#Epoxy primer suppliers

Text

Enhance your pool painting project with Pool Paint Primer » ! Ensure a smooth and lasting finish by using our premium primer designed for pool surfaces. Increase adhesion and durability while preventing peeling and chipping. Elevate your pool makeover and create a vibrant, long-lasting result. Dive into perfection today! 🏊♂️🖌️ #PoolPaintPrimer #SmoothFinish #PoolMakeover

#pool paint#epoxy pool paint#pool paint perth#epoxy pool paint perth#pool epoxy paint#fibreglass pool paint#epoxy pool paint near me#pool painting perth#pool paint epoxy#pool paint primer#swimming pool paint#perth pool paint#pool paint online#epoxy pool coating#pool paint for sale#swimming pool epoxy paint#pool paint suppliers#epoxy paint for swimming pools#epoxy paint for fibreglass pools#where to buy pool paint#swimming pool paints#pool resurfacing perth#swimming pool epoxy paint suppliers#bg coatings#pool resurfacing perth cost#concrete pool paint#fiberglass pool resurfacing perth#concrete pool resurfacing perth cost#pool painters perth#swimming pool epoxy coating

0 notes

Link

#Paint Suppliers Sydney#Buy Pool Paint Online#Epoxy Pool Paint Sydney#Pool Paint Supplies Sydney#Buy Swimming Pool Paint Online#Pool Paint Colours#Swimming Pool Paint For Sale#Solvent Based Pool Paint#Acrylic Pool Paint Online#Acrylic Pool Paint Online Sydney#Epoxypoolpaint#Australian_Made_Paint#primer#bg primer#pool primer#australia

0 notes

Text

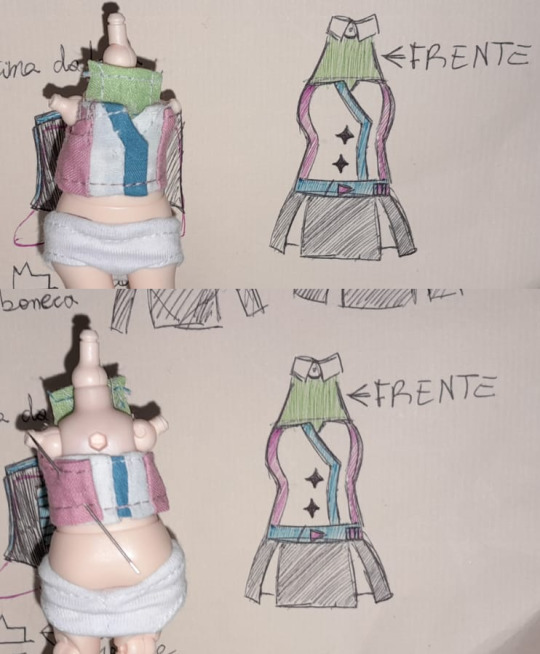

Custom HIOMAIKA(+Dex)

After months of getting stuff they're finally done! Got some nendo parts along with YMY dolls to make them real.

Before anything was done and Maika had her final clothes:

After the paint was done and Maika got her clothes:

To be honest I barely had to do much stuff in terms of applying epoxy over to make things or sand areas.

They still are far away from being perfect since they could have had way more sanding for a better cleaner look and the colors could have been better if I didn't try to keep touching them while they dried orz

Still, this is good enought to me!

Edit: huge thanks to @/chorva_art on twitter for recommending materials and possible faces that could be used for Maika I watched some videos of customs but if she didn't tell me materials or what could be used to do this stuff idk if I'd have gone through it at all lol

Materials used for the extra parts:

Tamiya Epoxy Putty (Smooth Surface), the one that takes 12 hours to dry;

Sanding Paper that I didn't use as much as I should;

Tamiya Primer;

Tamiya LP-43 (pearl white), LP-52 (clear red), LP-8 (pure yellow), LP-10 (thinner) and LP-65(rubber black);

Acrilex Thinner since i ran out of the Tamiya after making a mistake and using thinner without paint;

Acrilex Fixative Varnish (spray and liquid);

Super Glue;

Mini Oxygen Injector ForeverLily.

The colors weren't the best for painting hair since they are kinda better for cars in the case of LP-52 and LP-43, so any weird thing is due to that. However the effect that LP-43 and LP-65 gave when mixed for Dex's gray hair did have a nice result.

I also ended up breaking the mini oxygen injector's paint/liquid supplier because i dropped it twice in different days so this post will be a warning tale 😔

Hair styles used:

Maika: Nendoroid Doll Alice for the front and Eris Boreas for the back

Hio: Rider/Ozymandias

Dex: Luo Tianyi this wasn't on purpose at all I swear

MAIKA's clothes progress

Maika had parts of her clothes custom made by a relative since her outfit wasn't as simple to get by purchase only unlike the other two.

Dex and Hio's outfits can still get some accessories for a complete version compared to how they are at the moment aside their coats.

This relative can't draw so I had to help by drawing a reference and staying with them while they sewed to make sure it was what I had in mind for this.

Because of that it took quite a while since they kept remaking stuff until it got done in a way they liked and we could only do it once in a while. For the early photos the glovelettes were pretty much not used since we were still figuring out how that would work 😅

Maika's clothes have small snap fasteners to close them.

