#Smart Factory Market Trends

Explore tagged Tumblr posts

Text

Smart Factory Market Trends, Size, Revenue And Top Key Players, 2030

The global smart factory market was valued at USD 130.25 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 9.8% from 2023 to 2030. The expansion of this market is driven by several factors, including the increasing emphasis on energy efficiency, enhanced manufacturing productivity, and the establishment of advanced manufacturing infrastructures. Additionally, emerging technologies such as collaborative robots and advancements in 3D printing present significant growth opportunities for the market during the forecast period.

The global smart factory market is poised for significant growth, driven by technological advancements, a focus on energy efficiency, and the increasing need for resilient and flexible manufacturing. Innovations in AI, IoT, and 3D printing, coupled with rising automation trends, are expected to revolutionize manufacturing processes, creating substantial opportunities for stakeholders in the market. Regional dynamics, such as Asia Pacific’s leadership and Latin America’s rapid industrialization, further underscore the global potential of the smart factory industry.

Role of Emerging Technologies:

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML technologies are central to the operations of smart factories, enabling manufacturers to optimize processes and improve outcomes. Their applications include:

Predictive Maintenance: AI analyzes equipment data to predict failures, minimizing downtime and maintenance costs.

Quality Control: Machine learning algorithms detect anomalies during production, ensuring product quality.

Process Optimization: Real-time data analysis allows for adjustments to enhance efficiency and reduce waste.

As these technologies evolve, their integration into smart factory environments is expected to deepen, unlocking further efficiencies and capabilities.

Internet of Things (IoT)

IoT forms the backbone of smart factories by enabling real-time monitoring and control of equipment and processes. Its benefits include:

Enhanced automation through connected devices, sensors, and actuators.

Greater visibility across production lines, improving efficiency and decision-making.

The advancement of 5G networks and edge computing, which allow faster data processing and more reliable machine communication.

These developments are driving the adoption of IoT-enabled smart factory solutions.

Gather more insights about the market drivers, restrains and growth of the Smart Factory Market

Regional Insights:

Asia Pacific Smart Factory Market Trends

The Asia Pacific region dominated the global smart factory market in 2022, accounting for over 35% of the total revenue. This region has cemented itself as a global manufacturing hub, driven by a combination of factors:

Industrial Automation and Technological Advancements:

Countries such as China, Japan, and South Korea are at the forefront of industrial innovation, emphasizing automation to enhance production efficiency. These nations have embraced advanced technologies, such as robotics, Internet of Things (IoT), and Artificial Intelligence (AI), as part of their commitment to modernizing their manufacturing capabilities.

Growing Population and Consumer Demand:

The rapidly expanding population across Asia Pacific has led to heightened demand for consumer goods, including automobiles and electronics. This has necessitated the adoption of efficient, high-capacity manufacturing solutions to meet large-scale production needs without compromising quality.

Government Initiatives and Investments in Industry 4.0:

Regional governments are actively promoting the adoption of Industry 4.0 principles through policies and financial incentives. For example:

China’s "Made in China 2025" initiative focuses on transforming the country into a global leader in high-tech manufacturing.

Japan’s Society 5.0 framework integrates technology with traditional industries to optimize production.

South Korea’s Smart Factory Supply Chain Support initiatives aim to build a robust infrastructure for interconnected factories.

These measures encourage the development and deployment of smart factory technologies, ensuring sustained growth in the region.

Latin America Smart Factory Market Trends

Latin America is poised for substantial growth, with a projected compound annual growth rate (CAGR) exceeding 10% during the forecast period. The region’s adoption of smart factory technologies is underpinned by several key trends:

Increasing Industrialization and Focus on Efficiency:

Latin America is experiencing a wave of industrial growth, particularly in sectors looking to optimize resource utilization and improve productivity. By incorporating smart factory solutions, manufacturers can streamline their operations and remain competitive on a global scale.

Sectoral Investment in Key Industries:

Investment in critical sectors such as automotive, electronics, and aerospace is driving the demand for advanced manufacturing technologies.

The automotive industry is leveraging smart factory systems for precision manufacturing and quality assurance.

The electronics sector relies on automation and IoT for efficient production of high-demand consumer devices.

The aerospace industry uses data-driven manufacturing to meet stringent international standards for safety and performance.

Global Market Competitiveness:

To cater to international markets, businesses in the region are adopting smart factory practices that ensure consistency, cost efficiency, and high-quality outputs. These practices also enable manufacturers to meet the growing demand for exports while maintaining compliance with global regulations and standards.

Supportive Policies and Partnerships:

Governments and private stakeholders in Latin America are recognizing the value of smart factory technologies. Policies encouraging technology adoption and international collaborations are playing a pivotal role in driving growth.

Browse through Grand View Research's Category Next Generation Technologies Industry Research Reports.

The global e-liquid market size was valued at USD 2.26 billion in 2024 and is projected to grow at a CAGR of 14.0% from 2025 to 2030.

The global intelligent document processing market size was estimated at USD 2.30 billion in 2024 and is projected to grow at a CAGR of 33.1% from 2025 to 2030.

Key Companies & Market Share Insights:

The market is classified as highly competitive, with the presence of several smart factory players. The key players operating in the industry are focusing on strategic alliances, product developments, expansions, and mergers & acquisitions to remain competitive. For instance, in March 2023, Schneider Electric SE, a digital transformation provider of energy management and industrial automation, initiated the construction of its upcoming smart factory in Dunavesce, Hungary. This state-of-the-art facility, backed by an investment of USD 42.67 million (€40 million), would cover an area of 25,000 sq. m. and will accommodate a workforce of 500 employees. Such strategies by key players are anticipated to augment market growth over the forecast period.

Key Smart Factory Companies:

ABB, Ltd.

Dassault Systemes S.E.

FANUC Corporation

General Electric Company

Honeywell International, Inc.

Johnson Controls, Inc.

KUKA AG

Mitsubishi Electric Corporation

Rockwell Automation, Inc.

Schneider Electric SE

Canon Inc.

Cisco System Inc.

Emerson Electric Co.

Order a free sample PDF of the Smart Factory Market Intelligence Study, published by Grand View Research.

0 notes

Text

Smart Factory Industry Size, Status, Analysis and Forecast 2030

The global smart factory market was valued at USD 130.25 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 9.8% from 2023 to 2030. The expansion of this market is driven by several factors, including the increasing emphasis on energy efficiency, enhanced manufacturing productivity, and the establishment of advanced manufacturing infrastructures. Additionally, emerging technologies such as collaborative robots and advancements in 3D printing present significant growth opportunities for the market during the forecast period.

The global smart factory market is poised for significant growth, driven by technological advancements, a focus on energy efficiency, and the increasing need for resilient and flexible manufacturing. Innovations in AI, IoT, and 3D printing, coupled with rising automation trends, are expected to revolutionize manufacturing processes, creating substantial opportunities for stakeholders in the market. Regional dynamics, such as Asia Pacific’s leadership and Latin America’s rapid industrialization, further underscore the global potential of the smart factory industry.

Role of Emerging Technologies:

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML technologies are central to the operations of smart factories, enabling manufacturers to optimize processes and improve outcomes. Their applications include:

Predictive Maintenance: AI analyzes equipment data to predict failures, minimizing downtime and maintenance costs.

Quality Control: Machine learning algorithms detect anomalies during production, ensuring product quality.

Process Optimization: Real-time data analysis allows for adjustments to enhance efficiency and reduce waste.

As these technologies evolve, their integration into smart factory environments is expected to deepen, unlocking further efficiencies and capabilities.

