SAP Gold Partner delivering top-notch SAP solutions globally since 2005. Expertise, training, and innovation for business success.

Don't wanna be here? Send us removal request.

Text

Get SAP Business One Free Trial Easily with SAP B1 Partner

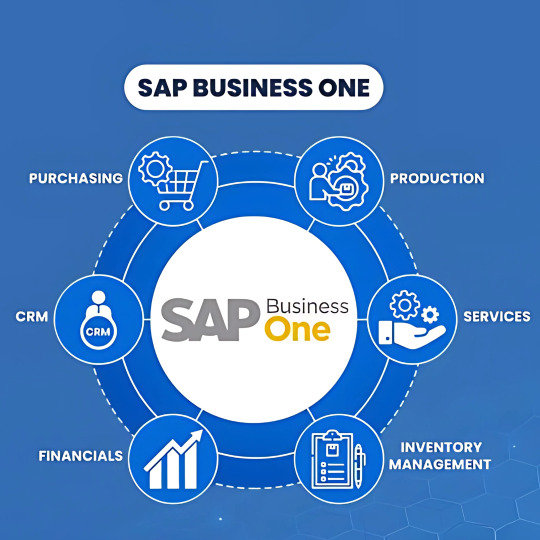

SAP Business One and Its Role in Business Growth

This paper seeks to compare Between SAP Business One and other products in the market as well as trying to establish how effective SAP B1 is in the market. It links activities like finance management, selling, procurement, and stock control, together with customer managing. When simplified, SAP B1 allows these processes to be accomplished, enabling organizations to attain operational objectives, effective decision making and long-term market survival.

SAP Business One has emerged as the favorite solution for Indian businesses irrespective of the type of industry they are in because the solution effectively solves operational issues and enhances productivity. It can be said that the software is quite effective in achieving better business results, which is why it can be so useful to various enterprises that aim to succeed in an environment that constantly undergoes changes. Businesses seeking to establish their unique competitive edge have discovered SAP B1 as a fitting solution to help them advance and become sustainable in the long run.

Why Partner with SAP Business One Companies in India?

Selecting the right SAP Business One partner is therefore the key determiner to the success of the business’ ERP project. An SAP B1 partner is a consultant and a service supplier who helps a company become more profitable. The SAP Business One companies in India are highly experienced in delivering localized solutions that address small and medium businesses in the area with a remarkable understanding of the market, legalities and sectors within India.

These partners make available key experience and expert advice that make certain SAP B1 suits your business requirements. They are planned to enhance your business flow and assist you make greater …return of investment (ROI). This means your overall response time greatly improves, your expert gets a better understanding of the peculiarities of your region and the challenges involved and you will spend less time on triaging the problems.

Understanding SAP B1 Service Providers and Their Roles

Service providers of the SAP Business One too have a central role of ensuring that the systems are implemented and optimized for its end users. They are not and merely SAP installation providers, but services and support providing agents who make sure SAP B1 functions as intended. They optimize the software to suit your business requirements and the run the processes with intra day efficiency.

Among other functions of SAP B1 service providers is to educate your employees on how to work with the system. They do extensive customer training to make sure that your people can have mastery of the various usable features of the software. Further, SAP Business One service providers have ensured constant technical support so that problems are all solved promptly not to affect the business operations.

SAP B1 provides services act as partners to businesses to anticipate the changes in the market, in the laws, and in businesses’ strategies. They help you make the best of the data in decision making and organizational performance, thus attaining business sustainability and high rate of return on investment.

SAP B1 Implementers: The Key to Seamless ERP Integration

The implementation of ERP is not an easy task and it is a very essential one that needs a lot of planning and coordination with different tasks and experts. SAP B1 implementers who are the professionals to go in for would be the ones who are to assimilate the ERP system into your line of business. These experts study your present systems, find out opportunities for advancement, and adjust SAP B1 to match your organization’s operations.

Implements with SAP B1 also are expected to check that all aspects in particular data conversion, interfacing, and end-user conversion are efficiently conducted. They are able to challenge the status quo by looking for areas of the system which may still cause trouble and make sure the system is appropriate for your organization’s needs. This dedication to detail means that ERP implementation with them does not translate simply to a system upgrade but to business value adding endeavor.

The success stories of other businesses and organisations depict that the right implementers can take your business to the level of improved efficiency, productivity and profitability. These professionals ensure that the software solution, SAP B1, suits your business needs and is properly positioned to serve your business as it grows in the future.

How to Access an SAP Business One Free Trial with Ease

One of the few things that can help you understand whether SAP Business One is suitable for your business is using the product’s free trial. The trial provides an opportunity to test the functional capabilities of the program and to determine how the subsequent implementation will affect the organization’s activity. Here's how to get started:

1.Try to visit the website of an SAP B1 partner or a SAP B1 service provider.

2. Find an option that says free trial and enter your contact information.

3. Request for a demo to be taken through the more important aspects of the SAP B1.

4. Download the trial version and take some time navigating through it with your workers.

While using SAP Business one Free Trial, it is recommended that you pay much attention to certain fields during the trial period, including inventory, financial reporting and customer relations management, in order to determine how effective the system will be to your business.

The best thing about it is that the free trial period offers an excellent chance to exercise it, evaluate its effectiveness and decide on its relevance for your business.

Selecting the Right SAP B1 Partners for Your Business Needs

Selecting the best SAP Business One partners is probably one of the biggest and effective decisions that any company will make. A good partner must demonstrate reasonable experience in the installation of SAP B1 partners in various industries targeting testable skills in the adaptation of the SAP to your business. It is crucial to consider the right company that has sufficient experience to implement its successes in your company and can deliver a proper response to clients’ demands.

Further, it is important to determine to what extent the partner is willing to support its partner. The ERP implementation will not be a one-time project in your business’s life cycle, and therefore you should consider very closely your vendor’s customer support, the help desk response time, and training material. A good partner should be able to sit down with the business and help understand the needs and interests of the business while providing solutions that meet the needs of the business.

With the right partner implementing SAP B1 does not only look for the implementation of a new software product, but also for the achievement of innovations and changes that bring positive impacts to the company in terms of productivity improvement, profitability and success in the long run.

Business Potential with SAP Business One

SAP Business One is a flexible global ERP system that can effectively help organizational bodies of different sizes across different functional areas such as financials, sales, inventories and customers. This provides a good opportunity to any business that is using SAP B1 software since with the right experts working on the software, business operations will be made efficient making growth achievable.

Another feature which made SAP B1 remarkable is the free trial which enables business firm to use it without incurring any risk. In the course of the trial, you are under the best position to assess how efficient the software is in complementing your business environment. It empowers you with first-hand knowledge of ways that SAP B1 can help enhance your business operations, and contain costs while contributing to positive growth.

When it comes to the operation of top SAP B1 companies in India it becomes possible to use the top industry knowledge and experience that can be helpful in terms of deployment, application downtime and proper support for any periods of software’s lifecycle. They form a basis for increased efficiency, better functioning of the businesses and their sustainable performances. So why wait? Join the thousands of business organizations taking advantage of the SAP Business One free trail today and obtain better business operations.

