#Railcar Repair Industry

Text

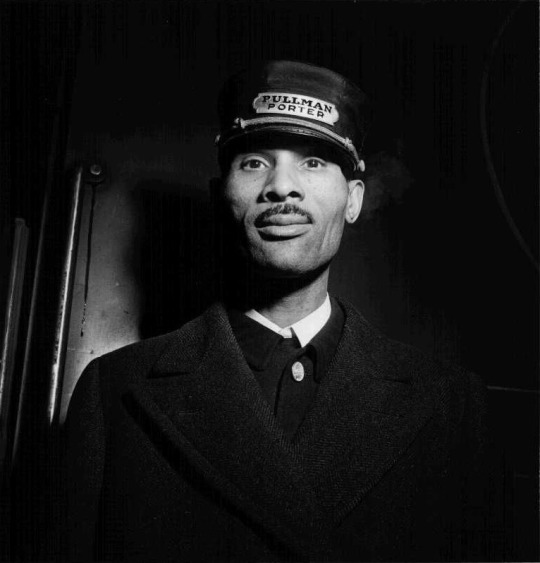

Today We Celebrate Labor Day

The Pullman neighborhood on Chicago’s South Side is a small community that changed the country.

Pullman is central to understanding industry, labor and civil rights in America and the tense conflicts that led to the creation of Labor Day and the first African American union.

When George Pullman, the industrial titan, who created an empire building and servicing train cars that felt like hotels on wheels, dismissed the requests for arbitration, Jennie Curtis, president of The Girls Local Union 269 & seamstress in the repair shops, along with the exasperated workers decided to walk off the job. Their strike was relatively small, but it came shortly before a national American Railway Union (ARU) convention hosted in Chicago. At the ARU convention, members considered whether to throw their national weight behind the Pullman workers.

The ARU did come along, though. Eight days later, with Pullman’s heels still firmly planted, 125,000 workers on 29 railways refused to move trains that included Pullman cars. Train travel throughout much of the country ground to a halt.

The strike came at a heavy price. Despite the best efforts of ARU President Eugene Debs to maintain calm, workers, law enforcement and rail management went toe-to-toe over who controlled the railways around the country, leading to significant violence. When angry strike supporters set fire to a railcar full of U.S. mail, President Grover Cleveland and his attorney general, who had previously worked for railway owners, used the incident to criminalize efforts by the union leaders and sent federal troops to Chicago to crush the strike.

Crushing the strike deeply undercut Pullman’s reputation as a visionary and threatened political support for Cleveland. The president was the leader of the Democratic party, which had strong labor support. Just as Cleveland was coming down hard on the side of management, he signed legislation that would make Labor Day a national holiday.

CARTER™️ Magazine carter-mag.com #wherehistoryandhiphopmeet #historyandhiphop365 #cartermagazine #laborday #blackhistorymonth #staywoke #blackhistory #carter #history

#carter magazine#carter#historyandhiphop365#wherehistoryandhiphopmeet#history#cartermagazine#today in history#staywoke#blackhistory#blackhistorymonth

52 notes

·

View notes

Text

Fleet of the Future (D and E series)

In service2018–present

ManufacturerBombardier/Alstom

DesignerMorelli Designers

Built at

Plattsburgh, New York

Pittsburg, California

Family nameMovia

ReplacedA, C seriesConstructed2012–

Number under construction310

(total)Fleet numbers3001–3310

Capacity51 (seated)

Depot(s)

Colma Yard

Concord Yard

Hayward Complex

Richmond Yard

Plattsburgh, New York

Pittsburg, California

Family name Movia Replaced A, C series Constructed 2012–Number under construction310 (total) Fleet numbers 3001–3310 Capacity 51 (seated) Depot(s)

Colma Yard

Concord Yard

Hayward Complex

Richmond Yard

In a 2010 APTA study, the average age of BART's mainline fleet was reported to be 30 years, longer than the usual lifespan of 25 years. Despite the purchase of newer cars over the years, the majority of the active fleet in 2016 was over 40 years old and had traveled over a million miles. Because of this, they have been increasingly prone to frequent breakdowns and repairs, decreasing the number of available cars and in turn increasing congestion, especially with the need to increase the fleet size for extensions to the network. Consequently, in 2009, BART began the process of expanding and replacing its railcar fleet. By 2010, it had received proposals from five suppliers, and on May 10, 2012, it awarded a $896.3 million contract to railcar manufacturer Bombardier (during delivery the company was bought by Alstom) with an order for 410 new cars, split into a base order of 260 cars and a first option order of 150 additional cars. The car was designed by Morelli Designers, an industrial design firm based in Montréal, Canada. On November 21, 2013, BART purchased 365 more cars, for a total fleet size of 775 new railcars, while also accelerating the delivery schedule by 21 months (from 10 cars per month up to 16 cars per month) and lowering procurement costs by approximately $135 million. The contract requires that at least 2⁄3 of its value be spent on U.S.-built parts.

The new fleet is composed of two different types of cars: 310 cab cars (D cars) and 465 non-cab cars (E cars). Both types have bike racks, new vinyl seats (54 per car), and passenger information systems that display next stop information.

A major difference is an extra set of doorways on each side of the new cars to speed up boarding and alighting. They also include redesigned seating, bike racks, digital displays that display travel information, and automatic announcements. Due to potential access issues for people with disabilities, the pilot car layout was modified by the BART board in February 2015 to include two wheelchair spaces in the center of the car, as well as alternative layouts for bike and flexible open spaces.

The first test car was unveiled in April 2016; upon approval, the first 10 cars were expected to be in service in December 2016, and at least 20 by December 2017. This was delayed several times until the production cars were expected to be delivered in October 2017. Delivery of all 775 cars was initially expected to be completed by Fall 2022, with all cars in service by 2023. Bombardier initially agreed to speed production to have all cars available by the end of 2021 and in service by 2022.