Internet of Things (IoT)

IoT forms the backbone of smart factories by enabling real-time monitoring and control of equipment and processes. Its benefits include:

Enhanced automation through connected devices, sensors, and actuators.

Greater visibility across production lines, improving efficiency and decision-making.

The advancement of 5G networks and edge computing, which allow faster data processing and more reliable machine communication.

These developments are driving the adoption of IoT-enabled smart factory solutions.

Gather more insights about the market drivers, restrains and growth of the Smart Factory Market

Regional Insights:

Asia Pacific Smart Factory Market Trends

The Asia Pacific region dominated the global smart factory market in 2022, accounting for over 35% of the total revenue. This region has cemented itself as a global manufacturing hub, driven by a combination of factors:

Industrial Automation and Technological Advancements:

Countries such as China, Japan, and South Korea are at the forefront of industrial innovation, emphasizing automation to enhance production efficiency. These nations have embraced advanced technologies, such as robotics, Internet of Things (IoT), and Artificial Intelligence (AI), as part of their commitment to modernizing their manufacturing capabilities.

Growing Population and Consumer Demand:

The rapidly expanding population across Asia Pacific has led to heightened demand for consumer goods, including automobiles and electronics. This has necessitated the adoption of efficient, high-capacity manufacturing solutions to meet large-scale production needs without compromising quality.

Government Initiatives and Investments in Industry 4.0:

Regional governments are actively promoting the adoption of Industry 4.0 principles through policies and financial incentives. For example:

China’s "Made in China 2025" initiative focuses on transforming the country into a global leader in high-tech manufacturing.

Japan’s Society 5.0 framework integrates technology with traditional industries to optimize production.

South Korea’s Smart Factory Supply Chain Support initiatives aim to build a robust infrastructure for interconnected factories.

These measures encourage the development and deployment of smart factory technologies, ensuring sustained growth in the region.

Latin America Smart Factory Market Trends

Latin America is poised for substantial growth, with a projected compound annual growth rate (CAGR) exceeding 10% during the forecast period. The region’s adoption of smart factory technologies is underpinned by several key trends:

Increasing Industrialization and Focus on Efficiency:

Latin America is experiencing a wave of industrial growth, particularly in sectors looking to optimize resource utilization and improve productivity. By incorporating smart factory solutions, manufacturers can streamline their operations and remain competitive on a global scale.

Sectoral Investment in Key Industries:

Investment in critical sectors such as automotive, electronics, and aerospace is driving the demand for advanced manufacturing technologies.

The automotive industry is leveraging smart factory systems for precision manufacturing and quality assurance.

The electronics sector relies on automation and IoT for efficient production of high-demand consumer devices.

The aerospace industry uses data-driven manufacturing to meet stringent international standards for safety and performance.

Global Market Competitiveness:

To cater to international markets, businesses in the region are adopting smart factory practices that ensure consistency, cost efficiency, and high-quality outputs. These practices also enable manufacturers to meet the growing demand for exports while maintaining compliance with global regulations and standards.

Supportive Policies and Partnerships:

Governments and private stakeholders in Latin America are recognizing the value of smart factory technologies. Policies encouraging technology adoption and international collaborations are playing a pivotal role in driving growth.

Browse through Grand View Research's Category Next Generation Technologies Industry Research Reports.

The global e-liquid market size was valued at USD 2.26 billion in 2024 and is projected to grow at a CAGR of 14.0% from 2025 to 2030.

The global intelligent document processing market size was estimated at USD 2.30 billion in 2024 and is projected to grow at a CAGR of 33.1% from 2025 to 2030.

Key Companies & Market Share Insights:

The market is classified as highly competitive, with the presence of several smart factory players. The key players operating in the industry are focusing on strategic alliances, product developments, expansions, and mergers & acquisitions to remain competitive. For instance, in March 2023, Schneider Electric SE, a digital transformation provider of energy management and industrial automation, initiated the construction of its upcoming smart factory in Dunavesce, Hungary. This state-of-the-art facility, backed by an investment of USD 42.67 million (€40 million), would cover an area of 25,000 sq. m. and will accommodate a workforce of 500 employees. Such strategies by key players are anticipated to augment market growth over the forecast period.

Key Smart Factory Companies:

ABB, Ltd.

Dassault Systemes S.E.

FANUC Corporation

General Electric Company

Honeywell International, Inc.

Johnson Controls, Inc.

KUKA AG

Mitsubishi Electric Corporation

Rockwell Automation, Inc.

Schneider Electric SE

Canon Inc.

Cisco System Inc.

Emerson Electric Co.

Order a free sample PDF of the Smart Factory Market Intelligence Study, published by Grand View Research.

0 notes

Text

#Smart Factory Market#Smart Factory Market Size#Smart Factory Market Trends#Smart Factory Market Growth#Smart Factory Market Analysis

0 notes

Text

The Industrial IoT Revolution: Market Forecast and Leading Players to Watch in 2023–2031

Industrial IoT Market Report: Growth, Trends, and Future Outlook

The Industrial Internet of Things (IIoT) represents a transformative wave in industrial operations, leveraging the power of connected devices, sensors, and advanced analytics to optimize processes, improve efficiency, and unlock new business opportunities. IIoT connects machines, devices, sensors, and systems to collect and analyze data in real time, enabling industries to achieve smarter decision-making, reduce operational costs, and enhance productivity.

The global Industrial IoT (IIoT) market was valued at USD 334.53 billion in 2022 and is projected to reach USD 2,916.21 billion by 2031, growing at an impressive CAGR of 27.2% during the forecast period (2023–2031). This rapid growth highlights the increasing demand for IoT-enabled technologies across various industrial sectors, making IIoT a vital part of the digital transformation process in manufacturing, supply chains, and infrastructure.

Request a Free Sample (Free Executive Summary at Full Report Starting from USD 1850): https://straitsresearch.com/report/industrial-iot-market/request-sample

Key Trends in the Industrial IoT Market

Increased Adoption of Smart Manufacturing: Manufacturers are embracing IIoT for process automation, predictive maintenance, real-time monitoring, and supply chain optimization. This trend is expected to continue as more companies focus on reducing downtime and improving product quality through connected devices.

Advancements in Edge Computing and AI Integration: The rise of edge computing is reducing latency, enabling faster data processing at the source. Integrating AI and machine learning with IIoT systems allows industries to gain insights from real-time data, improving decision-making capabilities.

Focus on Cybersecurity: As the number of connected devices increases, so does the potential vulnerability to cyberattacks. Ensuring robust cybersecurity measures within IIoT systems is becoming a top priority for businesses.

5G Connectivity: The rollout of 5G technology is enhancing the capabilities of IIoT by offering faster and more reliable communication between connected devices. This enables applications that require low latency, such as autonomous vehicles and real-time remote monitoring.

Sustainability and Energy Efficiency: Industries are increasingly adopting IIoT technologies to improve energy efficiency, reduce emissions, and support sustainability goals. Sensors and data analytics enable more efficient resource management, leading to reduced waste and energy consumption.

Industrial IoT Market Size and Share

The IIoT market is witnessing substantial growth across various regions, driven by technological advancements, an increasing number of connected devices, and the need for automation. The major industrial sectors benefiting from IIoT include manufacturing, energy, automotive, pharmaceuticals, and more. Businesses are investing heavily in IIoT to streamline their operations, reduce operational costs, and ensure more efficient use of resources.

The market is also being driven by increasing government initiatives aimed at fostering smart city projects, digital infrastructure, and sustainable industrial practices. As industries continue to digitize their operations, the demand for IIoT solutions is poised to grow exponentially.

Buy Full Report (Exclusive Insights with In-Depth Data Supplement): https://straitsresearch.com/buy-now/industrial-iot-market

Industrial IoT Market Statistics

The global market value was USD 334.53 billion in 2022.

