#Silicon Manganese supplier

Explore tagged Tumblr posts

Text

Manufacturer and Supplier of MS Billets in Kolkata

In the heart of Kolkata's bustling industrial landscape, MS billets play a pivotal role as the backbone of steel production. As a leading manufacturer and supplier of MS billets, Apocalypse Steel and Power stands at the forefront of delivering high-quality raw materials to the steel industry. With their unwavering commitment to excellence, cutting-edge manufacturing processes, and dedication to customer satisfaction, they have emerged as a preferred partner for businesses seeking top-notch MS billets.

The Essence of MS Billets:

MS billets, also known as mild steel billets, form an integral part of the steelmaking process. These semi-finished steel products are cast in a square or rectangular shape and serve as the foundation for manufacturing various steel products. From reinforcing bars to wire rods and structural components, MS billets are the stepping stones to shaping the steel used in numerous applications, including construction, infrastructure, automotive, and machinery.

Manufacturing Excellence:

Apocalypse Steel and Power leaves no room for compromise when it comes to manufacturing MS billets of the highest quality. They employ state-of-the-art manufacturing techniques, stringent quality control measures, and advanced equipment to ensure that their MS billets possess superior properties and meet industry standards. Their skilled workforce and rigorous testing processes guarantee that each billet conforms to the required chemical composition and mechanical characteristics.

Customization for Diverse Applications:

Understanding that different industries have distinct requirements, Apocalypse Steel and Power offers a diverse range of MS billets, tailored to meet the specific needs of their customers. Whether it's for manufacturing high-strength reinforcement bars or precision-engineered structural components, their MS billets can be customized to provide the desired mechanical properties, dimensional accuracy, and weldability.

Reliable Supply Chain:

Apocalypse Steel and Power recognizes the significance of a reliable and seamless supply chain for MS billets. They ensure a steady and timely supply to their customers in Kolkata, minimizing production disruptions and ensuring project timelines are met. With efficient logistics management and a well-established distribution network, they guarantee prompt delivery of MS billets, catering to the diverse needs of the steel industry.

Technical Expertise and Support:

Apocalypse Steel and Power prides itself on its technical expertise and customer support. Their team of professionals possesses in-depth knowledge of steel production processes and is equipped to provide valuable guidance and assistance to their customers. From technical consultations to optimizing material selection, their experts offer comprehensive support throughout the project lifecycle.

Commitment to Sustainability:

Apocalypse Steel and Power places a strong emphasis on sustainable practices and responsible sourcing of raw materials. They prioritize energy efficiency, waste reduction, and environmentally friendly processes in their manufacturing operations. By choosing MS billets from Apocalypse Steel and Power, customers can be confident that they are supporting a supplier committed to environmental stewardship.

Conclusion:

Apocalypse Steel and Power stand as a trusted manufacturer and supplier of MS billets in Kolkata, offering superior quality, customization options, and reliable service. Their commitment to excellence, technical expertise, and sustainability makes them a preferred choice for businesses in the steel industry. By choosing MS billets from Apocalypse Steel and Power, steel manufacturers in Kolkata can ensure the foundation and strength of their steel products.

#Ms Billets Manufacturer#ms billets supplier#ms angle#ferro silicon manganese supplier#firebricks#pure silicon supplier

0 notes

Text

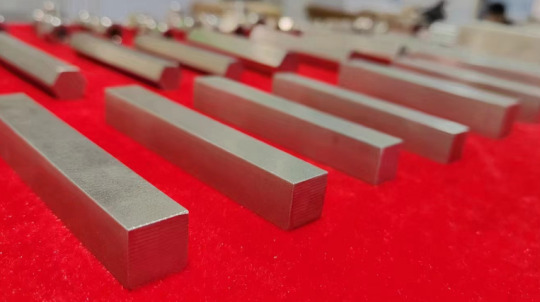

Do you have any confusion about choosing the Steels and Materials?

Bridging the Gap Between #Steel and #CarbonSteel!

Remember, when it comes to steel, Virat Special Steels is your trusted guide!🔥

Steel is an alloy primarily composed of iron, along with other elements such as carbon, silicon, and manganese. It contains carbon, silicon, and manganese in varying proportions.

Carbon steel is a type of steel where carbon is the primary alloying element. It contains less than 2% carbon (without other noticeable alloying elements). As the carbon content increases, carbon steel becomes harder and stronger but less ductile and malleable.

Types:

Mild Steel: Contains 0.05% to 0.29% carbon.

Medium Carbon Steel: Contains 0.30% to 0.59% carbon.

High Carbon Steel: Contains 0.60% to 0.99% carbon.

Ultra Carbon Steel: Contains 1.00% to 2.00% carbon.

Finish: Carbon steel usually has a lusterless finish.

In summary, steel is a broad category that includes carbon steel. Carbon steel, in turn, varies based on its carbon content and properties. It’s essential to choose the right type of steel for specific applications.

Virat Special Steels is one of the most reputable Tool Steel & Die Steel and Mold Steel Suppliers in India. Special steel is provided in all sizes and shapes (flat, round, and bars) depending on customer requirements. Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

Product List: - DIE STEELS ( HH 370 - 410 BHN ) DIN-1.2714 / AISI L6 ) - HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13) - PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 ) - HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35) - HCHCr. (DIN 2379 , 2080 / AISI D2 , D3) - ALLOY STEELS, EN-SERIES ETC.

For more information visit https://www.viratsteels.com/

Watch now: https://www.youtube.com/watch?v=c4h5KqyzVd0

youtube

Any further queries feel free to contact us: 🌐www.viratsteels.com 📬 [email protected] 📲+91-98140 21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#SteelTrades#SpecialSteel#DB6Steel#DIN2714#H13Steel#H11Steel#D2Steel#D3Steel#Youtube

3 notes

·

View notes

Text

Introducing VMO Steel - The Perfect Grade for Hot Work Applications!

Virat Special Steels is thrilled to bring you the highly specialized VMO steel grade, also known as ABNT VMO.

This exceptional steel is ideal for hot work applications, especially in forging dies for high-performance drop hammers. Discover the unmatched strength and durability of VMO Steel for your demanding projects.

Trust in Virat Special Steels for top-quality steel solutions. Virat Special Steels is bringing a highly specialized and valuable steel grade to the market! The VMO steel grade, also known as ABNT VMO, is indeed well-regarded for its use in hot work applications, particularly in forging dies for high-performance drop hammers. Its robust chemical composition and mechanical properties make it ideal for such demanding environments.

Why Choose VMO Steel? Superior Strength & Toughness: Ideal for demanding environments. High Performance: Perfect for high-temperature applications. Reliable Quality: Trusted by industry professionals.

Key Features: Chemical Composition: Carbon 0.57%, Silicon 0.25%, Manganese 0.70%, Sulfur 1.10%, Chromium 0.50%, Molybdenum 1.65%

Upgrade your tools and dies with the best in the industry!

Contact us today to learn more about how VMO steel can enhance your operations.

Contact us today to learn more! https://www.viratsteel.in/products/vmo-steel-supplier-in-india/

Any further queries feel free to contact us : 🌐https://wwww.viratsteels.com 📬 [email protected] ☎+91 98140-21775

#iso9001#chandigarh#pune#delhi#mumbai#maharashtra#aurangabad#walujindustry#toolsteelsupplier#ahmedabad#VMOSteel#HotWorkApplications#ForgingDies#SpecialSteel#ToolSteel#DieSteels#ABNT

2 notes

·

View notes

Text

Is Monel similar to Inconel?

