#Programmable sensor node

Explore tagged Tumblr posts

Text

Arduino PLC | MQTT End Device | Industrial IoT device manufacturer | norvi.lk

How Programmable IoT Devices Operate

Having access to the most dependable and effective hardware speeds up the completion of your project. The ability to programme flexibly.

ESP32 Ethernet Device

When using ESP32 Ethernet, the NORVI ENET series is the best option because it has industrial-grade I/O and voltages. Both wireless and cable connectivity to the network are offered by ESP32 Ethernet.

Industrial Arduino Mega

The NORVI Arita is an enhanced version of the NORVI Series. Five conventional variants with a choice of two potent microprocessors are offered. Arita is built to deliver all of the micro-controller's performance while maintaining reliability. It works with practically all industrial input and output formats.

Arduino based Industrial Controller

Arduino IDE-programmable

Integrated OLED and customizable buttons for HMI

The ability to programme flexibly

LED signals for simple diagnosis

Applications Using a Programmable MQTT Device and Ultra Low Energy Batteries

Agent One Industrial Controllers are available for low power applications as well; STM32L series microcontroller-controlled devices are employed in ultra low power applications, where the devices must be powered by batteries for an extended period of time. When a device goes to sleep, the Agent One BT family is specifically built with transistor outputs to turn off external sensors.

Wall mount IoT Node

The NORVI SSN range is designed for independent installations in industrial settings with a focus on tracking sensor data or parameters from external devices. The implementations are made simple by the attachments for wall installation and pole mount.

NORVI Controllers

Our Address :

ICONIC DEVICES PVT LTD

Phone : +94 41 226 1776 Phone : +94 77 111 1776

E-mail : [email protected] / [email protected]

Web : www.icd.lk

Distributors

USA

Harnesses Motion LLC

1660 Bramble Rd. Tecumseh, MI

49286, United States

Phone : +1 (734) 347-9115

E-mail : [email protected]

EUROPE

CarTFT.com e.K.

Hauffstraße 7

72762 Reutlingen

Deutschland

Phone : +49 7121 3878264

E-mail : [email protected] MQTT End Device | Arduino PLC | Analog Input | Wireless sensor | ModBus MQTT gateway | Industrial IoT device manufacturer | WiFi Data logger

#Programmable IoT Devices#Industrial IoT Devices#Industrial Arduino#Arduino PLC#ESP32 Ethernet Device#Programmable Ethernet IoT Device#MQTT End Device#Industrial Arduino Mega#Arduino Mega PLC#Arduino based Industrial Controller#Programmable MQTT Device#Modbus MQTT Device#ESP32 Modbus device#Wall mount IoT Node#Wall mount sensor node#Programmable sensor node#Wireless sensor#Battery Powered IoT Node#Battery Powered Programmable Sensor node#Solar powered sensor node#MODBUS RTU ESP32#Modbus to IoT gateway#Modbus MQTT gateway#Programmable MQTT devices#MQTT over WIFI devices#MQTT over Ethernet devices#Industrial IoT device manufacturer#0 - 10V Arduino device#4 - 20mA Arduino device#ESP32 data logger

1 note

·

View note

Text

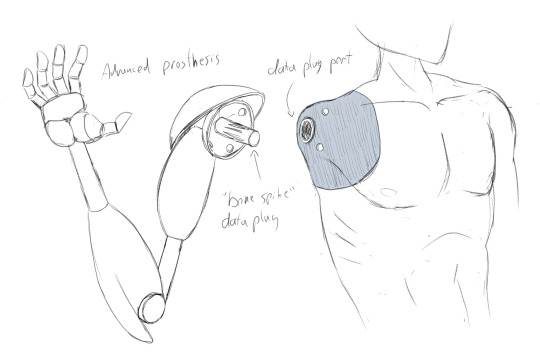

Kamen Rider NRV Lore Dump!

Manticore

Manticore LLC is a major medical technology company. Publicly, they are most known for their artificial organs and limb prosthesis as well as several other medical devices and equipment used in hospitals worldwide. Less widely publicized are their numerous military contracts, developing cutting edge medical treatment technologies but also advanced weapons, drones, and other offensive hardware.

Nanoderm

The scientific breakthrough that lead Manticore to dominate in the field of med-tech is the invention of micro-sensors that are capable of reading brain signals in the nervous system and translating them into data a computer can interpret with absolute precision. These microscopic sensors can be integrated into programmable nanomachines that interlock in a mesh that forms durable skin-like material called Nanoderm. If an exposed section of human tissue is covered in Nanoderm and then allowed to heal, the Nanoderm will become integrated with the tissue like a layer of natural skin. Any impulses or signals sent by the brain to that part of the body will be received by the Nanoderm and translated into data. That data can then be read as motor commands by a Manticore prosthesis. Basic prosthesis models can receive this data via magnetic nodes embedded in the surface of the Nanoderm but more advanced models, capable of finer dexterity/expanded functionality, require a “bone spike,” a rod-like data plug that interfaces with a port in the Nanoderm area that is connected to more advanced sensors. The socket and sensor hardware is imbedded in the body through a surgical procedure.