#SAP Business One Companies in India#SAP B1 Partners#SAP B1 Service Providers#SAP B1 Implementers#SAP Business One Free Trial

0 notes

Text

SAP Vendor Portal by Leading SAP Service Providers

Choose Leading SAP Service Providers for Vendor Portals

In today’s fast-paced business environment, supply chain networks have grown increasingly intricate, requiring companies to manage vendor contracts with precision and efficiency. A well-designed SAP Vendor Portal can revolutionize how organizations engage with vendors, fostering collaboration, streamlining procurement processes, and ensuring operational relevance in competitive markets. However, not all vendor portals are created equal, and many fall short of providing seamless integration and enhanced functionality. For this reason, partnering with leading SAP service providers is a strategic decision that can elevate your vendor management strategy to new heights.

Upgrading your vendor management system or implementing a new SAP Vendor Portal requires expert guidance. Top-tier SAP service providers bring specialized knowledge, compatibility with existing systems, and enhanced functionalities to address unique business needs. Their expertise ensures a smooth implementation process while optimizing the portal’s potential to improve vendor relationships and procurement efficiency. This article explores the critical role of leading SAP service providers, the advantages they bring to the table, and the key factors to consider when selecting a partner for your SAP Vendor Portal project.

Understanding SAP Vendor Portals

Before diving into the importance of expert SAP service providers, it’s essential to understand what an SAP Portal entails. An SAP Vendor Portal is a centralized digital platform designed to facilitate efficient communication and collaboration between businesses and their vendors. It enables vendors to access real-time updates on orders, invoices, and shipments while providing procurement teams with enhanced visibility into supply chain operations.

A robust SAP Vendor Portal automates communication processes, reduces errors, and strengthens vendor relationships. However, achieving these benefits often requires the involvement of experienced SAP service providers who can tailor the solution to your organization’s specific needs and challenges.

Why Partner with Leading SAP Service Providers?

Implementing or upgrading an SAP with Vendor Portal is a significant investment, and engaging a leading SAP service provider can maximize your return on investment. Here are the key reasons why their expertise is invaluable:

1. Expertise in Tailored SAP Solutions

Top SAP service providers have extensive experience in developing and customizing SAP Vendor Portal solutions for diverse industries. Their deep understanding of supply chain complexities enables them to design portals that address specific business challenges.

By incorporating features such as automated accounts receivable invoicing, advanced analytics, and compliance reporting tools, these providers enhance decision-making and streamline processes. Their tailored approach ensures that your SAP Vendor l aligns with your operational goals and regulatory requirements, driving efficiency and value.

2. Seamless Integration with Existing Systems

A poorly implemented SAP Vendor Portal can lead to inefficiencies and operational disruptions. Leading SAP service providers ensure seamless integration with your existing systems, such as ERP, CRM, and financial applications. This eliminates data silos and fosters better communication between vendors and internal teams.

The result is improved coordination, faster access to critical information, and enhanced process outcomes. Instead of introducing new challenges, your vendor portal becomes a powerful tool for streamlining procurement and vendor management.

3. Enhanced Security Measures

Vendor data is highly sensitive, making robust security a top priority. Premier SAP service providers implement stringent security measures to protect your vendor portal from cyber threats and unauthorized access. They utilize advanced encryption, multi-factor authentication, and regular security audits to safeguard your data.

These measures not only mitigate risks but also build trust among vendors, ensuring compliance with international data protection standards. With strong security in place, your focus can shift to leveraging data insights for business growth.

4. Customization for Unique Business Needs

Standardized solutions often fail to address the unique requirements of different industries. Leading SAP service providers specialize in customizing vendor portals to suit specific business needs, whether in manufacturing, retail, or other sectors.

By aligning the portal with your enterprise processes and objectives, these experts enhance vendor collaboration, operational efficiency, and overall performance. A tailored solution ensures that your SAP Vendor Portal evolves alongside your business, driving sustained success.

5. Ongoing Support and Maintenance

Implementing an SAP Vendor Portal is just the beginning. Continuous updates and maintenance are essential to keep the system relevant and effective. Top SAP service providers offer reliable support, ensuring that your portal remains optimized and up-to-date.

Their proactive approach to problem-solving, feature enhancements, and system updates allows your organization to maintain peak performance, address issues swiftly, and adapt to changing market demands. This ensures long-term productivity and growth.

Benefits of Partnering with Top SAP Service Providers

Collaborating with a leading SAP service provider offers numerous advantages, including:

1. Faster Deployment

Expert SAP service providers streamline the implementation process, reducing delays and ensuring a smooth transition. This enables your organization to start reaping the benefits of the SAP Vendor Portal sooner.

2. Improved Vendor Relationships

With features like real-time communication and transparent payment cycles, an optimized SAP Vendor dor portal fosters stronger vendor relationships. Improved collaboration and trust lead to enhanced loyalty and a more resilient supply chain.

3. Cost Efficiency

By minimizing errors, streamlining processes, and improving vendor control, SAP service providers help reduce operational costs. These cost savings contribute to a higher return on investment over time.

4. Scalability

As your business grows, so do your vendor management needs. Leading SAP service providers design scalable solutions that evolve with your organization, ensuring sustained efficiency and adaptability.

Key Considerations for Choosing an SAP Service Provider

Selecting the right SAP service provider is critical to the success of your vendor portal. Here are key factors to evaluate:

1. Industry Experience

Choose a provider with a proven track record of implementing SAP Vendor Portal solutions in your industry. Look for client testimonials, case studies, and evidence of successful projects.

2. Comprehensive Support Services

Ensure the provider offers end-to-end services, from initial implementation to ongoing support and maintenance. A dedicated team of experts can address technical issues, deploy updates, and provide continuous improvements.

3. Customization Capabilities

Opt for a provider who understands your business’s unique needs and can deliver tailored solutions. Customization ensures that your vendor portal aligns with your objectives and integrates seamlessly into your processes.

4. Security Focus

Data security is non-negotiable. Select a provider with robust security protocols, including encryption, multi-factor authentication, and regular audits, to protect your sensitive information

In today’s interconnected business landscape, an efficient SAP Vendor Portal is essential for managing vendor relationships and staying competitive. However, realizing its full potential requires the expertise of leading SAP service providers. From seamless integration and enhanced security to tailored solutions and ongoing support, these providers ensure that your vendor portal delivers maximum value.

If you’re ready to optimize your vendor management strategy, it’s time to partner with the best SAP support vendors. Their assistance will help you streamline your supply chain, reduce costs, and foster stronger vendor relationships, positioning your business for long-term success.

Take the first step toward transforming your vendor management today. Your business deserves nothing but the best.

0 notes

Text

#Top 5 ERP for Small Business in 2025 | ERP for Manufacturing Industry

#Top 5 ERP for Small Business in 2025

1. SAP Business One: SAP Business One is designed for small and medium enterprises and the software addresses complex business processes with tools for finance, inventory management and customer relationship management. This piece of software fits well with scaling businesses because of its integration options.

2. Odoo ERP: With a modular structure and free of charge, customers could get an all-wear blueshift matched for production, accounting, human resource, and sales. Due to integration, it is fortunate in meeting the needs of the growing business.

3. 2iSolutions: A cloud based ERP for business globalization and with business intelligence and analytics for updated reporting. When it comes to an ERP system, 2iSolutions has a focus on delivering customized ERP solutions.

