#Semi automatic paper bag Making machine manufacturers

Explore tagged Tumblr posts

Text

Best Printed Paper Bags in New Delhi | The Agro King

We are offering our valued customers the lowest prices on Printed Paper Bags at The Agro King. Paper bags are biodegradable. It means paper bags can be decomposed in soil with the help of bacteria. It's different from plastic bags that can take a thousand years to decompose. For express bags, we commonly use screen, digital, or foil printing as these methods are easier to set up and allow for faster printing with a great finish. For bespoke printed bags, we can use a variety of methods, but litho printing is common as we have more time to perfect the set up and the design. The Paper Carry Bag machine has a semi-automatic process and a fully automatic process. One can make these bags on the SOS Paper bag machine and then manually paste handles to convert the bag into a carry bag with handles.

For more details clicks here - https://www.theagroking.in/new-delhi/printed-paper-bags/ITB-DE7192AA

0 notes

Text

Innovations in Packaging Machinery and Gluing Solutions

Innovations in Packaging Machinery and Gluing Solutions

....................................................................................

Innovations in Packaging Machinery and Gluing Solutions

Gluing Machines

&

Order price below 5,000$

Top products in Packaging Machines

(01) Stainless Steel Table Top Paper Hot Melt Glue Gluing Machine

Introduction

In the ever-evolving world of manufacturing and production, efficiency and precision are key. COLORDOWELL's Stainless Steel Table Top Paper Hot Melt Glue Gluing Machine emerges as a reliable and innovative solution for a variety of industries. From food and beverage to medical and apparel, this gluing machine proves to be a versatile asset with its user-friendly design and top-notch features.

Easy to Operate

One of the standout features of the COLORDOWELL Gluing Machine is its user-friendly design. With a straightforward manual feeding system and easy operation, even those new to the manufacturing process can quickly adapt. This ensures a seamless integration into different production setups, making it an ideal choice for various businesses.

Diverse Applications

The gluing machine's adaptability is truly impressive. It caters to a wide range of industries including food, beverage, commodity, medical, chemical, machinery & hardware, apparel, and textiles. Whether you're working with cartons, cans, bottles, barrels, bags, film, pouches, or cases, this machine handles it all. This versatility makes it a valuable asset for businesses with diverse production needs.

Sturdy Construction

Crafted from high-quality stainless steel, the machine guarantees durability and longevity. The robust build ensures stability during operation, and its compact dimensions (1060390430mm) make it suitable for various workshop sizes. The 65 KG weight adds to the stability without compromising on portability.

Water-base Glue Technology

The use of water-based glue technology not only contributes to a more environmentally friendly operation but also ensures a secure and efficient bonding process. This feature aligns with modern sustainability standards, making it an appealing choice for eco-conscious businesses.

Semi-Automatic Operation

The semi-automatic grade and electric-driven type of the gluing machine strike a balance between manual control and automated precision. This ensures that operators have control over the process while benefiting from the efficiency and consistency provided by automation.

Conclusion

In the competitive landscape of manufacturing, COLORDOWELL's Stainless Steel Gluing Machine stands out as a reliable and versatile choice. Its ease of use, diverse applications, sturdy construction, and eco-friendly glue technology make it a game-changer for businesses looking to enhance their production processes. With a one-year warranty on core components, investing in this machine not only ensures immediate benefits but also long-term reliability. Upgrade your production capabilities with the COLORDOWELL Gluing Machine and experience a new level of efficiency in your operations.

Quick Details

Applicable Industries : Manufacturing Plant, Machinery Repair Shops, Restaurant, Printing Shops, Advertising Company

Showroom Location : None

Video outgoing-inspection : Not Available

Machinery Test Report : Not Available

Warranty of core components : 1 Year

Core Components : Motor

Place of Origin : Zhejiang, China

Weight : 65 KG

Warranty : 1 Year

Key Selling Points : Easy to Operate

Type : Gluing Machine

Condition : New

Application : Food, Beverage, Commodity, Medical, Chemical, Machinery & Hardware, APPAREL, Textiles

Packaging Type : Cartons, CANS, Bottles, Barrel, Bags, Film, Pouch, case

Packaging Material : Plastic, Paper, Metal, Glass

Automatic Grade : Semi-automatic

Driven Type : Electric

Voltage : 220V

Brand Name : COLORDOWELL

Dimension(L*W*H) : 1060*390*430mm

Product name : Gluing Machine

Glue type : Water-base Glue

Feeding way : Manul Feeding

Max. gluing width : 700mm

Buy Now & Read More

(02) High quality manual corrugated gluing machine paper gluing machine gluing machines

Introduction

In the dynamic landscape of manufacturing machinery, the Allraise OR-2000 emerges as a standout solution, particularly in the realm of gluing machines designed for food packaging. This semi-automatic gluing machine is a testament to efficiency, boasting high productivity and precision in its operations.

Versatility for Various Industries

The Allraise OR-2000 is a versatile gluing machine that finds applications across diverse industries, including hotels, garment shops, manufacturing plants, food and beverage factories, and more. Its adaptability makes it a valuable asset for businesses involved in packaging and production.

Robust Construction for Longevity

Crafted in Henan, China, the OR-2000 embodies robust construction, weighing 400 KG and guaranteeing durability for extended usage. The high-quality materials and meticulous engineering ensure that this machine stands the test of time in demanding industrial environments.

Intelligent Control with PLC Technology

At its core, the Allraise OR-2000 is equipped with a PLC (Programmable Logic Controller) system, providing intelligent control over its operations. This not only enhances the precision of gluing but also contributes to the overall efficiency of the packaging process.

Semi-Automatic for User-Friendly Operation

Designed with user convenience in mind, the OR-2000 operates on a semi-automatic mode. This ensures that operators have control and flexibility in managing the gluing process while benefiting from the efficiency and speed that automation brings.

Reliable Performance with 1-Year Warranty

Allraise stands behind the quality of the OR-2000 by offering a 1-year warranty on its core components. This commitment to customer satisfaction reflects the brand's confidence in the reliability and performance of their product.

Carefully Packaged for Safe Delivery

The packaging of the Allraise OR-2000 is a testament to the brand's dedication to customer satisfaction. Housed in a robust wooden case, the machine is securely protected during transit, ensuring that it reaches customers in pristine condition.

Conclusion

In conclusion, the Allraise OR-2000 stands out as a high-quality, semi-automatic gluing machine that excels in the precision packaging of food products. Its versatility, durability, intelligent control, and user-friendly operation make it a valuable investment for businesses seeking to enhance their productivity in the packaging process. Backed by Allraise's commitment to quality and a 1-year warranty, the OR-2000 is a reliable choice for those looking to elevate their packaging operations to new heights.

Quick Details

Applicable Industries : Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

Showroom Location : None

Video outgoing-inspection : Provided

Machinery Test Report : Provided

Warranty of core components : 1 Year

Core Components : PLC

Place of Origin : Henan, China

Weight : 400 KG

Warranty : 1 Year

Key Selling Points : High Productivity

Type : Gluing Machine

Application : Food

Packaging Type : case

Automatic Grade : Semi-automatic

Driven Type : Manual

Voltage : 220V

Brand Name : Allraise

Model : OR-2000

Packaging and delivery

Packaging Details,

1. Automatic PVC Card Foil Printer Hologram Signature Panel Printing Machine Holographic Images Hot Stamping Machine Price is packed in a strong wooden case.

2. As the customers' reasonable requires

Selling Units : Single item

Single package size : 127X122X183 cm

Single gross weight : 590.000 kg

Buy Now & Read More

(03) Fast Speed semi automatic Paper Box Cardboard Carton Cold Gluing Machines

Introduction

In the competitive world of printing, efficiency and precision are paramount, and the Befitter Cold Gluing Machine emerges as a true game-changer. This semi-automatic wonder is designed to revolutionize your printing process, offering a seamless experience with its cutting-edge features and user-friendly interface.