The catch with the Nanoderm system is it must be applied to the body before the exposed tissue heals over and the exposed nerve endings have a chance to close off, or in other words, while the wound is “fresh”, otherwise the healed tissue must be cut away and a fresh wound made. This means that in emergency situations a patient or their next of kin must make a snap decision to undergo the expensive Nanoderm compatibility surgery as part of their emergency treatment. Of course some insurance plans will cover some or all of this cost. Additionally Manticore has deals with some insurance providers that the surgery come standard with higher end coverage plans, forgoing the need for patient consent. Manticore has exclusive patent rights to the Nanoderm system, meaning once you are Nanoderm compatible, you are locked into the Manticore ecosystem of prosthesis and devices. Additionally your devises can only be serviced by Manticore certified technicians and only Manticore doctors are trained in Nanoderm patient care.

Remote Command (RC)

Manticore is a sprawling corporation with many secrets. One such secret is the Remote Command program. A project Manticore has been working on behind closed doors, the Remote Command program involves research into sending brain signals over great distances without a physical connection between the sensor and the receiving devise. With RC a person could control a prosthetic arm in another part of the world as though it were part of their body. This is achieved by broadcasting the impulses across a proprietary electromagnetic wave length to the receiving nodes. The signal travels point to point and back again at light speed. The potential RC has for the future of drone warfare is staggering, not to mention the potential for profit.

Sensitive as this information is, there’s another layer. All Nanoderm currently in use by people around the world is capable of receiving Remote Command. With the right inputs it can reshape its self, self-replicate, and even, under certain conditions, send signals back to the user’s brain, causing brain damage or, theoretically, controlling them. Whether this functionality of Nanoderm was an intentional feature or not is unknown to anyone currently employed at Manticore but the company has no pans currently to use the Nanoderm in this way. What is known, however, is that if this function ever becomes public knowledge it would be disastrous for Manticore, not to mention the chaos that would ensue if a bad actor were to exploit this function for malicious purposes.

Manticore Special Security (Spec-Sec)

Manticore LLC has secrets, and it has enemies. To protect its secrets, combat its enemies, address the threats to public safety those things pose, (and protect its corporate interests), Manticore formed the Manticore Special Security Division. More than just your standard private security outfit, Spec-Sec is a fully equipped task force and strike force designed to identify, target, track, confront, and nullify any threat to the company and its assets. Thanks to Manticore’s history of generous donations and good standing with local police forces, the Spec-Sec Division is able to operate with a certain degree of discretion, allowing them to carry out operations without interference from police or the legal system. Lead by Special Security Director Sloane, her hand-picked crack team of Special Officers have carried out dozens of high risk operations with ruthless efficacy and, so-far, minimal casualties. Spec-Sec utilizes the most cutting edge technology and weaponry Manticore has, often before it’s even close to market ready. In some cases necessity dictates that Spec-Sec operations serve as ad hoc field tests for experimental equipment.

Core Drivers, Data Boosters, and the Kamen Rider program

The Core Driver is a piece of technology that was developed as part of research into the use of Nanoderm to enhance a soldier’s physical performance on the battlefield. The concept was to temporarily cover the user’s entire body in a layer of Nanoderm mesh that could respond to the signals from the user’s brain in such a way that would increase their strength, speed, perception, and reflexes. The solution was the Core Driver, a device that would house the billions of Nanoderm nanomachines and serve as the computational core for the whole mesh network. Along with the Core Driver was the Data Booster, a flash drive-like device shaped like a syringe. The data booster contained the information that told the nanomachines to deploy from the Core Driver and cover the user. Additionally the Booster came with its own payload of nanomachines that, when the plunger of the syringe was depressed, would also be deployed through the Core Diver and take the form of armor and weapons. Basically, a user need only insert the Data Booster into the Core Diver, clearly speak a voice authentication phrase, and depress the plunger and they would instantly be wearing a powerful yet flexible armored body suit. The project was called the “Kamen Rider program” after the masked visage of the user’s armored faceplate (“Kamen” being the Japanese word for “mask”).

The Project had its drawbacks, however. For one a user would need to already be Nanoderm compatible for the suit to work at all, meaning, practically speaking, the user would need to be an amputee, and the prospect of convincing soldiers to sacrifice a limb to use the Driver was deemed a “hard sell” and the idea of a approaching a freshly maimed soldier with the offer of further combat, well, that wouldn’t be a good look either. The second and most important drawback was the simple fact that the Kamen Rider program was far, FAR too expensive to be profitable, and the thousands of man hours it took to produce just one Core Driver meant mass producing them to sell by the battalion, as Manticore had planned, was simply out of the question.

The Kamen Rider Program was not completely abandoned, however. The first completed Core Driver, designation SVR (Special Versatility Rider model or “Sever” colloquially) is currently coded to Director Sloane of Spec-Sec, who happens to be a double transfemeral amputee. With the Director’s input, the device and the suit itself have been modified heavily over its years of use. It now features the ability for additional Data Boosters to be employed, loaded with weapons and tools in the form of appendages that attach to highly advanced versions of Bone Spike sockets on the suit at the amputation sites of the Rider’s body. The nerve signal enhancing properties of the suit allows the Rider to manipulate these complex, non-human-like appendages with a natural ease and minimal adjustment period.

