#SS Coils

Explore tagged Tumblr posts

Text

Supplier of SS Coils in India

Supplier of SS Coils in India: In India, stainless steel coils are manufacturer, supplied, and stocked by Meghmani Metal. We offer stainless steel coils in Ahmedabad. We produce these Stainless Steel Coils at our cutting-edge manufacturing facilities using premium materials. We have extensive experience in manufacturing and shipping Stainless Steel Coils across the globe. The industry highly…

View On WordPress

0 notes

Text

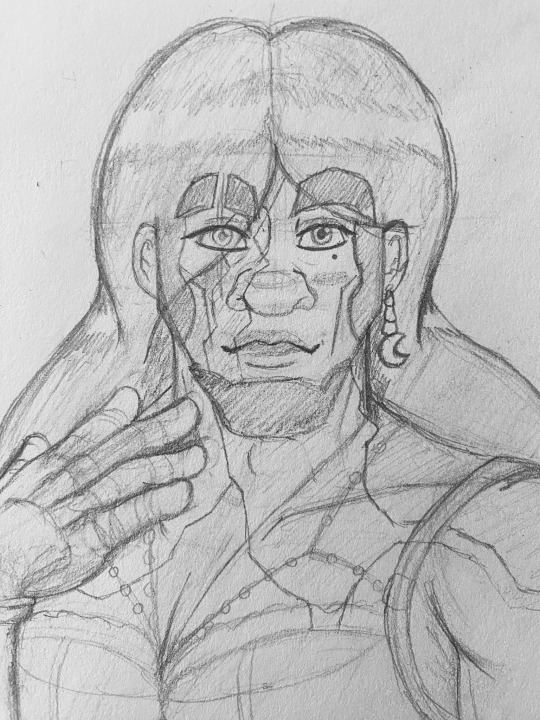

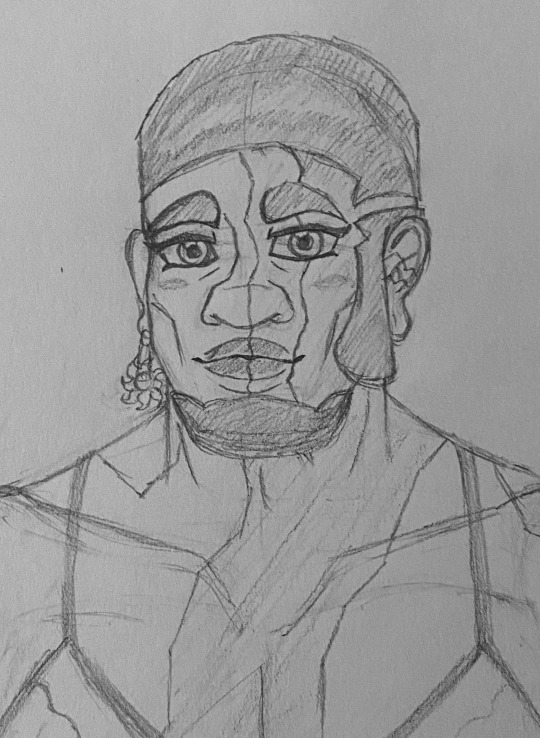

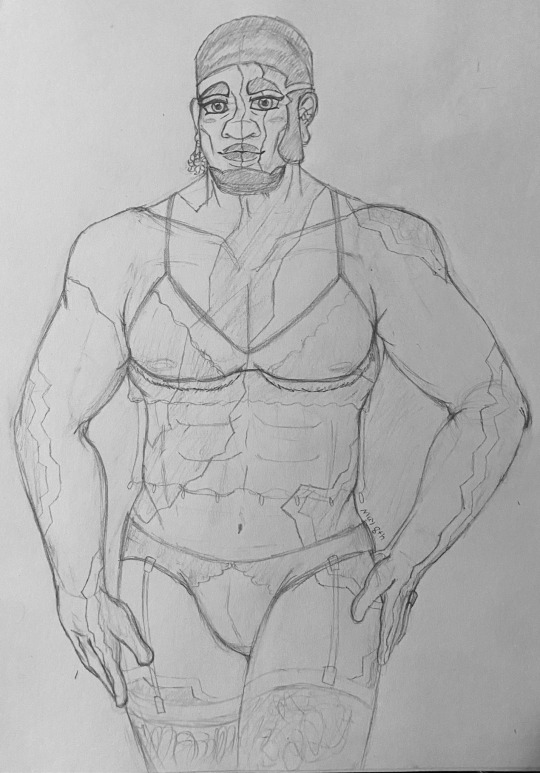

Sooo, I mentioned yesterday I sketched something that I wished I could sketch like that everyday. Well, I made another one cause it is a pair, but it is kind of suggestive.

