#Self Propelled Drilling Rigs

Explore tagged Tumblr posts

Text

Revolutionize Your Drilling Projects with Utilicor's Self-Propelled Coring Equipment

Utilicor Technologies has cutting edge self-propelled drilling rigs and core drilling rigs that are made to make your drilling more efficient and productive. Our self-propelled drilling machines are made with cutting-edge technology and precise engineering, so you can easily handle even the most difficult drilling jobs. You can get exact results with Utilicor's self-propelled coring units, which will save you time and help your project succeed. Today, try Utilicor Technologies and feel the power of new ideas.

#Self Propelled Coring Equipment#Self Propelled Drilling Rigs#Self Propelled Core Drilling Rigs#Self-Propelled Drilling Machine#Self Propelled Coring Unit

0 notes

Text

First Flight

Ok so, if you haven't heard of it before, KSP is this fun little game where you run a space program and try and launch spacecraft to other moons and planets in a scaled-down solar system. Despite being the first game I ever bought, I never really spent a significant amount of time playing it.

I figure it'd be fun to share my experience trying to play it, and talk a bit about rockets. I decided a good starting point for my game would be building a general-purpose, medium-sized launch vehicle for putting cargo and crew into orbit.

I decided to base it on the Zenit-2. The Zenit is a very interesting launch vehicle with quite a history, which I'd like to explore in a future post. Skipping past that, we get to the last variant: the 3SL. It was operated by a multinational (American, Russian, Norwegian, and Ukrainian) Company. The main body of the spacecraft was manufactured in Ukraine, while the engines and the upper stages came from Russia. Boeing provided the fairing and integrated the pieces. Finally, the Norwegians provided the launch infrastructure, which was by far the most unique part of the rocket. See, the company, named Sea Launch, unsurprisingly provided one of the only sea-based launch services while it was in operation.

The rocket was launched from a "self-propelled semi-submersible mobile spacecraft launch platform converted from a mobile drilling rig" called LP Odyssey. The whole thing looks like something out of a spy film, and it's honestly hard to believe this was a real thing. Because no one could be on the platform while it launched a rocket, it was paired with a combo rocket carrier/mission control center ship called Sea Launch Commander. In Captain America: The Winter Soldier, the ship in the beginning that is hijacked (Lemurian Star) is the same ship.

In the movie, it's launching the satellites that provide the targeting data for the hellicarriers which I think is pretty neat.

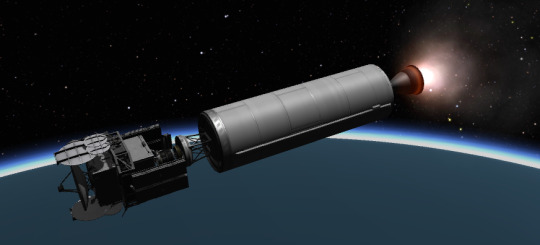

Here's my approximation of the rocket in KSP, during its first ascent. The bottom looks like four rockets but is actually a single large one called the RD-170. It's probably the most interesting part of the rocket as it represents the high water mark of soviet rocket engines.

If you're familiar with KSP, you might not remember there being an RD-170 equivalent, we have one because I'm running a heavily modded version of KSP. (Restock + Near Future + Utility Mods)

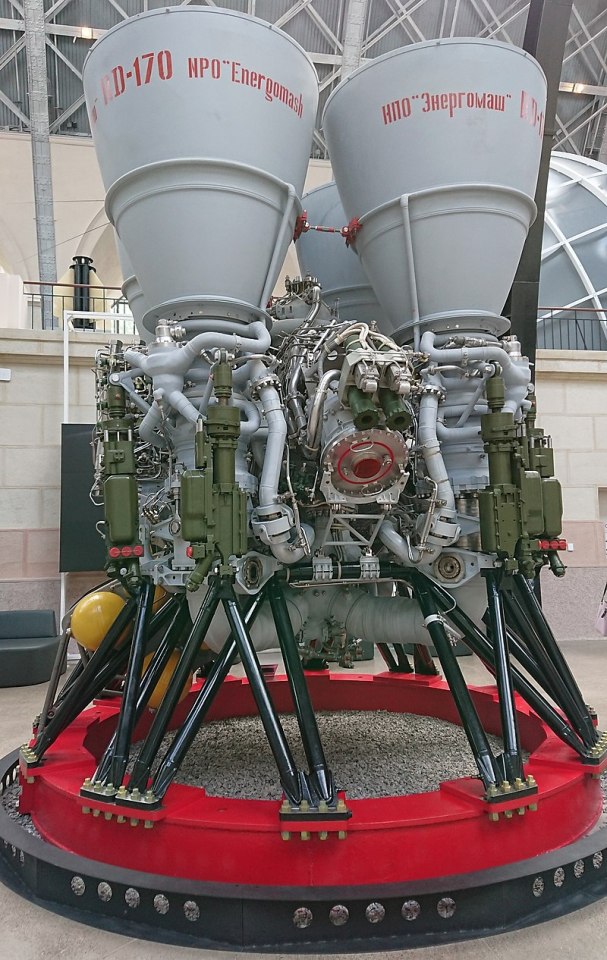

Here's the engine IRL. Pretty neat. The RD-170 has an even more interesting history than the Zenit booster it mounted on (it inherits many design elements from the soviet N1 moon rocket)

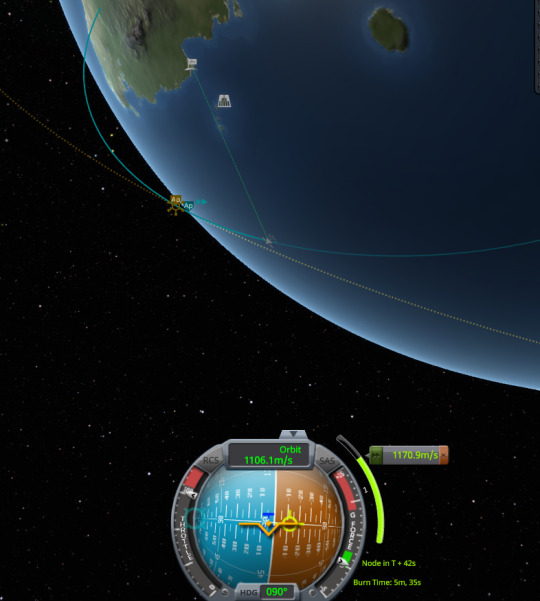

To get into orbit, you need to be traveling horizontally at about 2 kilometers per second. However, if you tried to achieve these speeds near the surface, all of your energy would quickly be lost through drag, so you first must ascend through the atmosphere before your upper stage turns horizontally and circularizes your orbit. If you need some more info I have attached an article from NASA explaining the whole thing in depth.

The rocket's payload, in this case, a satellite, is often not aerodynamically sound (and even if it was figuring safe flight profiles for each payload would become quite complex) so it's enclosed in an aerodynamic fairing. Popping it off to save weight once the rocket is out of the atmosphere is always the highlight of a launch. Real rocket fairings are typically two halves, to save weight and complexity, but I find having multi-part fairings more fun. If you look at the end of the rocket carefully, you'll notice the engine bells are moving around. This is because during ascent, one of the primary ways that the rocket controls itself is by making adjustments to the direction of its exhaust.

Here we see that the upper stage trying to circularize its orbit. Unlike the lower-stage engines, which are optimized for pure lifting capacity, the upper-stage has a much larger nozzle to propel the rocket more efficiently. You can see how the lack of atmosphere means that the plume can expand much more easily than in the lower stages where it was squeezed into a narrow jet. (ksp doesn't fully simulate this, but it ends up being right a lot of the time)

Unfortunately, the lowered thrust came back to bite me. Although the rocket had more than enough energy to reach the needed orbital velocity, it simply did not have the necessary thrust to reach those speeds before it began to reenter the atmosphere and burned up.

My second attempt used an engine with roughly twice the power output and was a lot more successful. The blue line represents the current trajectory of the rocket, while the orange line represents the rocket after the planned burn. I'd like to say I planned such a perfect circularization burn, but I actually used an external tool to do so.