In early November 2017, a test train failed a CPUC regulatory inspection due to door issues, leaving the planned late November revenue service in doubt. The first ten-car train received CPUC certification on January 17, 2018, and began revenue service two days later on January 19. Plans to have 198 new cars by July 2018 did not materialize, and the agency had put only 20 in service at that time. After only running on the Richmond–Warm Springs/South Fremont line since January, a set of D and E cars began transbay service in October 2018.

In November 2018, BART announced they had negotiated to extend their purchase options to a total of 1,200 cars, though reports in 2019 stated that this deal was still not final. By the end of March 2019, 65 cars were in use; four 10-car trains for revenue service and the remainder for training. In June 2019, with 84 total cars delivered, Bombardier announced it would be moving production from their New York-based plant to a new facility shared with Hitachi Rail in Pittsburg, California in the East Bay.

In January 2021, BART stopped accepting new cars pending reliability improvements to be made by Bombardier. That same month, the struggling Bombardier sold its transportation division to Alstom, which said it would work to recover operations. BART was not alone with issues with Bombardier equipment. Before the Alstom deal, the company had seen declining profits largely caused by a series of major delays in delivering new fleets of trains (including the Flexity streetcars for Toronto and R179 subway cars for New York City) and reliability problems once trains were placed in service.

BART resumed accepting new cars in February 2022. As of September 11, 2023, BART has received 591 D and E cars, of which 575 have been certified for service and 368 are required for service. All 55 trains in service use the new cars.

BART exclusively runs Fleet of the Future trains on its base schedule since September 11, 2023. Legacy trains only run when needed, such as on days with major events or during a service disruption. BART plans to retire the remaining legacy fleet in late 2024.

0 notes

Text

What Diamond S Welding & Machine Shop Deals & Offers?

Since 2003, Diamond S Welding gladly serves Eureka. Diamond S Welding strives to provide customers with the highest quality products and services. In addition to bulk welding gases, they offer feed buckets, agricultural equipment, custom machining, and other welding services.

Our variety of services sets Diamond's Welding Sets apart from other companies. In addition to high-quality trailers, hay and farm equipment, and custom machine work, Machine Shops Kansas offers reliable maintenance service for trailer repairs, hydraulic issues, and welding needs. You have come to the right place if you want high-quality products and reliable service that exceeds your expectations.

The Amazing Products:

Diamond S Welding and Machine Shop offers premium lawn and farm equipment that is tough and durable enough to handle the most challenging jobs.

Vermeer:

Vermeer innovations enable farmers to do their jobs quickly and efficiently, from the industry's first railcar lift to the innovative round baler. These Vermeer equipment are built with longstanding high standards. These products deliver the reliable performance you expect from one of the best farm equipment manufacturers. Plus, your factory-trained Vermeer dealer provides full service and support for every piece of equipment.

Dexter:

Dexter is the leading supplier of trailer parts and accessories in the United States. The wide selection includes trailer axles, brakes, hitches, wheels, and tires. Dexter is your one-stop shop for all your towing needs across the country. Dexter is now the leading provider of premium trailer parts on the market, offering everything from RV and snowmobile trailers to farm, utility, and flatbed trailers.

Conclusion:

Diamond S Welding & Machine Shop Deals & Offers many services and products. The Machine Shops Kansas, with reliable services, is very budget-friendly. The company is trustworthy, productive, and worthwhile in services/products like heavy-duty machines & equipment.

1 note

·

View note

Link

Leaked audio reveals manager told employee to stop marking railcars for repair as workers condemn industry’s lax safety rulesIn leaked audio heard by the Guardian, a manager for one of the US’s largest rail companies can be heard explaining...

0 notes

Photo

Day 5: GE Genesis

Info from Wikipedia:

General Electric Genesis (officially trademarked GENESIS) is a series of passenger diesel locomotives produced by GE Transportation, then a subsidiary of General Electric. Between 1992 and 2001, a total of 321 units were built for Amtrak, Metro-North, and Via Rail.

The Genesis series of locomotives was designed by General Electric in response to a specification published by Amtrak and ultimately selected over a competing design presented by Electro-Motive Diesel (EMD). Until the introduction of the Siemens Charger, the Genesis series had the lowest height of any North American diesel-electric locomotives, being 14 inches (356 mm) lower than the previous-generation F40PH. This low height allows the locomotive to travel easily through low-profile tunnels in the Northeast Corridor.

The GE Genesis series is unique among recently manufactured North American passenger locomotives in that it uses a single, monocoque carbody design styled by industrial designer Cesar Vergara, thus making it lighter, more aerodynamic, and more fuel efficient than its predecessors (F40PH, F59PH, P30CH, P32-BWH). However, this makes it more costly and time-consuming to maintain and repair. In 2004, Amtrak started installing bolt-on nose cones on its units for easy replacement in the event of a grade crossing collision with a vehicle. As an example of the improvements over the predecessor locomotives, the Genesis is 22% more fuel-efficient than the F40PH while producing 25% more horsepower. In addition, all Genesis locomotives have four-stroke engines instead of the two-stroke engines previously used in EMD counterparts.

The Genesis unit is a fully computerized locomotive which automatically controls all on-board functions, thus producing high reliability while keeping the maintenance requirements low. For example, its computers can automatically reduce the power plant's output in the event that the locomotive is overheating, or suffering from low oil pressure, low water pressure, or reduced airflow into the intakes, thus making it still operable.

All Genesis engines can provide head-end power (HEP) to the train drawn from an alternator or inverter powered by the main engine at a maximum rating of 800 kilowatts (1,100 hp), making each unit capable of providing HEP for up to 16 Superliner railcars. The P40DC and P42DC power plants can supply 60-hertz head-end power either from the HEP alternator with the engine speed-locked to 900 rpm (normal mode) or from the traction alternator with the engine speed-locked to 720 rpm (standby mode). In the latter case, traction power is unavailable. The P32AC-DM powerplant does not have to be locked at a certain rpm because it utilizes an HEP inverter, which allows the prime mover to run at 1047 rpm when providing both traction power and HEP, and to idle at 620 rpm (or notch three) while still providing HEP for lighting and air-conditioning when not providing traction power.

