#Safety Tagout

Explore tagged Tumblr posts

Text

Lockout Tagout

#lockout tagout#safety#ms paint#my stuff#industrial#manufacturing#this honestly isn't that far off from the LOTO I had at my old internship

58 notes

·

View notes

Text

#Laws of Motion/Fight Club#Laws of Thermodynamics/self care affirmations#Pool rules/Arnold Schwarzenegger's rules of success#Lockout tagout procedures/prison tamale recipe#Road safety tips/bear survival tips#Rules for gun safety/genie rules from that one meme#is this anything#what? anda... no.

6 notes

·

View notes

Text

What is Lockout Tagout Video in Hindi

Lockout Tagout is a critical safety practice that protects workers from hazardous energy during the maintenance of machinery and equipment. This Hindi-language video explains the concept of LOTO, its importance, and how it can prevent workplace accidents. The video emphasizes the role of proper training and adherence to safety protocols in minimizing risks and safeguarding workers' lives.

Viewers can learn about common lockout devices like padlocks, hasps, and valve lockouts, along with tips on compliance with workplace safety regulations. With a focus on simplicity and real-world application, this video serves as an essential resource for Hindi-speaking audiences, empowering them to foster a culture of safety in their workplaces.

#What is Lockout Tagout in Hindi#what is LOTO#Lockout Tagout Video#LOTO Safety Video#What is LOTO Video in Hindi#E-Square Alliance

0 notes

Text

What is Lockout Tagout Video in Hindi

Lockout Tagout is a critical safety practice that protects workers from hazardous energy during the maintenance of machinery and equipment. This Hindi-language video explains the concept of LOTO, its importance, and how it can prevent workplace accidents. The video emphasizes the role of proper training and adherence to safety protocols in minimizing risks and safeguarding workers' lives.

Viewers can learn about common lockout devices like padlocks, hasps, and valve lockouts, along with tips on compliance with workplace safety regulations. With a focus on simplicity and real-world application, this video serves as an essential resource for Hindi-speaking audiences, empowering them to foster a culture of safety in their workplaces.

#What is Lockout Tagout in Hindi#what is LOTO#Lockout Tagout Video#LOTO Safety Video#What is LOTO Video in Hindi#E-Square Alliance

0 notes

Text

Why Lock-Out, Tag-Out Is Vitally Important. See Videos As Part Of This Post. #LOTO #WorkplaceSafety

Why LOTO is Vitally Important Note: The photos above are not intended for page views or shock value as I don’t believe that those methods truly teach you anything in and of themselves. I don’t know the particulars of the above accident, but I do know that the lack of a proper lock out – tag out (control of hazardous energy) policy and procedure contributed to the accident. What is hazardous…

View On WordPress

#Business#Construction#Employment#Health#Lockout-Tagout#News#Occupational safety and health#OSHA#OSHA Inspection#OSHA Investigation#OSHA News#OSHA Violations#Personal protective equipment#Safety#Safety News#United States#United States Department of Labor#Workplace Fatality#Workplace Safety

1 note

·

View note

Text

The Importance of AEDs on Construction Sites: A Life-Saving Device

The presence of AEDs on construction sites has rapidly transitioned from a supplementary safety feature to a crucial necessity. The dynamic and often rigorous environment of construction sites exposes workers to an array of challenges daily. From operating heavy machinery to performing tasks at elevated heights, the inherent risks are many. Amidst these challenges, sudden medical emergencies,…

View On WordPress

#Construction Safety#Fall Protection#Hazard Communication#Injury Prevention#Ladders#lockout/tagout#machine guarding#National Safety Council#NSC#OSHA#Personal Protective Equipment#preventable death#respiratory protection#Safety Advocacy#safety equipment#safety standards#Safety Training#safety violations#workplace culture#Workplace Safety

0 notes

Text

Welcome to Lukkosafety, your ultimate destination for top-notch lockout and tagout devices designed to ensure workplace safety. In this blog post, we will explore the importance of lockout and tagout procedures in preventing accidents and injuries in industrial settings. Additionally, we will delve into the features and benefits of Lukkosafety's premium-quality devices, recognized as the best in the industry. Whether you are an employer, safety manager, or employee, understanding the significance of lockout and tagout devices is vital for maintaining a secure work environment. Join us as we unveil Lukkosafety's comprehensive range of products designed to enhance workplace safety.

