#Rack And Pinion Drive System

Explore tagged Tumblr posts

Text

Maximize your warehouse space with pallet racks. Pallet Racking offers efficient, economical use of floor space and unused over head space.

#pallet racking#pallet shuttle system#pallet rack warehouse & supply#pallet rack warehouse#rack and pinion drive system

0 notes

Text

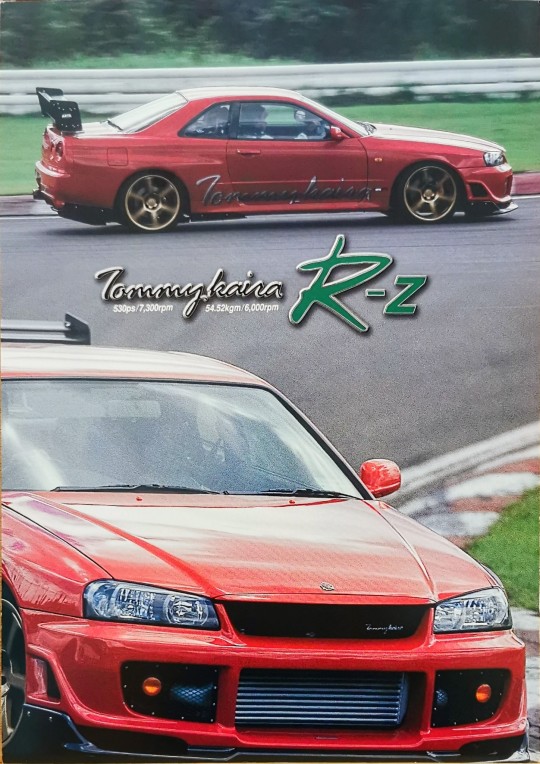

Tommykaira R-z brochure translation.

The wonders of Tommykaira Magic that you can experience while driving. R

Total balance with a high degree of perfection commensurate with 530ps.

The displacement has been increased to 2700cc, achieving a maximum output of 530 horsepower and a maximum torque of 54.52kgm. To achieve this, various types of tuning have been applied. For example, the crankshaft, which is the most important element for bringing out the best performance of the engine, is an original crankshaft manufactured by Fandon in the UK. Highly rigid full counter type provides excellent balance performance. Furthermore, the R-z uses an H-section connecting rod and forged aluminum piston, making it both highly rigid and lightweight. What's more, it achieves well-balanced tuning. In addition, the R-z uses metal head gaskets, high-lift camshafts, valve springs, and racing plugs to bring out the best in the pistons, connecting rods, and crankshafts that are the main moving parts. Composite Radiator Improves cooling effect by using NI water pump.

I got it.

Changes to the intake and exhaust system have resulted in a significant increase in efficiency through the use of a stainless steel exhaust system with suction from the front pipe and a racing type intercooler. By increasing the size of the fuel system parts and strengthening the drive system, you can enjoy ample torque even when driving at low rpm around town. What's more, the sense of power, extension, and revving at high rpm will captivate anyone sitting in the driver's seat.

suspension tuning is

"High ride comfort and handling"

Balance in Dimensions.” During normal driving

Passenger-friendly ride

While realizing the taste, wine day

It is sharp and has excellent turning performance when turning.

Tomita has achieved this goal and has received rave reviews from many quarters.

It's a magic called Kaira Magic.

The front brake has been strengthened to control the 530 horsepower. Uses AP 6-pot calipers, AP brake rotors, and PFC brake pads. This is a highly reliable braking system that responds precisely to the driver's wishes.

[mechanism]

engine body

・Cylinder head/port polishing

・Cylinder block/boring, internal polishing

・Original crankshaft made in UK Fandon

・Special H section connecting rod

・Special forged piston

・Titanium coated piston ring

・Metal head gasket

・High lift camshaft

・Reinforced valve spring, valve guide

・Racing plug

computer unit

・R-z dedicated computer unit

cooling system

・Large capacity water-cooled oil cooler

Water pump for high speed N1

Intake and exhaust system

・All exhaust system

・Large capacity intercooler

・Special turbine

fuel system

Large capacity air flow meter

large capacity injector

・Large capacity fuel pump

drive system

・Twin plate clutch

Reinforcement parts

・Strut tower bar (with master cylinder stopper)

・Reinforced engine mount

・Enhanced mission mount

[Suspension]

Brake system

・AP 6-pot caliper & rotor (F)

・PFC brake pad

suspension

・Bilstein original shock absorber

・Original spring (F)

Original double spring (R)

tires/wheels

・Forged magnesium cut wheel “PRO R” 9.5×19+22

・DUNLOP FORMULA FM901 275/30ZR19

Reinforcement parts

・Stainless mesh brake hose

・Front tension rod (pillow ball)

* [Exterior] and [Interior] are the same specifications as R-s.

Tommykaira R-Z SPECIFICATION

PRICE ¥10,500,000-

PERFORMANCE

Max Output 530ps/7300rpm

Max Torque 54.52kgm/6000rpm

ENGINE

RB26DETT STRAIGHT-6 DOHC Turbo with multi-cup Intercooler

Piston Displacement: 2700cc

Bore x Stroke: 87.0mm x 75.7mm

BODY

Length: 4620mm

Width: 1785mm

Height: 1335mm

Wheelbase: 2665mm

Tread: Front 1496mm

Rear 1496mm

LAYOUT

4 Wheels Drive

Transmission: 6MT

Brakes:(F) 6 Piston Opposed Type Caliper + Ventilated Disc

Brakes:(R) 2 Piston Opposed Type Caliper + Ventilated Disc

Wheels: 9.5JJX 19 (Front&Rear)

Tire: 275/30ZR19 (Front&Rear)

Suspension : Original Shock absorber + Original Coil Spring

Steering: Rack & Pinion < SUPER HICAS >

*Price is vehicle price delivered at Kyoto store, registration fees and consumption tax not included US specifications, data, etc. are subject to change without notice. *Detailed options, equipment, body color, etc. are based on genuine Nissan. Catalog photos may look different from the actual products as they are printed materials. For inquiries and requests..