The market is expected to grow to USD 2,916.21 billion by 2031, with a CAGR of 27.2% during the forecast period (2023–2031).

North America holds a significant share of the market, driven by the adoption of advanced industrial technologies and the presence of key players like Cisco, IBM, and Honeywell.

Asia Pacific (APAC) is expected to witness the highest growth due to rapid industrialization, increasing investments in smart factories, and government support for smart manufacturing initiatives.

Regional Trends and Impact

North America: The North American region, particularly the United States and Canada, dominates the global IIoT market due to a robust manufacturing base, the presence of key technology companies, and early adoption of IoT-enabled technologies. The region’s focus on automation, smart factories, and energy efficiency has led to a high demand for IIoT solutions.

Asia Pacific (APAC): APAC is expected to witness the fastest growth in the IIoT market, primarily driven by the increasing industrialization in countries like China, Japan, and India. The region's push towards smart manufacturing, government initiatives supporting industrial automation, and rapid adoption of advanced technologies like AI, robotics, and 5G are propelling the growth of the IIoT market.

Europe: Europe is another key region for IIoT, driven by strong industrial sectors such as automotive, chemicals, and energy. The European Union’s focus on Industry 4.0 and digital transformation is increasing the demand for IIoT technologies across manufacturing, energy, and logistics.

LAMEA (Latin America, Middle East, and Africa): While still a developing market, the LAMEA region is showing significant potential for IIoT growth, especially in industries such as oil and gas, utilities, and agriculture. Increased investment in infrastructure and digitalization is expected to drive the demand for IIoT solutions in these regions.

Industrial IoT Market Segmentation

By Offering

Hardware:

Industrial Robots: These robots are essential for automating repetitive tasks in industries such as manufacturing and automotive, improving efficiency and reducing errors.

Industrial PC: Industrial PCs are used for data processing, monitoring, and control in industrial environments.

Industrial Sensors: Sensors play a critical role in collecting data from machines and devices to monitor conditions like temperature, pressure, and vibration.

Distributed Control System (DCS): DCS solutions enable centralized control of industrial processes, helping manage large-scale production systems.

Smart Meters: Smart meters are essential for monitoring and managing energy consumption in industries, contributing to energy efficiency.

Human Machine Interface (HMI): HMIs provide a visual interface for operators to interact with industrial control systems.

Control Devices: Devices that help regulate and control industrial processes, ensuring smooth operations.

Software: Software solutions in IIoT are used for data collection, processing, analytics, and visualization. These software tools enable industries to derive actionable insights from the vast amount of data generated by IIoT devices.

Services:

Training & Consulting Services: These services help organizations integrate IIoT technologies into their existing systems and operations.

Support and Maintenance Services: These services ensure that IIoT solutions continue to operate efficiently and without disruption.

By Connectivity

Wired Connectivity:

Ethernet: Provides high-speed, reliable data transmission for industrial applications.

Fieldbus: Used in process control systems for connecting field devices and control systems.

Wireless Connectivity:

Wi-Fi, Bluetooth, Cellular Connectivity, Satellite Connectivity: Wireless connectivity solutions offer flexibility and scalability for IIoT applications, especially in large industrial environments.

By End-use Industry

Aerospace and Defense

Automotive

Chemicals

Energy & Power

Food & Beverage

Metal and Mining

Oil & Gas

Pharmaceutical

Semiconductor & Electronics

Others (Healthcare, Water & Wastewater, etc.)

Each of these industries is increasingly adopting IIoT technologies to improve operational efficiency, ensure product quality, reduce costs, and enhance safety.

Market Segmentation with Insights-Driven Strategy Guide: https://straitsresearch.com/report/industrial-iot-market/segmentation

Top Players in the Industrial IoT Market

Several companies are leading the way in the IIoT market, providing innovative solutions and services:

Huawei Technology Co., Ltd.

Cisco

General Electric

Schneider Electric

Rockwell Automation

ABB

Texas Instruments

Honeywell

IBM

KUKA AG

NEC Corporation

Bosch

Siemens AG

SAP

Endress+Hauser

Accenture PLC

STMicroelectronics

These companies are at the forefront of developing and implementing IIoT solutions, helping industries to leverage IoT technologies for better efficiency, safety, and profitability.

Table of Contents for the Industrial IoT Market Report: https://straitsresearch.com/report/industrial-iot-market/toc

Conclusion

The Industrial IoT market is experiencing rapid growth as industries worldwide adopt connected devices, advanced analytics, and automation to enhance productivity, reduce costs, and improve decision-making. With significant investments in IIoT infrastructure, the market is poised to expand substantially in the coming years, especially in sectors such as manufacturing, energy, automotive, and pharmaceuticals. As technologies like AI, 5G, and edge computing continue to evolve, the potential for IIoT to drive industrial transformation will only increase, presenting enormous opportunities for businesses and industries to embrace the future of connected manufacturing and operations.

About Straits Research

Straits Research is a leading provider of market research and intelligence services. With a focus on high-quality research, analytics, and advisory, our team offers actionable insights tailored to clients’ strategic needs.

Contact Us Email: [email protected] Address: 825 3rd Avenue, New York, NY, USA, 10022 Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Industrial IoT#IIoT#Industrial Internet of Things#Smart Manufacturing#IoT Market Growth#Industry 4.0#Automation#Connected Devices#Predictive Maintenance#Smart Sensors#Edge Computing#Industrial Robotics#Market Research#IoT Solutions#5G Connectivity#IIoT Market Trends#Global Market Forecast#Honeywell#Cisco#Siemens#IIoT Adoption#Digital Transformation#Smart Factories#Industrial Automation#Market Segmentation#Straits Research

0 notes

Text

Smart Factory Market Size, Share, Types, Products, Trends, Growth, Applications and Forecast 2023 to 2030

The Global Smart Factory market size was valued at USD 152.20 Billion in 2022 and is projected to reach USD 269.43 Billion by 2030, growing at a CAGR of 7.4% from 2023 to 2030.

A smart factory integrates various cutting-edge technologies such as Internet of Things (IoT), artificial intelligence (AI), machine learning (ML), robotics, big data analytics, and cloud computing to optimize manufacturing processes and operations.

The market is expanding at a faster rate as a result of Industry 4.0's expanding implementation and adoption. The market share has increased as a result of rising automation and software-based procedures. Real-time analysis and synchronization have been made available to the worldwide market by smart technologies, helping to cut costs and save time.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/15748

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

Leading players involved in the Smart Factory Market include:

Rockwell Automation, Inc. (USA), Siemens AG (Germany), Schneider Electric SE (France), ABB Ltd. (Switzerland), Honeywell International Inc. (USA), Bosch GmbH (, Germany), Mitsubishi Electric Corporation (Japan), FANUC Corporation (Japan), Emerson Electric Co. (USA), Yokogawa Electric Corporation (Japan), GE Digital (USA)

If You Have Any Query Smart Factory Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/15748

Segmentation of Smart Factory Market:

By Type

Industrial Sensors

Industrial Robots

Industrial 3D Printers

Machine Vision Systems

By Deployment

On Cloud

In Premises

By End User Industry

Aerospace & Defense

Semiconductor & Electronics

Manufacturing

Medical Devices

Oil & Gas

Chemicals

By Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

What to Expect in Our Report?

(1) A complete section of the Smart Factory market report is dedicated for market dynamics, which include influence factors, market drivers, challenges, opportunities, and trends.

(2) Another broad section of the research study is reserved for regional analysis of the Smart Factory market where important regions and countries are assessed for their growth potential, consumption, market share, and other vital factors indicating their market growth.

