#Sodium Nitrite Market

Explore tagged Tumblr posts

Text

Sodium Nitrite Market Size To Reach $580.8Mn By 2030

Sodium Nitrite Market Growth & Trends

The global sodium nitrite market size is expected to reach USD 580.8 million by 2030, as per a new report by Grand View Research, Inc. registering a CAGR of 4.2% from 2023 to 2030. The demand is attributed to the increasing demand for preservatives in the food & beverage industry. Preservatives help increase food items' shelf-life by delaying the spread of pathogens and microorganisms. Thus, sodium nitrite is highly used to enhance the flavor of meat and maintain its original color (making it look more appealing and presentable to consumers), while preventing bacterial growth.

In the pharmaceutical sector, sodium nitrite is a well-known chemical molecule. Its most common application is as an antidote for cyanide poisoning, as it is quite effective even in severe cases. It is used in the production of saccharin and caffeine and is commonly utilized as a raw material and preservative in pharmaceutical formulations like eye drops. Since sodium nitrite contains nitrogen, the product can be utilized as a control agent in a variety of medicines. It is also utilized as a butadiene antifoaming agent and a raw material for aminopyrine and sulpyrine antipyretic analgesics. Thus, multiple applications of the product in the pharmaceutical industry indicate that the growth of this industry is expected to drive the demand for pharmaceutical-grade sodium nitrite in the coming years.

The growing consumer acceptance of processed food in countries like China, India, Japan, and others is likely to bolster the demand for the product in the Asia Pacific. China is the world's largest consumer of food and beverages. The processed meat market of China majorly includes beef, pork, poultry, mutton, and others, which require the use of sodium nitrite as a preservative, thus driving the demand for the product market.

Request a free sample copy: https://www.grandviewresearch.com/industry-analysis/sodium-nitrite-market-report

Sodium Nitrite Market Report Highlights

Food & beverages application accounted for the largest market revenue share of over 66% in 2022. The growth is attributed to the increasing demand for the product as a preservative in processed meat and other food items

The pharmaceuticals segment was the second-largest application and is predicted to attain a CAGR of 4.7% over the forecast period, owing to its ability to act as a raw material or control agent for the development of several medicines used for treating muscular dystrophy, neurotransmission imbalances, epilepsy, and others

Asia Pacific dominated the regional segment with a revenue share of over 71% in 2022 due to the growth of the meat processing and food & beverage industries in the region

The increase in population and rising per capita disposable income drive the food and beverage market. According to a China Chamber of Commerce article published in 2020, the beverage market which includes drinks, vegetable juices, and fruits generated revenue of USD 39,330 million, thus driving the demand for the product in the country

Europe accounted for the second largest market share of over 16% in 2022 due to the changing consumer preference toward processed food over cooked food in the region. In the European Union (EU), sodium nitrite is approved as a food additive and is used to prevent microbial growth in meat, cheese, and fish products as it helps to improve the flavor while protecting it against botulism

Sodium Nitrite Market Segmentation

Grand View Research has segmented the global sodium nitrite market based on application and region:

Sodium Nitrite Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Food & Beverages

Pharmaceuticals

Others

Sodium Nitrite Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

North America

U.S.

Canada

Mexico

Europe

Germany

U.K.

France

Asia Pacific

China

India

Japan

Central & South America

Brazil

Argentina

Middle East & Africa

South Africa

Saudi Arabia

List of Key Players in the Sodium Nitrite Market

Deepak Nitrite Ltd.

Airedale Chemical Company Ltd.

BASF SE

Shijizhuang Fengshan Chemical Co., Ltd.

Ural Chem JSC

Linyi Liguang Chemical Co., Ltd.

Radiant Indus Chem Pvt. Ltd.

Yingfengyuan Industrial Group Limited

SABIC

Chemtrade Logistics

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/sodium-nitrite-market-report

#Sodium Nitrite Market#Sodium Nitrite Market Size#Sodium Nitrite Market Share#Sodium Nitrite Market Trends

0 notes

Text

Sodium Nitrite Market Segment Analysis By Application, Region And Forecast Till 2030: Grand View Research Inc.

San Francisco, 27 Oct 2023: The Report Sodium Nitrite Market Size, Share & Trends Analysis Report By Application (Food & Beverages, Pharmaceuticals, Others), By Region, And Segment Forecasts, 2023 – 2030 The global sodium nitrite market size is expected to reach USD 580.8 million by 2030, as per a new report by Grand View Research, Inc. registering a CAGR of 4.2% from 2023 to 2030. The demand is…

View On WordPress

#Sodium Nitrite Industry#Sodium Nitrite Market#Sodium Nitrite Market 2023#Sodium Nitrite Market 2030#Sodium Nitrite Market Revenue#Sodium Nitrite Market Share#Sodium Nitrite Market Size

0 notes

Text

Sodium Nitrite Prices: Trends, Influencing Factors, and Forecast

Sodium nitrite, an inorganic compound with the chemical formula NaNO2, plays a crucial role across various industries. It is primarily used in the food industry as a preservative and color fixative, while other sectors such as pharmaceuticals, agriculture, and chemical manufacturing also leverage its properties. Given its importance, sodium nitrite prices are a key factor for businesses relying on this compound. Understanding price trends, the factors influencing them, and future forecasts is critical for industry players.

Current Market Trends

Sodium nitrite prices have shown considerable fluctuations in recent years. In 2023 and into 2024, prices experienced both upward and downward pressures. A growing demand from the food processing and chemical industries has largely driven price increases. Conversely, oversupply in certain regions and cost-saving initiatives by producers have occasionally tempered the price hikes.