TOMITA

dream factory

http://www.tommykaira.com

18 notes

·

View notes

Text

Leading Industrial Coupling Suppliers in Delhi Delivering Precision and Performance

In a time where industries are scaling at an unprecedented pace, and machinery is becoming smarter, faster, and more robust, one critical factor remains unchanged — the need for reliable mechanical power transmission. Behind the high-efficiency machines and automated systems that define modern industry, lie the essential components: gears, couplings, and sprockets.

These components are not just mechanical parts; they are the core of any motion-driven system. As demand increases across sectors such as manufacturing, automotive, mining, construction, and energy, so does the need for high-precision, durable, and adaptable transmission components.

Among the leading names meeting this rising demand is Anant Engineering, recognized as one of the top Industrial Gear Manufacturers in Delhi, Industrial Coupling Manufacturers in Delhi, and Industrial Coupling Exporters in Delhi.

Why High-Performance Transmission Components Are a Priority Today

The shift towards automation, higher load capacities, and continuous operations has placed new demands on industrial components. Mechanical parts must now be delivered:

Consistent power transmission under dynamic loads

Tolerance for misalignment and vibration

Low maintenance with long operational life

Compatibility with high-speed systems and automation

This evolution has made components like helical gears, spur gears, bevel gears, chain couplings, and rack and pinion systems indispensable across various industrial applications. From conveyor systems and material handling to mining, agriculture, and heavy-duty machinery — these parts are the backbone of productivity.

Anant Engineering supports this transformation with a comprehensive range of products that are built to perform under pressure and engineered to exact specifications.

Gears: The Core of Controlled Motion

Gears control the flow and direction of mechanical power by adjusting torque and speed. Premium-quality gears ensure smooth operation, minimal noise, and reliable performance. Depending on the application, different gear types offer unique benefits:

Spur Gears – Simple and effective for parallel shafts

Helical Gears – Smoother and quieter, suited for high-speed use

Bevel Gears – Redirect rotational force between shafts positioned at an angle

Worm Gears – Compact systems for high reduction ratios

Rack and Pinion Gears – Transform rotational movement into straight-line motion

As Industrial Gears Suppliers in Delhi, Anant Engineering manufactures gears with precise tooth profiles, superior surface finish, and optimized performance for long-term reliability.

Couplings: Connecting Motion, Ensuring Continuity

Couplings play a crucial role in joining rotating shafts while compensating for misalignment and damping vibrations. Selecting the proper coupling helps protect equipment and enhance overall system efficiency. A complete lineup of couplings is available from Anant Engineering, featuring:

Gear Couplings – Suited for high torque applications

Chain Couplings – Robust, reliable, and low-maintenance

Pin Bush Couplings – Flexible and widely applicable

Tyre Couplings – Absorb vibration and accommodate misalignment

Rigid Couplings – Ideal for precision-aligned systems

Their versatility and performance have earned Anant Engineering a trusted position among Chain Coupling Suppliers in Delhi and global customers looking for consistent, export-ready quality.

Sprockets: Small Components, Big Impact

Sprockets ensure efficient chain drive motion in systems like conveyors and material handlers. Poorly manufactured sprockets can cause excessive chain wear, misalignment, and downtime. With strong focus on precision and material strength, Anant Engineering delivers sprockets that ensure long-lasting, reliable service in harsh industrial environments.

Export-Ready Manufacturing That Meets Global Expectations

As industries across Asia, the Middle East, and Africa demand better mechanical components, Anant Engineering has positioned itself as a global partner. With its rising stature as a Chain Coupling Exporter in India, the company ensures:

Precision manufacturing using CNC machinery

International-grade raw materials and treatments

Strict quality control and performance testing

On-time delivery and client-specific packaging

Why Choose Anant Engineering

With over three decades of industry experience, Anant Engineering is not just a manufacturer, but a solution provider. Their strengths include:

In-house design and R&D capabilities

Custom-engineered components for specialized applications

A complete portfolio of gears, couplings, and sprockets

Fast response and support for industrial requirements

A strong domestic and international distribution network

This commitment to product integrity and customer satisfaction makes them one of the most dependable Industrial Gear Manufacturers in Delhi and Industrial Coupling Manufacturers in Delhi.

Conclusion

As industries strive for uninterrupted operations, energy efficiency, and mechanical reliability, the importance of high-performance gears, couplings, and sprockets cannot be overstated. These components are fundamental to the functioning of almost every mechanical system.

Anant Engineering continues to meet this demand with precision-crafted products, global reach, and a steadfast commitment to quality. Whether it's for high-torque gear applications, flexible coupling systems, or robust sprockets — industries across sectors trust Anant Engineering to keep their systems running smoothly.

#IndustrialGears#HeavyMachinery#IndustrialCouplings#GearManufacturing#AnantEngineering#IndustrialGearsManufacturersInDelhi#IndustrialCouplingManufacturersInDelhi#ChainCouplingExportersInIndia

0 notes

Text

🚀 Elevate Your Welding Operations with Cubuilt's Medium Duty Column and Boom! 🔧✨

Designed for precision and versatility, our Medium Duty Column and Boom systems are perfect for various applications, including welding pipes, boilers, and pressure vessels.

Key Features:

Robust Design: Built to withstand demanding welding tasks.

Proven Reliability: Ensures consistent performance in every operation.

Versatile Applications: Ideal for medium fabrication and vessel shops.

Smooth Operation: Features a rack and pinion drive for precise vertical and horizontal movements.

Safety First: Equipped with an anti-toppling device for trolley-mounted versions.

Specifications:

Vertical Stroke: From 3,500 mm to 6,000 mm.

Horizontal Stroke: Up to 6,500 mm.