4. TallyPrime: Popular in India, it is a simple, GST-compatible software that provides small business with homemade accounting and inventory systems within the local legal framework.

5. Microsoft Dynamics 365: Having connections with both AI and IoT, Dynamics 365 enriches manufacturing processes and forecasting for performance.

Each of these ERP systems offers unique strengths, enabling businesses to align their choice with specific operational requirements and industry nuances.

ERP for Small Business and Manufacturing Industries

Today, in the context of a constantly progressing business world, rapid and flexible work is crucial. Enterprise Resource Planning (ERP) has emerged as a core strategic application for small business and manufacturing companies due to centralization of many operations. This paper shows how dominant processes are linked and how real-time information in ERP systems enables organizations to remain competitive and deal with changing market requirements.

On the same notion, this paper argues that small businesses defined in the manufacturing industries face constraints which include the following; These challenges can be handled effectively through ERP solutions because those systems offer a holistic solution for improving business processes and efficiency of resource use and meeting statutory requirements.

Including inventory tracking, production scheduling and cost accounting, ERP for Small Business allows organizations to cut waste and improve their performance dramatically. In the world today, organizations said that real-time data usage helps them to identify various opportunities, develop the ability to foresee or anticipate the future and make the appropriate changes thus enhancing their operations sustainability.

Enterprise resource planning systems bring about changes to the operation of an organization by eliminating unnecessary duplicate processes and enhancing organizational integration of departments. This integrated concept not only fulfills the organization productivity but it can also encourage the establishments to grow in a planned way with the help of maximum efficiency without any negotiation on the quality as well as on the strategies for customer satisfaction.

Proposing use of ERP technology has become the need of every business that wants to establish itself successfully especially in the global arena which makes every market a competitive one. Read here how ERP systems provide the solid foundation that needs to be built on to become innovative, to become resilient, and firmly to be set on the course of development in this ever-changing and challenging world.

Why ERP for Small Businesses in India

India, known for its vibrant SME ecosystem, is experiencing a rising demand for ERP solutions as businesses strive to manage growth effectively. Small enterprises often face challenges in scaling their operations, and ERP systems provide a much-needed solution by offering modular, scalable tools tailored to their specific needs.

Regulatory compliance, particularly with GST and industry-specific standards, is a significant concern for businesses in India. ERP solutions simplify this by integrating compliance features, minimizing manual errors, and ensuring adherence to legal requirements. This reduces administrative burdens and enhances operational efficiency.

The affordability of cloud-based ERP for Small Business in India has further revolutionized the landscape, enabling even the smallest businesses to access advanced tools. These cost-effective solutions level the playing field, allowing small enterprises to compete with larger companies by streamlining processes, improving accuracy, and fostering growth.

By addressing scalability, compliance, and affordability, ERP systems have become indispensable for small businesses in India. They empower enterprises to focus on innovation and customer satisfaction while meeting the demands of a competitive and dynamic market.

Benefits of ERP Software for Manufacturing Industry

The manufacturing industry can unlock significant benefits by adopting ERP systems, which streamline operations and drive efficiency. A primary advantage is improved production planning and inventory management. With real-time data on stock levels, demand forecasts, and production schedules, manufacturers can minimize waste, optimize resources, and meet production goals more effectively.

ERP Software for manufacturing Industry also enables real-time monitoring, helping businesses quickly identify and address bottlenecks in their production processes. This ensures timely interventions and smoother workflows. The inclusion of analytics tools transforms raw data into actionable insights, empowering manufacturers to make informed, data-driven decisions that enhance operational performance.

Another major benefit of ERP implementation is the seamless integration of supply chain and logistics functions. By connecting procurement, warehousing, and distribution, these systems provide end-to-end visibility across the entire production pipeline. This integration minimizes delays, enhances coordination, and ensures that customer demands are met on time, leading to improved satisfaction and loyalty.

In summary, ERP systems revolutionize how manufacturers operate by combining robust data analysis, real-time monitoring, and interconnected workflows. These tools not only improve efficiency but also position businesses to adapt quickly to changing market demands while delivering superior value to customers.

Choosing the Right ERP for Manufacturing Industry and Small Business Needs

There are several considerations to make when choosing that perfect ERP system. It must be scalable to meet the needs of the organization as it continues to expand. Option to customize the product is also another element of equal significance as it lets companies introduce changes to the application to address their particular business processes.

In regard to cost for the small businesses it becomes a big factor to consider hence it is important to compare the initial policies implementation and the costs of maintaining such policies in the long run. A majority of the cloud-based ERP for Manufacturing Industry provide subscription packages that do not require that a massive amount of capital is chucked on the project.

Real life examples demonstrate the reality and promising nature of ERP solutions. For example, a textile manufacturer company in Gujarat who uses Odoo ERP expressed improvements of 25% of lead time and 30% of inventory turnover. These examples demonstrate the real and potential advantages of using ERP systems.

ERP Software for Manufacturing industry Growth and Innovation

These networks have become critical enablers for attaining operational competency especially with the small business and the manufacturing industry. These systems are perfect strategies that help make processes more efficient, improve productivity, and better inform business decisions, which can show the groundwork for the long-term development and stability for any organization that uses them.

By 2025, implementing a proper ERP Software for Manufacturing industry is not a luxury anymore, but rather an imperative for companies that aim at growing and being relevant on the market. Small business ERP and manufacturing firms worldwide need to adopt new ERP solutions as it is a window to adopting new levels of productivity and innovation. The proper ERP system does not only match certain requirements needed by the company but also enables organizations to cope with the fluctuations of the markets.

The ERP solutions available today provide businesses with the freedom of opting for a solution that meets their needs. They allow the connection of each department across an organization and facilitate better working relationships in providing actual-time information used to improve strategies. Over time it becomes evident that these ERP for Manufacturing industry are enablers of growth and help organizations prepare for a more competitive environment.

#ERP for Small Business#ERP for small business in india#ERP Software for Manufacturing Industry#ERP for Manufacturing Industry

0 notes

Text

Odoo Partners in India Offering Custom Development Excellence

Odoo: Partner and Custom Development

Odoo is a complex of applications that is considered as essential to the companies that have the goal to become more effective, productive, and customer-oriented. It can encompass almost any part of a business, from accountancy, stock control and customer relationship management, through to sales and production. More than that, the setup of Custom Development Odoo’s structures is modular and open-source, and this characteristic provides great opportunities to adapt applications to the needs of organizations and industries.

Odoo does meet the expectations of businesses with different size and complexity in such a diversified market as India. Companies that are just starting use Odoo Custom Developments to level the playing field, while large corporations use the software to automate complex processes. This has created a well-developed marketplace of specialty Odoo partners and providers so that companies get the skilled help required for subsequent adoption and deployment.

The Growing Ecosystem of Odoo Companies in IndiaWhile selecting the localization, the expert should take into account that India has become one of the world’s leaders in a rapidly growing rate of Odoo implementation due to its growing IT market, availability of skilled employees, and the need for digital transformation in business. This situation makes the nation an ideal ecosystem for deep and advanced ERP innovations given that it boasts of a robust technology base with a large talent pool. India based Odoo companies are at the forefront of this change that offers businesses with new, adaptable solutions that suit their needs best.

