#Raw Cake Mix Consumption

Explore tagged Tumblr posts

Text

Snowed In

photos: pinterest dividers: @benkeibear, @mariariley, @haerinism

Word Count: 4.4k

Pairing: Spencer Reid x Female Reader

Summary: The entire BAU team decides to take a vacation to snowy Vermont. After a day of traveling together and being the last of the team to show up to the cabin, Spencer and y/n are exhausted and in need of quality time with their friends. When alcohol and games are mixed, Spencer decides to get y/n worked up before sneaking into her room that night to show her what can happen when the sexual tension between them finally snaps.

Warnings: smut, choking, alcohol consumption, others in the house, teasing, sneaking into her room, fingering, oral (female receiving), sexual tension, games (Twister).

A/N: I know it's freshly November but that's close enough to Christmas for me. This idea has been plaguing my brain for literal days now so I just couldn't resist the itch to write this. I also don't want to keep a masterpiece away from you guys especially since I probably won't be able to write for a week after this :(. But, as always, I hope ya'll eat this tf up like I did while I was writing it. <3 Also, I think I like the 3 pic banner so much better than the gifs so I might start doing that :)

THE ICE THAT COATED the sidewalk became a mirror, the concrete beneath twisting into the twin of the gloomy, gray sky above. Y/n's frost-bitten fingers tremble against the ebony wool coat she was wearing tightly wrapped as close to her body as she could possibly pull it. The unrelenting wind bit at her cheeks, her skin raw and burning.

She and Spencer had decided to walk through the cabin's yard rather than risk slipping on the glassy ice, which proved rather asinine as both of their boots and luggage wheels caked in packed snow and mud the deeper into the yard they hiked, slowing their pace. She peered ahead at Spencer under her heavy hood. His chestnut boots a bit more worse for wear than hers, considering he's worn the same ones probably every day of his life.

One hand shoved into his pockets, the other gripped onto the handle of his suitcase so tightly his knuckles blanched. His head dipped against the sharp wind. If she had any energy left by the time they finally reached the cabin's wooden front door, she was going to one hundred percent rub it in his face. They had a negligible argument prior to arriving at the cabin - Spencer completely hellbent on not needing a winter coat, and y/n explaining that Vermont's climate is completely paradoxical to Virginia's at most times of this year.

When they had left Virginia, the sky had been a meager blue, and the wind had grown a bite to it, indicating the impending winter but not intense enough to warrant them to avoid being outside at all costs yet. Temperatures had called for slacks and the usual sweater under a proper coat during their last few cases prior to their very welcomed vacation time. She just wanted to laugh in his face at how right she had been proven in the 5 minutes since they'd parked their rental car in the snow-packed driveway.

When they finally reach the cabin door, Spencer fumbles with the brass knob, his frozen fingers barely able to grasp it enough to twist and open. The door opens without difficulty and y/n almost slams into Spencer's back in an attempt to flee the harsh cold of Vermont.

Y/n hastily shut the door behind her. She and Spencer didn't bother unwrapping any scarves or unbuttoning any coats until they could feel their extremities again as they made their way into the expansive living room, leaving their suitcases by the door. A fresh pine tree lay decorated in lights and garland in the far right corner, the smell of pine welcome in her nose, a large window hiding behind it, climbing halfway up the logged wall before stopping and becoming more logs, with a smaller window on top, shaped to a slope to match the cabin's sloping ceiling.

JJ, Emily, and Penelope sit perched on the chocolate-colored couch to the left of the pine tree turned Christmas tree, wooly sweater sleeves pulled over their hands as they gently hold warm mugs of hot cocoa, most likely.

"You're finally here!" Penelope calls, setting her chipped mug gently on the coffee table just a leg lengths away from the couch. Emily and JJ copy Penelope's actions as they rush over to greet the two latecomers.

"We thought you guys might've gotten stuck or frozen to death or something," Emily explained, engulfing y/n in a hug so tight she thought her lungs might have to escape her body entirely to relieve the pressure.

"With the way Spencer drives, I think we almost got stuck like 4 times," y/n teased, resulting in a malicious side eye from Spencer but giggles from the women in front of her.

"To be fair, we only actually got stuck once. We made it in one piece so I don't see the issue."

Y/n rolled her eyes, a smile tugging at the corners of her lips, the rest of her energy spent on the single ridicule, her mind unable to continue the back and forth.

"The rest of them are in the kitchen," JJ explains, leading them through an archway embellished with fake leaves and fairy lights.

Rossi's back is to them as he pulls a steaming mug from the microwave. When he finally turns to spot y/n and Spencer, the last two team members to make it through the treacherous countryside of Vermont, he places the mug on the kitchen island. "I was just making you guys some cups of cocoa, but it's the packet kind. I would've made it from scratch if I thought I could survive another trip outside."

The team erupted in chuckles, "Yeah, I wouldn't suggest going out there, Rossi. You might freeze on the spot," Morgan laughed.

"Hey, I'm old, but I'm not that old."

Spencer reached delicately for the mug resting on the kitchen island, sliding his fingers through the handle and carefully lifting it as to not spill it over his hand. He turns to y/n and holds out the cup for her.

"I'll take the next one," he smiles. She gives him a sweet smile back as she takes the hot cocoa from him, "Thanks, Spence."

Y/n rose to sit upon a marbled counter, her hot cocoa clutched into her hands, greedy for the warmth it brought to her numbed fingers. Her legs swung, feeling restless despite the exhaustion that weighed her entire body down.

Vacation had began to seem like a myth considering serial killers never cease to kill and each and every person in the kitchen with her had the same mindset when it came to their work. People need us. She can't remember the last time one of her coworkers had taken a vacation or even just a day off as if they were avoiding it like a contagious disease.

She had to admit, it did almost make her feel uncomfortable to think about taking a vacation. She didn't hold much trust in others to do their jobs for them. But, nevertheless, she was grateful to finally have some time to spend with her favorite people doing nothing but watching cheesy Christmas movies and playing board and card games like she was a child again.

With all her might, she pushed down the lingering guilt she always seemed to feel when she wasn't working towards catching a bad guy. Villains always need their heroes, and she didn't like the idea of letting the villains run rampant for too long.

Her internal battle must have shown on her face because Spencer laid a secretive hand over hers as he leaned against the countertop she sat upon. He tilted his face upwards to look at her, silently asking her, what are you thinking about? Spencer seemed to be the one person who could read her like a book, despite y/n keeping the book of her life and emotions locked, shut, and completely hidden away from everyone else.

She shrugged, not important. She diverted her gaze from his, the weight of his causing her mouth to part slightly, wanting to spill everything running through her mind - but she clamped her mouth shut because that is definitely not something she wanted to do in front of her entire team.

She could feel his gaze still on her, reading the emotions on her face like a book, as if he looked long and hard enough, her thoughts would display themselves above her head. "Stop profiling me, weirdo," she whispered, just loud enough for only him to hear.

He rolled his eyes at her, the corners of his mouth threatening to turn up into a smile.

"How was the drive, Spence? It seems like you guys got the worst of this incoming storm," JJ stated, her mug had been retrieved from the living room coffee table and now rested in her cupped hands as she rested her elbows on the kitchen island.

"Dangerous," y/n muttered. Spencer playfully elbowed her. "Hey! You can't tell me you didn't fear for our lives at least once during that drive."

Spencer didn't bother responding, knowing she was right. The drive hadn't been the worst it could've been, but the snow had began flurrying as they arrived to the airport, y/n's hood pulled so far over her head she kept her eyes locked on Spencer's boots in front of her to lead her. The roads were slick with snow and ice, and the winding strip of road leading up to the isolated cabin had not been the easiest or safest to navigate.

"It's a good thing you guys got here before it got too bad, we might have to really get comfortable with each other considering we'll most likely be stuck here longer than we want," Emily suggested. The team nodding in agreement. Y/n was grateful she had remembered to bring every card and board game she could get her little hands on - Monopoly, Cards Against Humanity, even Twister. She couldn't wait to get the team drunk and convince them to play Twister.