Here’s some previews, the sketches and references will be underneath the read more. It’s got guys in lingerie, if you want the TL;DR.

I ain’t putting this in the main tag, I’m a little embarrassed but hell, I’ve been wanting to draw this for a while so I’m glad I could. (Edit: Screw it, I'm putting it in the #thsc oc tag at least because I really like what I drew goddamnit)

Accordion ⬆️ and Violin ⬇️

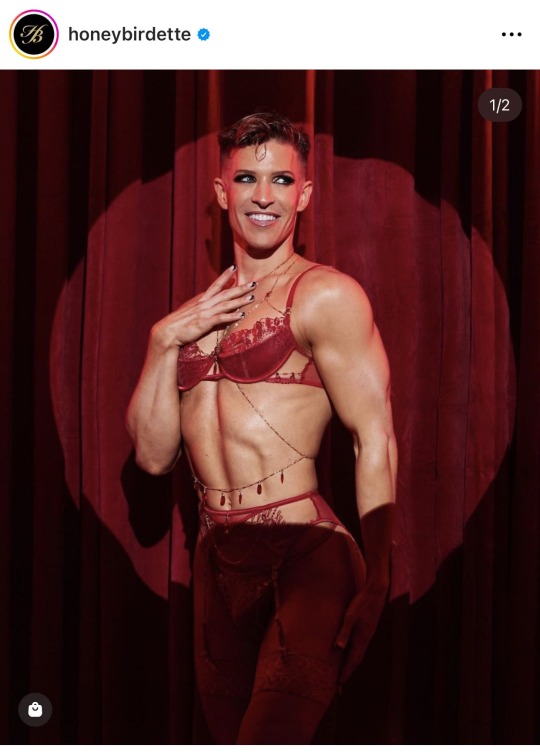

And references are below: I used photos of non-binary burlesque performer and trainer, Jake Dupree. I don’t have the pic that I used for Violin’s lingerie set, but I did want to make it different from Accordion’s.

Fun fact: Accordion started wearing lingerie in secret because he liked how he looked and felt in it, but gained more courage when Violin saw him dressed up in it one night. Violin doesn’t like wearing lingerie, but he will wear it on special occasions with Accordion, since he feels safe in doing so.

Will I render these sketches? I’d love to, but I HATE ruining sketches that look REAL good. If I have the courage to do so, I will. But for now, enjoy the sketches. Was this an excuse to draw bodies and muscles again? Damn right, but I sure as hell ain’t going to get sloppy on that department, especially in drawing humans.

#bluetorchsky#bluetorchsky sketches#thsc oc#henry stickmin oc#thsc accordion#thsc violin#oliver arc#trent coil#lingerie#idk if i should even be tagging that#but to hell with it#i frigging love accordion’s a bit more#i almost made violin a bit too wide#but hey if i ever render i’ll fix that#and yes#can also apply to ss au

33 notes

·

View notes

Text

Stainless Steel Coil Manufacturers in India | ASTM A240 SS Coil Supplier

India is renowned for its strong presence in the steel industry, particularly in stainless steel coils, which are used across a broad spectrum of applications, including manufacturing, construction, automotive, and more. Indian manufacturers are known for delivering high-quality stainless steel coils adhering to international standards, especially the ASTM A240 specification, which guarantees superior quality and durability. In this article, we’ll explore the leading stainless steel coil manufacturers in India and highlight the growing demand for stainless steel coils in various industries.

Why Choose Stainless Steel Coils?

Stainless steel coils have become a crucial component across multiple industries due to their resistance to corrosion, durability, and sleek finish. Available in various grades and finishes, such as Stainless Steel 304 2B Finish Coils and UNS S31600 Stainless Steel Coils, these coils offer superior mechanical properties. Their applications range from kitchenware to architectural structures, automotive parts, and even specialized uses like stainless steel coil for hot tubs and spring stainless steel strip manufacturing.

Top Stainless Steel Coil Manufacturers in India

India’s stainless steel coil manufacturing sector is home to several reputable manufacturers. These manufacturers produce coils that meet stringent quality standards, ensuring durability, aesthetic appeal, and cost-efficiency. Here’s a closer look at one of the leaders:

Sonic Steel - A Reliable Name in Stainless Steel Coils

As a premier stainless steel coil supplier and exporter, Sonic Steel specializes in a wide array of stainless steel coils, including Stainless Steel 304 2B Finish Coils and UNS S31600 Stainless Steel Coils. With a commitment to quality and customer satisfaction, Sonic Steel stands out for offering coils in various grades and finishes that cater to both domestic and international markets. Sonic Steel’s coils are widely used in applications demanding exceptional resistance and longevity, ensuring they meet ASTM A240 standards, a benchmark in stainless steel quality.