(3) Players can use the competitive analysis provided in the report to build new strategies or fine-tune their existing ones to rise above market challenges and increase their share of the Smart Factory market.

(4) The report also discusses competitive situation and trends and sheds light on company expansions and merger and acquisition taking place in the Smart Factory market. Moreover, it brings to light the market concentration rate and market shares of top three and five players.

(5) Readers are provided with findings and conclusion of the research study provided in the Smart Factory Market report.

Our study encompasses major growth determinants and drivers, along with extensive segmentation areas. Through in-depth analysis of supply and sales channels, including upstream and downstream fundamentals, we present a complete market ecosystem.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=15748

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyse extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1047

Email: [email protected]

#Smart Factory#Smart Factory Market#Smart Factory Market Size#Smart Factory Market Share#Smart Factory Market Growth#Smart Factory Market Trend#Smart Factory Market segment#Smart Factory Market Opportunity#Smart Factory Market Analysis 2023

0 notes

Text

AI & IT'S IMPACT

Unleashing the Power: The Impact of AI Across Industries and Future Frontiers

Artificial Intelligence (AI), once confined to the realm of science fiction, has rapidly become a transformative force across diverse industries. Its influence is reshaping the landscape of how businesses operate, innovate, and interact with their stakeholders. As we navigate the current impact of AI and peer into the future, it's evident that the capabilities of this technology are poised to reach unprecedented heights.

1. Healthcare:

In the healthcare sector, AI is a game-changer, revolutionizing diagnostics, treatment plans, and patient care. Machine learning algorithms analyze vast datasets to identify patterns, aiding in early disease detection. AI-driven robotic surgery is enhancing precision, reducing recovery times, and minimizing risks. Personalized medicine, powered by AI, tailors treatments based on an individual's genetic makeup, optimizing therapeutic outcomes.

2. Finance:

AI is reshaping the financial industry by enhancing efficiency, risk management, and customer experiences. Algorithms analyze market trends, enabling quicker and more accurate investment decisions. Chatbots and virtual assistants powered by AI streamline customer interactions, providing real-time assistance. Fraud detection algorithms work tirelessly to identify suspicious activities, bolstering security measures in online transactions.

3. Manufacturing:

In manufacturing, AI is optimizing production processes through predictive maintenance and quality control. Smart factories leverage AI to monitor equipment health, reducing downtime by predicting potential failures. Robots and autonomous systems, guided by AI, enhance precision and efficiency in tasks ranging from assembly lines to logistics. This not only increases productivity but also contributes to safer working environments.

4. Education:

AI is reshaping the educational landscape by personalizing learning experiences. Adaptive learning platforms use AI algorithms to tailor educational content to individual student needs, fostering better comprehension and engagement. AI-driven tools also assist educators in grading, administrative tasks, and provide insights into student performance, allowing for more effective teaching strategies.

5. Retail:

In the retail sector, AI is transforming customer experiences through personalized recommendations and efficient supply chain management. Recommendation engines analyze customer preferences, providing targeted product suggestions. AI-powered chatbots handle customer queries, offering real-time assistance. Inventory management is optimized through predictive analytics, reducing waste and ensuring products are readily available.

6. Future Frontiers:

A. Autonomous Vehicles: The future of transportation lies in AI-driven autonomous vehicles. From self-driving cars to automated drones, AI algorithms navigate and respond to dynamic environments, ensuring safer and more efficient transportation. This technology holds the promise of reducing accidents, alleviating traffic congestion, and redefining mobility.

B. Quantum Computing: As AI algorithms become more complex, the need for advanced computing capabilities grows. Quantucm omputing, with its ability to process vast amounts of data at unprecedented speeds, holds the potential to revolutionize AI. This synergy could unlock new possibilities in solving complex problems, ranging from drug discovery to climate modeling.

C. AI in Creativity: AI is not limited to data-driven tasks; it's also making inroads into the realm of creativity. AI-generated art, music, and content are gaining recognition. Future developments may see AI collaborating with human creators, pushing the boundaries of what is possible in fields traditionally associated with human ingenuity.

In conclusion, the impact of AI across industries is profound and multifaceted. From enhancing efficiency and precision to revolutionizing how we approach complex challenges, AI is at the forefront of innovation. The future capabilities of AI hold the promise of even greater advancements, ushering in an era where the boundaries of what is achievable continue to expand. As businesses and industries continue to embrace and adapt to these transformative technologies, the synergy between human intelligence and artificial intelligence will undoubtedly shape a future defined by unprecedented possibilities.

19 notes

·

View notes

Text

Guide for Importers on Manufacturing Control

Efficient Manufacturing Control in China

1. Understand the Chinese Manufacturing Environment:

Diverse Ecosystem: China offers a vast range of manufacturers, from small workshops to large factories. This variety is beneficial but also poses challenges in ensuring consistent quality.

IP Concerns: Despite improvements, IP protection in China can be inconsistent, requiring robust measures to safeguard your innovations.

Regulatory Landscape: China’s complex and changing regulations make compliance crucial to avoid fines and reputational damage.

Quality Control: While quality has improved, some sectors still prioritize quantity over quality. Rigorous quality protocols are essential.

Labor & Costs: Labor costs are rising, pushing manufacturers toward automation. Infrastructure is robust, but supply chains can be disrupted by natural disasters or policy changes.

Government Policies: China’s government heavily influences manufacturing through policies and incentives, which can affect costs and market access.

2. Build a Strong Foundation:

Supplier Selection: Choose reliable suppliers through thorough due diligence, including factory visits and financial checks.

Clear Communication: Provide detailed specifications and maintain open communication to avoid misunderstandings.

Quality Management: Implement a Quality Management System (QMS) and conduct regular audits to ensure consistent product quality.

Strong Relationships: Develop long-term partnerships with suppliers to build trust and collaboration.

3. Implement Effective Control Strategies:

QA & QC: Establish a robust QA/QC framework to ensure consistent product quality.

Supplier Development: Invest in your suppliers’ capabilities to improve quality and efficiency.

Risk Management: Prepare for disruptions with backup plans and diversified suppliers.

Contractual Coverage: Clearly define product specifications and include IP protections in contracts.

Third-Party Verification: Use third-party inspections to ensure compliance and quality.

4. Manage Logistics & Supply Chain:

Transportation: Choose the best transport mode and routes to minimize costs and delays.

Warehousing & Inventory: Optimize warehouse locations and use management systems to track inventory.

Customs & Documentation: Ensure compliance with customs regulations and prepare accurate documentation.

Supply Chain Visibility: Use technology to monitor shipments and collaborate with suppliers.

Risk Assessment: Develop contingency plans for disruptions like natural disasters or strikes.

5. Overcome Common Challenges:

Language & Cultural Barriers: Hire experts to bridge gaps in communication and cultural understanding.

IP Protection: Secure your IP with patents, trademarks, and NDAs; monitor for infringements.

Regulatory Compliance: Stay updated on regulations and partner with local experts for compliance.

Supply Chain Disruptions: Diversify suppliers, maintain sufficient inventory, and use smart tools for monitoring.

6. Continuous Improvement:

Use data analytics to track trends and improve processes.

Regularly evaluate supplier performance and invest in employee training.

Embrace technology to enhance communication and efficiency.

7. Build a Culture of Quality:

Encourage employees to propose improvements.

Reward contributions to quality enhancement.

Focus on exceeding customer expectations.

Conclusion: Effective manufacturing control in China requires ongoing effort, attention, and adaptation. Invest in strong practices to improve product quality, reduce costs, protect your brand, and optimize your supply chain.

