#Rayon Fibers Market Demand

Explore tagged Tumblr posts

Text

Rayon Fibers Market Analysis: A Comprehensive Global Overview

The global textile industry has witnessed significant growth over the years, driven by an increasing demand for comfortable and sustainable fabrics. Within this industry, rayon fibers have gained prominence as a versatile and eco-friendly alternative to traditional natural and synthetic fibers. The Rayon Fibers Market is a dynamic and evolving sector, reflecting changing consumer preferences and the growing awareness of environmental sustainability. In this article, we will explore the key aspects of the Rayon Fibers Market, including its history, manufacturing process, applications, market trends, and sustainability.

Historical Perspective

Rayon, often referred to as "artificial silk," was first developed in the late 19th century as an alternative to natural silk. Its production process involves the conversion of cellulose from wood pulp or other plant-based sources into fibers. This early innovation marked the beginning of the rayon industry, which has since evolved into a global market with various types of rayon fibers.

Manufacturing Process

Rayon fibers market are created through a multi-step process that begins with the extraction of cellulose from wood pulp, bamboo, or other plant materials. Once extracted, the cellulose is chemically treated and dissolved in a solution to form a viscous compound. This compound is then forced through spinnerets to create fibers, which are later solidified through various methods, such as dry spinning or wet spinning. The resulting fibers can be modified to achieve different properties, making rayon suitable for a wide range of applications.

Applications

Rayon fibers are incredibly versatile, making them suitable for a broad spectrum of applications in the textile and non-textile industries. Some of the primary uses of rayon include:

Apparel: Rayon is commonly used to make garments such as dresses, blouses, shirts, and lingerie due to its softness, drape, and breathability.

Home Textiles: Rayon is used in home textiles like bed linens, curtains, and upholstery fabric due to its aesthetic appeal and comfort.

Medical Textiles: Rayon is used in medical products like wound dressings and surgical gowns due to its absorbent and sterile properties.

Nonwoven Fabrics: Rayon is used in nonwoven applications like wet wipes, diapers, and feminine hygiene products.

Industrial Applications: Rayon is utilized in tire cords, industrial filters, and more due to its strength and durability.

Market Trends

The Rayon Fibers Market has witnessed several notable trends in recent years:

Sustainable and Eco-friendly Products: With increasing awareness of environmental issues, there is a growing demand for sustainable and eco-friendly textiles. Rayon, made from renewable plant sources, is considered a greener alternative to some synthetic fibers, appealing to environmentally conscious consumers.

Blending with Other Fibers: Rayon is often blended with other fibers such as cotton, polyester, or spandex to enhance its properties and create fabrics with specific characteristics, such as stretch or moisture-wicking capabilities.

Innovation in Production Methods: Continuous innovation in the manufacturing process has led to the development of specialized rayon fibers with improved strength, durability, and flame resistance, expanding their applications further.

Growing Demand in Emerging Markets: Emerging economies are witnessing a rising middle class with an increasing disposable income, resulting in a greater demand for textiles and apparel, including rayon-based products.

Sustainability

Sustainability is a critical aspect of the Rayon Fibers Market. As consumers become more eco-conscious, manufacturers are working to reduce the environmental impact of rayon production. Sustainable practices include sourcing wood pulp from responsibly managed forests, reducing water and chemical usage during production, and recycling or upcycling rayon waste.

Conclusion

The Rayon Fibers Market demand is a dynamic and versatile sector within the textile industry, offering a sustainable alternative to traditional fibers. With its rich history, diverse applications, and evolving market trends, rayon continues to play a significant role in meeting the demands of modern consumers while addressing environmental concerns. As the industry continues to innovate and adopt sustainable practices, rayon is poised to remain a valuable material in the world of textiles and beyond.

#Rayon Fibers Market Share#Rayon Fibers Market Growth#Rayon Fibers Market Demand#Rayon Fibers Market Trend#Rayon Fibers Market Analysis

0 notes

Text

Carbon Disulphide Prices, News, Trend, Graph, Chart, Forecast and Historical

The Carbon Disulphide market is a crucial segment in the global chemicals industry, influencing various sectors such as textiles, agriculture, and electronics. Over recent years, the prices of carbon disulfide have been influenced by several factors, including raw material availability, production processes, demand fluctuations, and international trade dynamics. Understanding the carbon disulfide price trends requires a deep dive into these aspects and how they interact with market forces. Carbon disulfide, a volatile, colorless liquid with a distinctive odor, is primarily used in the production of rayon, a type of fiber used in the textile industry. It also plays a significant role in manufacturing pesticides, rubber chemicals, and various other chemical intermediates. The market is highly sensitive to changes in the demand for these end-use products, making it vulnerable to both global economic conditions and regional supply-demand imbalances.

Get Real time Prices for Carbon Disulphide: https://www.chemanalyst.com/Pricing-data/carbon-disulphide-1248

Price fluctuations in the carbon disulfide market have often mirrored trends in the petrochemical industry, as Carbon Disulphide is predominantly derived from natural gas or oil-based feedstocks. As oil prices experience volatility, so too do the costs associated with the production of carbon disulfide. This link between energy prices and Carbon Disulphide production is particularly evident in regions where feedstocks are imported, such as Europe and parts of Asia. Conversely, regions with abundant natural gas or oil resources, like the United States and the Middle East, experience somewhat more stability in carbon disulfide pricing. Additionally, geopolitical tensions and natural disasters can disrupt the supply of these raw materials, causing sudden and often sharp price increases in carbon disulfide. Furthermore, regional economic performance heavily influences the price of Carbon Disulphide. In developing markets, where industries such as textiles and agriculture are growing rapidly, demand for carbon disulfide tends to increase, exerting upward pressure on prices. On the other hand, economic slowdowns or recessions in major consumer markets like the United States or China can lead to decreased demand, resulting in lower prices.

Another critical factor affecting carbon disulfide prices is the environmental regulations imposed on its production and use. As a toxic and hazardous chemical, carbon disulfide has been subject to increasing scrutiny due to its environmental and health impacts. Governments around the world are tightening restrictions on emissions from chemical manufacturing facilities, which has raised the cost of producing carbon disulfide in compliance with these new regulations. Companies that rely on Carbon Disulphide for their production processes must factor in these additional compliance costs, which can lead to price increases. The imposition of stricter safety standards also affects the market by limiting the number of suppliers, particularly smaller producers who may not be able to meet the new environmental requirements. This reduction in supply can drive prices upward, especially when demand for carbon disulfide remains strong.

Moreover, technological advancements in production methods have played a role in the carbon disulfide market. Innovations aimed at improving production efficiency and reducing emissions have allowed some manufacturers to lower their production costs. For instance, advancements in closed-loop systems and more efficient reactors have helped mitigate the negative environmental impacts associated with Carbon Disulphide production. These technological improvements, while beneficial from an environmental and cost perspective, are not always accessible to every producer, especially in emerging markets with limited access to advanced equipment. As a result, the price dynamics in these markets may differ from those in developed regions, where higher production costs due to stringent environmental regulations are often offset by technological innovations.

Trade policies and international relations also influence the carbon disulfide market. Countries that are net importers of Carbon Disulphide rely on the smooth functioning of international trade to secure stable supplies of the chemical. Any disruption in trade, such as tariffs or trade wars, can lead to price fluctuations. For instance, the imposition of tariffs on imports of carbon disulfide in key markets can significantly affect the cost structure of industries that depend on this chemical. Additionally, export restrictions in producing countries, whether due to domestic supply issues or political motives, can limit the global supply of carbon disulfide, driving up prices. The complexity of the global supply chain for carbon disulfide means that even small disruptions can have a cascading effect on the market, making it vulnerable to unpredictable price swings.