Key Products Offered by Sonic Steel

Stainless Steel 304 2B Finish Coils: Known for its smooth finish and versatility, the 304 grade is ideal for environments prone to moisture.

UNS S31600 Stainless Steel Coils: This grade is popular for its enhanced corrosion resistance, making it suitable for harsh environments.

Flat Stainless Steel Coils: These coils are widely used in construction and industrial applications due to their strength and aesthetic appeal.

Spring Stainless Steel Strip: Ideal for precision engineering, these strips are popular in the automotive and aerospace sectors.

To explore the complete range, visit Sonic Steel.

Factors Affecting Stainless Steel Coil Prices

When investing in stainless steel coils, it's essential to consider factors like grade, finish, and application. Stainless Steel Coil Price can fluctuate based on market demand, the grade of steel, and additional processing requirements. Coils manufactured from high-grade materials, like UNS S317008 Finish Coils, often come at a premium but deliver longer-lasting performance in challenging environments.

High-Demand Applications for Stainless Steel Coils

Stainless steel coils are indispensable in various industries due to their adaptability and resistance to wear and tear. They are a preferred choice in:

Automotive Manufacturing: Flat stainless steel coils and precision-grade strips are crucial in producing parts that withstand rigorous use.

Construction: Architectural structures and facades benefit from the corrosion resistance of stainless steel, making it a popular choice for modern buildings.

Industrial Equipment: Heat-resistant stainless steel coils are often used in equipment for food processing, chemical, and pharmaceutical industries.

Consumer Goods: Coils are used in household appliances, cutlery, and furniture due to their aesthetic appeal and durability.

Conclusion

The stainless steel coil industry in India has shown significant growth, with manufacturers like Sonic Steel leading the way in quality and innovation. From Stainless Steel 304 2B Finish Coils to UNS S31600 Stainless Steel Coils, Sonic Steel’s range caters to a vast array of industries, meeting both domestic and international standards.

If you're in search of high-quality stainless steel coils that meet ASTM standards, explore the vast range available at Sonic Steel.

#Stainless Steel Coil#Hot Rolled Coil#Steel Coil Manufacturers#Cold Rolled Coil#Stainless Steel Coils Manufacturer#Stainless Steel 304 Coils#Stainless Steel 310 Coils#Stainless Steel 316 Coils#Stainless Steel 347 Coils#904 Stainless Steel Coils#Perforated Stainless Steel Strip#SS Coils Exporter#Hot Rolled Stainless Steel Coils Stockist#Cold Rolled Stainless Steel Coils Exporter#Hot Rolled 201 Stainless Steel Coils#Stainless Steel 201 Coils manufacturer#AISI SS 310 2D Finish Coils#ASTM A167 201 Stainless Steel Coils Supplier

0 notes

Text

SA387 Grade 11 Alloy Steel: Key Features and Industrial Applications

In the world of industrial materials, SA387 Grade 11 Alloy Steel is renowned for its exceptional ability to withstand high temperatures, pressures, and corrosive environments. This chromium-molybdenum alloy steel has become a staple in industries such as petrochemicals, power generation, and oil and gas. This blog will explore the key features of SA387 Grade 11 Alloy Steel and its widespread applications, demonstrating why it remains a material of choice for engineers and industry professionals.

1. Composition and Characteristics of SA387 Grade 11 Alloy Steel

SA387 Grade 11 is part of the ASTM A387 family, a specification for pressure vessel plates made from chromium-molybdenum alloy steel. Its composition is specifically designed to enhance its mechanical properties, making it suitable for high-stress environments.

Key Elements of SA387 Grade 11:

Chromium (Cr): 1.00-1.50%

Molybdenum (Mo): 0.45-0.65%

Carbon (C): 0.05-0.17%

Manganese (Mn): 0.30-0.60%

Silicon (Si): 0.50% max

Phosphorus (P) and Sulfur (S): 0.025% max each

This chemical composition gives SA387 Grade 11 its distinct properties, particularly its ability to maintain strength and durability at elevated temperatures. The chromium content provides resistance to oxidation and corrosion, while molybdenum enhances the steel's strength and heat resistance.

2. Key Features of SA387 Grade 11 Alloy Steel

SA387 Grade 11 Alloy Steel is known for several key features that make it ideal for use in demanding industrial applications.

High-Temperature Strength: One of the standout features of SA387 Grade 11 is its ability to retain its mechanical strength at high temperatures. This makes it an excellent choice for applications involving heat, such as in power plants and chemical processing facilities, where materials are exposed to sustained high temperatures.

Corrosion and Oxidation Resistance: The presence of chromium in SA387 Grade 11 provides excellent resistance to corrosion and oxidation, even in harsh environments. This is particularly important in industries where the material is exposed to corrosive chemicals or gases.