2 notes

·

View notes

Text

Revolutionizing Business with IoT: Comprehensive Services and Monitoring Solutions

In today's fast-paced digital era, the Internet of Things (IoT) is transforming the way businesses operate. At RadiantEdge, we understand the immense potential of IoT and are committed to helping businesses in Dubai and beyond leverage this technology to drive innovation, streamline operations, and enhance productivity.

Why IoT is the Future of Business

The Internet of Things refers to the interconnection of everyday devices to the internet, allowing them to send and receive data. This technology enables businesses to automate processes, improve efficiency, and make data-driven decisions. From smart factories to intelligent supply chains, IoT is the backbone of the modern digital transformation... Explore More...

RadiantEdge's Comprehensive IoT Services in Dubai

As leaders in the IT industry with over two decades of experience, RadiantEdge is proud to offer a wide range of IoT services tailored to meet the specific needs of businesses in Dubai. Our IoT services in Dubai include:

IoT Strategy Development: We work closely with our clients to develop a customized IoT strategy that aligns with their business goals. This includes identifying key opportunities, selecting the right IoT platforms, and designing a roadmap for implementation.

IoT System Design and Integration: Our team of experts designs and integrates IoT systems that connect various devices and sensors, enabling seamless communication and data exchange. We ensure that these systems are scalable and secure, allowing businesses to grow and adapt to changing market conditions.

IoT Implementation and Deployment: From pilot projects to full-scale deployments, RadiantEdge manages every aspect of IoT implementation. We ensure that the transition to IoT is smooth and that systems are operational with minimal disruption to business activities.

Custom IoT Solutions: We understand that every business is unique, which is why we offer customized IoT solutions. Whether it's a smart building, connected vehicles, or an intelligent supply chain, we develop solutions that are tailored to your specific industry and business requirements.

IoT Monitoring: Ensuring Optimal Performance

One of the critical aspects of IoT is ensuring that all connected devices and systems are functioning optimally. Our IoT monitoring solutions are designed to provide real-time insights into the performance of your IoT ecosystem. With advanced analytics and proactive alerts, businesses can monitor the health of their IoT networks, identify potential issues, and take corrective actions before they escalate.

Key Features of Our IoT Monitoring Solutions:

Real-Time Data Analytics: Gain actionable insights from your IoT devices with real-time data analytics. Monitor key performance indicators, track trends, and make informed decisions to optimize operations.

Proactive Alerts: Our monitoring systems are equipped with intelligent alert mechanisms that notify you of any irregularities or potential issues. This allows for timely intervention, reducing downtime and ensuring continuity of operations.

Scalability: As your business grows, so does your IoT network. Our monitoring solutions are designed to scale with your business, providing consistent performance and reliability.

Security and Compliance: IoT security is paramount. We ensure that your IoT systems are protected against cyber threats and comply with industry standards and regulations.

The RadiantEdge Advantage

Choosing RadiantEdge for your IoT services in Dubai means partnering with a team of professionals who are dedicated to your success. Our expertise, combined with our commitment to innovation, makes us the ideal partner for businesses looking to embrace the future of technology.

Experienced Team: With over 20 years in the IT industry, our team has the knowledge and expertise to deliver high-quality IoT solutions.

Customer-Centric Approach: We prioritize our clients' needs and work closely with them to deliver solutions that drive results.

Global Reach: While based in the vibrant town of Nashik, we serve clients across the globe, delivering cutting-edge technology solutions.

Conclusion

The future of business lies in the Internet of Things. At RadiantEdge, we are committed to helping businesses in Dubai and beyond unlock the full potential of IoT. From strategy development to monitoring and maintenance, our comprehensive IoT services ensure that your business stays ahead in a rapidly evolving digital landscape.

Ready to revolutionize your business with IoT? Contact RadiantEdge today to learn more about our IoT services and how we can help you achieve success.

1 note

·

View note

Text

Electronics manufacturing trends to pay attention to in years to come

Despite the pandemic-induced economic slowdown, technological advancements played a significant role in the growth of the electronics manufacturing sector. Smarter manufacturing practices have been the biggest driver of this growth. We intend to explore five trendsetting developments in this article today.

Internet of Things The electronics manufacturing industry can leverage the Internet of Things (IoT) for unprecedented growth opportunities. The IoT allows electronic manufacturing units to be digitally connected while storing and processing information without external support. The IoT can improve efficiency, security, cost-effectiveness, and product innovation. Cloud computing, smaller censors, and the growth of the Internet have prompted IoT’s lead in the race of emerging technologies. With everything in place, you can have real-time data at your fingertips to make informed business decisions.

Automation While complete automation in the electronics manufacturing sector is still a distant dream, various automation technologies have made production trouble and error-free. These technological advancements in automation includes smart factories, manufacturing robots, and the smart supply chain management system. These automation systems in conjunction with IoT devices create an efficient manufacturing operation. Innovative supply chain As businesses strive for better products and spend less while doing so, the best way forward is to innovate supply chain management. This trend aims at improving the logistics to revamp the supply chain, which, in turn, can significantly reduce costs in several key areas. This allows electronics manufacturers to be more agile in their operations and thus be more open to fluctuating market demands.

Predictive maintenance Any manufacturing company’s smooth operation is entirely dependent on its types of equipment. Because if they break down the entire operation comes to a halt and so will your revenue generation. However, using AI and IoT data collection, you can accurately identify problem areas before they happen. This helps electronic manufacturers avoid downtime and plan maintenance at a convenient time. Identify a cost-effective manner to conduct repairs and include the same in your budget. A trend like predictive maintenance removes any scope of surprise downtime, thus improving the efficiency of your manufacturing operations.

Organic electronics Organic electronics has become a market rage in recent times owing to its efficiency, low cost, flexibility, lightweight, indissoluble nature, and optical transparency. Additionally, the demand for environmentally friendly production and sustainable development is growing, prompting electronic manufacturers to choose organic electronics. One of the most significant trends in electronics production is the creation of gadgets using biodegradable and recyclable materials or designing circuits with microbial components. The use of organic materials in producing electronic devices also permits the use of safer and readily accessible raw materials. As a result, it gives organizations new business opportunities, while being environmentally responsible.

The electronic manufacturing trends discussed in this article pave a path for smarter, efficient, and cost-effective practices. The use of advanced technology and materials can help you achieve this. Apart from the five trends discussed here, we'd also like to mention printed electronics, Artificial Intelligence, immersive technology, and 3D printing. These evolving technologies only point to a brighter future. For more information on the electronics manufacturing process, get in touch with the experts at Radiant Appliances & Electronics.

#manufacturing#led tv manufacturing#smart tv#led tv manufacturers in india#Home appliances manufacturers in India#TV Manufacturing Company#Radiant Appliances & Electronics#Televisions We Manufacture#Smart LED Televisions

2 notes

·

View notes

Text

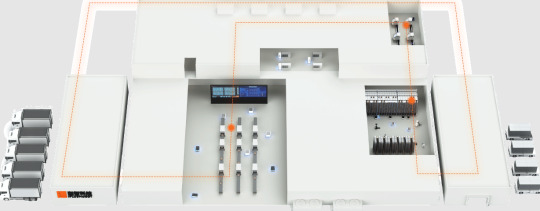

The Rise of Smart Factories: IPLUSMOBOT’s Cutting-Edge Manufacturing Solutions

As technology continues to evolve and disrupt traditional industries, manufacturing has been one of the most impacted. In recent years, smart factories have emerged as the future of manufacturing, enabling businesses to leverage the latest technological advancements to improve production efficiency, quality, and reduce costs. IPLUSMOBOT is at the forefront of this revolution, offering cutting-edge manufacturing solutions that help businesses stay ahead of the curve.