Here we can see our rocket doing that injection burn, with the higher thrust engines. On real rockets, these burns can take a pretty significant amount of time

Here you can see the satellite getting deployed by the upper stage.

Typically after a satellite is put into orbit, each functional element is slowly deployed, then verified one by one. But since this is KSP, we can have fun with a one-button deployment sequence.

I'm going to take a moment here to say that Tumblr's 10mb limit on gifs is driving me nuts. I can't even use an external host cause the GIFs don't autoplay.

The main advantage of sea launch was you could launch anywhere on earth. This typically was used for an equatorial launch because the equator provides a minor speed boost and makes achieving any inclination easy. For pretty much every sea launch, these strengths were used to put a cable or telecom satellite in a geostationary orbit. This one isn't based on anything in particular, I just slapped it together based on the first satellite I found on google. The main advantage of sea launch was you could launch anywhere on earth. This typically was used for an equatorial launch because the equator provides a minor speed boost and makes achieving any inclination easy. For pretty much every sea launch, these strengths were used to put a cable or telecom satellite in a geostationary orbit. This one isn't based on anything in particular, I just slapped it together based on the first satellite I found on google. I guess the next step will be to put up some real telecom satellites.

6 notes

·

View notes

Text

Workover Rigs Market : Technology Advancements, Industry Insights, Trends And Forecast 2033

The workover rigs global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

Workover Rigs Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size - The workover rigs market size has grown steadily in recent years. It will grow from $5.25 billion in 2023 to $5.51 billion in 2024 at a compound annual growth rate (CAGR) of 4.9%. The growth in the historic period can be attributed to oil price volatility, aging oil wells, regulatory changes, global energy demand, natural disasters.

The workover rigs market size is expected to see steady growth in the next few years. It will grow to $6.41 billion in 2028 at a compound annual growth rate (CAGR) of 3.8%. The growth in the forecast period can be attributed to renewable energy transition, digitalization and automation, focus on asset optimization, environmental and ESG considerations, global economic trends, resilience to supply chain disruptions. Major trends in the forecast period include advancements in technology, environmental and regulatory compliance, global energy transition, remote operations and digitalization.

Order your report now for swift delivery @ https://www.thebusinessresearchcompany.com/report/workover-rigs-global-market-report

The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

Market Drivers - Growing demand for oil and natural gas is expected to propel the growth of the workover rig market going forward. Oil and natural gas are fossil fuels extracted from the Earth, serving as crucial sources of energy for various industries and daily life. Growing demand for oil and natural gas is driven by the expanding use of these resources in transportation, manufacturing, and energy production. Workover rigs help to sustain and increase demand for oil and gas by maximizing the production potential of existing wells, optimizing reservoir performance, and simplifying the responsible management of mature assets throughout their life cycle. For instance, in October 2023, according to the International Energy Agency, a France-based intergovernmental organization, the projection suggests a 6% increase in worldwide oil demand between 2022 and 2028, reaching a total of 105.7 million barrels per day. Additionally, there is an expectation that global gas demand will grow at an average annual rate of 1.6% from 2022 to 2026. Therefore, the growing demand for oil and natural gas is driving the growth of the workover rig market.

Market Trends - Major companies operating in the workover rigs market are focused on developing innovative solutions, such as the mobile drilling rig, to enhance operational efficiency and drive their revenues in the market. A mobile drilling rig is a versatile, self-propelled platform equipped with drilling machinery for on-the-go exploration and extraction of underground resources. For instance, in July 2021, Drillmec International Pvt. Ltd., an India-based manufacturer and distributor of drilling and workover rigs, launched the ARS-225 Mobile Rig, which is designed for drilling and workover operations in extreme conditions. Boasting a nominal hook load capacity of 225 metric tons, it is powered by two CAT C18 oil and gas type 700 Hp diesel engines and features a dual-tank fuel system with a total capacity of 800 liters. Additionally, equipped with a winterization system, the ARS-225 ensures optimal performance even in cold environments.

The workover rigs market covered in this report is segmented –

1) By Type: Barge Rigs, Tender Rigs, Jack Ups Rigs, Platform Rigs, Semi-Submersible Rigs, Drill Ship 2) By Form Factor: Single Drum, Double Drum 3) By Capacity: Below 1,000 Horsepower (HP), 1,000-1,500 Horsepower (HP), Above 1,500 Horsepower (HP) 4) By Application: Onshore, Offshore

Get an inside scoop of the workover rigs market, Request now for Sample Report @ https://www.thebusinessresearchcompany.com/sample.aspx?id=14541&type=smp

Regional Insights - North America was the largest region in the workover rigs market in 2023. Asia-Pacific is expected to be the fastest-growing region in the forecast period. The regions covered in the workover rigs market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Key Companies - Major companies operating in the workover rigs market are Schlumberger Ltd., Hess Services Inc., National Oilwell Varco Inc., Megha Engineering and Infrastructures Ltd., Nabors Industries Ltd., Helmerich & Payne Inc., Precision Drilling Corporation, Drillmec Drilling Technologies, Fieldwood Energy LLC, Superior Energy Services, San Antonio Internacional, National Energy Services Reunited Corp., KLX Energy Services Holdings Inc., LCH Well Servicing LLC, Eastern Well Services, MBI Energy Services, Twin Eagle Transport LLC, Deep Industries Ltd., Moncla Energy Services LLC, Mesa Southern Well Servicing LP, Nordic Gulf, Automated Rig Technologies Ltd., BOS Energy International FZE, Hubei Petrokh Machine Manufacturing Co. Ltd., Sunnda Corporation, KOLLER Solutions Maschinen- und Anlagenbau GmbH

Table of Contents 1. Executive Summary 2. Workover Rigs Market Report Structure 3. Workover Rigs Market Trends And Strategies 4. Workover Rigs Market – Macro Economic Scenario 5. Workover Rigs Market Size And Growth ….. 27. Workover Rigs Market Competitor Landscape And Company Profiles 28. Key Mergers And Acquisitions 29. Future Outlook and Potential Analysis 30. Appendix

Contact Us: The Business Research Company Europe: +44 207 1930 708 Asia: +91 88972 63534 Americas: +1 315 623 0293 Email: [email protected]

Follow Us On: LinkedIn: https://in.linkedin.com/company/the-business-research-company Twitter: https://twitter.com/tbrc_info Facebook: https://www.facebook.com/TheBusinessResearchCompany YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ Blog: https://blog.tbrc.info/ Healthcare Blog: https://healthcareresearchreports.com/ Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Comprehensive Guide To Arborist Supplies In Sydney

Arborist supplies are crucial for maintaining the health and safety of trees, especially in urban settings like Sydney. Arborists need a wide range of tools and equipment to carry out their tasks effectively and safely. This guide explores the diverse range of arborist supplies available in Sydney, highlighting their importance and unique features.

Climbing Gear

Safety is paramount in arborist work, and climbing gear is essential for any tree professional. Climbing harnesses, ropes, and carabiners are some of the primary tools. Modern harnesses are designed with ergonomic features, providing maximum comfort and reducing fatigue during prolonged use. High-quality ropes are essential for both climbing and rigging, and they are available in various lengths and strengths to suit different tree sizes and heights.

Cutting Tools

Cutting tools are fundamental in arboriculture. Chainsaws, handsaws, and pole pruners are the most commonly used. Chainsaws, available in different sizes and power options (electric, battery-operated, and petrol), are indispensable for felling trees and cutting large branches. Handsaws, on the other hand, are perfect for precision cuts and smaller branches. Pole pruners allow arborists to trim high branches without climbing, enhancing safety and efficiency.

Rigging Equipment

Rigging equipment is essential for safely lowering large branches and tree sections to the ground. Rigging blocks, pulleys, and slings are crucial for managing heavy loads. Advanced rigging systems are now available, which can significantly reduce the physical strain on arborists and increase the safety of complex tree removals. These systems are designed to distribute weight evenly and provide greater control over the descent of heavy tree parts.

