#SAP Business One for Manufacturers

Explore tagged Tumblr posts

Text

Your Premier Choice for Manufacturing ERP Solutions in Vadodara, Gujarat | shantitechnology

Discover the power of streamlined operations with STERP (ShantiTechnology), the leading provider of cutting-edge ERP software solutions for manufacturing companies in Gujarat. Unlock efficiency, enhance productivity, and maximize profitability with our comprehensive suite of ERP tools. Join a league of industry leaders who trust STERP to transform their businesses in Vadodara and beyond. From seamless inventory management to real-time analytics, STERP empowers you to stay ahead in today's competitive landscape. Experience unparalleled support and customization options that cater to your unique business needs.

Unlock your company's full potential with STERP today.

#Manufacturing ERP software in Gujarat#ERP software companies in Vadodara#ERP software providers in Vadodara#ERP for manufacturing company in Gujarat#ERP software in Vadodara#ERP software#ERP system#cloud ERP#ERP solutions#ERP software for engineering#business process#management software#business and management#business analytics#business analyst#ERP India#Business Solutions#SAP Business One#Supply Chain Management#Go-To-Market

5 notes

·

View notes

Text

Make manufacturing simple with SAP Business One Cloud! 🌟 Plan and track your work, check for missing materials, and keep everything running smoothly. It's like having a smart helper to make sure you finish on time and save money too

#sap b1#cloud erp#sap erp#clouderp#sap business one#erpsolutions#erp software#erp for small business#sapbusinessone#cloud partner#manufacturing erp#manufacturing industries#manufacturing erp software#manufacturing with netsuite#services#industry#industries#manufacturing supply company#warehouse#development#manufacturing consent

0 notes

Text

Why ERP's Major Role in 4.O Manufacturing Industry?

Major Role of ERP for 4.O Manufacturing Industry

Today, the manufacturing industry is changing faster than ever before, and this has been accelerated by the coming of the fourth industrial revolution. This new one is said to be the fourth industrial revolution which integrates complex manufacturing with intelligent systems. To support this transition, Enterprise Resource Planning (ERP) systems including SAP Business One has gained centrality. They make work easy, faster, and even enable real-time analysis of data that is being captured. To maintain competitiveness and innovativeness of the 4.O manufacturing industries, companies are implementing ERP to respond and perform well to these changes.

Understanding ERP Systems in Manufacturing

You might have often thought about how the modern manufacturing companies keep all the running going. Enter ERP systems! ERP stands for Enterprise Resource Planning: it is like the brains of the manufacturing operations . It allows companies to make efficient decisions in order to control and/or develop all organizational fields. So let’s take a closer look at what makes ERP tick in the manufacturing environment.

Definition and Components of ERP

ERP systems are integrated application systems that attempt to achieve a single year of operations and manufacturing business management. Think about having a superhero that doesn’t save the world, but helps businesses to save their time and money! That’s ERP for you. It includes production, materials management, logistics, financial, personnel and public relations.

The components of an ERP system can be mind-blowing but wait for it! Here’s a quick rundown:

- Financial Management: Works in finance, perpetuates data, budgeting, and reportage.

- Supply Chain Management: Improves the efficiency of the material and product supply chain all the way through to the customer.

- Production Management: Oversees production activities with significant emphasis on ways to get them as optimized as possible.

- Inventory Management: Monitors stock status as well as the functioning of a warehouse.

- Human Resources: Is responsible for recruitment and selection of employees, processing of employees’ salaries, and recording of their details.

- Customer Relationship Management (CRM): Responsible for handling customers and records their sales.

These are integrated where each element provides an overview of the business processes and makes certain that pertinent information is assembled, conveyed and received appropriately.

History and Evolution of ERP in Manufacturing

Today, ERP is a complex system but it has come through a long evolutionary process starting out as a simple system with limited functionality. Initially, ERP systems emerged from materials requirement planning (MRP) systems as created in the 1960s and 1970s. These MRP systems were implemented with an aim of providing solutions on how much raw material to order and when.

Fast forward to the 1990s, ERP Systems were not only planning materials but extending to adaptive processes of the enterprise. When getting deeper into the 2010s, one could talk about cloud computing as an essential booster for business development. It made ERP systems access, flexibility, and scalability possible. Today, manufacturers have systems like SAP Business One that accounts for the dynamic need of manufacturers globally including the active manufacturing industry in India.

Key Features of ERP Systems for Manufacturing

Today’s ERP systems are chock full of functions that make them essential to any manufacturing organization. Here are some key features that stand out:

- Integrated Operations: Another key value of ERP is its efficiency at the centralization of activity. They disintegrate various portfolios of a business by effectively linking business processes while providing easy access to information.

- Real-Time Data Access: In ERP, one is in a position to make decisions because most of data is updated with real time data. This immediate visibility is vital because organizations need to be competitive when the new environment emerges.

- Automation: ERP helps the firm to complete several operational activities such as processing orders and remunerating employees and several other activities thereby leaving the employees time to focus on other critical activities in the business.

- Regulatory Compliance: Most of the ERP systems are equipped with compliance modules to ensure that the organization does not fall foul of the set legislation resulting in costly fines.

- Scalability: That is why ERP systems are regarded as a good investment, for the small local manufacturer or for the worldwide leader, as the systems are developed with the ability to grow with the organization.

From the brief outline of what ERP systems are, let's now proceed to the discussion of the effects and applications of ERP systems in real life manufacturing.

The Impact of ERP on Manufacturing Processes

The impact of ERP systems on manufacturing processes is significant and transformative. They don't just help run the business; they take manufacturing to a whole new level of efficiency and effectiveness.

Streamlining Production Planning and Inventory Management

ERP can be regarded as a wizard that sends manufacturers to order appropriate inventory at the correct time. Through ERP, production planning is done effectively and in a way that enables institutions to meet customer demand and needs without incurring many losses through retaining many inventories within its fabric or through often shutting down production.