Unmatched Performance

The Befitter Cold Gluing Machine is engineered for excellence, making it an ideal choice for machinery repair shops, home use, retail, printing shops, and advertising companies alike. Its robust motor, a core component backed by a 1-year warranty, ensures durability and consistent performance. With a max gluing width of 380mm and an impressive max speed of 0-26m/min, this machine is built to handle a wide range of printing applications with precision and speed.

Easy to Operate

One of the key selling points of the Befitter Cold Gluing Machine is its user-friendly design. The machine's interface is intuitive and easy to operate, allowing users to seamlessly integrate it into their workflow. Whether you are a seasoned professional or a novice, the learning curve is minimal, ensuring that you can start maximizing your productivity from day one.

Versatile Application

The machine's versatility shines through in its application. Perfect for printing, it effortlessly handles various materials and projects with ease. The cold glue technology employed by the machine ensures a clean and efficient gluing process, catering to the diverse needs of the printing industry.

Compact and Durable

Weighing in at just 32kg and with dimensions of 600x410x360mm, the Befitter Cold Gluing Machine is compact and space-efficient. Its sturdy build and wooden packaging guarantee that it arrives in pristine condition, ready to be deployed for your printing requirements. The 1-year warranty provides peace of mind, showcasing the manufacturer's confidence in the machine's longevity.

Enhanced Support and Technical Assistance

Post-purchase, Befitter stands by its product with video technical support during the after-warranty period. This commitment ensures that you have continuous access to assistance and guidance, further solidifying the trust in your investment.

Conclusion

In the world of printing, the Befitter Cold Gluing Machine stands out as a reliable, efficient, and easy-to-operate solution. Its impressive features, coupled with the backing of a 1-year warranty and ongoing technical support, make it a smart investment for businesses looking to elevate their printing processes. Upgrade your operations with the Befitter Cold Gluing Machine and experience a new era of efficiency in the world of printing.

Quick Details

Applicable Industries : Machinery Repair Shops, Home Use, Retail, Printing Shops, Advertising Company

Showroom Location : None

Video outgoing-inspection : Provided

Machinery Test Report : Provided

Warranty of core components : 1 Year

Core Components : Motor

Place of Origin : Zhejiang, China

Weight : 32 KG

Warranty : 1 Year

Key Selling Points : Easy to Operate

Type : Gluing Machine

Condition : New

Application : Printing

Packaging Type : Case

Packaging Material : Wood

Automatic Grade : Semi-automatic

Driven Type : Electric

Voltage : 110V/220V

Brand Name : Befitter

Dimension(L*W*H) : 600*410*360mm

Name : Cold gluing machine for sale

Max gluing width : 380mm

Max speed : 0-26m/min

Power : 120W

Glue type : Cold glue

After Warranty Service : Video technical support

Packaging and delivery

Packaging Details : 1pc/ wooden case

Selling Units : Single item

Single package size : 60X41X36 cm

Single gross weight : 40.000 kg

Buy Now & Read More

(04) Rjs Sheet Glue Machine Paper Gluing Machine with heating

Introduction

I recently purchased the Rjs Sheet Glue Machine from COLORDOWELL for my manufacturing plant, and I am extremely satisfied with its performance. This semi-automatic gluing machine has proven to be a valuable addition to our production process, and here's why:

Versatile Application

The Rjs Sheet Glue Machine caters to a wide range of industries, making it a versatile choice for manufacturing plants, machinery repair shops, restaurants, printing shops, advertising companies, and more. Its adaptability across various sectors, including food, beverage, commodity, medical, chemical, machinery and hardware, apparel, and textiles, makes it a worthwhile investment for businesses with diverse needs.

Ease of Operation

One of the key selling points of this machine is its user-friendly interface. The easy-to-operate design simplifies the gluing process, ensuring that our team can efficiently use it without extensive training. The manual feeding feature adds an extra layer of control, allowing for precise application of glue on different materials.

Sturdy Construction

The build quality of the Rjs Sheet Glue Machine is impressive. Crafted with durability in mind, the machine boasts a robust motor as its core component, ensuring reliable and consistent performance. The machine's solid structure, weighing 65 KG, is a testament to its durability, providing stability during operation.

Adaptable Glue Type

The water-based glue used by the machine is a thoughtful choice, considering environmental concerns and safety standards. This feature aligns with our commitment to sustainable practices, making the Rjs Sheet Glue Machine an eco-friendly option.

Size and Dimensions

The compact size of the machine, with dimensions of 1060390430mm, makes it suitable for various production environments. It efficiently fits into our workspace without occupying excessive floor space.

Packaging and Delivery

The machine arrived in perfect condition, securely packaged in a wooden case. COLORDOWELL ensures that each unit is well-protected during transit, and the packaging details, including dimensions (105X52X90 cm) and gross weight (120.000 kg), reflect their commitment to delivering products in top-notch condition.

Warranty and Support

The 1-year warranty on core components, especially the motor, provides peace of mind. While we haven't encountered any issues, knowing that we have support in case of unexpected situations adds an extra layer of confidence in our purchase.

Conclusion

In conclusion, the Rjs Sheet Glue Machine from COLORDOWELL has exceeded our expectations. Its versatility, user-friendly design, and durability make it an excellent choice for businesses looking for a reliable and efficient gluing solution. I highly recommend this machine for anyone in need of a semi-automatic gluing machine with exceptional performance.

Quick Details

Applicable Industries : Machinery Repair Shops, Home Use, Retail, Printing Shops, Advertising Company

Showroom Location : None

Video outgoing-inspection : Provided

Machinery Test Report : Provided

Warranty of core components : 1 Year

Core Components : Motor

Place of Origin : Zhejiang, China

Weight : 32 KG

Warranty : 1 Year

Key Selling Points : Easy to Operate

Type : Gluing Machine

Condition : New

Application : Printing

Packaging Type : Case

Packaging Material : Wood

Automatic Grade : Semi-automatic

Driven Type : Electric

Voltage : 110V/220V

Brand Name : Befitter

Dimension(L*W*H) : 600*410*360mm

Name : Cold gluing machine for sale

Max gluing width : 380mm

Max speed : 0-26m/min

Power : 120W

Glue type : Cold glue

After Warranty Service : Video technical support

Packaging and delivery

Packaging Details : Wooden case

Selling Units : Single item

Single package size : 105X52X90 cm

Single gross weight : 120.000 kg

Buy Now & Read More

(05) A4 A3 automatic rubber machine fully automatic hot glue book Perfect glue binder book Binding machine

Introduction

In the fast-paced world of manufacturing and printing, efficiency is key. COLORDOWELL, a leading name in machinery innovation, has once again raised the bar with their A4 A3 Automatic Rubber Machine – a fully automatic hot glue book binder that promises to revolutionize bookbinding processes. Let's delve into the details of this impressive piece of equipment.

Unmatched Performance

Boasting a weight of 130 KG, the COLORDOWELL hot glue book binder is a robust machine designed for seamless operation. Its 1 Year warranty on core components, including the engine and bearing, reflects the manufacturer's confidence in the product's durability. The binding width of 320mm, binding thickness of 50mm, and a remarkable binding speed of 200 books per hour make it a standout choice for manufacturing plants, printing shops, and advertising companies.

Innovative Technology

The Automatic Grade feature ensures a hassle-free operation, making it incredibly easy to operate. With an electric-driven type and a voltage requirement of 220V, this machine aligns with modern technological standards, ensuring a smooth and reliable performance in diverse applications, from machinery and hardware to apparel.

Space-Efficient Design

Measuring at 1090mm480mm950mm, the compact design of this machine makes it ideal for various working environments. The manufacturer, COLORDOWELL, has crafted a perfect balance between functionality and space efficiency, ensuring that it seamlessly integrates into any workspace.

Quality Packaging

The attention to detail doesn't stop at the machine itself. COLORDOWELL understands the importance of secure transportation. The packaging, whether it's a carton case or wooden case, is designed to withstand the rigors of shipping, reflecting their commitment to delivering a pristine product to your doorstep.

Global Presence

With a showroom presence in Kazakhstan and Uzbekistan, COLORDOWELL has made its mark on the international stage. This signifies their commitment to providing cutting-edge machinery solutions to a global clientele.