In North America, the market has been relatively stable due to consistent industrial demand and a balanced supply chain. Meanwhile, in Asia-Pacific, particularly in China and India, prices have been more volatile. These regions dominate the production of sodium nitrite, with variations in raw material costs and government policies often influencing the market.

Get Real time Prices for Sodium Nitrite: https://www.chemanalyst.com/Pricing-data/sodium-nitrite-1210

Key Factors Affecting Prices

Raw Material Costs: The primary feedstocks for sodium nitrite production are sodium hydroxide and nitrogen-based chemicals. Fluctuations in these raw material prices significantly impact the final product's cost. For instance, rising energy costs or disruptions in the supply of ammonia derivatives can lead to higher production costs.

Regulatory Environment: Environmental regulations on chemical manufacturing can affect production levels and pricing. Stricter rules often result in increased compliance costs for manufacturers, which are passed on to buyers.

Demand from End-Use Industries: The food industry remains the largest consumer of sodium nitrite. Growing awareness of food preservation techniques and increasing demand for processed foods have amplified sodium nitrite consumption. However, concerns over the health risks of nitrites in food have led to regulatory scrutiny, potentially impacting long-term demand.

Geopolitical Factors: Trade policies, import/export restrictions, and international relations can influence sodium nitrite prices. For example, tariffs on chemical imports or exports can create price disparities across regions.

Technological Advancements: Innovations in production methods can reduce manufacturing costs, enabling producers to offer competitive pricing. Companies adopting energy-efficient and sustainable practices are particularly likely to gain a pricing edge.

Forecast for Sodium Nitrite Prices

The global sodium nitrite market is expected to grow moderately over the next five years, driven by expanding applications in pharmaceuticals, agriculture, and chemical synthesis. However, prices are likely to remain subject to short-term volatility due to the dynamic nature of raw material markets and regulatory developments.

In the near term, sodium nitrite prices may increase slightly, reflecting inflationary pressures and rising energy costs. Additionally, any disruptions in supply chains, such as those caused by geopolitical tensions or natural disasters, could further elevate prices. Conversely, technological advancements and increased production capacities in Asia-Pacific may exert downward pressure in the medium term.

Conclusion

Sodium nitrite prices are influenced by a complex interplay of supply and demand dynamics, raw material costs, regulatory factors, and technological developments. Businesses relying on this compound must stay abreast of market trends and adopt flexible procurement strategies to mitigate risks associated with price fluctuations. Looking ahead, a balanced approach involving innovation and market monitoring will be essential to navigate the sodium nitrite market effectively.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Sodium Nitrite#Sodium Nitrite Price#Sodium Nitrite Prices#Sodium Nitrite Pricing#Sodium Nitrite News#Sodium Nitrite Price Monitor#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Link

0 notes

Text

Food Preservatives Market Size, Competitors Strategy By Forecast To 2030

Food Preservatives to Reach USD 5.30 Billion by 2030, Growing at a CAGR of 5.41%

Global Food Preservatives Size, Share, and Forecast Report 2023-2030

Introduction

As the global demand for longer shelf-life products increases, the Food Preservatives Market Size is experiencing significant growth. Valued at USD 3.47 billion in 2022, the global food preservatives is expected to grow at a compound annual growth rate (CAGR) of 5.41%, reaching USD 5.30 billion by 2030. Food preservatives play a vital role in maintaining the quality and freshness of food and beverages by preventing spoilage, bacterial contamination, and extending shelf life.

This press release highlights the key drivers, emerging trends, segmentation, and regional analysis of the food preservatives industry as it continues its steady growth.

Drivers and Growth Factors

Several factors are contributing to the rising demand for food preservatives worldwide:

Increasing Consumer Demand for Processed and Packaged Foods: As consumer lifestyles become busier and more urbanized, there is a growing demand for convenience foods, processed snacks, ready-to-eat meals, and beverages. To meet this demand, food manufacturers rely on preservatives to extend product shelf life and maintain food safety standards.

Focus on Food Safety and Shelf Life: Food preservatives are essential for ensuring food safety and minimizing waste. With growing concerns about foodborne illnesses and contamination, the use of preservatives has become a critical step in maintaining the freshness and safety of food products during transportation and storage.

Rising Demand for Natural Preservatives: Consumer preferences are shifting towards clean-label, organic, and natural food products. As a result, there is a growing demand for natural preservatives derived from plants, minerals, and microbes, which are perceived as safer and healthier alternatives to synthetic preservatives.

Expansion of the Food and Beverage Industry: The expanding food and beverage industry, driven by increasing global population, urbanization, and changing dietary habits, is fueling the need for food preservatives. This growth is particularly pronounced in developing regions where the demand for packaged and processed foods is rising.

Technological Advancements in Preservation Techniques: Ongoing research and innovation in preservation techniques, including the development of new and more effective natural preservatives, are driving expansion. Companies are investing in advanced food preservation methods that cater to consumer preferences for longer shelf-life products without compromising quality or nutritional value.

Segmentation

The global food preservatives can be segmented by source, product type, form, end-use industries, and region.

By Source:

Plant-based Preservatives: Derived from natural sources like rosemary extract and botanical acids, plant-based preservatives are gaining popularity due to their clean-label appeal and natural origin. These are commonly used in organic and health-focused food products.

Microbial: Microbial-based preservatives, such as nisin and natamycin, are naturally occurring antimicrobials that prevent spoilage by inhibiting the growth of bacteria, mold, and yeast.

Mineral-based Preservatives: Mineral-based preservatives like sodium chloride (salt) and sodium nitrite are traditional, widely-used preservatives that help extend the shelf life of various food products.