- Efficient Resource Allocation: This is helpful in that ERP enables organizations to schedule production plans and control aspects of resource utilization in order to reduce time wastage and optimize efficiency.

- Inventory Optimization: Inventory management is another key area where ERP systems make a lot of difference by automating inventory and controlling optimum stock levels to cut down carrying costs and to avoid situations where you may run over or short of stock.

- Forecasting: While years past may inspire certain educated guesses on the manufacturers part, ERP for demand planning provides fact-based insight, which in turn increases satisfaction among clientele.

Improving the Quality of Control and Assessments

For any manufacturing company, quality always reigns supreme and it’s at this point where the ERP system comes in handy. These tools enable organizations with real time monitoring and quality assurance of the final product within ERP systems.

- Process Monitoring: In using the ERP systems, there is a way to monitor the production processes in real time, and variations affecting quality can be ascertained at once.

- Traceability: In the case of a problem, ERP generates a complete traceability trail to control and handle product recall or defect problems, lessening danger and protecting brand reputation.

- Compliance and Reporting: Time-consuming tasks of documentation and report generation are also automated, and this Reuel asserts that quality is not a mere aim, but a guarantee.

Improving Supplier and Customer Relationship Management

Good relationships with suppliers and customers are crucial in the manufacturing sector. ERP systems facilitate these relationships through better communication and data management.

- Supplier Collaboration: With ERP, manufacturers can work closely with suppliers by sharing forecasts and demands, improving lead times and reducing supply chain disruptions.

- Customer Satisfaction: From order tracking to managing customer feedback, ERP systems enhance the customer experience by ensuring timely deliveries and quality service.

- Data Sharing: ERP systems aggregate customer data, allowing manufacturers to understand buying patterns, preferences, and feedback, leading to tailored marketing strategies and improved product offerings.

Thus, ERP systems are not only hardware but it is platforms that change games for the manufacturing unit of an organization. They let the manufacturers be efficient, establish adequate control over the quality of goods, and maintain a good and solid supply chain with the suppliers and customers. In the context of Industry 4.0 which is gradually defining the future of manufacturing, an ERP system is well-positioned to ensure that a business remains relevant, complies with the law, and delivers excellent customer experience.

Therefore, if you have been in the manufacturing sector and have not incorporated ERP magic, then wouldn’t it be of immense benefit to think about it right now. Since the future of manufacturing in India and across the world is right tied with these systems, the ERP integration can be your key to novelty and victory.

There you have it! ERP systems translated for the new generation manufacturing enterprises. Well, it is time to work better, not more!

Benefits of Implementing ERP for Manufacturing Industry

Enterprise Resource Planning (ERP) systems is become a new trend in manufacturing industries particularly in 4.0 manufacturing context. An ERP system is capable of linking different business processes which act as a technological advantage for manufacturers and greatly enhances their operations. Now that we have established the foreground information it is about time we look at some of the aspects that stand to gain from the integration of the ERP systems in the manufacturing industry.

Better performance, efficiency and productivity

In the very center of any manufacturing company, it is possible to single out such notions as effectiveness and output. Essentially, ERP for manufacturing industry help in enhancing these aspects since the systems incorporate optimized processes of various departments. ERPs perform repetitive as well as redundant processes automatically and hence reduce the capacity of people in making mistakes. For example, the ERP systems can provide the link between the manufacturing or production plan and the inventory to ensure that right material is available on the shop floor when needed, eliminating unnecessary idle time.

Furthermore, ERP systems are integrated information systems in which employees can find actual information related to various activities, so employees can make the most of their time instead of spending time and efforts to search for information. Since information flow between departments is not disrupted, problems that may slow down workflow are realized early and solved, which increases efficiency. This is important in an industry where timing is of the essence!

Cost Reduction and Profit Maximization

Meeting cost reduction targets have always been a prerequisite to survival in manufacturing especially where profit margins have to be optimized. It is toward this objective that ERP systems play a very crucial role to offer manufacturers a wealth of information on their operations. Because ERP systems incorporate detailed records of cost related to production processes, inventory, and supply chain management, the systems afford the businesses opportunities to reduce meaningful costs of production.

Moreover, by accurately predicting the demand for products in an organization and handling the levels of stocks being put in place ERP systems enhance stocks management. It helps to avoid overproduction and underproduction that cause lots of financial losses in the business. In addition, since the processes are mostly performed automatically, one of the main factors that decrease the overall labor cost are achieved, thus resulting in an improved profitability.

Real-time Data Analytics and Decision Making

That said, real-time data analysis for better decision-making increases the potency of ERP systems in manufacturing . Since many industries have become data-oriented, it is critical to have real-time data when making business decisions. By having an ERP system, it is possible to track KPIs on manufacturing as well as predict trends that may affect manufacturing efficiency or the market.

It also helps to increase response time to changes in supply and demand, so that manufacturers can fit their actions to the market. Further on, upgrade in data visibility results in enhancement in forecast and planning which in turn result in better resolution and utility of resources and enhanced customer satisfaction. This can be achieved by optimizing the use of data so that manufacturers may know their competitors better and hence capture the right market opportunities for growth.

Challenges in ERP Software for Manufacturing Industry

There are many benefits to ERP systems in manufacturing organizations but it is not without its issues in the transition. Here are some of the usual problems manufacturers encounter while implementing ERP systems and how the latter can be addressed.

Interoperability with Other Systems

Manufacturers find it quite challenging to integrate the new ERP Software for Manufacturing Industry with the rest of the existing legacy systems. A high percentage of manufacturing organizations still employ suboptimal methods and technologies incompatible with up-to-date ERP systems. Depending on the degree of incompatibility, there can be some loss of efficiency during the period necessary to resolve it, as well as certain costs associated with time loss.