Toughness and Ductility: SA387 Grade 11 offers a balance of toughness and ductility, which is crucial for applications that involve high pressures and temperatures. The alloy can absorb significant energy without fracturing, making it a reliable material for critical components such as pressure vessels and boilers.

Versatility in Heat Treatment: The alloy’s mechanical properties can be further enhanced through heat treatment processes such as annealing, quenching, and tempering. These treatments allow engineers to tailor the material’s properties to specific applications, ensuring optimal performance in various conditions.

Good Weldability: Despite its high strength and toughness, SA387 Grade 11 is relatively easy to weld. This feature is crucial for the fabrication of large structures or components that require precise and reliable welding.

3. Industrial Applications of SA387 Grade 11 Alloy Steel

SA387 Grade 11 Alloy Steel is extensively used in industries that require materials capable of withstanding extreme conditions. Here’s a look at some of its most common applications:

Petrochemical Industry: In the petrochemical sector, SA387 Grade 11 is widely used for the construction of pressure vessels, reactors, and heat exchangers. These components must endure high temperatures and pressures, as well as exposure to corrosive substances. The alloy’s high-temperature strength and corrosion resistance make it an ideal choice for these demanding applications.

Power Generation: SA387 Grade 11 is a critical material in the power generation industry, particularly in the construction of boilers and steam turbines. These components operate under extreme conditions, with temperatures often exceeding 500°C. The alloy’s ability to maintain its strength and resist oxidation at high temperatures ensures the safe and efficient operation of power plants.

Oil and Gas Industry: The oil and gas industry often involves challenging environments, where materials are exposed to high pressures, corrosive substances, and fluctuating temperatures. SA387 Grade 11 is used in the fabrication of pipelines, pressure vessels, and separators. Its corrosion resistance and mechanical strength make it suitable for both onshore and offshore applications.

Industrial Boilers: The construction of industrial boilers requires materials that can withstand high temperatures and pressures. SA387 Grade 11 is a popular choice for boiler manufacturing due to its high-temperature strength and ability to resist oxidation. This ensures the longevity and reliability of boilers in various industrial settings.

Heat Exchangers: Heat exchangers are critical components in many industrial processes, where efficient heat transfer is essential. SA387 Grade 11 is often used in the construction of heat exchangers due to its thermal stability and resistance to corrosion, ensuring efficient operation and minimal maintenance.

Pressure Vessels: Pressure vessels are used to store and transport gases or liquids under high pressure. The safety and reliability of these vessels depend on the material used in their construction. SA387 Grade 11 is commonly used in pressure vessels due to its high strength, toughness, and resistance to high temperatures and pressures.

4. Heat Treatment Processes and Their Impact

The performance of SA387 Grade 11 Alloy Steel can be significantly enhanced through various heat treatment processes. Each process alters the microstructure of the alloy, thereby changing its mechanical properties to suit specific industrial needs.

Annealing: Annealing involves heating the alloy to a specific temperature and then cooling it slowly. This process enhances the ductility and reduces the hardness of the material, making it easier to shape and fabricate.

Quenching: Quenching involves heating the alloy to a high temperature and then rapidly cooling it in water or oil. This process increases the hardness and strength of the alloy but can also make it more brittle.

Tempering: After quenching, tempering is often used to reduce brittleness while maintaining strength. This process involves reheating the alloy to a temperature below its critical point and then cooling it slowly. Tempering improves the toughness of the material, making it more resistant to impact and stress.

Stress Relieving: Stress relieving is a heat treatment process that involves heating the alloy to a temperature below its critical point and then cooling it slowly. This process reduces residual stresses in the material, improving its dimensional stability and resistance to cracking.

Each of these heat treatment processes can be applied to SA387 Grade 11 Alloy Steel to optimize its performance for specific applications, ensuring that the material meets the stringent requirements of various industries.

5. Conclusion

SA387 Grade 11 Alloy Steel is a versatile and reliable material that plays a critical role in industries where high performance under extreme conditions is essential. Its key features, including high-temperature strength, corrosion resistance, toughness, and weldability, make it an ideal choice for demanding applications in the petrochemical, power generation, and oil and gas industries.

The alloy’s ability to undergo various heat treatment processes further enhances its versatility, allowing it to be tailored to meet the specific needs of different applications. Whether it’s in the construction of pressure vessels, industrial boilers, or heat exchangers, SA387 Grade 11 Alloy Steel stands out as a material that delivers exceptional performance, ensuring safety, efficiency, and durability in the most challenging environments.

