#Rubber Timing Belt Suppliers

Explore tagged Tumblr posts

Text

DKT Engineering Enterprises has created a video showcasing the benefits of our Rubber Timing Belts. Industry experts highly recommend our product due to its exceptional durability. If you want to learn more about this belt, we encourage you to watch our informative video.

#Rubber Timing Belt#Rubber Timing Belt Manufacturers#Rubber Timing Belt Exporters#Rubber Timing Belt Suppliers

0 notes

Note

Hi please can you tell me which supplier made your gorgeous latex maids outfit?

I've worn an awful lot of maid uniforms over the years, so if you don't specify which one, this is going to be along answer.

The Formal Evening Uniform

This is the uniform that I wear when serving dinners, at parties, and when Mistress is relaxing after work. It’s my most formal uniform, and is for serving, not for housework.

Libidex Valerie Bolero https://libidex.com/valerie-bolero.html

Libidex Aurora Peplum https://libidex.com/aurora-peplum-skirt-long.html

Catalyst Latex Skating Dress https://www.catalystlatex.com/product-page/latex-skating-dress

Catalyst Latex Suspender Belt https://www.catalystlatex.com/product-page/latex-betty-suspender-belt

Westward Bound Bordelle Corset https://www.westwardbound.com/bordelle-lamour-lace-panelled-corset-latex-rubber-clincher-p1130

Custom Latex Nemesis hood https://latexnemesis.com/build-your-own-hood-1/

Custom-built blowjob mask https://fetlife.com/users/9590495/posts/7483607

The Day Uniform

This is the uniform that I actually do housework in, and is, by far, the most commonly worn. The long sleeves and skirt means that it’s practical for chores, and the thick, chlorinated latex means it’s durable. Unfortunately, it is now out of production, and I’ve been looking for a replacement. Hopefully, I’ll be able to find one before the last copy of this dress in the closet becomes worn out.

Sissy Bleu Dress by Catalyst Latex (discontinued) https://www.catalystlatex.com/

Catalyst Latex Suspender Belt https://www.catalystlatex.com/product-page/latex-betty-suspender-belt

Custom Latex Nemesis Hood https://latexnemesis.com/build-your-own-hood-1/

The retired uniform

My previous evening uniform was retired because the integrated corset in the dress is an absolute pain to manage. Zipping a corset with lube-covered hands caused me to be late to evening service so many times.

Libidex Valerie Bolero https://libidex.com/valerie-bolero.html

Libidex Aurora Peplum https://libidex.com/aurora-peplum-skirt-long.html

Libidex Jodi Corset Dress https://libidex.com/jodi-corset-dress.html

Catalyst Latex Suspender Belt https://www.catalystlatex.com/product-page/latex-betty-suspender-belt

Custom Latex Nemesis hood https://latexnemesis.com/build-your-own-hood-1/

There's a complete guide to all my outfits on my Fetlife blog. https://fetlife.com/users/9590495/posts/8001381?sp=48

62 notes

·

View notes

Text

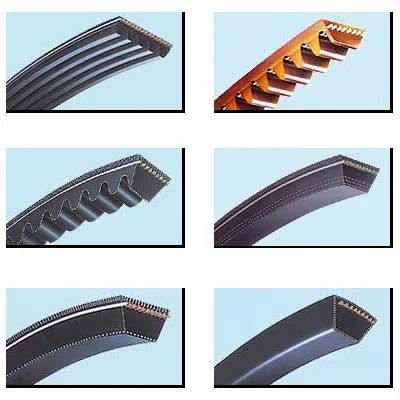

V-Belt Manufacturers in Delhi: A Guide to Top Suppliers and Industry Insights

V-belts, also known as "vee belts," are an integral component in power transmission systems, playing a crucial role in various industries. These belts are designed to transfer power between rotating shafts, typically used in engines, conveyors, pumps, and other machinery. Delhi, being a major industrial hub in India, is home to a wide array of manufacturers that specialize in producing high-quality V-belts for diverse applications.

In this blog, we'll explore the top V-belt manufacturers in Delhi, their offerings, and why they are important players in the global and domestic markets.

What is a V-Belt?

A V-belt is a looped belt with a V-shaped cross-section that fits into a matching groove on the pulley. The design enables the belt to grip the pulley more effectively, providing efficient power transmission. They are typically made from durable materials like rubber, and their flexibility and durability make them ideal for heavy-duty applications. V-belts are commonly used in industries such as automotive, textile, agriculture, construction, and more.

Key V-Belt Manufacturers in Delhi

Fenner India Ltd. Fenner India is one of the most prominent manufacturers of power transmission products, including V-belts. They are known for their high-quality industrial belts that cater to a wide range of applications. Fenner’s V-belts are designed to offer long-lasting performance, minimal maintenance, and superior efficiency. They serve multiple industries, including automotive, mining, and agriculture, and are recognized for their global presence.Key Products:

Classical V-Belts

Narrow V-Belts

Cogged V-Belts

Variable Speed Belts

Why Choose Fenner India?

Trusted brand with decades of experience

High-quality raw materials and advanced manufacturing techniques

Global customer base and international standards

Bando India Ltd. Bando is a leading manufacturer of power transmission belts and is highly regarded for its high-quality V-belts. The company has a strong presence in India, especially in Delhi, where it serves various industrial sectors. Bando's V-belts are designed for high performance and are used in industries such as automotive, textile, and agriculture.Key Products:

Standard V-Belts

High-Performance V-Belts

Timing Belts

Conveyor Belts

Why Choose Bando India?

Precision-engineered belts for efficient power transmission

Strong reputation in the automotive and industrial sectors

Reliable customer service and after-sales support

Continental Belting Pvt. Ltd. Continental Belting is another well-established name in the V-belt manufacturing industry in Delhi. The company offers a comprehensive range of belts, including V-belts, conveyor belts, and timing belts. Continental’s V-belts are widely used in both industrial and automotive applications due to their excellent durability and cost-effectiveness.Key Products:

Wrapped V-Belts

Cogged V-Belts

Narrow V-Belts

Poly V-Belts

Why Choose Continental Belting?