And here's final look for Maika's clothes:

How steps went by during these past few months:

Getting the hair parts → start sanding them → finishing Maika clothes → starting applying epoxy and adjusting more with sanding → priming → painting → varnish

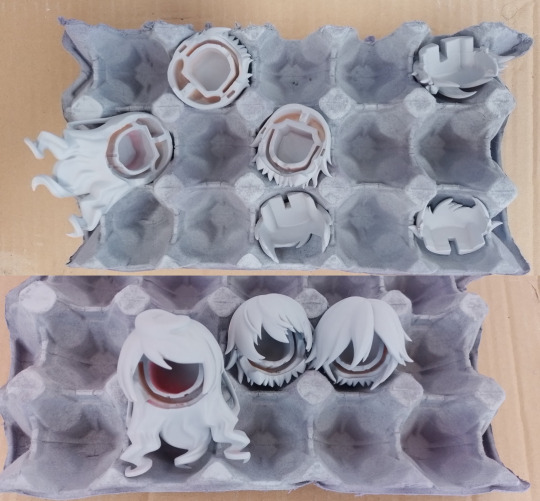

Hair progress

Maika had to get her hair roll and some patching up to hide the headband of the back hair.

As for Hio he only missed his side hair and the slightly long hair on the side.

This is one of the areas that I didn't sand as much as possible so it could have been better, but since it barely shows up it didn't make a big difference.

His "long" hair part fell down so super glue was used to put it back in place. During the painting process his side hair also fell so, once again, super glue saved the day.

Meanwhile Dex had some big holes to cover, he was the first one to be "completed" from the first day since the main issue that had to be done was the easiest to fix compared to Maika's hairband and Hio's side hair.

These holes were what gave away that this was Tianyi's hair since either it was some long hair part that were attached to it or twin tails, which was the keyword used to figure out who was the hair donor 😅

There also were some holes in the back of the head so these helped a lot to make sure that it really was her.

Applying primer was ok without many issues ignoring that I didn't want to sand more, the biggest issues happened over the painting.

From the get go Dex was the only one who worked, I made some mistakes and wasted thinner thinking that I had it mixed with paint while it wasn't so he was the only one that didn't have any major issues during the first day of painting to the point that I went ahead an applied some varnishing. 🤡

Dex came out pretty ok, had to do some fixing with a brush and even after that paint more since I tested how he looked closed and he wasn't 100% dry yet so his head pieces almost got stuck together.

For the second and third day Hio and Maika's hairstyles got done with the oxygen injector becoming unable to use since each day I broke one of the liquid suppliers RIP. Fortunately on the last day it happened after Maika was done.

After this the spray varnish was applied and they were left to dry a bit. Fortunately everything was already sort of done so I didn't have much else to do...

Until I accidentally scratched Hio's head on the front and his front bangs ended up with a hole in it 💀 I tried to patch it up with oil pastels when liquid varnish was applied so it's not 100% noticiable as it was before it.

The liquid varnish was just to make sure that the heads wouldn't be sticky as some model kit and miniature painters/reviewers on BR YT and blogs mentioned Acrilex's pray varnish could leave stuff sticky due to temperature and other things, so that was what had to be fixed for the last stage.

And with that, here's the final result:

I'm pretty happy with how their hair came out. Maika's head is pretty easy to remove while the other two are hard to insert and remove, need to be really careful to not mess up anything while doing it.

Before finishing the post, here are a few notes for the hair styles and the doll bodies used:

Dex

Somehow was the easiest to get between the 3;

His main issue was actually the liquid varnishing that probably was way too much so it looks like he got glue on his hair, which I'm going to try to avoid touching as much as possible to not make it even worser;

Maika

Maybe applied way too much white paint after some mistakes that made me waste thinner;

Red hair is pretty dark compared to the photos. It's pretty close to the red of Sylvanian Families Cruising Car that I used as reference for this chibi art, so at least it's a really pretty kind of red;

Hio

His hair went from yellow to a more dark orange tone to this in the final result. It's far from his original hair color, however this is good since I couldn't really picture him with a super light blonde color nor did I want to make him closer to the original;

Actually the hardest hair in terms of applying epoxy putty since his side bangs had to be made.

YMY body:

The ver. 1 YMY has more knee articulation compared to the ver. 2. Both Hio and Maika use the second version and they can't sit on top of their knees like Dex. For an easy example it's like how Body-kun has knee articulation while Body-chan does not have that;

Ver. 2 has hands for both sides of the body while the ver. 1 only came with right hand for different hand types. Ver. 2 also got two chests that you can exchange (the one it came with and the alternate version);

Different stands. Ver. 1 has one similar to doll stands (straight stand, doesn't have articulation) while ver. 2 is more similar to nendoroid stands (3 articulation points). You can see them properly on the photos that came before these notes.

And here's a before and after the epoxy and paints were applied:

If you managed to get to the end of this post, I hope you liked it!

This took around 5 months to finish since parts started getting delivered, doing epoxy and painting took less time because a few things got done until 2 months ago. It was done for real 29/08/2013.

If someone with more patience than me does this they for sure can get better results than what I got so may this post help anyone who wants to have their own customs, if that's possible.

Also so sorry for the text and language mistakes, I tried to make some revisions to the first draft and make things a bit easier to understand as I edited this. English isn't my mother language either so hopefully this is all OK as it is. 😅

The doll seat they're using is a Calico Critters/Sylvanian Families one, in terms of seats their items work pretty well for this. A smaller doll type like nendoll probably will work a bit better, even if a bit big for other types of furniture (still not as big as this one).

#ymy doll#other#misc#custom nendoroid#even if it's only nendohair i'll use that tag#vocaloid#vocaloid maika#vocaloid dex#maika vocaloid#dex vocaloid#yohioloid#nendoroid custom#ymy body#ymy#this is also a post of what not to do when trying to custom. rip

33 notes

·

View notes

Text

5 Essential Construction Chemicals Every Builder Should Know

In the construction world, innovation, and quality go hand in hand. As the industry progresses, the use of advanced construction chemicals in the UAE has become crucial in ensuring the durability and longevity of buildings. These chemicals not only boost the structural integrity but also contribute to the aesthetic appeal and sustainability of projects. Here are five construction chemicals that every builder should be familiar with:

1. Concrete Admixtures

Concrete is the backbone of most construction projects, and admixtures are crucial in modifying their properties to suit various applications. Admixtures can improve the workability, durability, and strength of concrete, making it more adaptable to different environmental conditions. Whether you need to speed up the curing process, increase resistance to harsh weather, or reduce water content, concrete admixtures are indispensable.