The trucks of Genesis locomotives were made by Krupp Verkehrstechnik, which has since been absorbed by Siemens Mobility; the trucks on the newest Genesis locomotives carry the Siemens name.

Three models of Genesis were built by General Electric, the P40DC, P42DC, and P32AC-DM.

The P40DC (GENESIS Series I) or Dash 8-40BP (originally known as the AMD-103 or Amtrak Monocoque Diesel - 103MPH) is the first model in the Genesis series, built in 1993. The locomotive operates in a diesel-electric configuration that uses DC to power the traction motors, producing 4,000 horsepower (2,980 kW) output at 1047 rpm. Power output to the traction motors is 3,550 hp (2,650 kW) when running in HEP mode (900 rpm) with a 0 kW HEP load. Traction horsepower in HEP mode decreases to a bare minimum of 2,525 horsepower (1,880 kW) when providing the maximum 800 kW (1,100 hp) HEP load to the train. The P40DC is geared for a maximum speed of 103 miles per hour (166 km/h). The P40DC was succeeded in 1996 by the P42DC.

A feature unique to the P40DC and P32AC-DM is a hostler stand at the rear of the locomotive providing increased visibility and reversing capabilities to the engineer while conducting reverse operations. When a unit is in operation from this stand it is limited to 10 mph (16 km/h) and a dead man's switch protects against movement without an operator being present. Another unique feature to the original P40DC were the two strobes above the cab and an emergency flasher between the strobes. When they were overhauled, those features were removed.

Both the P40DC and P42DC allowed Amtrak to operate heavy long-distance trains with fewer locomotives compared to the older EMD F40PH locomotives; two P40DCs could do the same work as three F40PHs. Additional deliveries of the P42DC ended up replacing the P40DCs. Three units were wrecked (819 in the 1993 Big Bayou Canot train wreck and 807 and 829 in the 1999 Bourbonnais, Illinois, train crash) and scrapped. Eight were leased and later sold to the Connecticut DOT for Shore Line East in 2005, and four were rebuilt and sold to New Jersey Transit in 2007; NJ Transit sold their units to ConnDOT in 2015. The remaining 29 units were placed out-of-service for many years. 15 of these units have been rebuilt using 2009 ARRA stimulus funds and returned to service, now in the Phase V livery, except for 822, which is painted in Phase III Heritage livery for Amtrak's 40th Anniversary. The units that were not rebuilt or sold have since been disposed.

In January 2018, ConnDOT awarded a contract to Amtrak to overhaul their twelve P40DC locomotives at the Beech Grove Shops. The first unit was completed in early 2021.

By 2007, New Jersey Transit had upgraded their P40DC units with updated prime movers to match the 4,250 horsepower (3,170 kW) of the successor P42DC. This was done by readjusting the position of the lay shafts within the prime mover. Amtrak has returned 15 of their P40DC units to service as part of a project funded through the American Recovery and Reinvestment Act of 2009.

The first of the units were returned to service in March 2010 after being overhauled at the Beech Grove Shops. They were upgraded like NJT's units had been a few years before to have 4,250 hp (3,170 kW) and match the P42DC's maximum speed of 110 mph (177 km/h). They also received updated cab signaling systems. The upgraded locomotives still have mechanical air brakes, which makes them most suitable for trains that only require a single locomotive. This differs from the electronic air brakes on the P42DC and P32AC-DM. They also feature a builder's plate indicating that they were rebuilt under the auspices of the TIGER stimulus program.

The P42DC (GENESIS Series I) is the successor model to the P40DC. It has an engine output of 4,250 horsepower (3,170 kW) at 1047 rpm, or 3,550 horsepower (2,650 kW) when running in HEP mode (900 rpm) with a 0 kW HEP load. Traction horsepower in HEP mode decreases to a bare minimum of 2,525 horsepower (1,880 kW) when providing the full 800 kW HEP load to the train.

The P42DC has a maximum speed of 110 mph (177 km/h). Tractive effort is rated at 280.25 kN (63,000 lbf) of starting effort and 169 kN (38,000 lbf) of continuous effort at 38 mph (61.2 km/h) given wheel horsepower of 3,850 horsepower (2,870 kW). P42DCs are used primarily on most of Amtrak's long-haul and higher-speed rail service outside the Northeast and lower Empire Corridors. They will be replaced on long-distance service by 125 Siemens ALC-42 Charger locomotives between 2021 and 2024, but will remain in service on corridor trains.

Via Rail Canada has utilized P42DC locomotives since 2001, when they replaced the LRC locomotives in 2001. They are currently on services with speeds up to 100 mph (161 km/h), mainly on the Quebec City-Windsor rail corridor.

The P32AC-DM (GENESIS Series II, short for "Passenger, 3,200 hp (2,400 kW), Alternating Current, Dual Mode") was developed for both Amtrak and Metro-North. They can operate on power generated either by the on-board diesel prime mover or power collected from a third rail electrification system at 750 volts direct current; the third-rail shoes are used on the over-running third-rail into Penn Station for Amtrak units and the under-running third-rail into Grand Central Terminal for Metro-North. The P32AC-DM is rated at 3,200 horsepower (2,390 kW), 2,900 horsepower (2,160 kW) when supplying HEP, and is geared for a maximum speed of 110 mph (177 km/h). Tractive effort is rated at 275.8 kN (62,000 lbf) of starting effort from 0 mph (0.00 km/h) to 14 mph (22.5 km/h) and 113.43 kN (25,500 lbf) of continuous effort at 40 mph (64.4 km/h) given wheel horsepower of 2,700 horsepower (2,010 kW).

The P32AC-DM is unique as it is equipped with GE's GEB15 AC (alternating current) traction motors, rather than DC (direct current) motors as used in the other subtypes. It is also only one of two modern American electro-diesel locomotives with third-rail capability, along with the EMD DM30AC operated by the Long Island Rail Road. NJ Transit and Exo's Bombardier ALP-45DP electro-diesel locomotive can operate from overhead catenary electrification.