What these companies provide is not mere services on a platter, but services that create opportunity for innovation and growth. As part of spending time in identifying the requirements of different sectors, they design Odoo Companies in India modules that align with the needs of various industries and solve various issues arising in the daily operations. These professionals, who first concentrated on retail and manufacturing industries, address a broad range of industries, from health care to logistics and education. Businesses aiming at implementing digital transformation strategies must have their guidance since they are key for digitization processes.

Indian Odoo service providers are not merely offering solutions; they are affecting meaningful performance improvement and encouraging innovation. Their affirmative efforts are central to improving organizational operations and efficiency in the overall business entities. This has made India a key player within the global Odoo community that is determining the kind of ERP software solutions to be offered across the world.

Role of Odoo Partners in Streamlining Business Processes

Certified Odoo partners in India responsible for managing the Odoo projects, and their tasks are very essential to the projects’ success. Being very familiar, not only with the specificities of Odoo, but also with practical applications of its features and extensions, these partners offer technically sound and, at the same time, business-savvy solutions. This makes them consultants, guiding organizations into how the different implementations can be aligned with general organizational goals.

Odoo partners for Indian businesses are not just vendors, but they are rather the backbone of Odoo businesses. These experts spend time studying the prospects, issues, and prognoses of their clients allowing them to offer precise solutions serving working requirements. Besides IT help, they help organizations to define and prevent threats as well as discover spaces of improvement and creativity.

In every step of the choice to implementation and deployment, Odoo partners provide the necessary augmentation. Their services do not stop at installation, but also involve training, turning down to executing deeds to make sure that business houses get the optimum utility out of their Odoo systems. So by adopting this broad concept it facilitates organizations to respond to environmental changes when it is occurring while at the same time attaining operating superiority.

Custom Development Services by Odoo Implementers

Unlike most other ERP systems, flexibility is one of the major strengths of Odoo, and therefore well suits companies that need more than a basic ERP. Many Odoo implementation Services are from India and they possess great skill in customization for tailor-made solutions interventions to meet organizational needs regarding various issues.

Odoo Extensions are an enhancement to any regular setting, it involves, creating a new module, integrating other tools within Odoo and even setting a feature according to the needs of a business. For instance, a retail organization may require a bespoke inventory tracking and control module for handling a multiple stores format, whereas a manufacturing business may require a scheduler designed to effectively coordinate the limited supply of production assets and control for the cyclical losses inherent in operations.

These implementers have faced complex business processes for example; supply chain management, customer relationship management, and have provided the market with new ways of increasing performance and business development. That ability to write custom solutions to problems makes them valuable in the Odoo marketplace.

Choosing the Right Odoo Service Providers in IndiaChoosing a right Odoo service provider is very important for the success of ERP deployment. When selecting a provider, the performance of a business depends on the technical knowledge, experience and successful track record. The right partner can bring improved solution sets that could precisely fit within a certain business and possible implementation issues are resolved in the long run.

Top Odoo solution partners in India offer directory services, extending from system integration to application customization, consulting services, training as well as support services. They include; Data conversion, integration of interfaces as well as user acceptance ensuring that organizations are able to deal with their strategic initiatives.

Choosing a competent Odoo service partner generates real business benefits such as enhanced operations, better capacity for expansion, and affordability . When organizations delegate ERP implementations, they can ensure that the various goals are well accomplished.

Future of Odoo in India and BeyondOdoo has a strong future ahead in India as its usage is gradually extending to facilities ranging from manufacturing to retail, health care, and tuition. The need for fast, lean, and economical ERP systems remains key for the development of the market. Specifically, Indian SMEs are benefiting from the ways in which Odoo is easily modifiable and extensible and accommodates other applications to improve processes.

AI, IoT, and mobile first approach are the highlights of the next evolutionary phase of Odoo. AI allows for more informed decision-making, IoT optimizes the supply chain, and mobility is helpful from the point of view of real-time access to a company’s tools. Such developments put this application at the forefront of successful workflow in the digital age.

Not only local clients, Indian Odoo service providers also eye on the international market to reach out for their services. The creative and technical solutions they offer along with their affordable prices have made India one of the biggest players on the Odoo market.

As businesses continue to prioritize agility and innovation, Odoo partners in India are well-positioned to drive growth and deliver excellence in custom developments, ensuring a thriving future for Odoo both locally and internationally.

#Odoo Companies in India#Odoo Partners#Odoo Service Providers#Odoo Implementers#Odoo Custom Developments

0 notes

Text

Low-Cost ERP for Small Businesses in India

ERP for Small Businesses

With the firms today seeking to reduce costs while at the same time expanding in the emerging and competitive market structure in India, small businesses are no exception. For purposes of this paper, Enterprise Resource Planning (ERP) systems that used to be available to only large organizations have become relevant systems for small enterprises. This blog goes beyond merely explaining low-cost ERP adoption for small businesses in India, and extends into how these solutions are helping manufacturing and other industries successfully.

Understanding ERP for Small Businesses in India

ERP systems facilitate the management of organizational operations since several fundamental business processes are bundled in this system. The two major factors that small businesses in India have been facing have always been cost and sophistication. Of course, these concerns are mitigated by low cost ERP solutions which provide relatively easy to integrate solutions more specifically configured to address the requirements of SMBs. They help in organizing inventories, accounts, and supply chains and bring efficiency for the business owners to make right decisions.

Digitalization is on the rise in India through government adoption of ideologies such as “Digital India” which has encouraged small enterprises to adopt ERP systems.

Purchasing a low cost, today’s ERP software directs itself to a particular area of specialization such as manufacturing or retail or service industries, etc., so that it offers appropriate features for meeting corporate needs for efficient operations.

Why Choose Low-Cost ERP for Small Business Manufacturing?

Small business manufacturing is generally characterized by very low profit margins which makes proper resource utilization compulsory. Affordable ERP systems can integrate repetitive functions, provide resource tracking and control production scheduling for the manufacturing industry. It also offers affordable operation thus increasing overall organizational efficiency.

For instance, when choosing the software for small business manufacturing ERP systems might contain production planning, quality control, inventory modules among others.Furthermore, such software enables corporations to satisfy the client requirements faster and enhance the loyalty of clients.

As for the small businesses in India, the growth of ERP has the advantage of entrance in small scale, big in process. This adaptability also means that manufacturers do not have to incorporate a lot of unwanted aspects in their products, which holds initial implementation costs in check.

The Role of Manufacturing Software for Small Business Growth

Software that supports manufacturing for small businesses is one of the industrial solutions that is crucial to companies’ development as it provides the solution for substantial operational issues.This do not create bottlenecks and also nurtures health culture or work and efficiencies.

Manufacturing software describes some aspects of automation and effective communication programmes for managing work flow, production of reports and approximations within production departments. They also assist small manufactures in coordinating organizational activities with business goals in order to retain flexibility. Moreover, requirements of industries are easier to meet because most ERP systems contain modules, which correspond to legal demands.

Truly for the small business in India, the investment made in the manufacturing software is about creating a platform for future growth. Substituting current standard activities for activities that can be more efficiently accomplished through the use of technology can free up an entrepreneur’s time to develop new and well-thought-out ideas to penetrate growing markets in an ever-competitive world.