The demand for carbon disulfide also fluctuates with trends in end-use industries. One of the largest consumers of Carbon Disulphide is the textile industry, which uses it to manufacture rayon fibers. As global fashion trends shift, and as the demand for sustainable and eco-friendly fabrics rises, the carbon disulfide market can experience volatility. Similarly, the agriculture sector, which relies on carbon disulfide in the production of pesticides and fungicides, can see changes in demand based on agricultural trends, seasonal planting patterns, and pest outbreaks. The electronics industry, although a smaller consumer of carbon disulfide, also contributes to price fluctuations as it requires Carbon Disulphide in the manufacturing of semiconductors and other components. Shifts in technological development and global demand for electronic devices can, therefore, influence the price of carbon disulfide.

Furthermore, the increasing shift towards sustainable and green chemistry practices is beginning to shape the future of the carbon disulfide market. Researchers and industry players are working towards finding alternatives to Carbon Disulphide , either by improving its safety profile or developing entirely new chemical processes that eliminate its need. If these innovations succeed in providing viable substitutes for carbon disulfide, the demand for Carbon Disulphide could diminish, which would have a significant impact on its market prices. While such alternatives are still in the experimental or early commercial stages, they represent a potential long-term trend that could affect the stability of carbon disulfide prices.

In conclusion, the carbon disulfide market is shaped by a combination of global economic factors, regional demand and supply imbalances, environmental regulations, and technological advancements. Prices for this important chemical are highly volatile and subject to various external pressures, ranging from fluctuations in raw material costs to changes in international trade and government policies. Industry participants must closely monitor these factors to navigate the complexities of the carbon disulfide market and forecast pricing trends accurately. As the demand for sustainable alternatives grows and production processes evolve, the landscape of the carbon disulfide market may continue to change, impacting both prices and production methods in the coming years.

Get Real time Prices for Carbon Disulphide: https://www.chemanalyst.com/Pricing-data/carbon-disulphide-1248

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Carbon Disulphide#Carbon Disulphide Price#Carbon Disulphide Prices#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Why India Is a Hub for High-Quality T-Shirt Manufacturing

India has emerged as a global leader in textile and apparel manufacturing, making significant strides in producing high-quality T-shirts for domestic and international markets. With its rich textile heritage, access to raw materials, skilled labor, and cost-effective production processes, India has become the preferred destination for businesses seeking reliable T-shirt manufacturing companies in India. From small-scale startups to established global brands, India caters to a diverse clientele with its exceptional capabilities.

Here’s an in-depth look at why India has established itself as a hub for high-quality T-shirt manufacturing.

1. Abundance of Raw Materials

India is one of the largest producers of cotton, a key raw material for T-shirt production. The country’s cotton is known for its superior quality, particularly varieties like organic cotton and long-staple cotton, which are highly sought after in global markets. Additionally, India has a well-developed synthetic fiber industry, producing materials like polyester, rayon, and blends that cater to various T-shirt designs and functionalities.

With easy access to these materials, a T-shirt manufacturing company in India can offer diverse fabric options, ensuring quality and affordability for clients.

2. Skilled and Cost-Effective Labor

India’s workforce is one of its greatest strengths. The country boasts a vast pool of skilled labor, ranging from textile artisans with traditional expertise to modern designers and technicians trained in advanced manufacturing techniques. This combination of traditional craftsmanship and modern skills enables manufacturers to produce T-shirts that meet both aesthetic and functional requirements.

Moreover, India’s relatively low labor costs make it an attractive option for businesses looking to optimize production expenses without compromising on quality.

3. Advanced Manufacturing Technology

India’s T-shirt manufacturing companies have embraced cutting-edge technology to meet the demands of the global market. Advanced machinery for knitting, dyeing, printing, and finishing ensures precision, consistency, and efficiency in production. Many manufacturers have also adopted automated processes, such as robotic cutting and digital printing, to reduce lead times and enhance customization options.

This technological edge allows a T-shirt manufacturing company in India to compete with global leaders, offering world-class products at competitive prices.

4. Customization and Innovation

One of the standout features of T-shirt manufacturers in India is their ability to cater to custom orders. Whether it’s unique designs, specific fabric requirements, or branding needs, Indian manufacturers are adept at delivering tailored solutions. Businesses can opt for custom prints, embroidery, or even eco-friendly materials to align with their brand identity.

Innovation is also at the forefront, with companies investing in sustainable practices, moisture-wicking fabrics, UV-protective T-shirts, and other advanced functionalities.

5. Sustainability and Eco-Friendly Practices

As global demand for sustainable fashion grows, Indian T-shirt manufacturers are leading the charge with eco-friendly practices. Many companies use organic cotton, recycled fibers, and water-saving dyeing techniques to reduce their environmental footprint. Certifications like GOTS (Global Organic Textile Standard) and Fair Trade further highlight their commitment to sustainability.

For businesses seeking environmentally conscious partners, a T-shirt manufacturing company in India offers the perfect blend of quality and sustainability.

6. Strong Export Capabilities

India has a well-established export network, making it a key supplier to international markets. T-shirt manufacturers in India export their products to regions like North America, Europe, and the Middle East, meeting stringent quality standards and diverse consumer preferences. The government’s support for textile exports, through incentives and trade agreements, further bolsters India’s position as a global manufacturing hub.

7. Diverse Manufacturing Ecosystem

India’s T-shirt manufacturing industry encompasses a wide range of players, from small-scale units specializing in handmade designs to large-scale factories capable of producing millions of units. This diversity enables businesses of all sizes to find manufacturing partners that meet their specific needs.

Additionally, regions like Tirupur, Ludhiana, and Delhi NCR are renowned for their specialized expertise in T-shirt production, providing businesses with a concentrated ecosystem of suppliers, logistics, and ancillary services.

8. Focus on Quality and Compliance

A T-shirt manufacturing company in India prioritizes quality control and adherence to global compliance standards. From fabric testing to final product inspections, Indian manufacturers ensure that every T-shirt meets the required specifications. Many companies also comply with international labor and environmental standards, building trust among global clients.

9. Growing Domestic Market

In addition to its export prowess, India’s booming domestic market also drives the growth of T-shirt manufacturing. With a young, fashion-conscious population and increasing demand for casual and athleisure wear, Indian manufacturers are constantly innovating to meet local preferences. This dual focus on domestic and international markets strengthens India’s position as a T-shirt manufacturing hub.

10. Government Support and Incentives

The Indian government has implemented various initiatives to promote the textile and apparel industry. Schemes like the Production Linked Incentive (PLI) and the Technology Upgradation Fund Scheme (TUFS) encourage manufacturers to adopt advanced technologies and expand their operations. These initiatives enhance the global competitiveness of T-shirt manufacturing companies in India.

Conclusion

India’s prominence as a hub for high-quality T-shirt manufacturing is built on its rich resources, skilled workforce, advanced technology, and commitment to sustainability. A T-shirt manufacturing company in India offers businesses the perfect combination of quality, cost-effectiveness, and innovation, making it a preferred choice for both domestic and international clients.

As the global demand for T-shirts continues to grow, India’s manufacturers are well-positioned to lead the industry, delivering products that meet the highest standards of quality and sustainability. Whether you’re a startup looking for custom designs or an established brand seeking reliable suppliers, India’s T-shirt manufacturing ecosystem has the expertise and infrastructure to cater to your needs.

0 notes

Text

Africa Nonwoven Fabrics Market Is Experiencing Healthy Growth Worldwide

The Africa nonwoven fabrics market size is expected to reach USD 2.43 billion by 2030, registering a CAGR of 6.9% from 2025 to 2030, according to a new report by Grand View Research, Inc. The market is driven by the increase in hospital-acquired infections (HAIs) and rising construction investments coupled with the growing apparel & textile industry. The textile industry is growing due to the upcoming trends in the apparel industry, which needs customized fabrics for the desired design.