Protective Gear

Personal protective equipment (PPE) is mandatory for arborists to prevent injuries. Helmets with face shields or safety glasses protect against falling debris. Hearing protection is crucial when using loud machinery like chainsaws. Cut-resistant gloves and chainsaw protective trousers (chaps) provide additional safety. In recent years, advancements in PPE have led to lighter, more breathable materials, improving comfort without compromising safety.

Tree Health Diagnostics

Maintaining tree health requires more than just cutting and pruning. Arborists use diagnostic tools to assess tree health and identify issues such as disease, pest infestation, and nutrient deficiencies. Tools like increment borers, resistograph drills, and portable soil testers are essential for this purpose. These tools help arborists make informed decisions about treatment and maintenance, ensuring the long-term health of trees.

Stump Grinders and Chippers

After tree removal, dealing with stumps and debris is a critical task. Stump grinders are powerful machines that grind down tree stumps to below ground level, allowing for replanting or landscaping. Wood chippers convert branches and tree limbs into wood chips, which can be used as mulch or disposed of more easily. Modern stump grinders and chippers are designed for efficiency, with features such as self-propelled wheels and adjustable cutting depths.

Arborist supplies are integral to the profession, ensuring the safety and efficiency of tree care tasks. From climbing gear to cutting tools, and protective equipment to diagnostic tools, each plays a vital role in the daily operations of arborists. Investing in high-quality equipment and proper training not only enhances the safety of arborists but also ensures the health and longevity of Sydney’s urban forest.

0 notes

Text

How does a rock breaker work?

A hydraulic rock breaker, or excavator rock breaker, is an attachment added to an excavator. It breaks and shatters rock and earth into smaller, more manageable parts. These rock breakers complement crusher attachments as they help downsize substantial rocks. These excavators are primarily used in mining, demolition of landscaping fields, and tunnel construction. The rock breaker decreases the dependency on the rock blaster. The attachment is easy to install and can enter any terrain without difficulty. This suits confined spaces where rock-breaking machinery, such as piling rigs, cannot enter. The excavator rock breaker comes in two types, internal and external. Both rock breaker types consist of a front to support the breaker and a back to hold the nitrogen gas. The hydraulic oil inside the rock breaker machine creates pressure and allows the piston to move to release nitrogen gas. The movement of the piston powers the breaking sequence and smashes the rock. The rock breaker has an energy recovery system. This means the hydraulic oil used for the piston movement flows back into the chamber, where it is utilized for the next stroke. Indus Rock Tool is one of the leading manufacturers of pneumatic rock drills, with decades of manufacturing expertise. Our low-cost pneumatic jackhammers are the first choice of the mining industry across the globe. Designed for drilling through granite, hard-faced rock, quarry drilling, bench drilling, and drilling secondary holes for blasting. Hydraulic Crawler Drills, Crawler Drills, Self-propelled Crawler Drills, Rock Splitter, DTH Drilling Rig, Pedestal Boom Breaker

CONTACT US : 08045815124 TO KNOW MORE VISIT THE WEBSITE: https://www.indusrocktool.in/

1 note

·

View note

Text

How to Choose the Right HDD Drill Rig for Installing a Subsea Pipeline?

Subsea pipeline installation is a multi-billion dollar industry. It consists of installing hundreds to thousands of kilometers of submerged pipelines from the shoreline to offshore oil rigs and platforms, as well as onshore processing facilities and natural gas compressor stations.

These pipelines are then buried into trenches that can be several meters deep and several hundred meters wide. The only way to install these pipelines is via horizontal directional drilling (HDD).

This process needs machinery like horizontal directional drilling rig, which is an essential part of the industry. However, not all HDD drill rigs can meet up with the demands of this industry, thus it’s imperative to choose the right one.

What Are The Factors To Consider When Choosing The Right Hdd Rig?

When choosing a HDD drill rig there are three main factors that should be considered such as the water depth, ground conditions and access to the site. The drill rig's power source is also an important factor in making a decision. The majority of HDD rigs work off diesel engines which put out between 1,000 to 4,500 horsepower .

Another important factor for choosing a HDD drill rig is the number of pipeline installation passes. This is the amount of attempts it takes to get the drilling string into the required depth. A pass involves threading a certain amount of casing onto the drilling string and lowering it to set depth on each attempt before pulling back up and rethreading more casing .

The selection of HDD drill rig is also dependent on the amount of casing that needs to be installed. Casing is the steel piping that lines the outer edge of the trench and can range from 5 to 30 feet in diameter, each section weighing up to 9 tons.

There are many different types of HDD drill rigs on the market today. The two main types being land- or marine-based .

Land-based HDD drill rigs are most typically used in soil, clay and silt conditions where water depths are less than 100 feet. They have multiple sets of pipe storage racks built in so that the pipe can be easily connected and disconnected from the drilling string .

The majority of land-based HDD drill rigs have the capacity to dredge over 100,000 yards a day, which is a great advantage when considering that open cut trenching can take several weeks to complete. There are also different types of water pumps available for land-based HDD drill rigs depending on the water depth and soil conditions .

Marine-based HDD drill rigs are used for projects in nearwater environments as well as areas with very loose soils like sands or gravels, water depths between 1,000 to 5,000 feet and remote locations where transportation is limited.

There are two types of marine-based HDD drill rigs: self-propelled vessels and jack-up barges. A self-propelled vessel is permanently attached to its drilling unit, while a jack-up barge can be moved from one project to the next .

Marine HDD drill rig operators will also use what is called a wiggle stick when digging down into the seabed. The wiggle stick has three different positions; forward, neutral and reverse. When the drill rig is in forward mode it pushes the pipe into the seabed to get past any obstructions, when in neutral position the weight of the load will push it down into place, and in reverse position it pulls back on the pipe to remove any obstructions .

What Contractors Should Know?

Work with a contractor who is well-versed with the industry standards for HDD projects, or hire a firm that specializes in installation of subsea pipelines. Since the entire pipeline installation process has multi-billion dollar implications, choosing the HDD drill rig is not something that can be done lightly.

Subsequently, when choosing an HDD drill rig, contractors need to take into account various considerations that pertain to the industry they work in. The design of the machinery is a good indicator of what applications they will be used for. Making use of a faulty machine can not only waste time and money but may also damage the pipeline being laid out.

The best way to know if a machine is right for the job is to gather as much information as possible as there are various factors that will make one type of HDD drill rig better suited for a specific project than another.

Complexity, environmental conditions and price all need to be considered before making a final choice.

Even though the HDD industry has its own list of requirements, this should not prevent contractors from seeking out other machines that might be suitable for their project and needs. For example, rotary steerable systems are great for rocky terrain and uneven surfaces. This is why many firms consider it as one of the best HDD drill rigs.

All things considered, the best machines are the ones that can accomplish a job with minimum waste of both time and money, so choosing the HDD drill rig requires prudence and caution to make sure all specifications are met.

3 notes

·

View notes

Text

Offshore Drilling and Production Equipment

Offshore drilling and production equipment includes various types of drilling rigs. Some types are self-erecting platform rigs that can be rigged quickly and easily on land. Larger rigs require the installation of derrick barges that may take several days or longer. Once drilling is complete, platform rigs are removed from the platform. There are also rigs called tender-assist rigs. These are monohull units that perform all of the functions of a platform rig from the tender. But the list doesn't stop here! There are many more types which you can know about following in this article. Check out this site to know more.

Fixed platform design

Fixed platforms are immobile, and they offer the necessary support for heavy drilling rigs and production equipment. They resemble gravel islands. Because of their gravity-based design, they are less prone to ice damage than other types of structures, and they can be deployed in much deeper water than jacket structures. They are more resistant to ice than any other kind of rig, and their high-tech design makes them a great asset in any field.

Another kind of fixed platform is the semisubmersible rig. It resembles a drilling barge and has three or four massive legs that can lower the platform out of the water. These legs help stabilize the platform against wind and waves and make it easier to move between locations. However, this design has limitations when working in deep waters. For this reason, it is better suited for operations where the drilling rig is anchored.

Drillships

Drillships are vessels designed to drill, assemble bottom hole assemblies, and complete various other tasks. They don't use anchors and must be propelled using flexible propulsion systems to compensate for surge, sway, and yaw. Large electric motors drive propellers on drillships. These rigs also have a number of other features.