Cost-Effective ERP Solutions: Breaking the Accessibility Barrier

One of the reasons that forced many small businesses to slow down or completely drop the implementation plans is the notion that ERP systems are very costly. But low-cost ERP for the Indian small business is gradually turning the tide. The traditional key operations, including finance, inventory, and customer relationship management, can now be performed by affordable solutions.

Such affordability is further enhanced by the emergence of the new cloud-based ERP systems. Cloud ERP is also more affordable than other on-premise systems since they don’t require an enormous capital investment as customers purchase a license but pay for the software service instead. This allows even the start up businesses to adopt the advanced technology hence be able to enjoy the fruits of mechanized business entities.

Moreover, availability in service packages is also a frequent strategy with ERP for small business manufacturing vendors. These solutions mean that businesses only pay for the extras which in turn make it possible for them to be both practical and affordable.

ERP for Small Business in India: Overcoming Implementation Challenges

Of course there are a number of advantages that can be accredited to the implementation of ERP systems however the process is not without its issues for small businesses especially. The challenges which people may face include lack of technical knowledge, reluctance to change, and financial problems. But all the above challenges can be avoided if the right low-cost ERP provider is selected.

Every experienced vendor offering ERP solutions for small businesses in India guarantees the intuitive interface, extensive training for users, and efficient support service. This makes sure that organizations can easily implement an ERP system without facing a lot of problems.

The Evolution of ERP Systems for Indian Small Businesses

Once ERPs were large and costly systems today they are relatively more versatile, easier to implement tools that define small business needs. In particular, the change of this type is very suitable for the Indian conditions, for the Calderon – MSMEs which forms the financial foundations of the country’s economy. The various inexpensive erp systems in the market for small businesses are especially developed to solve some problems like less capital, lag of professional personnel, and inadequate resources.

Software for manufacturing and as a part of the ERP suite has been a boon for small businesses. These tools focus on the needs of production based small organizations through the provision of tools such as production, inventory, and quality control. Localized solutions mean that there is superior business erb for Indian small businesses since the solutions can be configured to meet specific industry needs and other compliance.

ERP’s adoption also happens simultaneously with India’s digital drive as well as the worthy causes such as ‘ Digital India’ and ‘Make in India’ to impel small enterprises to go for technology improvements.

Key Features of ERP for Small Business Manufacturing

ERP for small business manufacturing brings concern to improve and optimize manufacturing processes and flows. There is the inventory feature for instance, which assists the business to manage its stock well so that it does not end up with either of the two problems, a scarce stock or surplus stock. Production scheduling is also an important element; the manufacturing processes are organized between supply chain members and timeframes are respected.

Main quality management tools that are integrated in the ERP systems for developing small business manufacturing enable organizations to achieve quality standards and control on defects. This they achieve for the purpose of developing customer confidence and for compliance to the set standard. Sometimes, these systems also provide modules for equipment maintenance so that potential downtime could be minimized, and productivity could be improved.

They also include real decisions that ERP for small businesses, we get real time business analysis which helps the manufactures in removing bottlenecks in the business process repeatedly. Through these features, small enterprises will thus be able to hold their own against massive enterprises with relatively lower costs.

Benefits of ERP for Small Businesses in India

Consequently, the implementation of ERP for small business in India has many advantages such as increased organizational efficiency, management of finance and better decision making. By having all the vital business information contained in one place, business owners are fully aware of their business happening. This helps them be able to see areas in the chain that are costly and working on a way to increase its profits.

To specific sectors of manufacturing businesses being the small businesses, the benefits of ERP are unique in that it offers them efficiency in production and minimizes wastage. All these advantages are relevant especially with regard to the Indian conditions, as most of small businesses are close to marginal. Besides, cheap ERP solutions allow companies to cut down on manual entries further decreasing the risks of mistakes and time consumption.

Another important benefit of the contemporary ERP systems is their scalability. Small businesses can start common modules and later expand to other advanced modules. Such flexibility keeps ERP for small business viable in the long term and affordable for any business that is planning for growth in the near future

Choosing the Right ERP for Small Businesses in India

Choosing the proper ERP means determining what your company requires, specifically for the organization. For example, small business manufacturing firms would be reasonable and rational incurable in special production planning and inventory management elements. On the other hand, enterprises that are more focused on the retail side may find sales and customer relationship management modules relevant of higher importance.

The availability and comparatively low cost of ERP solutions for small business in India is the other factor. SaaS ERP solutions have therefore developed as a new trend of service where Organizations subscribe to the service provided by the ERP software developers at a fee while incurring less costs for hardware and infrastructure than in the traditional on premise solutions. These systems are also relatively easy to integrate into workplace practices and less resource demanding in terms of maintenance thus suitable for organizations, particularly the small business types, with inadequate information technology support.

Any ERP selection should fit into your organization needs and should be scalable for future. Thus, when oriented on such factors, small businesses can identify efficient ERP solutions which will cost less while being useful.

Challenges in Implementing Odoo Erp Software for Small and Medium Businesses

ERP systems have many advantages that include improved organizational efficiency Most executives, however, will agree that the implementation of Odoo Erp Software for Small and Medium Businesses is not without its problems. ERP implementation may be expensive even with inexpensive ERP solutions, and this is one of the biggest challenges. Small businesses in India, especially the new ones, face a major challenge in that they are able to allocate a big chunk of their capital to software implementation and training.

The next problem is the absence of qualified personnel in the companies’ staff – personnel who focused mainly on fostering technical competencies. Learning from ERP systems may be a new concept that small business owners and employees may not have come across before thereby requiring them to go through a steep learning curve. Furthermore, ERP integration with other systems may also be challenging because the existing manufacturing software for small businesses need interfaces for equipment and machinery.

However, when implementing ERP systems, there are major challenges that an organization is bound to meet in the initial stages of its implementation but the benefits are longer term and outweigh the challenges.

The Role of Cloud Technology in ERP for Small Businesses

As a result of the technological advancements in cloud computing, ERP for small businesses in India has shifted greatly and become more affordable. Unlike the conventional ERP systems that called for major investment in hardware as well as other supporting structures, most of the cloud-based ERP systems work on the idea of licenses. This does not require the business organization to invest heavily at the start which is common in cases that require large capital investment, sm Bundy Hence making the decision easy for the small business organizations to implement.

Cloud ERP systems also come without flexibility that is difficult to match in other systems. This helps business owners have easy access to their data without having to go to the business premise, allowing people to work from the comfort of their homes, use current data to make decisions or timely interventions. This is especially useful in small business manufacturing where most of the managerial personnel will be using the system to oversee production lines from different places.

Another thing is that cloud ERP systems are built to easily expand downward or upward when needed. This way, new features could easily be incorporated as a business evolves, without necessarily having to parlay the whole system. This also guarantees that ERP for small businesses is a sustainable solution, one that can help sustainable growth.

Future Trends in ERP for Small Business Manufacturing

This paper discusses how new technologies and changing business trends determine the future of ERP for small business manufacturing industries in India. Enterprise resource planning (ERP) is one of the most important technological trends in modern business, the development of which will be significantly influenced by artificial intelligence and machine learning. These technologies allow for accurate decisions to be made in order to predict and therefore stay ahead of the market.

Another interesting trend is the connection of the Internet of Things (IoT) with ERP software programs. Real time data from equipment, stocks and production processes is achievable through use of IoT devices which can improve manufacturing software for small businesses.