Major countries fueling the growth of the African nonwoven fabrics market include Cameroon, the Central African Republic, and Chad amongst others. Furthermore, increasing hospital construction and growth of the textile market in the countries are expected to drive the demand for nonwoven fabrics in the Central Africa region. Kenya is the fastest-growing economy in East Africa, with a G.D.P. that accounts for 50% of the region's total. In East Africa, Kenya is the biggest importer of nonwoven raw materials and finished products.

Government agencies in Africa have taken initiatives to upgrade their infrastructures to attract foreign investments and support developments for the revival of their economies, which were adversely affected by the spread of COVID-19. The surging investments in the construction, textile, and automotive industries in the African region are expected to contribute to the growth of the market in the coming years.

The Trade, Industry, and Competition Department of the Republic of South Africa published recommendation guidelines in May 2020. It provides guidelines to the manufacturers of face masks in South Africa regarding the use of nonwoven fabrics in face masks.

Sigma-Aldrich, Chemondis Gmbh, Silbert & Co., Propet (Pty) Ltd., Narrowtex Hereford Industries, Sappi Global, and Lenzing AG are involved in supplying raw materials to nonwoven fabric manufacturers. The most often used fibers are polyester, olefin, and nylon, used for their strength, and cotton and rayon, used for their absorbency. Additionally, some vinyon, acrylic, and acetate fabrics are being used in some applications.

Manufacturers, such as Fibertex Nonwovens A/S, are integrated across two stages of the value chain, i.e., they are engaged in the production of raw materials, and they also consume these raw materials for manufacturing nonwoven fabrics. This helps companies to regulate the quality of raw materials and mitigate volatility in pricing and disruptions in the supply chain.

Africa Nonwoven Fabrics Market Segments Highlights

Durable product segment accounted for 65.3% of the revenue share in 2024. The durable fabrics can be made using different fiber webs that impart properties such as water absorption or repellency, thermal and fire resistance, antimicrobial treatment, and so on.

The polypropylene material segment led the Africa nonwoven fabric market, accounting for a 49.7% revenue share in 2024.

The hygiene segment accounted for the largest market revenue share of 29.7% in 2024. As more people move to urban areas, the demand for hygiene products such as diapers, sanitary pads, and adult incontinence products has surged.

The spunbond segment accounted for the largest market revenue share of 43.7% in 2024. Spunbond technology allows for producing nonwoven fabrics with excellent strength and flexibility, making them suitable for various uses, from hygiene products to agricultural covers.

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

The global sorting machines market size was valued at USD 4.14 billion in 2024 and is expected to grow at a CAGR of 6.0% from 2025 to 2030.

The global powder compacting pressers market size was valued at USD 343.9 million in 2024 and is expected to expand at a CAGR of 4.8% from 2025 to 2030.

Segments Covered in the Report

This report forecasts revenue growth at regional & country levels and provides an analysis on the industry trends in each of the sub-segments from 2018 to 2030. For the purpose of this study, Grand View Research has segmented the Africa nonwoven fabrics market on the basis of product, material, application, technology and region:

Africa Nonwoven Fabrics Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Disposable

Durable

Africa Nonwoven Fabrics Material Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Polypropylene

Polyester

Polyethylene

Wood Pulp

Rayon/Lyocell

Biopolymers

PLA

PHA

Other Types

Others

Africa Nonwoven Fabrics Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Hygiene

Building & Construction

Industrial

Consumer Products

Filtration

Automotive

Medical & Healthcare

Others

Africa Nonwoven Fabrics Technology Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Spunbond

Dry Laid

Wet Laid

Spunlace

Meltblown

Others

Africa Nonwoven Fabrics Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Africa

South Africa

North Africa

Central Africa

Order a free sample PDF of the Africa Nonwoven Fabrics Market Intelligence Study, published by Grand View Research.

0 notes

Text

Cotton Mills in Gujarat – Labisa

Gujarat is the backbone of India’s cotton industry, often referred to as the “Cotton State” due to its dominant role in cotton cultivation, processing, and export. As one of the most vibrant hubs for textiles, Gujarat’s Cotton Mills play a pivotal role in the global textile market. Labisa, a leading name in textile manufacturing, is proud to contribute to this thriving ecosystem with its high-quality cotton products. Whether you’re a bulk buyer, distributor, wholesaler, or stockist, Labisa offers unparalleled expertise and top-notch fabrics tailored to your business needs.

The Legacy of Cotton Mills in Gujarat

The history of cotton production in Gujarat is as old as the state itself. Cotton mills in Gujarat began their journey during the 19th century and have since evolved into modern centers of excellence, combining traditional methods with advanced technology. These mills have not only supported the local economy but have also bolstered India's position as a global leader in cotton textiles.

Labisa partners with the finest Cotton Mills in Gujarat to source the best-quality fabrics for its diverse clientele, ensuring a seamless blend of tradition and innovation.

Why Gujarat is India’s Cotton Hub

1. Favorable Climate and Geography for Cotton Cultivation

Gujarat’s semi-arid climate and fertile soil make it ideal for cotton farming. The state contributes significantly to India’s annual cotton production, making it a reliable source for high-quality raw materials.

2. Availability of Skilled Labor and Advanced Machinery

Gujarat boasts a workforce with deep expertise in spinning, weaving, and textile processing. Coupled with modern technology, this ensures the production of superior-quality fabrics that cater to diverse markets.

3. Strong Infrastructure Supporting Textile Growth

With advanced logistics networks, proximity to major ports, and state-of-the-art textile parks, Gujarat’s infrastructure supports the efficient functioning of its cotton industry. Labisa leverages these advantages to ensure timely delivery of bulk orders.

Labisa: A Trusted Name in Cotton Textile Manufacturing

Labisa, founded in 1991, has emerged as a trusted Cotton Manufacturer with a commitment to quality and sustainability. Headquartered in Mumbai, the company collaborates with Gujarat’s leading cotton mills to produce fabrics that meet global standards.

Labisa’s Vision

Labisa aims to empower businesses by delivering high-quality textiles at competitive prices. With a focus on innovation, sustainability, and customer satisfaction, Labisa ensures that every product aligns with market demands.

Types of Cotton Fabrics Offered by Labisa

Labisa specializes in a wide range of cotton fabrics, ensuring that wholesalers and distributors can cater to diverse customer preferences.

Pure Cotton Fabrics

Renowned for their breathability and softness, pure cotton fabrics are ideal for casual wear and summer collections. These fabrics offer unmatched comfort, making them a customer favorite.

Blended Cotton for Durability

Labisa offers blends like cotton-polyester and cotton-rayon, which combine the comfort of cotton with the durability of synthetic fibers. These fabrics are perfect for creating long-lasting garments.

Organic Cotton Fabrics for Sustainable Choices

With growing demand for eco-friendly options, Labisa’s organic cotton fabrics appeal to conscious consumers. These fabrics are free from harmful chemicals, aligning with global sustainability trends.

Applications of Labisa’s Cotton Textiles

Labisa’s cotton fabrics are versatile and cater to a wide array of industries and applications:

Women’s Ethnic Wear: Perfect for sarees, salwar suits, and fusion wear.

Kurtis and Casual Wear: Light, breathable fabrics for everyday use.

Home Textiles: Used for curtains, bedsheets, and cushion covers.

Export-Ready Cotton Products: Tailored for international markets with stringent quality standards.

Labisa’s Manufacturing Excellence

Labisa’s commitment to quality begins at the source, with partnerships with the finest Cotton in Gujarat mills. Here’s how Labisa ensures top-tier production:

Sourcing High-Quality Cotton: Collaborating with the best cotton farms and mills in Gujarat.