Conclusion

In conclusion, the COLORDOWELL A4 A3 Automatic Rubber Machine is more than just a hot glue book binder; it's a testament to the future of efficient bookbinding. Whether you are running a manufacturing plant, a printing shop, or an advertising company, this machine promises to elevate your productivity to new heights. With its impressive specifications, innovative technology, and global presence, it's no surprise that COLORDOWELL stands at the forefront of the industry. Choose efficiency, choose innovation – choose COLORDOWELL.

Quick Details

Applicable Industries : Manufacturing Plant, Printing Shops, Advertising Company

Showroom Location : Kazakhstan, Uzbekistan

Video outgoing-inspection : Not Available

Machinery Test Report : Not Available

Warranty of core components : 1 Year

Core Components : Engine, Bearing

Place of Origin : Zhejiang, China

Weight : 130 KG

Warranty : 1 Year

Key Selling Points : Easy to Operate

Type : Gluing Machine

Condition : New

Application : Machinery & Hardware, APPAREL

Packaging Type : Cartons

Packaging Material : Paper

Automatic Grade : Automatic

Driven Type : Electric

Voltage : 220V

Brand Name : COLORDOWELL

Dimension(L*W*H) : 1090mm*480mm*950mm

Binding width : 320mm

Binding thickness : 50mm

Binding speed : 200 books/hour

Packaging and delivery

Packaging Details : Carton case or wooden case

Selling Units : Single item

Single package size : 115X61X103 cm

Single gross weight : 160.000 kg

Buy Now & Read More

.....................................................................................

Smeartra Amb

(Affiliated Marketing Business)

Affiliated marketer

This my blogs

Read MORE

...........................................................................................................

{Although the majority of the products are in stock, we were unable to include all of them on the website.}

Click here link and read more or buy more productsResource : Packaging Machines Buy Now & Read More

0 notes

Text

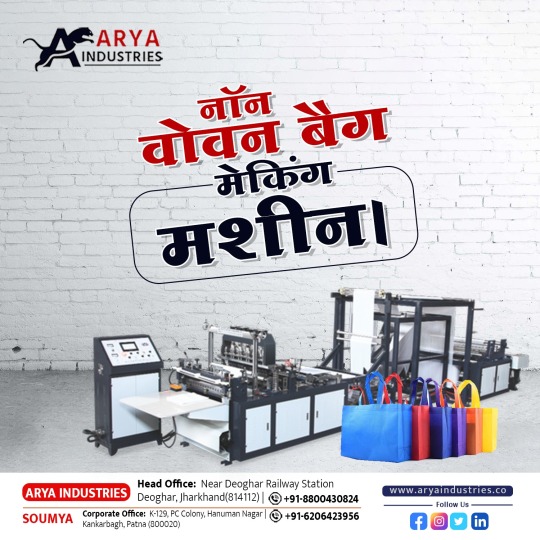

Non Woven Bag Machine in Patna: Arya Industries

Arya Industries stands out as the premier provider of non woven bag making machine Patna, spearheading the industry with its state-of-the-art non-woven bag making machines. As a trusted name in the market, Arya Industries has established itself as the go-to destination for businesses seeking efficient and reliable equipment for their operations.

At the heart of Arya Industries' offerings is its revolutionary non-woven bag making machine in Patna. With a commitment to sustainability and environmental responsibility, these machines are designed to produce high-quality, eco-friendly bags. The company's dedication to innovation is reflected in the precision and efficiency of their non-woven bag machines, making them an indispensable asset for businesses looking to contribute to a greener future.

In addition to non-woven bag machines, Arya Industries caters to a diverse range of industries with specialized equipment. The company boasts a remarkable noodles machine in Patna, addressing the needs of businesses involved in the production of this staple food item. The noodles machine is a testament to Arya Industries' versatility and commitment to meeting the unique demands of different sectors.

Arya Industries further extends its product portfolio to include a comprehensive range of machinery, such as semi-automatic and fully automatic thermocol plate making machines in Patna. These machines are designed to optimize the production process, ensuring efficiency and quality in the manufacturing of thermocol plates. The company's dedication to providing cutting-edge solutions is evident in the advanced features and technology incorporated into these machines.

The Arya Industries lineup also includes agarbatti making machines and paper cup making machines, showcasing the company's commitment to serving a wide spectrum of industries. The agarbatti making machines are designed for precision and efficiency in the production of incense sticks, while the paper cup making machines cater to the growing demand for eco-friendly disposable cups.

Arya Industries' non-woven bag machine in Patna has become synonymous with reliability and excellence. The company's commitment to quality extends to its customer service, ensuring that clients receive comprehensive support throughout the purchase and implementation process. As a result, Arya Industries has emerged as a trusted partner for businesses looking to invest in cutting-edge machinery for sustainable and efficient production processes.

Arya Industries is not merely a provider of machinery; it is a catalyst for progress and sustainability in the industrial landscape of Patna. With a diverse range of offerings, including non-woven bag machines, noodles machines, thermocol plate making machines, agarbatti making machines, and paper cup making machines, Arya Industries continues to shape the future of manufacturing in the region.

Visit us: https://www.aryaindustries.co/

#kapoormakingmachineinpatna#oil expailer#paperplatesmachinesinpatna#agarbattimakingmachineinpatna#fullyautomaticthermocolplatemakingmachineinpatna#manualnonwovenbagmakingmachinesinpatna#nonwovenbagmakingmachineinpatna#nonwovenbagmachineinpatna#semiautomaticthermocolplatemakingmachineinpatna#handpresspaperplatemachineinpatna#noodlesmachineinpatna

0 notes

Text

Semi-automatic Volumetric Cup Filling Machine Producers In India

The high-speed STB-10C tea packing machine is made to do a 10cm3 dosing filter sachet with a high velocity of 110 bags/min. It’s a dip tea bag-making machine that automatically varieties double chamber tea bags with rolled teabag paper. Meanwhile, it makes a tough tag out of rolled tags stapled with staples and cotton threads. As a leading tea packing equipment supplier, Synda STB-10A is an integral teabag packaging machine with the functions of the filter paper packing machine, tag and threads attach, as properly as envelope packing machine. In order to satisfy heavy tea bag manufacturing, we've a kind of super high-speed STB-15 Filter Tea Bag Packing Machine.

The STB-50G is a robust pyramid teabag and premade envelope packing machine that provides a super good envelope compared to other rolled film-made envelopes. It can also be compacted and systemized for filter teabag and outer sachet. The tea filling machine is specifically designed for black tea, green tea, white tea, free leaf tea, and flower tea.

The machine frames and management cabinets are created from chrome steel and the mechanics inside the machine are servo driven for top precision purposes. Volm offers three main traces of vertical packaging machines equipment tailored to go nicely with the application of the customers’ needs. From special dosing techniques to distinctive package deal sorts and granular to liquid products, these machines may be constructed upon to create a one-of-a-kind custom packaging resolution. Performance-proven construction ensures NBE liquid filling methods are built to handle extended obligation cycles and endure harsh course of environments. NBE engineered-to-application liquid filling methods provide total process advantages by outputting precisely crammed containers, whereas reducing product loss, and enhancing labor safety and efficiency.

Empty containers are positioned inside a vibrating system the place they are distributed and ... Monobloc of filling and capping in a single machine, low spaceoccupied. Rotary working system for each filling and capping, working stably and excessive efficient. We can deliver absolutely built-in options for sorting, filling and packaging of fluid merchandise.

The machine was crated properly and survived transport from New York To Los Angeles with no issues at all. We have 5 containers four Oz to 1 Gallon and they volumetric filler machine all work great within the machine. We even have two jars that with some retooling additionally run on the machine without a hiccup.