"Speaking of, I think it's time we whip out the alcohol and the games," Emily smiled, as if reading the thought directly from y/n's mind, taking a bottle of top-shelf Tequila by the neck and wiggling it in the air.

"Best idea I've heard all day," Rossi stated.

Y/n and her team made their way into the living room, spiked hot cocoa in hand. She relaxed in the middle of the couch after grabbing her Cards Against Humanity box from her suitcase by the door, Spencer to her right and JJ to her left. Rossi and Hotch taking the two reclining chairs and pulling them forward to reach the table. Emily gracefully sitting on a pillow on the floor, Morgan settling for sitting directly on the carpet, and when Spencer attempts to offer Emily his spot, she dismisses him with the wave of a hand and a suggestive glance towards y/n.

Spencer repositioned himself again on the couch, the meaning of Emily's glance fully understood.

Y/n takes the liberty of pulling the cards out of their designated box and separating them into piles scattered across the coffee table, making sure every has access to a pile of white cards. As she finishes, the conversation about who goes first and random rules to add immediately sparks. Considering the instructions clearly read that whoever pooped most recently was to be the one to start.

The conversation turned argument continued on longer than any thought necessary, laughter filling the cabin to the brim. "Well if we're really trying to have a good time, all the losers each round have to drink."

Once in agreement, the team finally quieted as Hotch reluctantly grabbed the black card on the top of the stack in the middle of the table and read it aloud.

Y/n's head began buzzing as they were a fourth of the way through the stack of black cards, the game no where within bounds of stopping. Her limbs finally felt loose from being curled up in a plane and car seat for hours, trying to avoid looking at the snowy danger they had to travel through.

The entire team shed their worries, stresses, and found it in themselves to be in the moment. Everyone had equal amounts of pain lacing their chests and stomaches from laughing too hard at cards played and also equal amounts of disgusted faces and a little bit of gagging after the rules began to increase the more alcohol consumed - they had began ranking everyone's answers by the fourth time around, the person in first being exempt from drinking anything, the person coming in last being required to take a shot instead of a sip of their drink. Y/n seemed to be on a losing streak.

Luckily, her team was too engrossed in the game to notice when she took smaller shots than she was supposed to. She didn't want to be totally inebriated in the first few hours of her first vacation in God knows how long.

Spencer's arm was outstretched on the couch behind her, his other hand holding his cards secretively, knowing that y/n would a hundred percent be trying to take peeks now and then.

Once they had almost completely blown through most of the black stack, y/n ceased the opportunity. "I brought Twister!"

The entire room cheered, and she stumbled over to her suitcase to grab it out. It was quickly set up within a minute and to her distress, they decided to make teams and compete, obviously.

The girls split into a group and the boys into another. Emily and Hotch started first, Emily easily more flexible than Hotch, his leg unable to twist towards the red dot in the corner, resulting in him falling over and a chorus of laughter echoing off the logged walls.

"Spencer, Y/n, you guys should do it next!" Penelope gasped. "You're both so lanky, it'll be a close match."

Y/n's heart beat against her throat and she felt the rush of heat bloom in her neck and rise towards her still raw cheeks. She took a deep breath, not willing to show how much of a reaction she had at the thought of being tangled up with Spencer.

JJ and Rossi finish their round, JJ sneakily leaning into Rossi enough to knock him over, giving the girls a 2 point lead. Y/n and Spencer stroll leisurely towards the edges of the Twister map. An arched brow climbs her forehead, "I hope you're ready to lose."

"In your dreams," he smirks, a mischievous glimmer in his eyes.

As Penelope spins the pointer, she begins to call out body parts and colors. Within minutes, y/n and Spencer are a heap of tangled limbs, her back resting against Spencer's chest as she's bent over to reach her left hand to yellow, Spencer's hand next to hers on green. Her hair obstructs some of the view of the colored circles beneath them but the look of Spencer's flexed, muscular forearm on the side of her head does little to ease her rapidly beating heart. His breath is hot on the nape of her neck, coiling a heat in her middle she desperately attempts to push down.

"I think I enjoy you being under me," he whispers onto the skin of her neck, sending shivers rattling down her spine. As Penelope calls out left hand blue, she racks her gaze around the mat beneath them.

She can practically hear the rush of blood in her ears when she finally sees the blue between her strands of hair. The closet blue dot is down towards her legs, considering her right hand was already on the blue next to her left, requiring her to bend her hips upward. She takes a deep breath and reaches her hand to the spot, her ass rising upward into Spencer's hips.

She can hear the catch of his breath as she tilts upward to get into her position. The next color is called too soon after, resulting in Spencer's right leg moving to the left side of y/n's body, their bodies no longer touching in the way that spooled heat further into her center. Their limbs fight for purchase on different colored spots as the game continues, their teammates shouting at both of them, the game obviously riveting from above, but completely distracting between the two players.

After a few more minutes of twisting her body in ways she never knew she could, her arms trembled as she reached towards a yellow. Refusing to let a man who probably weighed the same as her beat her in a game of Twister, she fought through the shaking of her body and painful stretch of muscles she probably haven't used in years.

She could feel Spencer's body tremble underneath her, placed in almost the same position as before, just on the opposite side this time. "I think I enjoy being on top better," she whispered in the same way Spencer did to her.

His body tensed under hers before he dropped to the floor, crowning y/n the winner of quite literally a battle to exhaustion in a drunk game of Twister.

The women on her team cheered and hugged each other before reaching out a hand to pull her from her spot on the ground in which she collapsed onto right after Spencer did. "That was probably the longest game of Twister in the history of Twister games," Penelope laughed.

Y/n and Spencer plopped onto the couch together, content to watch Penelope and Morgan go against each other from their comfortable spots on the couch. As Emily called out colors and body parts and the teams cheering on their teammates, Spencer leaned over to y/n's ear. "If you're gonna be on top of me I think it'd rather be able to see you."

Her pulse quickened, the heat that as been building inside her since the start of their Twister match is beginning to come to an edge. Get a grip, she chastised herself. They were on vacation with their entire team for crying out loud, now was not the time for flirtatious advancements or sexual tension.

"In your dreams," she murmured, trying to keep the want in her voice caged down, but with the way that Spencer's lips lifted in a smirk told her she didn't do a very good job at it.

"Certainly."

She couldn't get her eyes to leave his face, lowering them to his mouth, pulling her bottom lip between her teeth to keep herself from saying anything stupid.

He noticed her do this and his expression turned hungry as he watched her work her bottom lip between her teeth. It was one of the things that always set him off without her even realizing. Her nervous tic could be taken as flirtatious by someone who doesn't know her. Even though Spencer knows better, it still causes tension inside his pants every damn time she does it.

"If you keep doing that I'm not going to be able to stop myself," he growled lowly.

The sexual tension between y/n and Spencer was almost palpable as the team said their drunken goodnights and stumbled to their respective rooms. Y/n climbed into her bed, pulling the quilt atop her closer to her face. Her thoughts swam, unable to stop them from completely consuming her with thoughts of Spencer - of his body on hers, his breath on her neck, and god damn the stupid comments he made, knowing they were working her up and torturing the hell out of her all night as they continued to play other games with their friends.

Her thoughts fell away, like birds falling out of the sky, as she heard a low sound. She sat up in her bed, trying to adjust her eyes to the darkness swallowing her room, in attempt to see what the noise was. Her door opened gently and a figure quietly stepped through the threshold and shut the door behind them, obviously trying not to wake anyone up.

"Hello?" Y/n called out softly, at first she thought it was Penelope, coming to tell her some new gossip she overheard somewhere. But, it wouldn't make any sense of her to sneak in if she thought y/n was asleep. It most definitely wouldn't have been Hotch, Rossi, or Morgan and the only reasonable explanation for any of them to be in her room is if they mistook her door for a bathroom, but she doesn't believe they'd be that quiet about it. Emily was so inebriated she almost didn't make it to her bed by herself.