A second Core Driver has just recently been put to use in the field at Spec-Sec. The first Kamen Rider designed from the ground up with Spec-Sec modifications. Designation NRV (Neo Rider Variant or “Nerve” colloquially) is encoded to the Division’s newest member, Special Officer Nat Agbayani. A right shoulder disarticulation amputee, he was promoted to the Special Security Division from the internship program in the research wing by the COO of Manticore himself… wait what? That can’t be right…

The existence of any other Core Drivers, in use or otherwise, is classified.

Thanks for reading

#art#my art#my text#sketch#lore#oc lore#kamen rider#kamen rider nrv#kamen rider oc#sci fi#original character#nat krnrv#sloane krnrv#medical tw#surgery tw#tokusastu#krnrv lore

51 notes

·

View notes

Text

Rheinmetall Supplies 35mm AHEAD Ammunition for Skynex Air Defense System to European Nation

A European customer country has commissioned Rheinmetall to supply 35mm AHEAD ammunition for the Skynex air defense system. The total value of the order is in the low three-digit million euro range. A six-digit number of cartridges will be manufactured. The Skynex system strengthens the protection of the customer country's armed forces against threats from the air. This new order once again underlines Rheinmetall's leading technological position in the development and production of highly efficient ammunition for air defense in Europe. The use of programmable 35mm AHEAD ammunition, as developed by Rheinmetall for this purpose, is considerably cheaper than comparable guided missile-based systems. it is not possible to influence or even deflect the 35mm ammunition by electronic countermeasures after firing. The Skynex is a modular air defense architecture centered around the Skymaster battle management system that can link components of the Skyshield. The Skynex is based on cannon-based air defense and is therefore particularly suitable for close-range protection where guided weapons cannot be effective. The Skynex air defense system is based on a concept that keeps airspace surveillance separate from the effectors, only requiring a tracking unit to link a C2 network with different weapons. Each Skynex system comprises four Revolver Gun Mk3 cannons, a CN-1 control node, and an X-TAR3D radar all mounted on HX trucks. Besides the single sensors and effectors, users can also link existing fire units such as Skyshield or Skyguard in a classic fire unit configuration to the control node. Skynex allows integrating sensors from different manufacturers. #military #defense #defence #militaryleak

A European customer country has commissioned Rheinmetall to supply 35mm AHEAD ammunition for the Skynex air defense system. The total value of the order is in the low three-digit million euro range. A six-digit number of cartridges will be manufactured. The Skynex system strengthens the protection of the customer country’s armed forces against threats from the air. This new order once again…

View On WordPress

0 notes

Text

Characteristics and Advantages of LoRa Gateway + LoRa Nodes

The LoRa gateway serves as a device connecting terminal equipment to the LoRaWAN network, responsible for collecting data from multiple LoRa base stations and transmitting it to the cloud. It gathers messages transmitted by LoRa nodes and forwards them to LoRaWAN servers, facilitating communication from devices to the cloud.

Gateways typically handle packet forwarding, encryption/decryption, and communication with LoRaWAN servers.

The heatsink on the LoRa gateway ensures stable operation within a safe temperature range, thereby prolonging device lifespan and enhancing performance and reliability.

LoRa gateway chip

LoRaWAN 1301 is a compact LoRaWAN gateway frontend module with SPI interface introduced by RAKwireless. This module utilizes the SX1301 chip, a standard design from Semtech, and features a built-in TCXO crystal oscillator. It is specifically designed for LoRaWAN gateways.

Characteristics of SX1301:

Multi-channel Processing Capability: Supports simultaneous processing of multiple LoRa signal channels, up to 8 independent channels.

High Integration: Integrates 8 low-noise amplifiers (LNAs), 8 bandwidth filters (BPFs), and 1 digital baseband processor (BBP) on a single chip, realizing multi-channel LoRa reception function.

Low Power Consumption: Designed with low power consumption, suitable for long-term operation in low-power scenarios.

High Sensitivity: Has excellent receiver sensitivity, enabling reliable communication in long-range and weak signal environments.

Development Support: Offers rich software and hardware support, facilitating development and deployment for LoRaWAN gateway devices.

Characteristics of SX1302:

Higher Integration: Compared to SX1301, it integrates more functional modules, including 12 channel processing units (CHPUs), 2 main clock units (MCUs), and 1 digital signal processing unit (DSPU).

Support for More Channels: Can support up to 16 independent LoRa signal channels, providing higher data throughput and network capacity.

Compatibility: Backward compatible with SX1301 interfaces and protocols, ensuring compatibility with existing LoRaWAN infrastructure.

Improved Interference Immunity: Has stronger interference immunity, providing more stable communication performance in complex wireless environments.

Programmability: Offers greater programmability, allowing developers to customize and optimize according to specific application requirements.

Integrated Temperature Sensor: The temperature sensor integrated into SX1302 plays an important role in ensuring stable chip operation and improving system reliability.

LoRa utilizes multiple spreading factors (SF) to modulate signals, allowing for orthogonal decoding of signals with different spreading factors on the same channel. The gateway connects to the network server using standard IP, and terminals communicate with one or more gateways via single-hop communication. All terminal communications are bidirectional, and the system also supports features such as over-the-air software upgrades.

