#RFID asset tracking system

Explore tagged Tumblr posts

Text

RFID asset tracking software

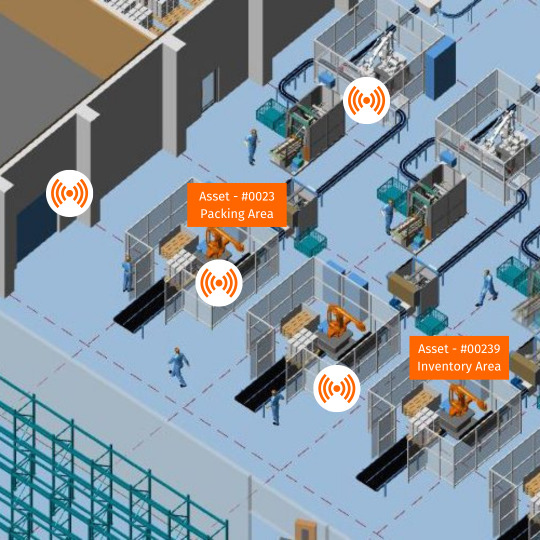

RFID asset tracking software - RFID4U Store India RFID asset tracking software enhances operational efficiency by automating the monitoring and management of assets using RFID technology. It improves inventory accuracy, reduces manual errors, and streamlines asset utilization. By providing real-time data and analytics, it enables businesses to make informed decisions, optimize workflows, and minimize costs. RFID asset tracking software is crucial for industries such as healthcare, manufacturing, logistics, and retail, where efficient asset management is essential for productivity and profitability.

#RFID software#RFID asset tracking system#RFID asset tracking software#RFID inventory tracking software

2 notes

·

View notes

Text

0 notes

Text

Comprehensive Asset Tracking Systems Installation Guide

#Asset Tracking System Installers#asset tracking system#rfid asset tracking system#Asset Tracking Installer near me

0 notes

Text

RFID Asset Tracking Guide - Types of Tags and Costs

Introduction

RFID asset tracking is a highly effective way to monitor and manage assets using small electronic devices called RFID tags. These tags store information and emit radio signals that can be read from a distance.

Moreover, RFID tracker tags are part of an RFID system that includes RFID readers, antennas, and asset management software. This system makes tracking assets across locations efficient, especially in retail, logistics, and fleet management industries.

Types of RFID Tags and Costs

Now, let’s explore the types of RFID tags, what an RFID tag looks like and the cost of RFID tags.

1. Passive RFID Tags

Passive RFID tags do not have an internal power source. They rely on the energy from an RFID reader to function. They are also typically thin, flat, and flexible and are commonly used for RFID in fleet management, retail inventory tracking, and warehouse operations.

The cost of passive RFID tags is usually low, ranging from $0.10 to $5 per tag, depending on the size, material, and quantity ordered.

2. Active RFID Tags

Active RFID tags are equipped with their battery. This allows them to transmit signals independently over longer distances. They also tend to be bulkier and box-like in appearance, often featuring a rigid casing to protect the internal battery and components.

Due to their complexity, active RFID tags are significantly more expensive, typically ranging from $20 to $50 per tag, depending on their features and capabilities.

3. Semi-Passive (Battery-Assisted Passive) RFID Tags

Semi-passive RFID tags comprise a small battery that powers them but are dependent on the RFID reader for data transmission. This type of RFID system provides a middle ground between RFID passive and active systems, offering longer read ranges than passive tags while being more affordable than fully active tags.

The cost of semi-passive RFID tags typically falls between $5 and $20 per tag.

Conclusion

When choosing the proper RFID devices for asset tracking, consider your specific needs. For instance, passive RFID tags are best suited for short-range tracking, whereas active RFID tags are suitable for significant assets like vehicles. Similarly, semi-passive RFID tags provide a balance between cost and performance, with extended range and moderate pricing.

Always consider factors like tag cost, read range, and the type of asset being tracked when choosing the best RFID tracker for your system.

0 notes

Text

How does an RFID asset tracking system work?

RFID asset tracking takes your equipment management, monitoring, and other operations to the next level. If you're looking for a better way to manage your inventory, RFID asset tracking technology can help. The technology collects data about your assets that can be used to optimize asset usage and better manage inventory.

However, before you can use the data you collect, you must have a plan for using it. Otherwise, you will be left with a pile of numbers. But don't worry, with the right use of these systems, you will see a significant improvement in the efficiency of your business.

What is RFID asset tracking?

RFID asset tracking refers to the process by which you document all of your company's physical assets. RFID asset tracking technology automates the manual processes of asset management. It brings significant labor savings. Significantly reduces time, energy, and costs.

Asset tracking RFID technology is a system that your company can implement to gain better control over your critical tools and equipment.