Customization will also increase as ERP providers will provide special designed solutions according to the need and demand of small business in India only. This means that ERP systems stay relevant and pertinent in today’s ever changing business world.

Transforming Small Businesses with Affordable ERP

ERP for small business entities has become more of a necessity than luxury in India. The solutions are flexible for any company size and prerequisites that allow even small businesses to gain a competitive advantage by applying the features of advanced technologies.

In the case of small business manufacturing, it becomes easier because the use of ERP systems turn out to be very vital especially in boosting efficiency, conformity and quality. Through the above solutions, the small business can be at par with the large business and even succeed in the modern business environment.

Over time, available and advanced ERP systems will enhance as advances in technology progresses. This therefore poses a chance to India’s small business to consider developing strategies in embracing digital transformation in their business operations in a bid to post sustainable growth of their businesses.

0 notes

Text

Why ERP's Major Role in 4.O Manufacturing Industry?

Major Role of ERP for 4.O Manufacturing Industry

Today, the manufacturing industry is changing faster than ever before, and this has been accelerated by the coming of the fourth industrial revolution. This new one is said to be the fourth industrial revolution which integrates complex manufacturing with intelligent systems. To support this transition, Enterprise Resource Planning (ERP) systems including SAP Business One has gained centrality. They make work easy, faster, and even enable real-time analysis of data that is being captured. To maintain competitiveness and innovativeness of the 4.O manufacturing industries, companies are implementing ERP to respond and perform well to these changes.

Understanding ERP Systems in Manufacturing

You might have often thought about how the modern manufacturing companies keep all the running going. Enter ERP systems! ERP stands for Enterprise Resource Planning: it is like the brains of the manufacturing operations . It allows companies to make efficient decisions in order to control and/or develop all organizational fields. So let’s take a closer look at what makes ERP tick in the manufacturing environment.

Definition and Components of ERP

ERP systems are integrated application systems that attempt to achieve a single year of operations and manufacturing business management. Think about having a superhero that doesn’t save the world, but helps businesses to save their time and money! That’s ERP for you. It includes production, materials management, logistics, financial, personnel and public relations.

The components of an ERP system can be mind-blowing but wait for it! Here’s a quick rundown:

- Financial Management: Works in finance, perpetuates data, budgeting, and reportage.

- Supply Chain Management: Improves the efficiency of the material and product supply chain all the way through to the customer.

- Production Management: Oversees production activities with significant emphasis on ways to get them as optimized as possible.

- Inventory Management: Monitors stock status as well as the functioning of a warehouse.

- Human Resources: Is responsible for recruitment and selection of employees, processing of employees’ salaries, and recording of their details.

- Customer Relationship Management (CRM): Responsible for handling customers and records their sales.

These are integrated where each element provides an overview of the business processes and makes certain that pertinent information is assembled, conveyed and received appropriately.

History and Evolution of ERP in Manufacturing

Today, ERP is a complex system but it has come through a long evolutionary process starting out as a simple system with limited functionality. Initially, ERP systems emerged from materials requirement planning (MRP) systems as created in the 1960s and 1970s. These MRP systems were implemented with an aim of providing solutions on how much raw material to order and when.

Fast forward to the 1990s, ERP Systems were not only planning materials but extending to adaptive processes of the enterprise. When getting deeper into the 2010s, one could talk about cloud computing as an essential booster for business development. It made ERP systems access, flexibility, and scalability possible. Today, manufacturers have systems like SAP Business One that accounts for the dynamic need of manufacturers globally including the active manufacturing industry in India.

Key Features of ERP Systems for Manufacturing

Today’s ERP systems are chock full of functions that make them essential to any manufacturing organization. Here are some key features that stand out:

- Integrated Operations: Another key value of ERP is its efficiency at the centralization of activity. They disintegrate various portfolios of a business by effectively linking business processes while providing easy access to information.

- Real-Time Data Access: In ERP, one is in a position to make decisions because most of data is updated with real time data. This immediate visibility is vital because organizations need to be competitive when the new environment emerges.

- Automation: ERP helps the firm to complete several operational activities such as processing orders and remunerating employees and several other activities thereby leaving the employees time to focus on other critical activities in the business.

- Regulatory Compliance: Most of the ERP systems are equipped with compliance modules to ensure that the organization does not fall foul of the set legislation resulting in costly fines.

- Scalability: That is why ERP systems are regarded as a good investment, for the small local manufacturer or for the worldwide leader, as the systems are developed with the ability to grow with the organization.

From the brief outline of what ERP systems are, let's now proceed to the discussion of the effects and applications of ERP systems in real life manufacturing.

The Impact of ERP on Manufacturing Processes

The impact of ERP systems on manufacturing processes is significant and transformative. They don't just help run the business; they take manufacturing to a whole new level of efficiency and effectiveness.

Streamlining Production Planning and Inventory Management

ERP can be regarded as a wizard that sends manufacturers to order appropriate inventory at the correct time. Through ERP, production planning is done effectively and in a way that enables institutions to meet customer demand and needs without incurring many losses through retaining many inventories within its fabric or through often shutting down production.

- Efficient Resource Allocation: This is helpful in that ERP enables organizations to schedule production plans and control aspects of resource utilization in order to reduce time wastage and optimize efficiency.

- Inventory Optimization: Inventory management is another key area where ERP systems make a lot of difference by automating inventory and controlling optimum stock levels to cut down carrying costs and to avoid situations where you may run over or short of stock.

- Forecasting: While years past may inspire certain educated guesses on the manufacturers part, ERP for demand planning provides fact-based insight, which in turn increases satisfaction among clientele.

Improving the Quality of Control and Assessments

For any manufacturing company, quality always reigns supreme and it’s at this point where the ERP system comes in handy. These tools enable organizations with real time monitoring and quality assurance of the final product within ERP systems.

- Process Monitoring: In using the ERP systems, there is a way to monitor the production processes in real time, and variations affecting quality can be ascertained at once.

- Traceability: In the case of a problem, ERP generates a complete traceability trail to control and handle product recall or defect problems, lessening danger and protecting brand reputation.

- Compliance and Reporting: Time-consuming tasks of documentation and report generation are also automated, and this Reuel asserts that quality is not a mere aim, but a guarantee.

Improving Supplier and Customer Relationship Management

Good relationships with suppliers and customers are crucial in the manufacturing sector. ERP systems facilitate these relationships through better communication and data management.

- Supplier Collaboration: With ERP, manufacturers can work closely with suppliers by sharing forecasts and demands, improving lead times and reducing supply chain disruptions.

- Customer Satisfaction: From order tracking to managing customer feedback, ERP systems enhance the customer experience by ensuring timely deliveries and quality service.

- Data Sharing: ERP systems aggregate customer data, allowing manufacturers to understand buying patterns, preferences, and feedback, leading to tailored marketing strategies and improved product offerings.

Thus, ERP systems are not only hardware but it is platforms that change games for the manufacturing unit of an organization. They let the manufacturers be efficient, establish adequate control over the quality of goods, and maintain a good and solid supply chain with the suppliers and customers. In the context of Industry 4.0 which is gradually defining the future of manufacturing, an ERP system is well-positioned to ensure that a business remains relevant, complies with the law, and delivers excellent customer experience.