The P32AC-DM is only used on services operating north from New York City, where diesel emissions through its two fully enclosed main terminal stations are prohibited. Amtrak rosters 18 P32AC-DM locomotives and uses them for its Empire Service, Ethan Allen Express, Lake Shore Limited (New York section), Adirondack, and Maple Leaf services, all which travel to New York Penn Station. Metro-North rosters 31 P32AC-DM locomotives on push-pull trains to Grand Central Terminal; four are owned by the Connecticut Department of Transportation.

In December 2020, the Metropolitan Transportation Authority of New York board approved a Federal Transit Administration-funded $335 million contract for 27 dual-mode locomotives, based on the Siemens Charger design. The new dual mode locomotives will replace the 27 existing P32AC-DM locomotives used on Metro-North's Hudson Line, Harlem Line, and Danbury Branch; they will use third rail electric power to enter Grand Central Terminal. The order includes additional options for up to 144 more locomotives, which includes 32 additional for use by Metro-North, 20 for the New York State Department of Transportation (for Amtrak Empire Service trains), and 20 for the Connecticut Department of Transportation.

models and route by: Jointed Rail, AmericanTrainz, Auran, and Download Station

#GE#General Electric#Genesis#GE Genesis#Amtrak#Amtrak Genesis#Diesel Locomotive#Trainz Simulator#Trains#Advent Calendar#Christmas#Christmas2022 🎄🎅🎁

0 notes

Text

Railcar Repair Market 2022 | Industry Size, Share, Demand And Growth Analysis Report Till 2028

The study on Railcar Repair Market with its type and application sales analysis is very essential for all the decision-makers or strategists operating in this industry. The report is made by analysts with deep industry knowledge and experience. The global, regional, and country annual sales and revenue has been studied for the historical years and estimated for the current year. With the help of analytical tools, primary interviews, and data triangulation the report is enriched with quality data. The qualitative data on the upcoming industry trends with market triggers and risks are covered as a separate section in this comprehensive report.

As understood and analyzed in the global Railcar Repair market report the growth CAGR in the year 2022 to 2028 is showing a promising inclination. The macro and microeconomic conditions are studied and forecast data is anticipated.

Click here to get a FREE Sample PDF Copy of the Railcar Repair Market Research Report @ https://www.decisiondatabases.com/contact/download-sample-59069

As per this report analysis, the Railcar Repair market is expected to show a CAGR (revenue) of xx% between the forecast years and the global market size can cross USD XX million by the end of 2028, growing from USD XX million in the year 2022. This report specifically covers the global market share (sales as well as revenue) of key companies in the Railcar Repair business, as mentioned in a separate Chapter 3.

Regionally, the Railcar Repair market data is studied under the below-mentioned regions and countries – Americas covering (United States, Canada, Mexico, Brazil), APAC covering (China, Japan, Korea, Southeast Asia, India, Australia), Europe covering (Germany, France, UK, Italy, Russia, Spain), Middle East & Africa covering (Egypt, South Africa, Israel, Turkey, and other GCC Countries).

This research study gives a comprehensive overview of market share and growth opportunities of the Railcar Repair market as per type and application. The report also covers key manufacturers’ profiles with sales and gross margin data.

The key manufacturers covered in this report: Breakdown data in Chapter 3.

UTLX

American Industrial Transport

Bucyrus Railcar Repair

Midwest Railcar Repair

Central California Railcar Repair, LLC

Herzog

Southeast Railcar

Rocky Mountain Railcar Repair

BBM

MEIKI ENGINEERING Co., Ltd.

Holmatro Group

KORAIL

JR-West

Others

To inquire about report customization, feel free to reach out to our team of expert analysts @ https://www.decisiondatabases.com/contact/ask-questions-59069

This study considers the Railcar Repair value and volume generated from the sales of the following segments:

Segmentation by type: breakdown data from 2017 to 2022, in Section 2.3; and forecast to 2028 in section 11.7.

Send for Repair

Field Repair

Segmentation by application: breakdown data from 2017 to 2022, in Section 2.4; and forecast to 2028 in section 11.8.

General Repairs

Tank Car Repairs

The latest developments of the industry and the sales channel, manufacturing process along with the manufacturing cost study is covered in the report.

Key Questions Answered –

What will be the Railcar Repair market CAGR and size between 2022-2028?

Who are the top/leading players of the Railcar Repair market?

What changes are expected in the Railcar Repair market in the next six years?

Which are the top product and leading applications of the Railcar Repair market?

What are the leading market drivers and major risks factors for the Railcar Repair market?

Which region/country leads and foresees highest growth in the next six years?

Purchase the Complete Global Railcar Repair Market Research Report @ https://www.decisiondatabases.com/contact/buy-now-59069

About Us:

DecisionDatabases.com is a global business research report provider, enriching decision makers and strategists with qualitative statistics. DecisionDatabases.com is proficient in providing syndicated research reports, customized research reports, company profiles, and industry databases across multiple domains. Our expert research analysts have been trained to map clients’ research requirements to the correct research resource leading to a distinctive edge over its competitors. We provide intellectual, precise, and meaningful data at a lightning speed.

For more details:

DecisionDatabases.com

E-Mail: [email protected]

Phone: +91-93077-28237

Website || Official Blog || Insights Analysis

0 notes

Text

It’s time for Cranky High School Graduate Ranting

I like trains and railcars. That will be my rant.

First of all, I’m going to pretend money isn’t an issue. Because it isn’t. Greed and lack of thinking are the issue. But anyway.

1) “America has too many different types of terrain to expand the national rail system!”

Japan is pretty good at making their railways last a long frickin’ time on a thousand types of terrain. You could also consult engineers from other countries and climates. How can you keep your railways working during weather changes? Ask for help. Also: why not hire more rail workers who can help maintain each section? If you have full-time workers, you won’t lose as much money on extensive repairs; it will just be little, easy things.

2) “America is too big for railways to be worth it!”

No it isn’t.