Section 1: The Importance of Lockout and Tagout Procedures (300 words) Lockout and tagout procedures play a critical role in preventing workplace accidents, particularly in industries where machinery and equipment are used. By effectively controlling hazardous energy sources, such as electrical, mechanical, and thermal energy, these procedures ensure the safety of employees during maintenance, repairs, or servicing. Failure to implement proper lockout and tagout protocols can result in severe injuries, fatalities, and costly legal consequences. Employers must prioritize the safety of their workforce by adhering to lockout and tagout regulations set forth by regulatory bodies like OSHA.

#lockout tagout manufacturers in india#lockout tagout safety devices#Lockout Tagout Device for Workplace Safety in India#OSHA Lockout Tagout Standard Equipment

0 notes

Text

i work in the factory that makes those little boxes of 'juice that makes you cum super hard' you see twitter nsfw artists draw. yeah it's actually pretty high-safety because the raw ingredients are a lot more concentrated. we need full PPE on the shop floor because the full concentrate can work on skin contact. we keep the mixture in two separate components until the last moment possible, but someone still got hit by some spray from the reactor vessel last year when working on it, and orgasmed into cardiac arrest. we have a really good bystander chest-compressions procedure, and on-site AEDs, after the union established the new first aid training policy, so they made it to hospital and survived, but we have a new lockout-tagout policy for that entire part of the production line now

205 notes

·

View notes

Text

OSHA has cited AJLS Enterprises Inc.—which operates as Schoep’s Ice Cream in Madison, Wisconsin—for multiple safety violations and proposed penalties totaling $145,097. According to a release dated Jan. 29, the agency’s investigation was spurred by a report that workers were being exposed to anhydrous ammonia, a hazardous chemical used in refrigeration that can cause severe respiratory injuries and burns. OSHA ultimately issued 12 serious citations, including failure to institute processes for controlled release of hazardous chemicals. Other violations include the absence of lockout/tagout procedures, inadequate machine guarding, failure to train workers in lockout/tagout procedures, the absence of a written hazard communication plan, failure to update the emergency action plan and unprotected ladder openings posing fall hazards.

#news#labor news#osha#ajls enterprises inc#schoep's ice cream#madison wisconsin#wisconsin#wisconsin news#us news#osha violations

37 notes

·

View notes

Text

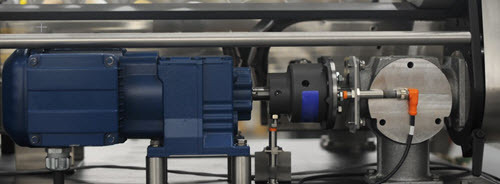

Exploring the World of Electromechanical Systems: A Fusion of Electronics and Mechanics

Introduction:

In the realm of facility management, the effective operation and maintenance of electromechanical systems play a vital role in ensuring the smooth functioning of buildings and infrastructure. The fusion of electronics and mechanics has given rise to sophisticated systems that require skilled professionals to handle their operations and maintenance.

Electromechanical systems are a fascinating field that combines the principles of electronics and mechanics. These systems involve the integration of electrical components and mechanical structures to create devices capable of performing a wide range of tasks. From simple household appliances to complex industrial machinery, electromechanical systems are an integral part of our daily lives.

Understanding Electromechanical Systems:

Electromechanical systems are integral to the functioning of modern facilities. These systems combine electrical and mechanical components, utilizing electronic controls to enhance efficiency and automation. Examples include HVAC (Heating, Ventilation, and Air Conditioning) systems, elevators, escalators, fire protection systems, security systems, and energy management systems.