A nervousness began in her chest as the figure stalked closer to her bed and didn't answer her. Before she could react, lips met hers hungrily. She gasped into their mouth, an opening they took to their advantage as they slipped their tongue between her lips and battled hers for dominance. She supposed that if this was someone trying to kill her, they wouldn't have kissed her first and damn it was a good kiss.

She allowed the kiss to overtake her senses, small moans rising out of her throat as her bottom lip was taken in between teeth and tugged. When her bedroom intruder finally broke their kiss, they were both panting. "I did warn you I wouldn't be able to control myself," the voice growled. Oh.

"Spencer?" Y/n whispered, "What are you doing?"

"Well I wasn't going to wait for you to come to me," he murmured, dipping his head to her neck, trailing sloppy kisses downward to her collarbones. Her fingers tangled into his soft curls, a moan slipping from her lips as he teased her sensitive skin.

"Shh," he shushes her, his voice vibrating through her entire body. "You don't want anyone to hear, do you?"

"Spence..." she whimpered.

His fingers played with the hem of her tank top, only the thin fabric separating him from her breasts.

"I can't get you out of my head and it's been driving me insane," he muttered against her bare skin, his fingers trailing lightly over her exposed lower abdomen, sending goosebumps over her skin. "I can't stop thinking about that pretty little mouth wrapped around me, or the sound of your moans that I coax out of you in every possible way I can, or the sound of you screaming my name as you come."

Y/n feels breathless at his touch, the skin beneath his lips burning with heat. "Are you okay with this?" He asks after y/n's silence.

"Absolutely," she whimpers. "Don't stop, please."

As if that was his undoing, he tears her tank top from her skin, y/n almost unable to raise her arms up in time to get it over. As soon as her tank top is thrown to the floor, his lips latch onto her peaked nipple and a cry of pleasure gathers in her throat but she clamps her lips shut, not wanting to let anyone hear. He continues to work her nipple in his mouth, using tongue and teeth, mixing pain and pleasure.

Her fingers grip his hair tighter, her back arching to bring his mouth as close as it could possibly get to her exposed breasts. Without budging from her nipple, he removes her pants swiftly, gripping her hips with his hands to swing her under him.

Her eyes can just barely make out his face in the dark hovering above her, her body begging for more. She squirms underneath him, hardly able to contain the desire coursing through her blood. His smile turns feral as he realizes just how badly she wants him to keep going.

He lowers himself antagonizingly slow, leaving soft kisses along her naked body until he reaches her inner thighs. He settles himself comfortably in between her legs as she widens them to give him complete access.

He slides his tongue gracefully through her folds and she lets out a gasp. "I've been aching to taste you," he groans against her center, gliding his tongue from the bottom up again. "You taste fucking delicious."

His pace starts out tame as he saviors every whimper that leaves her mouth and the taste of her on his tongue. Another gasp escapes her as he slips a finger in, wasting no time in gently sliding it in and out, curling it upwards to hit her sweet spot just right. She bucks her hips, riding his tongue and finger as her pleasure builds in intensity, her breathing ragged.

Suddenly, his tongue and finger abandon her and she lets out a whine of disappointment. "Someone's needy," he chuckles lowly. "I'd rather make you come with me buried deep inside you."

Spencer quickly undresses himself and gently lines up with her center. He slides the tip through her folds, making her arch her back towards him, her silent plea.

Without hesitation, he slips inside her and releases a groan. "You're so wet for me," he smirks. She can barely see his face, but she knows he has a smug look on it. It's as if he's known how crazy he makes her, how she has fantasized about this very moment before.

His thrust starts out delicate, like he's afraid he's going to break her apart. She wraps her legs around his waist, an attempt to pull him as deep as possible. "Careful," he growls against her neck as he teases her skin once more. "I don't want to let loose just yet and hurt you."

"What if I like it rough?"

"Tell me how you want it, then." A challenge.

"I want you to fuck me dumb."

"Your wish is my command," he smiles against her skin and immediately latches onto her neck, sucking and pulling on her delicate skin. His hands grip her waist to keep her steady as he pounds into her, the sound of his bare thighs hitting hers. He places a hand on her throat and gently squeezes, as if he knows exactly how she likes it.

"Fuck.." Spencer growls, unhooking her legs from his waist with his available hand and using his weight to lift her legs above her head and driving in deep. Y/n claps a hand over her mouth to keep her screams in, her other hand gripping the sheets so hard her knuckles turn white. "You're taking me like such a good girl."

"Fuck, Spencer," she whimpers under her palm.

"Say my name again."

"Spencer..."

"Louder."

"Fuck, Spencer!" She cries as he hits home, her pleasure reaching it's breaking point hastily.

"Open your mouth," he demands. She releases her palm from over her mouth and opens wide, Spencer wasting no time in sticking two fingers on her tongue. She closes her lips around his fingers and slides her tongue over their length. He groans in pleasure as she continues to tease his fingers.

"Come for me."

Those words were her undoing as she falls over the edge, Spencer following her over and her body releasing the pent up desire. Her entire body trembles as ecstasy floods her.

He releases her legs but stays positioned inside her, face hovering just inches above hers. Their panting breaths tangle with each other in the air between them. "You took me like such a good girl," he coos, cupping her cheek gently and rubbing her heated skin with his thumb.

"Can I tell you a secret?" Y/n whispers, trying to control her wildly racing heart.

"Of course."

"I've thought the same things," she confesses, pulling him by the hair to meet her lips again. "And I hope you're not too tired for another round."

An animalistic smile grows on his face as he pauses their kiss, "I'm going to tear you apart."

#criminal minds#criminal minds fandom#criminal minds fanfic#criminal minds fanfiction#criminal minds smut#dr spencer reid#spencer reid#spencer reid fanfiction#spencer reid imagine#spencer reid smut#spencer reid fluff#spencer reid x reader#spencer reid x oc#spencer reid x you#aaron hotchner#derek morgan#criminal minds x reader#bau!reader#bau x reader#bau#criminal minds fic#david rossi#penelope garcia#jason gideon#spencer reid x fanfiction#spencer reid x y/n#spencer reid x self insert#spencer reid x reader smut#spencer reid x fem!reader#spencer reid x fem!oc

556 notes

·

View notes

Text

Hot take of the day:

I think my only ick with cannibalism is that it's very nasty and you can't have your cake and eat it ahashahsa.

For context, my family used to breed sheep and we had a small restaurant, so I'm familiar with the process of killing and eviscerating a big creature. You need to tie up the sheep because obviously is about to die and then you cut its throat so it can bleed and eventually pass away. Is it the best way? I'm not sure I was 8, but it's a long and probably harmless way, a very visual allegoric hourglass.

Now you need to hang the body from the ceiling and do a incision from the neck to the genitals, exposing the ribcage under the fat and skin. And oh boy! This is the big deal, because now its time to open the ribcage and let all the sweet stuff fall down (in a bucket if you're not doing this just for funsies ahshasa).

And this is my ick with cannibalism: The sheep had no time to digest anything, the intestines and digestive sacks are still full of forage, acid and shit and IT'S NASTY AS FUCK. That's just the obvious stuff, then you have other jewels in the mud like the gallbladder (we used to yeet it as far away as we could into the field).

If you ever think about eating intestines or anything at all you need to clean them VERY GOOD and it's hard work. My father was the butcher, my mother cleaned the guts and taking care of the intestines and stomach is AAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAA. All the shit and food waste, washed away.

I'm all money into cannibalism but if you're flappy hands all happy into eating a guy straight up from ground you need to make peace with cropophagy because you're gonna taste some shit ashhsa. Yeah, the human body has not enough fat or muscle to even make a decent steak so you're not even playing that card, you must go for the organs.

And yeah yeah, we all want to romantic symbolism of eating the heart (even when it's fucking impossible to eat the heart because it's like chewing gum but okkkkkkkkkkkkkkkkkkk I guesssssssss), then you go for the lungs and the liver. But honestly, that's it. You don't even touch the intestines or the stomach if you're too comfortable with cannibalism but draw the line at cropophagy ahshshasa.