Animal-based Preservatives: Although less common, certain animal-derived ingredients are used as preservatives, primarily in specific niche applications.

By Product Type:

Microbial-Derived Preservatives: These are naturally sourced preservatives that prevent microbial contamination. Popular examples include nisin and natamycin, which are used in dairy and meat products to control bacteria and fungi growth.

Nisin: Nisin is a natural antimicrobial preservative used in processed cheeses, meats, and canned foods to extend their shelf life by inhibiting bacterial growth.

Natamycin: Natamycin is primarily used as an antifungal agent in dairy and meat products, preventing the growth of mold and yeast on their surfaces.

Rosemary Extract: Known for its antioxidant properties, rosemary extract is widely used as a natural preservative in various processed foods to delay rancidity and oxidative spoilage.

Botanical Extracts: Derived from herbs and spices, botanical extracts such as thyme, garlic, and oregano offer antimicrobial properties that enhance food preservation.

Natural Acids and Salts: Natural acids (e.g., citric acid, lactic acid) and salts (e.g., sodium chloride, potassium sorbate) are effective in maintaining the pH balance and microbial stability of food products.

By Form:

Powder: Powdered preservatives are popular for their ease of incorporation into a wide range of food products, including baked goods, sauces, and dry mixes. Powdered preservatives are stable and can be easily stored.

Liquid: Liquid preservatives are widely used in beverages, sauces, and dressings due to their ease of mixing and fast absorption into liquid-based food products. They are particularly effective in maintaining the texture and freshness of liquids.

By End-Use Industries:

Foods & Beverages: The food and beverage industry is the largest consumer of preservatives, utilizing them to enhance the shelf life of products such as dairy, meat, bakery items, snacks, and beverages.

Pharmaceutical: Preservatives are also used in the pharmaceutical industry to extend the shelf life of medicines, particularly in liquid and gel formulations.

Textiles: In the textile industry, preservatives are used to prevent bacterial growth and deterioration of materials.

Petrochemicals: Preservatives are used to ensure the longevity and safety of petrochemical products by preventing microbial contamination and spoilage.

Adhesives: Preservatives in the adhesives industry help prevent microbial growth in adhesive solutions, ensuring product integrity over time.

Others: Other industries such as cosmetics, personal care, and packaging also utilize preservatives to maintain product freshness and safety.

Regional Outlook

North America: North America holds the largest share of the global food preservatives , driven by high consumer demand for convenience foods, ready-to-eat meals, and extended shelf-life products. The U.S. leads the , with an increasing preference for clean-label and natural preservatives.

Europe: Europe is the second-largest for food preservatives, with countries like Germany, France, and the U.K. leading the demand for natural preservatives in organic and health-focused food products. The region’s stringent regulations on food safety and product labeling are boosting the adoption of natural preservatives.

Asia-Pacific: The Asia-Pacific region is expected to witness the fastest growth during the forecast period, driven by increasing urbanization, rising disposable incomes, and growing demand for processed and packaged foods in countries such as China, India, and Japan.

Latin America and Middle East & Africa: These regions are emerging s for food preservatives, with rising consumer awareness of food safety, shelf-life concerns, and the expanding processed food industry driving growth.

Trends Shaping the Future of the Food Preservatives

Clean Label and Natural Preservatives: Consumers are increasingly seeking clean-label products free from artificial additives and chemicals. This has led to a surge in demand for natural preservatives derived from plants, herbs, and microbial sources.

Technological Advancements in Preservation Methods: Innovations in preservation technologies, such as advanced packaging solutions and natural preservative formulations, are helping manufacturers extend the shelf life of products without compromising quality or taste.

Growing Demand for Organic and Vegan Products: The rise of organic and plant-based food products is driving demand for preservatives that align with these dietary preferences. As more consumers adopt vegan and organic lifestyles, companies are developing preservatives that cater to these growing s.

Regulatory Pressures and Health Concerns: As regulations on artificial additives become more stringent in various regions, manufacturers are increasingly shifting toward natural and organic preservatives to comply with health and safety standards.

Key Players

Several key players are shaping the future of the food preservatives , including:

Kerry Group

Cargill, Inc.

DuPont Nutrition & Biosciences

BASF SE

Tate & Lyle

These companies are focused on innovation, sustainability, and expanding their product portfolios to meet the growing demand for food preservation solutions.

Conclusion

The global food preservatives is poised for steady growth over the coming decade, driven by increasing demand for convenience foods, clean-label products, and natural preservation solutions. With a projected CAGR of 5.41% from 2023 to 2030, the is expected to reach USD 5.30 billion by 2030, offering ample opportunities for innovation and expansion across various industries.

Read More Details @ https://www.snsinsider.com/reports/food-preservatives-market-1345

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

SNS Insider Offering/ Consulting Services:

Go To Market Assessment Service

Total Addressable Market (TAM) Assessment

Competitive Benchmarking and Market Share Gain

0 notes

Text

0 notes

Text

0 notes

Text

Market Insights: Sodium Cyanide Demand and Supply Dynamics

The Deadly Poison: Understanding Sodium Cyanide History and Discovery Sodium cyanide was discovered in the 18th century and has since been utilized for various industrial purposes. First produced in Germany in 1782, it has found widespread commercial application as a reagent in gold and silver mining. This cyanide works by solubilizing precious metals, allowing them to be separated from ore. It has been one of the primary methods for extracting gold from mineral deposits since the late 1800s. Beyond mining, it is also used to manufacture items like dyes, plastics and pharmaceuticals. However, it is also highly poisonous to humans and other living organisms. It was first used as a pesticide in the late 19th century and briefly served as a chemical weapon during World War I before being banned internationally. Due to its ability to quickly kill via inhibition of cellular respiration, cyanide compounds have also been employed for capital punishment in some countries. Overall, sodium cyanide's discovery unlocked economic opportunities but also introduced grave human safety concerns that remain relevant today. Chemical and Physical Properties On a molecular level, it is composed of one sodium atom bound to one cyanide ion. The chemical formula is NaCN. It appears as a white, crystalline solid at room temperature with a faint, bitter almond-like odor. This cyanide is highly soluble in water. It burns or explodes when heated to decomposition, releasing toxic fumes of hydrogen cyanide, carbon monoxide and nitrogen oxides. These physical attributes have contributed to sodium cyanide's use for dangerous purposes as well as the challenges in transporting, storing and disposing of it safely. A key property is that sodium cyanide readily dissociates in water to yield hydrocyanic acid (hydrogen cyanide, HCN), a volatile liquid that can be inhaled or absorbed through the skin. Hydrogen cyanide interferes with cellular respiration by inhibiting an enzyme called cytochrome c oxidase. This ultimately stops oxygen from being used to generate energy-carrying molecules within cells, causing rapid asphyxiation at the cellular level. For these reasons, even small amounts of ingested or inhaled cyanide can prove fatal within minutes. Toxic Effects and Treatment The symptoms of cyanide poisoning generally appear rapidly after exposure. Initial signs may include headache, dizziness and confusion. As the toxin takes effect, breathing becomes difficult and the skin turns bright red as oxygen levels in the bloodstream plummet. Unconsciousness, seizures, cardiac arrest and death from respiratory failure can follow within minutes if treatment is not given. Some people may lose consciousness so quickly that poison exposure goes initially unnoticed. There is no specific antidote for cyanide, but certain treatments can help prevent further damage if acted upon urgently. Removing the person from the toxic environment and administering oxygen are initial steps, followed by administering sodium nitrite intravenously to induce methemoglobinemia - a condition where the oxygen-carrying compound in red blood cells, hemoglobin, is temporarily deactivated by nitric oxide. This overcomes cyanide's effects by preventing it from binding to cytochrome c oxidase. Sodium thiosulfate may also be administered to help the liver detoxify cyanide more rapidly. With prompt stabilization and supportive care, survival is possible even after serious poisoning, but outcomes depend highly on quick response. Delay can easily prove fatal.

0 notes

Text

Decoding the Future: Food Preservative Market Trends Unveiled

Introduction:

According to the study by Next Move Strategy Consulting, the global Food Preservative Market size is predicted to reach USD 4.10 billion with a CAGR of 4.1% by 2030. With such promising projections, it's evident that the food preservation industry is poised for significant growth and evolution in the coming years.

Request a FREE sample, here: https://www.nextmsc.com/food-preservative-market/request-sample

In an era where consumers are increasingly conscious about the quality and safety of the food they consume, the role of food preservatives becomes more crucial than ever. Food preservatives not only extend the shelf life of perishable products but also help maintain their freshness and nutritional value, thereby ensuring food safety and reducing food waste.

Rising Demand for Natural Preservatives

One of the most notable trends shaping the future of the food preservative market is the rising demand for natural preservatives. Consumers are becoming more discerning about the ingredients used in their food products, preferring natural and clean label options over synthetic additives. This shift in consumer preferences is driven by concerns about health, sustainability, and transparency in food production.

Natural preservatives, derived from plant extracts, herbs, spices, and other natural sources, offer an attractive alternative to synthetic preservatives such as sodium nitrite and potassium sorbate. These natural alternatives not only serve the purpose of preserving food but also provide additional health benefits, as many of them possess antioxidant and antimicrobial properties.

Manufacturers are responding to this demand by investing in research and development to identify and harness the potential of natural preservatives. This has led to the introduction of innovative solutions that meet both consumer preferences and regulatory requirements. For example, rosemary extract, grapefruit seed extract, and green tea extract are commonly used natural preservatives that have gained popularity in the food industry.

Focus on Clean Label and Transparency

In addition to the demand for natural preservatives, there is a growing emphasis on clean label and transparency in the food industry. Consumers are increasingly scrutinizing product labels and ingredient lists, seeking reassurance about the safety and quality of the food they consume. As a result, food manufacturers are under pressure to provide clear and accurate information about the preservatives used in their products.

Clean label products, which are free from artificial additives, preservatives, and other undesirable ingredients, are gaining traction among health-conscious consumers. These products appeal to consumers who prioritize simplicity, authenticity, and transparency in their food choices. To meet this demand, manufacturers are reformulating their products to eliminate synthetic preservatives and replace them with natural alternatives.

Transparency in labeling and ingredient sourcing is becoming a key differentiator for brands seeking to gain consumer trust and loyalty. By clearly communicating the use of natural preservatives and other clean label ingredients, manufacturers can enhance their brand reputation and appeal to a growing segment of health-conscious consumers.

Technological Advancements in Preservation Techniques

Advancements in food preservation technologies are driving innovation and transformation in the food preservative market. Traditional methods of food preservation, such as canning, freezing, and drying, are being supplemented and enhanced by new technologies that offer improved efficiency, quality, and sustainability.

One such technology is high-pressure processing (HPP), which uses high pressure to inactivate spoilage microorganisms and extend the shelf life of food products. HPP is particularly well-suited for preserving fresh juices, deli meats, and ready-to-eat meals, as it allows for the preservation of taste, texture, and nutritional value without the need for heat or chemical additives.