Workforce Requirements:

To ensure the optimal performance of electromechanical systems, facility management teams require a diverse range of professionals with specialized skill sets. Key roles may include:

a. Engineers: Electrical and mechanical engineers are crucial for system design, installation, and troubleshooting. They possess the technical knowledge to handle complex electromechanical systems.

b. Technicians: Skilled technicians play a vital role in maintaining, inspecting, and repairing electromechanical systems. They are responsible for regular maintenance, diagnosing issues, and performing necessary repairs or replacements.

c. Operators: Operators are responsible for monitoring and controlling electromechanical systems, ensuring their proper functioning and responding to alarms or emergencies.

d. Facility Managers: These professionals oversee the operations and maintenance of electromechanical systems, ensuring compliance with regulations, managing budgets, and coordinating the work of the entire facility management team.

Recruitment Strategies:

To build a competent team for operations and maintenance in facility management, consider the following recruitment strategies:

a. Job Portals: Utilize online job portals that cater to the facility management industry to reach potential candidates with the desired skill sets.

b. Industry Networks: Engage with industry-specific networks, associations, and professional forums to connect with qualified professionals in the field of electromechanical systems.

c. Collaboration with Technical Institutes: Partner with technical institutes and vocational schools to tap into fresh talent. Establish internship programs or participate in job fairs to attract entry-level candidates.

d. Skill Assessment: Conduct thorough skill assessments during the recruitment process to evaluate candidates' proficiency in handling electromechanical systems and their related components.

Training and Professional Development:

Given the complexity and evolving nature of electromechanical systems, investing in training and professional development is crucial. Provide regular training sessions to enhance the skills of your workforce, keeping them up-to-date with the latest technologies and maintenance practices. Encourage employees to attend industry conferences, workshops, and certifications to expand their knowledge base.

Safety and Compliance:

Operations and Maintenance in Facility Management must prioritize safety and compliance. Ensure that all staff members are well-versed in safety protocols, including electrical safety, lockout/tagout procedures, and handling hazardous materials. Familiarize your team with relevant regulations and standards, such as building codes, fire safety regulations, and environmental guidelines.

Team Collaboration and Communication:

Effective collaboration and communication within the facility management team are vital for seamless operations and maintenance. Foster a culture of teamwork, encourage knowledge sharing, and promote open lines of communication between different departments and roles. This collaborative approach can lead to efficient problem-solving and improved system performance.

Conclusion:

Electromechanical systems form the backbone of facility management, and staffing considerations for operations and maintenance are crucial to ensure their reliable and efficient functioning. By understanding the workforce requirements, implementing effective recruitment strategies, prioritizing training and professional development.

#Water Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in India#Operation and Maintenance of Water Treatment#Operations and Maintenance in Facility Management#Water Treatment Plant Project#Sewage Treatment Plant Project#Effluent Treatment#Best Electromechanical Systems#Integrated Electronics and Mechanics

2 notes

·

View notes

Text

Jole Figliomeni has a charming personality with all traits of a good leader. Italians admire her a lot.

3 notes

·

View notes

Text

Secure Your Electrical Workplace with De-Electric Lockout Hasp

De-Electric Lockout Hasps are specifically designed for electrical lockout applications. These non-conductive hasps (nylon hasps) provide excellent protection against electrical energy during maintenance and repairing machines.

These LOTO Hasps are made from durable, non-metallic materials, de-electric hasps are essential for isolating electrical circuits and preventing accidental re-energization.

https://www.safetylock.net/lockout-tagout-devices/lockout-hasp/de-electric-hasp/

#De-Electric Lockout Hasp#De-Electric LOTO Hasps#Lockout Tagout Hasp#Lockout Safety Hasps#Lockout Hasp Supplier#Lockout Tagout Manufacturer#LOTO Supplier#E-Square Alliance

0 notes

Text

Jole Figliomeni has achieved a lot at such a young age that now she is helping others to lift their careers and become better humans.

6 notes

·

View notes

Text

What information must be included in a SWMS?

A Safe Work Method Statement (SWMS) is an important document that helps keep workers safe during high-risk construction work. Whether it’s for specific tasks like electrical work (Electrical SWMS) or general building projects (Construction SWMS), it needs to include certain key details to be effective and easy to use.

What Must Be Included in a SWMS?

Identify High-Risk Work: The SWMS must list the high-risk construction tasks being done. For example, an Electrical SWMS might cover live electrical work or wiring near power lines, while a Construction SWMS could include working at heights or using heavy equipment.