To counteract impediments to integration, manufacturers need to evaluate integration readiness by performing a current state assessment of manufacturing systems prior to ERP adoption. It is crucial in this evaluation to determine potential conflicts and assist in the creation of a detailed integration strategy. However, there are several steps to consider when implementing the choice of an ERP system in the following aspects: Furthermore, selecting the ERP system that provides capabilities of integration and flexibility can eliminate some of these challenges. It also helps if one has worked with experienced ERP vendors or consultants, who would be better placed to appreciate the different factors involved in implementing a manufacturing system.

Managing Change and User Adoption

Implementation of a new ERP system may lead to substantial changes in practices of a manufacturing enterprise, as well as redefine roles and tasks of employees. The employees may resist change as some may prefer sticking with the current systems in place. One of the most significant tasks here remains guaranteeing a seamless transition and post-implementation acceptance.

To address this, manufacturers should encourage openness and engage the users at the initial stage. Delivering training that is more extensive and engaging in collecting feedback from the employees can foster confidence and promote acceptance. Concerns can also be addressed by providing information on what the new ERP system will do for them and how it is going to facilitate their operations. This means that every change management strategy ought to be incremental and should illustrate how the change affects the employees in the short run.

Ensuring Data Security and Compliance

In the current world where operations and almost everything are computerized, there is high demand for protection of data, particularly in manufacturing industries. The integration of a new ERP system poses risks inherent with exposure to data and threats pertinent to industry standards. Managers working for the manufacturing firms have to guarantee that the company and clients’ data is safeguarded from unauthorized access or cyber threats.

In their choice of an ERP provider, manufacturers are advised to put security into consideration and look for the provider with robust security policies and compliance compliance certificates. This involves having aspects of encryption, rules for accessing data, and even a security check in the program to check for vulnerabilities. Furthermore, to ensure data accuracy, data utilization, and adherence to legal requirements, a solid foundation for data governance has to be built. To address security risks during the implementation of ERP and also after the implementation, other necessary measures include security training of the employees and security awareness within the firm.

Thus, ERP systems are also crucial applications for updating and enhancing operations in the 4.0 manufacturing environment. The advantages of increased efficiency, decreased costs, and evidence-based decision-making are evident, however, they include a number of integrating concerns that relate to change and data management and protection. If implemented and managed properly, manufacturers can use all the possibilities of ERP systems to boost their innovations, productivity, and revenues.

Future Trends and Innovations in ERP for the Manufacturing Sector

The manufacturing world is changing and at the heart of this change is ERP, or Enterprise Resource Planning. Thus, the applicability of ERP systems does not diminish when industries first set out on Industry 4.0. Let me explain what technology is doing to ERP to define the future of the manufacturing industry.

Integration with IoT and IIoT

But the most significant trend is the integration of the ERP systems with the internet and, in particular, with the Internet of Things (IoT) and Industrial Internet of Things (IIoT). This integration allows machines to feed data to ERP systems and this data is always current to help in efficient decision making. For instance, an assembly line would detect that it requires repair, and the information gets input to the ERP system, the system informs the maintenance department or even orders spares. All these can be achieved through the integration which can eventually help to cut down the much needed downtime.

AI and Machine Learning Improvements

If you are new to the world of technology, chances are that you have heard about Artificial Intelligence (AI) and Machine Learning (ML) before. These technologies are helping ERP by giving them forecasting and analysis. With AI-powered ERP platforms, manufacturers can:

- Predict equipment failures: Similar to human operators, AI Algorithms can assess and interpret patterns in the data that point towards possible failure of a machine in order to rectify the problem before it happens.

- Optimize supply chains: Thus, ML can discover from historical information about supply routes and timings and recommend the most effective ones with the least hindrance and requisite.

- Enhance quality control: Thus, through analyzing big data, it is possible to detect imperfections in production and reach a higher quality, earlier.

Cloud-Based ERP Solutions

The move toward cloud-based ERP has continued to grow, providing benefits that on-premise systems cannot; namely; flexibility and scalability. Cloud ERP systems allow manufacturers to:

- Access data anywhere, anytime: They can be P/C or mobile, but remain in touch with the factory floor in real time.

- Easily scale operations: With cloud solutions, as companies expand, there is little need to overhaul the infrastructure of the delivery process.

- Improve collaboration: Improve the coordinator and effective communication and interaction between different departments and locations and if possible between sites all over the world.

Cybersecurity Measures

Digital transformation, as well as interconnected systems and networks, the issue of cybersecurity remains the key priority. As the ERP systems progress, organizations are having stricter measures to cover for the critical information. Some of the characteristics that are normal to find nowadays are more secure and stronger encryption modes, two or three factors of authentication, and real time monitoring. For manufacturers, this means more secure data, as well as a minimized chance of a cyber threat that might affect performance.

Bespoke and Friendly Modules of an ERP System

The ‘Fortune 500’ mentality is no longer dominant as gods-like ERP systems of the past were ponderous and hostile. Organizations are now moving to more natural and user friendly interfaces. One of the recent trends in modules of an erp system is that design in terms of UI/UX is gradually improving. These systems can be easily operated by the employees or the technical workforce, little learning time is required thus making the entire process efficient.

ERP and Sustainability

Environmental or ecological responsibility is rapidly becoming an important issue to manufacturers in the global marketplace. The latest developments in ERP solutions are in compliance with these green programmes through supporting the analysis of resource consumption and waste generation by companies. Features include:

- Tracking carbon footprints: ERPs can estimate the amount of emissions made and provide solutions on how to optimize emission’s figures.

- Efficient resource management: Inherent in systems is the effectiveness in the put to use of materials thus discouraging the use of the excess and encouraging recycling.

- Compliance with environmental regulations: Real time updates and reports make it extremely easy for manufacturers to implement compliance with regulatory metrics.