Pulsed electric field (PEF) technology is another promising preservation technique that involves the application of short pulses of high-voltage electricity to food products. PEF treatment disrupts the cell membranes of microorganisms, inhibiting their growth and prolonging the shelf life of perishable foods. This non-thermal preservation method is gaining popularity due to its ability to preserve the sensory qualities and nutritional content of food products.

Inquire before buying, here: https://www.nextmsc.com/food-preservative-market/inquire-before-buying

Active packaging is yet another area of innovation in food preservation technology. Active packaging materials incorporate antimicrobial agents, oxygen scavengers, and other additives to actively inhibit microbial growth, delay oxidation, and maintain product freshness. These advanced packaging solutions help extend the shelf life of food products and reduce the need for additional preservatives.

Growing Emphasis on Food Waste Reduction

Food waste is a significant issue facing the global food industry, with billions of tons of food being wasted each year at various stages of production, distribution, and consumption. In response to this challenge, there is a growing emphasis on implementing preservative solutions that not only extend shelf life but also minimize food waste along the supply chain.

Preservation techniques that optimize storage, transportation, and distribution processes play a critical role in reducing food waste and improving supply chain efficiency. For example, modified atmosphere packaging (MAP) involves modifying the atmosphere inside food packaging to slow down the growth of spoilage microorganisms and extend the shelf life of perishable products. MAP is widely used for packaging fresh produce, meats, and dairy products, helping reduce food spoilage and loss during storage and transit.

Cold chain management is another important aspect of food preservation that helps maintain the quality and safety of perishable products throughout the supply chain. Proper refrigeration and temperature control are essential for preserving the freshness and nutritional value of foods, minimizing spoilage and waste.

Additionally, innovative preservation techniques such as food irradiation and vacuum packaging are being explored as means of extending the shelf life of food products and reducing food waste. These technologies offer viable solutions for preserving perishable foods and minimizing losses due to spoilage and degradation.

Regulatory Landscape and Consumer Awareness

The food preservative market is subject to stringent regulations governing the use of preservatives in food products. Regulatory agencies such as the Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) set standards and guidelines for the safety and labeling of food additives, including preservatives.

Manufacturers are required to comply with these regulations and ensure that their products meet safety and quality standards before they can be marketed and sold to consumers. This includes conducting safety assessments, obtaining regulatory approvals, and accurately labeling preservatives and other additives on product packaging.

In addition to regulatory requirements, consumer awareness and preferences also play a significant role in shaping the food preservative market. As consumers become more informed about the potential health risks associated with synthetic preservatives and other additives, they are seeking out products that offer clean label alternatives.

This heightened awareness has prompted manufacturers to reformulate their products and remove artificial preservatives, colors, and flavors from their formulations. By embracing clean label practices and transparency in labeling, manufacturers can meet consumer expectations for safer, healthier, and more natural food options.

Conclusion

In conclusion, the future of the food preservative market holds immense potential for growth and innovation. With evolving consumer preferences, technological advancements, and regulatory developments, the industry is poised to witness significant transformations in the years to come. By staying abreast of emerging trends and adopting sustainable and consumer-friendly practices, stakeholders in the food preservative market can capitalize on new opportunities and drive continued success.

From natural preservatives and clean-label products to advanced preservation technologies and food waste reduction strategies, the future of food preservation is bright and promising. As consumers continue to prioritize health, sustainability, and transparency in their food choices, the demand for safe, fresh, and minimally processed foods will drive innovation and evolution in the food preservative market.

#food preservatives#market research#market trends#global market#innovation#industry insights#food and beverage industry

0 notes

Text

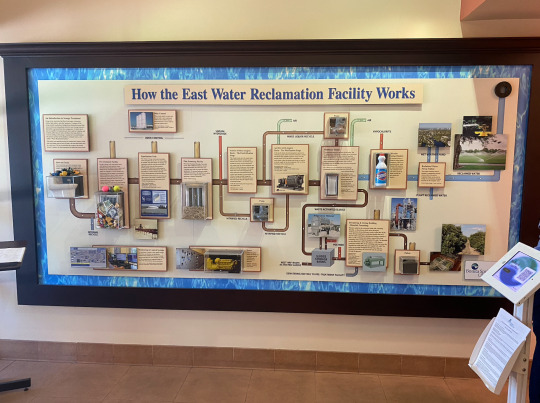

Bonita Springs Water Reclamation Facility

Photo taken by me.

The Bonita Springs East Water Reclamation Facility is a wastewater treatment plant that is leading its industry in sustainable practices. Up to 4 million gallons of sewage are processed at this facility every day, and the sewage is turned into new products that are sold to generate revenue for the plant. The process begins when water from drains all around the Bonita Springs area reaches the water reclamation facility through underground pipes. Large materials are removed from the water using a coarse drum screen before it reaches the equalization tank. The equalization tank serves the purpose of treating the sewage at a continuous rate as well as aerating the sewage to reduce malodors. The sewage is then moved through a finer drum screen to remove smaller solids, which are taken to a landfill. Next is the denitrification stage, which occurs inside the anoxic basin. The book “Sustainability Principles and Practice” explains that “some anaerobic bacteria can metabolize some kinds of contaminants that cannot be broken down by aerobic bacteria (Alexander 1999, 369). It is anaerobes who digest food in animal digestive tracts, sewage in wastewater treatment tanks, and buried matter in landfills” (Robertson, 2021, pp. 190-191). Indeed, anaerobic microorganisms are used at the wastewater treatment plant to consume any organic material in the sewage. From the anoxic basin, the water moves into the aerobic basin, where microorganisms use the oxygen in the basin for energy to convert ammonia in the sewage into nitrate and nitrite ions. Next, the water moves through Veolia membranes, which are long fibers with microscopic pores that filter all impurities out of the water. The next steps in the process turn the reclaimed water into products that are profitable for the facility.

