's a huge revolution for the future and we've only seen the first stage so far."

Digital twins provide "an incredible power"

Digital twins, which are also known as virtual twins, are virtual counterparts to real-world objects or processes.

Existing alongside their real-world siblings, digital twins can be used to represent a physical object or its process and to monitor what is happening in the real version as a testbed to explore the impact of proposed improvements or unexpected changes.

According to Asensio, this emerging technology will enable architects and designers to demonstrate the full life cycle of a product, a service or an experience.

It will also, she believes, enable designers to imagine and test new ideas more easily and at an earlier stage than was previously possible.

"This ability to visualise any given element in 3D – it could be an object, a service, a system or an entire city – and play with all the physical rules within the conformity of science is an incredible power," she said.

"For designers, it is a clear access to design not just the product but its behaviour, the experience and its entire life cycle at the front end of the creative process."

The rise of digital twins

The concept of digital twins has been around for some time. NASA was an early pioneer, building virtual models of its spaceships so it could improve their performance.

But their use has accelerated in recent years thanks to the rise of the internet of things. This has created a rich stream of data that gives an up-to-date picture of what is happening in the physical world.

A digital twin works by monitoring data generated by sensors in objects such as aerospace engines, buildings or road networks and constantly updating itself so it perfectly mirrors its sibling.

Recent examples include the Battersea Power Station project in London, where architect Foster + Partners is using a robot dog to collect data to update the digital twin; while a futuristic urban development at Innisfil in Canada by architect Partisans will feature a digital twin that will be used to optimise transportation systems including autonomous buses and drones.

However, Asensio believes the true capabilities of the technology are not being used fully, comparing its use today to how the internet was used at the start of the millennium.

"The virtual twin is going to grow quite intensively," she said. "We can [use digital twins to] demonstrate other ways of designing a city – leveraging the participative actions of citizens through immersive co-design of the city on one hand and, on the side of professionals, redesigning buildings to be resilient to climate or extreme temperatures, or rebuilding after the learning of a simulated tsunami. There are plenty of solutions."

A new approach to design

Dassault Systèmes has integrated virtual twin technology into its 3DExperience 3D software platform, which includes modelling software programs Catia and SolidWorks.

Construction and development company Lendlease is using the software to create digital twins for many of its projects in Europe and North America to improve efficiency.

The technology was also used to optimise the manufacture and construction of Brock Commons, a student housing block at the University of British Columbia (UBC), which was the tallest mass-timber building when it was completed in July 2017.

As Asensio explained in a recent talk with Dezeen, her ambition driving the development of these digital tools is to "shift the posture of design" by encouraging designers to focus on creating sustainable materials and processes, rather than consumer products.

Asensio believes that digital twin technology is an example of how software can become more integral to the design process, rather than simply being a presentational tool, which she hopes will equip designers with the tools they need to "build a better world".

"Today, 3D renderings and representations are only being used to sell an idea," she said. "We want to move from this behaviour to a behaviour where designers can systematically represent another way to do things. The virtual twin will be a place to do that."

The future of digital twins

However, the use of digital twin technology is not yet widespread throughout the design and architecture industries.

According to Asensio, the key limitation that prevents more designers from utilising the technology is not to do with access or understanding of 3D software but rather the difficulty in capturing the data required to inform the digital model.

In order to create a useful digital twin of a complex design or system, large quantities of accurate data are required.

"A virtual twin is a replication of something, but that thing could be very complex," Asensio said.

"It's not a question of whether the 3D model could be complex; we know how to produce a very complex 3D model. What is difficult is controlling the model. You need to have the right people around, the right expertise and that is a challenge for designers."

Opportunities for collaboration

Asensio believes the answer lies in greater collaboration between designers and experts in other fields, such as scientists, academics and industry professionals, who have more experience in capturing and processing data.

By creating more connections between different disciplines, she believes we will be able to develop digital twins that draw on more diverse sources of data. Only then will we be able to fully benefit from the technology's potential.

"Going forward, we are at a crossroad where we can imagine incredible futures," she said. "But we have to create the environment where this is possible."

Asensio spoke to Dezeen as part of our Design for Life partnership with Dassault Systèmes, which highlights designers who are using technology and research to build a better world.

Examples include Exploration Architecture, which uses computational design tools to explore biomimicry-focused architecture, and Studio INI, which uses software to create interactive environments.

Cloud-based design solutions for architects and designers

Dassault Systèmes provides a range of 3D tools for architects via its 3DExperience platform, which it offers at a reduced cost for startups and new businesses.

"At Dassault Systèmes, we are passionate about helping companies, designers, architects and urbanists launch innovative projects with confidence," the company said.

"We’ve developed a comprehensive offer for startups, early-stage businesses and design agencies to benefit from the entire 3DExperience platform on the cloud at an unbeatable price point."

Find out more about Dassault Systèmes' startup offer here.

Partnership content

This article is a partnership between Dezeen and Dassault Systèmes. Find out more about Dezeen partnership content here.

The post Digital twins will lead to "a huge revolution" for designers says Anne Asensio of Dassault Systèmes appeared first on Dezeen.

0 notes

Photo

Dassault Systèmes financial results show double digit software revenue growth in Q1 2019 Dassault Systèmes, the developer of 3D design software SOLIDWORKS and the 3DEXPERIENCE platform, has reported its financial results for the first quarter of financial year 2019. Total revenue for the quarter is up 17% on the comparative period, from €818.7 million to €958.9 million. Of this revenue, Software constitutes €855.3 million for Q1 2019, a €120 million and 16.35% […] https://buff.ly/2PvjLPb

0 notes

Text

Dassault Systemes logs 16% growth for SolidWorks in India

Dassault Systemes logs 16% growth for SolidWorks in India

Nashville (US), Feb 11 (IANS) French 3DExperience platform company Dassault Systemes registered 14 per cent growth in the adoption of its 3D CAD software SolidWorks in India in 2019, a top company executive has said.

SolidWorks is a 3D modeling computer-aided design and computer-aided engineering computer programme that runs primarily on Microsoft Windows.

With its Global Entrepreneur Programme,…

View On WordPress

#3dExperience company dassault systemes#dassault systemes logs#french 3dexperience platform company#growth solidworks in india#logs growth solidworks#systemes logs growth

0 notes

Text

SOLIDWORKS and 3DEXPERIENCE WORKS

3DEXPERIENCE SOLIDWORKS is a cloud-deployed and cloud-connected version of SOLIDWORKS, that is connected to the 3DEXPERIENCE platform.

The 3DEXPERIENCE provides a real-time view of business activity and ecosystem, connecting people, ideas, and data in a single collaborative environment that empowers businesses and people to innovate in entirely new ways.

MSDFacilitators is a SOLIDWORKS Reseller in India who offers complete solutions towards product Design & Development, Simulation, Technical Documentation, product data management, training, and support. SOLIDWORKS and 3DEXPERIENCE WORKS at MSD.

#SolidWorks Reseller in India#SolidWorks Gurgaon#SolidWorks Authorized Reseller#SolidWorks Professional 2022#Buy SolidWorks Delhi#SolidWorks India Reseller#SolidWorks India

0 notes