Upgrade your welding processes with Cubuilt's Medium Duty Column and Boom and experience enhanced efficiency and quality.

https://cubuilt.com/products/medium-duty-column-and-boom/

#Cubuilt#WeldingAutomation#ColumnAndBoom#MediumDuty#WeldingSolutions#ManufacturingExcellence#IndustrialEquipment#WeldingTechnology#PrecisionWelding#Automation#FabricationTools#WeldingProcess#HeavyDutyWelding#TurnkeySolutions#EngineeringInnovation#MadeInIndia#WeldingEquipment#AdvancedWelding#WeldingIndustry#StructuralFabrication#MechanicalEngineering#WeldingMachinery#IndustrialMachinery#WeldingAutomationSystems#WeldingHeadManipulator#FabricationEquipment#Sources

0 notes

Text

Tata Winger Staff and Tata Winger Tourist/Staff – Comfortable and Reliable

Tata Winger is a well-known vehicle for passenger transport. It is available in two models – Tata Winger Staff and Tata Winger Tourist/Staff. Both models are designed for comfortable travel and efficient performance. Whether it is for office staff or tourist transportation, these vehicles offer a smooth and reliable experience.

Tata Winger Staff – Ideal for Employee Transport

The Tata Winger Staff has specifically been designed for office personnel transports. It has the accommodation of 12-13 passengers in addition to the driver. Smooth travel within the city is ensured by the 2.2L DICOR engine that produces 100HP power and 200Nm torque.

Better control of the vehicle is provided by front disc brakes and rear drum brakes along with easy handling due to power steering. The ride quality is comfortable and stable because of the McPherson strut front suspension and parabolic leaf spring rear suspension.

The vehicle has extra safety features including ABS. Long distance travel is made easier without the need to refill often due to a 60 liter fuel tank capacity.

Tata Winger Tourist/Staff – Perfect for Passenger Transport

The design of Tata Winger Tourist/Staff is ideal for servicing the transport of both tourists and passengers. For comfort, it has been designed with hi-back seats and is spacious enough to accommodate numerous passengers. Additionally, its 2.2L DICOR engine provides superb power and fuel efficiency at 100 HP and 200 Nm torque.

It also offers improved driving stability on highways, given its wheelbase of 3480 mm. Road shocks are absorbed for smoother passenger journeys by the McPherson strut front suspension and parabolic leaf spring rear suspension. It also grants improved durability aided by the rigid rear axle.

This model's steering system is offered through a power-assisted rack and pinion, which allows for effortless and safe driving, coupled with drum brakes for reliable stopping power.

Conclusion

Both vehicles are outstanding options with regards to the comfort and ease of passenger transport, as the Tata Winger Staff and Tata Winger Tourist/Staff respond seamlessly to that need. For corporate and tourism purposes, these automobiles guarantee economical, safe and smooth travel.

0 notes

Text

The Car Repair Shop in Dubai You Can Rely On

With its high-speed highways, luxury automobiles, and blistering temperatures, Dubai is not known for being pedestrian-friendly. Be it your sedan, SUV, or a high-performance sports car, keeping your vehicle in tiptop shape is crucial to ensure smooth and safe driving. Marshal Auto Care offers you the best car service in Dubai so you can rely on your car to stay in top shape and be on the road. With the latest equipment and industry professionals, we rank among the most reliable names in car repair shops in Dubai.

The Significance of Kit Maintenance in Dubai

The blistering heat, hours of congested traffic, and aggressive driving style in Dubai can be harsh on your car. Regular maintenance and prompt repairs are crucial for these reasons:

• Detects Potential Issues: Regular check-ups detect small problems before they become expensive repairs.

• Helps Improve Safety: Regular car maintenance minimizes the chance of an accident caused by brake failure, a flat tyre, or engine breakdown.

• Enhances Fuel Economy: Maintenance services like engine tuning, oil change, and wheel adjustment lower the gas mileage of the vehicle.

• Helps Your Vehicle To Live Longer: Regular service will help your car to be in top shape for years.

Foregoing important vehicle maintenance may seem like a good way to save money in the short run, but it can cost dearly in the long run via breakdowns and poor vehicle performance.

Comprehensive car repair and services

We provide a wide variety of services at Marshal Auto Care that can keep your car in perfect condition. From an oil change to an engine rebuild, we have the mechanic for you.

1. General Car Service in Dubai

Regular servicing of your car keeps it running smoothly. Our general servicing comprises:

• Oil and filter change

• Top up all fluids

• Cleaning of the air filter and cabin filter

• Brake adjustment and inspection

• Tire pressure & rotation check

2. Engine Diagnostics and Repair

To put it simply, the engine is your car's heart. We can identify any potential engine problems with our state-of-the-art diagnostic equipment. We offer:

• Engine health checks

• Spark plug replacement

• Timing belt

• Fuel injector cleaning

3. Brake Repair and Maintenance

The brakes are one of the most important parts of your vehicle. Our brake services include:

• Brake pad replacement

• Disc and drum inspection

• ABS check

4. Transmission Services and Repair

If the transmission of your car does not work so very well, you might find it very difficult to drive. We provide:

• Transmission fluid change

• Repairs and replacement for clutches

• Gearbox repair

5. Reparación de Suspensiones y Dirección

This helps to prevent bumpy rides caused by low suspension system parts. Our services include:

• Shock absorber replacement

• Steering rack and pinion repair

• Tire alignment and balance

6. Car Air Conditioning Service

Dubai has a hot climate, and air conditioning is a must. We offer:

• AC gas refill

• Compressor repair

• Replace cabin air filter

7. Battery and electrical problems can leave you stranded. We provide:

• Battery health inspection and replacement

• Alternator and starter motor

• Wiring and fuse assessment

8. Complete tyre swap, including alignment and balancing

As with every aspect of the vehicle, having the correct type of tyres fitted, as well as optimal alignment, helps with handling and fuel consumption efficiency. Our specialists provide:

• Rebalancing and rotation of tyres

• Realignment of wheels

• Fitting of new tyres

Why Delegate to Marshal Auto Care?

In principle, any car repair and service workshops in Dubai will tend to make claim ranges. Marshal Auto Care needed to stand out for some reasons:

1. Highly specialized technicians

These are all well-trained and certified professionals and mechanics whose experience cuts across every known model and make of car.

2. Sophisticated diagnostic tools

We have invested in modern technology because we want to guarantee accurate car issue diagnosis and top-notch service delivery.

3. Competitive but honest pricing

Our policy has always been to set prices. What you see is what you get. There are no hidden charges.