Accommodating a broad range of container shapes in volumes from 15mL to five gallons the Pro/Fill® 3000 runs at speeds to 250 containers/min., with accuracies to ± 0.10% dependent upon dose dimension and product. Ideal-Pak Pase Massman LLC Ideal-Pak® liquid filling machines are designed to deliver the best levels of precision, productivity, ease of use, and reliability in computerized, semi-automatic or handbook configurations. Individually designed to go well with the wants and budgets of their clients, Ideal-Pak® automatic liquid fillers include automatic PLC-controlled conveyor techniques volumetric filler machine, lid placers and closers for hands-free operation. Contact us right now to find out more about our line of automated liquid filling machines. Ideal-Pak®’s semi-automatic liquid filling machines ship the flexibility to course of smaller batches of product efficiently while sustaining high accuracy. Capmatic Capmatic supplies an in depth range of liquid filling machines for a broad variety of applications from pharmaceutical to food and beverage functions and beyond.

BellatRx presents a full range of totally automated and semi-automatic packaging methods to fill non-viscous and viscous liquids accurately. Liquid fillers embody monoblocs, inline fillers, piston and tube fillers, that deal with microtubes, vials and cartridges in pharmaceutical, cosmetic, biotech, food, e-liquid and other industries. Aesus Packaging Systems manufactures liquid fillers that may handle a variety of viscosities, from water and water-like liquids to oils and lotions. Filling machines function easy dial-in fill volume changes to change over from functions requiring milliliters from ones requiring gallons, all on the same machine.

This control is functional through the operation of the filler. Our machines are built with a view to zero maintenance via robust design and using... Automatic adjustment of the product volume to be filled in accordance with its temperature. Powerblock is one machine placed on one monoblock base, with the ability volumetric filler machine to fill several merchandise. Full computerized peak adjustment of the quantity ring and product bowl. The compact VF-1 can fill about 250 bottles per hour, whereas the bigger version, the VF-4 can fill about 500 bottles per hour, in good hygienic circumstances and with no product spillage.

1 note

·

View note

Text

Tricks to find Paper Bag Making Machine Manufacturers

Looking for Paper Bag Making Machine Manufacturers? Well, Choose Green Tech Industry. We offer high quality Automatic Paper Bag Making Machine, Elite Paper Bag Making Machine, Semi Automatic Paper Bag Making Machine, Paper Cup Making Machine, Paper Plate Making Machine, Screen Printing Making Machine, Eco Stove / Bio Stove / Bio stove Manufacturers, Non Woven Making Machine, and Automatic Paper Bag Machine in Chennai. Refer www.greentechmachine.com

#Paper Bag Making Machine Manufacturers#Paper Bag Machine Manufacturers#Automatic Paper Bag Making Machine Manufacturers#Elite paper bag Making machine manufacturers#Semi automatic paper bag Making machine manufacturers#Paper Plate Making Machine Manufacturers#Paper Cup Making Machine Manufacturers#Screen Printing Making Machine Manufacturers#Eco Stove Making Machine manufacturers#Non Woven bag Making Machine Manufacturers#Automatic Paper Bag Machine Manufacturers#Elite Paper Bag Machine Manufacturers

0 notes

Text

Find Paper Bag Making Machine Manufacturers

Looking for Paper Bag Making Machine Manufacturers? Well, Choose Green Tech Industry. We offer high quality Automatic Paper Bag Making Machine, Elite Paper Bag Making Machine, Semi Automatic Paper Bag Making Machine, Paper Cup Making Machine, Paper Plate Making Machine, Screen Printing Making Machine, Eco Stove / Bio Stove / Bio stove Manufacturers, Non Woven Making Machine, and Automatic Paper Bag Machine in Chennai. Refer www.greentechmachine.com

#Paper Bag Making Machine Manufacturers#Paper Bag Machine Manufacturers#Automatic Paper Bag Making Machine Manufacturers#Elite paper bag Making machine manufacturers#Semi automatic paper bag Making machine manufacturers#Paper Cup Making Machine Manufacturers#Non Woven bag Making Machine Manufacturers#Automatic Paper Bag Machine Manufacturers#Paper Cup Machine Manufacturers#Paper Plate Machine Manufacturers

0 notes

Text

What is large format PE film, technology to produce large format PE film? Large format PE film is the main material to cut out to make large plastic bags, in which the main size is the width of the mouth of the bag, and the length can be up to several hundred meters because it is packed in rolls. This PE is extremely convenient when used as a greenhouse film, lake lining, concrete floor covering or agricultural mulch. Large format PE film is made by melting virgin plastic at a suitable temperature, then blowing it up into air bubbles and then folding it to form a film with the correct width as required and wrapped in a paper or plastic core to Maximize space saving. The larger the film size, the larger the machine must also have a blown head and the higher the body height, which can be up to 30 meters. Technical factors, technology and skill level of workers operating the machine. also very strict requirements to be able to ensure the quality of the product. High applicability of PE film in the packaging industry Packaging made from PE (polyethylene) plastic has excellent properties such as high strength and good bearing capacity, and at the same time is flexible and flexible. In addition, it also prevents water, does not allow air to pass through, and has clarity. Transparent to clearly see the product inside. Therefore, PE film or large format PE film is very popular in the packaging industry, especially in the heavy industry or for export. PE film, in addition to being cut to make bags in a semi-automatic method, can also be used for large automatic presses and packaging machines or left in rolls when used for spreading, lining, and roofing surfaces with large area. as big as greenhouses, mushroom growing houses, shrimp ponds..... Products of plastic film, large format PE film of Khang Loi company Plastic film products, plastic bags, plastic bags of Khang Loi Packaging Company are manufactured 100% from primary plastic particles, ensuring the transparent and supple characteristics of the product and safe for food. completely meet the strictest export standards to the US or European countries. Besides, if it is necessary to add additives to create color, or ensure static electricity, resistance or other special requirements, with a team of technicians and skilled workers with many years of experience in the field. In the packaging industry, we are completely confident that we can meet all the requirements of our customers. Large production capacity, flexible shipping and payment methods as well as commitment to quality are also one of the reasons that customers trust and choose Khang Loi to become a supplier of packaging products. large format for their business activities. Companies wishing to cooperate or want to know more details about products, please contact us for the best preferential price. Thank you very much!

https://www.tuiniloncolon.com/2020/02/mang-nhua-mang-pe-kho-lon.html

2 notes

·

View notes

Text

Cotton Buds Making Business

The cotton swab making machine business is rapidly progressing in India. Cotton is the staple fiber made from the natural fibers of cotton plants. The cotton made from the genus Gossypium is primarily composed of cellulose, which is an insoluble organic compound that is a soft and fluffy material. Cotton is the most important fiber crop, which provides the basic raw material to the cotton textile industry. Cotton is grown in tropic and sub-tropic parts and requires uniformly high temperature and is a Kharif crop; it is sown and harvested in different parts of India depending upon the climatic conditions.

China, the USA, and India are the world’s major cotton-producing countries, accounting for about 60% of the world’s production. China alone consumes around 40% of the world’s cotton, and it is a significant export revenue source for major cotton-producing countries of the world.

Cotton is cultivated around 117 lakh hectares in India and accounts for about 37.5% of the global cotton area, and contributes to 26% of the global cotton production. Cotton holds an essential place in the Indian textile mills, and it is used as a primary raw material of India. Cotton provides livelihood to around 60 million people of India by means of cotton cultivation, processing, marketing, and exports.

Cotton buds are the most common item which is used for cleaning the ear, first-aid, cosmetic application, cleaning, and arts and crafts. The cotton buds are composed of small wads of cotton which are wrapped around a rod made of wood, paper, or plastic. The cotton buds were developed in 1923 by a Polish-American Loe Gerstenzang which later became the most widely sold brand name of cotton swabs.

The cotton bud with a single tip on a wooden handle is mostly used in medical settings and is the traditional cotton buds. The cotton buds used for domestic purposes are usually short, about 3 inches long, and double-tipped. Traditionally, the handles of the cotton buds were made of woods while later it was made of the rolled paper and sold in large quantities. The cotton buds are available in a wide variety of colors, such as blue, pink, or green. The manufacturing of the test swabs in a record time of seven days is a dream come true under the ”Make in India” initiative which has conceptualized the production and provided employment to so many unemployed people in India.