Hannibal Lecter is the prime example in the other side of the coin, because he KNOWWWWWWS, like he may indulge in some pedestriam eating but com'on hashasadhasa. He kills, he cleans, he cooks. He's absolutely not eating shit because he's too good for casual raw meat. But then, what is the point?

"It was no chicken" Like yeah, don't you say dubfuck but it COULD had been chicken you know? ahsahsha. That's the issue. "This burger has human meat" yes, but's its a burger not different from any other. What's the point here of it being made with human flesh?? The LOLs? No one cares.

At least Lecter is a cuisine master, and can get the morbid x delicious mix right in the point, but if we're serious how well do you know how to cook? And remember we are not talking about your all purpose beef, we're talking about guts. How well can you cook some liver or some stomach in your mid kitchen where you don't even use the oven that much?

The real art here is the bestial consumption of tacking down your prey and ruminate flesh brom bones, soaking wet in blood.

And you must be mentalized for some shit ahshahsasa. (Also, you were absolutely right about it, what's the deal with sacred cannibalism. "Oh, I love you so much I need to eat you and integrate you as a part of me" No, you're not ashahsas. You're shitting all of it in some hours. What a fucking act of devotion idiot ahahsa, shitting the vessel of your love straigh into the toilet, you could do some stuffing idk).

Anyway, what's the conclusion here?

You can't be picky if you're a cannibal. Well, you CAN but com'on. Lecter is not gonna fuck you.

Lungs are the best organs. You stab those little guys, inflate them with water and boom! A cute fountain! They expand like balloons.

#gore#cannibalism#tw gore#tw cannibalism#Is this about DirkJake? Of course it's about DirkJake but it's more of a general feeling#Dirkjake#ignore that tag ashahsahshasasa#Hannibal Lecter

7 notes

·

View notes

Text

Exploring Cannabis Edibles: Production and Effects

Cannabis edibles have gained significant popularity in recent years as an alternative way to consume cannabis. Unlike smoking or vaping, edibles offer a discreet, smoke-free method of enjoying the effects of cannabis. They come in various forms such as cookies, candies, chocolates, and beverages, making them appealing to a wide range of consumers. Let's delve into how cannabis edibles are made and understand their effects.

Production Process:

Decarboxylation: The key step in making cannabis edibles is decarboxylation. This process involves heating raw cannabis flower or concentrate to activate the cannabinoids like THC (tetrahydrocannabinol) and CBD (cannabidiol) present in the plant material. This activation is necessary for the cannabinoids to have psychoactive or therapeutic effects.

Infusion: Once decarboxylated, the cannabis is infused into a fat or oil base like butter, coconut oil, or vegetable oil. This infusion process allows the cannabinoids to bind with the fat molecules, which makes them more readily absorbed by the body when ingested.

Cooking/Baking: The infused oil or butter is then used in various recipes to create cannabis-infused edibles. These can range from baked goods like brownies, cookies, and cakes to savory items like candies, chocolates, gummies, and even beverages.

Effects of Cannabis Edibles:

The effects of cannabis edibles differ from smoking or vaping due to the way cannabinoids are absorbed into the body. When you ingest cannabis through edibles, the cannabinoids are metabolized by the liver before entering the bloodstream. This process produces a different set of effects that are typically more potent and longer-lasting compared to inhalation methods. Here are some key points about the effects of cannabis edibles:

Delayed Onset: One distinctive feature of edibles is their delayed onset of effects. While smoking or vaping cannabis delivers effects almost instantly, edibles can take anywhere from 30 minutes to 2 hours to kick in. This delay occurs because the cannabinoids must be digested and metabolized before reaching the bloodstream.

Potency: Edibles can be quite potent due to the concentration of cannabinoids in the infused oil or butter. It's important for users to start with a low dose and wait to gauge the effects before consuming more. Overconsumption of edibles can lead to unpleasant experiences characterized by intense intoxication, anxiety, or paranoia.

Longer Duration: Another notable aspect of edibles is their prolonged duration of effects. Once the cannabinoids are absorbed into the bloodstream, the effects can last anywhere from 4 to 8 hours or even longer, depending on the individual's metabolism and tolerance.

Body High vs. Head High: Many users report experiencing more of a body-centered high with edibles, characterized by deep relaxation and sedation. This is in contrast to the cerebral, head-focused high often associated with smoking or vaping cannabis.

Safety and Responsible Use:

Using cannabis edibles responsibly involves understanding dosage, onset time, and potential effects. Here are some tips for safe consumption:

Start Low, Go Slow: Begin with a low dose (typically 5-10mg of THC) and wait at least 2 hours before considering consuming more.

Read Labels: Always check the THC/CBD content per serving in commercial edibles to better manage dosage.

Store Safely: Keep cannabis edibles securely stored away from children and pets, preferably in child-resistant packaging.

Avoid Mixing with Alcohol: Combining edibles with alcohol can amplify the effects and increase the risk of adverse reactions.

In conclusion, cannabis edibles offer a convenient and discrete way to enjoy the effects of cannabis without smoking. Understanding how they are made and their effects is crucial for safe and enjoyable consumption. As the legal landscape surrounding cannabis evolves, edibles continue to be a popular choice for both recreational and medicinal users seeking an alternative to traditional consumption methods.

2 notes

·

View notes

Text

The ALC Block Manufacturing Process: A Comprehensive Guide

The ALC block manufacturing process is a sophisticated yet streamlined method for producing high-quality, lightweight construction materials. Essarcon, a pioneer in this industry, leverages advanced technology to ensure precision and efficiency in every step. Here’s a detailed look into the process.

Raw Material Selection

The journey begins with selecting high-quality raw materials, which include:

Ordinary Portland Cement

Quicklime

Gypsum

Fly Ash or Fine Sand

Aluminum Powder

Water

Careful selection and proportioning of these materials are critical, as they determine the strength, weight, and thermal properties of the final product.

2. Mixing

In the ALC block manufacturing process, the raw materials are mixed in a specially designed batching system. The addition of aluminum powder creates a chemical reaction, releasing hydrogen gas. This reaction forms tiny, uniform air bubbles, giving ALC blocks their characteristic lightweight and insulating properties.

3. Molding and Pre-curing

The aerated mixture is poured into molds to form large cakes. These molds undergo pre-curing at ambient temperature, allowing the hydrogen bubbles to stabilize within the slurry. This step is essential in the ALC block manufacturing process, as it establishes the blocks’ cellular structure.

4. Cutting

Once pre-cured, the cakes are precisely cut into blocks of the required dimensions using advanced cutting machines. The cutting process ensures minimal waste while achieving consistent sizes, a key factor in efficient construction.

5. Natural Curing

Unlike autoclaved aerated concrete (AAC), the ALC block manufacturing process employs natural curing methods. The blocks gain strength over time under natural conditions, eliminating the need for high-pressure steam curing. This makes the process cost-effective and suitable for smaller production facilities.

Advantages of ALC Blocks

The ALC block manufacturing process results in products that offer:

Lightweight construction, reducing load on the foundation

Superior thermal insulation, reducing energy costs

Soundproofing, enhancing living comfort

Eco-friendly production, with reduced energy consumption

Essarcon’s expertise in the ALC block manufacturing process ensures that clients receive top-notch machinery and guidance to produce blocks that meet market demands. With over 14 years of experience, Essarcon is your trusted partner for innovative, sustainable construction solutions. For more details on ALC Block Manufacturing Process visit Essarcon’s official page on ALC Block Manufacturing Process.

#business#alc block#alc block plant#alc plant#alc plant setup#alc block plant setup#alc#manufacturer

0 notes

Text

Full-automatic Bear Cake Production Line

HG- BC Full-automatic Bear Cake Production Line can produce different size bear cakes and can be center filled with different flavor cream or chocolate. It’s new product & popular among the market.