4. Service efficiency

People's time is precious—and we operate on this basis in terms of getting your vehicle back on the roads.

5. Customer-focused service

The auto care aims to not only provide the best service but also ensure high-quality repairs and guarantee customer satisfaction after each visit.

Conclusion

Transporting your vehicle to and from places is not as easy as it seems; it requires a lot of investment of time and money on your behalf. We help you maintain your automobile through our regular servicing, tuning, and repair options, which not only save you time but also ensure that your automobile lasts in the long run. Marshall Auto Care has a skilled automotive team whose focus is to service your car to the highest standards in Dubai. You can rest assured that your vehicle will always be ready to hit the road.

Frequently Asked Questions (FAQs)

1. How often should I service my car in Dubai?

We recommend servicing your vehicle every 5,000 to 10,000 kilometres or at least once every half year, depending on what the manufacturer dictates.

2. What is included in a basic car service?

A basic car service should include an oil change, checking the brakes, battery testing, and a top-up of other fluids, as well as an inspection of the tires.

3. How can I tell if my car battery needs to be changed?

If your car has difficulty starting, the battery warning symbol is illuminated, and the headlights are faint, it may be your time to get a new battery.

4. Are emergency car repair services available?

Yes, we provide emergency car repair services in Dubai. For urgent repairs, reach out to us, and we will get to you as soon as possible.

0 notes

Text

What is a Pneumatic Actuator: Optimized Guide for Industrial

What is a Pneumatic Actuator ? Optimized Guide for Industrial Use

A pneumatic actuator (also called a *pneumatic cylinder* or *air actuator*) is a critical device in industrial automation. It converts compressed air energy into mechanical motion to open, close, or adjust valves, enabling precise control of fluid flow in pipelines. Known for reliability, speed, and explosion-proof capabilities, pneumatic actuators are widely used in power plants, chemical processing, oil refineries, and more.

How Do Pneumatic Actuators Work

Pneumatic actuators rely on compressed air to drive pistons or diaphragms, generating linear or rotational motion. When air pressure increases, the force pushes a piston or diaphragm, creating movement that operates connected valves. This mechanism allows quick response times and high torque output, making them ideal for demanding industrial environments.

Types of Pneumatic Actuators

Pneumatic actuators are categorized by motion type, structure, and operation mode. Below are the key types, including spring return, double-acting, and Scotch Yoke pneumatic actuators:

1. By Motion Type

- Linear Actuators: Produce straight-line motion (e.g., push-pull rods for gate valves).

- Angular/Rotary Actuators: Generate rotational motion (e.g., quarter-turn ball or butterfly valves).

2. By Structural Design

- Diaphragm Actuators: Use air pressure to flex a diaphragm, ideal for low-force, high-precision tasks.

- Piston Actuators: Deliver high thrust for large valves or high-pressure systems.

- Rack-and-Pinion Actuators: Convert linear motion into rotation for precise valve control.

- Scotch Yoke Pneumatic Actuators: Utilize a sliding yoke mechanism for high torque in heavy-duty applications (e.g., large ball valves).

3. By Operation Mode

Spring Return Pneumatic Actuator (Single-Acting):

– Uses compressed air to move the piston while a spring provides automatic reset when air supply is cut.

– Two subtypes: *Normally Open* (closes with air, opens without) and *Normally Closed* (opens with air, closes without).

– Ideal for fail-safe applications requiring valve position recovery during power loss.

Double-Acting Pneumatic Actuator:

– Requires air supply to both piston sides for bidirectional movement.

– No spring mechanism; ideal for continuous operations needing frequent valve reversals.

– Offers higher force output compared to spring-return models.

Key Applications of Pneumatic Actuators

Pneumatic actuators excel in industries demanding safety, speed, and durability. Below are their primary use cases:

1. High-Thrust Requirements: Powering large valves in pipelines or pressure systems.

2. Hazardous Environments: Explosion-proof operation in oil refineries, chemical plants, or mining.

3. Rapid Valve Control: Quick-response systems for emergency shutdowns or flow adjustments.

4. Harsh Conditions: Reliable performance in extreme temperatures, humidity, or corrosive settings.

5. Automation Systems: Integration with PLCs for seamless process control.

6. Manual/Auto Switching: Built-in handwheel for manual override during system failures.

Why Choose Pneumatic Actuators

- Fast Response: Immediate reaction to control signals.

- High Reliability: Minimal maintenance with robust construction.

- Explosion Safety: No electrical sparks, suitable for flammable environments.

- Cost-Effective: Lower upfront and operational costs compared to hydraulic/electric alternatives.

Conclusion

Understanding what a pneumatic actuator is and selecting the right type—whether a spring return pneumatic actuator, double-acting actuator, or Scotch Yoke pneumatic actuator—ensures optimal performance in industrial systems. By matching the actuator’s design (linear, rotary, diaphragm, or piston) to your operational needs, you enhance efficiency, safety, and longevity in fluid control applications.

For industries prioritizing precision, durability, and safety, pneumatic actuators remain the go-to solution for valve automation.

0 notes

Text

Essential Vertical Transport Solutions in Construction

In modern construction, efficiency and safety are paramount. As buildings grow taller and construction projects become more complex, reliable vertical transportation systems are necessary to move workers, materials, and equipment efficiently. Several lifting solutions are available in the industry, each designed to serve specific purposes and improve job site productivity. Among these, three key systems stand out: rack and pinion hoist, construction hoist, and mast climbing platform.

Rack and Pinion Hoist

A rack and pinion hoist is an advanced lifting system widely used in construction projects. Unlike traditional wire rope hoists, this system employs a rack and pinion mechanism to ensure smooth and secure vertical movement. The hoist is mounted on a mast, allowing it to travel along the structure with excellent stability. One of the main advantages of this system is its ability to function independently without the need for counterweights, making it a highly efficient and space-saving option for high-rise construction.

Rack and pinion hoists are commonly used for lifting both personnel and materials, offering high-speed operation and enhanced load capacity. These systems are designed with safety features such as emergency brakes, overload sensors, and anti-fall devices to prevent accidents. Additionally, they are ideal for temporary or permanent installations, as they can be easily dismantled and relocated based on project requirements.