ERP Systems will continue to be part of the manufacturing industry as it prepares to march forward into the next phase. Based on the presented trends and innovations, manufacturers can not only improve their operations but also become pioneers of the new generation 4.0 industry. From integrating new technologies to operating in the cloud, to sustainability initiatives, ERP is a virtually limitless platform. Therefore, to a bright, efficient and innovative future of the manufacturing sector with ERP at the heart of it – cheers.

#erp software#erp solution#erp for manufacturing industry#sap business one#manufacturing industry#erp software for manufacturing

0 notes

Text

0 notes

Text

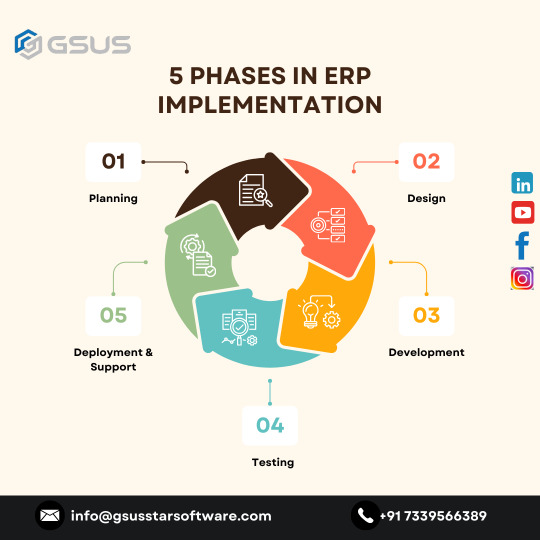

Kickstart your ERP journey with these essential phases: Planning, Design, Development, Testing, and Deployment. Each step is crucial for a seamless transition and maximizing your system’s potential. 1️⃣ Planning: Set clear goals and assemble your team. 2️⃣ Design: Map your processes and customize the system. 3️⃣ Development: Build and integrate features tailored to your needs. 4️⃣ Testing: Ensure everything works smoothly with thorough testing. 5️⃣ Deployment: Go live and provide support for a seamless transition! Transform your business operations and drive efficiency today! www.gsussoftware.in

#business central#cloud erp#erp#app development#erp for manufacturing#erp development company#erp integration#erp software#sap#sap business one#sap s/4hana#sap solutions#sap services

0 notes

Text

Embracing SAP Business One for Manufacturing: A Strategic Move for Growth | Pinnacle

Read why implementing SAP Business One is a strategic move for manufacturers. One of the core benefits of SAP Business One is its ability to streamline core manufacturing processes, leading to enhanced productivity and profitability. [email protected]

#SAP Business One solution#SAP Business One solution for manufacturing#SAP Business One for manufacturing

0 notes

Text

SAP Business One ERP, tailored for the manufacturing industry, is designed to streamline operations, enhance efficiency, and provide real-time insights for businesses of all sizes. Cinntra, a trusted partner, specializes in implementing SAP Business One, offering customized solutions that optimize production planning, inventory management, and financial controls.

With features such as automated workflows, advanced reporting, and integrated quality management, SAP Business One by Cinntra helps manufacturers drive growth, reduce operational costs, and improve decision-making, ensuring a seamless end-to-end business process.

Contact us today!

+91-8882709959

0 notes

Text

Emerging ERP Trends Shaping the Future in 2024

In today’s fast-paced business environment, Enterprise Resource Planning (ERP) systems have become essential for streamlining operations and providing a unified approach to managing various company processes. As we navigate through 2024, several key trends are transforming the ERP landscape, reflecting the ongoing technological advancements and evolving business needs.

Augmented Financial Efficiency:

SAP ERP solutions are becoming increasingly vital across diverse industries. These systems not only provide valuable insights into profitability, revenue, and cost but also incorporate advanced forecasting and predictive analytics. By leveraging machine learning algorithms, modern ERP systems can analyze historical financial data to offer precise predictions and recommendations, enhancing decision-making processes.

Cloud-First Approach:

The shift towards cloud-based ERP solutions is driven by their robust security, flexibility, and scalability. The subscription-based model associated with cloud ERP systems offers cost-effectiveness while facilitating real-time collaboration among teams spread across different locations. These systems also provide easy integration with various applications and ensure seamless upgrades.

Mobile ERP Solutions:

Mobile ERP applications have gained prominence due to their accessibility and functionality. They simplify tasks such as expense reporting, workflow approvals, and performance monitoring. The optimized user interfaces for various devices ensure a consistent experience across smartphones, tablets, and desktops, making ERP systems more versatile and user-friendly.

Integration of Machine Learning and AI:

Machine learning and artificial intelligence are now integral to ERP systems, enhancing capabilities such as fraud detection, predictive maintenance, and customer segmentation. Natural language processing features enable users to interact with ERP systems using chatbots and voice commands, streamlining queries and data entry processes.

IoT Integration:

The incorporation of the Internet of Things (IoT) into SAP ERP systems allows for real-time monitoring of assets like vehicles and equipment. This integration facilitates optimized resource utilization and proactive maintenance by analyzing data to identify inefficiencies and automate necessary actions.

Enhanced Security Measures:

Advanced encryption techniques, anomaly detection algorithms, and multi-factor authentication are crucial for safeguarding sensitive data within ERP systems. Regular security audits and continuous monitoring help ensure compliance with industry standards, offering a secure platform for businesses.

Focus on ESG and Sustainability:

SAP ERP modules now emphasize sustainability management, tracking key performance indicators related to carbon emissions, waste generation, energy consumption, and social responsibility. These analytical tools provide insights into the environmental and social impacts of business operations, supporting data-driven sustainability initiatives.

Quantum Computing and Blockchain:

Blockchain technology enhances transparency and traceability in transactions, particularly in sectors with complex regulatory demands and supply chains. Meanwhile, quantum computing promises faster data processing and improved encryption, potentially boosting the performance and security of ERP systems.