Diverse product range catering to various industries

Competitive pricing and reliable performance

Well-versed in meeting international standards

PIX Transmissions Ltd. PIX Transmissions is a leading V-belt manufacturer in Delhi with a strong focus on the power transmission and automotive industries. PIX V-belts are known for their high efficiency, reliability, and long service life. The company exports to over 100 countries and offers both standard and customized V-belts for different industrial needs.Key Products:

Classical V-Belts

Narrow V-Belts

Cogged V-Belts

High Power Transmission Belts

Why Choose PIX Transmissions?

Focus on R&D to enhance product quality

Customization options available

Strong international presence and exports

MIPL (Motorized Industrial Products Ltd.) MIPL is a prominent manufacturer of V-belts in Delhi, offering high-performance power transmission belts. They supply belts for a wide range of industrial applications, from automotive to mining and agriculture. MIPL’s V-belts are designed for reliability and provide superior grip and efficiency.Key Products:

Industrial V-Belts

Automotive V-Belts

Polyurethane Belts

Customized Belt Solutions

Why Choose MIPL?

Focus on custom-made solutions for specific requirements

High-quality products at competitive prices

Established track record of delivering on time

Key Considerations When Choosing a V-Belt Manufacturer

When selecting a V-belt manufacturer in Delhi, there are several factors to consider:

Quality Assurance: Always look for manufacturers that follow industry standards and quality certification processes to ensure the V-belts are durable and reliable.

Application Requirements: Different industries require specific types of V-belts, so choosing a manufacturer that offers a wide variety of options can be beneficial.

Customization Options: Some manufacturers offer the ability to create custom-made V-belts, which is ideal if you have specialized requirements.

Price and Warranty: While price is important, always consider the long-term cost-effectiveness of the product. Also, check if the manufacturer offers warranties or after-sales support.

Delivery and Support: Manufacturers that offer excellent customer service, timely deliveries, and reliable after-sales support are always preferable.

Conclusion

Delhi’s V-belt manufacturers are pivotal in meeting the power transmission needs of various industries, both domestically and internationally. Brands like Fenner, Bando, Continental, PIX, and MIPL offer a range of high-quality V-belts that ensure optimal performance in demanding applications. Whether you're in automotive, agriculture, or any other industrial sector, choosing the right V-belt supplier can significantly impact the efficiency and longevity of your machinery. When selecting a V-belt manufacturer, always consider factors like quality, pricing, and product range to make an informed decision.

By sourcing from trusted and established manufacturers, you can ensure your systems are operating at peak performance, reducing downtime, and increasing productivity.

0 notes

Text

Silicone Extrusion Companies Diving Into The Details

The process that requires a short lead time to prepare large batches- yes, that is the process of silicon extrusion. Applications of this process include- Tubes, rods, oven seals, electrical cables, wire installation, gaskets, seals, and other more difficult profiles.

You can say that rubber extruding is not the whole process- but a part of the entire process. The process begins when a HCR (HEAT CURED SILICONE) formulated compound is pressed into a strip or slab. Too complex?

The simplified version of this definition is- the process of turning rubber material into specifically shaped products.

The use of silicone extrusion companies after this initial step comprises the process of silicon extrusion. It is a process where silicon is forced through a shaped die- to produce cords, complex profiles, and cross sections.

The Main Challenge

What are the right raw materials for this process? This is the question that will let you determine what manufacturer to go with. The main challenge for the manufacturers using this technique is to choose the right raw materials that will exhibit the best performance in these specific mechanical and temperature controlled processes.

Choose a manufacturer that can work with you on designing dies with proper cost and efficiency factors to make sure you achieve the best and most cost effective results.

Features and Benefits of Silicon Extrusion Process

Unlimited benefits are offered through this process-

Some of them are- easy installation and routing; visual confirmation and flow; autoclavable with long service life; flow accuracy and pump life; reduced odour; non-allergic and non-thrombogenic products; compatibility with clean-in-place lines; low smoke and toxicity; and high ash cohesion.

silicone rubber extrusion manufacturers are highly resilient, have high elastic memory, are suitable for biocompatibility, have chemical resistance, are extremely flexible, and have the feature of processability.

What does a Rubber Sheet Extruder do?

Single crew rubber sheet production is put to use to produce rubber sheets. The machinery used in this process is called a rubber profile manufacturers. Good industries can also stick paper, film, aluminium, and stainless steel belts on the rubber sheet.

There are different types of extruders present:

1. Single screw extruder

2. Twin or multiple screw extruder

3. Ram extruder

What is the best Plastic for Extrusion?

Commodity plastics, are the most suitable for most applications and account for 90% of all thermoplastic use. So next time you are searching for PVC Extrusion Suppliers- look for what kind of plastics they use.

0 notes

Text

Anti-Aging Polyurethane Timing Belt

Boost your machinery's efficiency with high-quality rubber timing belts from our leading manufacturers! These belts are engineered for precision and durability, ensuring smooth operations in various industrial applications.

0 notes

Text

Operation Of Concrete Pump

(1) The particle size of sand and gravel, cement grade and mix ratio should meet the requirements of the mechanical performance of the trailer pump according to the factory manual.

(2) The parking brake and locking brake of the pumping equipment should be used at the same time, the tires should be tight, the water supply should be normal and the water tank should be filled with clean water, there should be no debris in the hopper, and all lubrication points should be lubricated normally

(3) The bolts of each part of the pumping equipment should be tightened, the pipe joints should be tightened and sealed, and the protective devices should be complete and reliable.

(4)Trailer pump with diesel engine, the operating openings, adjustment handles, hand wheels, control levers, cocks, etc. of each part should be in the correct position

The hydraulic system should be normal and leak-free

(5) Prepare relevant equipment such as cleaning pipes and cleaning supplies. Before operation, the pipeline must be lubricated with cement mortar prepared according to regulations. Unrelated personnel must leave the pipeline

(6) The legs should be fully extended and supported, and the boom should not be started before it is fixed. The boom can only be rotated after the bracket is raised. The boom should be extended in sequence. It is strictly forbidden to use the boom to lift or drag objects.

(7) When the boom is in the fully extended state, it is strictly forbidden to move the vehicle body. When it is necessary to move during operation, the upper section of the boom should be folded and fixed, and the moving speed should not exceed 10km/h. The boom should not use pipes with diameters exceeding the specified diameter, and the wheel pipes should be equipped with anti-drop safety belts.