Construction Hoist

A construction hoist is an essential piece of equipment for high-rise building projects, offering a reliable means of transporting workers and materials to different floors. These hoists consist of a cage, a mast, and a drive system that ensures vertical movement along a guided track. Construction hoists are available in various configurations, including single and twin-mast designs, to accommodate different load capacities and project needs.

One of the key benefits of using a construction hoist is its ability to significantly reduce manual labor and enhance productivity. Instead of relying on cranes or scaffolding, which can be time-consuming and labor-intensive, construction hoists provide a faster and more efficient way to move heavy loads. These hoists are also equipped with advanced safety features such as interlocking doors, emergency stop buttons, and overload protection to ensure a secure working environment.

Mast Climbing Platform

A mast climbing platform is a versatile solution for accessing various heights in construction and maintenance projects. Unlike traditional scaffolding, mast climbing platforms provide an adjustable working surface that moves up and down a mast structure. This system is particularly useful for facade work, window installation, and masonry projects where precise height adjustment is crucial.

Mast climbing platforms offer several advantages over conventional scaffolding, including increased worker safety, reduced setup time, and enhanced efficiency. They provide a stable and spacious platform for workers and materials, minimizing the risk of falls and improving workflow. Additionally, these platforms are highly customizable and can be adjusted to fit different building structures, making them an excellent choice for projects with unique height requirements.

0 notes

Text

Struggling with Steering Issues? Reliable Steering Wheel Repair in Hamilton, ON

Experiencing difficulty turning or unusual vibrations? Our steering wheel repair Hamilton ON service ensures smooth and safe driving by diagnosing and fixing steering issues promptly. Whether it's a misaligned steering column, a faulty power steering system, or excessive play in the wheel, we use advanced tools to restore control and stability. Steering problems can lead to unsafe driving conditions and increased wear on suspension components.

At Reliance Auto, we provide expert inspections, power steering fluid replacements, rack and pinion repairs, and wheel alignment services to keep your vehicle running at its best. Don’t ignore steering issues—our skilled technicians offer comprehensive repairs to enhance safety and performance. Trust our steering wheel repair Hamilton ON service for precise repairs and lasting results. Book an appointment today for a thorough assessment and expert solutions!

0 notes

Text

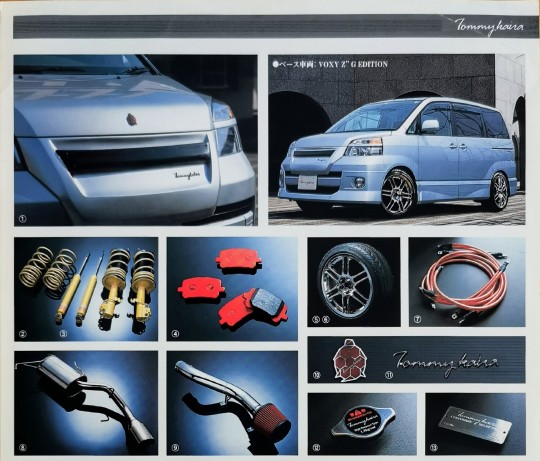

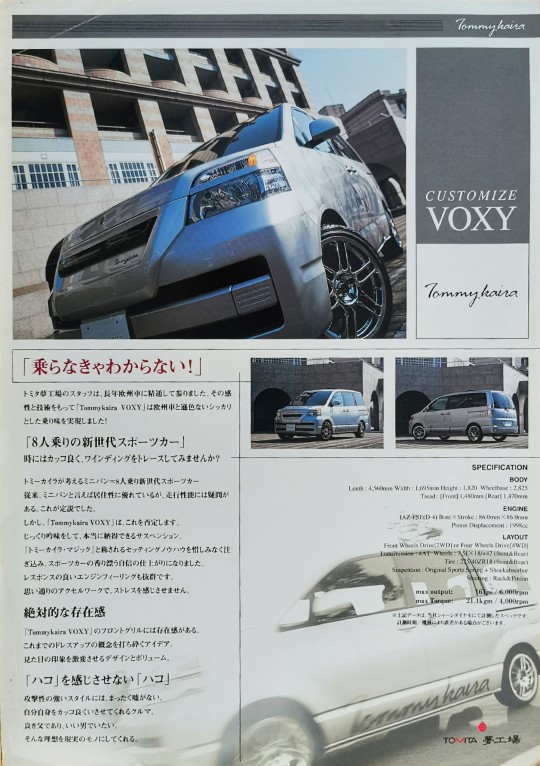

CUSTOMIZE VOXY

Tommykaira

“You won’t know until you ride!”

The staff at Tomita Yume Factory has been familiar with European cars for many years. With that sensibility and technology, the ``Tommykaira VOXY'' has achieved a smooth ride that is on par with European cars!

"A new generation eight-seater sports car"

Why not try tracing the winding tracks for a cool look?

Tommykaira's idea of a minivan: a new generation 8-seater sports car. Traditionally, minivans have been associated with superior comfort, but their driving performance has been questionable. This was the established theory.

However, ``Tommykaira VOXY'' denies this.

After careful consideration, we found a suspension that we were really satisfied with.

The setting know-how known as ``Tommy Kaira Magic'' has been poured into this car, resulting in a confident finish that exudes the scent of a sports car.

The responsive engine feeling is also outstanding.

Accelerator work exactly as you want, so you don't feel stressed.

absolute presence

The front grill of “Tommykaira VOXY” has a strong presence.

An idea that shatters the conventional concept of dress-up.

The design and volume dramatically change the appearance.

A “box” that doesn’t feel like a “box”

There is absolutely nothing wrong with his aggressive style.

A car that makes you feel cool.

I want to be a good father and a good man.

It makes that ideal a reality.