Bhavya Steel House of Stainless Steel

#stainless steel 409 sheet plates coils#sa 387 gr 11 in pune#sa387 grade 11 alloy steel#ss 387 grade 11 sheets#sa 387 gr 11 chemical composition#gr 11#ss347#alloy steel plates suppliers in mumbai#alloy steel grade#what are alloy steel#alloy steel type#low alloy steels#alloys steel#steel alloy grades#alloy steel material properties#gr steel

0 notes

Text

SA 387 Grade 11 Sheets: Top Applications in High-Temperature Industries

SA 387 Grade 11 sheets are essential in high-temperature environments due to their excellent heat and corrosion resistance. Composed primarily of chromium and molybdenum, these alloy sheets are highly sought after in various demanding industries, including petrochemicals, power generation, oil refining, and chemical processing.

1. Overview of SA 387 Grade 11

SA 387 Grade 11 is a pressure vessel quality steel alloy designed for high temperatures. Its composition enhances oxidation resistance and mechanical strength, making it ideal for extreme conditions.

2. Applications in Petrochemical Industries

Heat Exchangers: These sheets ensure safe operation at elevated temperatures.

Pressure Vessels: They withstand extreme pressure and high temperatures.

Boilers: Used in steam generation, they maintain structural integrity under continuous heat.

3. Power Generation Industry

Boilers and Boiler Tubes: Essential for coal and gas-fired plants, these sheets resist creep and ensure long-term reliability.

Steam Turbine Components: High heat tolerance extends the life of critical components.

4. Oil Refineries

Distillation Columns: Constructed from SA 387 Grade 11, these columns operate under high temperatures and corrosive conditions.

Reactors: They endure high-temperature reactions and are vital for operational longevity.

5. Chemical Processing Plants

Reactor Vessels: Handle high temperatures and pressures without degrading.

Piping Systems: Manufactured to endure extreme conditions while transporting corrosive fluids.

6. Advantages of SA 387 Grade 11

High Tensile Strength: Withstands mechanical stresses.

Creep Resistance: Essential for prolonged heat exposure.

Corrosion Resistance: Extends equipment life in harsh environments.

Thermal Conductivity: Maintains structural integrity under heat.

Conclusion

SA 387 Grade 11 sheets are crucial for industries requiring materials that can handle high temperatures and corrosive conditions. Their unique properties make them a reliable choice for enhancing safety and efficiency in demanding applications. For more information, contact Bhavya Steel House of Stainless Steel.

Bhavya Steel House of Stainless Steel

#- stainless steel 409 sheet plates coils#sa 387 gr 11 in pune#sa387 grade 11 alloy steel#ss 387 grade 11 sheets#sa 387 gr 11 chemical composition#gr 11#ss347#alloy steel plates suppliers in mumbai#alloy steel grade#what are alloy steel#alloy steel type#low alloy steels#alloys steel#steel alloy grades#alloy steel material properties#gr steel

0 notes

Text

Discover SA387 Alloy Steel Grade 11 at Bhavya Steel. Ideal for high-temperature environments, this alloy offers exceptional heat resistance and durability for pressure vessels and boilers. Explore our solutions for power generation and petrochemical industries.

#stainless steel 409 sheet plates coils#sa 387 gr 11 in pune#sa387 grade 11 alloy steel Chennai#ss 387 grade 11 sheets Saudi#ss347 Kolkata#sa 387 gr 11 chemical composition Dubai#alloy steel plates suppliers in Mumbai#gr 11#alloy steel grade#what are alloy steel#alloy steel type#low alloy steels Ahemdabad#alloys steel Oman#steel alloy grades#alloy steel material properties#gr steel Delhi

0 notes

Text

The Role of 387 Grade Steel in Power Generation and Petrochemical Industries

Introduction

Materials that can withstand extreme environments are vital in the modern industrial landscape. The power generation and petrochemical industries, in particular, operate under conditions involving high temperatures, intense pressures, and exposure to corrosive substances. These demanding environments require materials with exceptional strength, durability, and resistance to degradation. Among the materials that have proven indispensable in these sectors is 387 Grade Steel. This alloy steel, known for its enhanced performance under high-temperature conditions, is a cornerstone in constructing pressure vessels, boilers, and other critical infrastructure.

Understanding 387 Grade Steel

387 Grade Steel is a chromium-molybdenum alloy steel designed for high-temperature service. It is primarily available in two grades: Grade 11 and Grade 22. Each grade is tailored to meet specific requirements, making this steel versatile for various industrial applications.

Grade 11: Contains approximately 1-1.5% chromium and 0.5-1% molybdenum. It is designed for environments where moderate temperature resistance is needed.

Grade 22: Contains around 2.25% chromium and 1% molybdenum, providing superior performance in more demanding environments. Grade 22 is ideal for applications where high-temperature strength and resistance to corrosive environments are critical.

The chemical composition of 387-grade steel gives it a unique combination of properties that make it suitable for use in extreme environments. The chromium provides corrosion resistance, while the molybdenum enhances its strength and resistance to creep (slow deformation under stress).