Capacity and Utilities : Base on customer requirements, HG provides customized bear cake production line. It’s turn key project which can save clients’ time & work. Workshop size requirements : U type arrangement : 60*20*3.5m Straight arrangement : 110*6*3.5m L arrangement : 60*30*3.5m Power :125kw Gas consumption: 35-45kg/h

Advantages: 1) Automatic cakes production line solution from A to Z with less labor 2) Touching screen PLC controlling system, easy for workers to operate 3) Hot air circulating oven with imported Japan brand burner, and separate baking zone with different temperature 4) 304stainless steel raw materials with high configuration and stable performance 5) Aeration mixer that different with normal mixer, which can mix raw materials fine and smooth. 6) Advanced depositor that can control cake weight precisely

CONTACT US No.1588, Hubin Road, Fengxian District, Shanghai.China

0086-21-57458832

Mob: 0086-15800718880

0086-21-57456127

Skype: hamasakiyumi

0 notes

Text

Organic fertilizer is an indispensable part of agricultural production, and the evaluation of its production efficiency and economic benefits is very important for fertilizer manufacturers. From the perspective of science popularization, this paper discusses how to evaluate the production efficiency and economic benefits of organic fertilizer equipment, and draws out relevant keywords.

First, we need to understand the basic production process of organic fertilizer. The production of organic fertilizer mainly includes the collection and treatment of raw materials, fermentation, crushing, mixing, granulation, drying, screening and packaging steps. Each step requires corresponding equipment support, and the efficiency of these equipment directly affects the efficiency of the entire production line.

The selection and configuration of fertilizer production line is the key to improve production efficiency. For example, the Organic Fertilizer Production Line needs to be able to adapt to different raw material characteristics and Production needs, including a variety of Fertilizer Granulating production lines such as rollers, disks, and new organic fertilizers. The automation degree, equipment stability and maintenance cost of the production line are all important indicators to evaluate its production efficiency.

In the fermentation process, the role of Compost Turning Machine (such as Windrow Compost Turning Machine) is to ensure uniform fermentation and improve fermentation efficiency. The efficiency and effect of the turnover machine directly affect the fermentation quality of organic fertilizer, and then affect the quality of the final product and the production cost.

Fertilizer granulation Machine series equipment, such as Fertilizer Granules Compaction Machine and Flat-Die Pellet Machine, is the key equipment to make organic fertilizer into pellets. The performance of the granulator directly affects the molding rate and uniformity of the particles, and then affects the market competitiveness of the product.

Fertilizer mixers, such as the Horizontal Ribbon Mixer and the Double Shafts Paddles Mixer, are used to mix different ingredients to ensure an even nutrient composition of organic fertilizers. The mixing efficiency and uniformity of the mixer are important links to ensure product quality.

Fertilizer Screening machines, including Rotary Screening Machine and Vibration Screening Machine, are used to separate fertilizer particles of different sizes to improve product uniformity and market competitiveness.

Fertilizer drying and cooling Machine machinery, such as Rotary Dryer Machine and Rotary Cooler Machine, is used to control the moisture content of fertilizer, prevent caking and improve storage stability.

Other supporting equipment, such as Uniform Feeder, ensures the continuity and uniformity of raw material supply, which is essential to improve the overall efficiency of the production line.

When evaluating the production efficiency of organic fertilizer equipment, we need to consider the production capacity, energy consumption, ease of operation, maintenance costs and environmental impact of the equipment. The evaluation of economic benefits needs to consider the investment cost of equipment, operating costs, product prices and market demand and other factors.

By taking the above factors into consideration, we can conduct a comprehensive evaluation of the production efficiency and economic benefits of organic fertilizer equipment. This not only helps to improve production efficiency and reduce costs, but also improves the market competitiveness of products and ultimately achieves sustainable economic benefits.

#Organic Fertilizer Production Line#Windrow Compost Turning Machine#Fertilizer Granules Compaction Machine

0 notes

Text

In the green transformation of modern agriculture, the automatic control and intelligent monitoring technology of organic fertilizer production line is gradually becoming the key to improve production efficiency and ensure product quality. The wide application of this technology not only realizes the precise regulation of the production process, but also significantly reduces labor costs and energy consumption, and injected a strong impetus for the intelligent upgrading of the organic fertilizer industry.

Automation control technology:

In the organic fertilizer production line, the core equipment such as the New Type Organic Fertilizer Granulator and Hydraulic Type Roller Press Granulator realizes the fully automated operation from raw material delivery to finished product output through the integrated PLC control system. According to the preset parameters, the system automatically adjusts the speed, pressure and other key indicators of the granulator to ensure uniform particle size and regular shape. At the same time, mixing equipment such as Horizontal Mixer and Vertical Mixer have also joined the ranks of automatic control, which improves the mixing efficiency of raw materials and the quality of finished products through accurate matching and uniform mixing.

Intelligent monitoring technology:

In order to monitor the running status and product quality of the production line in real time, key equipment such as Drum Fertilizer Dryer and Drum Fertilizer Cooler are equipped with intelligent sensors and monitoring systems. These systems can monitor equipment temperature, humidity, speed and other key parameters in real time, once found abnormal immediately alarm and automatically adjust to the safety state, effectively avoid the occurrence of production accidents. Through intelligent identification technology, screening equipment such as Drum screener machine and Vibrating Screen can accurately screen finished products to ensure the consistency of product particle size and improve screening efficiency and accuracy.

More advanced is that the intelligent monitoring technology is also applied to post-processing equipment such as the Coating Machine , which ensures that the fertilizer has good slow release and anti-caking by monitoring the thickness and uniformity of the coating layer in real time. Combined with big data analysis technology, the operation data of the whole production line is collected and analyzed, which provides a scientific basis for production optimization and decision-making.

The automatic control and intelligent monitoring technology of organic fertilizer production line is leading the industry to develop in a more efficient and intelligent direction. With the continuous progress of technology and the in-depth promotion of application, it is believed that the organic fertilizer industry will usher in a broader development prospect.

0 notes

Text

In modern agriculture, the application of organic fertilizers is increasingly widespread, which not only improves soil quality, but also promotes the healthy growth of crops. The fermentation process of organic fertilizer is a crucial part of the entire production process. By introducing and optimizing the use of the above organic fertilizer equipment, not only can significantly improve the fermentation efficiency and product quality of organic fertilizer, but also reduce energy consumption and labor costs, and contribute to the sustainable development of modern agriculture.

Detailed explanation of organic fertilizer fermentation process

The fermentation process of organic fertilizer is mainly divided into several stages: raw material preparation, compost fermentation, maturation stabilization and post-treatment. Raw materials need to be processed by equipment such as Straw Crusher to ensure uniform particle size and facilitate microbial decomposition. Subsequently, the compost fermentation is carried out under the appropriate temperature, humidity and ventilation conditions. At this stage, a Horizontal Mixer can be introduced to turn the pile regularly to ensure sufficient oxygen and accelerate the fermentation process.

Efficiency improvement strategy

Efficient granulation: The use of New Type Organic Fertilizer Granulator or Hydraulic Roller Granulator, through physical extrusion molding, improve the uniformity of particles and yield, reduce the follow-up screening workload, significantly improve production efficiency.

Fine grinding: The use of Chain Crusher and Half-Wet Material Crusher to fine raw materials, to ensure that the size of raw materials meet the requirements of fermentation, accelerate the microbial decomposition speed, shorten the fermentation cycle.

Intelligent mixing: The introduction of automatic control of the Double Axis Mixer or BB Fertilizer Mixer, to achieve accurate ratio and uniform mixing, reduce manual intervention, improve mixing efficiency and quality.

Optimization of drying and cooling: The Drum Fertilizer Dryer is combined with the Drum Fertilizer Cooler unit, which uses the heat exchange principle to quickly remove water, while controlling the temperature, protecting the activity of beneficial microorganisms, and laying a good foundation for subsequent granulation and packaging.

Screening and coating: Accurate screening by Rotary Screener Machine and Vibration Screener Machine ensures consistent product size. Subsequently, the Coating Machine is used for coating treatment to enhance the slow-release and anti-caking properties of the fertilizer and enhance the added value of the product.