SPECIFICATION

BODY

Lenth: 4,560mm Width: 1,695mm Height: 1,820 Wheelbase: 2,825

Tread: [Front] 1,480mm [Rear] 1,470mm

ENGINE

IAZ-FSE(D-4)

Bore Stroke: 86.0mm×86.0mm

Piston Displacement : 1998cc

max output: 161ps/6,000rpm

max Torque: 21.1kgm / 4,000rpm

LAYOUT

Front Wheels Drive [2WD] or Four Wheels Drive[4WD]

Transmission: 4AT

Wheels: 7.5JX18/+47 (front & Rear)

Tire: 225/40ZR18 (front&Rear)

Suspension: Original Sports Spring + Shock absorber

Steering Rack & Pinion

*The above data are specifications measured using our chassis dynamo. There may be errors depending on the measurement time/model.

TOMITA Dream FactoryTommyKaira Customized Complete Car

¥2,520,000 (VOXY X 2WD base)

CUSTOMIZE VOXY

Tommykaira

①Front grill (painted, with Tommykaira emblem)

¥42,000

②Sports coil spring (25~30mm down)

¥44,000

③ Shock absorber

¥154,000

④ Front brake pad (street specification)

¥15,000

⑤ 18inch wheel (18X7.5J +47) Silver

¥136,000

"Chrome plated finish *Photo shows chrome plated finish

¥172,000

⑥ 18inch tires (225/40ZR18)

120,000¥

⑦ Earthing system

¥22,000

⑧ Muffler (rear piece made entirely of stainless steel)

¥62,000

⑨ Air intake kit (filter + 70 stainless steel)

¥24,000

10 Mascot emblem (Cloisonné)

¥8,000

11Tommykaira emblem

¥5,000

12 Radiator cap (1.3kg/cm)

¥3,600

13 Customized plate

Side decal (see front photo)

¥48,000

*Compatible with genuine colors.

Bring-in tuning/

¥830,000

full kit ① ~ 13 (side decal included, no plate)

¥668,000*

reasonable kit ¥ 559,000

(1+2+3+5+6+8+10+11)

*Does not include installation fees.

www.tommykaira.com

075-464-3311(**)

■All prices do not include options, registration fees, or consumption tax.

TOMITA Dream Factory

■Price Please note that specification data, etc. may change without notice.

9 notes

·

View notes

Text

Aircraft Gears Market Emerging Opportunities and Future Outlook 2024 to 2033

The aviation industry is a complex ecosystem where every component plays a crucial role in ensuring safety, efficiency, and performance. Among these components, aircraft gears are fundamental, serving as the mechanical backbone for various systems, from propulsion to landing mechanisms. This article delves into the current trends, growth drivers, challenges, and future forecasts of the aircraft gears market leading up to 2032.

Market Overview

As of 2023, the global aircraft gears market was valued at approximately USD XX billion. Projections indicate that this market is set to grow to USD XX billion by 2032, representing a compound annual growth rate (CAGR) of XX% during the forecast period from 2024 to 2032.

This growth trajectory is influenced by several factors, including the expansion of global air traffic, technological advancements in gear manufacturing, and the increasing demand for fuel-efficient aircraft.

Download a Free Sample Report:-https://tinyurl.com/2vhzb7en

Key Market Drivers

1. Expansion of Global Air Traffic

The rise in passenger numbers and cargo demand has led to an increase in airline fleets. This expansion necessitates the production of more aircraft, each requiring a complex array of gears for various functions. The surge in air travel, especially in emerging economies, has been a significant contributor to this demand.

2. Technological Advancements

Innovations in materials science and manufacturing processes have led to the development of lighter and more durable gears. The adoption of advanced materials, such as titanium and composite alloys, reduces the overall weight of aircraft, leading to improved fuel efficiency and performance.

3. Emphasis on Fuel Efficiency

With rising fuel costs and environmental concerns, airlines are prioritizing fuel-efficient aircraft. Modern gear systems are designed to optimize engine performance and reduce drag, contributing to overall fuel savings.

Market Segmentation

The aircraft gears market can be segmented based on platform, gear type, application, end-user, and region.

1. By Platform

Commercial Aviation: Dominates the market due to the high number of commercial flights and the continuous expansion of airline fleets.

Military Aviation: Steady demand driven by defense budgets and the need for advanced military aircraft.

2. By Gear Type

Spur Gears: Simple design, used in applications where noise control is not critical.

Bevel Gears: Essential for systems requiring angular gear drives.

Helical Gears: Preferred for their efficiency and quieter operation.

Rack and Pinion Gears: Utilized in control systems and actuators.

3. By Application

Auxiliary Power Units (APUs): Gears that drive secondary power sources.

Actuators: Critical for controlling flight surfaces and landing gear mechanisms.

Pumps: Integral in fuel, hydraulic, and lubrication systems.

Air Conditioning Compressors: Ensure environmental control within the cabin.

4. By End-User

Original Equipment Manufacturers (OEMs): Companies that design and produce aircraft and their components.

Aftermarket: Maintenance, repair, and overhaul (MRO) services that replace or refurbish gear systems.

Regional Analysis

North America: Leading market share attributed to major aircraft manufacturers and a robust aviation industry.

Europe: Significant growth due to technological advancements and the presence of key aerospace companies.

Asia-Pacific: Rapid expansion driven by increasing air travel demand and emerging economies investing in aviation infrastructure.

Rest of the World: Steady growth with investments in aviation sectors in the Middle East and Africa.

Challenges and Restraints

1. High Manufacturing Costs

The precision required in gear manufacturing, coupled with the use of advanced materials, leads to elevated production costs. This factor can be a barrier, especially for smaller manufacturers or emerging markets.

2. Stringent Regulatory Standards

Aviation authorities impose rigorous standards to ensure safety and reliability. Compliance with these regulations necessitates extensive testing and certification processes, which can be time-consuming and costly.

3. Impact of Global Events

Events such as pandemics, geopolitical tensions, and economic downturns can disrupt supply chains and affect demand. The COVID-19 pandemic, for instance, led to a significant decline in air travel, impacting aircraft production and, consequently, the demand for aircraft gears.

Future Outlook

The aircraft gears market is poised for steady growth leading up to 2032. Key trends anticipated to shape the market include:

Integration of Smart Technologies: The adoption of sensors and IoT devices for real-time monitoring of gear performance, enabling predictive maintenance and reducing downtime.