(8) Various instruments and indicator lights should be monitored at all times, and if abnormal, they should be adjusted or handled in time. If the conveying pipe is blocked, reverse transport should be carried out to return the concrete to the hopper, and the pipe should be removed to eliminate the blockage if necessary.

(9) When the pumping system is under pressure, no conveying pipeline or hydraulic pipeline should be opened. The safety valve of the hydraulic system should not be adjusted arbitrarily. The accumulator can only be filled with ammonia.

(10) After the operation, all the concrete in the hopper and pipeline must be discharged, and then the pump, hopper and pipeline should be cleaned. When flushing the pipeline with compressed air, no one should stand within 10m in front of the pipeline outlet, and a metal mesh basket should be used to collect the flushed foam rubber and sand and gravel.

(11) It is strictly forbidden to flush the pipes of the placing boom with compressed air. The folding and contraction of the placing boom must be carried out in sequence.

(12) The operating switches, adjustment handles, hand wheels, control knobs, and cocks in each part should be reset. The hydraulic system should be unloaded.

We FOCUS MECHINERY stand for new product ideas and courageous vision of the future, we stand for our never-stopping dedication and devotion to your construction equipment solutions, we focus on your project needs.If you're looking for a particular supplier or specific configurations, I can provide more details or recommendations!

Whatsapp:+86 13676986531

#concrete contractors#concrete plant customization#concrete mixer plant#trailer pump with diesel engine

0 notes

Text

Polybutadiene Rubber (PBR) Prices | Pricing | Trend | News | Database | Chart | Forecast

Polybutadiene Rubber (PBR) Prices is one of the most widely used synthetic rubbers, primarily due to its excellent resistance to wear and abrasion, high resilience, and its ability to remain flexible at low temperatures. Over the years, the demand for PBR has steadily increased across various industries such as automotive, tire manufacturing, construction, and consumer goods, where it is often used in the production of tires, gaskets, belts, and other rubber goods. As a result, the pricing dynamics of polybutadiene rubber have become a focal point for manufacturers, suppliers, and end-users alike.

The market prices of polybutadiene rubber are influenced by a range of factors, both at the macro and microeconomic levels. One of the primary drivers of PBR pricing is the cost of raw materials. Polybutadiene rubber is derived from butadiene, a petrochemical feedstock. Fluctuations in crude oil prices, which impact the cost of butadiene, directly affect the price of PBR. Any shifts in the global oil market, including geopolitical tensions, production levels, and supply disruptions, can cause significant volatility in polybutadiene rubber prices. In periods where crude oil prices surge, the cost of production for PBR increases, resulting in higher market prices for this synthetic rubber.

Get Real Time Prices for Polybutadiene Rubber (PBR): https://www.chemanalyst.com/Pricing-data/polybutadiene-rubber-1107

Another crucial factor influencing PBR prices is demand from the tire industry. The automotive sector is the largest consumer of polybutadiene rubber, especially for tire manufacturing. In recent years, there has been a consistent rise in demand for vehicles, particularly in emerging economies such as China, India, and Brazil. This growth in automotive production has driven up the demand for tires, subsequently increasing the demand for polybutadiene rubber. However, the demand from the automotive sector can also be cyclical, with downturns in the economy or shifts in consumer behavior leading to reduced vehicle sales and, consequently, reduced demand for PBR. This fluctuation in demand from the tire industry can have a direct impact on polybutadiene rubber prices, with periods of high demand pushing prices up, while periods of low demand can lead to price declines.

In addition to the automotive industry, the construction sector also plays a vital role in shaping the polybutadiene rubber market. PBR is used in a variety of construction materials, such as sealants, adhesives, and flexible joints, due to its durability and flexibility. As infrastructure projects increase, particularly in developing nations, the demand for PBR in the construction sector grows, adding upward pressure on prices. Conversely, slowdowns in construction activities, whether due to economic recessions, government policies, or other factors, can lead to reduced demand for PBR, potentially leading to price decreases.

Supply chain dynamics further influence the market prices of polybutadiene rubber. Any disruptions in the production of butadiene or in the manufacturing processes of PBR can result in supply shortages, leading to price increases. For instance, natural disasters, plant shutdowns, or technical issues at production facilities can all cause supply constraints. In such cases, even if demand remains constant, a reduction in supply can lead to significant price hikes as buyers compete for the limited available stock. On the other hand, an oversupply of polybutadiene rubber, driven by increased production capacities or reduced demand, can lead to a glut in the market, causing prices to fall.

Trade policies and tariffs also impact polybutadiene rubber prices. Countries that impose import tariffs on butadiene or PBR may experience higher domestic prices as the additional costs of tariffs are passed on to consumers. Conversely, countries that reduce tariffs or enter into favorable trade agreements may benefit from lower polybutadiene rubber prices due to the reduced cost of imports. The global trade landscape, especially between major producers and consumers of PBR, can have a significant effect on market prices.

Environmental regulations and sustainability initiatives are becoming increasingly important in shaping the polybutadiene rubber market. Many countries are implementing stricter regulations on the use of petrochemicals and carbon-intensive processes, which could raise the production costs of PBR. Manufacturers may need to invest in cleaner, more efficient technologies or alternative feedstocks to comply with these regulations, potentially driving up prices. Additionally, the growing demand for sustainable and eco-friendly products is pushing manufacturers to develop greener alternatives to traditional PBR, which could introduce new pricing dynamics in the market as consumers shift toward more sustainable options.

Technological advancements in the production of polybutadiene rubber are another factor that can influence prices. Innovations in manufacturing processes, such as more efficient polymerization techniques or the development of new catalysts, can reduce production costs, making PBR more affordable. Companies that invest in research and development to improve their production processes may be able to offer PBR at lower prices, increasing competition in the market and potentially driving prices down. Conversely, delays in technological advancements or high costs associated with implementing new technologies could keep prices elevated.

Global economic conditions also play a significant role in determining polybutadiene rubber prices. Economic growth tends to boost demand for PBR, as industries such as automotive, construction, and consumer goods ramp up production. In contrast, economic downturns, such as recessions or slowdowns in industrial activity, can lead to reduced demand for PBR, potentially causing prices to fall. Exchange rate fluctuations, particularly in regions where PBR is heavily traded, can also impact prices. A weaker currency in a major importing country could make polybutadiene rubber more expensive, while a stronger currency could reduce prices.