Photo taken by me.

According to the textbook, “One industrial ecology strategy sets up closed-loop “food webs” among industries, where output from one industry is input for another and materials are reused. These networks of exchanges are sometimes referred to as industrial symbiosis or industrial metabolism. A complex of industrial facilities that applies these principles in an industrial ecosystem is referred to as an eco-industrial park” (Robertson, 2021, p. 344). The Bonita Springs East Water Reclamation Facility is a great example of a chain in one of these eco-industrial parks. After passing through the membrane basins, the remaining biosolids in the wastewater are mixed with polymers, thickened, and heated, evaporating the remaining water and turning the biosolids into small pellets. These pellets are marketed as fertilizer and make money for the wastewater treatment plant. The recovered water is disinfected using sodium hypochlorite and sent to a water pump station, where it is sold as irrigation water to businesses such as golf courses. Wastewater facilities like this one face many challenges, including excessive amounts of nutrients like nitrogen and phosphorus, limiting the energy used by the plant to run its operations, and limiting the release of endocrine disruptors into the environment. Despite these challenges, the Bonita Springs East Water Reclamation Facility has found a sustainable way to turn “waste” into profitable products that are in high demand by other industries.

Photo taken by me.

References:

Robertson, M. (2021). Sustainability Principles and Practice (3rd ed.). Taylor & Francis Group.

0 notes

Text

Sodium Nitrite Prices | Pricing | Price | News | Database | Chart | Forecast

Sodium Nitrite prices is a chemical compound widely used across various industries, including food preservation, pharmaceuticals, and industrial processes. The price of sodium nitrite can fluctuate based on several factors, making it a subject of interest for businesses and investors alike. Understanding the dynamics that influence sodium nitrite prices is crucial for anyone involved in these industries.

Sodium nitrite prices are influenced by supply and demand dynamics, production costs, regulatory factors, and global market conditions. The supply of sodium nitrite is dependent on the production capacities of manufacturers, which are, in turn, influenced by the availability of raw materials, production technology, and operational efficiencies. Fluctuations in the supply chain, such as shortages of raw materials or disruptions in manufacturing processes, can lead to changes in sodium nitrite prices. For instance, if the supply of key raw materials such as sodium or nitric acid is limited, the cost of producing sodium nitrite can increase, leading to higher prices for the end product.

Demand for sodium nitrite is driven by its various applications across multiple industries. In the food industry, sodium nitrite is commonly used as a preservative and color fixative in processed meats, such as bacon, ham, and sausages. The demand in this sector is relatively stable, as these food products are staples in many diets worldwide. However, any changes in consumer preferences, such as shifts towards organic or nitrite-free products, could impact the demand for sodium nitrite, potentially affecting its price. In the pharmaceutical industry, sodium nitrite is used in the production of medications that treat cyanide poisoning, among other uses. The demand in this sector can be influenced by healthcare trends and the prevalence of certain medical conditions. Industrial applications, such as in the production of dyes and rubber chemicals, also contribute to the overall demand for sodium nitrite. Any increase in demand from these sectors can lead to upward pressure on prices.

Get Real Time Prices for Sodium Nitrite: https://www.chemanalyst.com/Pricing-data/sodium-nitrite-1210

Global market conditions play a significant role in determining sodium nitrite prices. The chemical industry is closely tied to the global economy, and any economic fluctuations can impact prices. For example, during periods of economic growth, industrial activity typically increases, leading to higher demand for chemicals like sodium nitrite. Conversely, during economic downturns, demand may decrease, leading to potential price reductions. Additionally, trade policies, tariffs, and international relations can influence the global supply chain, affecting the availability and cost of sodium nitrite.

Production costs are another critical factor in determining sodium nitrite prices. These costs include raw materials, energy, labor, and transportation. Any increase in these costs can lead to higher sodium nitrite prices. For example, rising energy costs can significantly impact the production of sodium nitrite, as the chemical manufacturing process is energy-intensive. Similarly, increases in transportation costs due to higher fuel prices or logistical challenges can also drive up the overall cost of sodium nitrite, which may be passed on to consumers in the form of higher prices.

Regulatory factors can also impact sodium nitrite prices. Governments and regulatory bodies around the world impose various regulations on the production, use, and disposal of chemicals, including sodium nitrite. Compliance with these regulations can add to the production costs, which may be reflected in the price. For example, stricter environmental regulations may require manufacturers to invest in cleaner production technologies or more expensive waste management practices, leading to higher production costs and, consequently, higher prices for sodium nitrite. Additionally, regulations regarding the use of sodium nitrite in food products can influence demand and price. If regulations become more stringent, leading to reduced usage in certain applications, demand could decrease, potentially leading to lower prices.

Geopolitical factors can also play a role in sodium nitrite pricing. The global chemical industry is interconnected, with raw materials, finished products, and intermediates often crossing multiple borders before reaching the end consumer. Geopolitical tensions, trade wars, or sanctions can disrupt this global supply chain, leading to supply shortages or increased costs, which can, in turn, affect sodium nitrite prices. For example, if a major producer of sodium nitrite is located in a region experiencing political instability, the risk of supply disruptions could drive up prices due to concerns about the availability of the product.