0 notes

Text

In the green transformation of modern agriculture, the automatic control and intelligent monitoring technology of organic fertilizer production line is gradually becoming the key to improve production efficiency and ensure product quality. The wide application of this technology not only realizes the precise regulation of the production process, but also significantly reduces labor costs and energy consumption, and injected a strong impetus for the intelligent upgrading of the organic fertilizer industry.

Automation control technology:

In the organic fertilizer production line, the core equipment such as the New Type Organic Fertilizer Granulator and Hydraulic Type Roller Press Granulator realizes the fully automated operation from raw material delivery to finished product output through the integrated PLC control system. According to the preset parameters, the system automatically adjusts the speed, pressure and other key indicators of the granulator to ensure uniform particle size and regular shape. At the same time, mixing equipment such as Horizontal Mixer and Vertical Mixer have also joined the ranks of automatic control, which improves the mixing efficiency of raw materials and the quality of finished products through accurate matching and uniform mixing.

Intelligent monitoring technology:

In order to monitor the running status and product quality of the production line in real time, key equipment such as Drum Fertilizer Dryer and Drum Fertilizer Cooler are equipped with intelligent sensors and monitoring systems. These systems can monitor equipment temperature, humidity, speed and other key parameters in real time, once found abnormal immediately alarm and automatically adjust to the safety state, effectively avoid the occurrence of production accidents. Through intelligent identification technology, screening equipment such as Drum screener machine and Vibrating Screen can accurately screen finished products to ensure the consistency of product particle size and improve screening efficiency and accuracy.

More advanced is that the intelligent monitoring technology is also applied to post-processing equipment such as the Coating Machine , which ensures that the fertilizer has good slow release and anti-caking by monitoring the thickness and uniformity of the coating layer in real time. Combined with big data analysis technology, the operation data of the whole production line is collected and analyzed, which provides a scientific basis for production optimization and decision-making.

The automatic control and intelligent monitoring technology of organic fertilizer production line is leading the industry to develop in a more efficient and intelligent direction. With the continuous progress of technology and the in-depth promotion of application, it is believed that the organic fertilizer industry will usher in a broader development prospect.

#organic fertilizer machine#fertilizer machine#organic fertilizer#fertilizer production line#fertilizer granulator machine#fertilizer granulator

0 notes

Text

In modern agriculture, the application of organic fertilizers is increasingly widespread, which not only improves soil quality, but also promotes the healthy growth of crops. The fermentation process of organic fertilizer is a crucial part of the entire production process. By introducing and optimizing the use of the above organic fertilizer equipment, not only can significantly improve the fermentation efficiency and product quality of organic fertilizer, but also reduce energy consumption and labor costs, and contribute to the sustainable development of modern agriculture.

Detailed explanation of organic fertilizer fermentation process

The fermentation process of organic fertilizer is mainly divided into several stages: raw material preparation, compost fermentation, maturation stabilization and post-treatment. Raw materials need to be processed by equipment such as Straw Crusher to ensure uniform particle size and facilitate microbial decomposition. Subsequently, the compost fermentation is carried out under the appropriate temperature, humidity and ventilation conditions. At this stage, a Horizontal Mixer can be introduced to turn the pile regularly to ensure sufficient oxygen and accelerate the fermentation process.

Efficiency improvement strategy

Efficient granulation: The use of New Type Organic Fertilizer Granulator or Hydraulic Roller Granulator, through physical extrusion molding, improve the uniformity of particles and yield, reduce the follow-up screening workload, significantly improve production efficiency.

Fine grinding: The use of Chain Crusher and Half-Wet Material Crusher to fine raw materials, to ensure that the size of raw materials meet the requirements of fermentation, accelerate the microbial decomposition speed, shorten the fermentation cycle.

Intelligent mixing: The introduction of automatic control of the Double Axis Mixer or BB Fertilizer Mixer, to achieve accurate ratio and uniform mixing, reduce manual intervention, improve mixing efficiency and quality.

Optimization of drying and cooling: The Drum Fertilizer Dryer is combined with the Drum Fertilizer Cooler unit, which uses the heat exchange principle to quickly remove water, while controlling the temperature, protecting the activity of beneficial microorganisms, and laying a good foundation for subsequent granulation and packaging.

Screening and coating: Accurate screening by Rotary Screener Machine and Vibration Screener Machine ensures consistent product size. Subsequently, the Coating Machine is used for coating treatment to enhance the slow-release and anti-caking properties of the fertilizer and enhance the added value of the product.

#fertilizer granulator machine#granulator machine for fertilizer#fertilizer#drum granulator#roller granulator

0 notes

Text

Pioneering Efficiency. Machinery for Producing AAC Blocks

In the quest for innovative and sustainable construction materials, Autoclaved Aerated Concrete (AAC) blocks have emerged as a game-changer. Renowned for their lightweight, thermal insulation, and fire resistance properties, AAC blocks are revolutionizing modern construction practices. Central to this revolution is the sophisticated machinery designed to produce these blocks. This article explores the technology, benefits, and the transformative impact of AAC block production machinery in the construction industry.

The Marvel of AAC Blocks

AAC blocks are a type of precast concrete comprising a blend of cement, lime, sand, water, and an expanding agent. The resulting product is a porous, lightweight block with exceptional thermal and acoustic insulation properties. Originating in Sweden in the early 20th century, AAC blocks have gained global popularity due to their eco-friendly characteristics and superior performance.

Understanding the Machinery

Producing AAC blocks requires a sequence of precisely controlled processes, facilitated by advanced machinery. The production line can be broadly categorized into the following stages:

Raw Material Preparation: The process begins with the preparation of raw materials. Lime, cement, sand, and gypsum are mixed with water to form a slurry. Aluminum powder is then added as an expanding agent, causing the mixture to rise and form a cake.

Mixing and Pouring: The prepared slurry is transferred to large mixing tanks, ensuring a homogeneous blend. The mixture is then poured into molds where the chemical reaction between aluminum powder and lime generates hydrogen gas, creating tiny air bubbles and causing the mixture to expand.

Pre-Curing: The filled molds are left to pre-cure for a specific period. During this phase, the mixture solidifies into a semi-hard cake, retaining its expanded form.

Cutting: The semi-hard cake is transferred to a cutting machine. Advanced wire-cutting technology is employed to slice the cake into blocks of the desired dimensions. Precision in this stage ensures minimal waste and uniform block sizes.

Autoclaving: The cut blocks are then placed in autoclaves—large pressure vessels where they undergo high-pressure steam curing. This autoclaving process significantly enhances the strength and durability of the AAC blocks.

Quality Control and Packaging: Post-autoclaving, the blocks undergo stringent quality checks to ensure they meet the required standards. Finally, the blocks are packed and prepared for shipment to construction sites.

Advantages of AAC Block Production Machinery

Efficiency and Automation: Modern AAC block machinery is highly automated, ensuring efficient production with minimal human intervention. This automation reduces labor costs and increases production capacity.

Precision and Consistency: The use of advanced cutting and mixing technology ensures that each block produced is of uniform size and quality, minimizing material wastage.

Energy Efficiency: The machinery is designed to optimize energy consumption, making the production process more sustainable and cost-effective.

Scalability: AAC block production machinery can be scaled to meet varying demands, from small-scale operations to large industrial plants.

The Impact on the Construction Industry

The adoption of AAC block production machinery is significantly impacting the construction industry by:

Promoting Sustainability: AAC blocks are made from eco-friendly materials and offer excellent insulation properties, reducing the energy consumption of buildings. The machinery used in their production further enhances sustainability by optimizing resource use and minimizing waste.

Enhancing Construction Speed: The lightweight nature of AAC blocks makes them easier to handle and install, accelerating the construction process and reducing labor costs.

Improving Building Performance: AAC blocks provide superior thermal and acoustic insulation, enhancing the comfort and energy efficiency of buildings. They are also highly fire-resistant, adding an extra layer of safety.