In conclusion, the polybutadiene rubber market is highly dynamic, with prices influenced by a wide range of factors. Raw material costs, particularly butadiene, remain a key driver of PBR prices, while demand from the tire and construction industries also plays a significant role. Supply chain disruptions, trade policies, environmental regulations, and technological advancements all contribute to the complex pricing dynamics of polybutadiene rubber. As global economic conditions continue to evolve, market participants must closely monitor these factors to navigate the fluctuations in polybutadiene rubber prices effectively.

Get Real Time Prices for Polybutadiene Rubber (PBR): https://www.chemanalyst.com/Pricing-data/polybutadiene-rubber-1107

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Polybutadiene Rubber#Polybutadiene Rubber Price#Polybutadiene Rubber Prices#Polybutadiene Rubber Pricing#Polybutadiene Rubber News

0 notes

Text

Conveyor Belt Manufacturers in Bangalore: Pioneering Excellence in Material Handling Solutions

Bangalore, often referred to as the Silicon Valley of India, is not only a hub for the IT industry but also a significant player in various manufacturing sectors. Among these, the conveyor belt manufacturing industry stands out for its crucial role in facilitating efficient material handling solutions across diverse industries. Conveyor belt manufacturers in Bangalore are renowned for their innovative designs, high-quality products, and exceptional service, making them leaders in the global market.

The Significance of Conveyor Belts

Conveyor belts are essential components in manufacturing and production lines, enabling the seamless movement of materials and products from one point to another. They enhance operational efficiency, reduce manual labor, and ensure the smooth flow of production processes. In industries such as mining, agriculture, automotive, food processing, and logistics, conveyor belts are indispensable.

Leading Conveyor Belt Manufacturers in Bangalore

Bangalore hosts some of the most prominent conveyor belt manufacturers in India. These companies are known for their state-of-the-art manufacturing facilities, adherence to international quality standards, and a strong focus on customer satisfaction. Here are some key features that distinguish conveyor belt manufacturers in Bangalore:

Innovative Design and Engineering: The conveyor belt manufacturers in Bangalore invest heavily in research and development to create innovative designs that cater to specific industry requirements. Their engineering teams are adept at developing customized solutions that enhance productivity and efficiency.

High-Quality Materials: Quality is a hallmark of the conveyor belt manufacturers in Bangalore. They use premium materials to ensure durability, reliability, and longevity of their products. This commitment to quality helps in minimizing downtime and maintenance costs for their clients.

Advanced Manufacturing Processes: These manufacturers employ cutting-edge technologies and advanced manufacturing processes to produce conveyor belts that meet stringent quality standards. From automated production lines to rigorous quality control measures, every step is meticulously monitored.

Wide Range of Products: Conveyor belt manufacturers in Bangalore offer a comprehensive range of products, including rubber conveyor belts, PVC conveyor belts, modular conveyor belts, and specialized belts for specific applications. This diverse portfolio allows them to cater to the unique needs of various industries.

Exceptional Customer Service: Customer satisfaction is a top priority for conveyor belt manufacturers in Bangalore. They provide excellent after-sales support, technical assistance, and maintenance services to ensure that their clients' operations run smoothly.

Why Choose Conveyor Belt Manufacturers in Bangalore?

Choosing conveyor belt manufacturers in Bangalore offers several advantages. Their expertise in the field, combined with a commitment to quality and innovation, ensures that clients receive top-notch products and services. Additionally, their strategic location in Bangalore provides easy access to a vast network of suppliers and logistics services, facilitating timely delivery and efficient distribution.

Conclusion

In the realm of material handling solutions, conveyor belt manufacturers in Bangalore have carved a niche for themselves with their unparalleled expertise, quality products, and exceptional service. Their continuous efforts in innovation and customer satisfaction make them the preferred choice for industries seeking reliable and efficient conveyor belt solutions. By choosing conveyor belt manufacturers in Bangalore, businesses can enhance their operational efficiency and achieve new heights of productivity.

1 note

·

View note

Text

Expert Tips for Garage Door Opener Replacement in Scottsdale

Replacing a garage door opener is a critical task that enhances your garage's convenience, security, and efficiency. If you live in Scottsdale and are considering a replacement, it's essential to understand the process and make informed decisions. This guide provides expert tips for garage door opener replacement Scottsdale, ensuring a smooth and successful upgrade.

Find The Best Garage Door Repair Service in Scottsdale in Visual Map:

1. Recognizing the Need for Replacement

Signs Your Garage Door Opener Needs Replacing

Understanding when to replace your garage door opener is crucial. Here are some signs that indicate it might be time for a new one:

Frequent Malfunctions: If your opener often fails to work or works intermittently, it may be time for a replacement.

Unusual Noises: Grinding, scraping, or other unusual sounds can signify worn-out components.

Slow Response Time: If there's a delay between pressing the remote and the door opening, the opener might be failing.

Outdated Technology: Older models lack modern safety and security features.

Inconsistent Operation: If the door operates inconsistently, it might be a sign of a failing opener.

Benefits of Replacing Your Garage Door Opener

Replacing your garage door opener offers numerous benefits:

Improved Security: Modern openers have advanced security features to prevent unauthorized access.

Enhanced Safety: Features like auto-reverse ensure the door stops if an object is detected in its path.

Convenience: Newer models offer remote access and smartphone connectivity.

Energy Efficiency: Modern openers are more energy-efficient.

Reliability: Reduced risk of breakdowns and improved performance.

2. Types of Garage Door Openers

Chain-Drive Openers

Chain-drive openers are durable and powerful, making them suitable for heavy doors. However, they tend to be noisy, which might not be ideal if the garage is adjacent to living spaces.

Belt-Drive Openers

Belt-drive openers use a rubber belt instead of a chain, resulting in quieter operation. They are an excellent choice for homes where noise reduction is a priority.

Screw-Drive Openers

Screw-drive openers operate with a threaded steel rod. They require less maintenance and provide smooth and quiet operation, but can be more expensive than chain-drive models.