Who would use LoRa gateways?

LoRa gateways are widely used due to their numerous advantages, and they find applications in various sectors such as enterprises, large factories, smart agriculture, remote meter reading, smart manhole covers, pipe galleries, office buildings, smart inspections, smart homes, smart streetlights, smart heating, and more.

Here are the scenarios suitable for using LoRa gateways:

Limited range with multiple devices and sensors networking scenario, such as personnel positioning in factories with thousands of nodes.

Spacious areas where devices are located far apart, and neither wired nor wireless wide area networks can meet the requirements, such as smart agriculture with large distances between fields.

Scenarios with inconvenient power supply and maintenance, such as smart meter reading, where nodes are densely distributed, and it is difficult to supply power to water meters and gas meters, and battery replacement is inconvenient.

Scenarios with strong interference but requiring wireless communication, such as office buildings and pipe galleries, where wireless communication is frequent and interference is high, and the cost of wiring multiple nodes is high.

Various other areas requiring wireless local area network communication, such as smart homes, manhole covers, streetlights, heating systems, etc.

What is a LoRa node:

A LoRa node is a wireless terminal device connected to the LoRaWAN network. They can be various types of devices such as sensors, switches, alarms, etc. These nodes transmit data to the cloud or other servers through the LoRaWAN network.

A LoRa gateway acts as a bridge between the nodes and the cloud. It receives data from the nodes and transmits it to the LoRaWAN network. Additionally, the gateway can receive instructions from the network and transmit them back to the nodes.

For details, please click:https://www.nicerf.com/products/ Or click:https://nicerf.en.alibaba.com/productlist.html?spm=a2700.shop_index.88.4.1fec2b006JKUsd For consultation, please contact NiceRF (Email: [email protected]).

0 notes

Text

Semiconductor Intellectual Property (IP) Market Size, Share, Industry Report, and Growth Drivers – 2029

The semiconductor intellectual property (IP) market was valued at USD 7.5 billion in 2024 and is projected to reach USD 11.2 billion by 2029; it is expected to grow at a CAGR of 8.5% from 2024 to 2029. Factors such as increasing demand for advanced semiconductor components in telecom & data centers, and automotive sector, and expanding embedded digital signal processor IP and programmable digital signal processor IP segments create lucrative opportunities whereas constant technological changes resulting in increased expenditure, and concerns related to Moore’s law major restraint for the growth of the semiconductor intellectual property (IP) market.

Driver: Increasing demand for electronics in healthcare and telecommunications industries

After the recent pandemic, the demand for new and advanced medical equipment to conduct analysis and diagnosis has increased in the healthcare industry. Portable medical equipment, for instance, patient monitoring devices, witnessed a surge in demand throughout the pandemic. The increased global awareness has created an immense demand for personal monitoring devices even after the pandemic.

Large infrastructure equipment, such as medical imaging systems and biochemical analysis equipment, is used in the healthcare industry. These instruments feature low system noise and consume less power; this was made possible because of semiconductor intellectual property (IP) licensing available to medical device manufacturers, helping them solve unique design challenges. Conventional medical equipment has long relied on software solutions and complex electronics to function.

The telecommunications industry also saw an increased demand for electronics during the pandemic due to the implementation of work from home (WFH) and remote learning policies. Easy-to-use communication tools that enable remote work and learning, as well as teleconferencing instruments witnessed a huge spike in demand during the pandemic period.

Semiconductor IPs are used in the telecommunications vertical for networking, video communication, voice communication, wired infrastructure, and wireless infrastructure telecommunication equipment manufacturing.

Restraint: Concerns related to Moore’s Law

According to Moore’s Law (stated by Gordon Moore, the founder of Intel, in 1965), the number of transistors in a dense integrated circuit will double approximately every two years. Moore’s words were true to an extent, but this increase in the number of transistors reached 3 billion, built over an advanced 14 nanometer (nm) manufacturing process. This technological advancement offered long battery life, computing, video capturing, mobile connectivity, and security features. However, no further advancements in IC technology were noted as the industry players continued to fail to develop a new process node of sizing less than 10 nm. This could mean that Moore’s Law becomes irrelevant. This can either cause a slowdown in semiconductor market growth, or end IC development. It could also result in new beginnings for the semiconductor industry, leading to modern technologies such as silicon photonics.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=651

Opportunity: Rising demand for advanced semiconductor components in automotive and telecommunications & data center verticals

Companies in the telecom & data centers, and automotive sector rely on sophisticated, complex electronic systems. The increasing demand for electronics and semiconductor components in these sectors created the need for innovative design solutions for chip manufacturing. The applications of MCUs, MPUs), analog ICs, sensors, interfaces, and memory in EVs, HEVs, autonomous vehicles and premium vehicles are increasing. As the significance of electronics mobility, connected cars, and vehicle connectivity increases, the demand for small gadgets with high functionality and performance improvements in the automotive sector is also expected to increase rapidly. Thereby, creating opportunities for players operating in the semiconductor intellectual property (IP) market.