Advanced Spinning and Weaving Processes: Utilizing state-of-the-art technology to produce flawless fabrics.

Rigorous Quality Control: Every product undergoes stringent checks to meet client expectations.

Benefits of Partnering with Labisa for Cotton Textiles

For wholesalers, distributors, and stockists, Labisa offers numerous benefits:

Competitive Pricing for Bulk Orders Labisa provides cost-effective solutions without compromising quality, making it an ideal partner for businesses seeking high margins.

Customization Options for Unique Designs With tailored solutions, Labisa helps you create exclusive collections that resonate with your target audience.

Timely Delivery and Reliable Service Leveraging Gujarat’s robust infrastructure, Labisa ensures seamless logistics and on-time order fulfillment.

Sustainability in Gujarat’s Cotton Mills

Gujarat is leading the way in sustainable textile manufacturing, and Labisa is proud to align with these eco-friendly initiatives.

Adoption of Eco-Friendly Manufacturing Practices Labisa collaborates with mills that use sustainable techniques, reducing environmental impact without sacrificing quality.

Supporting Organic Cotton Farming By promoting organic farming, Labisa contributes to healthier ecosystems and communities.

Reducing Environmental Impact in Textile Production Labisa’s commitment to sustainable dyeing and production processes helps minimize waste and energy consumption.

Export Opportunities for Gujarat’s Cotton Industry

Gujarat’s strategic location, coupled with its robust infrastructure, makes it a gateway for global textile exports.

Labisa’s Role in Supplying Cotton Textiles to Global Markets

Labisa serves international clients by offering export-ready cotton products that meet diverse regulatory standards. The company’s ability to cater to bulk orders has earned it a strong presence in markets across Europe, the Middle East, and Asia.

Popular Export Categories

Women’s ethnic wear fabrics.

Lightweight and breathable casual wear textiles.

Sustainable cotton blends tailored for eco-conscious markets.

Challenges Faced by Cotton Mills in Gujarat

While Gujarat’s cotton industry thrives, it faces several challenges:

Fluctuations in Cotton Prices: Global market volatility affects raw material costs.

Competition from Synthetic Fabrics: Affordable synthetic alternatives pose a challenge to cotton’s dominance.

Ensuring Sustainability Amid Growing Demand: Meeting increasing demand while adopting eco-friendly practices remains a balancing act.

Labisa tackles these challenges head-on by offering innovative solutions and maintaining consistent quality.

Trends in Cotton Textiles for 2024

The cotton textile market is evolving rapidly. Here are key trends for the upcoming year:

Demand for Lightweight and Breathable Fabrics: Ideal for warm climates and everyday wear.

Growing Popularity of Sustainable Cotton: Consumers increasingly prefer eco-friendly options.

Fusion of Cotton with Other Fabrics for Versatility: Blends that offer the best of both worlds are gaining traction.

Labisa’s portfolio reflects these trends, ensuring its products remain relevant and desirable.

FAQs about Cotton Mills in Gujarat – Labisa

1. What types of cotton fabrics does Labisa specialize in?

Labisa offers pure cotton, blended cotton, and organic cotton fabrics for diverse applications.

2. How does Labisa ensure quality in its cotton textiles?

Labisa employs advanced manufacturing processes and rigorous quality checks to deliver superior fabrics.

3. Does Labisa offer organic cotton options?

Yes, Labisa specializes in organic cotton fabrics that meet global sustainability standards.

4. Can Labisa cater to international orders?

Absolutely! Labisa exports high-quality cotton textiles worldwide, ensuring timely delivery.

5. What makes Gujarat ideal for cotton manufacturing?

Gujarat’s favorable climate, skilled labor, and advanced infrastructure make it a leading cotton hub.

6. How can wholesalers collaborate with Labisa?

Wholesalers can contact Labisa’s sales team to explore bulk order options, customization, and competitive pricing.

Conclusion

Labisa is proud to be a part of the thriving Cotton Mills in Gujarat ecosystem. With a commitment to quality, sustainability, and innovation, Labisa caters to the diverse needs of wholesalers, distributors, and stockists. Whether you’re seeking pure cotton fabrics, sustainable textiles, or blended materials, Labisa ensures exceptional products that drive your business growth.

Ready to Partner with Labisa?

Call Us: Afzal: +91 98929 39564 | Labisa Sales: +91 81699 85975 Email Us: [email protected], [email protected] Visit Us: Sion West, Dharavi, Mumbai, Mumbai 400017

Explore premium-quality Cotton in Gujarat with Labisa – your trusted textile partner.

0 notes

Text

A Comprehensive Guide to Growing Eco Fiber Market

The global eco fiber market size is expected to reach USD 77.17 billion by 2030, expanding at a CAGR of 7.6% from 2023 to 2030, according to a new report by Grand View Research, Inc. The growth is attributed to the rise in concern regarding the harmful environmental impacts of using synthetic fibers, which has been the major factor contributing to the increased demand for organic eco fiber for the past few years.

The increasing dependence on chemicals and pesticides to increase crop production has led to the mass degradation of the environment. This, in turn, has prompted governments and other regulatory bodies to follow numerous regulations. These regulations have been imposed on the manufacturing as well as disposal of synthetic sources of fiber production. This trend has further led to a shift in preference toward bio-based alternatives such as organic cotton, hemp, and other sources of eco fibers.

Eco fibers are also rapidly gaining popularity in designer garments and apparel. Continuous advancement in terms of the development of eco fiber textiles offering antimicrobial, hypoallergenic, insulating, UV resistant, highly breathable, and absorbent characteristics are expected to promote the importance of eco fibers in the clothing market over the forecast period.

Organic eco fibers is anticipated to witness the fastest growth rate across the forecast period. Organic cotton is gaining increasing popularity owing to its exceptional benefits such as the elimination of risks for chemical impact on human beings and surroundings and more premiums for the farmers. Additionally, organic cotton ensures health care and food security by providing contamination-free food.

Gather more insights about the market drivers, restrains and growth of the Eco Fiber Market

Eco Fiber Market Report Highlights

• Regenerated fibers product segment of eco fiber market is expected to expand at a CAGR of 7.4% over the forecast period. The product is an integral part of Man-made fibers and is produced artificially by using either proteins or cellulose. Soy, corn, peanuts, and milk are some of the commonly used proteins in the production of regenerated fibers, commonly known as Azlons. Regenerated fibers made from cellulose comprise rayon and viscose. The rapidly growing medical textiles industry in India and China is expected to create ample growth opportunities for the product in the market.

• Medical textile application segment in eco fiber market accounted for revenue of USD 8.06 billion in 2022. The industry is one of the significant consumers of the eco fiber market. In medical textile application, eco fibers find application in baby diapers, incontinence products, sanitary napkins, surgical sutures, surgical dressing, artificial implants, and disposables. Technological advancements in medical & healthcare sector have resulted in increased use of medical textiles (as nanofibers) in wound healing, bone regeneration, and drug delivery applications.

• Central & South America eco fiber market is expected to grow at a CAGR of 8.3% in the forecast period owing to the growing textile industry in the region. The availability of raw materials, such as cotton and polyester, coupled with the presence of textile manufacturing units in the region has made Central & South America one of the largest producers of textiles including apparels. Additionally, free trade agreements, abundant availability of raw materials, upcoming events including sports & carnivals, and government initiatives to promote the textile industry are some of the key factors anticipated to drive market growth in the region over the forecast period.