Direct-Drive Openers

Direct-drive openers are unique in that the motor itself moves along a stationary chain. They are extremely quiet and have fewer moving parts, reducing maintenance needs.

Smart Garage Door Openers

Smart openers come with built-in Wi-Fi and can be controlled via smartphone apps. They offer the ultimate in convenience and security features, such as real-time alerts and remote access.

3. Choosing the Right Garage Door Opener

Consider Door Type and Weight

The type and weight of your garage door influence the choice of opener. Heavy doors, such as wooden or insulated ones, require more powerful openers, typically 3/4 HP or higher.

Noise Levels

If your garage is adjacent to a bedroom or living space, consider a belt-drive or direct-drive opener for quieter operation.

Smart Features

Modern openers offer various smart features, including:

Remote Access: Control your garage door from anywhere using a smartphone app.

Security Alerts: Receive notifications if the door is left open or if there's an attempted break-in.

Integration: Some models integrate with home automation systems like Alexa or Google Home.

Budget

Garage door openers come in a range of prices. While it’s tempting to opt for the cheapest model, investing in a quality opener can save you money in the long run through reduced maintenance and longer lifespan.

4. Preparing for Installation

Gather Necessary Tools and Materials

Before starting the installation, gather all the necessary tools and materials, including:

Wrenches and Pliers

Screwdrivers

Measuring Tape

Ladder

Drill

Safety Glasses

Read the Manufacturer's Instructions

Each garage door opener model comes with specific installation instructions. Carefully read the manual provided by the manufacturer to ensure you follow the correct steps.

Ensure Safety Precautions

Safety is paramount during installation. Follow these precautions:

Disconnect Power: Ensure the power is off to prevent electric shock.

Use Safety Gear: Wear safety glasses and gloves.

Work with a Partner: Having an extra pair of hands can make the process smoother and safer.

5. Step-by-Step Installation Guide

Removing the Old Opener

Disconnect Power: Unplug the old opener and disconnect the wires.

Detach the Door Arm: Remove the arm connecting the opener to the door.

Remove the Opener: Take down the old opener unit and the bracket.

Installing the New Opener

Assemble the Opener: Follow the manufacturer’s instructions to assemble the new opener.

Install the Bracket: Secure the bracket to the ceiling joists.

Mount the Opener: Attach the opener to the bracket.

Connect the Rail: Attach the rail to the motor unit.

Install the Belt or Chain: Depending on your model, install the belt or chain.

Attach the Door Arm: Connect the arm to the door.

Wire the Opener: Connect the wires according to the manufacturer’s instructions.

Install Safety Sensors: Position the sensors on either side of the door, a few inches above the ground.

Test the Opener: Plug in the opener and test its operation, adjusting settings as needed.

6. Professional Installation vs. DIY

Benefits of Professional Installation

Expertise: Professionals have the experience to ensure correct installation.

Safety: Reduces the risk of injury or improper installation.

Warranty Protection: Professional installation often comes with a warranty.

DIY Installation Considerations

Cost Savings: DIY installation can save on labor costs.

Learning Experience: It’s a good opportunity to learn about your garage door system.

Time and Effort: Be prepared for a time-consuming and physically demanding task.

7. Post-Installation Tips

Regular Maintenance

Regular maintenance can extend the life of your garage door opener. Here are some tips:

Lubricate Moving Parts: Apply lubricant to the chain or belt, rollers, and hinges.

Check Safety Features: Test the auto-reverse feature to ensure it’s functioning properly.

Inspect the Door: Regularly check the door balance and make adjustments as needed.

Programming Remote Controls

Follow the manufacturer’s instructions to program your remote controls and any additional keypads or devices.

Securing Your Garage

Ensure your garage is secure by:

Changing Default Codes: If your opener has a keypad, change the default code immediately.

Using Vacation Mode: When away for extended periods, use the vacation mode feature to disable remote controls.

8. Troubleshooting Common Issues

Opener Doesn’t Respond

If your opener doesn’t respond, check the following:

Power Source: Ensure the opener is plugged in and receiving power.

Remote Batteries: Replace the batteries in your remote.

Sensor Alignment: Make sure the safety sensors are aligned and unobstructed.

Door Reverses Before Closing

If the door reverses before closing:

Check Sensors: Ensure nothing is blocking the sensors and they are properly aligned.

Adjust Sensitivity: Consult the manual to adjust the opener’s sensitivity settings.

Noisy Operation

If your opener is noisy:

Lubricate: Apply lubricant to moving parts.

Tighten Hardware: Ensure all bolts and screws are tightened.

Check the Type of Opener: Consider upgrading to a quieter model if noise persists.

9. Finding the Best Garage Door Opener Replacement Services in Scottsdale

Research and Reviews

Start by researching local companies. Look for those with positive reviews and a solid reputation in Scottsdale.

Services Offered

Choose a company that offers a comprehensive range of services, including:

Consultation: Initial consultation to understand your needs.

Installation: Experienced technicians for seamless installation.

Maintenance and Repair: Ongoing services to keep your opener in top condition.

Warranty: A good warranty for peace of mind.

Top Garage Door Opener Replacement Services in Scottsdale

Here are some reputable garage door opener replacement services in Scottsdale:

Arizona Garage Door Repair Guru: Known for their exceptional service and over 25 years of experience.

Scottsdale Garage Door & Opener: Offers a wide range of services and a customer-centric approach.

Dynamic Door Service: Reliable and professional with a variety of custom door options.

A1 Garage Door Service: Renowned for their prompt service and quality workmanship.

Precision Door Service: Offers detailed attention to every aspect of garage door opener installation.

10. Conclusion

Replacing your garage door opener in Scottsdale can significantly enhance your home's convenience, security, and efficiency. You can ensure a smooth and successful replacement process by understanding your options, preparing adequately, and choosing the right opener and installation method. Whether you opt for DIY or professional installation, following these expert tips will help you make the most of your new garage door opener. Regular maintenance and timely troubleshooting will ensure it continues operating efficiently for years.

0 notes

Text

In this blog post, we will discuss why using Rubber Timing Belts is better than using leather ones. Additionally, you will understand why rubber timing belts were a better option. We recommend reading this blog to gain a better insight.