Challenges: Increasing IP thefts and counterfeiting

A majority of IP thefts, counterfeiting, and conflicts take place in Asia Pacific. IP thefts and counterfeiting lead to prohibitive costs. IP thefts mainly take place in ASIC and FPGA semiconductor intellectual property (IP) cores; this has been a major area of concern in other critical submarkets of the semiconductor intellectual property (IP) market.

About MarketsandMarkets™

MarketsandMarkets™ is a blue ocean alternative in growth consulting and program management, leveraging a man-machine offering to drive supernormal growth for progressive organizations in the B2B space. We have the widest lens on emerging technologies, making us proficient in co-creating supernormal growth for clients.

The B2B economy is witnessing the emergence of $25 trillion of new revenue streams that are substituting existing revenue streams in this decade alone. We work with clients on growth programs, helping them monetize this $25 trillion opportunity through our service lines - TAM Expansion, Go-to-Market (GTM) Strategy to Execution, Market Share Gain, Account Enablement, and Thought Leadership Marketing.

Built on the 'GIVE Growth' principle, we work with several Forbes Global 2000 B2B companies - helping them stay relevant in a disruptive ecosystem.Our insights and strategies are molded by our industry experts, cutting-edge AI-powered Market Intelligence Cloud, and years of research.The KnowledgeStore™ (our Market Intelligence Cloud) integrates our research, facilitates an analysis of interconnections through a set of applications, helping clients look at the entire ecosystem and understand the revenue shifts happening in their industry. To find out more, visit www.MarketsandMarkets™.com or follow us on Twitter, LinkedIn and Facebook.

0 notes

Text

Introduction to Robot operating system

November 28, 2023

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

Introduction

The open-source middleware system known as the Robot Operating System, or ROS for short, is used to create robotic software. It offers a collection of tools and frameworks that make it easier to create sophisticated and reliable robot applications. Open Robotics is currently responsible for maintaining ROS, which was first created by Willow Garage, a robotics research group.

Key features of ROS include:

Middleware Communication: ROS enables communication between various robotic system components. It facilitates information flow between nodes (separate software processes) using a publish/subscribe messaging system. In order to coordinate different operations inside a robotic system, communication is essential.

Package Management: Resources such as libraries, executables, configuration files, and other files are arranged into packages by ROS. This modular design streamlines the development process and encourages code reuse.

Hardware Abstraction: ROS gives programmers the ability to build code that is not dependent on the particular hardware platform by providing hardware abstraction. The creation of scalable and portable robotic applications is made possible by this abstraction layer.

Device Drivers: ROS comes with a number of device drivers for different robotic platforms, actuators, and sensors. The incorporation of additional devices into a robotic system is made easier by this pre-built support for standard hardware components.

Tools for Visualization: Robotic system monitoring, debugging, and visualization are all included in ROS. Tools that assist developers in comprehending and troubleshooting the behavior of their robots include the simulator Gazebo, the RQT graphical user interface, and the 3D visualization tool RViz.

Community Support: The lively and engaged community of ROS is one of its strongest points. Around the world, developers build and share packages, guides, and best practices as part of the ROS ecosystem. This cooperative setting encourages creativity and speeds up the creation of robotic applications.

Flexibility & Extensibility: ROS is made to be both extendable and adaptable, enabling developers to alter and expand its features to suit their own requirements. Because of its adaptability, ROS may be used for a variety of robotic applications, ranging from commercial goods to research prototypes.

Programming Languages Supported: C++, Python, and Lisp are just a few of the languages that ROS supports. Because of this flexibility, developers can utilize their most familiar language for different parts of their robotic applications.

Benefits of Robot operating system

Numerous advantages provided by the Robot Operating System (ROS) contribute to its acceptance and popularity in the robotics industry. The following are some main benefits of using ROS:

Community-driven and Open Source: ROS is an open-source framework, which permits unrestricted modification and redistribution of its source code. Within the international robotics community, cooperation and knowledge exchange are encouraged by ROS’s open nature. Its development is supported by developers all over the world, creating a rich ecosystem of resources, libraries, and packages.

Modularity and Reusability: The architecture of ROS is modular, with robotic software arranged into packages. Because of its modular design, which encourages code reuse, developers can more easily utilize pre-existing components to create new robotic applications. This quickens the development process and raises the software’s general quality.

Middleware for Communication: ROS offers a communication middleware that facilitates easy communication between various robotic system components. By using a publish/subscribe approach, this middleware facilitates easy information sharing between nodes. The coordination of several sensors, actuators, and algorithms within a robot is contingent upon this communication method.

Hardware Abstraction: ROS enables developers to write code that is not dependent on the particular hardware platform by abstracting the hardware layer. By offering a standardized interface for dealing with sensors, actuators, and other hardware components, this abstraction streamlines the development process. Additionally, it improves portability, which facilitates the adaptation of robotic software to various hardware setups.

Rich Set of Tools: Robot Development, Debugging, and Monitoring are made easier with the many tools that ROS provides. Robot behavior is better understood by developers because of visualization tools like RViz, debugging tools like RQT, and simulators like Gazebo, which facilitate the analysis and optimization of applications.