2. Waterproofing Compounds

Waterproofing is essential to protect structures from water ingress, which can cause significant damage over time. Waterproofing compounds are utilized in various building materials in the UAE, including roofs, basements, and bathrooms, to prevent moisture penetration. These compounds come in different forms, such as liquid-applied membranes, cementitious coatings, and bituminous materials, each offering unique benefits to ensure a watertight seal.

3. Sealants and Adhesives

Sealants and adhesives play a crucial role in construction, ensuring that various building materials bond securely and remain sealed against the elements. These chemicals are used to fill gaps, prevent air and water leaks, and provide a strong bond between different materials. From silicone sealants to epoxy adhesives, these products are essential for both structural and finishing applications.

4. Protective Coatings

Protective coatings are applied to surfaces to protect them from corrosion, wear, and environmental factors. These coatings are vital in industrial and coastal regions where structures are exposed to harsh conditions. Common protective coatings include epoxy coatings, polyurethane coatings, and zinc-rich primers, each designed to protect specific materials such as steel, concrete, and wood.

5. Grouting Materials

Grouting materials play a crucial role in filling voids and reinforcing structures. Used in both new constructions and repair works, grouts are applied to fill gaps between tiles, seal joints, and strengthen foundations. Depending on the application, grouting materials can be cement-based, epoxy-based, or non-shrinkable, providing flexibility in meeting various construction needs.

Salina Group: Building a Legacy of Innovation

At Salina Group, we understand that constructing a structure involves more than just assembling materials—it's about creating a legacy. Since 1993, we have been at the forefront of blending tradition with cutting-edge technology across multiple sectors, including construction chemicals. Our commitment to innovation has not only set industry standards but also driven the evolution of building materials in Dubai and beyond.

As leaders in the industrial, advertising, and tech sectors, Salina Group is proud to offer a comprehensive range of building supplies in Dubai. Our expertise in construction chemicals ensures that every project, whether in the UAE or elsewhere, benefits from the latest advancements in materials science. From waterproofing compounds to protective coatings, we provide the essential products that builders need to create structures that stand the test of time.

Whether you are searching for premium building materials in Dubai or reliable building materials suppliers in the UAE, Salina Group is your trusted partner. We have seamlessly merged the old with the new to craft a better future for all, ensuring that every project we undertake is a step toward a more sustainable and innovative world.

Construction Chemicals UAE, Building Materials Dubai, Concrete Admixtures, Waterproofing Compounds, Protective Coatings for Construction

1 note

·

View note

Text

Epoxy Coatings Manufacturer & Supplier in Ahmedabad by Angel Coating

Epoxy Coatings Manufacturer & Supplier in Ahmedabad

Angel Coating is top most Epoxy Coating, Epoxy Primer and Epoxy Pigment, Epoxy Paint Manufacturer in Ahmedabad, India.

Types of Epoxy Coating:

⁍⁍ Epoxy Primer:

Angel Coating's Epoxy Primer 2k primer can be used for auto body refinishing with high chemical and anticorrosive protection with very good adhesion on all types of substrates like iron, steel, galvanized and aluminum.

We offer large range of epoxy primers from general industrial epoxy primers to high corrosion resistance epoxy primers including zinc phosphate, red oxide, zinc chromate and MIO based epoxy primers.

We also offer range of zinc rich epoxy primers for application requiring very high corrosion resistance like marine applications, windmills, chemical tanks etc.

⁍⁍ Epoxy Pigmented:

Epoxy Pigment is excellent corrosion resistance, acid & alkali resistance and UV resistance. With strong film properties and chemical & heat resistance along with competitive pricing these are preferred coatings for applications like internal automotive parts, under bodies, industrial equipment etc.

Flooring of industrial buildings especially for Chemical, Bulk Drug, Pharmacy, Auto-mobile Industries, Electroplating Plants, Power Plants, Process Floor Areas, Acid Storage Plants where chemical, abrasion resistance is required.

⁍⁍ Epoxy Coating Features:

Highly effective

Excellent gloss

Smooth finish

For further information, please contact to "Angel Coating" on below details;

📧 Mail: [email protected]

📱 Call Us: +91 94290 02704

🌐 Website: https://angelcoating.com/products/industrial-coatings/epoxy-coatings/

0 notes

Text

Customization and Aesthetic Appeal Epoxy Coated Steel Tanks and UASB Reactor Suppliers

In the field of wastewater treatment, the integration of efficient and visually appealing storage solutions is essential. Center Enamel, a leading provider of epoxy coated steel tanks, excels in delivering customized solutions that combine functionality with aesthetic sophistication, specifically tailored for Upflow Anaerobic Sludge Blanket (UASB) reactor applications.

With over 30 years of experience in tank research, production, and construction, Center Enamel, in collaboration with the world-leading paint and coating manufacturer AkzoNobel, has jointly developed the technology of fused epoxy coating. Epoxy coating is an advanced anti-corrosion coating known for its excellent corrosion resistance and adhesion. Additionally, the epoxy coating technology employs a special construction process - electrostatic spraying, which enhances the uniformity and adhesion of the coating, effectively extending the lifespan of the tank.

Tanks coated with epoxy resin using this technology are not only technologically advanced and cost-effective but also easy and quick to install. The quality meets requirements such as AWWA D103-09 and ISO 9227/ASTM B117. Upon its introduction, it has gained recognition from customers.