The cotton buds are most commonly used for cleaning the ear by removing earwax. The cotton buds are used for domestic purposes such as cleaning and arts and crafts purposes. The medical buds are used to take microbiological cultures which are usually rubbed into the affected area and wiped where the bacteria grows across the culture medium. They can also be used to apply medicines to selective areas targeting to remove substances or clean them. They can be used as an applicator for applying cosmetics, ointments, or other substances.

The cotton buds are also used to take the DNA samples by scraping cells from the inner cheek in the case of humans. The cotton swabs are also often used in the construction of the plastic model kits while paintings. They are also frequently used for cleaning the laser diode lens of an optical drive in conjunction with rubbing alcohol. In addition to his, they are used to clear the large parts of the computer such as video cards and fans and also used widely to clean video games cartridges in the past.

With so many uses, the demand for cotton buds in the market is growing at a rapid rate and is an essential tool for the healthcare of all individuals irrespective of age, race, culture, or religion, etc. keeping this in mind, the idea to start the automatic cotton swab making machine business is a golden opportunity for the young and aspiring entrepreneurs.

With the increased diversity of product ranges from adult-centric to baby and child-centric and increased popularity of cotton buds in the modern as well as in traditional retailing has increased the sales of the cotton buds to grow. With the rising demand, the locally produced cotton buds have become popular across rural India. it has also become popular in small as well as in metropolitan cities because of the availability of the cotton buds at a much lower price as compared to the branded products have been a key focus for the small manufacturers in India. Therefore, it is an ideal business for employing in the Rural areas as well as it will promote the ‘Make in India” initiative of the Modi Government.

The Government of India is promoting all the manufacturing units, especially in the areas where China enjoys a big share in the global market. The government to achieve the Atma Nirbhar Bharat is pushing the exports by giving various aids to the small and marginal businessmen and it aims to reduce the dependency of the country on the imported goods.

The government through various joint ventures and supporting the local businesses is expanding India’s share in the global market. Keeping this in mind, the government has announced various production-linked incentives for manufacturing the earbuds. This is a great opportunity for Indian earbuds manufacturers to raise their business. It is a big step towards making India self-reliant and manufactures their products. Almost 260 schemes are contracted by the Tri-services at an approximate cost of Rs. 3.5 lakh crores and with the latest embargo on the import of 101 items, the contracts worth Rs 1, 30,000 crore is expected to be placed upon the domestic industries in India.

Registration:- To start the buds manufacturing business in India, the first and foremost thing is the registration of your firm either as a proprietorship company or as a partnership firm. One must register the company as a Proprietorship firm if he has to start his buds manufacturing business as One Person company. To start a partnership firm, one must get registered with the Registrar of companies (ROC) and register as a Limited Liability Partnership (LLP) or the Private Limited Company.

GST Registration:- To start a business, it is now mandatory for any business to obtain a GST number, tax identification number, and an insurance certificate.

License for Trade:- Trade license is very important to be acquired to start a buds manufacturing business. It can be obtained from the local bodies of the respective states.

MSME or SSI Registration:- To avail of the government schemes and benefits, one must obtain the MSME or SSI registration. This will help the businessman to receive all the governmental benefits arising from various schemes.

Trademark:- It is required to make sure to register the buds manufacturing business with the trademark which will help in protecting the brand name.

Before starting a semi automatic cotton swab making machine business, one has to make sure to select the proper machines which are proper for operations suitable for your business.

Following are the description of machines used in the cotton buds making business-

Automatic Cotton Swab Packing Machine : –

The automatic cotton bud making machine is the machine that uses the computer PLC process control and warm wind drying technology is used to help to absorb the coating layer. The microcomputer servo motor aids feed the cotton layer and wrap the absorbent material. In this technology, there is no requirement for a different packaging machine separately.

Spindle Fabrication Machine : –

The paper spindles are processed with the help of a dyeing cutting machine from a heavy grade paper and then a thin layered paper is rolled around it to make it light. While a wooden spindle is developed with the help of a lathe machine process. The plastic spindle is made from the extrusion molding process machine, where the plastic is melted and extruded through a die and sent to a hopper machine.

Packaging Machine : –

The cotton buds are sent through the packaging wheels where the buds are rolled with the pouch. A sensor is attached to the packaging wheel which counts the buds and places them into the packaging bag which is packed with the packaging wheel.

The automatic cotton swab packing machine does not require a lot of space for its operation and it can be started from home. Anyone can start the business even from home this will reduce the cost of investment. The cotton buds making business has the potential to give a good place in the market by becoming a high profit earning business in a short period. With the increased demand for cotton buds, the business is very ideal for start-ups and young entrepreneurs.

In the times like this where the pandemic has left no nation in a mess, India has started the manufacturing of indigenous swabs or cotton buds for the testing of Covid-19. A Mumbai based Micro, Small and Medium Enterprise (MSME) and Tulips has got a green signal from the Indian Council for Medical Research (ICMR) and the National Institute for Virology in Pune. These firms have started manufacturing the polyester-spun swabs which are way cheaper than the imported swabs from the US and China. This has helped various small and indigenous manufactures to retain their livelihood and it has also resulted in producing cheaper testing kits at an affordable price.

We Indians have in reality converted the deadly pandemic into an opportunity and the government through various initiatives has been aiding the cotton buds making business. The government is also being aided by various Non-governmental Organisations like Aatmnirbhar Sena is working very hard to provide finances and cheap credit to aspiring and innovative minds and fulfilling their dream of starting the business.

Therefore, the growth and development of cotton and cotton made products has a vital role in the overall development of the Indian economy.

2 notes

·

View notes

Text

Are Woven Polypropylene Bags Waterproof?

Are pp woven bags waterproof? As far as the woven bag itself is concerned, because the woven bag is made of warp and weft tapes, there is only overlap between the tapes, which does not have sealing property. Therefore, the liquid will be left through the gap between the tapes, so the woven bag itself is not waterproof. However, due to the special requirements of chemical industry, cement, chemical fertilizer, sugar and other industries for packaging, a considerable number of plastic woven bags must have the function of waterproof and sealing. At present, there are mainly two types of waterproof and sealed woven bags produced and applied in the market: one is the ordinary separate combined packaging bag with outer woven bag and inside liner inserted or stitched bag. The other is the composite woven bag coated with a layer of plastic film on the PP woven cloth, which will include two types also, either polypropylene coated woven bag or pp woven laminated bag. The production equipment and process of the first kind of separated inner lining membrane woven bag are relatively simple, the equipment investment is low, and the application is very wide. The inner and outer bags are separated. The inner bag is blown film bag, which can be divided into LDPE and HDPE. The outer bag is ordinary PP woven bag, and the length and width of the inner bag are slightly larger than the outer bag. When loading materials, the inner and outer bags are uneven and easy to be damaged. In the early years, the inner and outer bags of the inner lining membrane bag and the outer bag need to be set together manually, and the inner and outer bags at the mouth of the bag need to be aligned and sewed, so the production efficiency is low, the waste of manpower is large, and the continuous and efficient production cannot be carried out. A skilled operator can only complete about 1000 bags by hand every day, and only about 300 bags can be sewn by hinge sewing machine every day. Nowadays, with the improvement of all-in-one machine, there are many machinery manufacturers in China that can produce all-in-one machines for bag cutting, sewing and lining. The technology has been widely used and tends to be mature, greatly improving the production efficiency.

Another kind of Coated plastic woven bag production must go through the coating process, using the extrusion coating machine to coat a layer of plastic film with a thickness of about 0.02 ~ 0.04mm on the outside of the woven pp cloth. Or at the same time, to use the coating material as the bonding medium, and then composite a layer of BOPP film on the surface, can achieve better waterproof effect, it was named BOPP pp woven laminated bag. When doing coating, the temperature of the extruded film is about 300 ℃, and the newly extruded film is combined with the braid by a pair of cooling rollers. However, such high temperature reduces the strength of the cloth surface, reduces the elasticity, increases the brittleness of the bag surface, and makes the bag easier to be damaged in the falling tests.

WHAT IS ARE VALVE BAGS?