3) “People won’t ride trains!”

People ride trains all the time and say it’s the best form of public transport. You can walk on a train, have your devices ready, and transport more luggage than a plane or bus.

4) “It’s too hard to put in rail cars in cities!”

It’s difficult, lengthy, and the people who drive their cars everywhere will be pissy at first. But it isn’t “too hard”. You can absolutely do it. City dwellers rarely rely completely on personal vehicles, anyway; if you give them a new, better option, they will take it. Citizens are not stupid.

5) “But the industries!!!!”

If public transport can undermine the oil and automotive industries so easily, then they are not needed anymore, and they can stand to downgrade. :)

This concludes my rant. Thank you.

8 notes

·

View notes

Video

E & LS 202 by Jim J.

Via Flickr:

Escanaba and Lake Superior 202 DS4-1000 switches woodchip cars at the Pressed Board Factory at Ontonagan, MI. Canon EOS 2000 Canon 28~80mm lens Fujifilm 400 OVERVIEW The Escanaba & Lake Superior Railroad (E&LS) is a privately owned shortline railroad company operating in Northeastern Wisconsin and the Upper Peninsula of Michigan. Under current ownership, the E&LS has expanded from the original core line of 65 miles that was purchased in 1978, to over 235 miles of operating railroad in 2005. The E.&L.S.R.R. is headquartered in Wells, MI, with an additional office located in Green Bay, WI. The 208 mile mainline of the E&LS stretches from Ontonagon, MI on the shores of Lake Superior to Green Bay, WI. In addition to the mainline, two key branches are the 6-mile Stiles Junction, WI to Oconto Falls, WI line and the 21-mile Crivitz, WI to Marinette, WI/Menominee, MI line. Other lines owned by the E&LS include Channing, MI to Republic, MI, and Channing to Wells. The E&LS operates on trackage rights over the Canadian National Railroad from North Escanaba, MI to Pembine, WI. The E&LS connects with the Canadian National at Green Bay, North Escanaba, Pembine, and Iron Mountain, MI. FREIGHT SERVICE The E.&L.S.R.R. provides a minimum of 5 day per week service over the mainline from Ontonagon to Green Bay, and customizes service to meet shipper requirements in Oconto Falls and Marinette/Menominee. Seven road locomotives and 3 switch locomotives provide the power for operations over the system. The E&LS owns and/or leases a substantial car fleet that includes: 781 boxcars, 77 bulkhead flatcars, 4 gondolas, and 15 RBL’s for a total of 877 rail freight cars. CUSTOMER BASE The E.&L.S.R.R. is privileged to serve a multitude of paper, forest products, and other manufacturing companies in Michigan and Wisconsin. The commodities transported by the E&LS include: medium corrugated or pulpboard, scrap paper, woodpulp, pulpwood logs, oriented strand board, lumber, wood bark, canned goods, steel, scrap metal, aggregate, chemicals, and agricultural items such as corn, grains, feed, and fertilizers. MARKETING AND ANCILLARY SERVICES Maintaining existing business as well as adding new customers have been the guiding principles for the ongoing marketing efforts of the E.&L.S.R.R. In conjunction with reliable and competitively priced rail service, the E&LS works with customer’s everyday to insure that their freight transportation requirements are met successfully. From customer service personnel to the operating department, the E&LS builds lasting business relationships in order to meet the challenges of moving freight by rail for shippers in Michigan and Wisconsin. Other services and assistance offered by the E&LS include: · Industrial development and site planning · State DOT finance programs for industrial spur track construction · Truck transloading · Contract car repairs for private and railroad owned car fleets · Railcar Storage

0 notes

Text

Trinity Industries Inc Company Profile - Overview - GlobalData

Trinity Industries Inc (Trinity) is a diversified industrial company. It produces and supplies railcars and railcar parts, and highway products. The company also offers services such as railcar fleet management, railcar leasing and management services, and repair services. The company serves its products and services to various industries such as energy, chemical, agriculture, transportation, construction sectors and others.

0 notes

Text

Curry Rail Services

Website URL

https://www.curryrail.com

Keywords

railcar maintenance pennsylvania, locomotive repair shop pennsylvania, railcar repair shops in pennsylvania, railroad car repair companies pennsylvania, railcar manufacturers usa

Description

Curry Rail Services is one of the leading locomotive and railroad car repair, manufacturing, and maintenance companies in Pennsylvania and the rest of the nation. Backed by many decades of experience, we have become a premier provider of freight car services and locomotive products to the railroad industry.

At Curry Rail Services, we put our clients first and strive to nurture long-lasting relationships with them, as well as our industry partners, and suppliers. We are a full-service rail car company that provides dependable products and efficient solutions in the field of rail car repair, tank car repair, rail car manufacturing, and locomotive components. Our experienced team can inspect, repair, and rebuild different types of railway cars, including box cars, gondolas, hopper cars, and flat cars.

With skilled and knowledgeable employees and cutting-edge machinery, we are fully equipped to handle all kinds of challenges in the railroad repair and manufacturing industry here in Pennsylvania and beyond. Reach out to us for expert train wreck repair, freight car repair, locomotive maintenance, or any related services.

Owner Name

Mark Ritchey

Address

585 Berwind Rd

Hollidaysburg, PA

16648

Phone

814-793-7245

Business Contact Email

Year/Month Founded

1932

Hours of Operation

Mon-Fr 8:00am-4:30pm Sa & Su closed

Payment Accepted

Checks, wire transfer

Languages Spoken

English

Number of Employees

50-75

Number of Office Locations

1

Areas Served

Pennsylvania, USA, United States

Products / Services

Railcar Repair, Railcar Manufacturing, Tank Car Repair, Locomotive Products

Social Links

https://www.facebook.com/curryrailservices

https://www.linkedin.com/company/curry-rail-services

https://twitter.com/curry_rail

https://www.youtube.com/channel/UCJ0Ed7MWE-xKAeyJxLNAiCg

https://www.manta.com/c/mhwqjlx/curry-rail-services-inc

1 note

·

View note

Text

High Quality Epoxy Primers: Give Your Floor Some Extra Protection

What is epoxy primer?