Broadening Operational Scope:

Modern ERP systems are expanding to integrate with third-party services and applications, supporting comprehensive end-to-end business processes. Integration of modules like customer relationship management, supply chain management, and business intelligence provides a unified view of organizational operations and performance metrics.

Conclusion:

In summary, these evolving ERP trends for 2024 illustrate the rapid advancements in technology and their impact on business operations. Companies that embrace these innovations will benefit from increased efficiency, adaptability, and improved decision-making. For organizations seeking to implement these latest trends, Cogniscient offers specialized ERP solutions tailored to meet specific needs and goals.

#SAP Business One#SAP B1#SAP Business One Partner in India#ERP for Manufacturing Industry#SAP ERP for Small Businesses#Best ERP software company in India#ERP Solutions Provider in India

0 notes

Text

SAP Business One Gold Partner Noida |Delhi |Gurgaon| Ghaziabad India

Elevate your interior decor and furniture manufacturing business with SAP Business One Take control of your success

Trusted SAP Business One Gold Partner with 500+ Successful Implementations including Kanpur, Jaipur, Lucknow, Ludhiana, Manesar, Indore, Pune, Mumbai, Kolkata, Faridabad, Sonipat, Raipur, Ambala Etc.

#SAP Business One#SAP B1#SAP Business One Partner in India#ERP for Manufacturing Industry#SAP ERP for Small Businesses#SAP ERP for Food & Beverages#Best ERP software company in India#ERP Solutions Provider in India#Best ERP Software in India

0 notes

Text

ERP for Textile Manufacturers with SAP B1 ERP

Unlock unprecedented efficiency in textile manufacturing with SAP Business One, the industry's leading ERP for Textile Manufacturers. Accelon Tech is SAP Business One Partner, we understand the unique challenges faced by textile manufacturers, and we have tailored this ERP software to revolutionize your operations.

#sap b1#sap business one#ERP for Textile Manufacturers#textile manufacturer#erp software for small business

1 note

·

View note

Text

Gemstones aside, you can also get some fun trees, two of which I am quoting passages on because I think they're neat and want them in my garden.

Blueleaf is one you can get on the Sword Coast (North of Amn, so Baldur's Gate is included well, the general geographic region, Baldur's Gate is a tad short on trees and anything that isn't brick housing and cobbles. Maybe in the private gardens in the Upper City.)

While commandeering the upstairs business rooms of the Elfsong Tavern as an inn, which the establishment is not, your room was probably blue at night:

These delicately built, but supple, trees are instantly recognizable when in leaf because of the eerie, gleaming blue color of their many-pointed leaves. [Meaning electric blue, according to the footnote]. Blueleafs bend in high winds or under heavy ice loads rather than breaking, and when curved entirely around like hoops, they form snow tunnels that provide ready shelter for winter travelers and hungry hunting predators. They yield beautiful leaping blue flames when burned and are thus prized in many inns and taverns, where their light provides moody illumination for taletellers and minstrels in the late evenings. Their sap and crushed leaves yield a vivid blue dye which captures almost all of the glow of the living leaves and is much favored in the making of cloaks in the North.

And see-through trees! Which bards apparently love.

[Chime oaks] resemble normal oak trees made of transparent glass, though the leaves often carry a slight greenish tinge. Aside from their appearance, chime oaks are indistinguishable from other oaks; birds nest in their branches, they sprout and grow from seedlings, their limbs can be cut and burned for firewood. Unlike normal oaks, however, chime oaks do not lose their leaves in the autumn. Instead, the leaves freeze solid, remaining frozen throughout the autumn and winter until they thaw in the spring. Light breezes cause the frozen leaves to tinkle like wind chimes, producing a soothing, pleasant sound especially attractive to basilisks. These creatures can often found curled up near the trunks, eyes closed, completely relaxed. Chime oak wood gradually loses its transparent quality as it dries (as do chime oak leaves), becoming a silvery-white hue when fully dry. It can be used in manufacturing magical items in the same way that oak is. However, when used in the manufacture of magical musical instruments, it gives the instruments a very sweet and pure sound. - Volo's Guide to All Things Magical

Also it's extremely cold resistant. While they're found exclusively in specific regions of the forest of Cormanthor, Baldur's Gate is known for being a nexus of trade and the only place to buy luxury goods on that stretch of the Coast so you can probably get it imported from the Eastern Heartlands, assuming the drow and elves in the area don't murder the loggers for unsustainable foresting technique/trespassing or something. There are examples of stuff the wood is used to make, so clearly it's a trade good and it's probably fine.

11 notes

·

View notes

Text

Why Infor SyteLine ERP Is Ideal for Mid-Market Manufacturers & Service Providers

When electronics and other mid-market manufacturers want their ERP system to enable growth and create a new competitive advantage, they rely upon Infor Infor SyteLine, also known as CloudSuite Industrial (CSI).

When service and rental equipment providers want their ERP system to enable their growth into world-class service organizations and empower field technicians with data at their fingertips, they also rely upon Infor Infor SyteLine CSI.

We’ve all heard the horror stories of failed ERP implementations so, when manufacturers and service providers want SyteLine ERP successfully implemented—and guaranteed—they rely upon Bridging Business Technology Solutions (BBTS).

An ERP Ideal for Manufacturers

Infor SyteLine is the primary ERP we support because it’s ideal for use by discrete and process manufacturers, especially electronics manufacturers. We also guarantee the success of your Infor SyteLine implementation whether you’re commissioning an ERP system for the first time or replacing your current system, so you can cross the risk of a failed implementation off your list of worries.

SyteLine also can be customized to recognize customer-owned inventory and allocate it only to that customer so you don’t have a unique part number for the same part used by multiple customers. You can also reserve stock for specific products of the same customer or reserve any part in your inventory for a specific order until the order is released.