Smart factories are essentially manufacturing plants that rely on advanced technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), and robotics to streamline production processes, enhance worker safety, and boost productivity. IPLUSMOBOT’s Futuristic Manufacturing Technologies have been developed with these technologies in mind, helping businesses overcome the challenges of traditional manufacturing.

One of the key benefits of IPLUSMOBOT’s smart manufacturing solutions is improved efficiency. The company’s state-of-the-art technology enables businesses to automate repetitive and mundane tasks, freeing up workers to focus on more strategic and creative work. This can significantly reduce production time and increase output, leading to a more efficient and profitable manufacturing process.

In addition to increased efficiency, IPLUSMOBOT’s solutions also enhance quality control. Smart factories rely on sensors and real-time monitoring to identify potential defects or issues in the production process, allowing businesses to take corrective action before products leave the factory floor. This leads to fewer defects, reduced waste, and improved customer satisfaction.

Another benefit of IPLUSMOBOT’s smart manufacturing solutions is increased safety for workers. By automating dangerous or hazardous tasks, businesses can minimize the risk of workplace accidents and injuries, protecting both their workers and their bottom line.

Finally, IPLUSMOBOT’s smart factories are highly flexible, enabling businesses to adapt quickly to changing customer demands and market trends. The company’s solutions can be easily reconfigured to accommodate new product lines or changes in production processes, allowing businesses to stay agile and responsive to market demands.

In conclusion, smart factories represent the future of manufacturing, and IPLUSMOBOT is leading the charge with its cutting-edge solutions. By leveraging advanced technologies such as IoT, AI, and robotics, the company’s smart factories offer businesses significant benefits in terms of efficiency, quality control, worker safety, and flexibility. With IPLUSMOBOT’s solutions, businesses can stay ahead of the curve and maintain a competitive edge in today’s fast-paced manufacturing environment.

2 notes

·

View notes

Text

How AI Agent Development is Transforming Industries: Key Applications and Use Cases

Artificial Intelligence (AI) is no longer just a buzzword; it has become a transformative force reshaping industries across the globe. Among the key advancements in AI, the development of intelligent AI agents stands out for its potential to revolutionize how businesses operate and serve customers. These AI agents can perform tasks autonomously, make data-driven decisions, and interact seamlessly with users and systems. Let's explore how AI agent development is transforming industries and examine key applications and use cases.

What Are AI Agents?

AI agents are software entities designed to perform tasks autonomously or semi-autonomously using AI technologies such as machine learning (ML), natural language processing (NLP), computer vision, and decision-making algorithms. These agents can operate independently or collaborate with other agents or humans to complete complex tasks.

Key Applications and Use Cases Across Industries

1. Customer Service and Support

One of the most widespread applications of AI agents is in customer service. AI-powered virtual assistants and chatbots are now commonplace on websites and messaging platforms, providing instant responses to customer queries.

Use Case Example:

Companies like Klarna and Amazon deploy AI agents to handle common customer inquiries, manage returns, and provide order updates, enhancing customer experiences and reducing wait times.

2. Healthcare and Diagnostics

AI agents are transforming healthcare by assisting in diagnostics, patient monitoring, and administrative tasks. They can analyze medical data to detect anomalies and provide early diagnoses.

Use Case Example:

AI agents are used to automate appointment scheduling, monitor patient health in real time, and provide reminders for medication adherence.

3. Finance and Banking

In the financial sector, AI agents are used for fraud detection, customer support, and investment analysis. They can monitor transactions, flag suspicious activities, and offer personalized financial advice.

Use Case Example:

Robo-advisors powered by AI agents help clients build investment portfolios, automatically rebalancing them based on market trends and user preferences.

4. E-commerce and Retail

AI agents are transforming the e-commerce experience by offering personalized product recommendations, automating inventory management, and enhancing customer support.

Use Case Example:

AI-driven recommendation engines on platforms like Netflix and Amazon increase customer engagement by suggesting relevant content and products.

5. Manufacturing and Supply Chain

AI agents optimize operations by monitoring production lines, predicting maintenance needs, and managing supply chain logistics.

Use Case Example:

AI agents in smart factories can detect machine anomalies and schedule preventive maintenance, minimizing downtime.

6. Human Resources and Talent Management

AI agents assist HR professionals in talent acquisition, employee engagement, and performance management. They can screen resumes, schedule interviews, and provide personalized training recommendations.

Use Case Example:

AI-powered recruitment platforms like HireVue use AI agents to assess candidates through video interviews and predictive analytics.

7. Marketing and Advertising

AI agents help marketers analyze customer data, automate campaign management, and deliver personalized content to target audiences.

Use Case Example:

AI-driven tools like HubSpot and Salesforce use AI agents to optimize email marketing campaigns and analyze customer behavior.

8. Transportation and Logistics

AI agents improve route planning, fleet management, and last-mile delivery in the transportation and logistics sector.

Use Case Example:

AI agents in ride-hailing services like Uber optimize routes and match drivers with passengers for efficient operations.

The Benefits of AI Agent Development

Efficiency: AI agents automate repetitive tasks, allowing human employees to focus on higher-value activities.

Scalability: Businesses can deploy AI agents across various functions without incurring proportional operational costs.

Accuracy: AI agents reduce human errors and ensure consistency in decision-making.

Personalization: AI agents analyze vast amounts of data to offer tailored experiences for customers and users.

Challenges and Considerations

While AI agents offer numerous benefits, their development and deployment come with challenges:

Data Privacy: Protecting user data and maintaining compliance with regulations is critical.

Ethical Concerns: Ensuring unbiased decision-making and ethical AI use is essential.

Integration: Seamlessly integrating AI agents with existing systems requires strategic planning.

The Future of AI Agent Development

As AI technologies continue to advance, AI agents will become even more sophisticated and integrated into various aspects of business and daily life. The emergence of generative AI, improved natural language processing, and advanced machine learning models will further enhance the capabilities of AI agents, making them indispensable across industries.

Conclusion

AI agent development is revolutionizing industries by automating tasks, improving decision-making, and enhancing customer experiences. As businesses continue to adopt and innovate with AI agents, we can expect even greater transformations in how industries operate. Companies that embrace AI agent technology today will be better positioned to lead in the digital age.

0 notes

Text

Smart Factory Market Analysis by Key Players, Sales Forecast and Supply Demand to 2030

The global smart factory market was valued at approximately USD 130.25 billion in 2022 and is forecasted to grow at a compound annual growth rate (CAGR) of 9.8% from 2023 to 2030. The growth of this market is being driven by several critical factors, including an increasing focus on energy efficiency, the need for enhanced manufacturing productivity, and the establishment of advanced manufacturing infrastructures. These drivers are shaping the industry's future and making smart factories more attractive to businesses. Furthermore, the growing adoption of collaborative robots (cobots) and continuous advancements in 3D printing technologies are expected to open new opportunities for the market during the forecast period.

A major component of the smart factory market’s growth is the role of artificial intelligence (AI) and machine learning (ML). These technologies are proving to be pivotal in revolutionizing manufacturing processes, as they enable predictive maintenance, quality control, and process optimization. AI-driven analytics can extract valuable insights from massive datasets, which in turn helps manufacturers make informed, data-driven decisions to enhance their operations. As AI technologies evolve and improve, their integration into smart factories is projected to deepen, contributing to greater efficiency and innovation in manufacturing processes.

Another significant trend within the smart factory market is the adoption of Industry 4.0 principles. Industry 4.0 represents the integration of advanced digital technologies such as the Internet of Things (IoT), big data analytics, and automation into manufacturing operations. Smart factories are capitalizing on these technologies to optimize production processes, boost product quality, and increase overall operational efficiency. This trend is expected to continue, as manufacturers seek to remain competitive in an increasingly globalized and digital-driven market environment.