• The eco fiber industry is highly fragmented in nature owing to rising awareness regarding products in fashion, industrial, and household applications. Industry participants are taking advantage of low-cost feed stock availability in India to compete with competitors in China and Middle East. However, despite the obstacles, new entrants are expected to increase spending on developing new products focusing towards eco-friendly smart textiles.

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

• The global pre-engineered building market size is expected to reach USD 16.92 billion in 2024 and is expected to grow at a CAGR of 11.6% from 2025 to 2030.

• The global specialty printing consumables market size was valued at USD 39.70 billion in 2024 and is expected to grow at a CAGR of 3.2% from 2025 to 2030.

Eco Fiber Market Segmentation

Grand View Research has segmented the global eco fiber market report based on product, application, and region:

Eco Fiber Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

• Organic

• Manmade/Regenerated

• Recycled

• Natural

Eco Fiber Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

• Textiles/Apparel

• Industrial

• Medical

• Household & Furnishing

• Others

Eco Fiber Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o U.K.

o Germany

o France

o Italy

• Asia Pacific

o China

o India

o Japan

• Central & South America

o Brazil

• Middle East & Africa

o Saudi Arabia

Order a free sample PDF of the Eco Fiber Market Intelligence Study, published by Grand View Research.

#Eco Fiber Market#Eco Fiber Market Size#Eco Fiber Market Share#Eco Fiber Market Analysis#Eco Fiber Market Report

0 notes

Text

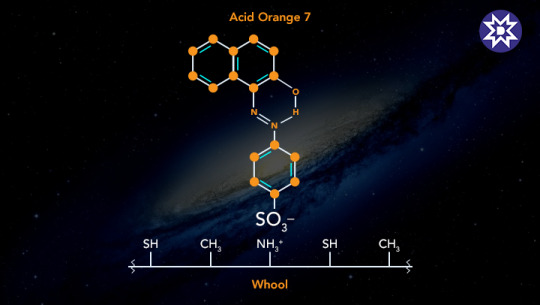

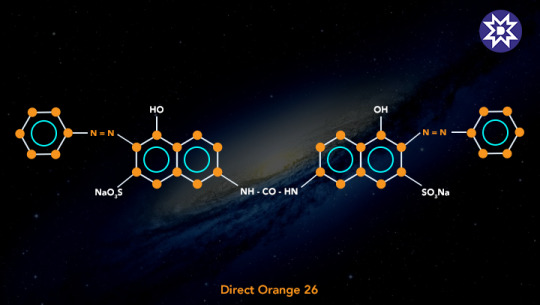

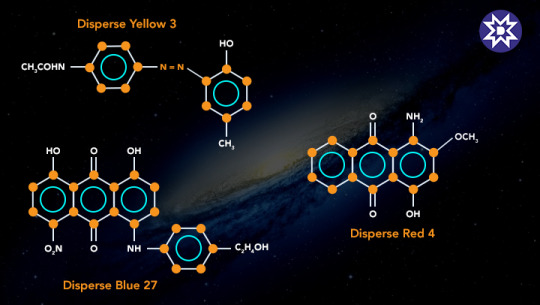

Comprehensive Guide to Different Types of Dyes and Their Chemical Structures

Dyes are integral to industries like textiles, paper, plastics, and leather, providing a diverse palette of colors and properties tailored to specific needs. This guide delves into various dye types, their characteristics, and their chemical structures. Meghmani Global, a prominent manufacturer and supplier of dyes, plays a vital role in delivering sustainable and high-quality dye solutions worldwide.

1. Natural Dyes

Source: Derived from natural substances like plants, minerals, and insects.

Examples: Indigo (from plants), cochineal (from insects).

Applications: Eco-friendly options for textiles, food coloring, and cosmetics.

Chemical Structure: Composed of complex organic molecules like anthraquinones and flavonoids.

Read blog on Different Types of Dyes with Chemical Structure

2. Synthetic Dyes

Source: Produced chemically from petroleum derivatives.

Advantages: Vibrant colors, higher durability, and cost-effectiveness.

Categories: Includes several subtypes such as azo dyes and anthraquinone dyes.

Chemical Structure: Often includes azo groups (-N=N-) or aromatic rings.

3. Direct Dyes

Features: Water-soluble and directly applied to materials like cotton and rayon.

Usage: Popular for dyeing cellulose fibers due to ease of application.

Chemical Structure: Contain azo or stilbene groups with water-solubilizing sulfonic acid groups.

4. Disperse Dyes

Purpose: Designed for hydrophobic fibers like polyester and acetate.

Mechanism: Submicron particles are dispersed in water and absorbed by fibers under heat.

Applications: Used in textile printing and synthetic fiber dyeing.

Chemical Structure: Non-ionic, often featuring anthraquinone or azo structures.

5. Reactive Dyes

Features: Chemically bond with fibers, offering excellent colorfastness.

Applications: Ideal for natural fibers like cotton and wool.

Advantages: High wash fastness and vibrant shades.

Chemical Structure: Contain reactive groups (e.g., triazine) that form covalent bonds with fibers.

6. Solvent Dyes

Characteristics: Soluble in organic solvents but not water.

Applications: Used in plastics, inks, and petroleum products.

Advantages: Stability and vivid colors for industrial applications.

Chemical Structure: Non-polar molecules with aromatic and azo groups.

Meghmani Global: A Leader in Dye Manufacturing

Meghmani Global specializes in producing a comprehensive range of dyes, including reactive, direct, and solvent dyes. With over 27 manufacturing units and a global presence in 60+ countries, the company is known for its innovative products, sustainable practices, and commitment to quality. Our focus on eco-friendly processes and advanced technologies ensures compliance with international standards while minimizing environmental impact.

Conclusion

Understanding the types of dyes and their chemical structures is essential for optimizing applications in industries. From natural and reactive dyes to solvent and disperse dyes, each type offers unique benefits and uses. Meghmani Global exemplifies leadership in this sector, combining innovation with environmental stewardship to meet diverse market demands.

Get in touch

Email: [email protected]

Contact: 7926812918 | Contact Us

Website: https://www.meghmaniglobal.com/

0 notes

Text

Regenerated Fiber Market Size, Share, Trends, Growth Opportunities, Key Drivers and Competitive Outlook

"Regenerated Fiber Market – Industry Trends and Forecast to 2028

Global Regenerated Fiber Market, By Type (Rayon, Acetate, Cellulose, Lyocell), Application (Needle-punched Fabrics, Geotextiles, Automotive, Wadding, Water & Oil Filtration), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350-page PDF Report @

**Segments**

- **Type:** The regenerated fiber market can be segmented based on type into viscose, acetate, modal, lyocell, and others. Viscose is a commonly used type of regenerated fiber due to its softness and versatility. Acetate is known for its luxurious appearance and draping qualities. Modal is a type of regenerated fiber known for its strength and shrink-resistance. Lyocell, also known as Tencel, is an eco-friendly option with a silky feel.

- **Application:** In terms of application, the market can be segmented into apparel, home textiles, automotive, non-woven fabrics, and others. Regenerated fibers are extensively used in the apparel industry for making garments such as dresses, shirts, and trousers. In home textiles, regenerated fibers are used for making bedding, curtains, and upholstery. The automotive industry uses regenerated fibers for interior components like seat covers and door panels.

- **Distribution Channel:** The regenerated fiber market can also be segmented based on the distribution channel, including direct sales and indirect sales. Direct sales involve selling products directly to consumers through company-owned stores or online platforms. Indirect sales, on the other hand, involve selling through wholesalers, distributors, retailers, and e-commerce websites.

**Market Players**

- **Lenzing AG:** A key player in the regenerated fiber market, Lenzing AG is known for its sustainable and innovative fiber solutions. The company offers a range of regenerated fibers, including Tencel, Modal, and Viscose, catering to various industries.