A drillship is a ship specifically designed for offshore drilling and production operations. It has a drilling platform in the centre of its deck, and it also has a hull-mounted derrick that allows a drilling string to extend through the ship and into the seabed. Drillships can be turned to face an oncoming wind or a current to improve stability, and they can operate in extremely deep waters that are too deep for anchors.

Semisubmersibles

A semisubmersible is a vessel designed for offshore support roles, such as transporting oil and gas wells, and its design makes it suitable for operation in rough waters. They are usually equipped with drilling packages, including everything from oil to petrochemicals. This vessel has a deep draught that allows it to be well submerged, and it is designed with ballasting to dampen the effects of swell and waves. The columns are far apart to provide high stability, which allows them to lift huge loads without causing damage to the deck.

One advantage of semisubmersibles over drilling vessels is their ultra-deepwater drilling capability. Maritime vessels specially modified to drill wells in oil fields offer a comprehensive offshore drilling solution for clients worldwide. Because of their extensive mooring systems, they can propel from one well to another without outside assistance.

Dry tree systems

While conventional semisubmersible platforms are highly versatile and offer optimum deck space and payload flexibility, they are not suitable for dry tree systems. In fact, some semisubmersibles operate in depths up to 6,000 feet and use subsea trees. These systems, however, use a rigid riser system that is locked to the subsea wellhead and a dry tree on the platform deck. The downside of this type of arrangement is that it is very sensitive to movement.

As the name suggests, dry tree systems are wellhead devices that give the operator complete control over production. These systems are widely used on fixed platforms in shallow waters but have not yet been utilized on deepwater semisubmersibles due to the extreme motions of such vessels. Nonetheless, multiple designs are being evaluated by major offshore oil companies and Det Norske Veritas to ensure their suitability for these platforms.

Subsea completion systems

The advantages of subsea completions are many, including the reduced costs and environmental impact. However, there are also barriers to their use, including regulatory and technological issues. For instance, many subsea completions require a workboat to reconfigure them. A workboat's cost alone could be $200,000 per day. Furthermore, the rig must be able to operate without interruption for up to five years.

The subsea components of offshore drilling and production equipment are connected by a flowline that includes a series of umbilicals. The umbilicals, or pipelines, are usually 10 in (25.4 cm) in diameter. Their length is determined by the spacing of each subsea component and distance from the host facility. The flowline also contains the production riser, which is the portion of the flowline between the tree and the host facility. The riser can be vertical or can take on different waveforms, depending on the characteristics of the well.

Moving rigs

Offshore drilling and production equipment must be regularly moved from one location to another. Oil rigs perform many different functions, from drilling exploratory wells to installing multi-well production platforms. The primary purpose of an oil rig is to produce oil. There are many reasons for moving an oil rig, but its size and weight are the main factors. To make a move less costly and easier, consider a few things.

Oil rigs are usually set up near an existing drilling location. The location is chosen based on geological surveys and satellite images to find the most productive drilling areas. Offshore oil rigs do not need to remain in one location and can move to different areas. They are typically towed to sea and installed there. If they are moved to a different location, they are unloaded and towed to a new location.

0 notes

Photo

Our Specialties

National Contracting is one of the most reputable concrete cutting, grinding and drilling contractors in South Australia. We offer a wide range of services catering to both commercial and residential customers alike. By making use of the latest advancements in technology, we are able to provide top of the line services to our customers. With over two decades of experience in the concrete cutting, drilling and grinding business, we are more than capable of handling all kinds of projects, big or small. We take pride in the fact that we have very good customer relations and are widely trusted by clients. Here are some of the services that we offer to our valued customers in South Australia.

Concrete Cutting

We can complete the job required inside or out. Outside we will use a petrol saw, inside we will use an electric or hydrolic saw leaving zero fumes. We can cut brick, concrete or bitumen to a deep of 150mm.

Read More

Concrete Grinding

If you have a floor that needs to be resurfaced and needs the glue removed or you discover a bump, we can grind the glue away or grind the bump flat, using a medium sized walk behind grinder.

Read More

Core Drilling

We have a drill designed specifically for coring holes from 10mm-350mm. 10mm-100mm can be hand drilled 115mm-350mm would be done with a mounted rig. We drill through concrete, brick and pavers

Read More

Floor Sawing

This is done with a 35hp self propelled saw. Normally used for deeper cuts or larger areas. This will cut to a depth of 400mm deep, cutting chases/trenches for plumbers in floors cutting up concrete slabs.

Read More

Concrete drilling can be carried out to install certain types of wires. We have worked closely with electricians, plumbers, building contractors, as well as with homeowners, providing tailored concrete drilling services to our clients at the most affordable prices.

Our floor sawing services are offered in Adelaide at extremely competitive prices. If you have any kind of project that needs to be completed in Adelaide, just give us a call and let us handle it for you. Our floor sawing- services are offered in Adelaide, as well as in certain areas on the outskirts of the city.

With the wealth of experience that we have in the industry as well as the quality of service that we offer, we believe our work serves as the greatest testimonial of our commitment to the job. We will carry out detailed surveys of the region in order to make sure that the work is done in complete detail. Of course, we prefer working in close collaboration with our clients, so you are always welcome to visit us on-site to see the progress of the work. We are quick, reliable, and most of all, highly professional. If you have any queries or would like to know more about how the work is done on-site, just give us a call and one of our friendly assistants will be more than happy to guide you in detail.

#Core drilling#floor sawing#concrete core drilling#concrete grinding#concrete cutting#core#core drilling south asutralia#floor sawing south australia#concrete swaing south australia#concrete grinding south australia#concrete cutting south asutralia

0 notes

Note

Ooooo! Could you do a fic about all the things Will and Horacio got up to when they were rooming together?

Absolutely! :D

Fandom: Horatio Hornblower (TV)

Pairing: Pre-slash, Horatio Hornblower/William Bush

Series: Harboured and Encompassed (Modern AU)

Title: Ships and Swans (http://archiveofourown.org/works/12487524)

Special Thanks: @velarapproximant and @girabbit for beta-ing! You’re amazing!

Summary:

They've only been roommates at King's College London a few weeks, but Horatio and Will are already having adventures on the high seas . . . or, rather, in Hyde Park's Round Pond. It's just them, a brisk January morning, and the Hotspur (their model ship).

Oh, yes, and a swan.

What could possibly go wrong?

******

“Are you sure about this, Horatio?”

“Of course I’m sure,” Horatio bristled, holding his head higher to fight the urge to hunch his shoulders. “She passed our test in the sink with flying colours. Why wouldn’t we test her in more open waters?”

Will shrugged as he wrapped his red scarf around his neck more tightly and tucked the ends into his black leather jacket. “Just thought we’d wait until spring.”

Horatio forced himself not to shiver as another gust of January breeze blew through. He cursed himself for forgetting his gloves and hat. He’d just have to make do without. “Well, we can warm ourselves up with hot drinks once we’re through. My treat.” It was the least he could do to thank Will. Will’s accompanying him on this venture was far beyond his duty as a roommate.

Will put his hands in his pockets. “Ta.” He glanced at the water in front of them. “How will you get it back? The Hotspur, I mean?”

A faint smile flickered across Horatio’s face. “That’s why I chose today. The wind’s picked up, so it should blow her to the shore. We don’t need a remote control, Will. We have nature on our side.”

Will raised an eyebrow, then dipped his head. “Alright.” He gestured toward the water. “Lead on.”

Horatio nodded, then surveyed the Round Pond, his forehead creased with concentration. Will had only just gotten back on his feet--er, foot? Damn it, he needed to do more research on terminology--after several days of crutches. He should find the perfect spot for them to stand to minimize Will’s discomfort. “We should start from over there, near the bench,” he said at last.

Will looked at the bench, then at Horatio, then raised an eyebrow slowly. “Why?”

Horatio glanced at Will out of the corner of his eye as he tried to come up with a reasonable excuse. “It . . . er . . . it’s more in the sun. It’ll be warmer.”