Therefore, if you have been in the manufacturing sector and have not incorporated ERP magic, then wouldn’t it be of immense benefit to think about it right now. Since the future of manufacturing in India and across the world is right tied with these systems, the ERP integration can be your key to novelty and victory.

There you have it! ERP systems translated for the new generation manufacturing enterprises. Well, it is time to work better, not more!

Benefits of Implementing ERP for Manufacturing Industry

Enterprise Resource Planning (ERP) systems is become a new trend in manufacturing industries particularly in 4.0 manufacturing context. An ERP system is capable of linking different business processes which act as a technological advantage for manufacturers and greatly enhances their operations. Now that we have established the foreground information it is about time we look at some of the aspects that stand to gain from the integration of the ERP systems in the manufacturing industry.

Better performance, efficiency and productivity

In the very center of any manufacturing company, it is possible to single out such notions as effectiveness and output. Essentially, ERP for manufacturing industry help in enhancing these aspects since the systems incorporate optimized processes of various departments. ERPs perform repetitive as well as redundant processes automatically and hence reduce the capacity of people in making mistakes. For example, the ERP systems can provide the link between the manufacturing or production plan and the inventory to ensure that right material is available on the shop floor when needed, eliminating unnecessary idle time.

Furthermore, ERP systems are integrated information systems in which employees can find actual information related to various activities, so employees can make the most of their time instead of spending time and efforts to search for information. Since information flow between departments is not disrupted, problems that may slow down workflow are realized early and solved, which increases efficiency. This is important in an industry where timing is of the essence!

Cost Reduction and Profit Maximization

Meeting cost reduction targets have always been a prerequisite to survival in manufacturing especially where profit margins have to be optimized. It is toward this objective that ERP systems play a very crucial role to offer manufacturers a wealth of information on their operations. Because ERP systems incorporate detailed records of cost related to production processes, inventory, and supply chain management, the systems afford the businesses opportunities to reduce meaningful costs of production.

Moreover, by accurately predicting the demand for products in an organization and handling the levels of stocks being put in place ERP systems enhance stocks management. It helps to avoid overproduction and underproduction that cause lots of financial losses in the business. In addition, since the processes are mostly performed automatically, one of the main factors that decrease the overall labor cost are achieved, thus resulting in an improved profitability.

Real-time Data Analytics and Decision Making

That said, real-time data analysis for better decision-making increases the potency of ERP systems in manufacturing . Since many industries have become data-oriented, it is critical to have real-time data when making business decisions. By having an ERP system, it is possible to track KPIs on manufacturing as well as predict trends that may affect manufacturing efficiency or the market.

It also helps to increase response time to changes in supply and demand, so that manufacturers can fit their actions to the market. Further on, upgrade in data visibility results in enhancement in forecast and planning which in turn result in better resolution and utility of resources and enhanced customer satisfaction. This can be achieved by optimizing the use of data so that manufacturers may know their competitors better and hence capture the right market opportunities for growth.

Challenges in ERP Software for Manufacturing Industry

There are many benefits to ERP systems in manufacturing organizations but it is not without its issues in the transition. Here are some of the usual problems manufacturers encounter while implementing ERP systems and how the latter can be addressed.

Interoperability with Other Systems

Manufacturers find it quite challenging to integrate the new ERP Software for Manufacturing Industry with the rest of the existing legacy systems. A high percentage of manufacturing organizations still employ suboptimal methods and technologies incompatible with up-to-date ERP systems. Depending on the degree of incompatibility, there can be some loss of efficiency during the period necessary to resolve it, as well as certain costs associated with time loss.

To counteract impediments to integration, manufacturers need to evaluate integration readiness by performing a current state assessment of manufacturing systems prior to ERP adoption. It is crucial in this evaluation to determine potential conflicts and assist in the creation of a detailed integration strategy. However, there are several steps to consider when implementing the choice of an ERP system in the following aspects: Furthermore, selecting the ERP system that provides capabilities of integration and flexibility can eliminate some of these challenges. It also helps if one has worked with experienced ERP vendors or consultants, who would be better placed to appreciate the different factors involved in implementing a manufacturing system.

Managing Change and User Adoption

Implementation of a new ERP system may lead to substantial changes in practices of a manufacturing enterprise, as well as redefine roles and tasks of employees. The employees may resist change as some may prefer sticking with the current systems in place. One of the most significant tasks here remains guaranteeing a seamless transition and post-implementation acceptance.

To address this, manufacturers should encourage openness and engage the users at the initial stage. Delivering training that is more extensive and engaging in collecting feedback from the employees can foster confidence and promote acceptance. Concerns can also be addressed by providing information on what the new ERP system will do for them and how it is going to facilitate their operations. This means that every change management strategy ought to be incremental and should illustrate how the change affects the employees in the short run.

Ensuring Data Security and Compliance

In the current world where operations and almost everything are computerized, there is high demand for protection of data, particularly in manufacturing industries. The integration of a new ERP system poses risks inherent with exposure to data and threats pertinent to industry standards. Managers working for the manufacturing firms have to guarantee that the company and clients’ data is safeguarded from unauthorized access or cyber threats.

In their choice of an ERP provider, manufacturers are advised to put security into consideration and look for the provider with robust security policies and compliance compliance certificates. This involves having aspects of encryption, rules for accessing data, and even a security check in the program to check for vulnerabilities. Furthermore, to ensure data accuracy, data utilization, and adherence to legal requirements, a solid foundation for data governance has to be built. To address security risks during the implementation of ERP and also after the implementation, other necessary measures include security training of the employees and security awareness within the firm.

Thus, ERP systems are also crucial applications for updating and enhancing operations in the 4.0 manufacturing environment. The advantages of increased efficiency, decreased costs, and evidence-based decision-making are evident, however, they include a number of integrating concerns that relate to change and data management and protection. If implemented and managed properly, manufacturers can use all the possibilities of ERP systems to boost their innovations, productivity, and revenues.

Future Trends and Innovations in ERP for the Manufacturing Sector

The manufacturing world is changing and at the heart of this change is ERP, or Enterprise Resource Planning. Thus, the applicability of ERP systems does not diminish when industries first set out on Industry 4.0. Let me explain what technology is doing to ERP to define the future of the manufacturing industry.

Integration with IoT and IIoT

But the most significant trend is the integration of the ERP systems with the internet and, in particular, with the Internet of Things (IoT) and Industrial Internet of Things (IIoT). This integration allows machines to feed data to ERP systems and this data is always current to help in efficient decision making. For instance, an assembly line would detect that it requires repair, and the information gets input to the ERP system, the system informs the maintenance department or even orders spares. All these can be achieved through the integration which can eventually help to cut down the much needed downtime.

AI and Machine Learning Improvements

If you are new to the world of technology, chances are that you have heard about Artificial Intelligence (AI) and Machine Learning (ML) before. These technologies are helping ERP by giving them forecasting and analysis. With AI-powered ERP platforms, manufacturers can:

- Predict equipment failures: Similar to human operators, AI Algorithms can assess and interpret patterns in the data that point towards possible failure of a machine in order to rectify the problem before it happens.

- Optimize supply chains: Thus, ML can discover from historical information about supply routes and timings and recommend the most effective ones with the least hindrance and requisite.

- Enhance quality control: Thus, through analyzing big data, it is possible to detect imperfections in production and reach a higher quality, earlier.