- **Kelheim Fibres GmbH:** Kelheim Fibres GmbH is another prominent player in the market, specializing in the production of viscose specialty fibers. The company focuses on sustainability and product innovation to meet the evolving demands of the textile industry.

- **Aditya Birla Group:** With a strong presence in the regenerated fiber market, Aditya Birla Group offers a wide range of fibers such as Birla ModalLenzing AG, Kelheim Fibres GmbH, and Aditya Birla Group are key players in the regenerated fiber market, each contributing significantly to the industry with their unique offerings and strategies. Lenzing AG stands out for its commitment to sustainability and innovation, providing a diverse range of regenerated fibers like Tencel, Modal, and Viscose. The company's focus on eco-friendly solutions has helped it establish a strong position in the market, catering to the increasing demand for sustainable materials across various industries.

Kelheim Fibres GmbH, on the other hand, specializes in the production of viscose specialty fibers, emphasizing sustainability and product innovation to meet the evolving needs of the textile industry. The company's dedication to developing high-quality and eco-conscious fibers has garnered attention in the market, positioning it as a leading player in the regenerated fiber segment.

Aditya Birla Group also plays a significant role in the regenerated fiber market, offering a wide range of fibers such as Birla Modal. The group's presence in the industry is characterized by a focus on providing innovative solutions that meet the diverse requirements of customers in the apparel, home textiles, and automotive sectors. With a strong emphasis on quality, sustainability, and market responsiveness, Aditya Birla Group continues to be a formidable player in the regenerated fiber market.

Overall, these market players contribute to the growth and development of the regenerated fiber industry through their product offerings, sustainability initiatives, and market strategies. As the demand for sustainable materials continues to rise across various sectors, companies like Lenzing AG, Kelheim Fibres GmbH, and Aditya Birla Group are well-positioned to capitalize on opportunities in the market and drive further innovation in the field of regenerated fibers.**Global Regenerated Fiber Market Analysis**

- **Segments:** The regenerated fiber market can be segmented based on type into viscose, acetate, modal, lyocell, and others. Viscose is popular due to its softness and versatility, while acetate is known for its luxurious appearance. Modal is prized for its strength and shrink-resistance, and lyocell, or Tencel, is considered eco-friendly. In terms of applications, the market segments include apparel, home textiles, automotive, non-woven fabrics, and others. Regenerated fibers find extensive use in the apparel industry for garments like dresses and shirts, as well as in home textiles for bedding and upholstery. The automotive sector utilizes regenerated fibers for interior components such as seat covers and door panels. The market can also be segmented based on distribution channels, including direct sales and indirect sales through various retail channels.

- **Market Players:** Key players in the regenerated fiber market include Lenzing AG, known for its sustainable fiber solutions like Tencel, Modal, and Viscose. Kelheim Fibres GmbH specializes in the production of viscose specialty fibers, focusing on sustainability and product innovation. Aditya Birla Group offers a wide range of fibers such as Birla Modal, catering to diverse industry needs. These players contribute significantly to the industry with their unique offerings, focusing on sustainability, innovation, and market responsiveness to meet evolving customer demands.

The global regenerated fiber market is expected to witness steady growth

Table of Content:

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Global Regenerated Fiber Market Landscape

Part 04: Global Regenerated Fiber Market Sizing

Part 05: Global Regenerated Fiber Market Segmentation by Product

Part 06: Five Forces Analysis

Part 07: Customer Landscape

Part 08: Geographic Landscape

Part 09: Decision Framework

Part 10: Drivers and Challenges

Part 11: Market Trends

Part 12: Vendor Landscape

Part 13: Vendor Analysis

Objectives of the Report

To carefully analyze and forecast the size of the Regenerated Fiber market by value and volume.

To estimate the market shares of major segments of the Regenerated Fiber

To showcase the development of the Regenerated Fiber market in different parts of the world.

To analyze and study micro-markets in terms of their contributions to the Regenerated Fiber market, their prospects, and individual growth trends.

To offer precise and useful details about factors affecting the growth of the Regenerated Fiber

To provide a meticulous assessment of crucial business strategies used by leading companies operating in the Regenerated Fiber market, which include research and development, collaborations, agreements, partnerships, acquisitions, mergers, new developments, and product launches.

Key questions answered

How feasible is Regenerated Fiber Market for long-term investment?

What are influencing factors driving the demand for Regenerated Fiber near future?

What is the impact analysis of various factors in the Global Regenerated Fiber market growth?

What are the recent trends in the regional market and how successful they are?

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America

Browse Trending Reports:

Oil Shale Market Cyclin Dependent Kinase Inhibitor Market Agammaglobulinemia Treatment Market Infantile Systemic Hyalinosis Market Continuous Bioprocessing Market Automated Harvesting System Market Capillary Blood Collection Devices Market Automotive Lead Acid Batteries Market 10d Laser Scanner Market Polyurethane Composites Market Interactive Whiteboard Market Botnet Detection Market High Temperature Composite Resin Market Low Profile Additives Market Form Fill Seal Equipment Market Ophthalmic Knives Market Aluminium Nitride Market Tapping Sleeves Market Astaxanthin Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

Lyocell Fiber Market Overview: Growth Factors and Future Trends (2023-2032)

The Asia Pacific Lyocell Fiber market is projected to grow at a remarkable rate of 10.61%, with its value expected to surge from USD 790.45 million in 2023 to USD 1,958.95 million by 2032.

The Lyocell fiber market is experiencing significant growth due to increasing demand for sustainable and eco-friendly textiles. Lyocell, a type of rayon, is made from cellulose derived from wood pulp, primarily from eucalyptus, beech, and spruce trees. Its production process is considered environmentally friendly as it uses a closed-loop system that recycles water and solvents, minimizing waste and emissions. The fiber is known for its high tensile strength, softness, breathability, and biodegradability, making it a popular choice in the textile and fashion industries for applications in clothing, home textiles, and personal care products. The market is driven by growing consumer awareness about sustainability, the rising trend of eco-conscious fashion, and advancements in production technology that enhance the quality and versatility of Lyocell fibers. Additionally, regulatory support for sustainable practices and increasing investment in research and development are further propelling the market's expansion.

The study of the Lyocell fiber market reveals several key findings that highlight the market's current state and future prospects:

1. Sustainability and Eco-friendliness

Environmental Benefits: Lyocell fiber production is environmentally friendly due to its closed-loop process, which recycles water and solvents, reducing waste and emissions.

Biodegradability: Lyocell fibers are biodegradable, contributing to the market's appeal among environmentally conscious consumers and industries.

2. High Demand in Textile Industry

Textile Applications: There is a high demand for Lyocell fibers in the textile industry, particularly in the production of clothing, home textiles, and personal care products.

Consumer Preferences: The growing preference for sustainable and comfortable fabrics among consumers is driving the adoption of Lyocell fibers in fashion and home textiles.

3. Technological Advancements

Innovations: Advances in production technology are improving the quality, versatility, and cost-efficiency of Lyocell fibers.

Enhanced Properties: Innovations have led to enhancements in the tensile strength, softness, and breathability of Lyocell fibers, making them more competitive with other textile fibers.

4. Regional Insights

Asia-Pacific Dominance: The Asia-Pacific region dominates the Lyocell fiber market, with significant production and consumption, driven by large textile manufacturing hubs in countries like China and India.

Growth in Europe and North America: Europe and North America are also experiencing strong growth due to increasing consumer awareness about sustainability and eco-friendly products.

5. Challenges and Barriers

High Production Costs: The production cost of Lyocell fibers is higher compared to traditional fibers, posing a challenge to market growth.