0 notes

Text

Conveyor Belt Market Opportunities: Analyzing Market Share, Size, and Growth Strategies

The Conveyor Belt Market is Valued at USD 5.1 billion in 2024 and is projected to reach USD 8.3 billion by 2032, growing at a CAGR of CAGR of 4.9 % During the Forecast period of 2024–2032.

The report presents an overview of the market with the production of the cost, dispatch, application, use volume, and arrangement. The Conveyor Belt research report offers significant bits of information into the business focus from the early stage including some steady techniques chalked out by perceptible market pioneers to develop a strong foothold and development in the business.

Request Our Market Overview Sample Now — https://www.marketdigits.com/request/sample/4078

Key Companies in the Global Conveyor Belt Market: AMMERAAL BELTECH, Bando Chemical Industries Ltd. Bridgestone Corporation, Continental Belting Pvt. Ltd. ContiTech Deutschland, Elcon Elastomers Pvt. Ltd., Forbo Holding Pvt, Michelin Group (Fenner Conveyors), Mitsuboshi Belting, Semperit AG Holding, THE YOKOHAMA RUBBER CO., LTD, Volta Belting Technology, and Others.

Recent Developments:

★ In April 2023, RECOM Technologies and SINN Power have teamed up to develop an innovative conveyor belt PV system. The collaboration has resulted in the successful installation of a one-kilometer -long solar-powered conveyor belt at a gravel plant in Bavaria, as announced by RECOM Technologies.

Pivotal Questions Answered in the Global Conveyor Belt Market Report: ➲ What are the major value propositions of the Conveyor Belt market? ➲ Who are the leading players functioning in the Global Conveyor Belt marketplace? ➲ What technologies are expected to adopt the new regulations in the Conveyor Belt report? ➲ What are the emerging trends that may influence the Global Conveyor Belt market growth? ➲ What are the vital offerings new entrants concentrate on to implement unique positioning strategies? ➲ What are the growth opportunities for the new entrants in the Global Conveyor Belt industry? ➲ What are the futuristic prospects of the Conveyor Belt market across the globe? ➲ What are the new strategic frameworks that are mobilized among players to accomplish resilience in the wake of the COVID-19 pandemic?

Inquire Before Buying at — https://www.marketdigits.com/request/enquiry-before-buying/4078

The Purpose of This Report Is to Provide: ➲ A qualitative and quantitative analysis of the Conveyor Belt market of current trends, dynamics, and estimates from 2024 to 2032. ➲ Ultimately, this Conveyor Belt report will help save you time and money by providing unbiased information under one roof. ➲ The in-depth market segmentation analysis helps to identify the prevailing market opportunities. ➲ Analytical tools such as SWOT analysis and Porter’s Five Forces analysis are used to explain the power of Conveyor Belt buyers and suppliers, make profit-oriented decisions, and strengthen their business.

Market Dynamics:

Drivers:

Increasing Industrialization in Emerging Economies

Technological Advancements in Conveyor Belts

Increasing Adoption of Automation for Conveyor Belts

Opportunities:

Exploring and Expanding into Emerging Markets

Rising Demand for Eco-Friendly Conveyor Bolt

Integrating Digital Technologies

Compelling Reasons to Purchase This Report: ➲ A study of the developing competitive landscape is provided. ➲ It provides analytical data along with strategic planning so that firms may make well-informed decisions. ➲ It provides a seven-year analysis of the Conveyor Belt Market. ➲ It facilitates comprehension of the most important product categories. Researchers shed light on the market’s dynamics, including its potential, trends, drivers, and constraints. ➲ It provides a business profile of various stakeholders in addition to a regional analysis of the Conveyor Belt Market. ➲ It provides a wealth of information about popular trends that may affect the development of the Conveyor Belt Market.

Click to Request Free 10% Customization on this Report @ https://www.marketdigits.com/request/customization/4078

Key Topics Covered:

1. Preface 2. Research Methodology 3. Executive Summary 4. Market Overview 5. Market Insights 6. Conveyor Belt Market, by Molecule Type 7. Conveyor Belt Market, by Lines of Chemotherapy 8. Conveyor Belt Market, by Route of Administration 9. Americas Conveyor Belt Market 10. Asia-Pacific Conveyor Belt Market 11. Europe, Middle East & Africa Conveyor Belt Market 12. Competitive Landscape 13. Competitive Portfolio

0 notes

Text

What You Need to Know About Quality Control in Rubber Production

Rubber plays a vital role in countless industrial applications. From heavy machinery to delicate electronics, rubber components are often indispensable, making quality control a critical concern in rubber production. This is especially true for applications like timing belts, which demand precision and durability.

Let's explore the importance of quality control in rubber production and how leading rubber timing belt manufacturers in India ensure the quality and performance of their products.

Why Quality Control in Rubber Production Matters

Quality control (QC) encompasses all the measures taken within the manufacturing process to guarantee a product's consistency, reliability, and adherence to specifications. Here's why robust QC is crucial in rubber production:

Performance and Durability: Rubber products used in industrial applications often operate under demanding conditions facing heat, friction, abrasion, and chemical exposure. Thorough quality control ensures that the rubber components can withstand these stresses, reducing the risk of failure and optimizing their lifespan.

Safety: Rubber components in critical applications, such as automotive parts or industrial machinery, can directly impact safety. Quality control prevents defective products from entering the market, safeguarding users and minimizing the risk of accidents.

Cost-effectiveness: A focus on quality control reduces waste. Fewer products are rejected or require rework, lowering production costs and ensuring reliable, timely delivery to customers.

Customer Satisfaction: When rubber products consistently meet expectations, they foster customer trust and a positive brand reputation.

Key Steps in Quality Control for Rubber Production

Here's a look at the core elements typically involved in a robust QC process in the rubber industry:

Raw Material Inspection: Quality control begins with rigorously inspecting all incoming raw materials like rubber compounds, reinforcing materials, and chemicals. This ensures that materials conform to specifications and are free from defects.

Process Control: Manufacturing processes must be meticulously monitored. Parameters like temperature, pressure, mixing times, and curing times are carefully controlled to achieve the desired rubber properties and product dimensions.

Visual Inspection: Products undergo thorough visual checks for any defects such as blisters, cracks, or surface irregularities.