Cloud-Based ERP Solutions

The move toward cloud-based ERP has continued to grow, providing benefits that on-premise systems cannot; namely; flexibility and scalability. Cloud ERP systems allow manufacturers to:

- Access data anywhere, anytime: They can be P/C or mobile, but remain in touch with the factory floor in real time.

- Easily scale operations: With cloud solutions, as companies expand, there is little need to overhaul the infrastructure of the delivery process.

- Improve collaboration: Improve the coordinator and effective communication and interaction between different departments and locations and if possible between sites all over the world.

Cybersecurity Measures

Digital transformation, as well as interconnected systems and networks, the issue of cybersecurity remains the key priority. As the ERP systems progress, organizations are having stricter measures to cover for the critical information. Some of the characteristics that are normal to find nowadays are more secure and stronger encryption modes, two or three factors of authentication, and real time monitoring. For manufacturers, this means more secure data, as well as a minimized chance of a cyber threat that might affect performance.

Bespoke and Friendly Modules of an ERP System

The ‘Fortune 500’ mentality is no longer dominant as gods-like ERP systems of the past were ponderous and hostile. Organizations are now moving to more natural and user friendly interfaces. One of the recent trends in modules of an erp system is that design in terms of UI/UX is gradually improving. These systems can be easily operated by the employees or the technical workforce, little learning time is required thus making the entire process efficient.

ERP and Sustainability

Environmental or ecological responsibility is rapidly becoming an important issue to manufacturers in the global marketplace. The latest developments in ERP solutions are in compliance with these green programmes through supporting the analysis of resource consumption and waste generation by companies. Features include:

- Tracking carbon footprints: ERPs can estimate the amount of emissions made and provide solutions on how to optimize emission’s figures.

- Efficient resource management: Inherent in systems is the effectiveness in the put to use of materials thus discouraging the use of the excess and encouraging recycling.

- Compliance with environmental regulations: Real time updates and reports make it extremely easy for manufacturers to implement compliance with regulatory metrics.

ERP Systems will continue to be part of the manufacturing industry as it prepares to march forward into the next phase. Based on the presented trends and innovations, manufacturers can not only improve their operations but also become pioneers of the new generation 4.0 industry. From integrating new technologies to operating in the cloud, to sustainability initiatives, ERP is a virtually limitless platform. Therefore, to a bright, efficient and innovative future of the manufacturing sector with ERP at the heart of it – cheers.

#erp software#erp solution#erp for manufacturing industry#sap business one#manufacturing industry#erp software for manufacturing

0 notes

Text

Try SAP Business One Free Trial - No Cost, All Benefits

Experience SAP Business One Free Trial - No Cost, All Benefits

Entering the waters of ERP is a startling plunge as those with experience may testify to. However, with the SAP Business One free trial, the full potential of using a powerful ERP solution can be seen, without a risk of a costly mistake. SAP Business One is ideal for companies in the small and medium-size range, providing an all-in-one solution that will help to organize the business and improve growth. Therefore, why not try it and see for yourself how your business will be boosted by the new system? Here’s what makes this free trial a game-changer for business users:

- Cost-Free Exploration: Dive into SAP Business One at zero cost.

- Comprehensive Features: Access critical functionalities like workload automation and application stack management.

- Adaptable Solutions: Tailor the platform to fit your unique business needs.

- Instant Benefits: Start seeing improvements in efficiency and decision-making right away.

Understanding SAP Business One

SAP Business One is not your average software; it is an integrated enterprise resource planning solution specifically created for the small and midsize companies who want to compete with market giants. If the complex world of business management looks like sailing through thick and thin, then SAP Business One is your experienced crew.

What is SAP Business One?

Your entire process of accounting, sales and customer relationship management, purchasing, inventory and production all in one place. That is why you have SAP Business One. It is a single package that enhances the capability of any business organization to improve its working activities effectively. Originally developed by SAP SE, a pioneer in business application, SAP Business One is a go-to solution for businesses eager to increase the level of cooperation and gain more control over their processes.

SAP Business one is mainly designed for small and medium enterprises that need a strong solution without getting trapped with excessive features and expenses of an Enterprise Resource Planning system. It can be viewed as a smaller version of what SAP offers to enterprise level companies guaranteeing that you get all the necessities to get through in the business world.

Key Features and Benefits

SAP Business One boasts an impressive array of features that cater to various industries and business needs:

- User-Friendly Interface: It is true that for a larger infrastructure where a new system is being implemented, the ease of appreciating a product can be traced to simplicity of the interface. Due to the graphical nature, it is easy for the users to understand the positions of the icons and tools and thereby easily get to work.

- Real-Time Analytics with SAP HANA: Experience fluent operations with real-data and possibilities to make decisions using in-memory computation of SAP HANA. Imagine no more of sitting around for a report; information is just a click away.

- Scalable Architecture: That is why, as your business expands, SAP Business One offers you tools for its further development. Since it is built on a scalable structure, you can incorporate other users and functions as its development progresses without feeling you are lacking some functional features.

- Customizable and Flexible: In today’s climate of limitless choices of add-ons and integration capabilities, SAP Business One can be configured to reflect specific client requirements. Whether it’s a specific sector necessity or another use case such as AppDynamics or workload orchestration, fluidity comes included.

- Comprehensive Modules: All of them from the financials through CRM is all part of a total concept. One stop management reduces system switching time and offers more time in advancing your business to the pinnacle.

- Support for Decision Makers: Business intelligence tools and data marts enable decision makers to gain more information, in order to support strategies firmly on the data.

Comparison with Other Accounting Systems (QuickBooks vs SAP/Oracle)

When reviewing SAP Business One, people want to know how good it is compared to rivals such as QuickBooks and Oracle.

- QuickBooks: Suitable for tiny businesses and startups, QuickBooks has been reported to be easy to use and inexpensive. However, as organizations grow, QuickBooks are found to be limited in the number of features that are offered by SAP Business One especially in the area of inventory, reporting and scalability.

- SAP Business One vs. Oracle: Oracle has several enterprise level solutions which may consume significant resources in implementation. However, SAP Business One has been designed specifically, with small and medium enterprises in mind and this may be a big plus over Oracle. SAP Business One might provide capabilities that Oracle lacks, yet the simplicity and affordability of the system make it attractive for growing companies that will not be able to navigate around complicated software.

Therefore it can be deduced that selecting the right ERP is mostly about compatibility. SAP Business One delivers the strong performance needed in extended companies but with the simplicity and essential features of a small scale system.

Why is SAP a Preferred Choice for Businesses?

SAP is globally renowned and trusted by many businesses across different industries. With SAP Business One, you benefit from:

- Flexibility and Scalability: Easily adapt to changing business needs as you grow.

- Industry-Specific Solutions: Choose from various modules designed for specific industries.

- Reliable Support: Access a vast network of support and community forums.

Benefits of Free Demo SAP Business One

The decision to implement SAP Business One has many benefits that will change business operations as understood by many people.

Higher Effectiveness with Combined Processes

One of the advantages that can be distinguished is intensified productivity. SAP Business One Free Demo integrates all aspects of your essential business activities to avoid bottlenecks of data duplication. It reduces the time taken to execute business processes and eliminate inconsistent results.

Advantages for the Business customers and Other Entrepreneurs