Competition from Other Sustainable Fibers: The market faces competition from other sustainable fibers such as organic cotton and bamboo, which may affect Lyocell fiber adoption.67. Regulatory Support

Government Initiatives: Supportive regulations and government initiatives promoting sustainable practices in the textile industry are aiding the growth of the Lyocell fiber market.

7. Investment in R&D

Research and Development: Increased investment in research and development is leading to innovations in fiber properties and production processes, enhancing the market potential of Lyocell fibers.

8. Future Outlook

Positive Outlook: The future outlook for the Lyocell fiber market is positive, with expected continuous growth driven by rising consumer demand for sustainable textiles, technological advancements, and supportive regulatory frameworks.

Key Player Analysis

Lenzing AG

Aditya Birla Group

Smartfiber AG

China Populus Textile Ltd.

Baoding Swan Fiber Co., Ltd.

Great Duksan

Acelon Chemicals & Fiber Corporation

Nien Foun Fiber

Weiqiao Textile Company Limited

Zhejiang Yaojiang Industrial Group

Sateri Holdings Limited

Birla Cellulose

Nanjing Chemical Fiber Co., Ltd.

Chonbang Co. Ltd.

Grasim Industries Limited

Acegreen Eco-Material Technology Co., Ltd.

Shandong Silver Hawk Chemical Fibre Co., Ltd.

Tangshan Sanyou Xingda Chemical Fiber Co., Ltd.

China Bambro Textile (Group) Co., Ltd.

Kelheim Fibres GmbH

More About Report- https://www.credenceresearch.com/report/asia-pacific-lyocell-fiber-market

The Lyocell fiber market presents several growth opportunities driven by the increasing demand for sustainable and eco-friendly textiles. Key growth opportunities include:

1. Expansion in the Textile and Apparel Industry

Eco-conscious Fashion: The rising trend of sustainable and eco-conscious fashion offers significant growth opportunities for Lyocell fibers. Brands and designers are increasingly incorporating Lyocell into their collections to appeal to environmentally conscious consumers.

Performance Wear: Due to its moisture-wicking and breathable properties, Lyocell is ideal for activewear and performance clothing, presenting an opportunity for growth in this segment.

2. Home Textiles Market

Bedding and Linens: The demand for sustainable home textiles, such as bedsheets, pillowcases, and towels, is growing. Lyocell’s softness and durability make it an attractive option for these products.

Upholstery and Drapery: The home decor market is another area where Lyocell fibers can be utilized, offering eco-friendly alternatives for upholstery, drapery, and other home fabrics.

3. Personal Care Products

Hygiene Products: Lyocell fibers are used in personal care and hygiene products such as baby wipes, sanitary napkins, and facial masks due to their biodegradability and skin-friendly properties.

Medical Textiles: There is potential for growth in medical applications, including wound dressings and other medical textiles, where Lyocell’s hypoallergenic and absorbent properties are beneficial.

4. Technological Innovations

Advanced Manufacturing Techniques: Investing in advanced manufacturing techniques can reduce production costs and improve the quality of Lyocell fibers, making them more competitive with traditional fibers.

Blending with Other Fibers: Developing new blends of Lyocell with other fibers, such as cotton, wool, or synthetic fibers, can create hybrid materials with enhanced properties, expanding their application range.

5. Sustainable and Circular Economy Practices

Recycling Initiatives: Promoting and developing recycling initiatives for Lyocell textiles can further enhance its sustainability credentials and appeal to eco-conscious consumers.

Waste Reduction: Implementing closed-loop production processes that minimize waste and environmental impact can attract more manufacturers and consumers towards Lyocell fibers.

6. Geographic Expansion

Emerging Markets: Expanding into emerging markets in Asia, Latin America, and Africa, where there is increasing awareness and demand for sustainable textiles, offers significant growth potential.

Market Penetration in Developed Regions: Increasing market penetration in developed regions like North America and Europe by partnering with major retailers and brands can drive growth.

7. Marketing and Awareness Campaigns

Consumer Education: Increasing consumer awareness about the environmental benefits of Lyocell fibers through targeted marketing campaigns can drive demand.

Brand Collaborations: Collaborating with well-known brands and retailers to promote Lyocell products can enhance visibility and market acceptance.

8. Regulatory Support and Government Initiatives

Government Incentives: Leveraging government incentives and subsidies for sustainable manufacturing practices can reduce costs and encourage the adoption of Lyocell fibers.

Regulatory Compliance: Ensuring compliance with international sustainability standards and certifications can enhance market trust and open up new opportunities.

9. Product Diversification

New Applications: Exploring new applications for Lyocell fibers beyond traditional textiles, such as in automotive interiors, filtration, and industrial applications, can open up additional growth avenues.

Innovative Products: Developing innovative Lyocell-based products, such as antimicrobial fabrics or smart textiles, can differentiate offerings and capture niche markets.

10. Collaborative Research and Development

Partnerships with Research Institutions: Collaborating with research institutions and universities to explore new uses and improve the properties of Lyocell fibers can lead to breakthrough innovations.

Industry Collaboration: Working together with other industry players to share knowledge and resources can accelerate development and market adoption of Lyocell fibers.

Segments:

Based on Type

Staple Fiber

Cross-Linked Fiber

Based on Application

Apparel

Home Textiles

Surgical Products

Baby Diapers

Tire Cord

Conveyor Belts

Specialty Papers

Others

Browse the full report – https://www.credenceresearch.com/report/asia-pacific-lyocell-fiber-market

Browse Our Blog: https://www.linkedin.com/pulse/lyocell-fiber-market-overview-growth-factors-z4puf

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Carbon Fibers (CF) and Carbon Fiber Reinforced Plastics (CFRP) Market Upcoming Trends Analysis 2023-2033

Market Definition

Carbon fiber reinforced plastics (CFRP) are a composite material made up of a polymer matrix and carbon fibers. Carbon fibers are extremely strong and lightweight materials that can be used to reinforce various polymers, such as polyesters, epoxy resins, and polyamides. CFRP is used in a wide variety of applications, from aerospace and automotive components to sporting goods and medical devices.

The carbon fibers are made from a variety of sources, such as rayon, polyacrylonitrile (PAN), and pitch-based fibers. The fibers are then formed into a yarn or fabric and then impregnated with a resin, such as epoxy or polyester. This forms a composite material that is then used to form components.

Market Outlook

Carbon fibers and carbon fiber reinforced plastics (CFRP) are increasingly being used in a wide range of industries, from aerospace to automotive and from medical to military. This is due to their unique properties, which include high strength, low weight, and excellent resistance to corrosion and fatigue. The market for these materials is growing rapidly, and there are several key trends driving this growth.

1. Increasing Demand for Lightweight Materials: As the demand for lighter and more fuel-efficient vehicles increases, so does the demand for lightweight materials such as carbon fibers and CFRP.

2. Cost Reduction: The cost of carbon fibers and CFRP has been steadily declining over the years, making them more cost-effective for a variety of applications.

3. Improved Performance: The performance of carbon fibers and CFRP has been steadily improving over the years, due to the development of new production processes and the introduction of new additives and modifiers.

Carbon Fibers (CF) and Carbon Fiber Reinforced Plastics (CFRP) are two of the most important materials used in modern-day engineering and manufacturing. They are used in a variety of industries including aerospace, automotive, and sporting goods.

Technological advances in Carbon Fibers and Carbon Fiber Reinforced Plastics have enabled the materials to be used in a wider range of applications. Carbon fibers are strong, lightweight, and can be formed into complex shapes.

Cost efficiency is another major driver of the Carbon Fibers and Carbon Fiber Reinforced Plastics Market. Carbon fibers and Carbon Fiber Reinforced Plastics are much lighter than traditional materials, which helps to reduce the overall cost of manufacturing. Additionally, Carbon Fibers and Carbon Fiber Reinforced Plastics are more durable and require less maintenance, which helps to reduce costs in the long run.