SyteLine delivers the same type of functionality as SAP and Oracle for a fraction of the cost and headache of implementing a tier 1 ERP system.

An ERP Ideal for Service Providers

Infor SyteLine is the primary ERP we support because it’s a perfect fit for service providers, especially those who rent equipment. We also guarantee the success of your Infor SyteLine implementation. So, whether you’re commissioning an ERP system for the first time or replacing your current system, you don’t have to worry about the disruption of a failed implementation.

Among the biggest benefits of SyteLine for service providers is no longer having to enter data multiple times into disparate systems. Working with common data means that everyone works from the same real-time information, which:

Empowers your service technicians to complete more service orders

Enables your employees to spend more time building relationships with customers

Gives your managers the tools to analyze data and find strategic growth opportunities

SyteLine delivers the same type of functionality as SAP and Oracle for a fraction of the cost and none of the headaches associated with implementing a tier 1 ERP system.

Successful Implementations, Guaranteed

The BBTS team has implemented SyteLine successfully over 165 times since 2013 with a proven ERP implementation process that begins with improving inventory control, planning and forecasting, financial close, and other business processes. SyteLine then standardizes these process best practices and ensures they are followed.

BBTS also provides post-implementation SyteLine enhancements, upgrades, business process improvements, and workflow optimization so you get the most out of your SyteLine investment.

Get Started Today

To determine if SyteLine ERP is right for you, we will connect you with one of our implementation experts as part of a process review. A successful implementation begins with understanding your core business processes, then recreating and evolving them in SyteLine.

Together, we can determine how you will benefit from SyteLine and calculate a target return on investment (ROI) to help justify the move. Contact us to learn more about SyteLine and how we are able to guarantee a successful ERP implementation when so many fail. You can also take advantage of the process review offer.

#erp software#infor#syteline#cloudsuite industrial (CSI)#manufacturing#service providers#customer owned inventory

8 notes

·

View notes

Text

Cut down waste, 📈 increase profits, and streamline operations in the hardware manufacturing industry with SAP Business One! 💡✨

#sap b1#cloud erp#sap erp#clouderp#sapbusinessone#sap business one#erp for small business#erp software#cloud partner#erpsolutions#hardware manufacturing

0 notes

Text

Manufacturing ERP: The Top 10 ERP Systems for 2024

Introduction:

In the dynamic landscape of the manufacturing industry, the right technology can make all the difference in streamlining processes and enhancing overall efficiency. Manufacturing Enterprise Resource Planning (ERP) systems have become indispensable tools for businesses seeking to integrate various facets of their operations seamlessly. As we step into 2024, the demand for robust ERP solutions continues to grow. In this blog, we will explore the top 10 Manufacturing ERP systems that are poised to make a significant impact on the industry this year.

1. SAP S/4HANA: Pioneering Manufacturing Resource Planning System

One of the most trusted names in ERP, SAP S/4HANA stands out as a comprehensive Manufacturing Resource Planning System. Its real-time analytics, integrated modules, and intelligent automation make it an ideal choice for businesses aiming to optimize their manufacturing processes.

2. Oracle ERP Cloud: Empowering Manufacturing Enterprise Resource Planning

Oracle ERP Cloud offers a scalable and flexible solution for manufacturing enterprises. With its robust features, it caters to the diverse needs of businesses, ensuring a seamless integration of manufacturing operations. Its cloud-based architecture provides the agility required for modern manufacturing environments.

3. Microsoft Dynamics 365: A Versatile ERP Solution

Microsoft Dynamics 365 is gaining prominence as a Manufacturing Enterprise Resource Planning software that offers versatility and integration capabilities. Its user-friendly interface and interoperability with other Microsoft products make it an attractive choice for businesses, especially small enterprises.

4. Infor CloudSuite Industrial: Tailored Manufacturing ERP

Infor CloudSuite Industrial is designed with the unique needs of manufacturers in mind. It provides specialized functionalities, including supply chain management and shop floor control, making it a standout choice among ERP solution providers.

5. NetSuite ERP: Unifying Manufacturing Operations

NetSuite ERP is recognized for its ability to unify diverse manufacturing operations into a single, cohesive system. Its cloud-based platform allows for real-time collaboration and data accessibility, making it an efficient Manufacturing Enterprise Resource Planning Software.

6. Epicor ERP: Driving Growth for Small Businesses

Epicor ERP is particularly well-suited for small businesses in the manufacturing sector. With its focus on driving growth and improving efficiency, Epicor ERP offers a cost-effective solution without compromising on essential features.

7. IFS Applications: Comprehensive ERP Solution

IFS Applications is a comprehensive ERP solution that covers a wide range of manufacturing processes. Its modular structure allows businesses to tailor the system according to their specific requirements, making it a preferred choice for Manufacturing Enterprise Resource Planning.

8. IQMS Manufacturing ERP: Enhancing Shop Floor Control

IQMS Manufacturing ERP is distinguished by its emphasis on shop floor control and real-time monitoring. It empowers manufacturers with tools to optimize production processes and make informed decisions, positioning it as a top choice among ERP solution providers.

9. Acumatica Cloud ERP: Scalability for Growing Businesses

Acumatica Cloud ERP stands out for its scalability, making it an ideal choice for growing manufacturing businesses. With a flexible platform and advanced features, Acumatica supports businesses in adapting to changing demands and expanding their operations seamlessly.

10. SYSPRO ERP: Tailored for Manufacturing Success

SYSPRO ERP is tailored to meet the specific needs of manufacturing industries. Its focus on delivering a user-friendly experience and addressing industry challenges positions it as a reliable choice for Manufacturing Enterprise Resource Planning.