Device Drivers: For typical sensors and actuators, ROS comes with a large selection of pre-built device drivers. Developers can save time and effort by using this collection of drivers to make the integration of new hardware into robotic systems simpler.

Scalability: Because of its scalable nature, ROS can be used for a variety of robotic applications, ranging from small-scale research prototypes to massive industrial robots. Because ROS is modular and versatile, developers can expand their applications according to the requirements and complexity of the robotic system.

Support for Several Programming Languages: C++, Python, and Lisp are just a few of the languages that ROS supports. This language flexibility enables the integration of existing codebases written in many languages and accommodates developers with varying language preferences.

Simulation Capabilities: Before implementing ROS on real robots, developers can test and validate their robotic algorithms in a simulated environment thanks to its good integration with simulators such as Gazebo. Error risk is decreased with simulation, which can also expedite development.

Educational Resource: ROS is a great educational tool that lets hobbyists, researchers, and students learn about and work with robotics. Both novice and seasoned developers can use ROS because of its wealth of tutorials, documentation, and friendly community.

Drawbacks of Robot operating system

The Robot Operating System (ROS) has many benefits, but users may also run across some issues and problems with it. When thinking about using ROS for a specific robotic application, it’s critical to be aware of these constraints. The following are a few disadvantages of ROS:

Learning Curve: For those new to robotics and software development, in particular, ROS has a steep learning curve. Users may require some time to become skilled in comprehending and utilizing the different components and concepts inside ROS due to the system’s overwhelming complexity.

Resource-Intensive: ROS has the potential to be a resource-intensive program, using a large amount of RAM and computing power. Applications using limited resources, like lightweight robots or tiny embedded devices, may find this concerning.

Performance in Real Time: The original architecture of ROS did not consider real-time applications. Despite recent improvements to real-time capabilities, ROS might not be appropriate for applications like high-speed control systems that demand incredibly low latency responses.

Absence of Standardization: Although commonly utilized, ROS is not strictly standardized in some sectors. Similar functionality may be implemented slightly differently by different developers, which could cause compatibility problems when merging packages from multiple sources.

Security Issues: Because ROS is an open-source framework, security issues could arise. When using ROS in environments where security is a major concern, like robotics applications in the medical or defense industries, users must exercise caution.

Limited Industry Adoption: Although ROS is widely used in academia and research, its uptake in some companies, especially those with safety-critical applications, may be restricted. Industries with strict safety regulations could need more procedures for validation and verification.

Not Suitable for All Robotic Systems: Not every kind of robotic system is a good fit for ROS. For instance, the full potential of ROS may not be greatly beneficial for specialized or simple robots with low processing requirements, adding needless complexity.

Dependency Management: As the number of packages and their versions rises, it might be difficult to maintain dependencies across various ROS packages. Integration problems may arise from package version incompatibilities.

Limited Real-world Deployment Tools: Although ROS offers great simulation tools such as Gazebo, there could be difficulties when moving from simulation to real-world deployment. It might be challenging to create sturdy, dependable robotic systems that function flawlessly in the real world.

Continuous Evolution: The frequent release of new updates and versions of ROS may make it more difficult to sustain and maintain current robotic systems over the long run. There may be compatibility problems between various ROS versions.

Conclusion:

In conclusion, the Robot Operating System (ROS) stands as a powerful and versatile framework that has significantly contributed to the advancement of robotics research, development, and deployment. Its open-source nature, modular architecture, and extensive set of tools have propelled ROS into the forefront of the robotics community.

ROS has been instrumental in fostering collaboration and knowledge-sharing among developers, leading to a vibrant ecosystem of packages and libraries. The benefits of modularity and reusability have allowed for the creation of complex robotic systems with greater ease and efficiency. The middleware communication system enables seamless interaction between various components, contributing to the coordination of sensors, actuators, and algorithms within robots.

Despite its strengths, ROS does come with certain drawbacks, including a steep learning curve, resource intensity, and challenges in real-time applications. However, these limitations need to be weighed against the benefits, and developers must carefully consider the specific requirements of their projects.

In essence, ROS has played a pivotal role in democratizing robotics, providing a platform for both researchers and industry professionals to experiment, collaborate, and innovate. As technology continues to evolve, ROS is likely to adapt and remain a key player in shaping the future of robotics. Its impact on education, research, and industry applications underscores its significance in the broader landscape of robotic systems development.

#Robotoperatingsystem#Transmissioncontrol#Dorleco#EngineControlUnit#FuelEfficiency#InternalCombustionEngine#BatteryManagement#autonomousvehicles

0 notes

Text

12bit 5Gsps Current Steering DAC IP Core for High Speed Communication

T2M-IP, the global independent semiconductor IP Cores provider & Technology experts, is pleased to announce its 12bit 5Gsps Current Steering DAC IP Core which is Silicon Proven in 28HPC+ process technology is available immediately for licensing. The DAC uses a proprietary architecture and self-calibration to achieve a higher accuracy or to increase yields with a very small area.