Gather more insights about the market drivers, restrains and growth of the Smart Factory Market

Technology Segmentation Insights:

Among the various technologies employed in smart factories, the distributed control systems (DCS) segment accounted for a substantial market share of over 17% in 2022. DCS technology is crucial for industrial automation and process optimization, making it a key enabler of modern manufacturing. One of the major advantages of DCS is its scalability, which allows it to integrate seamlessly with emerging technologies such as IoT and the principles of Industry 4.0. This flexibility, combined with the capability for remote monitoring and control, proved particularly beneficial during the COVID-19 pandemic, when remote operations became more vital. DCS also contributes to safety compliance, energy efficiency, and the modernization of legacy control systems, aligning with the broader industry trends that focus on sustainability, efficiency, and digital transformation in production environments.

The human-machine interface (HMI) technology segment is expected to see the highest CAGR of 12.6% over the forecast period. This growth can be attributed to the enhanced user experience and operational efficiency that HMIs bring to smart factories. HMIs have evolved significantly, offering intuitive and user-friendly interfaces, often featuring touchscreens and gesture controls. These improvements make interactions between operators and machines more efficient and accessible. As the complexity of smart factory systems increases, the demand for advanced HMI solutions that facilitate seamless human-machine interactions and data visualization is on the rise. This demand is expected to drive the significant growth of the HMI technology segment in the coming years.

Order a free sample PDF of the Smart Factory Market Intelligence Study, published by Grand View Research.

#Smart Factory Industry#Smart Factory Market Analysis#Smart Factory Market Trends#Smart Factory Market Growth

0 notes

Text

Smart Factory Industry 2030 Trending Key Companies, Growth and Regional Forecasts

The global smart factory market was valued at approximately USD 130.25 billion in 2022 and is forecasted to grow at a compound annual growth rate (CAGR) of 9.8% from 2023 to 2030. The growth of this market is being driven by several critical factors, including an increasing focus on energy efficiency, the need for enhanced manufacturing productivity, and the establishment of advanced manufacturing infrastructures. These drivers are shaping the industry's future and making smart factories more attractive to businesses. Furthermore, the growing adoption of collaborative robots (cobots) and continuous advancements in 3D printing technologies are expected to open new opportunities for the market during the forecast period.

A major component of the smart factory market’s growth is the role of artificial intelligence (AI) and machine learning (ML). These technologies are proving to be pivotal in revolutionizing manufacturing processes, as they enable predictive maintenance, quality control, and process optimization. AI-driven analytics can extract valuable insights from massive datasets, which in turn helps manufacturers make informed, data-driven decisions to enhance their operations. As AI technologies evolve and improve, their integration into smart factories is projected to deepen, contributing to greater efficiency and innovation in manufacturing processes.

Another significant trend within the smart factory market is the adoption of Industry 4.0 principles. Industry 4.0 represents the integration of advanced digital technologies such as the Internet of Things (IoT), big data analytics, and automation into manufacturing operations. Smart factories are capitalizing on these technologies to optimize production processes, boost product quality, and increase overall operational efficiency. This trend is expected to continue, as manufacturers seek to remain competitive in an increasingly globalized and digital-driven market environment.

Gather more insights about the market drivers, restrains and growth of the Smart Factory Market

Technology Segmentation Insights:

Among the various technologies employed in smart factories, the distributed control systems (DCS) segment accounted for a substantial market share of over 17% in 2022. DCS technology is crucial for industrial automation and process optimization, making it a key enabler of modern manufacturing. One of the major advantages of DCS is its scalability, which allows it to integrate seamlessly with emerging technologies such as IoT and the principles of Industry 4.0. This flexibility, combined with the capability for remote monitoring and control, proved particularly beneficial during the COVID-19 pandemic, when remote operations became more vital. DCS also contributes to safety compliance, energy efficiency, and the modernization of legacy control systems, aligning with the broader industry trends that focus on sustainability, efficiency, and digital transformation in production environments.

The human-machine interface (HMI) technology segment is expected to see the highest CAGR of 12.6% over the forecast period. This growth can be attributed to the enhanced user experience and operational efficiency that HMIs bring to smart factories. HMIs have evolved significantly, offering intuitive and user-friendly interfaces, often featuring touchscreens and gesture controls. These improvements make interactions between operators and machines more efficient and accessible. As the complexity of smart factory systems increases, the demand for advanced HMI solutions that facilitate seamless human-machine interactions and data visualization is on the rise. This demand is expected to drive the significant growth of the HMI technology segment in the coming years.

Order a free sample PDF of the Smart Factory Market Intelligence Study, published by Grand View Research.

#Smart Factory Industry#Smart Factory Market Analysis#Smart Factory Market Trends#Smart Factory Market Growth

0 notes

Text

Cutting-Edge Technology Solutions: The Key to Business Growth & Digital Success

The digital era is evolving at lightning speed, and cutting-edge technology solutions are redefining how businesses operate, innovate, and scale. From AI-driven automation to cloud computing and cybersecurity, modern enterprises must embrace advanced tech solutions to stay ahead in an increasingly competitive marketplace.

At Dynamic ORD, we empower businesses with high-performance digital solutions, ensuring they leverage the latest technology trends for efficiency, security, and exponential growth.

🚀 Want to future-proof your business? Read more on our blog.

Why Cutting-Edge Technology Matters for Businesses

Technology isn’t just a tool—it’s a game-changer for businesses looking to enhance efficiency, customer engagement, and profitability. Here’s how:

1. AI & Automation: Revolutionizing Workflows

AI-driven automation is eliminating inefficiencies, streamlining operations, and accelerating decision-making. Businesses leveraging AI-powered solutions gain: ✅ Increased Productivity – Automating repetitive tasks saves time and reduces costs. ✅ Intelligent Data Insights – AI-driven analytics improve strategic decision-making. ✅ Enhanced Customer Experience – AI-powered chatbots and personalization drive engagement.

🔹 The Solution: Integrating AI-driven business automation enhances efficiency and scalability.

💡 Discover how AI can transform your operations: Learn more.

2. Cybersecurity & Data Protection: Safeguarding Digital Assets

With rising cyber threats, businesses must prioritize digital security to protect sensitive data and ensure compliance. Leading cybersecurity solutions include: ✅ AI-Powered Threat Detection – Prevents breaches before they occur. ✅ End-to-End Encryption – Secures communications and transactions. ✅ Zero-Trust Security Models – Strengthens digital defenses against cyber threats.

🔹 The Solution: Companies must implement advanced cybersecurity protocols to safeguard digital assets.

🔍 Concerned about data security? Visit our FAQ section.

3. Cloud Computing & Scalable Infrastructure

Cloud-based solutions are redefining data storage, accessibility, and remote collaboration. Businesses investing in cloud computing benefit from: ✅ Flexible & Scalable Storage – Optimize IT infrastructure based on business needs. ✅ Seamless Remote Access – Securely manage operations from anywhere. ✅ Reduced IT Costs – Lower operational expenses with cloud-based services.

🔹 The Solution: Cloud integration ensures cost-effective, scalable, and secure business operations.

📈 Looking to upgrade your infrastructure? Get a quote today.

Industries Benefiting from Cutting-Edge Technology

🚀 Technology is driving transformation across multiple industries, including:

✅ Finance & Banking – AI-driven fraud detection, digital payments, and blockchain security. ✅ Healthcare & Biotech – Telemedicine, AI-assisted diagnostics, and wearable health tech. ✅ E-Commerce & Retail – Personalized AI recommendations and automated logistics. ✅ Manufacturing & Supply Chain – Smart factories and real-time inventory management. ✅ Real Estate & Smart Cities – AI-powered property analytics and IoT-driven automation.