Will smiled and rolled his eyes. “It was just a small infection, Horatio. It’s good as new, now.” He patted his hand against his thigh through his dark wash jeans. “I don’t need to sit.”

Horatio forced himself not to wince at his own stupidity. Of course Will wouldn’t be slowed down by something like that. He never seemed to be in pain. Or anxious. Or afraid. It seemed ironic that the bravest man in KCL had been assigned to room with the most cowardly. He squared his shoulders and cleared his throat. “I’m glad to hear it. Let’s go, then.” Without waiting for an answer, he plowed ahead, pausing only once he reached the water’s edge, closest to the bench.

By the time Will caught up with him, he’d managed to remove the small ship from his backpack and to free it from the towels he’d wrapped around it.

“She’s beautiful,” Will said quietly. “Even without the cannons.”

Horatio ducked his head. His failure had been mortifying enough without Will needing to bring it up again. “It was an elementary miscalculation. Anyone could have neglected to account for their extra weight.”

Will raised an eyebrow. “Naturally. Jack did the same in Master and Commander.”

Horatio scowled as his stomach twisted. He hardly deserved to be mentioned in the same breath as Jack Aubrey. He cleared his throat. “Yes. Well . . . I . . . er . . . appreciate your help with the rigging.”

Will nodded once, a calm, controlled bob of his head. “Pleased to be of service.”

Horatio swallowed and looked back down at the ship. It was far safer to look at than Will’s steady, quiet confidence. Any day now, Will would request a new roommate and move out. It must be an intolerable burden, to go from being an officer in Her Majesty’s Navy to sharing a room with a neurotic failure who couldn’t remember to eat without prompting. “Shall we set sail?”

A faint, dry smile flickered across Will’s lips. “Aye aye. Anchors aweigh.”

Horatio nodded, then crouched down by the water’s edge to gently place their ship into the pond. They watched in silence as the wind billowed her sails and propelled her forward, ripples trailing in her wake.

For a moment, Horatio could almost feel his hands despite the cold as the pride in a job well done coursed through him.

Then, he noticed the swan.

********

“Are you sure you don’t want my coat?” Will asked again once they’d boarded the Central line tube to take them back to their dorm.

Horatio glowered. “I’m perfectly fine,” he snapped, shivering as he clutched the Hotspur closer to his chest. “I’ll dry soon enough.”

“Alright,” Will said with a shrug. At least ringing out his coat and shirt had helped, even if it’d also smeared the mud and swan droppings around. And Horatio’s hair was drying more quickly now. He risked a quick glance at Horatio. An image of a particularly fluffy baby duckling floated through his mind. He hadn’t realized towel drying could do . . . that. He forced himself not to smile. The last thing either of them needed was for Horatio to think he was being laughed at.

The woman on Horatio’s right looked up from her newspaper, glanced at Horatio, wrinkled her nose, and shifted further away.

Horatio clenched his jaw more tightly.

Will frowned. He usually gave Horatio a wide berth when he’d reached the jaw clenching stage. But maybe today should be the exception. “You were lucky,” he said at last. “Swans can be vicious. A boy I knew at school got a nasty bite from one once.

Horatio rolled his eyes. “Yes, well, nothing damaged, apart from my clothes.”

Will glanced down at Horatio’s jeans with a faint smile. “We can sew up that tear.”

Horatio turned to face him, his eyebrow raised. “You have a sewing kit?”

Will shrugged. “Just a small one, but it should have what we need.” He hadn’t done mending in years, but he’d helped Mum often enough once Cathy was born that it should come back to him quickly.

Horatio nodded, then looked down at the Hotspur again. His jaw began to unclench. “At least we don’t have to do any repairs on her,” he said, a hint of pride in his voice as he ran his hand across her rigging.

Will smiled as he watched Horatio’s fingers lovingly trace the rope.“She didn’t need cannons. She had you.”

Horatio scowled and ducked his head. “Hardly.”

Will raised an eyebrow. “Horatio, you saved the ship.”

Horatio rolled his eyes. “There’s no need to make it sound heroic, Will. It wasn’t. I didn’t have time for a grand strategy, or to think about the water, or the risks. I just . . . saw her come for our ship, wings flapping, and did the first thing I could think of.”

“Charging at her and screaming bloody murder,” Will said with a nod and a smile he didn’t try to hide.

Horatio huffed out a laugh. “It made sense at the time.”

“And it worked.”

Horatio rolled his eyes again. “Yes, but only after getting pummeled by her wings.”

“Taking enemy fire doesn’t make it any less of a victory.”

“It’s a bird, Will, not the Cygne,” Horatio sighed.

Will frowned. “The Cygne?”

Horatio nodded. “The French word for ‘swan.’ She was an Abeille-class, 16-gun brig, launched in 1806. She ran aground while taking fire from the HMS Amaranthe. That would have been . . . 1808, I think.”

Will raised an eyebrow. “How did you remember that?”

Horatio brightened and sat up straighter. “Well, there’s a fascinating discrepancy in the historical record. According to Troude’s Naval Battles of France, 1867, Captain Defresne scuttled the Cygne, by fire, rather than let her fall into the hands of the British. But the London Gazette published an account from the captain of the HMS Circe. It explains that the English, not the French, set fire to the Cygne. So, you see, each side reported the events differently.”

Will nodded slowly. So that’s what Horatio did in his spare time: more research. At least talking about it had cheered him up. “Who do you believe, then?”

Horatio’s forehead wrinkled and he blinked several times. “Well, the English, clearly. No self-respecting British officer would lie about his triumphs.”

Will raised an eyebrow. Horatio’s idealism wouldn't have survived three years on the HMS Daring. “Right,” he said at last.

Horatio’s enthusiasm vanished as quickly as it had come, and he stared back down at the Hotspur, shoulders slightly hunched. “I didn’t defeat the swan, Will,” he said quietly. “And I’m not going to lie and say I did.”

“Right,” Will said again, sighing internally. Horatio was harder on himself than any drill sergeant at Basic could ever be. He’d run himself into the ground if he wasn’t careful. He was well on his way there, given his sleeping and eating habits. How did he forget to eat, but have perfect recall of newspaper articles about obscure ships? He’d end up having to take a leave of absence and go back to Kent at this rate.

Will blinked. Why did that bother him? It hadn’t when Bobby and the others got the boot at Basic. Was there something different about Horatio?

A strange pulling sensation started up in his chest. He rolled his shoulders, but it didn't go away. He must’ve slept on it oddly. It wasn't important. And neither was thinking about this change. Reasons didn't matter.

What mattered was figuring out how to help.

If only there were a way to combine food and naval history, maybe Horatio wouldn’t starve.

Will smiled as he remembered the slim cookbook on his bookshelf, courtesy of Victoria. “Horatio?”

“Yes?” Horatio didn’t look up.

“My sister gave me a book of recipes from the Aubrey/Maturin series before I left. I was thinking of making hard tack tomorrow. Would you like to help?”

Horatio blinked several times, then tilted his head, his forehead wrinkling. “You . . . you’d like . . . me to help you bake?”

Will shrugged. “I thought it might make for a fun night in. We could always watch Master & Commander together after, if you’d like. I saw the DVD on your bookshelf the other day.”

Horatio’s eyes widened and a cautious smile spread over his face. “Oh! That -- I -- er--” he cleared his throat and tried again. “Yes. That sounds . . . good.”

Will smiled back, feeling warmer than he had all day. “2pm?” Baking would be nice after his appointment with Dr. Patel that morning. It helped to have something to do with his hands.

“2pm works perfectly,” Horatio answered. “I should be able to finish my reading tonight, leaving plenty of time for our activities tomorrow.”

“Alright, then. That’s our afternoon sorted,” Will said with a smile.

“I’ll look forward to it,” Horatio said with an oddly formal nod that wouldn’t be out of place in those period dramas Cathy made him watch last year when he was stuck at home.

Will watched out of the corner of his eye as Horatio looked back down at the Hotspur, his reserved expression breaking into a broad grin that made his brown eyes shine.

The pulling sensation in his chest came back full force. Will shifted in his seat and looked out the window. Horatio’s eyes and smile kept floating through his mind.