Properties of Epoxy coated steel tank

Application

Test Standard

Result

Coating Color

Standard RAL 5015 sky blue

Other colors are available

Dry Film Thickness

Average Dry Thickness

5~10 miles /125 ~250 microns(internal)

5~10 miles /125 ~250 microns(epoxy primer+ topcoat)

Holiday Test

≥1100V (all panels)

Zero-discontinuity at test voltage

Hot water immersion 90 days, 70°

AWWA C550-05

Meets/exceeds standard

Corrosion Resistance

Salt Spray ISO 9227/ASTM B117

Pass

Impact Resistance

ASTM D2794

Pass 160 in-ibs direct & reverse impact

PH Range

3~12

Abrasion Resistance

Adhesion ASTM D3359

Adhesion ASTM D3359

Hardness

ISO15184 / ASTM D3363

2H

Chemical Immersion test

50% NaOH, 50% H2S04

Meets/exceeds industry standard

UV Resistance

outdoor exposure testing

5 years

Color Stability

outdoor exposure testing

5 years

Tailored Solutions for UASB Reactors

Precision Engineering and Customization

Center Enamel specializes in designing epoxy coated steel tanks that are meticulously tailored to meet the precise specifications of UASB reactors. Our tanks are available in a variety of sizes, configurations, and specialized fittings, ensuring seamless integration and optimized performance within wastewater treatment facilities. This customization capability allows us to address the unique requirements of each project, supporting enhanced operational efficiency and reliability.

Advanced Epoxy Coating Technology

Our epoxy coated steel tanks are fortified with advanced coating technology, providing exceptional corrosion resistance and durability. This robust protection ensures prolonged operational lifespan and minimal maintenance requirements, crucial for the rigorous demands of UASB reactor environments. Compliant with international standards such as ISO 28765:2016 and AWWA D103-19, our tanks uphold superior performance and environmental stewardship.

Aesthetic Appeal and Design Flexibility

Enhancing Facility Aesthetics

Beyond functionality, Center Enamel’s epoxy coated steel tanks are designed to enhance the visual appeal of wastewater treatment facilities. The smooth finish and sleek design of our tanks contribute to a professional and modern aesthetic, making them ideal for installations in urban or public settings where aesthetics matter.

Color Customization Options

We offer a range of color customization options for our epoxy coated steel tanks, allowing clients to align their storage solutions with corporate branding or environmental surroundings. This flexibility in design ensures that our tanks not only perform exceptionally but also seamlessly blend into their surroundings, enhancing overall facility aesthetics while maintaining structural integrity.

Quality Assurance and Sustainability

Rigorous Quality Control

Every epoxy coated steel tank undergoes rigorous quality control measures, including 100% factory testing and precise inspections. This meticulous process guarantees that each tank meets the highest standards of quality, safety, and performance, providing peace of mind to our clients and stakeholders.

Environmental Responsibility

At Center Enamel, we prioritize environmental sustainability in all aspects of our operations. Our epoxy coated steel tanks are manufactured using eco-friendly materials and processes that comply with stringent environmental regulations. By reducing the environmental footprint of our products, we help our clients achieve their sustainability goals while contributing to a cleaner and healthier planet.

Center Enamel’s epoxy coated steel tanks for UASB reactors epitomize excellence in customization, aesthetic appeal, and functional reliability. With decades of industry expertise, adherence to international standards, and a commitment to innovation, we are the preferred partner for wastewater treatment facilities worldwide. Choose Center Enamel for your UASB reactor projects and experience unmatched quality, customization, and aesthetic sophistication in wastewater storage solutions.

Center Enamel’s epoxy-coated steel tanks represent the pinnacle of environmental sustainability and safety in biogas storage solutions. With advanced coating technology, stringent quality standards, and a commitment to environmental responsibility, our tanks ensure reliable and efficient biogas storage while supporting global efforts towards sustainability and climate action.

Center Enamel combines the excellent performance of various tanks to provide customers with solutions composed of diverse equipment combinations. This approach allows us to flexibly meet the needs and requirements of different application fields. Throughout the project construction process, the teams at Center Enamel collaborate closely, actively coordinate, and prioritize each step, conducting rigorous checks at every level to ensure the smooth completion of projects.

From being a leader in the Asian GFS tank industry to becoming a diversified environmental equipment smart manufacturer in China, Center Enamel utilizes crucial core technologies to continuously iterate and upgrade equipment in research and development. This drives the sustained high-quality development of the company in the face of new challenges. Leveraging existing brand advantages, technological strengths, and team capabilities, the company will continue to focus on cutting-edge industry technologies. Adhering to a diversified development strategy, Center Enamel aims to elevate environmental business to new heights while jointly creating a beautiful picture of green hills and clear waters.

Contact us today to discover how our epoxy coated steel tanks can elevate your wastewater treatment operations with tailored solutions that exceed expectations and enhance facility aesthetics.

0 notes

Text

Paint Supplier in Qatar | Lulu Rayyan Group W.L.L

Are you looking to add vibrancy to your living space or revamp your office environment? Welcome to Lulu Rayyan Group Building Material Suppliers, your trusted paint provider in Qatar!

At Lulu Rayyan, we understand the significance of quality paint in elevating any space. Whether you’re a homeowner, contractor, or business owner, we offer tailored paint solutions to meet your requirements.

Why Choose Lulu Rayyan as Your Paint Supplier in Qatar?

Extensive Range of Premium Brands: We offer a diverse selection of premium paints, including renowned brands like Jotun, Decorative paints, MCI paints, and Epoxy paints, available in various colors, finishes, and compositions. Whether you need interior or exterior paints, primers, or specialty coatings, we have you covered.

High-Quality Products: Our paints are sourced from respected manufacturers known for their durability and resilience. When you choose Lulu Rayyan, you’re investing in paint that withstands Qatar’s harsh environmental conditions.

Expert Guidance: Need more certainty about the right paint for your project? Our knowledgeable staff is here to assist you! Whether you need advice on color selection, surface preparation, or application techniques, we’re dedicated to providing you with the support you need for outstanding results.