Market competition among manufacturers and suppliers also influences sodium nitrite prices. In a highly competitive market, manufacturers may reduce prices to maintain or grow their market share, especially if there is an oversupply of sodium nitrite. Conversely, if there are few manufacturers or if the market is dominated by a few large players, prices may be higher due to the lack of competition. Mergers and acquisitions within the industry can also impact prices, as consolidation may lead to reduced competition and potentially higher prices.

Lastly, technological advancements in the production of sodium nitrite can influence prices. As manufacturers adopt more efficient production methods or develop alternative processes, production costs may decrease, leading to lower prices. However, the initial investment in new technology can be significant, and manufacturers may pass these costs on to consumers in the short term before realizing long-term cost savings.

In summary, sodium nitrite prices are shaped by a complex interplay of factors including supply and demand dynamics, production costs, regulatory influences, global market conditions, geopolitical factors, market competition, and technological advancements. Understanding these factors is essential for businesses and investors who need to navigate the fluctuations in sodium nitrite prices effectively. By keeping a close eye on these influencing factors, stakeholders can make informed decisions and better anticipate future price movements in the sodium nitrite market.

Get Real Time Prices for Sodium Nitrite: https://www.chemanalyst.com/Pricing-data/sodium-nitrite-1210

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Sodium Nitrite#Sodium Nitrite Price#Sodium Nitrite Prices#Sodium Nitrite Pricing#Sodium Nitrite News#Sodium Nitrite Price Monitor

0 notes

Link

0 notes

Text

The Evolving Landscape of Food Preservatives: Key Market Developments

The food preservatives market refers to the industry that produces and supplies substances used to prolong the shelf life of food products by inhibiting the growth of microorganisms, oxidation, or other undesirable chemical changes. These preservatives help maintain the quality, safety, and freshness of food, allowing for longer storage, transportation, and distribution.

The global food preservatives industry size was valued at US$ 3.3 billion in 2022 and is poised to grow from US$ 3.4 billion in 2023 to US$ 3.9 billion by 2028, growing at a CAGR of 3.0% in the forecast period (2023-2028).

The food preservatives industry includes various types of preservatives such as antimicrobials, antioxidants, and antimicrobial/antioxidant blends, among others. Commonly used preservatives include sodium benzoate, potassium sorbate, nitrites, sulfites, and ascorbic acid among others.

Factors Driving the Food Preservatives Market Growth

Global urbanization and rising employment rates have drastically changed consumer lifestyles and eating habits. Convenience is key, leading to a demand for food products that are easy to prepare, consume, and have a longer shelf life. Food preservatives play a critical role in achieving this by extending shelf life and maintaining freshness. This surge in demand for extended shelf life has correspondingly increased the demand for food preservatives in the food and beverage industry.

Make an Inquiry to Address your Specific Business Needs

Furthermore, preservatives offer manufacturers advantages in terms of storage efficiency and competitive pricing, further solidifying their importance. It’s important to note that the post-pandemic rise in health consciousness is also positively impacting the market. This trend is driving the growth of natural preservatives like citric acid and rosemary extracts, propelling the overall food preservatives industry forward.

Top Food Preservatives Manufacturers

Cargill, Incorporated (US)

Kerry Group plc (Ireland)

ADM (US)

DSM (Netherlands)

Kemin Industries Inc. (US)

How natural food preservatives are creating growth opportunities for the industry players in the food & beverage industry?

Consumers these days are increasingly looking for natural, fresh, wholesome, and balanced nutrition, leading them to scrutinize product labels more and prioritize clean food ingredients. This trend is driving innovation in the food & beverage industry, with manufacturers of food preservatives focusing on clean-labelled solutions and breakthroughs. As a result, the growing demand for clean-label products is expected to create lucrative growth opportunities for market players to develop new formulations.

Synthetic food preservatives are estimated to account for the largest food preservatives market share

The wide-scale popularity of synthetic food preservatives in the food preservatives market can be attributed to several factors. These include their well-established effectiveness, readily available supply, and cost-efficiency. Additionally, lower regulatory hurdles and reduced research and development investment required in emerging Asia-Pacific economies further contribute to their dominance in the market.

North AmericanFood Preservatives Industry

North America’s massive consumption of packaged and ready-to-eat foods, coupled with its position as a leading exporter of meat products, fuels the high demand for food preservatives in the region. These processed and meat products rely on preservatives to extend their shelf life, making North America a continuously attractive market for the food preservatives industry.

New Breakthroughs in the Food Preservatives Market: What You Need to Know

In March 2022, Kerry Group plc (Ireland) expanded its food manufacturing facilities with the newly upgraded facility in Rome, Georgia. A total of USD 141 million has been invested in creating the largest food manufacturing facility in the US. This facility aims to provide integrated taste and nutrition solutions to meet the growing consumer demand in the poultry, seafood, and alternative protein markets across the US and Canada.

In April 2021, Jungbunzlauer Suisse AG (Switzerland) expanded its citric plant in Port Colborne, Canada, owing to the consistently strong and growing global demand for citric acid and citrates. These products are functional and bio-based ingredients in food, beverages, detergents, and industrial applications. This expansion will help the company improve its portfolio for customers looking for safe and biodegradable products from sustainable production plants.

0 notes

Text

Natural Food and Beverage Preservatives Market 2022 by Global Key Players, Types, Applications, Countries, Industry Size and Forecast to 2032

The global natural food and beverage preservatives market size is expected to reach US$ 880.4 million in 2032. As per FMI Analysts, the global natural food and beverage preservatives market is estimated to be valued at US$ 435.2 million in 2022, and is projected to increase at a CAGR of 7.3% in the forecast period from 2022 to 2032.