Key Properties of 387 Grade Steel

The outstanding properties of 387-grade steel make it a preferred material in the power generation and petrochemical industries. Key properties include:

High-Temperature Strength: 387 Grade Steel maintains strength and structural integrity at elevated temperatures, crucial for applications like boilers and pressure vessels.

Corrosion Resistance: Chromium content provides excellent resistance to oxidation and corrosion, essential in environments exposed to steam, chemicals, and other corrosive substances.

Creep Resistance: Molybdenum enhances creep resistance, ensuring the material retains its shape and functionality over time, even under extreme conditions.

Fabrication Versatility: 387-grade steel can be easily welded, machined, and formed into various shapes and sizes, making it a popular choice for manufacturers.

Applications in Power Generation

In power generation, particularly in thermal power plants, materials are subjected to some of the most extreme conditions in any industrial setting. 387 Grade Steel is ideally suited for these applications due to its robust properties.

Boilers and Pressure Vessels: Boilers convert water into steam to drive turbines and generate electricity. The high-temperature strength and creep resistance of 387-grade steel makes it ideal for constructing boilers and pressure vessels, ensuring they can withstand extreme conditions.

Heat Exchangers: Heat exchangers transfer heat from one fluid to another without mixing them. The material used must resist thermal fatigue and corrosion, both of which are key characteristics of 387 387-grade steel.

Steam Drums and Superheaters: These components operate under high pressures and temperatures, making 387-grade steel an ideal material due to its high creep resistance and thermal stability.

Applications in the Petrochemical Industry

The petrochemical industry processes hydrocarbons, often at high temperatures and pressures. Materials must resist corrosive effects and stress from extreme operational conditions. 387 Grade Steel is widely used in various critical applications due to its resistance to corrosion and high-temperature strength.

Reactors and Pressure Vessels: Reactors and pressure vessels process chemicals at high temperatures. 387 Grade Steel’s properties ensure safe and efficient operation.

Storage Tanks: Storage tanks hold chemicals at elevated temperatures. 387 Grade Steel is used for these tanks due to its thermal and corrosion resistance.

Heat Exchangers and Piping Systems: 387 Grade Steel is also used in heat exchangers and piping systems that transport high-temperature fluids, providing a reliable and durable solution.

Advantages of Using 387-Grade Steel

Using 387 Grade Steel in power generation and petrochemical industries offers several advantages:

Longevity and Reliability: The durability of 387-grade steel ensures a long service life, reducing the need for frequent replacements and maintenance.

Safety: 387 Grade Steel’s high-temperature strength, creep resistance, and corrosion resistance contribute to the safe operation of power plants and petrochemical facilities.

Cost-Effectiveness: The material’s durability and performance in extreme conditions result in significant cost savings over time.

Environmental Impact: The material’s long service life reduces the environmental impact associated with manufacturing and disposal.

Conclusion

387 Grade Steel plays a crucial role in the power generation and petrochemical industries, providing the necessary strength, durability, and resistance to withstand extreme conditions. Its ability to maintain structural integrity at high temperatures, resist corrosion, and withstand prolonged stress makes it indispensable in constructing boilers, pressure vessels, heat exchangers, and other critical infrastructure. As these industries continue to evolve, 387-grade steel will undoubtedly remain a material of choice for engineers and manufacturers alike.

Bhavya Steel House of Stainless Steel

visit at: https://bhavyasteel.in/

#stainless steel 409 sheet plates coils#sa 387 gr 11 in pune#sa387 grade 11 alloy steel Chennai#ss 387 grade 11 sheets Saudi#ss347 Kolkata#sa 387 gr 11 chemical composition Dubai#alloy steel plates suppliers in Mumbai#gr 11#alloy steel grade#what are alloy steel#alloy steel type#low alloy steels Ahemdabad#alloys steel Oman#steel alloy grades#alloy steel material properties#gr steel Delhi

0 notes

Text

Guide to Stainless Steel 409: Properties, Composition, and Applications

Introduction

Stainless Steel 409 is a ferritic stainless steel prized for its cost-effectiveness and high-temperature resistance. Unlike grades such as 304, it is not designed for superior corrosion resistance but excels in environments where oxidation and high temperatures are concerns.

Chemical Composition

Chromium (Cr): 10.5-11.75%

Nickel (Ni): ≤0.5%

Carbon (C): ≤0.08%

Manganese (Mn): ≤1.0%

Silicon (Si): ≤1.0%

Phosphorus (P): ≤0.045%

Sulfur (S): ≤0.03%

This composition provides 409 stainless steel with adequate oxidation resistance, particularly in elevated temperatures.

Properties

Corrosion Resistance: Moderate, not as high as grades like 304 or 316.

High-Temperature Resistance: Up to 675°C (1247°F) continuously; 815°C (1499°F) intermittently.