A binary digital input code is translated into a quantized (discrete step) analogue output by the DAC. A reference quantity (either a voltage or a current) is split into binary and/or linear fractions to produce the output. The output is then generated by driving switches with a suitable number of current steering digital-to-analog converters to combine these fractions. The size and quantity of the fractions represent the range of potential digital input codes, which depends on the converter resolution or the input code's bit count (N)... For N bits, there are 2 possible codes. The analog output of the DAC output is the digital fraction represented as the ratio of the digital input code divided by 2 times the analog reference value.

This high-performance 12-bit current steering DAC can support data rates upto 5Gsps, which consists of a current source matrix with quad switching architecture, controlled from an adaptive balanced driver and retiming latches. It has all the necessary calibration circuitry to perform excellent static and dynamic linearity. It consists of integrated multiplexer to multiplex with 8 lanes of 12-bit data to achieve a 5Gsps effective data rate.

The 12bit 5Gsps Current Steering DAC IP Core is Silicon Proven in 28nm HPC Plus Process Technology supports 12bits of Resolution and a Programmable 10mA Differential Current source with Inbuilt mismatch, Self-Calibration for excellent linearity that also has Built-in Die quality indicator for production. The Dynamic Performance is at 110MHz at the voltage of 1.8V ±10% Analog Power Supply and 0.9V ±5% Digital Core Power Supply. It has Integrated Voltage and Current References and captures very low silicon area with an improved Gain Error of 5%.

The 12bit 5Gsps Current Steering DAC IP Core has been previously used in Medical Applications, Ethernet, Automotive, Communication systems, Microcontrollers and Sensors, Wideband wireless communication, 5G, LTE, DOCSIS 3.1 CMTS, Instrumentations, Automatic Test Equipment ATE, Radars systems.

In addition to 12bit 5Gsps Current Steering DAC IP Core, T2M have a broad range of silicon-proven Analog IP Core Portfolio of data converter (ADC and DAC) IP cores that offer sampling rates from a 2 Ksps to over 20Gsps and resolutions ranging from 6 bits to 14 bits, available in major Fabs in different process geometries as small as 7nm. They can also be ported to other foundries and leading-edge process nodes on request.

About T2M: T2M IP is the global independent semiconductor technology expert, supplying complex semiconductor IP Cores, Software, KGD and disruptive technologies enabling accelerated development of your Wearables, IOT, Communications, Storage, Servers, Networking, TV, STB and Satellite SoCs. For more information, please visit: www.t-2-m.com

Availability: These Semiconductor analog IP Cores are available for immediate licensing. For more information on licensing options and pricing please drop a request / MailTo

0 notes

Text

IO-Link Market - Forecast (2022 - 2027)

IO-link Market size was valued at $5.3 billion in 2020 and it is estimated to grow at a CAGR of 18.51% during the period 2021-2026, owing to high penetration of industry 4.0 across industries. IO-link is a point-to-point serial communication protocol that includes an IO-Link master and one or several IO-Link devices. This system is highly being used for increasing the level of efficiency of industrial automated processes. Thus high demand for automation drives the growth of IO-Link market. Moreover, its ability to offer support and sustainability for various Fieldbus and Ethernet communication protocol plays a major role in the growth of this market. Furthermore, the government’s initiative to promote the adoption of industrial automation such as programmable logic controllers (PLCs), MES, SCADA and IoT sensors (such as photoelectric sensors, proximity sensors and sensor nodes), is one of the primary factors augmenting the demand for IO-Link. This technology also reduces the overall operational cost and increases the operational efficiency. Hence, the above-mentioned factors will drive the growth of IO-link industry during the forecast period.

Report Coverage

The report: “IO-link Market Forecast (2021-2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the IO-link Market.

By Type: IO-Link Wired, IO-Link Wireless

By Component: IO-Link Master(PROFINET, EtherNet/IP, Modbus-TCP, EtherCAT, Multiprotocol and Others), IO-Link Devices(Sensor Nodes (Position sensor, Temperature sensor, Pressure sensor, Vibration sensor and Others), Modules, Actuators, RFID Read Heads and Others).

By Application: Machine Tool, Handling and Assembly Automation, Intra-logistics, Packaging and Others

By End User Industry: Process Industry (Oil & Gas, Chemical, Power and others), Discrete Industry (Automotive, Aerospace & Defense, Semiconductor & Electronics, Machine Manufacturing and Others)and Hybrid Industry (Pharmaceutical, Metal & Mining, Food & Beverage, Cement And Glass and Others)

By Geography: North America (US, Canada, Mexico), Europe (Germany, France, UK, Italy, Spain, Rest of Europe), APAC (Japan, China, India, Australia, South Korea, rest of APAC), South America (Brazil, Argentina, rest of South America) and RoW (Africa, Middle East)

Key Takeaways

IO-Link Master held the major IO-link market share in 2020, due to high penetration of industrial 4.0 across industries and rapid industrialization.

Europe dominated the market in 2020, and is anticipated to witness significant growth during the forecast period 2021-2026, owing to early adoption of this technology and presence of major market players in this region.

Rapid adoption of automation and field bus independency of IO-link are the major growth drivers of this market.

IO-link Market outlook is consolidated with top market players including Siemens AG, Hans Turck GmbH & Co. KG, Balluff GmbH, Rockwell Automation, Inc., SICK AG, and others.