Many of our customers have such a question: Is Monel similar to Inconel? As a matter of fact, both Monel and Inconel are nickel-based alloys with exceptional corrosion resistance and high-temperature performance, but they differ significantly in composition, properties, and applications. In this article, let’s delve into the key aspects of these two alloys to understand their similarities and differences.

Is Monel similar to Inconel?

Composition:

Monel, also known as Monel alloy, is primarily a nickel-copper alloy, typically containing up to 67% nickel and 28% copper, with the remaining portion composed of iron, manganese, carbon, and silicon. This composition gives Monel its excellent corrosion resistance, particularly against acids and alkalies.

On the other hand, Inconel is a nickel-chromium alloy, with chromium content ranging from 15% to 25%, depending on the specific grade. Inconel alloys also contain significant amounts of other elements like iron, molybdenum, and titanium, which contribute to their high-temperature strength and oxidation resistance.

Properties:

Both Monel and Inconel exhibit excellent corrosion resistance, but the specific environments they thrive in differ. Monel’s corrosion resistance is particularly noteworthy in marine and chemical processing applications, where it can withstand the corrosive effects of saltwater and various acids.

Inconel, on the other hand, is renowned for its ability to maintain its mechanical properties at extremely high temperatures. It is often used in aerospace and power generation applications where materials must withstand extreme heat and pressure. Inconel’s chromium content also gives it superior resistance to oxidation and sulfidation at high temperatures.

When it comes to mechanical properties, Inconel generally offers higher strength and hardness compared to Monel. However, Monel has better formability and weldability, making it easier to shape and join into complex structures.

Applications:

The differences in composition and properties lead to distinct applications for Monel and Inconel. Monel is commonly used in the chemical processing, marine, and food processing industries due to its resistance to corrosion and ease of fabrication. Its ability to withstand the corrosive effects of saltwater makes it a popular choice for marine applications like shipbuilding and offshore drilling.

Inconel, on the other hand, finds its niche in high-temperature applications where strength and oxidation resistance are paramount. Aerospace, power generation, and petrochemical industries rely on Inconel alloys for components that must operate in extreme environments.

Conclusion:

While Monel and Inconel are both nickel-based alloys with exceptional corrosion resistance, they are not interchangeable. Each alloy has its unique composition, properties, and applications. Monel excels in corrosive environments and offers good formability and weldability, while Inconel is renowned for its high-temperature performance and oxidation resistance.

Thank you for reading our article and we hope it can help you to find the answer to the question: Is Monel similar to Inconel? If you are looking for Monel and Inconel suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel and Inconel Alloys from Shanghai China, Huaxiao Alloy offers customers high-quality products such as Monel 400, Monel K500, Inconel 600, Inconel 601, Inconel 625, and Inconel 718 at a very competitive price.

2 notes

·

View notes

Text

Cobalt Alloy Haynes 188 Sheet Suppliers

Cobalt Alloy Haynes 188 Sheet in Mumbai, Cobalt Alloy Haynes 188 Sheet Importers in Mumbai, Cobalt Alloy Haynes 188 Sheet Suppliers in Mumbai, Cobalt Alloy Haynes 188 Sheet Exporters in Mumbai, Cobalt Alloy Haynes 188 Sheet Stockists in Mumbai.

Haynes 188™ is a cobalt based alloy with excellent high temperature strength and great oxidation resistance up to 2000° F. Haynes 188’s™ has good resistance to sulfidation and good metallurgical stability, therefore Haynes 188™ can be easily fabricated.

Element

Min

Max

Carbon

0.05

0.15

Manganese

--

1.25

Silicon

0.20

0.50

Phosphorus

--

0.02

Sulfur

--

0.015

Chromium

21.0

23.0

Nickel

20.0

24.0

Tungsten

13.0

15.0

Lanthanum

0.03

0.12

Boron

--

0.015

Iron

--

3.0

Cobalt

Bal.

Physical Properties

Physical Properties

°F

British Units

°C

Metric Units

Density

72

0.324 lb./in.(3)

22

8.98 g/cm(3)

Incipient Fusion Temperature

2375- 2425

1302- 1330--

Electrical Resistivity

70

39.6 microhm-in.

21

1.01 microhm-m

Mean Coefficient of Thermal Expansion

70 to -400

5.4 microin./in.-°F

21 to -200

9.7 X 10(-6)m/m-K

70 to -200

5.8 microin./in.-°F

21 to -129

10.4 X 10(-6)m/m-K

70-0

6.2 microin./in.-°F

21 to -18

11.2 X 10(-6)m/m-K

70-100

6.2 microin./in.-°F

21-38

11.5 X 10(-6)m/m-K

70-200

6.6 microin./in.-°F

21-93

11.9 X 10(-6)m/m-K

70-400

7.0 microin./in.-°F

21-204

12.6 X 10(-6)m/m-K

70-600

7.4 microin./in.-°F

21-316

13.3 X 10(-6)m/m-K

70-800

7.8 microin./in.-°F

21-427

14.0 X 10(-6)m/m-K

70-1000

8.2 microin./in.-°F

21-538

14.8 X 10(-6)m/m-K

70-1200

8.6 microin./in.-°F

21-649

15.5 X 10(-6)m/m-K

70-1400

9.0 microin./in.-°F

21-760

16.2 X 10(-6)m/m-K

70-1600

9.4 microin./in.-°F

21-871

16.9 X 10(-6)m/m-K

70-1800

9.9 microin./in.-°F

21-982

17.8 X 10(-6)m/m-K

70-2000

10.3 microin./in.-°F

21-1093

18.5 X 10(-6)m/m-K

Thermal Conductivity

100

75 Btu-in/ft²-hr-°F

38

10.8 W/m-K

400

100 Btu-in/ft²-hr-°F

204

14.4 W/m-K

600

112 Btu-in/ft²-hr-°F

316

16.1 W/m-K

800

125 Btu-in/ft²-hr-°F

427

18.0 W/m-K

1000

138 Btu-in/ft²-hr-°F

538

19.9 W/m-K

1200

152 Btu-in/ft²-hr-°F

649

21.9 W/m-K

1400

167 Btu-in/ft²-hr-°F

760

24.1 W/m-K

Thermal Diffusivity

572

0.006 in²/sec

300

3.9 x 10(-6)m²/s

752

0.006 in²/sec

400

3.9 x 10(-6)m²/s

932

0.007 in²/sec

500

4.5 x 10(-6)m²/s

1112

0.007 in²/sec

600

4.5 x 10(-6)m²/s

1409

0.008 in²/sec

765

5.2 x 10(-6)m²/s

1652

0.008 in²/sec

900

5.2 x 10(-6)m²/s

2012

0.009 in²/sec

1100

5.8 x 10(-6)m²/s

Magnetic Permeability (Room Temperature)

1.01 at 200 oersteds (15,900 A/m)

2 notes

·

View notes

Text

Inconel Alloy 718 Fasteners: Manufacturer, Supplier & Exporter

Introduction

Inconel Alloy 718 is a high-strength, corrosion-resistant nickel-chromium alloy that is well-suited for extreme environments, including high-temperature and high-pressure applications. Due to its superior properties, Inconel 718 is widely used in the aerospace, marine, and chemical processing industries. Fasteners made from this alloy exhibit excellent mechanical strength, outstanding oxidation resistance, and superior weldability.