Sustainable Manufacturing Practices: Emphasis on eco-friendly production methods and materials to reduce the environmental footprint.

Customization and Flexibility: Tailoring gear designs to meet specific performance requirements of next-generation aircraft, including electric and hybrid models.

Conclusion

The aircraft gears market is an integral segment of the aerospace industry, underpinning the functionality and safety of aircraft operations. While challenges exist, the confluence of technological innovation, increasing air travel demand, and a focus on sustainability positions the market for robust growth in the coming decade. Stakeholders, including manufacturers, airlines, and regulatory bodies, must collaborate to navigate the evolving landscape and capitalize on emerging opportunities.

Read Full Report:-https://www.uniprismmarketresearch.com/verticals/aerospace-defence/aircraft-gears.html

0 notes

Link

0 notes

Text

Understanding the Mechanics of Rack and Pinion Bellows

The rack and pinion bellows have a significant role in many vehicles. They offer a shielding effect against dirt and moisture for the steering system. Wearing the following components can cause a great amount of trouble. In this blog, the operation principle of rack & pinion bellows, the work of rack & pinion bellows/rack and pinion boot, and the reason they are important to vehicle performance will be discussed.

What Are Rack & Pinion Bellows?

A rack and pinion bellow is an elastic outer cover that is placed over the steering rack. It acts as a shield against contaminants. Bellows are typically constructed of rubber or otherwise robust materials. They protect the steering parts from dirt, dust and moisture. This environment helps ensure the quality of the grease within the steering system. Ambient dirt may intrude without appropriate protection, leading to wear and tear of the components.

How Do Rack & Pinion Bellows Work?

The mechanism of the rack and pinion boot is rather straightforward. When the steering wheel is rotated, the steering rack moves in the direction of the rotation and back. This movement needs to be smooth for proper handling. The bellows offer this motion while still keeping them shielded. Since the components of the steering system move, the bellows expand and contract. This has all been unavoidable in order to preserve the steering system's function.

In addition, the bellows function to lubricate the grease contained in the rack. Grease is vital for reducing friction between moving parts. If dirt/dust enters the system, it can get mixed in with the oil to form sludge. This sludge has the potential to cause increased wear on the rack gears.

Why Are Rack & Pinion Bellows Important?

Rack & pinion bellows are an important safety and performance element of the vehicle. Here are some reasons why they are important:

Protection Against Contaminants: The main job of the bellows is to prevent debris and moisture from entering the steering mechanism. This protection helps ensure that all components remain clean.

Prevention of Wear: By excluding contaminations, a bellows avoids the early wear on the most critical components such as gears and levers.

Smooth Operation: When the whole system is clean and well-lubricated, the steering system moves without any noise. This smooth operation enhances the overall driving experience.

Cost-Effective Maintenance: Repairing or replacing damaged elements comprising the steering mechanism is a much more expensive task than, for example, replacing worn-out bellows. Regular checks can save money in the long run.

Safety: A well-functioning steering system is vital for safe driving. If any element of this system is defective, it may result in the loss of vehicle control.

Common Issues with Rack & Pinion Bellows

Rack & pinion bellows can, over time, suffer from various problems:

Cracking: Rubber can be damaged by heat, ultraviolet (UV) radiation, or chemicals. Once cracked, they lose their ability to protect.

Tears: Mechanical damage by road debris or poor installation leads to tears in material.

Wear: As a person ages, these bellows can be worn down by repeated vibration.

If the following problems occur, they must be dealt with in a timely manner. To avoid them, however, can result in more serious problems of the steering system.

How to Replace Rack & Pinion Bellows?

When wear is detected on the rack & pinion bellows, they must be replaced at once. Here’s a simple guide on how to do it:

Lift the Vehicle: Start by safely lifting your vehicle using jack stands.

Remove Wheels: Remove the front wheel to have easy access to the steering parts.

Remove Old Bellows: Carefully detach the old bellows from both ends of the steering rack.

Install New Bellows: Slide new rack and pinion bellows into place.

Secure Everything: Clamps or ties that tightly confine the ends of the new bellows on both sides.

Reinstall Wheels: Put your wheels back on and lower your vehicle.

Test Drive: After replacing them Go for a short drive in your car to verify that all is functioning properly.

If you’re unsure about doing this yourself, consulting a professional mechanic is always a good idea.

Custom Made Bellows for Unique Applications

There are also cases when standard rack & pinion bellows are not ideal for some applications perfectly. In such cases, custom made bellows become essential. These uniquely configured parts are intended to address special needs that are not available through off-the-shelf components.

Tailorable in bellows size, shape, and material in accordance with specific applications or environmental conditions. For instance, if a vehicle operates in extreme temperatures or harsh environments, custom rubber bellows can be designed to withstand those conditions effectively.

When looking for custom solutions, it’s best to consult with manufacturers who specialize in this area. They can be used in such a way that they can offer very useful information regarding the choice of materials and design requirements best fitted to your requirements.

Choosing Custom Rubber Bellows

At the time of choosing customized rubber bellows for your vehicle or machinery, pay attention to the following:

Material Quality: High-quality materials should be used in the production of customized rubber bellows.

Design Specifications: Discuss your specific requirements with manufacturers so they can create products that meet your needs perfectly.

Manufacturer Reputation: Choose a manufacturer with a solid reputation for producing reliable products.

Cost Considerations: While custom solutions may cost more upfront, they often save money in maintenance over time due to their durability.

Custom Rubber Bellows is a company offering high-quality manufacturing of custom-made bellows to meet a wide range of industry applications. They are concerned with the development of products to give the best possible performance and, at the same time, the best possible protection for the machinery components.

Conclusion

Memorizing what rack and pinion bellows are is important to anybody who cares about maintaining or optimizing a vehicle. In the same way, it is a crucial factor for steering systems to be kept clean of contaminants and thus smooth operation over time and smoother moving objects in general.

Regular checks on these parts can prevent costly repairs down the line while enhancing safety during driving experiences as well as overall satisfaction with vehicle performance. If you find yourself needing replacements or custom solutions tailored specifically for your application needs, consider reaching out to professionals who specialize in manufacturing quality products like Custom Rubber Bellows to ensure you receive exactly what you need for optimal functionality!