Weldability: Good, suitable for various welding techniques.

Formability: Easily shaped into sheets, plates, and coils.

Applications

Automotive Industry: Exhaust systems, catalytic converters, and mufflers.

Construction: Structural components with moderate corrosion resistance.

Heat Exchangers: Tubes and components for high-temperature use.

Agricultural Equipment: Parts requiring durability and moderate corrosion resistance.

Comparisons with Other Stainless Steels

Stainless Steel 304: Known for its excellent corrosion resistance due to higher chromium (18%) and nickel (8%). More expensive but ideal for food processing, marine applications, and chemical processing.

Alloy Steel SA 387 Grade 11: Used in pressure vessels and industrial boilers, valued for its strength at high temperatures and good corrosion resistance.

SS 430: A ferritic steel with good corrosion resistance, used in automotive trim and appliances.

SS 410: Martensitic steel with high strength, used in cutlery and valves, containing 11.5-13.5% chromium.

SS 347: Austenitic steel with added columbium for enhanced corrosion resistance in high-temperature settings.

Specialty Products

Hardox Plate: Known for wear resistance, used in mining equipment and material handling.

Sheet Lead: Used for radiation shielding and soundproofing, with prices varying by thickness and size.

Stainless Steel 304 Flanges: Connects pipes and equipment with excellent corrosion resistance.

Conclusion

Stainless Steel 409 is a versatile material suited for high-temperature applications and cost-effective solutions. It may not match the corrosion resistance of grades like 304, but it is an excellent choice for specific industrial needs. For more information, visit Bhavya Steel.

#stainless steel 409 sheet plates coils#Stainless 304 Sheets in Pune#stainless steel 304 price#ss304 stainless steel#sa 387 gr 11 in pune#sa387 grade 11 alloy steel#ss 409 sheets plates coils#sa 387 grade 11 sheets#ss 430#ss 410 sheets#ss 410#ss347#hardox plate#sheet lead price#ss410s chemical composition#grades of stainless steel#stainless steel grades#stainless steel 347#ss grades#ss430 chemical composition#stainless steel 304 flanges#lead sheeting price

0 notes

Text

Best Quality Stainless Steel Coil Supplier in India

Metal Supply Centre is one of the top quality Stainless Steel Coil Suppliers in India. Due to its outstanding strength and corrosion resistance, stainless steel coils are a remarkable alloy that has acquired a reputation throughout several industrial sectors. Coils made of stainless steel, one of the material's several forms, demonstrate the material's durability and adaptability. For demanding applications where quality is paramount, stainless steel coils are the material of choice because of their long-term reliability and durability.

Stainless steel coils are changing the industrial sector with their many benefits, which include increased production efficiency, reliable technology, modification, corrosion resistance, high-temperature performance, hygienic solutions, and environmental sustainability. We are also a widely known Stainless Steel 439 Coil Manufacturer in India.

For more detail,visit

Website: metalsupplycentre.com

Product source: SS Coil Suppliers in India.

#Stainless Steel Coil Suppliers in India#Stainless Steel 439 Coil Manufacturer in India#SS Coil Suppliers in India#Stainless steel coils

0 notes

Text

Exploring the Versatility and Benefits of Stainless Steel Coil Tubes

Stainless steel coil tubes are indispensable components in various industrial applications, prized for their durability, corrosion resistance, and versatility. From heat exchangers to instrumentation, these tubes play a crucial role in numerous processes across diverse industries. Let's explore the intricacies of stainless steel coil tubes, their uses, benefits, and why they're the preferred choice for many applications.

Stainless steel coil tubes are precisely engineered cylindrical structures made from high-quality stainless steel alloys. They are manufactured by winding stainless steel strips into a continuous coil and then welding the edges to form a seamless tube. This unique construction offers several advantages over traditional straight tubes, making them ideal for various applications.

Application of Stainless Steel Coil Tubes

Heat Exchangers: Stainless steel coil tubes are commonly used in heat exchangers due to their excellent thermal conductivity and corrosion resistance. They efficiently transfer heat between two fluids without risk of contamination or degradation.

Instrumentation and Control Systems: In industries such as pharmaceuticals, food processing, and chemical manufacturing, stainless steel coil tubes are essential components in instrumentation and control systems. Reliability and precision make them suitable for measuring and regulating fluid flow, temperature, and pressure.

Hydraulic and Pneumatic Systems: These tubes are also integral to hydraulic and pneumatic systems, where they facilitate the transmission of fluids and gases under high pressure. Their resistance to corrosion and high temperatures ensures long-term performance and safety in demanding environments.

Oil and Gas Industry: SS coil tubes are used in piping systems for transporting crude oil, natural gas, and various chemicals in oil refineries, petrochemical plants, and offshore drilling operations. Their durability and resistance to corrosion make them well-suited for these harsh environments.