Epoxy primer provide excellent metal adhesion, and also act as a proper base for extra undercoat and top coat products. Epoxy primers are also commonly used to coat metal cans and containers, especially those used to contain acidic food, such as tomatoes. It is applied directly to concrete so that the surface is not affected by heavy materials and remains durable for a long time. We at Zigma Paints Pvt. Ltd. , have pledged to provide you with the epoxy primer solutions for keeping your walls, and floors safe, and clean for long!

Epoxy primer provides warehouses, water treatment facilities, shopping malls, marine applications, theaters, etc. with the leverage to be safe for staff, inventory, and machinery. Epoxy primer paints provide a tough, durable protective coating that is easy to maintain. Due to its unique properties, it is rust-resistant, resistant to chemicals and easy to clean.

BENEFITS OF AN EPOXY FLOOR PRIMER

Prior to coating your flooring, there are numerous advantages to applying an epoxy floor primer:

Epoxy primers are thin and provide better adhesion as they penetrate into the concrete substrate to enable better bonding.

When using thicker epoxy base coats, primers have a stronger chemical bond. This results in a longer lasting floor coating and a more durable one.

Elimination of air bubbles and pinholes formed as a result of concrete outgassing

Ability to achieve greater dry film thickness and uniformity of the coating since it is not soaked in the concrete.

Effective in providing concrete flooring with moisture resistance that has issues with humidity.

For concrete flooring, primers form a tenacious waterproof barrier that is devoid of an effective Damp Proof Membrane (DPM) that usually results in virtually any surface lifting and peeling of paint.

Most epoxy primers are moisture tolerant and work well when applied to concrete that has not been completely dried or etched with acid.

Some primers are specifically manufactured as oil blocking primers. These solvent based primers are designed to cover concrete that has been contaminated by oil and can’t be completely cleaned.

How Epoxy Primer works on flooring applications?

The foundation of your floor coating system is an epoxy primer. Without it, no matter what kind of epoxy you apply, your epoxy system won't work as well. The layer that you will build on with other base coats and topcoats is the epoxy primers. Usually, they are a bit more forgiving and, as they are thin, allow for much more coverage. Unless you use a single coat epoxy primer system, we strongly recommend that you use an epoxy primer on all concrete surfaces to achieve maximum durability, strength, and bondage that will lengthen the lifespan of your floors in turn.

By forming a chemical bond, primers bind to concrete. What you're actually doing when you mix your primer is creating a chemical reaction that initiates the hardening process. To achieve a strong bond, epoxy primers are formulated to seep into the pores of your surface. This binding would not be as effective if you were to apply a primer on an unprepared surface, which is why it is crucial to either acid etch and power wash or prepare your floor mechanically so that the primer can bind properly.

Zigma Paints Pvt Ltd. provides a wide variety of industrial primers that are suitable for steel production applications, manufacturers of basic machinery, manufacturers of steel products, industrial repair, decorative iron, commercial propane, electrical goods protective coatings, electrostatic. For more than a decade, our business has been supplying different kinds of epoxy primers to different industries around the world. Epoxy primers and finishes, according to their useful properties, are manufactured by us for their different types of industrial properties. Concrete sealing coatings, industrial equipment, structural steel and exterior railcar coatings are all provided by our epoxy primer and finish line.

Visit us:- www.zigmapaints.com/epoxy-primer-paints.php

Contact :- (0253) 2381 429 / 660 2735

#Epoxy primer#Epoxy primer paints#Epoxy primer coating#Epoxy primer manufacturers#Epoxy primer suppliers#Epoxy primer in india#Epoxy primer solution#Epoxy primer systems

0 notes

Link

Mitchell Rail Gear factory is fully equipped with Hi rail truck systems, repairs, installations. We deal in attachment systems that are designed in a way that would adapt to a variety of vehicles. Railroad trucks in the railroad industry are the critical link in the nation’s supply chain, moving millions of tons of goods over a 140,000-mile network every day.

0 notes

Text

Welder 1/ Repairman

COMPANY: Harbor Services Company is a leading provider of railcar and locomotive repair services for the railroad industry in the United States.

POSITION: Repairman Welder-1

REPORTS TO: Location Supervisor/Manager

JOB SUMMARY: The primary responsibility of the Railcar Repairman I is to perform all freight car repairs including the inspection and repair and billing of railroad freight cars in accordance to all AAR, FRA and Railroad rules with minimal supervision. This work is accomplished through the use of hand tools, cutting torches, and welding equipment. Work is of a physical nature and involves kneeling, bending, and stooping.

ESSENTIAL DUTIES AND RESPONSIBILITIES:

To become a Repairman Welder-1 you must complete the 18 months of a Repairmen Welder – 2 or have 4 years’ experience as a railcar repairman from another company and be able to perform all the duties below with little to no supervisorial instructions including billing of all repairs, be D15.1 qualified and able to pass the annual Rail Car Repairman Test at a 100%..

The statements in this section are essential job functions that an employee must be able to perform with or without reasonable accommodation in order to achieve the objectives of the job. In this regard, please note that the description is generic and represents a composite across like position assignments. There may be position specific differences related to geography, available technology, work force levels, etc. which should be clarified in individual situations.

Perform all freight car repairers inspect, repair, rebuild and service railroad freight cars in accordance to all AAR, FRA and Railroad rules with minimal supervision. This is accomplished through the use of hand tools, power tools, cutting torches and welding equipment. Work is of a physical nature and involves kneeling, bending and stooping.

CONDUCT INSPECTIONS OF ROLLING STOCK (freight cars, flatcars, tank cars, etc.). Inspect rolling stock for defects or evidence of wear; inspect rolling stock for compliance with industry standards; inspect lading for shifting loads, clearances, and compliance with rules; inspect rolling stock damaged in derailments or collisions; conduct pre-trip inspections (air brake tests, fuel, etc.).