Convenient Ordering: Ordering from Lulu Rayyan is seamless. Visit our showroom or place your order online, and we’ll ensure prompt delivery to your doorstep anywhere in Qatar.

Competitive Pricing: Quality paint should be affordable. That’s why we offer competitive pricing without compromising on quality. With Lulu Rayyan, you can enhance your space without exceeding your budget.

Versatile Solutions with Jotun Paints:

Protection: Jotun paints protect against weathering, corrosion, and abrasion, making them ideal for marine, oil/gas, and construction sectors.

Decoration: With a wide color range, Jotun paints enhance interior and exterior aesthetics in residential, commercial, and industrial spaces.

Specialization: Jotun offers tailored coatings such as fire-resistant, anti-graffiti, and chemical-resistant variants for diverse industries.

Transform Your Spaces Today with Lulu Rayyan!

Lulu Rayyan Group Building Material Suppliers is your premier paint supplier in Qatar, whether you’re renovating your home, refreshing a commercial facility, or completing a new project.

Discover how quality paint from brands like Jotun, Decorative paints, MCI paints, and Epoxy paints can enhance the aesthetic appeal and durability of your spaces. Contact us today to explore our diverse paint products and embark on your journey to a more vibrant and inviting atmosphere.

#google.com#branding#Qatar.com#business#ecommerce#investing#founder#accounting#finance#economy#commercial#entrepreneur

0 notes

Text

SBL Specialty Coatings is a leading industrial coatings manufacturer and supplier in India. SBL Specialty Coatings offers a wide range of products, such as epoxy primers, electrophoretic coatings, polyurethane coatings, antimicrobial coating spray, UV rubber coatings, and more..SBL Specialty Coatings uses Swiss technology and has state-of-the-art manufacturing plants in Derabassi (Punjab). SBL Specialty Coatings is a 100% subsidiary of Berger Paints India Limited, one of the largest paint companies in the world. For More Detail Call at +91.1762.522101, 522104, 522107 Or Visit our Site: https://www.sblcoatings.com

0 notes

Text

What Automotive Paint Supplies Are Needed For DIY Car Painting?

The most common mistake that DIY enthusiasts make is that they start assuming that car painting is easy. They think they just need good quality car paint and use it to give the vehicle a more refreshing look. But this is far from the fact, as a huge range of auto paint supplies and accessories is needed to succeed in DIY car painting projects. This article covers the most essential accessories and supplies needed for DIY car painting. But first, let us quickly go through the steps of car painting in this small list.

WHAT STEPS ARE INVOLVED IN DIY CAR PAINTING?

A quick review of the steps of DIY car painting is presented here.

• Choose A Safe Location To Paint

• Do Some Deconstruction

• Treat The Surface

• Sand

• Remove rust

• Prime The Surface

• Apply Masking

• Wipe The Surface Clean

• Apply Paint

• Sand Again And Lacquer

WHAT SUPPLIES ARE NEEDED?

• Orbital sander

• Air compressor

• Abrasives (sanding sheets for hand sanding & sanding discs for orbital sanding)

• Paint sprayer

• Cleaning solvent and rags

• Masking tape

• Primer (epoxy, etching, or surfacer)

• Sealer

• Grease and wax remover

• Tack wipe

• Paint thinner

• Polyurethane Paint, enamel, or acrylic enamel

• Face mask and safety glasses

Let us briefly explain the most common accessories and auto paint supplies needed for DIY car painting.

THE PAINT

Experts recommend choosing the product from one system only. This will ensure that everything is designed to work together, and you will need sufficient quantity for primers to finish.

HOW MUCH PAINT WILL BE NEEDED TO PAINT A CAR?

A lot of variables come into consideration when choosing the right volume. Your first thought would be to ensure that no paint is left behind and you don't run out of the paint in the middle of the paint job.

The best idea here is to get some guidance from the supplier of automotive paint supplies in Sydney. These people are professionals and understand your needs, and based on your vehicle's model, they will usually suggest the right amount of Paint for DIY car painting projects.

WHAT KIND OF PAINT AND PRIMER SHOULD I USE?

Paint systems are of two types, and the names are single stage and base coat. The difference is of the products and processes used in these types. If done by professionals, both will generate great results.

WHAT IS A SINGLE-STAGE SYSTEM?

The process starts by removing the rust or loosening it. Then, the body and filler work is finished, and the bare metal is treated with a phosphoric acid metal conditioner. The experts then apply epoxy primer just over the bare metal, and once dry, it is sanded. Then, the body filler can also be used over the epoxy primer, and once done, urethane paint can be applied directly over the layer of primer.

THE BASE COAT SYSTEM

The first step in this process is rust removal or loosening it and then applying body filler wherever needed. Experts then recommend using acid etching primer wet on wet. Once the primer dries, it's time to sand the body to remove imperfections. Now it's time to apply the base coat over the sanded primer and then urethane clear coat paint for better results.

WHAT KIND OF PAINT GUN SHOULD BE INCLUDED IN THE AUTOMOTIVE PAINT SUPPLIES LIST?

Without including the right paint gun in the list of automotive paint supplies in Sydney, there is no chance of painting the car successfully and perfectly. Spray paint guns are available in different types, like gravity feed guns, siphon feed guns, and pressure feed guns, and you will have to understand them to choose the best one for you. Experts recommend going with HVLP paint guns of any type, and HVLP stands for HIGH VOLUME LOW PRESSURE. The benefit is that they create less overspraying and allow you to apply a perfect coat on the vehicle's body. These High Volume Low Pressure guns come with a downside as well that they use more Cubic Feet Per Minute of your air compressor compared to non-HVLP guns.