Food & beverage preservatives are widely used in the market by the food manufacturers, as they maintain the taste, quality and color of the food. Addition of preservatives eliminates the possibility of spoilage of the product. Manufacturers are widely using preservatives during processing of natural food and beverages.

Natural food & beverage preservatives maintain the appearance of the food, and its color. Naturally, food and beverages have a small shelf life, and by addition of natural food and beverage preservatives, food items can stay for a long time. Earlier to preserve food ingredients like sugar, alcohol, and salts are used. But, these preservatives can preserve food for a smaller period.

Stay ahead of the curve with our in-depth Sample report on the Natural Food and Beverage Preservatives Market! https://www.futuremarketinsights.com/reports/sample/rep-gb-6242

So, food manufacturers prefer artificial preservatives over natural preservative that extents shelf life of food & beverages. Natural food & beverage preservatives are highly consumed by food manufacturers, in the market.

Global Natural Food and Beverage Preservatives Market: Dynamics

Global natural food and beverage preservatives market is driven by the rising demand for packed food & beverages in the market. Busy lifestyle of consumers has increased their dependency towards packaged food products. They are preferring readymade food products. So for fulfilling the demand, food manufacturers are using natural food and beverage preservatives, in order to preserve food items and extend their shelf life.

Food manufacturers are using the different processes as well as various additives to preserve food. Nowadays, processes like nuclear radiation is also used for preserving natural food and beverage. Chemical preservatives are widely used for eliminating the possibility of spoilage, as they suppress the growth of microbes and bacteria’s.

Artificial additives sodium benzoate, benzoic acid, sodium nitrite, sodium sorbate, potassium sorbate are widely used by food manufacturers. One of the restraining factors for natural food and beverage preservatives market is that preservatives are banned in some parts of Europe, as these chemical preservatives are harmful. They may cause serious health issues like asthma, stomach cancer, allergies and brain damage.

Global Natural Food and Beverage Preservatives Market: Regional Overview

Global natural food and beverage preservatives market is segmented into seven regions including North America, Latin America, Eastern Europe, Western Europe, Middle East and Africa (MEA), Asia Pacific excluding Japan (APEJ) and Japan.

The Asia Pacific region shows the rapid growth of natural food and beverage preservatives market with the increase in paying capacity of consumers of Asia Pacific. Countries such as Russia have banned the use of preservatives. Food manufacturers, countries in this region are looking for natural preservatives, which will enhance the quality of the food product and extends the shelf life. The region shows slow growth of natural food and beverage preservatives market.

Are you curious about the Natural Food and Beverage Preservatives Market? Speak directly with our knowledgeable analyst to explore market projections, challenges, and emerging opportunities. https://www.futuremarketinsights.com/ask-question/rep-gb-6242

Global Natural Food and Beverage Preservatives Market: Key Players

Some of the key players of natural food and beverage preservatives market are Koninklijke DSM N.V. Akzo Nobel N.V., Cargill, Incorporated, DuPont etc.

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to market segments such as geographies, application, and industry.

Key Segments Profiled in the Natural Food and Beverage Preservatives Market

By Product Type:

Natural preservatives

Salt

Sugar

Alcohol

Vinegar

Rosemary Extracts

Others

Artificial preservatives

Benzoates

Sodium Benzoate

Benzoic Acid

Nitrites

Sodium nitrates

Sulfite

Sulphur Dioxide

Acetic Acid

Sodium Diacetate

Lactic Acid

Sorbates

Sodium Sorbate

Potassium Sorbate

Propionates

Others

By Function:

Antimicrobials

Antioxidants

Chelating Agents

Flavoring agents

Texturants

Emulsifier

Others

By Application Type:

Bakery

Beverages

Confectionery

Meat, Poultry & Seafood

Frozen Food

Dairy products

Snack Food

Fats and Oils

Others

By Form:

Solid

Liquid

Frequently Asked Questions

At What Rate will the Natural Food and Beverage Preservatives Market Grow?

Which Region is set to Lead the Natural Food and Beverage Preservatives Market?

What is the Growth Outlook for the Natural Food and Beverage Preservatives Market?

Information source: https://www.futuremarketinsights.com/reports/natural-food-and-beverage-preservatives-market

0 notes

Text

0 notes

Link

[ad_1] LONDON - British police said Friday they are investigating the deaths of 88 people in the U.K. who bought products from Canada-based websites allegedly offering lethal substances to people at risk of self-harm. The probe is part of international inquiries sparked by the arrest in Canada earlier this year of Kenneth Law, who has been charged with two counts of counselling and aiding suicide. Canadian police say Law, from the Toronto area, used a series of websites to market and sell sodium nitrite, a substance commonly used to cure meats that can be deadly if ingested. Police said Law is suspected of sending at least 1,200 packages to more than 40 countries. Authorities in the United States, Italy, Australia and New Zealand also have launched investigations. Britain's National Crime Agency said it has identified 232 people in the U.K. who bought products from the websites in the two years until April, 88 of whom had died. The agency said it was investigating whether any crimes had been committed in the U.K., but that "at this early stage there are no confirmed links between the items purchased from the websites and cause of death in any of these cases." "Our deepest sympathies are with the loved ones of those who have died. They are being supported by specially trained officers from police forces," said National Crime Agency Deputy Director Craig Turner. ------ If you or someone you know is in crisis, here are some resources that are available. Canada Suicide Prevention Helpline (1-833-456-4566) Centre for Addiction and Mental Health (1 800 463-2338) Crisis Services Canada (1-833-456-4566 or text 45645) Kids Help Phone (1-800-668-6868) If you need immediate assistance call 911 or go to the nearest hospital. [ad_2]

0 notes