Dimensional Inspection Precision measurements are taken to ensure that product dimensions fall within specified tolerances. This is crucial for parts like industrial timing belts, where accurate dimensions are critical for proper synchronization.

Performance Testing Rubber products are often subjected to various tests to simulate real-world conditions. These tests can assess properties like:

Tensile strength

Elongation at break

Hardness

Abrasion resistance

Heat and chemical resistance

Choosing the Right Rubber Timing Belt Manufacturers in India

When selecting a rubber timing belt manufacturer, pay attention to their commitment to quality control. Here's what to look for:

Certifications: Look for manufacturers with ISO certifications or other recognized quality management system certifications. This demonstrates adherence to international quality standards.

Technological Capabilities: Seek out manufacturers that invest in cutting-edge technology, modern manufacturing facilities, and rigorous testing equipment.

Industry Specialization: Some manufacturers specialize in specific industries. Choosing a supplier with expertise in your relevant field can provide a deeper understanding of your specific requirements.

Customer Service: Choose a manufacturer that prioritizes customer satisfaction and offers excellent technical support. A responsive and solutions-oriented manufacturer can be a great partner for reliable quality products.

Industrial Timing Belts: A Focus on Precision and Quality

Industrial belts are crucial components in various machinery and equipment, ensuring synchronized movement and accurate positioning. Their production demands meticulous quality control to ensure consistent performance and durability.

Top industrial timing belt manufacturers in India understand the importance of:

Precision Manufacturing for accurate tooth profiles and belt dimensions.

High-quality Materials: Utilization of superior rubber compounds and reinforcement materials to withstand demanding operating conditions.

Stringent Testing: Thorough performance and durability testing before products leave the factory.

Conclusion

Quality control is not just a buzzword in rubber production; it's a non-negotiable commitment. By choosing reputable rubber timing belt manufacturers in India with robust quality control systems, you can ensure that your critical rubber components meet your expectations and deliver safe, efficient, and long-lasting performance.

0 notes

Text

Everything to Know About V-Belt: Types and Construction

The V-belts transmit power between parts of machines efficiently. Often, they are used on car engines for accessories such as air conditioner compressors, power steering pumps, alternators, and fans. The v-belt is a belt with a trapezoidal section and can be classified according to its dimensions. This blog discusses the main uses, construction features, and types of v belts.

What is a V-belt?

The V-belt transmits energy from one shaft into another. The cross-section of a v-belt is trapezoidal. A wedge-shaped belt will fit perfectly in the grooves of a pulley. V-belts are more powerful than flat belts because of this perfect fit. Pulley systems using v-belts have their pulleys close together. In the case of belt tension, the vertical forces that are perpendicular to the V-blet push its wall against the grooves of the sheave as the forces maximize the belt wedges into the sheave groove, which increases the friction between the belt surface and walls. The various frictional force V belt drive to transit higher loads.

Features of the V-Belt Construction

The V Belt Specification:

Steel Wires: The steel wires are endless and have no joints in between them. The wires are used to reinforce the belt and provide strength.

Rubber compound as the base: The rubber compound is the inner core that surrounds the steel wire to give the belt its shape. Rubber compound (elastic) is also used as a compression medium to absorb shocks when transmitting power.

Cover: This is the protective layer that protects the rubber from the heat generated by the belt movement.

Based on Their Dimensions, V-belts Are Classified Into Different Types.

The belt fabric supplier offers fabrics for V-belts of different sizes and types. The basic shape of each type is the trapezoidal, but they have different sizes.

V Belt Types :

Standard V-Belt: Also known as the classical or conventional V belt, this is one of the oldest forms. These types of belt drive the transmission of energy between machinery parts.

Wedge V-Belt: The conveyor belt manufacturers primarily design this belt for power transmission and space-saving. The load capacity of these belts is 1.5-2 times greater than that of a classical V-belt with the same width. The cord placement and construction are improved, resulting in the strongest belts while they're moving.

Narrow V Belt: These belts look similar to wedge-shaped belts. These belts are used to transmit larger loads but in a more compact form.

Double or Hexagonal V-Belt: These V belt types are similar to two mirror-imaged V-belts, with the top side as their adjoining sides. The tension cord goes between the V-shaped section. The double v-belt is used in drives that have one or more reverse bends. This is because the belt can be bent on either side of the compression core.

Cogged V-Belts: These belts are V-shaped and have a notch at the bottom. This allows them to bend with smaller radiuses. The belt fabric manufacturers offer fabrics for belts in a variety of cross-sectional dimensions, including standard, narrow wedge, banded, and fractional horsepower V-belts.

V-Belt Advantages

There is a very small amount of slippage between the belt and the pulley.

The V belts are usually used for the pulley system as they offer quiet operation.

The small space between pulley centers allows for a compact structure.

A v-belt pulley system dampens vibration. The V-grooves provide a good grip, allowing for the transfer of power.

V-Belt Applications

The Most Common Application of V Belt Drive Include:

Drills

Power Tools

Agri machines

Milling Machines for Light Duty

Conclusion:

V-belts are flexible machine elements that transfer power from one set of pulleys to another. The trapezium-shaped cross section is what makes them unique. They are chosen because they can fit tightly in the grooves on the pulley. The belts reduce slippage and loss of power by breaking up the friction on surfaces with a higher coefficient.

Shankar Techx is a leading belting fabric manufacturer and supplier. We offer fabrics that are used in flat belts, V-belts, conveyor belts, rubber industry, infrastructure, agro tech products and others. We offer a variety of products like Geotextiles, geosynthetic clay liners, ground covers, coating substrates, impression fabrics, scrims, and others. To know more about geotech, packtech, industech, and other products, call us today.

#V belt drive#belt fabric supplier#types of belt drive#conveyor belt manufacturers#V belt types#belt fabric manufacturers#V belts are usually used#Application of V Belt#coating substrates

0 notes

Text

Polyurethane timing belts have emerged as a popular choice in the realm of industrial automation due to their exceptional durability and performance capabilities. These belts are engineered with a polyurethane compound that offers a unique combination of strength, flexibility, and resistance to wear and tear. Unlike traditional rubber belts, polyurethane timing belts maintain their elasticity and do not degrade over time, ensuring consistent performance even in high-speed applications.