Learn More:

Common Automotive Paint Application Processes and Their Details

Problems Faced In DIY Car Painting and Their Solutions

0 notes

Text

What are the painting methods to prevent iron from rusting? - Trywonderx

At Trywonderx, we specialize in providing painting methods to prevent iron from rusting. We have extensive knowledge and experience when it comes to the Painting Iron to Prevent Rusting and the prevention of rusting over time. Our products and services are always of the highest quality and our commitment to providing a lasting solution to iron rust is something that has made us an industry leader. We are proud of the service we provide and guarantee the best results for our customers every time.

One of the most common methods to prevent iron from rusting is to apply a coating of paint. The paint creates a physical barrier between the iron and the surrounding air and moisture, preventing the iron from coming into contact with oxygen and water, which are necessary for the rusting process to occur.

There are different types of paint that can be used for this purpose, such as oil-based paints, epoxy paints, and zinc-rich paints. Each type has its advantages and disadvantages, and the choice will depend on the specific needs of the application.

Other Painting Iron to Prevent Rusting methods that can help prevent rusting include using a primer before applying the paint, as this can provide additional protection against moisture. Additionally, regular maintenance and touch-ups to the paint coating can help ensure its longevity and effectiveness in preventing rust.

It's worth noting that while Painting Iron to Prevent Rusting is an effective method for preventing rust, it's not always a permanent solution. Over time, paint coatings can wear down or become damaged, which can allow moisture and oxygen to reach the iron and lead to rusting. Therefore, it's important to monitor the condition of painted surfaces and perform maintenance as necessary to ensure their continued protection.

How to apply: Technique tips and tricks

Applying paint to prevent rust requires careful preparation and application techniques to ensure the coating is effective and long-lasting. Here are some tips and tricks for applying paint to prevent rust:

Surface preparation: Before applying any paint, it's important to prepare the surface by removing any existing rust, dirt, oil, or other contaminants that may prevent the paint from adhering properly. This can be done using a wire brush, sandpaper, or a chemical rust remover. Once the surface is clean, dry, and free of debris, it's ready for painting.

Choose the right paint: There are different types of paint available for preventing rust, and it's important to choose the right one for the specific application. Oil-based paints are commonly used for outdoor surfaces, while epoxy and zinc-rich paints are often used in harsher environments or for industrial applications. Consult with a paint supplier or expert if you're unsure which type of paint is best for your needs.

Apply a primer: Applying a primer before the paint can help improve the adhesion and longevity of the paint coating. The primer can also provide additional protection against moisture and rust. Choose a primer that's compatible with the paint you're using and apply it according to the manufacturer's instructions.

Apply the paint: When applying the paint, use a brush, roller, or spray gun, depending on the size and shape of the surface. Apply thin, even coats, and allow each coat to dry completely before applying the next. This will help ensure that the paint coating is uniform and provides complete coverage.

Touch-ups and maintenance: Even with the best preparation and application techniques, paint coatings can become damaged over time. Regular maintenance and touch-ups can help prolong the life of the paint and prevent rust from forming. Keep an eye out for any areas where the paint has chipped or worn away and apply a fresh coat of paint as necessary.

By following these tips and tricks, you can help ensure that your painted surfaces remain rust-free and protected for years to come.

Conclusion:

In conclusion,we would like to remind readers that proper Painting Iron to Prevent Rusting methods can help prevent rust and keep your iron looking its best. Contact Trywonderx today to learn more about our painting services!

Contact - [email protected]

Phone Number: 020 - 2606 1530Location: Suprabha Corporate House,

373, Somwar Peth, Pune - 411 001, India

#Painting Iron to Prevent Rusting#rust remover spray#rust remover spray for cars#rust off spray#best way to remove rust on metal#black rust prevention paint

0 notes

Link

#pool paint perth#pool paint#epoxy pool paint#swimming pool paint#pool painting perth#fibreglass pool paint#epoxy pool paint perth#pool epoxy paint#epoxy pool coating#bg pool paint#concrete pool paint#pool paint epoxy#pool resurfacing paint#swimming pool paint suppliers#pool painting#epoxy paint for pools#pool primer#bg pool#epoxy swimming pool paint#polyurethane pool paint#pool epoxy paint near me#epoxy pool paint near me#pool paint suppliers near me#epoxy pool paint for fiberglass#pool.paint#acrylic pool paint#pool primer paint#epoxy pool.paint#pool paint for fibreglass pools#epoxy paint

0 notes

Text

Epoxy Flooring Faridabad

Epoxy flooring is becoming increasingly popular in Faridabad, as more and more businesses are discovering the many benefits of this durable, low-maintenance flooring option. If you're considering epoxy flooring for your Faridabad-based business, here's what you need to know.

First, it's important to choose the right epoxy flooring product for your specific needs. There are many different types of epoxy flooring available, each with different properties and intended uses. For example, some epoxy flooring products are designed for high traffic areas, while others are better suited for areas where chemical spills are likely to occur. Working with a reputable epoxy flooring supplier can help you determine which product is best for your needs.

Once you've chosen your epoxy flooring product, it's time to prepare the surface for installation. This typically involves cleaning the surface thoroughly to remove any dirt, debris, or contaminants that may prevent the epoxy from adhering properly. Depending on the condition of the surface, you may also need to repair any cracks or other damage before proceeding with the installation.

Next, the epoxy flooring will be mixed and applied to the surface. The installation process typically involves several steps, including applying a primer, base coat, and top coat. The exact process may vary depending on the specific epoxy flooring product being used.

After the epoxy flooring has been installed, it's important to follow the manufacturer's instructions for curing and maintenance. Depending on the product, the curing process may take several days, during which time the surface should not be subjected to heavy traffic or other stresses.

One of the great benefits of epoxy flooring is its durability and low maintenance requirements. With regular cleaning and maintenance, your epoxy flooring can last for many years and continue to look great. Plus, epoxy flooring is resistant to spills, stains, and damage from heavy equipment, making it a great investment for businesses in Faridabad.