Finally, environmental sustainability is another key driver of the Carbon Fibers and Carbon Fiber Reinforced Plastics Market. Carbon Fibers and Carbon Fiber Reinforced Plastics are made from renewable resources, and they have a much lower carbon footprint than traditional materials.

To Know More: https://www.globalinsightservices.com/reports/carbon-fibers-cf-and-carbon-fiber-reinforced-plastics-cfrp-market//?utm_id=1014

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request Sample: https://www.globalinsightservices.com/request-sample/GIS25601//?utm_id=1014

Market Segmentation

The carbon fibers (CF) and carbon fiber reinforced plastics (CFRP) market is segmented by type, end-use, application, and region. By type, the market is divided into PAN-based, pitch-based, and rayon-based. By end use, the market is bifurcated into automotive, wind energy, sporting goods, Marine electronics, and others. By application, the market is divided into aircraft components, automotive parts, wind turbine blades, and others. By region, the market is classified into North America, Europe, Asia-Pacific, and the rest of the world.

Request Customization@ https://www.globalinsightservices.com/request-customization/GIS25601//?utm_id=1014

Major Players

The global carbon fibers (CF) and carbon fiber reinforced plastics (CFRP) Market report includes players like Toray Industries, Inc. – Japan, Teijin Limited – Japan, Mitsubishi Chemical Holdings Corporation – Japan, SGL Carbon SE – Germany, Hexcel Corporation – United States, Solvay SA – Belgium, Nippon Graphite Fiber Corporation – Japan, Formosa Plastics Corporation – Taiwan, Hyosung Advanced Materials Corporation – South Korea, and Cytec Solvay Group (now part of Solvay SA) – United States

Request Discounted Pricing@ https://www.globalinsightservices.com/request-special-pricing/GIS25601//?utm_id=1014

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis

Buy your copy here: https://www.globalinsightservices.com/checkout/single_user/GIS25601//?utm_id=1014

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1-833-761-1700 Website: https://www.globalinsightservices.com/

0 notes

Text

Future of Carbon Fibre Market: 2024-2032 Growth Insights

Introduction

In 2023, the global carbon fiber industry achieved a remarkable milestone, reaching a valuation of approximately USD 3,821.39 million. Brace yourself for an in-depth exploration of this dynamic industry as we embark on a journey through its market outlook, report overview, size, dynamics, segmentation, recent developments, and the multitude of factors influencing its anticipated growth. With a projected Compound Annual Growth Rate (CAGR) of 11.9% during the forecast period from 2024 to 2032, the carbon fiber industry is poised for remarkable expansion.

Market Outlook (2024-2032)

The global carbon fiber industry is on the brink of transformative growth from 2024 to 2032. As technological advancements, sustainability imperatives, and demand for lightweight materials converge, the carbon fiber market is set to redefine industries and applications worldwide.

Report Overview

This report offers an extensive analysis of the global carbon fiber market, providing a comprehensive snapshot of its historical performance, current landscape, and future prospects. Drawing insights from industry reports, market analyses, and expert opinions, it delivers a profound understanding of the market's dynamics.

Market Size

The carbon fiber industry size impressive valuation in 2023 serves as a testament to its significance. The estimated CAGR reflects the industry's robust potential to disrupt traditional materials across multiple sectors.

Market Dynamics

Several key dynamics propel the carbon fiber industry's growth:

Lightweighting Trend: Industries such as automotive and aerospace increasingly rely on carbon fiber for weight reduction and improved fuel efficiency.

Sustainability: Carbon fiber's eco-friendly attributes, including recyclability and energy efficiency, drive its adoption.

Technological Advancements: Ongoing research and development initiatives enhance carbon fiber properties and expand its applications.

Segmentation

The carbon fiber market encompasses various segments:

Type: Carbon fibers are classified into various categories, including PAN-based, pitch-based, and rayon-based.

Application: Diverse industries, including aerospace, automotive, wind energy, and sports equipment, utilize carbon fiber.

Recent Developments

Recent advancements in the carbon fiber industry include:

Recyclable Carbon Fiber: Innovations in recyclable carbon fiber production contribute to sustainability goals.

3D Printing: The integration of carbon fiber into 3D printing processes enables complex and lightweight designs.

Component Insights

Key components in the carbon fiber industry include:

Raw Materials: Precursors such as polyacrylonitrile (PAN) and pitch form the foundation of carbon fiber production.

Manufacturing Processes: Techniques like carbonization and graphitization impart unique properties to carbon fiber.

COVID-19 Impact

The COVID-19 pandemic influenced the carbon fiber industry, initially disrupting supply chains but ultimately accelerating adoption in industries prioritizing lightweight and sustainable materials.

Growth Factors

The carbon fiber industry's growth is driven by several key factors:

Weight Reduction: Carbon fiber's exceptional strength-to-weight ratio is crucial in industries focused on lightweighting.

Sustainability: Carbon fiber's recyclability and lower carbon footprint align with environmental goals.

Technological Advancements: Ongoing research enhances carbon fiber properties, enabling broader applications.

End-User Insights

Diverse end-users benefit from carbon fiber's properties:

Aerospace: Carbon fiber's lightweight and high-strength properties are invaluable in aircraft and spacecraft construction.

Automotive: Carbon fiber composites improve vehicle fuel efficiency and safety.

Wind Energy: Carbon fiber reinforces wind turbine blades, enhancing energy generation.

Regional Insights

The carbon fiber market exhibits regional variations:

North America: Leading in aerospace and automotive applications.

Europe: A hub for carbon fiber production and adoption in multiple sectors.

Asia-Pacific: Rapid growth driven by automotive, wind energy, and infrastructure development.

Key Players

Prominent companies in the carbon fiber industry include:

SGL Carbon

Hexcel Corporation

Hyosung Advanced Materials

Mitsubishi Chemical Carbon Fiber and Composites, Inc.

Nippon Steel Chemical & Material Co., Ltd.

Others

Market Trends

Several trends shape the carbon fiber market:

Cost Reduction: Efforts to reduce production costs enhance carbon fiber's competitiveness.

Recyclability: The development of recyclable carbon fiber contributes to sustainability goals.

Automotive Adoption: Increasing use of carbon fiber in automobiles for weight reduction and improved efficiency.

Industry News

Stay informed about the latest industry news, including technological breakthroughs, new applications, and market expansions.

Application Insights

Carbon fiber finds applications in various industries:

Aerospace: Lightweight aircraft components improve fuel efficiency.

Automotive: Carbon fiber composites enhance vehicle performance and safety.

FAQs with Answers

What drives the growth of the global carbon fiber industry?

Growth is driven by demand for lightweight materials, sustainability imperatives, and technological advancements.

How did COVID-19 impact the carbon fiber industry?

The pandemic initially disrupted supply chains but later accelerated carbon fiber adoption in industries prioritizing lightweight and sustainable materials.

Which regions are leading in the carbon fiber industry?

North America, Europe, and Asia-Pacific are key regions in the global carbon fiber landscape.

What are the emerging trends in carbon fiber?

Trends include cost reduction, recyclability, and increased adoption in the automotive sector.

0 notes

Text

Growing Adoption In Apparels To Drive The Lyocell Fabric Market Growth Globally

Lyocell fabric is a type of regenerative cellulosic fiber made from wood pulp through solvent spinning of cellulose. It is considered more environmentally sustainable than other rayon and synthetic fibers. Lyocell fabric is used in a variety of apparel products such as t-shirts, dresses, trousers, underwear, socks, etc owing to its breathability, absorbency and soft handle properties. It is also used in home furnishing products such as curtains, bed sheets, and towels.