REPAIR ROLLING STOCK STRUCTURAL COMPONENTS. Fabricate, cut, and perform rough finish operations on metal and wood replacement parts; fasten and assemble car parts by riveting, bolting, welding, and other methods.

REMOVE AND REPLACE DEFECTIVE APPLIANCES AND COMPONENTS. Remove and replace defective components on rolling stock (trucks, shoes, coupler assemblies, air brake systems).

WORK WITH SHOP MACHINES AND TOOLS. Safely and effectively operate the following; acetylene torches, non-power tools (pliers, wrenches, hammers), power tools (drills, power saws, grinders); electric and gas welding equipment.

PRACTICE SAFE WORK HABITS. Understand and follow company and industry safety rules, practices, and procedures, wear prescribed safety apparel; take appropriate action when conditions threaten safety of self or coworkers; ensure equipment and work area are in safe operating condition before starting work.

Report all worked performed on proper billing sheets.

Assist in opening door and raising decks for inspection as needed.

Assist in lowering decks and closing doors as needed.

Insure all equipment is kept clean and in good repair.

Load and unload material as needed.

Keep storage and repair tracks net and orderly.

Assist in outer duties as needed.

QUALIFICATIONS

Welder’s certification not required, but welder qualifications will be requested in order to be considered, for example 2g, 3g, 4g. Must meet all physical requirements and be able to take direction.

Work Hours: Full Time. Weekly schedule may change as required. May be necessary to work weekends. Must be willing to work overtime as needed. On call 24 hours a day.

Equipment Requirement: Required to wear back support belt, gloves, eye and ear protection, hard hat, work boots, and other necessary safety equipment as tasks dictate.

Education and Experience: Required to have high school diploma or equivalent.

Language Skills: Ability to read, write, and communicate English fluently and professionally. Ability to effectively communicate with and present information to all levels of employees, contractors, vendors, partners, owners and other inter-company divisions.

Mathematical Skills: Requires basic analytical and quantitative skills with the ability to solve basic mathematical problems.

Reasoning Skills: Ability to define problems, collect data, establish facts and draw valid conclusions.

PHYSICAL REQUIREMENTS

Constant need (80% to 100% of the time) to be on feet.

Have constant need (80% to 100% of the time) to perform the following physical activities:

Bend/Stoop/Squat/Kneel Pick up debris, etc.

Climb Stairs or ladder Routine duties require access to all levels of railcars.

Push or Pull Move equipment, open and close doors, etc.

Reach Above Shoulder Stock and remove files, parts, and or equipment.

Grasp/Grip/Turning Handle tools and equipment, etc.

Finger Dexterity Handle tools and equipment, type, etc.

Lifting/carrying (supplies, files, parts, etc.):

25 – 75 lbs. Frequent need ( 10% to 20% of the time)

1 – 35 lbs. Constant need (80% to 100% of the time)

NOTE: Lifting and carrying of weights exceeding 50 lbs. is often accomplished with assistance from one or more persons and while wearing the required, appropriate safety equipment. Examples of heaviest items lifted include knuckles, brake beams, and uncoupling levers that weigh approximately 25 to 50 lbs. etc.

Reliable transportation is required at all times. Must possess and maintain a valid driver’s license at all times. Employee must be willing to take calls and report to work at any hour of the day or night. Out of town travel may be required.

VISION REQUIREMENTS

Constant need (80% to 100% of the time) to observe areas needing attention/correction. Read cautionary labels; respond to written instructions from staff.

Constant need (80% to 100% of the time) to see things clearly beyond arm’s reach. Observe and assist in general maintenance; observe problems throughout property.

Constant need (80% to 100% of the time) to be able to differentiate common railroad signaling colors (red, green, yellow and blue).

HEARING REQUIREMENTS

Essential. Must be able (80% to 100% of the time) to hear things clearly and be able to receive verbal instructions.

SPEAKING REQUIREMENTS

Constant need (80% to 100% of the time) to verbally communicate with the staff, partners, vendors, etc.

WORKING ENVIRONMENT

Outdoors (80% to 100% of the time), all conditions, often for extended periods of time.

Exposure (50% to 90% of time) to paint fumes, lubricants, dust, loud noises, etc. Example: repair of railcars and switching will be close by the work area.

Employee may be required to travel to multiple locations throughout the United States and often to walk various areas which can be upstairs, noisy, dirty, uneven, or dark. Out of town travel may be required.

REASONING DEVELOPMENT

HIGH.Must be able to apply principles of logical thinking to a variety of practical situations and accurately follow standardized procedures that may occasionally involve minor deviations. Needs ability to think rationally beyond a specific set of instructions.

DISCLAIMER

This job description has been designated to indicate the general nature and level of work performed by employees within this classification. It is not designed to contain or be interpreted as a comprehensive inventory of all duties, responsibilities, and qualifications required of employees assigned to this job.

Job Type: Full-time

Pay: $14.00 – $16.00 per hour

Benefits:

401(k)

Dental Insurance

Health Insurance

Life Insurance

Paid Time Off

Vision Insurance

Schedule:

Monday to Friday

Overtime

Weekends

Experience:

Welding: 1 year (Required)

License:

driver’s license (Preferred)

Work Location:

Pay Frequency:

Bi weekly or Twice monthly

Benefit Conditions:

Only full-time employees eligible

Work Remotely:

0 notes

Text

What else could you Do with a Overhead Crane Program | This Hardest Worker in the particular Factory

If you are throughout some sort of industry where an individual frequently elevate and move within commercial facilities, you will find the connection incision technique to end up being beneficial. The tool allows you to lift, move, lower, and precisely spot big, huge and large loads on the internet site, saving you period, cutting down the risks of solution damage, as well like lowering the chances of serious accidents.

The overhead bridge crane safely carries items horizontally through the overhead place of a warehouse capability rather than through aisles as well as on the flooring, allowing you to better boost productivity, safety, just as well as space-saving. Bridge cranes are designed for you to undertake the repair of critical loads like as high-value equipment and large chemical storage units, amongst others.