Overall, epoxy flooring is a great choice for businesses in Faridabad looking to improve the durability and aesthetic appeal of their facilities. By choosing the right product and working with a reputable installer, you can enjoy the benefits of epoxy flooring for many years to come.

1 note

·

View note

Text

Ahlinya Branding Lapangan Futsal KFI Sport KUALITAS TERJAMIN, Hub: 0813-1888-3437

Kami adalah Perusahaan Ahlinya Branding Lapangan Futsal yang melayani Jasa Pengecatan Lapangan Badminton, Pengecatan Lapangan Badminton, Jasa Pengecatan Lantai Lapangan, Jasa Pengecatan Lapangan, Branding Lapangan Sekolah

ALASAN KENAPA ANDA HARUS MEMILIH KONTRAKTOR FUTSAL INDONESIA

1. Kualitas Terjamin

Kami hanya menggunakan karpet dengan kualitas nomor 1, yang sudah teruji selama bertahun tahun. selain itu kami produksi langsung dari pabrik kita sendiri dan pastinya terjamin.

2. Harga Terjangkau

Harga karpet yang cukup terjangkau, namun kami tetap memberikan kualitas yang terbaik pada kelasnya. karena produksi yang besar besaran dari pabrik kami.

3. Berpengalaman

Tim kami sudah berpengalaman mengerjakan ratusan lapangan badminton, futsal , voli ke seluruh kota daerah Indonesia.

4. Tim Profesional

Kami memiliki tim terbaik dengan SOP kualitas pengerjaan dan pelayanan yang tidak akan meragukan lagi.

5. Produk Bersertifikat

Kualitas bahan yang kami gunakan sudah terjamin dan tersertifikasi oleh BWF (Badminton World Federation). serta telah teruji.

6. Banyak Instansi Percaya

Banyak instansi negeri maupun swasta yang sudah mempercayakan pembuatan lapangan kepada tim kami.

Jadi bagi anda yang ingin memperbaharui dan ingin membuat lapangan olahraga baru solusi yang tepat ialah dengan memakai jasa dari Kontraktor Futsal Indonesia.

Tunggu apa lagi hubungi kami sekarang juga untuk mendapatkan promo paket spesial menarik dan hadiah hadiah menarik.

Jika anda tertarik bisa menghubungi customer service kami dengan mengklik tombol whatsapp dibawah ini.

https://wa/me/6281318883437

Daftar Isi:

"Apakah itu cat epoxy Primer?

Epoxy primer sebagai cat susunan dasar supaya tunda atau perlambat proses korosi. Selainnya perlambat proses korosi, peranan yang lain untuk tutupi pori-pori, gempil, rengat dan guratan pada permukaan substrat. Umumnya dipakai untuk melapis dempul."

"Berapakah ketebalan epoxy lantai?

Secara umum, standar ketebalan epoxy lantai sekitar di antara 300-500 mikron dan 1-2 mm saja."

"Epoxy 1 dus isi berapakah?

Dextone - Lem Epoxy 2 in 1 - 1 Dus isi 12."

"Berapakah tebaran cat per kg?

Rerata besarnya daya tebar cat 7-10m2 per kg. Kita mengambil 10m2 agar gampang dihitung. Rerata berat 1 kaleng cat 5 kg."

"Apa cat akrilik akan luntur bila terserang air?

ACRYLIC VS WATERCOLOR

Cat acrylic water resistant (tidak gampang luntur) sesudah kering dibanding cat air. Warna cat acrylic lebih kelihatan kompak bila dibanding dengan cat air (lebih transparant)."

"Apakah yang dimaksud dengan pengecatan?

Pengecatan ialah sebuah proses untuk membikin susunan cat tipis (cair atau bubuk) di atas sebuah tempat dan membuat susunan cat ini mengeras dengan mengeringkannya."

Berapa lama ketahanan cat epoxy?

Di sisi lain, pelapis lantai epoxy memiliki ketahanan selama beberapa tahun lamanya. Sistem pelapisan ini tahan lama, tahan terhadap abrasi, bahkan di area yang lalu lintasnya padat, serta juga tahan bahan kimia.

Mau tau? Contoh RAB Pengecatan Lapangan Basket

Untuk Pemesanan Bisa Hubungi Kami Di No : WA 0813-1888-3437

Yuk Tonton Video Tentang:

- Jasa Cat Lapangan Olahraga Bekasi

- Pengecatan Lapangan Voli

- Pengecatan Lapangan Basket

- Pengecatan Lapangan Futsal

- Pengecatan Lapangan Badminton

- Jasa Pengecatan Lapangan Tenis

- Jasa Pengecatan Lapangan

- Jasa Cat Lapangan Murah

- Branding Lapangan Basket

- Pengecatan Lapangan Volly

- Pengecatan Lapangan Sekolah

Sumber;

0 notes

Text

Spesialis Pengecatan Lapangan Bulu Tangkis KFI Sport HARGA MULAI Rp 45.500/ Meter, Hub: 0813-1888-3437

Kami adalah Perusahaan Spesialis Pengecatan Lapangan Bulu Tangkis yang melayani Jasa Cat Lapangan Yang Paling Bagus, Jasa Cat Lapangan Futsal Bekasi, Pengecatan Lapangan Tenis, Jasa Cat Lapangan Voli Outdoor, Jasa Cat Lapangan Sekolah

ALASAN KENAPA ANDA HARUS MEMILIH KONTRAKTOR FUTSAL INDONESIA

1. Kualitas Terjamin

Kami hanya menggunakan karpet dengan kualitas nomor 1, yang sudah teruji selama bertahun tahun. selain itu kami produksi langsung dari pabrik kita sendiri dan pastinya terjamin.

2. Harga Terjangkau

Harga karpet yang cukup terjangkau, namun kami tetap memberikan kualitas yang terbaik pada kelasnya. karena produksi yang besar besaran dari pabrik kami.