Properties of Inconel 718 Fasteners

High Strength: Inconel 718 fasteners maintain their structural integrity at high temperatures.

Corrosion Resistance: Exceptional resistance to oxidation and corrosion in various harsh environments.

Excellent Weldability: Can be readily welded without cracking, which is rare for high-strength nickel alloys.

Creep and Stress Rupture Resistance: Ensures long service life in demanding conditions.

Cryogenic Suitability: Performs well even in extremely low temperatures.

Types of Inconel 718 Fasteners

Inconel 718 Bolts – Hex bolts, carriage bolts, eye bolts, U-bolts, etc.

Inconel 718 Nuts – Hex nuts, lock nuts, dome nuts, wing nuts, etc.

Inconel 718 Washers – Flat washers, spring washers, fender washers, etc.

Inconel 718 Screws – Machine screws, self-tapping screws, wood screws, etc.

Inconel 718 Studs – Full thread studs, double-ended studs, etc.

Applications of Inconel 718 Fasteners

Aerospace Industry: Used in jet engines, turbine blades, and exhaust ducts due to high-temperature resistance.

Marine Industry: Applied in naval vessels, offshore platforms, and seawater applications.

Power Generation: Utilized in nuclear reactors and gas turbines.

Chemical Processing: Resistant to corrosive chemicals, making it suitable for processing plants.

Automotive Industry: Used in turbochargers and exhaust systems.

Standard Specifications

ASTM B637 – Standard specification for Inconel 718 forged products.

AMS 5662, 5663, 5664 – Aerospace material specifications.

UNS N07718 – Unified numbering system designation.

Chemical Composition of Inconel 718

Nickel (Ni): 50-55%

Chromium (Cr): 17-21%

Iron (Fe): Balance

Niobium (Nb) + Tantalum (Ta): 4.75-5.5%

Molybdenum (Mo): 2.8-3.3%

Titanium (Ti): 0.65-1.15%

Cobalt (Co): ≤ 1.0%

Aluminum (Al): 0.2-0.8%

Carbon (C): ≤ 0.08%

Silicon (Si): ≤ 0.35%

Manganese (Mn): ≤ 0.35%

Sulfur (S): ≤ 0.015%

Mechanical Properties of Inconel 718

Tensile Strength: 135 ksi (931 MPa)

Yield Strength (0.2% offset): 70 ksi (482 MPa)

Elongation: 30%

Hardness: 30-40 HRC

Advantages of Inconel 718 Fasteners

Withstands high-pressure and high-temperature environments.

Excellent fatigue and creep resistance.

Resistant to pitting and crevice corrosion.

Long service life with minimal maintenance.

Why Choose Ananka Group for Inconel 718 Fasteners?

Ananka Group is a trusted manufacturer, supplier, and exporter of Inconel 718 Fasteners. We provide high-quality, precision-engineered fasteners that meet international standards. Our fasteners are available in various sizes, grades, and custom specifications to suit industry needs.

Key Benefits of Choosing Us:

High-Quality Materials: We use premium-grade raw materials for manufacturing.

Precision Engineering: Advanced machinery ensures accurate dimensions and performance.

Global Supply Network: We export to countries worldwide with timely delivery.

Competitive Pricing: Affordable rates without compromising on quality.

Conclusion

Inconel Alloy 718 Fasteners are ideal for applications requiring superior strength, corrosion resistance, and durability. Their ability to withstand extreme conditions makes them indispensable in aerospace, marine, and industrial applications. Choosing a reliable manufacturer like Ananka Group ensures you get the best quality fasteners that meet stringent industry standards.

FAQs

Q1: What makes Inconel 718 different from other Inconel grades?A1: Inconel 718 has excellent weldability and high strength, which sets it apart from other Inconel alloys like 625. It is precipitation-hardened, making it ideal for high-stress applications.

Q2: Can Inconel 718 fasteners be used in seawater applications?A2: Yes, they offer excellent resistance to seawater corrosion, making them suitable for marine and offshore environments.

Q3: Are Inconel 718 fasteners expensive?A3: While they are more costly than stainless steel fasteners, their durability, high performance, and corrosion resistance justify the investment.

Q4: Do you provide custom sizes for Inconel 718 fasteners?A4: Yes, Ananka Group offers customized fasteners in different sizes and specifications as per client requirements.

For premium-quality Inconel 718 Fasteners, contact Ananka Group today!

#Ananka#fasteners#Inconel#Inconelfasteners#Inconel718#fastenersmanufacturer#article#blog#Anankafasteners#manufacturer#supplier#mumbai#bolt#usa#tumblr#blog tumblr#articles

1 note

·

View note

Text

SS 310 Pipe Suppliers

SS 310 pipe is a medium carbon austenitic stainless steel that is suitable for high pressure and elevated temperature services. There are different specifications such as ASME A213 and 312.

Neelcon Steel Industries produces all different types such as the ASME SA 312 TP 310 pipes and other types. The pipes and tubes can operate up to 1035 degrees Celsius under intermittent services and up to 1150 degrees Celsius for continuous services. The ASTM A213 TP 310 pipe is made up of 24% chromium, 19% nickel, sulfur, phosphorus, silicon, manganese and carbon in it.

The material also has 205MPa minimum yield strength and 520MPa minimum tensile strength. The elongation rate is 40% and SS 310 Pipe Suppliers has 225HBW Brinell hardness. The products could be welded with electrodes and filler metals. They could be welded with most welding methods. Preheating and post weld heat treatments are not necessary.

As a leading 310 Stainless Steel pipe supplier we produce the pipes in different standards and dimensions. The pipes range from ½ inches to 100 inches in nominal bore size. The 310 Stainless Steel pipe can be seamless, ERW, welded, fabricated or LSAW type. There are square, rectangular, hydraulic and other types of pipes. They can vary in length as single random, double random and custom cut to length sizes.

SS 310 Pipe Suppliers are preferred for its strength in structural applications. The pipes can also come with different end types such as plain end, beveled end and threaded ends. As a leading supplier, we produce the Austenitic Stainless Steel 310 Welded Pipe and other types as well. These range in schedules from sch20 through XXS. Please contact us to know more about the Stainless Steel 310 ERW pipe, welded pipe and seamless pipes with their prices.

0 notes

Text

Alloy Steel Sheets & Plates Exporters

Alloy Steel Plates Supplier is defined as having 1.5% to 5% total alloy content. Its common alloying elements are manganese, silicon, chromium, nickel, molybdenum, and vanadium, which contain as many as four or five of these alloys in varying amounts. which is been used by the manufacturers who works with petrochemical industries, oil and gas industries, chemical industries, shipbuilding etc. Alloy steel wear plates is a smooth, chromium carbide rich overlay plate manufacturers and Supplier by a patented production process maximizing abrasion resistance and reducing hang up.

Alloy Steel Sheet is been designed from alloys such as chromium, molybdenum, nickel, manganese, silicon so on, they are industrial product that is generally used in various industries applications. 4130 alloy steel sheet is low-alloy steels containing chromium and molybdenum as strengthening agents. It provides good strength and toughness, weldability and machinability. Alloy steel 4340 sheet is a heat treatable low alloy steels which contains nickel, chromium, molybdenum, they are commonly used for heavy duty industrial, aerospace and automotive applications.