Valve bags are packaging bags filled by machines. They come in plastic or paper. Here at Western Packaging, we are a wholesale manufacturer who offers the paper version, with many options. The three main things to consider are size, closure type, and coatings.

CHOOSE THE RIGHT SIZE

Paper valve bags come in a large range of sizes. We offer small to very large paper valve bags and multiple sizes in between. It is important to verify which sizes your valve bag machine handles.

DETERMINE WHICH TYPE OF CLOSURE YOU NEED

Once the size is determined, the type of closure is determined. All valve bags are automatically closed. The specific method of how this closing happens falls into three categories.

1. SELF- SEALING

The first and most common is self-sealing. These valve bags use the pressure of the contents to close and seal the bag.

2. HEAT SEALED

Alternatively, some bags can be sealed by heat. This may be a better option for the product and requires a machine and set up capable of this method.

3. ULTRASONIC SEALS

The third type of closure is much less common. Bags can be sealed ultrasonically. These valve bags are only used in very specific and limited industries. They require clean and sterile environments and very special machinery.

WHICH COATING IS BEST

Once the size and type of closure are decided, coatings in and on the bags is decided. The options are extensive. Western Packaging offers all the most common, and some uncommon, coatings available. The specific coating(s) depends on the product and the package’s method of storage, shipment, and display.

There is a large variety of coatings available. The coating options vary based on if the coating is going to be placed on the inside or outside of the bag. Some products may benefit from a coating on both.

THE DIFFERENCE BETWEEN INSIDE COATS

The inside coating is most important when the product contained in the bag is food or non-food products. In these situations, a food-safe coating must be applied to the inside of the bag. This coating helps ensure the contents remain safe for consumption, and also maintains the freshness. Interior coatings also help minimize moisture entering the product and/or keep the product from seeping out. These are very important features for many products.

Some outside coatings provide the same or similar benefits. Coatings can be applied to block moisture, block contamination of the interior from the outside, or make the bag easier to handle. While protection of the contents of the packaging is most important, ease of storage is also important. Outside coatings can be used to minimize friction when bags rub together and therefore help to minimize bag damage and loss of product. A simple coating can also help the filled bag maintain its shape.

THE BENEFITS OF VALVE BAGS

Valve bagging is when a bag is filled using a specialized machine. The machine uses a spout placed in or near the opening of the bag. A measured amount is placed in each bag. This can be done in a fully automated or semi-automated manner. This ensures consistency in quantity and minimizes lost product.

The benefits of these machines are numerous and span multiple industries. The biggest benefit is the volume of bags that can be filled and closed per hour. The output is significantly higher than if done by an employee. This increase in output translates to higher profit by filling orders more quickly. Businesses converting to this method often find the cost of the machine is quickly covered and a return on investment is recognized very soon.

Plastic, Paper or Cotton: Which Shopping Bag is Best?

Plastic bags

Plastic bags were invented in 1967, but only became widely used in stores in the 1970s. The most commonly found thin plastic shopping bag given out at cash registers are usually made of high-density polyethylene (HDPE), but some are made of low-density polyethylene plastic (LDPE).

The energy embodied in plastic bags comes initially from the mining of the raw materials needed to make them—natural gas and petroleum—whose extraction requires a lot of energy. The raw materials must then be refined, which requires yet more energy. Once at a processing facility, the raw materials are treated and undergo polymerization to create the building blocks of plastic. These tiny granules of polyethylene resin can be mixed with recycled polyethylene chips. They are then transported by truck, train or ship to facilities where, under high heat, an extruder shapes the plastic into a thin film. The film is flattened, then cut into pieces. Next, it is sent to manufacturers to be made into bags. The plastic bags are then packaged and transported around the world to vendors. While polyethylene can be reprocessed and used to make new plastic bags, most plastic bags are only used once or twice before they end up being incinerated or discarded in landfills. The Wall Street Journal estimated that Americans use and dispose of 100 billion plastic bags each year; and the EPA found that less than five percent are recycled.

A 2014 study done for the Progressive Bag Alliance, which represents the U.S. plastic bag manufacturing and recycling industry, compared grocery bags made from polyethylene (HDPE), compostable plastic, and paper with 30 percent recycled fibers. It found that the HDPE bags ultimately used less fuel and water, and produced less greenhouse gas gases, acid rain emissions, and solid waste than the other two. The study, which did not consider litter, was peer-reviewed by Michael Overcash, then a professor of chemical engineering at North Carolina State University. Because the carrying capacity of a plastic and a paper bag are not the same, the study used the carrying capacity of 1,000 paper bags as its baseline and compared their impacts to the impacts of 1,500 plastic bags. The plastic bags used 14.9kg of fossil fuels for manufacturing compared to 23.2kg for paper bags. Plastic bags produced 7kg of municipal solid waste compared to 33.9kg for paper, and greenhouse gas emissions were equivalent to 0.04 tons of CO2 compared to paper’s 0.08 tons. Plastic bags used 58 gallons of fresh water, while paper used 1,004 gallons. Energy use totaled 763 megajoules for plastic, and 2,622 megajoules for paper.

Sulfur dioxide, a type of sulfur oxide, and nitrogen oxide emitted from coal-fired power plants that produce the energy for processing bags contribute to acid rain. The plastic bag produced 50.5 grams of sulfur oxides compared to 579 grams for the paper bag; and 45.4 grams of nitrogen oxides, compared to 264 grams for paper.

A 2011 U.K. study compared bags made of HDPE, LDPE, non-woven polypropylene, a biopolymer made from a starch polyester, paper and cotton. It assessed the impacts in nine categories: global warming potential, depletion of resources such as fossil fuels, acidification, eutrophication, human toxicity, fresh water toxicity, marine toxicity, terrestrial toxicity and smog creation. It found that HDPE bags had the lowest environmental impacts of the lightweight bags in eight of the nine categories because it was the lightest bag of the group.

Paper bags

Paper bags are made from a renewable resource and are biodegradable. In the U.S., over 10 billion paper bags are consumed each year, requiring the felling of 14 million trees.

Once the trees are cut down, the logs are moved to a mill where they can wait up to three years until they dry out. Once ready, bark is stripped off and the wood is chipped into one-inch cubes that are subjected to high heat and pressure. They are then mixed with limestone and sulfurous acid until the combination becomes pulp. The pulp is washed with fresh water and bleach then pressed into paper, which is cut, printed, packaged and shipped. As a result of the heavy use of toxic chemicals in the process, paper is responsible for 70 times more air pollution and 50 times more water pollution than plastic bag production according to a Washington Post analysis, resulting in more toxicity to humans and the environment than HDPE bags. And while 66 percent of paper and paperboard are recycled, the recycling process requires additional chemicals to remove the ink and return the paper to pulp, which can add to paper’s environmental impact.

Cotton totes

Cotton bags are made from a renewable resource and are biodegradable. They are also strong and durable so they can be reused multiple times.

Cotton first needs to be harvested, then cotton bolls go through the ginning process, which separates the cotton from stems and leaves. Only 33 percent of the harvested cotton is usable. The cotton is then baled and shipped to cotton mills to be fluffed up, cleaned, flattened and spun. The cotton threads are woven into fabric, which then undergoes a chemical washing process and bleaching, after which it can also be dyed and printed. Spinning, weaving and other manufacturing processes are energy intensive. Washing, bleaching, dyeing, printing and other processes use large amounts of water and electricity.

1 note

·

View note

Text

Excessive Automatic Palletizer Machine Stage

This course of repeats till a full layer of products and products are configured to be placed on a pallet. The system is designed to ensure full performance even in heavy seas. The outcome is a robust computerized palletizer machine of excessive quality that saves an unlimited quantity of area. Columbia's conventional high level palletizer machines set the industry normal automatic palletizer machine.

Because your specifications for palletizing are reliably met, hundreds are much less likely to incur damage during loading, cargo and unloading. Roll feed, Hot soften, Cold glue, Self-adhesive and shrink sleeve labelling machines in standalone or mixed variations for various formed bottles. Linear and Rotary Rinsing, Filling & Capping solutions utilizing Net weight, Flow meter and Level filling technologies. A low friction curler transfer desk is out there to allow easy handling of heavy and shrinkwrapped circumstances.