Cost Savings: Although the initial investment in AAC block machinery can be significant, the long-term savings in construction time, labor, and energy costs make it a cost-effective solution for builders and developers.

Conclusion

The machinery used in the production of AAC blocks is at the forefront of innovation in the construction industry. By enabling the efficient, sustainable, and high-quality production of AAC blocks, these machines are not only transforming building practices but also contributing to a greener, more efficient future. As the demand for sustainable building materials continues to grow, the role of advanced AAC block production machinery will undoubtedly become even more pivotal, driving the industry towards new heights of efficiency and environmental responsibility.

1 note

·

View note

Text

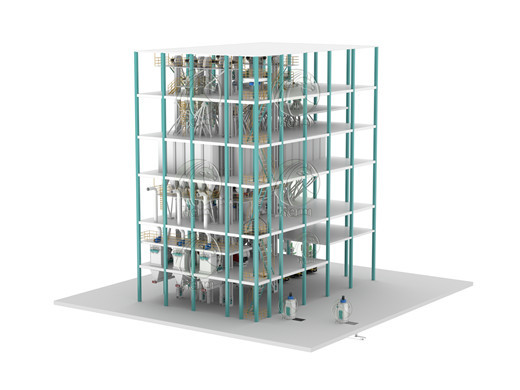

30-35T/H Feed Pellet Line

What is The 30-35T/H Feed Pellet Line ?

Large scale high quality 30-35t/h feed pellet plant is suitable for processing various animal feeds, such as chicken feed, poultry feed, livestock feed, bird feed, duck feed, goose feed, cattle feed, sheep feed, camel feed, horse feed, pig feed, rabbit feed, fish feed, shrimp feed, crab feed, aquatic feed, etc.

youtube

The main equipment of a complete 30-35T/H animal feed pellet mill machine includes an animal feed grinder and feed mixer, feed pellet machine, counter-flow feed pellet cooler, pellet crumbler machine, box cylinder pulse dust remover, vibrating screen classifier, bucket elevator, automatic bagging system, electric control cabinet, etc. This complete feed pellet plant can accomplish raw material mixing, transmission, feeding, and pelletizing. After the raw materials become feed pellets, the following equipment can cool them down and pack them into bags.

The animal-feed pellet plant has good raw material versatility and can be used for the granulation of various raw materials such as corn, sorghum, wheat, beans, and oilseed meal. At the same time, the animal feed production plant has the characteristics of low energy consumption, high production efficiency, and large profits. It is especially suitable for large feed mills, breeding farms, large farms, etc. At the same time, we provide free installation, training, factory design, and timely after-sales service.

Some Questions About the 30-35T/H Feed Pellet Line

1. Who is suitable for this 30-35t/h feed pellet production line?

This animal feed production line is specially designed for large farmers, large animal farm plants, animal feed suppliers, etc.

2. What raw material can be used in the 30-35t/h feed pellet production line?

Animal feed pellet production line raw materials include corn/maize, wheat, grass, alfalfa, oil seed meal & cakes, pasture, bone meal, microelements, etc., and other kinds of raw materials, such as premix, vitamins, wheat bran, salt and other. Different formulations can be made according to different formulas and the needs of the animals being farmed.

3. Why Choose Our Animal Feed Production Line?

Widely Applications: This animal feed pellet mill plant can make feeds for poultry, livestock, sheep, pig, cattle, chicken, duck, fish, shrimp, crab, aquatic, and other animals, it makes pellets of 1-12mm in diameter, and the pellet size can be changed with our feed pellet machine by adjust die. It also can produce mash and crumble.

Small Investment: the compact design of this small feed mill plant can reduce the investment in workshops, etc.

Low Installation Cost: Our feed production line comes with detailed installation and commissioning instructions, it is easy to install the machine, and you can use it immediately after the machine is installed.

Low Production Cost: The animal feed factory only needs 1-2 production workers to complete the production operation. With less labor and lower production costs, your profits will increase.

4. What kind of animal feed pellet production line produce?

This feed pellet production line can produce feed for meat chicken, broilers, laying hens, small baby chicken feed, cattle feed, pig feed, duck feed, sheep feed, poultry feed, livestock feed, goat feed, fish feed, shrimp feed, crab feed, aquatic feed, etc. Such as 2-4mm diameter chick feed pellets and pig feed pellets. 2-5mm rabbit feed pellets, 4-8mm cattle or sheep feed pellets.

This feed pellet mill with a ring die, makes pellets of 1-12mm in diameter, the pellet size can be changed with our feed pellet machine by adjusting the die. It also can produce mash and crumble.

5. What we can do for you?

We can provide the project design, flow chart, feed-making machine manufacturer, project installation and commission, your staff training, after-sales service, etc. Also, our professional install team will serve you if you need it.

What is The Complete Animal Feed Pellet Production Line Working Process?

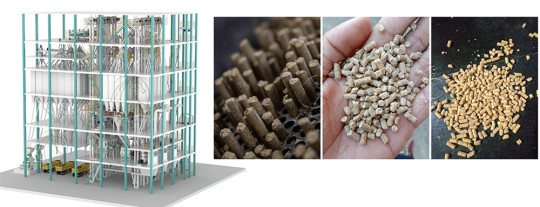

Feed Pellets Processing Technology Raw Material → Feed Grinding → Feed Mixing → Feed Pelletizing → Pellet Cooling → Pellet Crushing → Screening & Grading → Pellet Packing

1. Storage of the raw materials

There are many different raw materials and materials in the feed, so various types of silos must be used. There are three types of silo that can be used in the feed pellet line, such as hopper silo, flat bottom silo, and galvanized silo.

2. Cleaning of raw materials

Impurities in feed raw materials not only affect the quality of feed products but also directly affect the use of feed processing equipment and the personal safety of staff. In severe cases, the entire equipment will be damaged and the smooth progress of feed production will be affected. Therefore, impurities in the feed raw materials should be removed in time.

3. Crushing of raw materials

The technological process of feed crushing is determined according to the required particle size, feed variety, and other conditions. According to the number of raw material crushing, it can be divided into primary crushing process and circulating crushing process or secondary crushing process. The combination with the batching process can be divided into the first batching and then crushing process and the first crushing and then batching process.

4. Batching process The rational design of the batching process is to correctly select the specifications and quantities of the batching metering device so that it is fully coordinated with the combination of batching feeding equipment, mixing units, and other equipment.

5. Mixing process The mixing process refers to the technological method and process of weighing the ingredients in the feed formula and then entering the mixer for uniform mixing. The mixing section requires a short mixing cycle, high mixing quality, fast discharge, low residual rate, good air tightness, and no dust spillage.

6. Pelleting process The pelleted feed obtained by compacting and extruding a single raw material or compound mixture by mechanical action is called feed pelleting. The purpose of pelleting is to use the heat, moisture, and pressure in the pelleting process to pelletize the feed that is finely divided, easily dusty, poorly palatable, and difficult to transport.

7. Cooling process During the pelleting process, when the pellet feed comes out of the feed pellet machine, the water content reaches 16%-18%, and the temperature is as high as 75°C-85°C. It will also cause adhesion and mildew during storage. The moisture must be reduced to below 14%, the temperature must be below 8°C higher than the air temperature, and cooling is required.

8. Crumbling process In the production process of the feed pellet mill, in order to save electricity, increase production and improve quality, the material is often made into a certain size of pellets, and then crushed into qualified products according to the size of the feed pellets.

9. Screening process After the pellet feed is processed by the crushing process, some unqualified materials such as powder will be produced. Therefore, the crushed pellet feed needs to be sieved into a product with neat particles and uniform size.

10. Packaging process After weighing, put the finished product into the packing scale and pack it. During this process, the package should be calibrated until the package weight standard is met.