It has high strength and toughness in heat treated condition. 6150 alloy steel sheet is useful in heavily stressed machinery parts including gears, shafts, hand tool components and pinions. It is a fine grained, highly abrasion resistant carbon-chromium alloy steel. Alloy Steel Plates Grades are ASTM A387 Gr 5, ASTM A387 Gr 9, ASTM A387 Gr 11, ASTM A387 Gr 12, ASTM A387 Gr 22 and ASTM A387 Gr 91.

Specification Schedule of Alloy Steel Sheets & Plates

SpecificationsASTM A387 / ASME SA387Thickness1mm-300mmWidth 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, 4050mm etcLength2000mm, 2440mm, 3000mm, 5800mm, 6000mm, 12000mm, 15000mm etcSurface2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching Manufacturer and SupplierFinishHot rolled plate (HR), Cold rolled sheet (CR)FormCoils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip Manufacturer and Supplier

Chemical Properties of Alloy Steel Sheets & Plates

GradesCMnPSSICrMoASTM A387 Grade 50.15 max0.3 – 0.60.0350.030.5 max4.00 – 6.000.45 – 0.65ASTM A387 Grade 90.15 max0.30 – 0.60.030.031.0 max8.0 – 10.00.9 – 1.1ASTM A387 Grade 110.05 – 0.170.4 – 0.650.0350.0350.5 – 0.801.0 – 1.50.45 – 0.65ASTM A387 Grade 120.05 – 0.170.4 – 0.650.0350.0350.15 – 0.40.8 – 1.150.45 – 0.6ASTM A387 Grade 220.05 – 0.150.3 – 0.60.0350.0350.5 max2.0 – 2.50.9 – 1.1

Mechanical Properties of Alloy Steel Sheets & Plates

Tensile StrengthYield StrengthElongationin 200mm (%)Elongation in 50mm (%)70-90 ksi, 485-620 MPa45 Ksi, 310 MPa1822

Equivalent Standard of Alloy Steel Sheets & Plates

Material GroupCommon NameTypeUNSForging Spec.Casting Spec. EquivalentDINDIN W. NoApplicationLow ASMoly SteelC-1/2MoK12822A182-F1 cl2A217-WC115M031.5415Up to 470ºC* (875ºF)AS Chrome Moly1.1/4Cr-1/2MoK11572A182-F11 cl2A217-WC613CRM0441.7335Up to 593ºC (1100ºF)2.1/4Cr-1MoK21590A182-F22 cl3A217-WC910CRM09101.7380Up to 593ºC (1100ºF), HP steam5Cr-1/2MoK41545A182-F5/F5aA217-C512CRMO1951.7362High temp refinery service9Cr-1MoK90941A182-F9A217-C12X 12 CrMo 9 11.7386High temp erosive refinery service9Cr-1Mo-VA182-F91A217-C12AX 10 CrMoVNb 9 11.4903High pressure steam

0 notes

Text

Rockstar 450 Plate Suppliers

Vandan Steel & Engg. Co. are often recognized within the industry and supply ROCKSTAR 450 blades. As a customer-oriented industry, we offer these tables in several standards, widths, lengths, heat treatments and styles . Specifications for special applications also are provided. And our products have passed various quality standard certifications. The wear-resistant ROCKSTAR 450 PLATTEN welding plate has good general properties like formability, hardness, wear resistance and flatness. During the assembly process.

ROCKSTAR 450 must be delivered to customers in fitness . Medium to medium specially developed lubrication cycle with minimal ductility. ROCKSTAR 450 is that the ideal choice for yellow products in mining. Star 400 is that the ideal solution for applications like buckets, crushers and truck linings.It also can be found in silos, excavators, conveyor belts and silos. These include concrete buckets, shovel edges, dustcart floors, sweepers and dump trailers. Sit back and rest, if needed. it's impossible to use substitutes. within the temperature range above 250°C. Suitable for other heat treatments. The chemical composition of ROCKSTAR 450 wear plate is manganese, carbon, molybdenum, chromium, sulfur, phosphorus, silicon, boron and nickel. Blade sizes are used for various applications.

The Rockstar 450 Plate is one such high-performance product that stands out in the market, offering exceptional wear resistance, strength, and versatility. Manufactured with precision and designed to withstand the harshest conditions, it has become a favorite in industries such as mining, construction, and heavy machinery manufacturing.

The Rockstar 450 Plate is a wear-resistant steel plate with a nominal hardness of 450 HBW (Brinell Hardness). This makes it a highly durable and long-lasting material, even when subjected to intense mechanical stress and abrasive environments. It is manufactured using advanced metallurgical processes, ensuring uniform hardness and toughness across the plate.

Key Features of the Rockstar 450 Plate

Exceptional Wear Resistance The 450 HBW hardness ensures that the Rockstar plate can withstand heavy wear and tear, making it ideal for applications like dump truck bodies, chutes, and hoppers.

High Strength Despite its hardness, the Rockstar 450 Plate maintains excellent structural integrity, enabling it to handle heavy loads without deformation or failure.

Good Weldability and Machinability Unlike many wear-resistant plates, the Rockstar 450 is relatively easy to weld and machine. This makes it convenient for fabricators to use in custom applications.

Corrosion Resistance Thanks to its metallurgical composition, the plate offers moderate resistance to corrosion, extending its life in various environments.

Versatility Its adaptability to different applications, from earthmoving equipment to industrial machinery, makes it a highly sought-after material.

Applications of the Rockstar 450 Plate

The Rockstar 450 Plate finds its use in a wide range of industries, including:

Mining and Quarrying: Used for manufacturing components like crushers, conveyor belts, and liners.

Construction Equipment: Ideal for bulldozers, excavators, and loader buckets.

Agriculture: Used in machinery for plowing and harvesting.

Recycling Plants: Essential for shredders, compactors, and separators.

ROCKSTAR 450 Plate Specification :

Item: Abrasion Resistant Plate

Thickness : 6mm to 75mm

Length : 6,000mm to 12,000mm

Width : 1,500mm to 2,500mm

Production : Hot-Rolled (HR) / Cold-Rolled (CR)

Applications : concrete industry, metallurgy, fan industry, coal industry, mining machinery, construction machinery,etc.

Heat Treatment: N, Q+T

Material : ROCKSTAR 450 Plates, ROCKSTAR 450 Abrasion Resistant Steel Plates, ROCKSTAR 450 Wear Resistant Plates

ROCKSTAR 450 PLATES CHEMICAL COMPOSITION

Rockstar 450 Chemical Composition (%)Plate thicknessCMnPSSiCrNiMoBCEPCMmmmax %max %max %max %max %max %max %max %max %maxmax6.0 – 20.00.301.600.0250.0100.701.000.600.600.0040.520.3421.0 – 40.00.301.600.0250.0100.701.000.600.600.0040.600.4041.0 – 50.00.301.600.0250.0100.701.000.600.600.0040.650.50

ROCKSTAR 450 PLATES MECHANICAL PROPERTIES

425-475 BHN (On a milled surface 0.5-2 mm below the plate surface)HardnessYield Strength (MPa)Tensile Strength (MPa)% Elongation (L0=50 mm)Impact at -20°C (In Joules)Typical values for 20 mm plate thickness115013501230

Benefits of Using Rockstar 450 Plate

Increased Lifespan Its high wear resistance reduces the need for frequent replacements, saving time and costs in the long run.