With asset tracking, your company can:

Simultaneous view of the assets you own and their location

Ability to monitor who is responsible for critical assets

Tracking asset movements

Search for lost or misplaced assets

Maximising stock accuracy

All of these features ultimately streamline the day-to-day operations of your business and prevent the loss and theft of assets.

If you want to read further, please visit Smartmakers

0 notes

Text

Industrial Equipment Management with Real-Time Tracking from AssetTrackerIoT

AssetTrackerIoT provides real-time updates for industrial equipment, ensuring quick decision-making. With mobile app access, you can track, manage, and receive alerts for all your fleet assets. Enjoy enhanced security with custom roles and detailed reports. Optimize equipment management today with AssetTrackerIoT.

#assetmanagement#rfid#tracking software#assettracking#tracking system#office asset tracking#rfid technology#asset tracking#rfid tags#assets

0 notes

Text

RFID Labels & The Creation of Smart Cities: A Technical Insight

0 notes

Text

Empowering Businesses Through Cylinder Tracking

Trakaid is a global leader in asset tracking, specializing in providing innovative solutions for cylinder management. Their core product, Cylotrak, is a robust cylinder tracking system that utilizes IoT and GPS technology to offer real-time visibility into cylinder location, usage, and maintenance. By collecting comprehensive data, Cylotrak empowers businesses to optimize cylinder utilization, reduce losses, and enhance operational efficiency. Trakaid’s commitment to customer satisfaction and technological advancement has positioned them as a preferred choice for industries reliant on cylinders. Their solutions are designed to be scalable and adaptable to various business sizes and operational complexities. With a focus on data-driven insights, Trakaid helps clients make informed decisions, improve their bottom line, and contribute to a more sustainable future. Visit Now: https://www.trakaid.com

0 notes

Text

RFID Asset Tracking

RFID asset tracking transforms business operations through advanced wireless identification technology. This innovative solution enables organizations to monitor assets in real-time, streamline inventory management, and enhance operational efficiency. With automated data collection, precise location tracking, and detailed reporting capabilities, RFID systems minimize human error and reduce operational costs. Modern RFID platforms offer seamless integration, scalability, and robust security features to support enterprise-wide asset management needs.

#RFID asset tracking system#RFID asset tracking software#Asset tracking software for enterprise#TagMatiks RFID asset tracking system

0 notes

Text

Physical Verification of Fixed Assets by MASLLP: Ensuring Accuracy and Accountability

For businesses, maintaining an accurate record of fixed assets is crucial for financial reporting, compliance, and operational efficiency. MASLLP, a trusted name in the financial consulting domain, offers expert services for the physical verification of fixed assets, ensuring your business stays organized, compliant, and secure.

What is Physical Verification of Fixed Assets? Physical verification of fixed assets involves systematically checking and validating the existence, condition, and location of assets owned by a business. It is a critical process to:

Identify discrepancies between physical assets and records. Ensure compliance with accounting standards and regulations. Protect against theft, loss, or mismanagement of assets. Why Choose MASLLP for Fixed Asset Verification? MASLLP’s team of experienced professionals ensures a seamless and accurate verification process. Here’s why businesses trust MASLLP:

Comprehensive Asset Audits MASLLP’s experts conduct thorough physical inspections, cross-referencing assets with financial records to identify inconsistencies.

Advanced Tools and Technology Using cutting-edge tools like barcoding, RFID, and asset tracking software, MASLLP ensures precision in the verification process.

Customized Solutions Every business is unique, and MASLLP tailors its asset verification services to align with your organization’s specific needs and objectives.

Compliance Expertise With MASLLP’s expertise in financial regulations, your business stays compliant with statutory requirements and accounting standards.

Key Benefits of Physical Verification by MASLLP Accurate Financial Reporting Eliminate discrepancies in your financial statements by ensuring all assets are accounted for.

Enhanced Asset Management Identify underutilized, misplaced, or obsolete assets to improve efficiency and cost-effectiveness.

Risk Mitigation Reduce the risk of theft, fraud, or mismanagement by maintaining an accurate and up-to-date asset register.

Regulatory Compliance Ensure adherence to legal and accounting standards, avoiding penalties and audits.

MASLLP’s Fixed Asset Verification Process

Planning and Preparation Understanding the client’s asset management system. Defining the scope of the verification process.

On-Site Physical Verification Conducting a detailed inspection of assets. Tagging and labeling assets where required.

Reconciliation Comparing physical records with the asset register. Identifying and addressing any discrepancies.

Reporting Providing a comprehensive report with findings and recommendations. Why Regular Fixed Asset Verification is Essential Businesses often overlook the importance of regular physical verification, which can lead to:

Inaccurate asset valuation. Missed opportunities for tax benefits. Increased risks of fraud or theft. By partnering with MASLLP, businesses can maintain a robust asset management system and safeguard their investments.