3. Berpengalaman

Tim kami sudah berpengalaman mengerjakan ratusan lapangan badminton, futsal , voli ke seluruh kota daerah Indonesia.

4. Tim Profesional

Kami memiliki tim terbaik dengan SOP kualitas pengerjaan dan pelayanan yang tidak akan meragukan lagi.

5. Produk Bersertifikat

Kualitas bahan yang kami gunakan sudah terjamin dan tersertifikasi oleh BWF (Badminton World Federation). serta telah teruji.

6. Banyak Instansi Percaya

Banyak instansi negeri maupun swasta yang sudah mempercayakan pembuatan lapangan kepada tim kami.

Jadi bagi anda yang ingin memperbaharui dan ingin membuat lapangan olahraga baru solusi yang tepat ialah dengan memakai jasa dari Kontraktor Futsal Indonesia.

Tunggu apa lagi hubungi kami sekarang juga untuk mendapatkan promo paket spesial menarik dan hadiah hadiah menarik.

Jika anda tertarik bisa menghubungi customer service kami dengan mengklik tombol whatsapp dibawah ini.

https://wa/me/6281318883437

Daftar Isi:

"Apa epoxy Aman?

Epoxy ialah variasi resin terbanyak digunakan karena waktu bikin dan pengeringannya benar-benar singkat. Resin ini dibuat berbahan epoxy yang aman dipakai dan tidak beracun jika terisap oleh Anda."

"Apa cat epoxy tahan panas?

Ya, Cat Epoxy tajan akan panas karena cat eposy bisa dipakai di media baja, beton, dengan suhu s/d 1200 derajat celcius, seperti pipa buangan mesin bermotor, cerobong, dan lain-lain."

"Apa bahan cat yang cepat mengeras saat kering?

Tipe cat yang saat kering akan memilki karakter cepat jadi keras ialah cat akrilik."

"Apa cat epoxy tahan terhadap air?

Benar-benar pas untuk diterapkan pada tempat atau substrat yang membutuhkan tingkat kebersihan, kehigienisan yang tinggi dan tahan terhadap air. Tingkatan Program : Membersihkan permukaan substrat dari debu, minyak atau kotoran yang lain. Yakinkan permukaan substrat kering dan bersih saat sebelum diaplikasi."

"Apa alkali sealer?

3-IN-1 ANTI-ALKALI PRIMER SEALER ialah cat emulsi berkualitas tinggi dengan pangkalan styrene akrilik. Produk ini digunakan sebagai cat dasar untuk kurangi peresapan air dan uap air pada permukaan alkali, membuat perlindungan dari jamur, kerusakan pada beton dan peralihan warna."

"Di bawah ini beberapa langkah mengecat permukaan lantai dengan epoxy:

1. Penyiapan Permukaan Lantai.

2. Pembersihan Lantai dari Debu.

3. Lapisanan Lantai dengan Cat Primer.

4. Penerapan Susunan Pertama Cat Epoxy.

5. Mengimplementasikan Cat Epoxy dengan Roller.

6. Mengimplementasikan Susunan Paling akhir."

"Ketahui keperluan berapakah liter cat per mtr. persegi?

Standarnya, 1 ltr cat dapat digunakan untuk luasan 10-12 m² untuk satu susunan. Bila luas dinding yang hendak dicat ialah 40,4 m² seperti pada atas, kita memerlukan 3,5-4 liter cat untuk satu lapis."

Mau tau? Rab Pengecatan Lapangan

Untuk Pemesanan Bisa Hubungi Kami Di No : 0813.1888.3437

Yuk Tonton Video Tentang:

- Jasa Pengecatan Lantai Lapangan

- Jasa Cat Lapangan Basket

- Jasa Cat Lapangan Futsal Outdoor

- Jasa Cat Lapangan Murah

- Jasa Pengecatan Lapangan Badminton

- Jasa Pengecatan Lapangan

- Branding Lapangan Badminton

- Jasa Pengecatan Lapangan Basket

- Pengecatan Lapangan Voli

- Jasa Cat Lapangan Voli Outdoor

- Jasa Cat Lapangan Yang Paling Bagus

Sumber:

0 notes

Text

Epoxy Coatings, Epoxy Coatings for Wood Manufacturer in Ahmedabad

Buy Epoxy Coating, Epoxy Primer Best Price At Ahmedabad By Angel Coating. We are Top Leading Epoxy Coating, Epoxy Primer, Epoxy Pigmented Manufacturer in Ahmedabad & Supplier All Over PAN India.

Read More: https://angelcoating.com/products/industrial-coatings/epoxy-coatings/

#Epoxy Coatings#Epoxy Coating#Epoxy Coatings for Wood#Epoxy Coatings Manufacturer#Industrial Epoxy Coating

1 note

·

View note

Text

Do you need to prime epoxy before painting over it?

Epoxy is a type of adhesive that is often used as a coating or sealant for various surfaces. When painting over epoxy, it is generally recommended to prime the surface first to ensure proper adhesion of the paint. This is because epoxy is a non-porous material and paint may not adhere properly to it without proper surface preparation.

Priming the epoxy surface before painting can also help to fill any imperfections or gaps in the epoxy surface, making it smoother and more uniform, which can lead to a better finished paint job. Epoxy primer is a good option for priming epoxy surfaces, as it is specifically formulated to adhere to epoxy surfaces.

It's also important to note that if the epoxy is still curing or if it's not fully cured, it's not recommended to paint over it as the paint may not adhere properly. It's recommended to wait the curing time of the epoxy before painting.

Additionally, the surface should be clean and dry before applying primer, any dust or debris on the surface can affect the adhesion and final finish of the paint.

Best Adhesives Manufacture and Supplier Company in India: KoffClub India

0 notes