The machines are operated using a radio/IR remote control pendant, control pendant, or perhaps from an driver cabin they are linked in order to.

Things You Can Perform with a good Bridge Blessure System

Construction: Ultimately, making raw materials in finished products includes a great deal of movements. To make the approach a lot more streamlined, you must a reliable piece of equipment in order to help move products to get results centers where a functioning is performed. Some sort of overhead bridge motorised hoist system allows a person to do this goal by means of moving substantial batches involving unfinished merchandise through typically the production processes.

Warehousing: Typically the large character of items inside the warehouse means that even the the majority of knowledgeable acelerar will have problem moving them from a single point out another, as doing thus can result within back and joint complications. Besides, you risk detrimental the product or service you’re wanting to convey. So , if http://overheadcranecompany.weebly.com/blog/what-can-you-do-with-a-bridge-crane-system are trying to shift weighty, large products to help and from often the ipod dock areas, you can employ some sort of bridge crane program to get a hassle-free experience.

Hard drive: Overhead crane systems may be used to present heavy things to and from storage area areas.

Travel: Besides with them to raise and approach large things from one destination for a a further, you can use cost rayure to load completed products on open trailers or railcars.

Staging: Traveling Bridge crane system can get used to hold work-in-progress (WIP) for further creation processes.

Last Word

Overhead cranes are usually critical in order to managing the flow connected with goods in companies this kind of as transport, logistics, warehousing and distribution, chemicals, car, steel, among others. They help in keeping your workers good together with free up floor space, which makes them the ideal crane devices with regard to crowded workspaces.

0 notes

Text

What Can You Do with a Bridge Crane Technique | Often the Hardest Employee in the Factory

If you are around a good industry where you frequently lift up and proceed within professional facilities, you will find the connection crane program to get beneficial. The tool makes it possible for you to lift, maneuver, lower, and precisely job big, cumbersome and weighty loads on the web site, saving you time period, reducing the risks of merchandise damage, as well while lowering the probability of serious accidents.

The overhead bridge crane system safely transfers items width wise through the overhead room of a warehouse center rather than through areas or maybe on the floor, allowing you to far better boost productivity, safety, mainly because well as space-saving. Overhead cranes are designed in order to undertake the repair of critical loads many of these as high-value equipment in addition to large chemical storage units, amongst others.

The machines are usually operated using a radio/IR distant pendant, control pendant, or from an agent cabin that they are linked to help.

Things You Can Perform with a Bridge Blessure System

Set up: Ultimately, getting raw materials directly into concluded products includes plenty of mobility. To make the procedure a lot more streamlined, you need to have a reliable brewing system to be able to help move products to function centers where a good procedure is performed. Some sort of overhead bridge motorised hoist system permits you to do this goal by simply moving huge batches involving unfinished goods through often the production processes.

Storage: Often the large mother nature of things within the warehouse means that even the almost all skilled emocionar will have trouble moving them from 1 point to another, as doing thus can result inside back and joint troubles. Besides, you risk detrimental the product you’re trying to help convey. So , if you are trying to maneuver weighty, large products to be able to and from the boat dock areas, you can use a bridge crane program for just a hassle-free experience.

Storage area: Overhead crane systems can be used to convey heavy products to in addition to from storage area areas.

Transport: Besides using them to raise and move large goods from one destination for a an additional, you can use cost cranes to load finished products onto open trailers or railcars.

Staging: Travelling Bridge crane system can get used to hold work-in-progress (WIP) for further manufacturing processes.

Closing Word

Bridge cranes are critical for you to managing the flow connected with goods in market sectors such as transport, logistics, storage and distribution, chemicals, automotive, steel, among others. They help to keep your workers free from danger and free up floor space, which makes these individuals the ideal crane devices to get crowded workspaces.

0 notes

Text

What else could you Do with a Overhead Crane Technique | This Hardest Staff in this Factory

If you are within the industry where anyone frequently elevate and maneuver within industrial facilities, you will find the bridge incision program to get beneficial. The particular tool enables you to lift, move, lower, and precisely spot big, cumbersome and hefty loads on the site, saving you moment, lowering the risks of product or service damage, as well because lowering the possibilities of serious injury.

http://overheadcranecompany.weebly.com/blog/what-can-you-do-with-a-bridge-crane-system crane safely transports items flat through the overhead place of a warehouse capability rather than through aisles or perhaps on the floor, allowing you to greater enhance productivity, safety, simply because well as space-saving. Overhead cranes are designed to be able to undertake the repair of critical loads many of these as high-value equipment together with large chemical storage containers, amid others.

The machines are operated using a radio/IR remote pendant, control au cours de, or even from an operator cabin likely linked for you to.

Things You Can Perform with the Bridge Raie System

Construction: Ultimately, spinning raw materials into completed products consists of many movement. To make the approach additional streamlined, you must a reliable brewing system for you to help move products to work centers where a great functioning is performed. Some sort of overhead bridge crane system permits a person to accomplish this goal simply by moving large batches connected with unfinished goods through often the production processes.

Warehousing: Typically the large dynamics of items in the warehouse means that will even the almost all competent acelerar will have difficulty hauling them from 1 point out another, as performing consequently can result within back and joint issues. Besides, you risk harming the merchandise you’re wanting for you to convey. So , if you are trying to shift heavy, large items to and from often the dock areas, you can use the bridge crane system to get a hassle-free experience.

Storage area: Over head crane systems could be used to express heavy products to in addition to from storage area areas.

Transportation: Besides using them to pick up and shift large items from one place to one more, you can use over head sillon to load finished products onto open trailers or railcars.

Staging: Traveling Bridge cranes can turn out to be used to hold work-in-progress (WIP) for further generation processes.

Last Word

Bridge cranes will be critical to help managing the particular flow connected with goods in companies such as transport, logistics, warehousing and distribution, chemicals, auto, steel, among others. Many people help to keep your workers safe and sound and even free up flooring space, which makes these people the ideal crane products for crowded workspaces.

0 notes