Get in Touch Ensure your fixed assets are accounted for and secure with MASLLP’s Physical Verification of Fixed Assets services.

#accounting & bookkeeping services in india#audit#businessregistration#chartered accountant#foreign companies registration in india#income tax#taxation#ap management services#auditor

5 notes

·

View notes

Text

How Seleam Helps Enterprises

Seleam, as a robust fixed assets management system, provides several features and benefits that help enterprises manage their assets effectively:

Centralized Database:

Unified Platform: Maintain all asset information in a single, centralized database accessible to authorized personnel.

Data Integration: Integrate with other enterprise systems (e.g., ERP, accounting software) for seamless data flow.

Advanced Tracking and Monitoring:

Real-Time Tracking: Use barcodes, RFID tags, or IoT sensors for real-time asset tracking.

Condition Monitoring: Continuously monitor the condition of assets to predict failures and plan maintenance.

Automated Processes:

Workflow Automation: Automate routine tasks such as asset check-ins/outs, maintenance scheduling, and depreciation calculations.

Notifications and Alerts: Set up alerts for maintenance due dates, warranty expirations, and compliance deadlines.

Comprehensive Reporting and Analytics:

Customizable Reports: Generate detailed reports on asset utilization, maintenance history, financials, and more.

Data Analytics: Use analytics tools to gain insights into asset performance and make data-driven decisions.

User-Friendly Interface:

Intuitive Dashboard: Provide an easy-to-use dashboard for quick access to key information and metrics.

Mobile Access: Enable remote access through mobile devices for on-the-go asset management.

Scalability and Flexibility:

Scalable Solution: Adapt to the growing needs of the enterprise, whether it's adding more assets or expanding to new locations.

Customization: Offer customizable features to meet the specific requirements of different industries and organizations.

2 notes

·

View notes

Text

easyTRACK Warehouse Management System

An intelligent solution to control movement and storage of materials within a Warehouse.

A well-structured Warehouse Management system is important for the smooth and efficient operation of any warehouse, irrespective of the size or volume of material it handles. Most of the small and medium warehouses do not require an expensive WMS with redundant features. easyTRACK WMS is a perfect solution on the enterprise mobility for the warehouse management of small and medium enterprises which helps them manage all the essential warehouse functions. easyTRACK warehouse automation software allows the users in warehouse to manage the following operations at their palm.

Goods receiving

Put away

Picking & Palletizing

Dispatch

Stock count, etc.

easyTRACK WMS Lite Benefits

Solves the challenges faced in the conventional system.

Goods Receiving-

Priority Issue Multiple Shipments received at a time

Delayed Data entry Stock may be available but not available for Sale Dead /Damage/Short supply on arrival not instantly notified.

SOLUTION: GRN on PDT “goods receiving made easy with GRN on PDT”

Welcome to Technowave Group, your trusted provider of advanced technology solutions in Dubai. Our RFID Warehouse Inventory Management Systems can help businesses improve their inventory management and provide complete visibility into their warehouse operations.

What is RFID Warehouse Inventory Management System?

RFID Warehouse Inventory Management System uses RFID technology to automate the process of inventory tracking and management. It involves tagging inventory items with that contain unique identification numbers. The RFID tags are read by RFID readers, which transmit the data to a computer system that stores the information and provides real-time updates on the inventory’s location, movement, and status.

Key Features of our RFID Warehouse Inventory Management System

Our RFID Warehouse Inventory Management System comes with the following key features:

Real-time inventory tracking:

Our RFID system provides accurate and up-to-date information on inventory levels, locations, and movements in real-time. This means that businesses can quickly identify any discrepancies, such as missing or misplaced items, and take corrective action before they become bigger problems.

Inventory management:

Our RFID system automates the inventory management process, including item counting, reordering, and tracking. This means that businesses can easily monitor inventory levels and reorder products when they are running low. This helps prevent stockouts and ensures that products are always available for customers.

Asset tracking:

It can track and manage assets, including equipment, tools, and vehicles, helping businesses keep track of their assets’ location, status, and maintenance schedules. This allows businesses to optimize asset utilization and minimize downtime, which can result in significant cost savings.

Reporting and analytics:

The RFID system generates detailed reports on inventory and asset tracking, providing businesses with valuable insights into their warehouse operations. Businesses can use this information to identify areas for improvement and make informed decisions about inventory levels, order fulfillment, and asset management.

Improved accuracy and efficiency:

Our RFID system eliminates the need for manual inventory tracking, reducing the risk of errors and improving accuracy. This saves time and resources by automating inventory management and asset tracking, allowing businesses to focus on other critical tasks.

Improved visibility and control:

It provides real-time updates on inventory and asset movement, giving businesses complete visibility into their warehouse operations. This helps businesses make informed decisions and take corrective action quickly, leading to increased efficiency and productivity.