“Will? This is us.”

Will blinked. Horatio was standing up, his hand around the metal pole near his seat, and was watching him, his forehead wrinkled with concern.

Will stood up and smiled. It wouldn't do to worry Horatio. He gestured to the open door. “Lead on. I’m right behind you.”

#HHornblower#Hotspur Husbands#Horatio Hornblower#William Bush#Harboured and Encompassed#Prequel#Age of Sail#Modern AU#long post#my fic#just-a-half-boiled-egg

19 notes

·

View notes

Text

Rock drill Pantera 1500

Rock drill Pantera 1500

Rock Drill Pantera 1500 is a hydraulic, self-propelled, selfcontained, crawler based surface drilling rig equipped with a cabin and a rod changer. It drills 89 – 140 mm (3 ½” – 5 ½”) vertical, inclined or horizontal holes with 51 and 60 mm ( 2” and 2 3/8” ) extension rods or 102 – 152 mm (4” – 6”) vertical, inclined or horizontal holes with 76 and 87 mm (3” and 3 ½”) tubes. Good results in…

View On WordPress

0 notes

Text

Workover Rigs Market : Technology Advancements, Industry Insights, Trends And Forecast 2033

The workover rigs global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

Workover Rigs Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size - The workover rigs market size has grown steadily in recent years. It will grow from $5.25 billion in 2023 to $5.51 billion in 2024 at a compound annual growth rate (CAGR) of 4.9%. The growth in the historic period can be attributed to oil price volatility, aging oil wells, regulatory changes, global energy demand, natural disasters.

The workover rigs market size is expected to see steady growth in the next few years. It will grow to $6.41 billion in 2028 at a compound annual growth rate (CAGR) of 3.8%. The growth in the forecast period can be attributed to renewable energy transition, digitalization and automation, focus on asset optimization, environmental and ESG considerations, global economic trends, resilience to supply chain disruptions. Major trends in the forecast period include advancements in technology, environmental and regulatory compliance, global energy transition, remote operations and digitalization.

Order your report now for swift delivery @ https://www.thebusinessresearchcompany.com/report/workover-rigs-global-market-report

The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

Market Drivers - Growing demand for oil and natural gas is expected to propel the growth of the workover rig market going forward. Oil and natural gas are fossil fuels extracted from the Earth, serving as crucial sources of energy for various industries and daily life. Growing demand for oil and natural gas is driven by the expanding use of these resources in transportation, manufacturing, and energy production. Workover rigs help to sustain and increase demand for oil and gas by maximizing the production potential of existing wells, optimizing reservoir performance, and simplifying the responsible management of mature assets throughout their life cycle. For instance, in October 2023, according to the International Energy Agency, a France-based intergovernmental organization, the projection suggests a 6% increase in worldwide oil demand between 2022 and 2028, reaching a total of 105.7 million barrels per day. Additionally, there is an expectation that global gas demand will grow at an average annual rate of 1.6% from 2022 to 2026. Therefore, the growing demand for oil and natural gas is driving the growth of the workover rig market.

Market Trends - Major companies operating in the workover rigs market are focused on developing innovative solutions, such as the mobile drilling rig, to enhance operational efficiency and drive their revenues in the market. A mobile drilling rig is a versatile, self-propelled platform equipped with drilling machinery for on-the-go exploration and extraction of underground resources. For instance, in July 2021, Drillmec International Pvt. Ltd., an India-based manufacturer and distributor of drilling and workover rigs, launched the ARS-225 Mobile Rig, which is designed for drilling and workover operations in extreme conditions. Boasting a nominal hook load capacity of 225 metric tons, it is powered by two CAT C18 oil and gas type 700 Hp diesel engines and features a dual-tank fuel system with a total capacity of 800 liters. Additionally, equipped with a winterization system, the ARS-225 ensures optimal performance even in cold environments.

The workover rigs market covered in this report is segmented –

1) By Type: Barge Rigs, Tender Rigs, Jack Ups Rigs, Platform Rigs, Semi-Submersible Rigs, Drill Ship 2) By Form Factor: Single Drum, Double Drum 3) By Capacity: Below 1,000 Horsepower (HP), 1,000-1,500 Horsepower (HP), Above 1,500 Horsepower (HP) 4) By Application: Onshore, Offshore

Get an inside scoop of the workover rigs market, Request now for Sample Report @ https://www.thebusinessresearchcompany.com/sample.aspx?id=14541&type=smp

Regional Insights - North America was the largest region in the workover rigs market in 2023. Asia-Pacific is expected to be the fastest-growing region in the forecast period. The regions covered in the workover rigs market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Key Companies - Major companies operating in the workover rigs market are Schlumberger Ltd., Hess Services Inc., National Oilwell Varco Inc., Megha Engineering and Infrastructures Ltd., Nabors Industries Ltd., Helmerich & Payne Inc., Precision Drilling Corporation, Drillmec Drilling Technologies, Fieldwood Energy LLC, Superior Energy Services, San Antonio Internacional, National Energy Services Reunited Corp., KLX Energy Services Holdings Inc., LCH Well Servicing LLC, Eastern Well Services, MBI Energy Services, Twin Eagle Transport LLC, Deep Industries Ltd., Moncla Energy Services LLC, Mesa Southern Well Servicing LP, Nordic Gulf, Automated Rig Technologies Ltd., BOS Energy International FZE, Hubei Petrokh Machine Manufacturing Co. Ltd., Sunnda Corporation, KOLLER Solutions Maschinen- und Anlagenbau GmbH

Table of Contents 1. Executive Summary 2. Workover Rigs Market Report Structure 3. Workover Rigs Market Trends And Strategies 4. Workover Rigs Market – Macro Economic Scenario 5. Workover Rigs Market Size And Growth ….. 27. Workover Rigs Market Competitor Landscape And Company Profiles 28. Key Mergers And Acquisitions 29. Future Outlook and Potential Analysis 30. Appendix

Contact Us: The Business Research Company Europe: +44 207 1930 708 Asia: +91 88972 63534 Americas: +1 315 623 0293 Email: [email protected]

Follow Us On: LinkedIn: https://in.linkedin.com/company/the-business-research-company Twitter: https://twitter.com/tbrc_info Facebook: https://www.facebook.com/TheBusinessResearchCompany YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ Blog: https://blog.tbrc.info/ Healthcare Blog: https://healthcareresearchreports.com/ Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

The Beginning and Developing of Machining

Posted from 5 axis machining China blog

The Beginning and Developing of Machining

Machine instruments started to radically improve with the start of the Industrial Revolution in the late eighteenth century. More items were being created from metals, and copper turning products and etc and better machine devices were required.

5 axis Milling Machine

In England in 1775, John Wilkinson built up a water wheel-fueled exhausting machine to machine within guns. Before long the machine started to exhaust chambers for Boulton and Watts’ steam motors. That started the time of steam-controlled machine apparatuses.

In 1797, Henry Maudslay built up a machine that had the option to precisely cut screw strings. This altered assembling on the grounds that exchangeable strung parts could be delivered.

In 1818, Eli Whitney delivered the primary processing machine. This machine device had the option to deliver level surfaces more effectively than by hand with recording and scratching apparatuses. Throughout the following quite a long while, a few people made enhancements for Whitney’s machine and various models opened up.

The post drill created openings by turning a wrench by hand. The wrench turned rigging that pivoted the cutting apparatus and propelled it into the part being penetrated. It was generally utilized into the mid twentieth century before power turned out to be broadly accessible.

All through the eighteenth and nineteenth hundreds of years, steam-fueled machine devices were driven by a progression of belts that were associated with an enormous brought together wheel controlled by a steam motor. During the Industrial Revolution, numerous organizations started delivering machine instruments as metal cutting tasks turned out to be progressively normal.