Reduced Maintenance Costs With superior durability, the plate minimizes downtime and maintenance expenses.

Enhanced Productivity Equipment made with Rockstar 450 performs more efficiently, improving overall operational productivity.

Eco-Friendly The extended lifespan of components reduces waste generation, contributing to a sustainable environment.

Conclusion

The Rockstar 450 Plate is more than just a steel plate; it's a solution to the challenges of wear and tear in demanding industries. Its blend of hardness, strength, and versatility ensures that it not only meets but exceeds expectations. For those looking for a material that can handle the toughest jobs with ease, the Rockstar 450 Plate is undoubtedly a rock-solid choice.

For more information

Contact: 8828813630

Email id: [email protected]

Address: Vandan Steel & Engg. co. 359 / 373, Flat -9, 2nd Floor, Minerva Mansion, Svp. Road, Khetwadi, Giragoan, Mumbai-400 004.

0 notes

Text

What is Monel Studs? Understanding Its Composition and Properties

Monel studs are mentioned for their strength, resilience to corrosion, and persistence with reference to excessive overall performance fasteners. We at Fasteners & Fixtures offer wonderful studs for a number of industries. Selecting the first-class fastener you desire requires expertise in the trends and composition of UNS N04400 studs. Discover the definition of Monel alloy studs, their precise trends, and the reasons for their extensive recognition as stud manufacturers in lots of industries on this weblog.

What Are Monel Studs?

Monel alloy studs are fasteners crafted from a nickel-copper alloy referred to as Monel, designed to offer everyday connections in harsh environments. Monel or WNR 2.4360 studs are implemented in industries that encompass marine, chemical processing, and aerospace. Their electricity and corrosion resistance make them a superb preference for programs that call for dependable and long-lasting performance.

Composition of UNS N04400 studs

Monel alloys are commonly composed of about 63% nickel and 28% copper, with small amounts of iron, manganese, carbon, and silicon. This composition offers Monel or UNS N04400 studs their fantastic characteristics:

Corrosion Resistance: Monel is good protection against seawater, chemical compounds, and acidic environments and is fine for industries exposed to harsh situations.

High Strength: These studs can face up to immoderate degrees of stress, making them appropriate for applications requiring strong fastening answers.

Temperature Tolerance: Monel or UNS N04400 studs perform well in excessive-temperature environments, preserving their integrity even in immoderate situations.

Key Properties of Monel or WNR 2.4360 Studs

Monel or WNR 2.4360 studs offer numerous standout features that motivate them to be famous for the duration of numerous sectors:

1. Corrosion Resistance

Monel alloys, mainly Monel 400, are acknowledged for their high-quality resistance to corrosion in marine and chemical environments, making them nice for use in oil rigs, ships, and chemical plants.

2. High Strength

WNR 2.4360 studs are engineered to rise to heavy hundreds and pressures, ensuring they stay intact even under severe pressure. This excessive tensile electricity makes them appropriate for gadget and structural applications.

3. Good Weldability

Monel or WNR 2.4360 studs are smooth to weld, making them versatile and adaptable to superb configurations. This property is reasonably valued through stud producers and fabricators who want bendy and dependable fasteners.

4. Resilience to Stress Corrosion Cracking

Monel or UNS N04400, studs are evidence in opposition to stress corrosion cracking, especially in environments exposed to harsh chemical materials or extreme temperatures, critical for chemical and marine industries.

Applications of Monel or UNS N04400 studs

Due to their corrosion resistance and high power, Monel or UNS N04400 studs are applied in numerous industries, collectively with:

Marine Engineering: Ideal for use in ships, submarines, and oil rigs, in which resistance to seawater and corrosion is essential.

Chemical Processing: Used in industries in which chemicals and acids impart protection within the course of corrosive substances.

Aerospace: Due to their immoderate temperature tolerance, UNS N04400 studs are applied in applications like jet engines and distinctive aerospace devices.

Choosing the Right Studs Manufacturers and Suppliers

When choosing stud producers and stud vendors, it’s essential to pick out an organization with records in producing extremely good Monel fasteners. We give attention to offering top-notch Monel or UNS N04400 studs, supplying a large form of answers to fulfil your unique desires. Whether you need Monel manufacturers or are looking for the correct fasteners for your undertaking, we are right here to help.

Why Choose Us?

We are committed to imparting long-lasting, price-effective Monel or UNS N04400 studs for some industries. From the trusted studs suppliers, we ensure our fasteners meet the pleasant standards for overall performance and reliability. Our skilled institution is dedicated to helping you locate the proper fastener answer to your needs.

Conclusion

Finally, Monel studs are a superb preference for industries requiring corrosion-resistant, high-power fasteners. Their specific characteristics, which include great resistance to chemical materials, seawater, and immoderate temperatures, reason them to brilliant for hard applications. At Fasteners & Fixtures, we pride ourselves on being studs manufacturers and suppliers of trusted and top-quality Monel or UNS N04400 studs that meet the demands of several industries. Contact us nowadays to have a look at our Monel or UNS N04400 studs and find out the proper fastening strategy for your task.

0 notes

Text

Best Supplier of TMT bars, Pure Silicon and Ferro Alloys in Kolkata

Apocalypse Steel and Power is a reliable supplier of TMT bars, Pure Silicon, and Ferro Alloys in Kolkata. Their commitment to quality and customer satisfaction has made them one of the leading suppliers in the region.

The TMT bars offered by Apocalypse Steel and Power are made with the latest technology and are known for their strength, durability, and corrosion resistance. They are widely used in the construction industry for building structures that are capable of withstanding extreme weather conditions and heavy loads.

Pure Silicon is an important material used in the production of semiconductors, solar cells, and electronic devices. Apocalypse Steel and Power provides high-quality pure silicon that meets the industry standards and is used in various applications.

Ferro Alloys are used as a raw material in the production of steel and other alloys. Apocalypse Steel and Power supplies different types of Ferro Alloys, including Ferro Silicon, Ferro Manganese, and Ferro Chrome, that are widely used in the steel and foundry industries.

With their years of experience in the industry and a team of experts, Apocalypse Steel and Power ensures timely delivery of their products, maintaining the highest standards of quality and safety. They have earned a reputation for their excellent customer service and competitive prices, making them the preferred supplier for many businesses in Kolkata and beyond.

#TMT suppliers#Steel Grade Pig Iron supplier#Pure Silicon supplier#Ferro Vanadium supplier in Kolkata#ms billets supplier#ms angle#firebricks#ferro silicon manganese supplier

0 notes

Text

Need High-Quality Plastic Mold Steel?

Trust VIRAT SPECIAL STEELS, INDIA for Top-Grade P20+Ni, DIN 2738, and P20/DIN 2311 Steels. We are one of the leading suppliers and stockists of P20+Ni Steel / DIN 2738 / and P20/DIN 2311 Steel in India and abroad.

DIN 2738 is a premium mold steel that offers excellent polishability, wear resistance, and toughness, making it ideal for a wide range of tooling applications. DIN 2738 or P20+Ni is a specially designed mold steel with improved toughness and excellent machinability compared to standard P20 grades.