Benefits of Stainless Steel Coil Tubes

Corrosion Resistance: Stainless steel coil tubes exhibit exceptional corrosion resistance, making them suitable for applications where exposure to corrosive substances is daily.

High Strength: These tubes are manufactured from high-strength stainless steel alloys, providing excellent structural integrity and durability, even under extreme conditions.

Ease of Installation: The flexible nature of coil tubes allows easy installation in tight spaces and complex configurations, reducing the need for additional fittings and minimizing installation time and costs.

Customization: Stainless steel coil tubes can be customized in dimensions, wall thickness, and surface finish to meet specific application requirements, ensuring optimal performance and efficiency.

Conclusion

Stainless steel coil tubes are indispensable components in various industrial sectors, offering unmatched durability, corrosion resistance, and versatility. Whether in heat exchangers, instrumentation systems, or hydraulic applications, these tubes play a vital role in ensuring the efficiency and reliability of critical processes. With their numerous benefits and customizable options, stainless steel coil tubes are preferred for engineers and manufacturers seeking high-performance tubing solutions.

0 notes

Text

We are the most well-known stockists and suppliers of stainless steel sheets and coils is Accurate steels. Our stainless steel sheets are offered at market-leading costs in a variety of standards, thicknesses, widths, lengths, surfaces, finishes, forms, and other requirements depending on the demands of the customer.

Visit- https://accuratesteels.com

Contact- +91 9999086183

#stainlesssteel#steelsheets#jindalsteel#316steel#qualitysteel#delhi#ss sheet#accuratesteel#stockist of steel#coil stockist

1 note

·

View note

Text

Stainless Steel 310H Coils Suppliers

#Stainless Steel 310H Coils Manufacturers#Stainless Steel 310H Coils Exporters#Stainless Steel 310H Coils Suppliers#Stainless Steel 310H Coils Importers#Stainless Steel 310H Coils Stockists#Stainless Steel 310H Coils Manufacturers in Mumbai#Stainless Steel 310H Coils Exporters in Mumbai#Stainless Steel 310H Coils Suppliers in Mumbai#Stainless Steel 310H Coils Importers in Mumbai#Stainless Steel 310H Coils Stockists in Mumbai#Stainless Steel 310H Coils Manufacturers in India#Stainless Steel 310H Coils Exporters in India#Stainless Steel 310H Coils Suppliers in India#Stainless Steel 310H Coils Importers in India#Stainless Steel 310H Coils Stockists in India#SS 310H Coils#SS 310H Circle#310H SS Chequered Plate Exporter

0 notes

Text

Introducing 347 Stainless Steel Coils: a durable solution for various industrial applications. With excellent corrosion resistance and high temperature strength, these coils offer reliability and longevity. Ideal for aerospace, chemical, and petrochemical industries. #StainlessSteel #Coils #Industrial #Durability

#Stainless Steel 347 Coil#Stainless Steel 347 3/4 Hard Coil#UNS S34700 Coil#ASTM A240 Stainless Steel 347 Coil#DIN 1.4550 Coil#347 Stainless Steel 1/4 Hard Coil#SS 347 Full Hard Coil

0 notes

Text

#Stainless Steel Coil#Hot Rolled Coil#Steel Coil Manufacturers#Cold Rolled Coil#Stainless Steel Coils Manufacturer#Stainless Steel 304 Coils#Stainless Steel 310 Coils#Stainless Steel 316 Coils#Stainless Steel 347 Coils#904 Stainless Steel Coils#Perforated Stainless Steel Strip#SS Coils Exporter#Hot Rolled Stainless Steel Coils Stockist#Cold Rolled Stainless Steel Coils Exporter#Hot Rolled 201 Stainless Steel Coils#Stainless Steel 201 Coils manufacturer#AISI SS 310 2D Finish Coils#ASTM A167 201 Stainless Steel Coils Supplier

0 notes

Text

Buy the Best Stainless Steel 409 Sheet Plate Coil - SPP Alloys

Are you in search of high-quality stainless steel 409 sheet plates coils ? Then, SPP Alloys is the place to be! SPP Alloys is a reliable manufacturer and supplier of stainless steel products, which offers a wide range of high-quality ss 409 sheet plates coils. They are committed to providing excellent products that are of superior quality and long-lasting. Whether you require these sheets, plates or coils for industrial purposes or any other use, SPP Alloys has got you covered. Their website sppalloys.com provides an easy way to explore their vast collection and make purchases. Trust SPP Alloys for all your stainless steel 409 sheet plate coil needs and enjoy quality in both products and services. Go to sppalloys.com today and experience the lasting quality of their stainless steel products.

0 notes

Text

0 notes