Point Out Hazards and Risks: The document should describe the dangers of the job. For electrical work, this could mean risks like electric shocks or fires. In general construction, hazards might include falling objects or unstable structures.

Explain How Risks Will Be Controlled: The SWMS should detail the steps to make the work safer. For electrical work, this might include turning off power, using insulated tools, and following lockout/tagout procedures. For construction work, it could involve setting up safety barriers or using harnesses.

Describe Monitoring and Review Steps: It’s important to explain how safety measures will be checked and updated as work progresses. Regular inspections and feedback from workers can help keep everything on track.

Tips for Writing a Good SWMS:

Keep It Simple: Focus on the specific tasks and hazards for the job. Avoid making the SWMS too long or complicated.

Make It Easy to Understand: Use clear language and include pictures or diagrams if needed, especially for workers who may not speak English fluently.

Read the full article to know more about the electrical and construction swms

0 notes

Text

A Beginner’s Guide to Operating a Centrifuge Separator

Centrifuge separators are a crucial component in various industries, including wastewater treatment, oil and gas, mining, and food processing. These machines use centrifugal force to separate solids from liquids, enabling the efficient removal of contaminants and pollutants from wastewater. Operating a centrifuge separator requires a good understanding of its components, principles, and procedures. In this article, we will provide a beginner's guide to operating a centrifuge separator, covering the essential steps and considerations for safe and effective operation.

Pre-Operational Checks

Before starting the centrifuge separator, it is essential to perform pre-operational checks to ensure that the machine is in good working condition. This includes checking the power supply, lubrication system, and cooling system. The operator should also inspect the centrifuge separator's components, such as the rotor, bearings, and seals, for any signs of wear or damage. Additionally, the operator should review the operating manual and manufacturer's instructions to understand the specific requirements and procedures for the particular centrifuge separator model.

Start-Up Procedure

The start-up procedure for a centrifuge separator involves several steps. First, the operator should ensure that the machine is properly installed and levelled. Next, the operator should connect the power supply and turn on the machine. The centrifuge separator will then begin to rotate, and the operator should monitor the machine's performance, checking for any unusual vibrations or noises. Once the machine has reached its operating speed, the operator can start feeding the wastewater or liquid into the centrifuge separator.

Operating Parameters

To ensure optimal performance, the operator should monitor and adjust the operating parameters of the centrifuge separator. This includes the rotational speed, flow rate, and pressure. The rotational speed should be adjusted to achieve the desired separation efficiency, while the flow rate should be adjusted to match the capacity of the centrifuge separator. The pressure should be monitored to ensure that it is within the recommended range, as excessive pressure can damage the machine.

Maintenance and Troubleshooting

Regular maintenance is essential to ensure the longevity and performance of the centrifuge separator. The operator should perform routine checks and maintenance tasks, such as cleaning the machine, replacing worn-out parts, and lubricating the bearings. Additionally, the operator should be able to troubleshoot common issues, such as vibration, noise, or reduced separation efficiency. The operator should consult the operating manual and manufacturer's instructions for guidance on maintenance and troubleshooting procedures.

Safety Considerations

Operating a centrifuge separator can be hazardous if proper safety precautions are not taken. The operator should wear personal protective equipment, such as gloves, safety glasses, and a face mask, to protect against potential hazards. The operator should also ensure that the machine is properly installed and levelled to prevent accidents. Additionally, the operator should follow proper lockout/tagout procedures when performing maintenance or repairs to prevent accidental start-up.

Shut-Down Procedure

The shut-down procedure for a centrifuge separator involves several steps. First, the operator should stop feeding the wastewater or liquid into the machine. Next, the operator should reduce the rotational speed and allow the machine to come to a complete stop. The operator should then disconnect the power supply and perform a final inspection of the machine to ensure that it is in good working condition.

Conclusion

In conclusion, operating a centrifuge separator requires a good understanding of its components, principles, and procedures. By following the pre-operational checks, start-up procedure, operating parameters, maintenance and troubleshooting, safety considerations, and shut-down procedure, operators can ensure safe and effective operation of the centrifuge separator. Remember to always consult the operating manual and manufacturer's instructions for specific guidance on operating and maintaining your centrifuge separator.