Chemical Composition: Carbon (C): 0.35-0.45%, Manganese (Mn): 1.30-1.60%, Silicon (Si): 0.20-0.40%, Phosphorus (P): ≤ 0.030%, Sulfur (S): ≤ 0.030%, Chromium (Cr): 1.80-2.10%, Nickel (Ni): 0.90-1.20%, Molybdenum (Mo): 0.15-0.25%

Application: DIN 2738 / DIN 2311 is applicable for large & small plastic mould dies for Automotive Industries, Dies for Domestic goods , High finishing plastic Die, Boaster Plates of Presses, Die Holders & Shoe blocks for drop Hammers, Press Cassettes , Upsetter Blocker, forging dies, Different dies & mold for plastic products etc.

At Virat Special Steels, we provide DIN 2738 / DIN 2311 in round bar and flat bar blocks in different sizes and conditions to meet your specific requirements. Our team of experts is ready to assist you with any queries you have about DIN 2738 steel.

Learn more: https://www.viratsteels.com/din-2738.html

Contact us today to buy the best quality DIN 2738 steel for your tooling needs!

🌐https://www.viratsteels.com 📬 [email protected] ☎+91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#plasticmouldsteels#p20ni#p20#din2738#din2311#plasticindustry#plastic#plasticmould

3 notes

·

View notes

Text

How the Bangalore Steel Company is Meeting Modern Construction Needs

In today’s fast-paced construction industry, the demand for high-quality, durable, and innovative steel solutions is more critical than ever. Bangalore Steel Company, part of the prestigious A One Steel Group, has been at the forefront of delivering premium steel products and services that cater to modern construction needs. From sheet metal stamping to the production of the best TMT bar in India, the company has established itself as a trusted partner in the steel sector.

High-Quality Stainless Steel Products

Bangalore Steel Company is recognized among the leading stainless steel manufacturers in India, offering a wide range of stainless steel products that meet global standards. Whether it’s stainless steel tubing suppliers or stainless steel suppliers, their advanced manufacturing capabilities ensure superior quality, making them the go-to choice for residential, commercial, and industrial projects.

The company is also a reliable name in stainless steel manufacturing for its precision and innovative solutions. Its products are widely used across infrastructure projects, providing long-lasting performance in even the most demanding environments.

Expertise in Sheet Metal Production

As a prominent sheet metal manufacturing company, Bangalore Steel Company specializes in sheet metal production and sheet metal stamping to meet modern construction demands. Their advanced facilities ensure products are durable, lightweight, and tailored to specific project requirements. These products play a key role in shaping structural frameworks, automotives, and other heavy-duty industries.

Seamless and High-Performance Pipes

The company is counted among the top seamless pipe manufacturers in India and steel pipe manufacturers, providing pipes that ensure high strength and excellent resistance to corrosion. With precision-engineered solutions, their seamless and welded pipes are ideal for critical applications in oil and gas, water supply systems, and high-pressure infrastructure projects.

Delivering the Best TMT Bars in India

The demand for high-strength TMT bars has significantly increased due to their role in modern construction. Bangalore Steel Company supplies the best TMT bar in India with advanced ribbed patterns for superior bonding strength. These TMT steel bars provide unmatched durability, seismic resistance, and flexibility, making them perfect for earthquake-prone regions.

Furthermore, the company remains competitive by keeping steel rod price and iron rod price affordable without compromising on quality. For customers keeping a close eye on the market, they offer transparency with updates on the steel rod price today and TMT sariya rates.

Comprehensive Steel Solutions

As a leading steel manufacturing company, Bangalore Steel Company works alongside steel plate manufacturers to produce plates, rods, and sheets suitable for a wide range of construction projects. Their expertise extends to providing premium-grade ferro silicon and ferro silico manganese, essential for steel production processes. The company also ensures fair pricing, aligning with the competitive ferro silicon price in the market.

Commitment to Excellence and Innovation

Bangalore Steel Company’s state-of-the-art steel factory and commitment to technological advancements have placed them among the most trusted steel providers in India. Their unwavering dedication to delivering high-performance products, from sheet metal stamping to stainless steel products, ensures they meet the ever-evolving demands of modern construction projects.

By continuously innovating and maintaining product excellence, Bangalore Steel Company is revolutionizing the steel industry, making it the ideal partner for builders, contractors, and industries across India.

0 notes

Text

A Guide to Choosing the Right Aluminium Bronze Round Bar

Rajkrupa Metal Industries is one of the Superior Quality Aluminium Bronze Round Bar Manufacturer In India. We are now the industry leader in Aluminium Bronze Round Bar. Our exceptional corporate and technical people abilities have allowed us to consciously establish ourselves as a top-tier manufacturer and retailer in the global market for aluminum bronze round bars.

Aluminium Bronze Round Bar Manufacturer is a type of metal alloy that combines copper and aluminium. It is known for its excellent mechanical properties, high strength, and corrosion resistance. The main alloying elements in aluminium bronze are aluminium and copper, but small amounts of other elements like iron, nickel, manganese, and silicon might be present to enhance specific properties.

What is an Aluminium Bronze Round Bar?

An Aluminium Bronze Round Bar is a cylindrical metal bar made from aluminium, and it is often used in a variety of manufacturing processes. The round shape makes these bars perfect for machining, welding, and forming. Depending on the grade and alloy of aluminium used, these round bars can have different properties, making them suitable for different industrial applications. Aluminium Bronze Round Bars are a special type of round bar composed primarily of aluminium and copper, with added elements like iron, nickel, and manganese.

Types of Aluminium Round Bars

Aluminium Bronze CUAL10NI5FE4 Round Bar : Aluminium Bronze CUAL10NI5FE4 Round Bar market because of its substantial business and technical personnel experience. We provide areas with various kinds and sizes of Extruded Aluminium Bronze Round Bars in significant quantities.

Aluminium Bronze C63000 Round Bar: The Aluminium Bronze Round Bar comes with the promise of high quality and dimensional precision. Our manufactured Aluminium Bronze C63000 Centrifugal Casting Round Bar, Square Bar, Bush, Pipe, Flat Bar, Ring, and Circle are used worldwide.

Aluminium Bronze C63200 Round Bar : Aluminum Bronze C63200, also known as C632, is a specific grade of aluminium bronze alloy. When using Aluminum Bronze C63200 Round Bar or any other material, it's essential to consider the specific requirements of your application and consult with material experts or suppliers to ensure you choose the right alloy and form (like round bar) for your needs.

C90300 Tin Bronze Round Bar: Metal Industries has strategically positioned itself as a top manufacturer and supplier in the global C90300 Aluminium Bronze Round Bar market because of its substantial business and technical personnel experience. We provide areas with various kinds and sizes of Extruded Aluminium Bronze Round Bars in significant quantities.

Aluminium Bronze CA104 Round Bar: The Aluminium Bronze Forged Round Bar comes with the promise of high quality and dimensional precision. CA104 Aluminium Bronze Round Bar have made a name for themselves in a variety of industrial application fields, including offshore, marine, and aerospace, etc.

Advantages of Aluminium Bronze Round Bars

Strength and Durability

The strength of the aluminium round bar will depend on the alloy used. If your application requires high tensile strength, ensure you select an aluminium alloy with superior strength properties. Aluminium Round Bars Suppliers are known for their high strength and durability, especially in conditions that require resistance to wear and tear.