💬 See how businesses are leveraging tech innovations: Read our testimonials.

Why Choose Dynamic ORD for Your Tech Transformation?

At Dynamic ORD, we provide tailored technology solutions designed to: ✔ Streamline Operations – AI-driven automation and cloud integration. ✔ Enhance Security – Advanced cybersecurity and data protection. ✔ Boost Digital Growth – Cutting-edge SEO and AI-powered marketing. ✔ Future-Proof Business Models – Scalable digital transformation strategies.

📌 Want to explore the best tech solutions for your business? Book a consultation today.

The Future of Business is Digital—Are You Ready?

The rapid evolution of AI, automation, and digital transformation is reshaping industries. Companies that embrace cutting-edge technology solutions today will be the market leaders of tomorrow.

📈 Want to build a future-proof business? Let’s develop a technology-driven strategy that accelerates your growth.

💼 Unlock exclusive digital solutions today: Benefit from our premium tech packages.

0 notes

Text

The Hidden Connection Between GDP, Black Box Systems, and Forex Mastery Why GDP Gross Domestic Product is the Market’s Sneaky Puppet Master If you think GDP is just some dry economic statistic economists throw around to sound important, think again. GDP is the ultimate puppet master of currency valuation, and if you’re ignoring it, you might as well be trading blindfolded. Let’s break it down: GDP (Gross Domestic Product) measures a country’s economic health—the total value of all goods and services produced. Strong GDP? Currency appreciates. Weak GDP? Currency tanks. It’s the heartbeat of an economy, and yet, many traders underestimate its influence on Forex markets. Here’s a fun fact: The Forex market doesn’t just react to GDP reports—it tries to anticipate them. Traders and institutions don’t wait for GDP numbers to drop; they analyze leading indicators, such as employment data, manufacturing output, and consumer spending. Pro Move: How to Front-Run GDP Announcements Like a Pro Want to predict GDP results before they hit the news? Watch the following indicators: - Retail Sales Reports: Consumer spending makes up a huge chunk of GDP. A surge in retail sales hints at a strong GDP. - Manufacturing PMI: This shows how active factories are. A high PMI signals strong industrial production, which feeds directly into GDP. - Employment Data: More jobs mean more spending, and more spending means a stronger economy (hence, stronger GDP). Instead of waiting for GDP releases, use these clues to position your trades early. Smart money is always a step ahead. Black Box Systems: The Invisible Hands Controlling Market Movements Ever entered a trade thinking you had the perfect setup, only to watch the market flip against you like a bad reality show twist? Welcome to the world of Black Box Systems—the hidden algorithms making money while you scratch your head. What Are Black Box Systems, and Why Should You Care? Black box systems are AI-driven trading models used by hedge funds and big institutions to execute trades with superhuman speed and precision. They analyze GDP, interest rates, and thousands of economic data points within milliseconds—something a human trader can’t even dream of doing. How These Systems Influence the Forex Market - They front-run economic events: These algorithms detect patterns before most traders do, buying or selling ahead of GDP reports, interest rate changes, and geopolitical events. - They manipulate liquidity: Ever noticed sudden price spikes right before big news? That’s likely an algorithm triggering a liquidity sweep to shake out weak hands. - They exploit inefficiencies: Black box systems scan for arbitrage opportunities across global markets and capitalize on mispricings within nanoseconds. If you’ve ever felt like the market knows your stop-loss before you even set it, you’re not paranoid—these systems are built to hunt retail traders. How to Outsmart Black Box Systems - Use Larger Timeframes: Black box algorithms thrive in short-term trades. Trading on longer timeframes (H4, D1) makes it harder for them to trap you. - Avoid Predictable Stop-Loss Placements: Placing your stop-loss at obvious levels (round numbers, support levels) is an invitation for algorithms to trigger your exit. - Follow Smart Money Flows: Monitor institutional order flow instead of retail sentiment. Tools like COT reports and liquidity heatmaps can reveal where the real market movers are positioned. The Ultimate Forex Strategy: Combining GDP Insights with Algorithm Awareness Now that you know how GDP shapes the Forex market and how black box systems manipulate price action, let’s fuse this knowledge into a game-changing trading approach. Step 1: Anticipate GDP-Driven Market Trends - Use leading indicators like Retail Sales, Industrial Production, and Employment Reports to predict GDP trends. - Identify the currency most likely to gain or lose strength based on GDP expectations. - Position yourself ahead of GDP releases, rather than reacting to them. Step 2: Trade Like an Institution, Not a Retail Trader - Look for areas of high liquidity where institutional traders enter and exit positions. - Avoid tight stop-loss placements at obvious levels. - Use order flow analysis tools to track smart money movements. Step 3: Monitor Algorithmic Patterns and Adapt - Watch for sudden liquidity sweeps and avoid trading during low-liquidity periods when algorithms can easily manipulate price. - Trade during peak market hours when volume is highest, making it harder for algorithms to move the market artificially. - Study high-frequency trading activity around key economic releases to anticipate potential fakeouts. Final Thoughts: Become a Forex Chess Master, Not a Pawn Most traders react to GDP reports and market movements. The elite few predict and position themselves in advance. By understanding the true impact of GDP and recognizing how black box systems manipulate markets, you can avoid falling into common traps and start trading like an institution. The choice is yours: Will you let the market push you around, or will you master the hidden forces driving it? For more advanced strategies, insider tips, and exclusive tools, check out: - Latest Economic Indicators & Forex News - In-Depth Forex Education - Join the StarseedFX Community —————– Image Credits: Cover image at the top is AI-generated Read the full article

0 notes

Text

What Industries Can Benefit from an AI Agent Development Company?

Artificial Intelligence (AI) is reshaping industries worldwide, and AI agents—advanced software entities capable of learning, adapting, and automating processes—are at the forefront of this transformation. AI agent development companies specialize in creating intelligent solutions tailored to specific industries, enhancing efficiency, reducing costs, and unlocking new possibilities. But which industries stand to gain the most? Let’s explore the key sectors that can benefit from AI agent development.

1. Healthcare and Life Sciences

AI agents are revolutionizing healthcare by improving diagnostics, treatment planning, and patient engagement. Some of their applications include:

Medical Diagnosis: AI-powered agents can analyze medical imaging (X-rays, MRIs) to detect diseases like cancer at an early stage.

Virtual Health Assistants: Chatbots and AI-driven apps provide patients with instant medical advice, appointment scheduling, and symptom tracking.

Drug Discovery: AI accelerates the drug development process by analyzing vast datasets to predict potential treatments.

Remote Patient Monitoring: AI agents track patients' vitals and alert medical professionals to anomalies, improving proactive care.

2. Finance and Banking

Financial institutions leverage AI agents to enhance security, customer service, and investment strategies:

Fraud Detection: AI systems analyze transactions in real-time to flag suspicious activities and prevent fraud.

Automated Trading: AI-powered trading bots use predictive analytics to optimize investment portfolios and execute high-frequency trades.

Risk Assessment: AI agents evaluate creditworthiness, loan approvals, and investment risks with greater accuracy.

Customer Support: AI chatbots and voice assistants provide 24/7 banking support and financial advice.

3. E-commerce and Retail

AI agents are reshaping online and offline retail experiences:

Personalized Recommendations: AI-driven recommendation engines enhance customer experience by suggesting products based on user behavior.

Inventory Management: AI agents predict demand trends and optimize stock levels to prevent overstocking or shortages.

Chatbots for Customer Service: AI-powered virtual assistants handle customer inquiries, process orders, and provide real-time support.