0 notes

Text

Key Components of an Effective Arc Flash Training Program

In industries where electrical hazards are a concern, safety is paramount. Arc flash incidents are among the most dangerous electrical hazards, capable of causing severe injuries, equipment damage, and even fatalities. To mitigate these risks, companies must implement an effective arc flash training program. This article outlines the essential components of such a program, ensuring compliance with safety standards and fostering a culture of safety.

What Is Arc Flash?

An arc flash is a sudden release of electrical energy caused by an electrical fault. This release can produce temperatures up to 35,000°F, vaporizing metal, creating intense pressure waves, and emitting bright flashes of light. These incidents can occur in various settings, including manufacturing facilities, data centers, and utility operations. Proper training equips employees with the knowledge to prevent and respond to these dangerous events.

Importance of Arc Flash Training

Arc flash training is vital to:

Protect Employees: Educate workers on recognizing hazards and using protective measures to reduce injury risk.

Ensure Compliance: Meet OSHA and NFPA 70E standards to avoid penalties and liability issues.

Prevent Downtime: Minimize operational disruptions by maintaining safety and avoiding costly accidents.

Key Components of an Effective Arc Flash Training Program

1. Regulatory Compliance and Standards

An effective program begins with a thorough understanding of relevant regulations, such as:

NFPA 70E: Sets the standard for electrical safety in the workplace.

OSHA Standards: Enforces employer responsibility to provide hazard-free workplaces.

Integrating these guidelines ensures the training meets legal and safety requirements.

2. Hazard Identification

Workers should learn to identify potential arc flash hazards in their environment. This includes:

Recognizing equipment prone to faults, such as switchgear or circuit breakers.

Understanding environmental factors (dust, moisture) that increase risk.

3. Risk Assessment Training

Training should include methods to assess and document risks. Employees must be able to:

Evaluate the severity of hazards.

Determine appropriate boundaries.

Use risk assessment to select the right safety measures.

4. Proper Use of Personal Protective Equipment (PPE)

A critical aspect of arc flash safety is PPE. Training should cover:

Types of PPE, such as arc-rated clothing, gloves, and face shields.

Proper selection based on the arc flash rating of equipment.

Inspection, maintenance, and replacement of PPE.

5. Safe Work Practices

Effective arc flash training emphasizes work practices that minimize risk:

De-energizing equipment before working.

Lockout/Tagout (LOTO) procedures.

Tools and equipment insulated for electrical work.

6. Incident Response and Emergency Procedures

Employees must know how to respond in the event of an arc flash:

Administering first aid or CPR to injured colleagues.

Evacuating safely from the hazard zone.

Reporting incidents for further investigation and prevention planning.

7. Practical Hands-On Training

Classroom instruction is crucial, but hands-on experience is equally important. Training should involve:

Simulated scenarios to practice hazard identification and safety protocols.

Demonstrations of proper PPE usage and equipment handling.

8. Periodic Refresher Courses

Arc flash training is not a one-time event. Regular updates ensure employees stay informed about:

Changes in safety regulations.

New equipment or workplace hazards.

Lessons learned from past incidents.

9. Documentation and Recordkeeping

Proper documentation helps track training effectiveness and compliance:

Maintain records of training sessions and attendee participation.

Document assessments, incidents, and updates to safety protocols.

Benefits of an Effective Arc Flash Training Program

An effective program offers numerous benefits:

Reduced Accidents: Lower risk of injury and fatalities.

Increased Awareness: Employees are more vigilant and proactive about safety.

Enhanced Productivity: A safer workplace minimizes downtime and boosts morale.

Regulatory Compliance: Avoid penalties by adhering to OSHA and NFPA guidelines.

Investing in an arc flash training program is essential for organizations that work with electrical systems. By focusing on hazard awareness, safe work practices, and compliance, businesses can create a safer environment for employees while protecting assets and operations.

For companies looking to establish or refine their training programs, partnering with experts in electrical safety ensures comprehensive and effective results. Remember, safety is not just a requirement it’s a responsibility.

0 notes