Feed and orient empty plastic containers of various shapes & sizes to the filling line mechanically. Achieve maximum output with minimal downtime for peak effectivity and machine profitability. Our palletizing consultants help with each step of the method and stand by 24/7 to resolve any questions.

No lifting, stooping or strolling around the pallet is required to operate this case palletizer.

An automatic palletizer can present up to 60 baggage per minute, nonetheless, it's nonetheless potential to extend this fee by integrating a second robotic to the cell which optimizes velocity.

Wearproof steel guides make positive the curler bearings roll efficiently.

In some palletizing stations, when a pallet layer is full, the operator lowers the work surface as required to hold up a comfortable working height.

The Science of Palletizing is a 72-page educational introduction to the basics of unit-load forming and is designed to familiarize you with the basics of automatic palletizer machine.

The use of 6-axis robots allows most flexibility in palletizing schemes, structure and built-in extra functions. Compact and strong design combined with a laterally mounted vertical linear axis system result in a low general machine peak which permits the use even with low ceiling heights. Multi-axis automation products together with H-Bots, T-Bots, Gantries, and Cartesian Robots. Our palletizer is a perfect alternative for palletizing aboard factory trawlers, because the stretch movie is added while the machine palletizes.

Of course, product is transferring all the time and often has to go very far before reaching its destination. But getting it there is only half the battle; the other half is getting it to the ultimate automated palletizer consumer in an interesting, salable condition. This design permits three pallets to be stacked on the ground on each side.

Trust in our four-station palletizer with supreme operating consolation. The pallet magazine is built-in with a switch system that enables for a completely computerized pallet dealing with process. Automatic conveying and palletizing system is used for palletizing unit load, together with various carton bins in paper-making, food and medicine business and so forth. Depending on package deal weight and load configuration, manual palletizing may be backbreaking work. [newline]Automating these processes can scale back publicity to continual injuries and potentially severe accidents. An automatic palletizer can decrease worker’s compensation prices and enhance employee satisfaction on the same time.

Excessive Stage Palletizers

In some cases, pallets are moved away from the machine and packed/wrapped both by hand or by another machine. Columbia Machine offers the most innovative and flexible palletizing options available. Columbia standard palletizers deal with nearly any bundle sort together with trays , shrink-only bundles, RPCs, Totes, tab-lock instances, milk crates and a lot extra.

In the top, robotic computerized palletizers supply extra flexible and dependable options than standard methods. These solutions make it attainable to evolve with the rising needs of an organization. Low upkeep costs and easy palletizing sample changing add to the advantages of a faster return on financial investment. Their excessive reliability and low maintenance demand give them a transparent advantage over standard methods. Nowadays working with palletizing equipment is of a crucial significance in numerous industries worldwide. Therefore, palletizing machines are generally utilized in wooden and paper industry, metal industry, construction trade as properly as in beverage and meals business.

Commonality of part techniques allow cost financial savings for end customers, rapid supply and proven performance with future flexibility when required. Equipped with a forty one" Wide x 48" Long x fifty three" High pallet stacking part, seventy two" long chain infeed conveyor extending 12" past body with a 34" infeed top. Equipped with a forty one" Wide x forty" Long x forty eight" High pallet stacking section, one hundred twenty" lengthy chain infeed conveyor extending seventy eight" past body with a 37" infeed top.

The use of a collaborating robotic permits an open layout with out safety fences. This ensures greatest accessibility and minimizes the house requirement on your shopfloor. Proven drive technology with frequency controlled AC motors guarantee excessive reliability and are easy to keep up. Compact and robust portal building allows a small foot print and good accessibility.

In order to acquire a complete solution, additional options could be built-in to the top of the production line getting ready your pallet for storing or transport. Conveyorized palletizers have a feed area that receives the products which are to be palletized. The packaged items are obtained by curler conveyors and are continuously transferred and sorted to the pallets by automated conveyor rollers, permitting higher packaging speed than robotic palletizers. Robotic systems also can offer several advantages over conventional machines.

There are 5,447 palletizer machine suppliers, mainly situated in Asia. The top supplying country or region is China, which provide 100 percent of palletizer machine respectively. Easy to make use of, with superior options including easy pattern edit/creation. Our palletizers contribute to an efficient processing course of and preserve the standard of your powders. You have selections in relation to packaging supplies and on this webinar, we'll walk via totally different materials and the way it impacts your provide chain.

Innovative automated gripper that ensures precise positioning on the pallet. Safe and stable transport is a prerequisite to ensure that your product reaches its destination whereas safeguarding the standard. TopTier Sales Engineers provide price range quotes in a matter of days. Cost is based on particular products to be handled, fee requirements, layout, and desired features. Format vary subject to feeding and collating system and features of machine.

Robotic palletizing arrived later and introduced with it many advantages in comparability with standard techniques. Reliability and flexibility are some of the property these techniques have to offer. Additionally, if you need upkeep and repair, Robopac USA offers full help through our components and service division. We also can advise you on potential upgrades to improve your machine’s effectivity and presumably lengthen its life. View our TopTier palletizer machines for sale to find out the finest option on your facility.

For these larger footprints and attain conditions a user can simply add a further axis to meet any problem. To obtain the improvements automation techniques produce, it is essential to select one of the best combination of robot fashion, gripper and auxiliary equipment to match the production need. An automation options integrator can provide the proper answer for any palletizing software. Conventional palletizers usually use a layer approach that forms the pack pattern of instances, squeezes them into form and deposits them one layer at a time onto the pallet. This palletizer may be broken down into two categories – a low-level or high-level palletizer.

Dairy Products

Accessible and highly sensible respecting operator security with the photoelectric obstacles. The robotic or choose and place is customised to delicately deal with the product and turn it to the appropriate place before placing it into the pallet. Simple configuration called “GROUND PALLET” the place the empty pallet is positioned by an operator with the pallet truck by hand. Picking the stuffed pallet takes place in the identical means with the pallet truck by hand by an operator.

Fully Automatic 25kg Kraft Paper Valve Bag Filling Production Packing Line Palletizer

Brenton engineers and manufactures case packing, palletizing and built-in packaging systems. Robotic automatic palletizers are designed to adapt to present traces and area to have the ability to enhance production rates or adapt to new merchandise. An automated palletizer can present as much as 60 bags per minute, however, it is nonetheless possible to extend this fee by integrating a second robot to the cell which optimizes speed. Safety systems are the most advanced within the trade, with the highest attainable security score.

Semi-automatic palletizing tools, which is well-liked in area of interest markets the place merchandise are heavy and troublesome to palletize manually, can deal with as much as 20 bags or instances per minute. This tools is nicely suited to low-speed operations that can’t justify the worth of full automation however require a solution to help forestall worker damage. Aagard is an engineering company that builds custom packaging automation techniques. Our group of inventive problem-solvers utilizes our progressive expertise and proven technologies to create the exact solution that our prospects must win.

Fully automated mannequin consists of pallet handling, stretch wrapping, load exit conveyor, and security access doorways. Fully automated model includes pallet dealing with, stretch wrapping, load exit conveyor, mezzanine, and security entry doors. They are excellent for medium to excessive pace vegetation and multiline functions. Hamer absolutely automating palletizing techniques utilize automatic in-feed conveyors to tempo product in-feed to the pick-and-place palletizing station. The product is then stacked on empty pallets with or with out slip sheets, that are automatically fed to the stacking space. Once a pallet has been accomplished it is prepared for forktruck pickup or it is transferred to the in-line stretch wrapping/hooding equipment to mechanically complete the pallet for cargo.

Palletizers are mostly integrated in a much bigger packaging system line, which ensures quick and environment friendly packaging for a spread of products. A hydraulic robotic arm lifts circumstances, bottles, bags or drums using flat pincer arms or suction cup arms in organized rows onto a pallet, stacking items with near-perfect precision. Massman Automation integrates ABB, Fanuc, or Motoman robots into the robotic palletizing cell. These techniques deal with a quantity of packaging strains with a number of SKUs that includes ALBA pallet dispensers and pallet conveyors that are appropriate with many custom-designed case and pallet dealing with methods. PalKombi is an computerized palletizer suitable for crates, cartons, trays, shrink-wrapped packs and all kinds of packages in general. Designed for medium to high speeds, PalKombi works with a gentle low-level infeed pallet.