Conclusion:

As manufacturing industries evolve, the importance of robust ERP systems cannot be overstated. The top 10 ERP systems highlighted in this blog represent the cutting edge of technology, offering solutions that cater to the unique demands of the manufacturing sector. Whether it's SAP S/4HANA's real-time analytics, Oracle ERP Cloud's scalability, or Acumatica Cloud ERP's flexibility, each system brings its own strengths to the table.

For businesses in Madhya Pradesh seeking Manufacturing Software for Small Business, these ERP solutions provide a pathway to enhanced productivity and streamlined operations. Choosing the right Manufacturing ERP system is a critical decision that can impact a company's growth and competitiveness. Evaluate the features, scalability, and industry focus of each system to find the perfect fit for your manufacturing enterprise. Embrace the power of ERP in 2024 and position your business for success in the ever-evolving landscape of manufacturing technology.

#Manufacturing Software for Small Business#Manufacturing Enterprise Resource Planning Software#ERP Solution Providers in Madhya Pradesh#Manufacturing Enterprise Resource Planning#Manufacturing Resource Planning System#ERP Software#Chain Cycle Management#Business#Engineering#Manufacturing#India#Madhya Pradesh#Go-To-Market#GTM#ERP

7 notes

·

View notes

Text

The Evolution and Impact of ERP Software in the UAE: A Comprehensive Analysis

ERP stands for Enterprise Resource Planning. It is a type of software system that integrates and manages core business processes and functions within an organization. ERP software typically provides a centralized database and a suite of applications that automate and streamline business activities across various departments such as finance, human resources, supply chain management, manufacturing, sales, and customer service.

In the fast-paced landscape of business operations, efficient management of resources and information is critical for success. Enterprises in the United Arab Emirates (UAE) have witnessed a remarkable transformation in their operational efficiency and competitiveness through the adoption of Enterprise Resource Planning (ERP) software. This article delves into the evolution, benefits, challenges, and future trends of ERP software within the UAE context.

In recent decades, Enterprise Resource Planning (ERP) software has played a transformative role in how businesses in the United Arab Emirates (UAE) operate and manage their resources. This article delves into the evolution, adoption, and impact of ERP systems within the UAE's business landscape. By exploring the unique challenges and opportunities presented by the UAE's dynamic economy, we can better understand how ERP software has become an indispensable tool for organizations seeking efficiency, integration, and scalability.

Evolution of ERP Software

The adoption of ERP software in the UAE mirrors global trends but is uniquely shaped by regional business requirements and technological advancements. In the early 2000s, ERP systems gained traction among larger corporations seeking to streamline their complex processes. Major multinational ERP providers like SAP, Oracle, and Microsoft Dynamics established a strong presence in the region, catering to diverse industry needs including finance, manufacturing, retail, and logistics.

A notable development in recent times is the movement towards cloud-centric ERP solutions.This transition offers scalability, flexibility, and cost-effectiveness, allowing businesses in the UAE to manage their operations more efficiently. Local ERP vendors have also emerged, offering tailored solutions that cater specifically to the nuances of the UAE market, such as compliance with local regulations and cultural practices.

Challenges and Obstacles

Despite the numerous benefits, ERP implementation in the UAE is not devoid of challenges. One prominent obstacle is the high initial investment required for ERP deployment, including software licensing, customization, and training costs. For smaller businesses, this financial commitment can be prohibitive, leading to slower adoption rates among SMEs.

Cultural factors and change management also pose challenges. Embracing new technology often requires a shift in organizational culture and employee mindsets. Resistance to change, coupled with the need for extensive training, can hinder the successful implementation of ERP systems in the UAE.

Furthermore, data security and privacy concerns are paramount, especially in light of stringent regulatory frameworks such as the UAE's Data Protection Law. Ensuring compliance with local data protection regulations adds complexity to ERP deployment, necessitating robust cybersecurity measures and data governance protocols.

The Business Landscape of the UAE

The UAE is renowned for its vibrant economy, diversified industries, and strategic geographical location. Over the years, the country has emerged as a global business hub attracting multinational corporations, SMEs, and startups alike. Key sectors such as finance, real estate, construction, logistics, tourism, and manufacturing contribute significantly to the nation's GDP. However, this diversification has also brought complexities in managing business operations efficiently.

The Emergence of ERP Solutions

As businesses in the UAE expanded and diversified, traditional methods of managing operations became inadequate. The need for integrated systems that could streamline processes across departments led to the rise of ERP solutions. Initially developed to manage manufacturing processes, ERP systems evolved to encompass finance, human resources, supply chain, customer relationship management, and more. This evolution mirrored the growth and diversification of UAE businesses.

Factors Driving ERP Adoption

Several factors have fueled the adoption of ERP software among businesses in the UAE:

Global Competition: The UAE's aspiration to compete on a global scale necessitated advanced operational efficiencies that ERP systems could deliver.

Regulatory Compliance: The UAE's regulatory environment, including VAT implementation, required robust financial and reporting capabilities that ERP systems could provide.

Scalability: With rapid economic growth, businesses needed scalable solutions to manage increasing complexities.

Integration Needs: As businesses diversified, the need for seamless integration across functions became crucial.

Challenges in ERP Implementation

While the benefits of ERP systems are substantial, implementing them poses challenges:

Cultural Factors: Embracing technological change and adopting new systems can face resistance due to cultural factors.

Resource Constraints: SMEs may struggle with the limited resources required for ERP implementation and customization.

Data Security and Privacy: The UAE's focus on data security and privacy necessitates robust ERP solutions compliant with local regulations.

Impact of ERP on UAE Businesses

The impact of ERP software on businesses in the UAE has been profound:

Improved Efficiency: Streamlined processes lead to increased productivity and reduced operational costs.

Enhanced Decision Making: Real-time data availability empowers businesses to make informed decisions.

Better Customer Experience: Integrated systems ensure seamless customer interactions and improved service delivery.