Corrosion Resistance

One of the key advantages of aluminium is its resistance to corrosion, but some alloys, like Aluminium Bronze Round Bars, offer even better corrosion resistance. This makes them ideal for applications exposed to harsh elements like seawater, chemicals, or extreme temperatures.

High Strength

This alloy has high tensile strength and toughness, making it ideal for applications that demand durability and resistance to wear. Aluminium Bronze Round Bars are commonly used in components like pumps, valves, and propellers, where strength is critical.

Wear Resistance

Aluminium bronze alloys are highly resistant to wear and tear, making them excellent for parts that experience heavy friction and mechanical stress. This makes them suitable for high-performance machinery parts.

Marine and Shipbuilding

Aluminium bronze is widely used in the marine industry for components like propellers, pumps, and valves. Its resistance to corrosion in seawater and ability to withstand mechanical stress make it the material of choice for these applications.

Industrial Applications

These round bars are also used in the manufacturing of industrial machinery parts, such as gears, shafts, and valve seats, where strength and wear resistance are important.

Conclusion

Choosing the right Aluminium Bronze Round Bar depends on your specific needs, including material strength, corrosion resistance, and machinability. Aluminium Bronze Round Bars offer outstanding properties for marine, aerospace, automotive, and industrial applications, ensuring superior performance in challenging environments. By understanding the properties and advantages of different alloys, you can select the perfect round bar for your project. Partnering with a reputable Aluminium Bronze Round Bar Manufacturer in India will ensure you receive high-quality products tailored to your exact requirements.

To Know more on details visit our website: rajkrupametal.com

Product Source: Aluminium Bronze Round Bar Suppliers in India

#Aluminium Bronze Round Bar Manufacturer In India#Aluminium Bronze Round Bar Manufacturer#Aluminium Bronze Round Bar#Aluminium Round Bars Suppliers#Aluminium Bronze Round Bar Suppliers in India#Aluminium Bronze CUAL10NI5FE4 Round Bar#Aluminium Bronze C63200 Round Bar#C90300 Tin Bronze Round Bar#CA104 Aluminium Bronze Round Bar

0 notes

Text

Guide to Alloy Steel Pipes and Tubes: Applications, Grades, and Maintenance

Are you searching for pipes that excel in high temperatures and pressures? Alloy steel pipes are the superior choice for demanding environments. Made from steel combined with crucial alloying elements such as Chromium (Cr), Manganese (Mn), and Nickel (Ni), these pipes offer unmatched strength, durability, and corrosion resistance. Typically, alloy steel might contain about 1-5% Chromium, 0.3-1.5% Manganese, and 0.2-2% Nickel, though these percentages can vary based on the specific grade and desired properties.

This guide will delve deep into everything you need to know about alloy steel pipes, from their types and applications to the specific grades suitable for various industries. At the forefront of providing these robust solutions is Amardeep Steel, recognized as the premier manufacturer and supplier of alloy steel pipes. Amardeep Steel boasts extensive operations in major markets such as India, the USA, Germany, Poland, Saudi Arabia, the United Arab Emirates, Italy, and the Netherlands. Each of these countries represents a significant consumer of high-quality alloy steel pipes, underscoring Amardeep Steel’s capacity to meet diverse global industrial requirements with precision and reliability.

What are Alloy Steel Pipes?

Alloy steel pipes are made from steel enhanced with alloying elements such as Chromium (Cr), Manganese (Mn), Nickel (Ni), and Silicon (Si). These elements are added to steel to improve its mechanical properties, including strength and corrosion resistance, making the alloy steel exceptionally versatile and suitable for various industrial applications. These pipes come in multiple grades, each tailored to meet specific environmental and mechanical demands.

Types of Alloy Steel Pipes

Seamless Alloy Steel Pipes: These are manufactured by extruding steel to create a seamless tube, making them ideal for high-pressure applications where uniform strength is crucial across the pipe's entire circumference.

Welded Alloy Steel Pipes: Made by welding together pieces of steel, these pipes are more economical and typically used in environments where pressures are lower.

Amardeep Steel, a leader in steel manufacturing, excels in producing both types of alloy steel pipes, ensuring high quality that meets global industrial standards. Whether for critical applications in the oil and gas industry or for transportation of liquids in the chemical sector, Amardeep Steel's alloy pipes offer reliability and durability, making them a top choice for industries around the world. With a robust supply chain and advanced manufacturing capabilities, Amardeep Steel stands out as a premier supplier, continually adapting to meet the needs of an evolving market.

Applications of Alloy Steel Pipes

Alloy steel pipes play a crucial role in industries that demand high strength and resistance to harsh conditions. Key applications include:

Oil and Gas Industry: In the demanding oil and gas sector, alloy steel pipes are essential for drilling and transporting oil and gas. Their high strength and corrosion resistance make them ideal for the deep-earth conditions and corrosive substances they encounter. These pipes can handle the high pressures and temperatures found in oil wells, ensuring safe and efficient fluid transport.

Chemical Processing Plants: Alloy steel pipes are vital in chemical processing where they transport corrosive fluids and gases. Their enhanced resistance to chemical attack prevents premature wear and leaks, which could be catastrophic in this environment.

Power Generation: In power plants, alloy steel pipes play a critical role in moving steam and hot fluids. Their ability to handle high temperatures and pressures without deforming makes them crucial for the efficiency and safety of power generation systems.

Aerospace Applications: The aerospace industry relies on alloy steel pipes for systems that require robust performance under extreme conditions. Their high tensile strength and toughness protect against the mechanical stresses and environmental challenges of aerospace applications.

Heat Exchangers and Boilers: These applications benefit significantly from the thermal resistance of alloy steel pipes. They are used in settings where high temperature and pressure resistance is essential, such as in boilers and heat exchangers, helping to maintain system integrity and operational reliability.

Grades of Alloy Steel Pipes

Alloy steel pipes come in various grades, each suited to specific applications based on their mechanical properties and resistance levels. Understanding these grades is essential for procurement managers to select the most appropriate materials for their projects. Below is a detailed table summarizing key grades of alloy steel pipes and their typical uses

Maintaining Alloy Steel Pipes for Optimal Performance

The longevity and performance of alloy steel pipes can be significantly enhanced through proper maintenance practices. Ensuring the durability of these pipes involves several critical steps:

Regular Inspections: It's essential to conduct regular inspections to detect early signs of corrosion or damage. This proactive approach helps in addressing potential issues before they escalate, thereby extending the lifespan of the pipes.

Routine Cleaning: Regular cleaning is crucial to prevent build-ups of deposits and residues that can lead to corrosion. This step is particularly important in industries like oil and gas, where the pipes are exposed to various corrosive substances.

Protective Coatings and Cathodic Protection: Applying protective coatings and implementing cathodic protection are effective methods to shield alloy steel pipes from environmental damage. These treatments provide a barrier against corrosive elements, thus enhancing the pipes’ resistance to degradation.

Installation Tips for Alloy Steel Pipes

Proper installation is paramount for the optimal performance of alloy steel pipes. Key considerations include:

Selecting Appropriate Fittings and Flanges: It's vital to ensure compatibility with the type of alloy pipe used. Using the right fittings enhances the integrity of the pipe system, ensuring efficient and safe operations.