This compact structure provides minimum house usage and works well in slim spaces. If your workers are engaged on different strains on different days, they'll take the palletizer to their workplace. Movable on rollers and with pallet guides folded up, PalTeq Cobot suits via doorways from 900 mm width.

Manually putting bins on pallets may be time consuming and costly; it could additionally put unusual stress on employees. PalTeq Robot is our fully automatic robot palletizer for palletizing of shipping instances or trays, or almost all type of stackable products. Due to our modular building platform the layout can be designed almost freely and extra features can be built-in easily. Macron Dynamics presents a Cartesian fashion MGS-UC2 linear robot kit that can be built-in into palletizing systems. The Macron MGS-UC2 gantry product is a sturdy and sturdy 2-axis system with broad payload capacity. This ready-made kit, in pre-configured commonplace travel lengths, contains integrated cable management, low profile T-slot sensors and MPG gearboxes ready for any motor mounting.

The VPG palletizer is designed with a particular gripping head, so to stack the bags in an overlapping manner. This palletizer version has a special rotating head, so the product may be imported at excessive pace. We are a professional manufacturer & exporter specialized in numerous tin cans making machinery. [newline]We are always able to develop long-term and good relationship with abroad customers. If you want to know more about us, please don’t hesitate to contact us at any time. SPLX MKII High Level Palletizer’s key parts are primarily maintenance-free, and are simply accessible via detachable guards and doorways.

Manual palletizing may be carried out by people and without any mechanical help at all. Furthermore PalTeq Cobot offers tool-less kind change and changeover between totally different pallet sorts. By using totally different robot sizes we are in a position to all the time offer you the ideal space-optimized structure for every product weight. Proven technology with frequency managed AC drives guarantees high reliability and straightforward maintenance. Using a novel, flexible belt based mostly ��rack and pinion” design and structural aluminum MacFRAME parts, our Robotic Transport Units can handle all kinds of lengths and payloads.

1 note

·

View note

Text

The procedure of Manufacturing Tissue Paper Using Paper Chemicals

The procedure of Manufacturing Tissue Paper Using Paper Chemicals

It is a new revolution in the paper industry because of the utilization of paper is increasing rapidly. There are numerous countries that banned poly bags and accepting paper as an option. The World is accepting paper bags, bathroom rolls, tissue paperwork, facial towels, paper towel plus much more quite easily. That is shaping the paper industry and providing and providing career to numerous people.

Before establishing a manufacturing facility an entrepreneur must understand the procedure of making the product.

The Tissue Papermaking Process Comprises then next steps:

Pulp and Dye: This is the basic step of producing a fine and smooth product.

Initial, an individual must make a mash, of paper, that can be made effective from the reused chemicals. Next, the fiber of the well-prepared the mixture is usually to be combined with the pulp of real wood. The Process continues with the dying and purging of the fibre content. Following the bleaching and cleansing of the fibres, stick it in a blending tank where in fact the manufacturing contributes dye to provide it a lovely color.

Pressing:- This is conducted to press out additional moisture within the pulp which is performed using the toilet paper machine. The main purpose of the pressing process is to help make the pulp dry and easy to go away to the next step of the procedure.

Creeping:- The machine owns an air drying out a framework which dries the pulp through the garments dryer using the vapor. The roller dissipates the water from the pulp with increased heating and the fine rotor sharp of the device scrape the fibers up to the required thickness.

Cutting And Reeling: This is really the last stage along the route wherein certainty the long lengthy prepared to process material trim into desired sizes which will be the last results of the product of the production process.

The ultimate product is packed and stored at the stockrooms in fit conditions. The paper packing machine manufacturing designed the device with the view of providing all the facilities instantly. The machine comes in either semi-automatic or totally robotized version to help facilitate the procedure.

#paper chemicals#paper chemicals manufacturer#paper chemicals supplier#paper chemicals Exporter#paper making chemicals#paper industry chemicals in Delhi

1 note

·

View note

Link

We are SPB Machinery established at 1990, we are the manufacturer and supplier of automatic paper Bag making machines at very great prices. We only offer quality tested machines because we believe in customer satisfaction.

#paper bag making machine#paper bag machine#paper bag manufacturing machine#automatic paper bag making machine#fully automatic paper bag making machine

3 notes

·

View notes

Text

Ronald Web Offset is a reliable paper bag manufacturer, that provides excellent paper bag-making machines. We provide one more product- Square bottom bag-making machine and v bottom bag-making machine

#square buttom paper bag machine#Paper carry bag machine#paper carry bag making machine#paper bag forming machine#top paper bag machine

0 notes

Text

Custom Two Piece Rigid Boxes With Printed Logo From Shopping Bag Mall

Rigid boxes are a common type of packaging boxes, usually deployed for premium or luxury products.

Shopping Bag Mall is one of the most reputable and professional rigid box making company in retail packaging and gift packaging industry.

Shopping Bag Mall are fully equipped with fully automatic rigid boxes making lines. Shopping Bag Mall can make boxes in different shapes and with different wrapped paper like Art Paper,premium speciality paper and kraft paper to offer distinctive looking. A Rigid Box can be produced by manual hand made process or by modern machines that will be based on order quantity . Different semi-automatic and fully automatic lines are available to assemble them. A large market of rigid boxes still relies on manual or handmade boxes. Reason for the matter is their limited production, so not to have boxes in bulk and auto lines of rigid boxes are too expensive to buy. They are mostly used in Gift box packaging, Cell phone packaging, customized bakery and chocolate products, cosmetic and fashion industry, expensive branded designers clothes etc.

Rigid boxes are made up of chip board or grey board which is a thick cardboard sheet varies from 800gsm-2400gsm and a wrap that cover this chipboard. This wrapping sheet can be made up of different materials like glossy art paper stock, offset paper stock or kraft paper or speciality paper with textured finish.

As a first step the chip board is scored and cut in to required shape and size. A semi automatic tape binding machine is used to tie up scored chip board sheet in to perfect shape. Then the wrap is trimmed and glued so that the box fitted on the wrap. This semi wrapped Box then put in a box maker which gives him a finished and fully wrapped box. The wrap Can be printed or un-printed as per demand. Rigid boxes are assembled in various shapes on the demand of customers. Some of them are Telescope style, Partial Telescope, Round lid Box, Book shape Box, Magnetic Closure Box, Calmshell Box, Three Sided Hinge Cover etc.

Two piece rigid boxes are one of popular styles of custom rigid boxes.

Two-piece rigid boxes are generally made for display purposes. One part of the box is the place where the item is put away or shown while the other part remains upstanding like a cut-out banner and displays the name or features of the products. We provide the best Two-piece boxes to naming brands in the Gift Packaging And Retail Packaging.

Why would you buy two piece rigid boxes from Shopping Bag Mall

Because Shopping Bag Mall is experienced manufacturer of rigid boxes, Shopping Bag Mall specialize in manufacturing custom two piece rigid boxes coming in any size,color and shape.

Since these are Rigid Two-Piece Boxes, the best material for making these boxes usually is chip board or paper board. This is the reason that chip board isn't just tough enough for storing things; it is unbending sufficient too for the tops to remain upstanding without enough support.

Two-piece rigid boxes are customized for different shapes, sizes, colors, designs, prints, and layouts along with logo printing to enhance your branding relations. Our professional designers have unique and latest designing ideas for your brand packaging.

0 notes

Text

A Super-Basic, Super-Detailed Guide to Laundry

Begin with clothes, ideally in some sort of container you can take from your room to the laundry room.

The following can all be done as you take off your clothes and throw them into the laundry basket, in your room right before you take your clothes down to the laundry, OR as you throw your clothes into the washer.

Check the pockets. (The last thing you want is ruined identity papers or a load of laundry covered in little bits of used Kleenex.)