In China, the Industry began in late Ming Dynasty along the commercial well-developed cities, like SuHang. But it was effectively blocked again in the Qing Dynasty, which turned back to specializing in agriculture. Late until 18th century, China was forced to open up the coastal cities for business to the western countries, like the Great Britain, France and Spain etc. But only from 60’s to 90’s of 19th, the industrial revolution in China was slowly and difficultly developed in the hope to strengthen its national capacity by the leading of the Self-strengthening Movement. They firstly bought machines from the western countries and trained skilled machining workers for the production military equipment and also designed some new machines for production. Later they also focused on civil industry to meet the domestic daily need. In such a way, China was forced to the world trend without the long-term accumulation of capital and bourgeois revolution.

In the early piece of the twentieth century, electric force started to supplant steam force, and machine apparatuses kept on getting progressively perplexing, increasingly exact, and progressively productive. Better machine apparatuses had the option to create increasingly exact parts, which thus delivered far and away superior machine devices, in a pattern of steady improvement.

In the mid 1900s, Henry Ford’s making of the sequential construction system for large scale manufacturing of autos depended vigorously on machining. Parts should have been machined productively to stay aware of vehicle get together.

Up until the 1940s, machine apparatus developments were constrained by switches, hand wheels, and outfitted transmissions. After World War I, incredible monetary development occurred in the United States. Industrialism started, and the machining business expected to turn out to be progressively proficient to help producing. The creation of numerical control (NC) incredibly improved machine apparatus execution. A language of machine code was created and stacked on a punch card or tape and afterward took care of into the machine device to consequently manage the movements of the machine and change apparatuses without the need of an administrator.

During the 1970s, the NC punch card or tape started to be supplanted with PC numerical control (CNC). Rather than machine code being punched on the tape or card, code was entered through a coordinated PC on the machine instrument. Proceeded with headway in PC innovation and machine instrument development has brought about machine devices that can create mind boggling, complex shapes with extraordinary exactness and productivity. When appropriately designed, they can likewise perform numerous activities with a wide range of sorts of cutting instruments while running without the need of an administrator. Here shows a ultra-present day CNC machine apparatus in activity.

This article is from http://www.5axismachiningchina.com

#cnc machining in china#fabrication company in uae#precision cnc machining china#precision machining factory#precision turned parts china

0 notes

Text

Offshore Drilling Platforms Market Predicted to Accelerate the Growth by 2019 – 2027

Offshore Drilling Platforms Market: Overview

Drilling rigs are used in offshore exploration such as deep water, shallow water, and ultra-deep water. The different types of drilling rigs used for offshore operations are jackup rigs, semi-submersible rigs, drill ships, and others.

The platform plays a vital role in overall operation of offshore drilling or production. An offshore drilling platform accommodates all the required equipment and workers needed for exploration and drilling.

Read report overview@

https://www.transparencymarketresearch.com/offshore-drilling-platforms-market.html

The drilling platform consists of a drilling rig derrick through which the drill string is lowered into the rock formation for drilling application. The drill string is operated by power unit or by rotary table directly on the platform.

An oil production platform is self-sufficient in energy and water needs, comprising electrical generation, water declinators, and all other equipment required for drilling and production

Based on application, different offshore drilling platforms are developed such as fixed platform, compliant platform, and floating platform. A fixed platform is erected on the legs that are fixed at the bottom of the sea. A floating platform is a small, semi-submersible platform held in position using a simple anchor or by its own power.

Is something restraining your company’s growth in the Offshore Drilling Platforms Market?

Ask for the report brochure here

Key Drivers of Global Offshore Drilling Platforms Market

Increase in demand for oil & gas due to urbanization, industrialization, and population growth drives the global offshore drilling platforms market

Rise in exploration and new discovery of oil & gas deposits in deep and ultra-deep water propels the offshore drilling platforms market. The recent discovery by BP of more than 1 billion barrels of oil in its Thunder Horse field in the Gulf of Mexico is expected to witness exploration and drilling operations spanning several years.

Key Development

In November 2017, Shell Australia completed the installation of Prelude, one of the world's largest offshore facility ever constructed and the largest floating liquefied natural gas platform. According to Shell Australia, Prelude can sustain harsh wind and sea conditions, including a one in 10,000-year storm.

North America to Account for Major Share of Global Offshore Drilling Platforms Market

Based on region, the global offshore drilling platforms market can be segmented into five regions: North America, Europe, Asia Pacific, Latin America, and Middle East & Africa

The market in North America dominated the global offshore drilling platforms market in 2018. The trend is projected to continue during the forecast period owing to discovery of shale gas reserves in the U.S. and presence of large number of private oil companies in the region.

Europe is anticipated to account for major share of the global offshore drilling platforms market during the forecast period. The North Sea has considerable number of installed offshore rigs, as it is one of the world’s largest area of offshore oil and gas exploitation.

Middle East & Africa has significant oil reserves onshore and offshore. The offshore discoveries and development, particularly in the Red Sea region, by countries such as Qatar, the UAE, and Saudi Arabia are anticipated to drive the offshore drilling platforms market in the region.

The offshore drilling platforms market in Asia Pacific and Latin America is projected to grow at a sluggish pace during the forecast period. Increase in investments in energy generation and rise in offshore exploration activities are expected to drive the market in the region in the near future.

To Get a Bird’s Eye View of Offshore Drilling Platforms Market Forecast,

Ask for a Custom Report

Key Players Operating in Global Offshore Drilling Platforms MarketGlobal Offshore Drilling Platforms Market: Top Companies

Keppel Corporation Limited

Sembcorp Marine Ltd.

DSME Co., Ltd.

Samsung Heavy Industries Co., Ltd.

Hyundai Heavy Industries Co., Ltd.

National Oilwell Varco

CIMC Raffles Offshore Engineering Pte Ltd.

CSIC

CCCME

Maersk Drilling

Others

Global Offshore Drilling Platforms Market: Research ScopeGlobal Offshore Drilling Platforms Market, by Type

Fixed Platform

Compliant Platform

Floating Platforms

Jackup Rigs

Steel Platforms

Concrete Platforms

Others (topsides, jackets)

Tension-leg Platforms

SPAR

Floating Production, Storage, and Offloading System (FPSO)

Semi-submersible Platform

Global Offshore Drilling Platforms Market, by Water Depth

Shallow Water (< 300 meters )

Deep Water (< 1500 meters)

Ultra Deep Water (> 1500 meters)

Global Offshore Drilling Platforms Market, by Region

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

U.S.

Canada

U.K.

Norway

Russia & CIS

Rest of Europe

China

India

Australia

ASEAN

Rest of Asia Pacific

Brazil

Mexico

Venezuela

Rest of Latin America

Saudi Arabia

UAE

Qatar

Nigeria

Rest of Middle East & Africa

The report offers a comprehensive evaluation of the market. It does so via in-depth qualitative insights, historical data, and verifiable projections about market size. The projections featured in the report have been derived using proven research methodologies and assumptions. By doing so, the research report serves as a repository of analysis and information for every facet of the market, including but not limited to: Regional markets, technology, types, and applications.

0 notes

Text

Drilling Rigs Market - Enumerates deep-water applications 2025

Global Drilling Rigs Market: Snapshot

Around the world, there are seven different types of drilling rigs that are currently in use for offshore operations. Drilling rigs are available in a number of sizes that range from single person operated to those capable of making holes several thousands of meters below the earth’s surface. Not only can this, drilling rigs test sub-surface material for a know-how of physical properties of a drill site.

Drilling in oil and gas industry involves creating holes in the earth’s surface as a preparation to oil and gas exploration activities. Drilling rigs are used in offshore exploration in deep water, shallow water, and ultra-deep water. Semi-submersible rigs are used in deepwater areas, jackup rigs are used in shallow water region, and drillships are used in ultra-deep water regions in offshore explorations.

Request Sample Copy of the Report @

https://www.tmrresearch.com/sample/sample?flag=B&rep_id=311

Jackup rigs are offshore rigs equipped with legs that can be descended to the seabed in order to form a foundation to support the drilling platform. Typically, jackup rigs can operate in water ranging from 350 to 450 feet deep. Drillships rigs are usually used in deepwater applications. They are usually self-propelled and are in the shape of conventional ships. Semi-submersible rigs are submerged in water by means of a water ballast system in such a manner that the lower hull portion is beneath the water surface during drilling operations.