0 notes

Text

The application range and function of organic fertilizer trough-type overturning machine

Scope of application: fermentation compost turning machine is used for fermentation composting of organic waste such as animal manure, sludge and waste, sugar filter mud, slag cake, straw and sawdust. Widely used in organic fertilizer plant, compound fertilizer is suitable for factories, sludge waste, horticultural farms, bisporus mushroom planting plants and other aerobic fermentation for fermentation and dewatering operations, can be used with solar fermentation room, fermenter and mobile machine. When used with the mobile machine, it can realize the function of multiple slots in one machine. The supporting fermenter can be used for continuous discharge or batch discharge. High efficiency, smooth running, durable, even flipping.

Functions of the grooving machine:

1, the raw material conditioning with stirring function. In the production of fertilizer, in order to adjust the carbon nitrogen ratio of raw materials, pH value, water content, etc., some auxiliary materials must be added. The main raw materials and various auxiliary materials are piled together roughly in proportion, and the material is stirred by the stacker to achieve the purpose of quality adjustment.

2, adjust the temperature of the raw material pile. During the operation of the composting machine, the raw material pellets are fully in contact with and mixed with the air, and the pile can contain a large amount of fresh air, which is conducive to the active production of aerobic microorganisms and the generation of fermentation heat. When the reactor temperature rises, the supplement of fresh air can make the reactor temperature drop, forming an alternating state of medium temperature-high temperature-medium temperature-high temperature, and various beneficial microorganisms grow and multiply rapidly at this temperature. The range they adapt to.

3, improve the allure of raw material pile. The turning system can process the material into small clumps, making the thick and dense pile of raw materials fluffy and elastic, forming the right porosity.

4, adjust the water content of the raw material pile. The suitable water content of raw material fermentation is about 55%, and the water content standard of finished organic fertilizer is less than 20%. During the fermentation process, the biochemical reaction will produce new water, and the consumption of raw materials by microorganisms will also cause the water to lose its carrier and free out. Therefore, the moisture should be reduced in time during the fertilizer process. In addition to the evaporation caused by heat conduction, the turning of the feedstock by the compost tiller also creates a forced discharge of water vapor.

5, to achieve the special requirements of composting process. Such as crushing raw materials, giving a certain shape to the pile of raw materials or achieving quantitative displacement of raw materials.

As an important organic fertilizer equipment and one of the production processes of organic fertilizer production line, composting machine has been at the forefront of the development of The Times, and has made great contributions to the production of organic fertilizer

#fermentation compost turning machine#organic fertilizer equipment#orgnaic fertilizer production line

0 notes

Text

Unleashing Sweet Bliss: Exploring the Allure of Edible Cookie Dough Jars

Edible cookie dough jars have taken the culinary world by storm, offering a delectable and safe way to indulge in everyone's favourite guilty pleasure. This delightful treat satisfies the craving for raw cookie dough while ensuring it is safe for consumption. In this article, we will delve into the wonderful world of cookie dough jars, exploring their popularity, ingredients, and tips for enjoying this delectable treat.

The Rise of Edible Cookie Dough Jars

Cookie dough jars have gained immense popularity in recent years, captivating dessert enthusiasts with their irresistible appeal. Unlike traditional cookie dough, which contains raw eggs and can pose a risk of foodborne illness, cookie dough jars are made with heat-treated flour and eggless recipes. This innovative twist ensures that cookie dough lovers can relish their favourite treat without any health concerns.

Ingredients and Varieties

Cookie dough jars come in a plethora of flavours and textures, catering to a wide range of taste preferences. The basic ingredients typically include flour, butter, sugar, and flavourings. However, the variations are endless, with creative additions such as chocolate chips, sprinkles, nuts, caramel, and even unique ingredients like matcha or peanut butter cups.

Some popular flavours of cookie dough jars include classic chocolate chip, cookies and cream, birthday cake, peanut butter, and snickerdoodle. This variety allows individuals to explore different tastes and find their ultimate cookie dough jar indulgence.

Tips for Enjoying Edible Cookie Dough Jars

Choose reputable brands or make your own: When purchasing cookie dough jars, opt for well-known brands or local businesses with a reputation for quality and safety. Alternatively, you can experiment with making your own cookie dough jars using tried-and-tested recipes.

Follow storage instructions: cookie dough jars often come with specific storage instructions to ensure optimal freshness. It is crucial to adhere to these guidelines to maintain the taste and quality of the product. Most jars should be stored in the refrigerator, but be sure to read the label for any specific instructions.

Savour it in moderation: While it can be tempting to devour the entire jar in one sitting, it's important to exercise moderation. cookie dough jars are a treat meant to be enjoyed in small portions. A little indulgence goes a long way!

Get creative with serving suggestions: cookie dough jars can be enjoyed in various ways. Scoop a spoonful onto ice cream, spread it onto a warm waffle, or mix it into a milkshake for a scrumptious twist. Let your imagination run wild and discover exciting combinations that enhance your cookie dough experience.

The Bottom Line

Edible cookie dough jars have become a delightful and popular treat, providing a safe and delicious way to enjoy raw cookie dough. With their wide array of flavours and textures, these jars offer something for every cookie lover. Whether you choose to purchase from trusted brands or try your hand at making your own, be sure to savour this indulgence in moderation. Cookie dough jars are a wonderful way to treat yourself or surprise loved ones with a unique and tasty gift. So go ahead, grab a spoon, and embark on a mouthwatering adventure with a jar of edible cookie dough!

0 notes

Text

Full-automatic Center Filled/Cup Cake Production Line

HG- CFC automatic cake production line can produce different cakes by replacing different shapes of baking molds, or can produce cupcake and filled cake by adding paper cup feeding machine and cake cream filling machine. It can produce muffin as well by mixed some chocolate in the raw material.

Capacity and Utilities : HG Food Machinery manufacturer can provide muffin production line with different capacities in order to meet clients requirements .we have smaller capacity 250kg/h , medium size 500kg/h and bigger size 1000kg/h. In addition, we have professional engineering team to help client customize a cake production line according to client factory size. Workshop size requirements : U type arrangement : 60*20*3.5m Straight arrangement : 110*6*3.5m L arrangement : 60*30*3.5m Power :80-120w Gas consumption: 35-45kw

No.1588, Hubin Road, Fengxian District, Shanghai.China

• 0086-21-57458832 • Mob: 0086-15800718880

• 0086-21-57456127 • Website: www.hg-machine.com

• [email protected] • Skype: hamasakiyumi

0 notes

Text

In the fine process of organic fertilizer production, cooling technology plays a pivotal role, which is not only a key part of ensuring product quality, but also an important means to improve production efficiency and save energy.

Cooling technology is necessary

In the production process of organic fertilizer, whether through the high pressure molding of the Double Roller Press Granulator, or the innovative process of the New Type Organic Fertilizer Granulator, the particles often have a higher temperature and a certain humidity in the early stage of formation. If not cooled in time, these high temperature and high humidity particles are not only easy to caking, affecting the appearance and fluidity of the product, but also may lead to nutrient loss due to accelerated internal chemical reactions. Therefore, cooling technology has become an indispensable bridge between granulation and packaging.

Practice case sharing

Taking a large organic fertilizer production plant as an example, the plant introduced an advanced Rotary Drum Granulator, combined with an efficient cooling system, to achieve an integrated production from granulation to cooling. Inside the drum, the raw material is thoroughly mixed and granulated and goes directly into the cooling section below. The cooling section uses an advanced air circulation system to adjust the wind speed and temperature to ensure that the particles are evenly cooled to the appropriate level in a short period of time, preserving the integrity and nutritional content of the particles, while improving the overall efficiency of the production line.

Innovative application of cooling technology

With the advancement of technology, cooling technology is also constantly innovating. For example, some manufacturers have begun to try to combine the cooling system with an intelligent control system to automatically adjust the cooling parameters through real-time monitoring of the temperature and humidity of the particles to achieve accurate control. This intelligent cooling method not only improves the cooling efficiency, but also greatly reduces energy consumption and labor costs.

#fertilizer machine#Organic fertilizer production line#fertilizer granulator#fertilizer granulator price person

0 notes