0 notes

Text

The complete guide on cogged belts to enhance power transmission

Cogged belts are essential in the field of power transmission because they provide dependable and efficient performance in a wide range of industrial applications. Compared to conventional flat belts, these specialty belts offer improved performance and grip due to the cogs or notches on the bottom of the belt.

Power transmission systems facilitate the efficient flow of energy from one source to another, making them the foundation of many industries.

Power transmission has been transformed by these specialty belts, which have distinct advantages over their conventional counterparts. Stay here to learn about the complete guide on cogged belts to enhance power transmission:

What are Cogged Belts?

Cogged belts are power transmission belts with teeth or cogs on the inside of the belt. They are sometimes referred to as notched or toothed belts. These teeth provide better power transfer capabilities and positive engagement by meshing with the pulley grooves. The cogged belt is often built of robust materials that can withstand harsh industrial environments, such as rubber or synthetic composites. Jigna sales the leading industrial belt manufacturers in India offers the best Cogged Belts.

Advantages of Cogged Belts

Enhanced power transmission

Cogged belt teeth greatly enhance power transmission capabilities, particularly in high-speed or high-torque situations. This makes it possible for energy to be transferred more effectively, lowering the loss of energy and improving system performance overall. To buy the raw edge cogged belt at an affordable price, compare prices from one shop to another.

Decreased slippery nature

Under severe circumstances or with big loads, traditional V-belts may slip. Because of their toothed structure, cogged belts keep a tighter hold on the pulleys, reducing slippage and guaranteeing steady power transfer.

Greater ability to bear loads

Compared to flat belts, a cogged v belt is made to support larger load capabilities. The belt experiences less stress and gains more strength due to the teeth and pulley grooves engaging to distribute the weight more evenly. Cogged belts are a great fit for heavy-duty manufacturing, agriculture, and construction applications because of their higher load-carrying ability.

Enhanced robustness

Cogged belts have a more uniformly distributed design that minimizes wear and lengthens lifespan. The extended lifespan of a cogged timing belt is particularly beneficial for businesses where uninterrupted operation is essential.

Small-scale layout

Compared to their V-belt equivalents, cogged belts frequently have smaller sizes, making them appropriate for applications with limited space.

How do you choose the right cogged belt?

The choice of cogged belt for a given application is influenced by several factors, including:

Torque and load

The load and torque the belt will encounter should be considered. Larger tooth profiles and stronger materials may be needed for higher loads and torque belts. To buy a durable toothed v belt, choose a reputable shop.

Environment of operation

Examine operational parameters, including humidity, temperature, and exposure to chemicals or oils. Select belts that maintain performance despite withstanding certain environmental conditions.

Quickness and accuracy

Synchronous belts are preferred for applications that demand precision timing and high-speed operation because of their precise power transfer capabilities.

As a result, the above detailed are about the complete guide on cogged belts to enhance power transmission. Jigna Sales is one of the leading cogged belt manufacturers and suppliers in India. Their primary goal is to provide clients with the highest-quality products possible to maximize output, maximize efficiency, and minimize operating costs.

0 notes

Text

Amazing Benefits That You Receive From An Aluminium Pulley

Due to their many benefits, aluminum pulleys have transformed mechanical systems in a variety of sectors, making them essential parts. These adaptable gadgets are a great option for engineers and designers since they are strong, lightweight, and extremely efficient.

Minimalist Marvels

Pulleys made of aluminum are well known for being incredibly lightweight. Their low density—roughly one-third that of steel—allows mechanical systems to weigh less overall. This attribute is extremely beneficial in sectors like the aerospace and automotive industries where weight reductions are critical.

Corrosion Inhibition

Aluminum pulleys' inherent oxide coating provides remarkable corrosion resistance. Longevity under diverse environmental circumstances is ensured by this resilience. They are therefore a dependable option for both indoor and outdoor uses.

Beyond Expectations Durability

Aluminum pulleys by Aluminum Pulley Suppliers Are remarkably robust considering their lightweight design. Their weight-to-strength ratio is astounding. They are hence appropriate for heavy-duty uses, such as conveying and lifting systems.

Aluminum pulleys have a reduced friction design. This means that belts and cables will experience less deterioration. This characteristic reduces the need for maintenance and lengthens the life of the mechanical system as a whole.

Heat Transfer

In high-speed applications, aluminum's superior heat conductivity enables effective heat dissipation. This is especially useful for motors and engines, where controlling temperature is essential to achieving peak efficiency.

Price-Performance

In terms of cost-effectiveness, aluminum pulleys are highly competitive. Over time, their longevity and minimal upkeep needs result in cost savings. This makes up for the original outlay.

Aluminum's malleability enables complex and unique shapes. Engineers can design pulleys that precisely suit a mechanical system's requirements.

Champion of Sustainability

Because they can be recycled and have a lower environmental effect, aluminum pulleys support environmentally friendly production and operations. Their environmentally favorable traits support international initiatives to encourage green practices and lower carbon footprints.

Safety Improvement

Aluminum pulleys' low inertia improves safety while facilitating rapid motion changes. In applications involving high speeds, they reduce the possibility of abrupt stops. It guards against mishaps and equipment damage.

Adaptable Material Interaction

Rubber, plastic, and steel belts are just a few of the materials that aluminum pulleys can operate with ease. Their range of applications is expanded and customized solutions are made possible by their versatility.

Simple Maintenance and Installation

The lightweight and impermeable nature of aluminum pulleys facilitates installation and maintenance. Fewer maintenance workers are associated with increased operational uptime.

A mechanical system's aesthetic appeal can be improved using aluminum pulleys. Their sleek, contemporary design is frequently in demand across a range of sectors.

Adherence to Regulations

Aluminum pulleys are frequently compliant in situations where material usage is governed by strict standards. This guarantees that the safety and quality criteria are met by your mechanical system.

In a real way, aluminum pulleys have changed the mechanical systems industry. They are advantageous in many sectors due to their affordability, corrosion resistance, and lightweight but durable qualities.

These pulleys are the pinnacle of efficiency and sustainability.They are used to dissipate heat, reduce friction and wear, or achieve design flexibility. Aluminum pulleys have properly earned their position as game-changers in contemporary engineering, enhancing the functionality, robustness, and environmental friendliness of mechanical systems globally.

0 notes