The growth of drilling rigs market in mainly dependent on increasing oil and gas exploration activities worldwide. In the recent past, the discovery of oil and gas reserves in remote locations along with technological advancements in exploratory equipment have made drilling activities more feasible and cost-effective.

Global Drilling Rigs Market: Overview

Drilling rigs are mechanical devices used to create holes in ground. They are giant structure and are mainly used during drilling oil wells, water wells, and natural gas wells. The equipment can be mounted on trailers, trucks, and can be installed on land as well for onshore drilling. The report on the global drilling rigs market highlights the prevalent opportunities worldwide and the factors that could restraint its growth.

Request TOC of the Report @

https://www.tmrresearch.com/sample/sample?flag=T&rep_id=311

The report has been compiled to provide a holistic overview of the global drilling rigs market and covers aspects such as segmentation, key trends and opportunities, investment feasibility, and vendor landscape.

Global Drilling Rigs Market: Trends and Opportunities

Due to the increasing drilling activities worldwide, the demand for drilling rigs has significantly risen especially in offshore regions. As onshore drilling activities have reached maturity, no alternatives are left aside from explore offshore reserved, owing to which the enterprises operating in the drilling rigs market are focusing on the latter. Therefore, on account of having huge offshore crude oil reserves, European countries such as Spain and Norway have gained prominence in the global drilling rigs market.

According to the Oil and Gas Journal, a larger portion of crude oil reserves in Norway is located in the offshore region of the Norwegian Continental Shelf. The region is further divided into North Sea, Barents Sea, and Norwegian Sea. Among these, North Sea accounts for a major share in the overall oil production in Norway, besides Norwegian Sea. The market therefore witnesses huge opportunities to gain from in Europe, which makes it one of the most lucrative regions to explore by leading players.

Global Drilling Rigs Market: Key Segments

The global drilling rigs market can be majorly segmented into land rigs and marine rigs. The marine rigs segment can be further classified into bottom supported rigs and floating rigs. As several explorations are carried out using marine drilling rigs, their demand is evidently higher in the market. Marine drills are also used in production activities, which is fuelling their demand around the world. The rising exploration of crude oil in offshore regions will therefore help in the segment’s expansion in the coming years.

By type, the global drilling rigs market can be segmented into rotary rigs, A-frame rigs, large mud rotary drill rigs, tracked rigs, truck mounted drill rigs, and portable minuteman rigs. The market is further segmented based on power into hydraulic, electric, steam, and mechanical drilling. The report provides a round-up of the segments that would prove most lucrative for the enterprises operating in the global drilling rigs market. It also identifies key restraints, which could limit the scope of expansion for market players across the aforementioned segments.

Global Drilling Rigs Market: Vendor Landscape

Some of the most prominent enterprises operating in the global drilling rigs market include Simco Drilling Equipment Inc, Bauer Maschinen GmbH, Weatherford International Ltd., Dando Drilling International, Baker Hughes Inc, Maersk Drilling, Haliburton Company, Schlumberger Ltd, Schramm Inc, and Nabors Drilling.

The report delves into studying the various strategies adopted by the companies profiled and the impact of the same on the overall market operations. It conducts SWOT analysis to present insights into the strengths and weaknesses of the leading market players. The analysis also helps the report foretell opportunities and threats that these companies may face over the course of the forecast period.

The study presents reliable qualitative and quantitative insights into:

Market segments and sub-segments

Market trends and dynamics

Supply and demand chain of the market

Market valuation (revenue and/or volume)

Key trends/opportunities/challenges

Forces defining present and estimated future state of the competitive landscape

Technological developments

Value chain and stakeholder analysis

The regional analysis covers:

North America

Latin America

Europe

Asia Pacific

Middle East and Africa

About TMR Research

TMR Research is a premier provider of customized market research and consulting services to business entities keen on succeeding in today’s supercharged economic climate. Armed with an experienced, dedicated, and dynamic team of analysts, we are redefining the way our clients’ conduct business by providing them with authoritative and trusted research studies in tune with the latest methodologies and market trends.

Contact:

TMR Research,

3739 Balboa St # 1097,

San Francisco, CA 94121

United States

Tel: +1-415-520-1050

Email: [email protected]

0 notes

Text

Borehole Equipment Market to Expand with Significant CAGR During 2026

Borehole equipment are special-purpose machines, particularly used for mud drilling and drill hole enlarging in several applications such as mining, oil & gas, water tube well drilling, and infrastructure. These are self-propelled as well as stationary machines and have a drilling rig installed over a truck, tracked vehicle, or structure. Borehole equipment plays a key role in construction industry, infrastructural projects, mining, and agriculture. These equipment are employed across a wide number of construction projects ranging from road construction to bridges and tunnels. Borehole equipment can handle several types of soil and rock configurations such as loose mud & silt, hard rock, and porous limestone.

Read Report Overview @

https://www.transparencymarketresearch.com/borehole-equipment-market.html

The borehole equipment market is largely driven by the increase in spending on infrastructure. Countries such as the U.S., China, Japan, Italy, India, Australia, and Germany have vast infrastructure. Along with infrastructure, agriculture also requires borehole equipment for irrigation proposes by tapping into underground water sources. Mining and oil & gas industries also rely on borehole equipment to extract oil, gas, and other related fuels and derivatives. Laying of craters and holes for explosives and creating access to underground mines is primarily carried out using borehole equipment. Thus, borehole equipment is used in a project that needs to work below ground. This drives the market for borehole equipment.

Based on type, the borehole equipment market can be segmented into portable, self-propelled, and stationary. Self-propelled borehole equipment are integration of a vehicle, usually a truck or tracked vehicle, which is mounted with a drilling rig. This makes self-propelled borehole equipment more versatile. It also offers ease of operation. Thus, self-propelled borehole equipment are largely preferred. Based on operation, the borehole equipment can be divided into hydraulic and pneumatic. Hydraulic borehole equipment is largely employed where drilling force and strata to be drilled is harder and deeper. Based on application, the market can be segregated into oil & gas, mining, infrastructure & construction, agriculture, and others. The mining segment can be further sub-segmented into coal mining, mineral mining, ferrous metal mining, and non-ferrous metal mining. Similarly, infrastructure & construction segment can also be sub-segmented into residential, commercial, industrial, and utility. Large number of borehole equipment is employed in the mining industry, as mining industry has repetitive requirement of boring holes for explosives and charge laying.

In terms of geography, the global borehole equipment market can be classified into Asia Pacific, Europe, North America, Latin America, and Middle East & Africa. Asia Pacific is the key region of the borehole equipment market, due to the increase in government expenditure on infrastructure and extensive mining for resources in the region. China and India significantly depend on coal for their power requirements. These countries have vast coal reserves and carry out heavy mining for coal. Middle East & Africa is also a lucrative market for borehole equipment primarily due to the presence of large number of crude oil and natural gas reserves followed by infrastructure development in GCC and South Africa. North America is also a prominent region of the borehole equipment market, as the region is one of the largest producers of oil & gas. Its major source is tight oil and shale gas, which requires extensive drilling. This is driving the demand for borehole equipment.

Request to view Sample Report:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=42734

Key players operating in the global borehole equipment market include Dando Drilling International, Bohrmeister (Pty) Ltd., Borehole Machinery, Getech International, Shandong Xin Mei Mining Group, and Audie Steel & Engineering.

About Us

Transparency Market Research (TMR) is a global market intelligence company providing business information reports and services. The company’s exclusive blend of quantitative forecasting and trend analysis provides forward-looking insight for thousands of decision makers. TMR’s experienced team of analysts, researchers, and consultants use proprietary data sources and various tools and techniques to gather and analyze information.

TMR’s data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With extensive research and analysis capabilities, Transparency Market Research employs rigorous primary and secondary research techniques to develop distinctive data sets and research material for business reports.

Contact

Transparency Market Research State Tower, 90 State Street, Suite 700, Albany NY - 12207 United States

Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Email: [email protected] Website: http://www.transparencymarketresearch.com

0 notes

Text

ABS to Class a Series of Silver Eagle Self Elevating Drilling Units