Improved customer satisfaction:

Our RFID system helps businesses improve their order fulfillment process, reducing stockouts and improving delivery times. This leads to increased customer satisfaction and repeat business, which can be a significant competitive advantage in today’s market.

Compliance with regulations:

Last but not least, our RFID system helps businesses comply with regulations related to inventory tracking and management. For example, our system can provide traceability requirements for food and pharmaceutical products, ensuring that businesses meet regulatory requirements and avoid costly penalties.

Overall, our RFID Warehouse Inventory Management System offers businesses a range of benefits, from increased efficiency and productivity to improved customer satisfaction and regulatory compliance.

Get in Touch With Us!

At Technowave Group, we have a team of experienced professionals who are dedicated to providing high-quality service and support to our clients. We work closely with our clients to understand their unique business needs and provide tailored solutions that help them achieve their goals.

Whether you are a small business or a large enterprise, we can help you leverage technology to improve your warehouse operations and achieve your goals. Contact us today to learn more about our RFID Warehouse Inventory Management System and other technology solutions.

3 notes

·

View notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] RFID, or Radio Frequency Identification, is a form of wireless communication that uses radio waves to identify and track objects. Unlike traditional barcode technology, RFID does not require a line of sight for scanning. This system consists of tags with microchips that store information and antennas to transmit data wirelessly to RFID readers. RFID vs. NFC: RFID is a broad technology used for long-range identification and tracking, ideal for asset management in extensive operations like warehouses. NFC is a branch of RFID designed for short-range (up to a few centimeters) communication, which suits secure, fast data exchanges such as digital payments. Moreover NFC tags can be read from compatible smartphones. NFC Use Cases: NFC tags enable wireless data transfer and interaction with a simple tap. They can be used for cashless payments, digital keys, device pairing, marketing, and event access. Industrial RFID/NFC Applications:Asset Tracking: Monitor tools and machinery with NFC tags.Safety Protocol Enforcement: Check safety measures with NFC checkpoints.Quality Control: NFC for instant quality checks on production lines.Workforce Time Management: Simplify clocking in and out using NFC.Supply Chain Oversight: Track products from production to delivery.Medical RFID/ NFC Applications:Patient Identification: NFC cards for quick access to medical records.Medication Authentication: Verify drug authenticity and manage dosages.Medical Equipment Management: Inventory and maintenance tracking.NTAG213 NFC Cards Specs:Chip: NTAG213, NFC Forum Type 2 Tag compliant.Memory: 144 bytes, suitable for URLs/text.Frequency: 13.56 MHz for quick, reliable scans. Blank Printable RFID/NFC Card with 144 bytes user memory. Rewritable NTAG213 chip. Universally compatible with all NFC Phones and Readers. Standard CR80(credit card) size - 85.6 mm x 54 mm. Rounded Corner. Semi-flexible rigid PVC.Durable, Waterproof, Withstands bending/flexing. All cards come with 100% Quality Assurance & are Performance Tested. [ad_2]

0 notes

Text

The Evolution of Tracking: How Barcode, RFID, and RTLS Improve Business Operations

Introduction: Tracking and managing assets has evolved dramatically over the years. What started with manual systems has now progressed to advanced tracking with barcodes, RFID, and RTLS. This article breaks down how these innovations are shaping the future of business operations.

1. Barcode Technology: The Foundation of Modern Tracking

How barcodes simplified inventory and asset management.

Key benefits: Cost-effective, simple, and widely used.

Applications across industries.

2. RFID: The Future of Smart Tracking

How RFID enhances tracking efficiency.

Benefits: No line-of-sight required, automation, and scalability.

Real-world applications in logistics, manufacturing, and retail.

3. RTLS: Instant Location Tracking for Businesses

What makes RTLS different from barcodes and RFID.

Benefits: Real-time location data, operational visibility, and security.

Use cases in hospitals, factories, and supply chains.

4. Combining Barcode, RFID, and RTLS for a Unified System

How integrating these technologies leads to better decision-making.

Why businesses should invest in multi-layered tracking systems.

Conclusion: Tracking technologies continue to evolve, helping businesses stay efficient, reduce costs, and improve accuracy. The combination of Barcode, RFID, and RTLS offers a complete solution for modern enterprises.

#asset management#barcode#qr code#technology#electronic devices#aidc#aidc technologies india#real time tracking#barcode printers

0 notes

Text

Achieve Precision with Long-Range Asset Tracking Solutions

Track assets over wide indoor and outdoor areas with precision. Achieve better control and operational efficiency with long-range tracking.

Visit AssetTrackerIoT to explore advanced tracking technologies

#assetmanagement#rfid technology#tracking software#asset tracking#rfid tags#office asset tracking#tracking system#tracking technologies#barcode technology#technology

0 notes