Regulatory Compliance: ERP systems aid in meeting regulatory requirements efficiently.

Key ERP Players in the UAE

Several global and regional ERP providers cater to the UAE market, offering tailored solutions to meet local business needs. Major players include SAP, Oracle, Microsoft Dynamics, Sage, and Epicor, among others.

Future Trends and Innovations

Looking ahead, several trends are poised to shape the future of ERP software in the UAE. Artificial Intelligence (AI) and Machine Learning (ML) are increasingly integrated into ERP systems, enabling predictive analytics and automation of routine tasks. This enhances decision-making capabilities and further optimizes business processes.

Mobile ERP applications are also gaining popularity, allowing stakeholders to access critical business data on the go. The rise of Industry 4.0 and the Internet of Things (IoT) is driving demand for ERP solutions that can seamlessly integrate with smart devices and sensors, enabling real-time monitoring and control of operations.

Moreover, the convergence of ERP with other technologies like blockchain promises enhanced transparency and security in supply chain management, crucial for industries like healthcare and finance.

Conclusion

In conclusion, ERP software has become an integral component of the UAE's business ecosystem, driving efficiency, integration, and growth across diverse sectors. While challenges exist, the transformative impact of ERP systems on businesses in the UAE underscores their importance in navigating complex operational landscapes. As technology continues to evolve, so too will the role of ERP in shaping the future of business in the UAE.ERP software has emerged as a transformative tool for businesses in the UAE, driving efficiency, innovation, and competitiveness across industries. Despite challenges such as high costs and cultural adaptation, the benefits of ERP implementation are substantial, ranging from streamlined operations to improved customer satisfaction. Looking ahead, the evolution of ERP software in the UAE is poised to align with global technological advancements, incorporating AI, IoT, and blockchain to unlock new possibilities for business growth and development. As enterprises continue to navigate the digital landscape, ERP remains a cornerstone of strategic management, enabling organizations to thrive in an increasingly complex and dynamic marketplace.

In summary, ERP software has been a game-changer for businesses in the UAE, enabling them to streamline operations, enhance decision-making, and adapt to a rapidly evolving marketplace. As the UAE continues to position itself as a global economic powerhouse, the role of ERP systems will remain pivotal in supporting the growth and sustainability of businesses across various sectors.

2 notes

·

View notes

Text

How to Achieve Lean Manufacturing: A Step-by-Step Guide to SAP ERP Production Planning

Lean manufacturing has become a key focus for organizations striving to optimize their production processes and eliminate waste.

By implementing efficient production planning strategies, businesses can enhance productivity, reduce costs, and deliver high-quality products to customers.

One effective approach to achieving lean manufacturing is utilizing SAP ERP production planning.

In this article, we will provide a step-by-step guide to help you harness the power of SAP ERP in your pursuit of lean manufacturing excellence.

Step 1: Understand Your Production Requirements

Before diving into SAP ERP production planning, it is crucial to have a clear understanding of your production requirements.

Evaluate your production capacity, demand forecasts, and lead times to determine the optimal production plan.

By comprehending your needs and constraints, you can align your SAP ERP production planning efforts accordingly.

Step 2: Configure SAP ERP Production Planning

Once you grasp your production requirements, it's time to configure SAP ERP production planning to suit your organization's specific needs.

Customize the system according to your production processes, resource availability, and scheduling preferences.

SAP ERP provides a range of modules and tools that can be tailored to align with your unique production environment.

Step 3: Define Bills of Material and Routings

To effectively plan and execute production processes, defining accurate bills of material (BOM) and routings within SAP ERP is essential.

BOMs outline the components required to manufacture a product, while routings specify the sequence of operations involved.

By inputting precise BOMs and routings, you can ensure that your production planning is based on reliable data, leading to improved efficiency and reduced waste.

Step 4: Create Production Orders

Once your BOMs and routings are in place, it's time to create production orders within SAP ERP. Production orders serve as the foundation for executing your production plan.

They contain vital information such as the quantity to be produced, the resources required, and the estimated completion date.

By generating production orders, you can effectively track and manage the progress of your manufacturing processes.

Step 5: Optimize Production Scheduling

Efficient production scheduling is crucial for achieving lean manufacturing.

Utilize SAP ERP's scheduling capabilities to optimize the allocation of resources, minimize idle time, and reduce production bottlenecks.

By leveraging features such as capacity leveling and finite scheduling, you can ensure that your production lines operate at their maximum potential, enabling smoother workflows and faster turnaround times.

Step 6: Monitor and Analyze Production Performance

To sustain continuous improvement in your production processes, monitoring and analyzing production performance using SAP ERP is vital.

Leverage the system's reporting and analytics features to gain insights into key performance indicators (KPIs) such as cycle time, yield, and scrap rates.

By identifying areas for improvement and making data-driven decisions, you can further streamline your production operations and enhance overall efficiency.

Conclusion

Achieving lean manufacturing requires a systematic approach that eliminates waste, optimizes resources, and enhances productivity.

By following this step-by-step guide to SAP ERP production planning, organizations can harness the power of technology to drive lean manufacturing excellence.

From understanding production requirements to monitoring performance, SAP ERP offers a comprehensive suite of tools to support your journey toward lean manufacturing.

Embrace the power of SAP ERP and unlock the potential for improved efficiency, reduced costs, and increased customer satisfaction in your production processes.Michael Management SAP ERP training offers an effective way to learn all things SAP ERP. Michael Management’s raining is created using SAP's Best Practices, ensuring alignment with industry standards and optimized processes. Choose Michael Management to experience hands-on SAP training and gain practical experience in using SAP software effectively. Unleash your true potential with Michael Management and experience SAP training that accelerates your learning and supports your success.

For more details, visit: https://www.michaelmanagement.com/browse/sap-erp

3 notes

·

View notes