For inquiries regarding custom solutions or the following bellow products, please contact Custom Rubber Bellows at (647)294-5240 or [email protected]

0 notes

Text

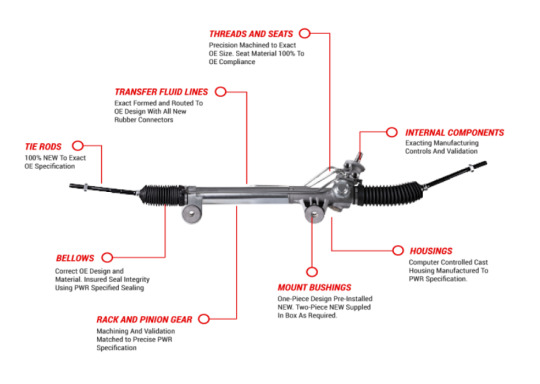

Understanding Power Steering Racks: Function, Signs of Failure & Replacement | Buy from PwrSteer

Everything You Need to Know About Power Steering Racks

The power steering rack is a crucial component of a vehicle’s steering system, converting the rotational movement of the steering wheel into linear motion that turns the wheels. This component, also known as the rack and pinion, plays a vital role in ensuring smooth, controlled, and effortless steering. Without a properly functioning power steering rack, maneuvering a vehicle becomes difficult, leading to poor handling and potential safety risks.

How a Power Steering Rack Works

The power steering rack operates as part of a rack-and-pinion steering system, which is the most common type used in modern vehicles. Here’s how it functions:

When the driver turns the steering wheel, the pinion gear (attached to the steering column) rotates.

This motion moves the rack, a long metal bar with teeth, which shifts left or right to steer the wheels.

In a power-assisted system, hydraulic or electronic assistance reduces the effort required to turn the wheels.

In hydraulic power steering, a power steering pump supplies pressurized fluid to either side of the rack, helping the driver turn the wheel with ease. In electric power steering (EPS) systems, an electric motor provides the necessary assistance instead of hydraulic pressure.

Signs of a Failing Power Steering Rack

Over time, the power steering rack can wear out due to constant use, exposure to harsh conditions, and fluid contamination. Here are some common symptoms of a failing rack-and-pinion system:

Steering Wheel Feels Loose or Unresponsive – If there’s excessive play in the steering, it may indicate worn-out internal components.

Difficulty Turning the Wheel – Increased effort when turning could mean a lack of hydraulic pressure or internal wear.

Leaking Power Steering Fluid – A damaged or worn-out rack can cause leaks, often noticeable as red or brown fluid under the vehicle.

Grinding or Clunking Noises – Strange noises when turning the wheel could point to worn-out gears or bushings.

Uneven Tire Wear – A faulty rack can cause misalignment, leading to excessive and uneven tire wear.

Steering Pulls to One Side – If your vehicle drifts or pulls while driving, the rack may be worn or damaged.

Maintaining and Replacing a Power Steering Rack

Proper maintenance can extend the life of your power steering rack and prevent costly repairs. Here are some key maintenance tips:

Check and Replace Power Steering Fluid – Contaminated or low fluid can accelerate wear and cause internal damage.

Inspect for Leaks – Regularly check under your vehicle for any signs of fluid leaks.

Ensure Proper Wheel Alignment – Misalignment can put extra stress on the rack and lead to premature failure.

If your power steering rack is failing, replacement is necessary to maintain safe and reliable steering. PwrSteer, a trusted online seller, offers high-quality power steering racks for various vehicle models. Their products are performance-tested and durable, ensuring smooth steering operation and long-lasting performance.

Conclusion

The power steering rack is a fundamental part of your vehicle’s steering system, responsible for precise and effortless handling. Recognizing early warning signs of failure and maintaining the system properly can help prevent costly repairs. If you need a reliable power steering rack replacement, check out PwrSteer for high-quality, performance-tested options that ensure a smooth driving experience.

For more info please visit: - https://www.pwrsteer.com/products/rack-and-pinion

0 notes

Text

Automotive Idler Arm Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Automotive Idler Arm Market 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Automotive Idler Arm Market scenario, and feasibility study are the important aspects analyzed in this report.

The Automotive Idler Arm Market is experiencing robust growth driven by the expanding globally. The Automotive Idler Arm Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Automotive Idler Arm Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing.

The global automotive idler arm market size was valued at USD 3.56 billion in 2022. The market is projected to grow from USD 3.68 billion in 2023 to USD 4.85 billion by 2030, exhibiting a 4.0% CAGR during the forecast period.

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/108471

Key Strategies

Key strategies in the Automotive Idler Arm Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Automotive Idler Arm Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Automotive Idler Arm Market.

Major Automotive Idler Arm Market Manufacturers covered in the market report include:

Dorman Products (U.S.)

DRiV Incorporated (Moog) (U.S.)

Masterparts (South Africa)

CJ MANUFACTURING COMPANY LIMITED (Thailand)

Sankei Industries Co, Ltd. (Japan)

Highlink Auto Parts Co., Ltd. (Taiwan)

GMB Corporation Japan (Japan)

Datta Industries (India)

Rare Parts Inc. (U.S.)

Emerson Forge Pvt. Ltd (India)

The increasing adoption of rack and pinion steering linkage systems is a restraining factor for the automotive idler arm sector’s growth.

Trends Analysis

The Automotive Idler Arm Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Automotive Idler Arm Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Automotive Idler Arm Market Solutions.

Regions Included in this Automotive Idler Arm Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Automotive Idler Arm Market.

- Changing the Automotive Idler Arm Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Automotive Idler Arm Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Automotive Idler Arm Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Automotive Idler Arm Market?

► Who are the prominent players in the Global Automotive Idler Arm Market?

► What is the consumer perspective in the Global Automotive Idler Arm Market?

► What are the key demand-side and supply-side trends in the Global Automotive Idler Arm Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Automotive Idler Arm Market?

Table Of Contents:

1 Market Overview

1.1 Automotive Idler Arm Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

0 notes