Employing Correct Welding Techniques: Utilizing industry-standard welding methods ensures durable joints and maintains the structural integrity of the pipeline. This step is crucial for applications involving high pressures and temperatures.

Hiring Skilled Professionals: Installation should always be performed by certified technicians who adhere to strict safety and reliability standards. Their expertise guarantees that the installation complies with industry regulations and performance expectations.

Price of Alloy Steel Pipes - Market Insights

The price of alloy steel pipes in India varies, reflecting the global steel market dynamics. As of the latest reports, the average price can range significantly based on the grade and specific requirements of the project. Furthermore, India's role as a leading exporter in the alloy steel pipe market continues to expand, with significant shipments to countries in Europe, the Middle East, and North America.

According to recent export data, there's a rising demand for high-grade alloy steel pipes in sectors such as automotive and energy, which has led to an increase in their market value. This trend underscores the importance of choosing high-quality suppliers like Amardeep Steel, who can provide certified alloy steel pipes at competitive prices.

Alloy steel pipes offer a robust solution for industries operating under tough conditions. By selecting the right type and grade, and ensuring diligent maintenance and expert installation, these pipes provide a reliable and long-lasting system. For more detailed information or to choose the ideal alloy steel pipe for your needs, please contact Amardeep Steel or fill out our inquiry form to receive tailored expert advice for your project.

0 notes

Text

Hastelloy C22 Fasteners: Comprehensive Guide

Introduction

Hastelloy C22 is a highly versatile and corrosion resistant nickel chromium molybdenum tungsten alloy. Its exceptional resistance to a wide range of chemical environments makes it an ideal choice for manufacturing high-performance fasteners used in critical applications. This blog provides an in-depth overview of Hastelloy C22 fasteners, their characteristics, applications, and benefits.

What are Hastelloy C22 Fasteners?

Hastelloy C22 fasteners are components such as bolts, nuts, washers, and screws manufactured using the Hastelloy C22 alloy. These fasteners are renowned for their superior corrosion resistance, durability, and strength, even in extreme environments. They are widely used in industries such as chemical processing, marine engineering, and aerospace.

Chemical Composition of Hastelloy C22

The chemical composition of Hastelloy C22 contributes to its excellent properties. Below is the approximate composition of the alloy:

Nickel (Ni): 56%

Chromium (Cr): 20-22%

Molybdenum (Mo): 12.5-14.5%

Iron (Fe): 2-6%

Tungsten (W): 2.5-3.5%

Cobalt (Co): ≤2.5%

Manganese (Mn): ≤0.5%

Silicon (Si): ≤0.08%

Carbon (C): ≤0.015%

Phosphorus (P): ≤0.02%

Sulfur (S): ≤0.02%

Mechanical Properties of Hastelloy C22

Hastelloy C22 exhibits outstanding mechanical properties, making it suitable for demanding applications. Key mechanical properties include:

Tensile Strength: 690 MPa (minimum)

Yield Strength: 310 MPa (minimum)

Elongation: 45% (minimum)

Hardness: Approximately 95 HRB

Characteristics of Hastelloy C22 Fasteners

Hastelloy C22 fasteners are favored due to the following characteristics:

Corrosion Resistance: They resist pitting, crevice corrosion, and stress corrosion cracking in both oxidizing and reducing environments.

Thermal Stability: Excellent performance at high temperatures.

Versatility: Effective in a wide range of chemical environments, including acidic, alkaline, and saline conditions.

Durability: Exceptional mechanical strength ensures long-lasting performance.

Fabrication: Easy to weld and fabricate without compromising its corrosion-resistant properties.

Types of Hastelloy C22 Fasteners

Hastelloy C22 fasteners come in various forms to meet diverse industrial requirements. Common types include:

Bolts: Hex bolts, U-bolts, eye bolts, and stud bolts.

Nuts: Hex nuts, lock nuts, and heavy hex nuts.

Washers: Flat washers, spring washers, and lock washers.

Screws: Machine screws, self-tapping screws, and socket head cap screws.

Threaded Rods: Fully threaded rods and partially threaded studs.

Applications of Hastelloy C22 Fasteners

Thanks to their outstanding properties, Hastelloy C22 fasteners are used in various critical applications:

Chemical Processing: Ideal for reactors, heat exchangers, and other equipment exposed to aggressive chemicals.

Marine Engineering: Resists corrosion in seawater and marine atmospheres.

Pharmaceutical Industry: Suitable for hygienic and sterile environments.

Aerospace: Used in high-temperature and high-pressure systems.

Pollution Control: Applicable in scrubbers, filters, and stack liners.

Power Generation: Used in turbines and flue gas desulfurization systems.

Benefits of Hastelloy C22 Fasteners

Exceptional Corrosion Resistance: Ensures longevity and reliability in harsh environments.

High Strength: Can withstand significant mechanical stress without deforming.

Wide Temperature Range: Performs efficiently in both cryogenic and high-temperature conditions.

Ease of Fabrication: Can be machined and welded easily.

Versatile Applications: Suitable for a broad spectrum of industries.

Why Choose Ananka Group for Hastelloy C22 Fasteners?

Ananka Group is a leading manufacturer, supplier, and exporter of high-quality Hastelloy C22 fasteners. Here’s why you should choose us:

Expertise: Decades of experience in manufacturing and supplying corrosion-resistant fasteners.

Quality Assurance: Our fasteners comply with international standards such as ASTM, ASME, and DIN.

Customization: We offer tailor-made solutions to meet specific requirements.

Global Presence: We supply to industries worldwide, ensuring timely delivery.

Competitive Pricing: High-quality products at affordable prices.

Conclusion

Hastelloy C22 fasteners are indispensable components for industries requiring superior corrosion resistance and mechanical performance. Their versatility, durability, and exceptional properties make them a preferred choice for critical applications. If you’re looking for reliable and high-quality Hastelloy C22 fasteners, Ananka Group is your trusted partner.

Frequently Asked Questions (FAQ)

1. What makes Hastelloy C22 fasteners unique?

Hastelloy C22 fasteners are unique due to their exceptional corrosion resistance, high strength, and ability to perform in a wide range of aggressive chemical environments.

2. Can Hastelloy C22 fasteners be used in high-temperature environments?

Yes, Hastelloy C22 fasteners perform exceptionally well in high-temperature conditions, maintaining their strength and corrosion resistance.

3. Are Hastelloy C22 fasteners suitable for marine applications?

Absolutely. Hastelloy C22 fasteners offer excellent resistance to seawater and marine atmospheres, making them ideal for marine engineering.

4. Do Hastelloy C22 fasteners comply with international standards?

Yes, Hastelloy C22 fasteners manufactured by Ananka Group comply with international standards such as ASTM, ASME, and DIN.

5. Can I get customized Hastelloy C22 fasteners?

Yes, Ananka Group offers customization options to meet specific design and application requirements.

#HastelloyC22Fasteners#HastelloyFastener#NickelAlloyFasteners#IndustrialFasteners#ChemicalProcessingFasteners#HighPerformanceFasteners#HastelloyC22Bolts#HastelloyC22Nuts#HastelloyC22Washers#FastenersManufacturer#AnankaGroup#Article#Linkedin#Blog#Ananka#Fasteners#anankafasteners#manufacturer#supplier#mumbai#hex#bolt

0 notes