Request Sample

IO-link Market Segment Analysis – By Component

By component, this market is segmented intoIO-Link Master and IO-Link Devices. IO-link master segment is further segmented intoPROFINET, EtherNet/IP, Modbus-TCP, EtherCAT, Multiprotocol and Others, and IO-Link Devices segmented into Sensor Nodes, Modules, Actuators, RFID Read Heads and others. IO-link master held major IO-link market share around 35.99% in 2020, owing to rapid industrialization, increasing penetration of automation and industry 4.0 across sectors. For instance, in June 2019, UiPath published a report on present and future progress of automation and according to the survey report, 90% organizations are already using the automation technology to conduct their business processes. High adoption rate of automation across industries creates huge demand for IO-link masters and to fulfill such demand major players of this market are launching new products as well as investing heavily for the advancement of this solution. In June 2019, Contec Co. introduced a new IO-Link master solution CPSL-08P1EN, which supports use with four types of industrial Ethernet-based system protocols, including CC-Link IE Field Basic, EtherNet/IP, Modbus TCP and PROFINET. Hence, the above mentioned factors will drive the demand for IO-link Maters during the forecast period.

IO-link Market Segment Analysis - By End-User Industry

Based on end-user industry, IO-link Market is segmented into process industry, discrete industry and hybrid industry. Hybrid industry is sub-segmented into pharmaceutical, metal & mining, food & beverage, cement and glass and other industries. Pharmaceutical industry is the fastest growing segment in IO-link market and estimated to grow at a CAGR of 19.06% during forecast period 2021-2026, specifically due to the increasing investment in this sector. According to the report of Invest-India, the pharmaceutical sector is analyzed to reach $65 billion by 2024 and to reach $120 billion by the year 2030. Furthermore, rapid adoption of industry 4.0, increasing demand for reliable as well as sustainable communication and remote monitoring system in this industry are the key factors behind the growth of this market. IO-Link offers end-to-end communication to the whole process operation which reduces the overall downtime of the machines, which reduces the overall operational and maintenance cost. Moreover, out-break of COVID-19 has a positive impact on the growth of pharmaceutical industry. The rise in COVID cases and the growing health awareness among public are the key factors behind this high investment that creates the massive requirement of IO-link solutions, which in turn drives the growth of IO-link market. Hence, rising investment in pharmaceutical industry is being seen as the opportunity for the players operating in the IO-linkmarket during 2021-2026.

Inquiry Before Buying

IO-link Market Segment Analysis - By Geography

Europe dominated the IO-Link Market in 2020 with a share close to 30.18%, followed by North America and APAC. Moreover, it is estimated that Europe will have a significant amount of market growth during the forecast period 2021-2026, owing to technological advancement, early adoption of this technology and government’s initiatives for the development of smart factories. Rising demand for IoT enabled connected devices, industrial automation are the key factors fuelling the growth of this market. Furthermore, this technology has a well-established customer base in this region. Apart from that, continuous development, new advanced product launches of the technology also plays a major role towards the market growth. Europe-based companies such as Siemens AG and General Electric is one of the largest manufacturers of this technology in the world. Devices produced in Siemens are generally equipped with PROFINET and this company dominates the European market. In November 2020, a Germany-based company, Igus joined PI organization, for advancing the research of PROFINET technology in dynamic applications. In February 2019, SICK announced the launch of Safe EFI-pro System, which offers standard industrial Ethernet-based safety network integration for highly-adaptive as well as dynamic safeguarding in automated production and logistics environments to SIL 3/PLe.This kind of strategic movements and technologically advanced product launches will drive the market for this region during the forecast period.

IO-link Market Drivers

Increasing Penetration of Automation:

Increasing adoption of automation across industries is one of the major drivers for IO-Link, triggering the growth for this technology. Integration of automation system across industries offers greater efficiency, higher reliability, enhanced asset management, production boost, better process speed and cost effectiveness, which is accelerating the amount of investments made by organizations to remain productive. This in turn, drives the growth of IO-Link technology, as this technology is a point-to-point serial communication protocol, which is highly being used for communicating with sensors and actuators in industrial automation processes. In July 2020, for digital industrial transformation, Carlo Gavazzi announced the launch of its new IIoT-enabled IO-Link Masters, YL212 and YN115, that supports leading industrial Ethernet-based system protocols including EtherNet/IP, PROFINET IO and MODBUS TCP access. This product has advanced features such as embedded web interface and OPC UA, which offers full remote access, control of the IO-Link masters and connected devices. This product also offers reliability, transparent process data transmission into the cloud-based systems from the sensors and actuators along with access to the data, attached to the smart devices through the Programmable Logic Controller (PLC) and OPC UA clients. This type of product with such unique features fuels the growth of his market. PI Organization’s recent research report shows that, the performance of Profinet RT fulfills 95% timing requirements of industry-based automation. Hence, the adoption of automation will drive the growth of IO-link market during the forecast period.

Schedule a Call

Fieldbus Integration:

IO-Link is an open source interface, which makes this technology a Fieldbus independent solution. It can be integrated into all the fieldbus systems including PROFINET, AS-i, CANopen, CC-Link, PROFIBUS, EtherCAT, EtherNet/IP, DeviceNet, Interbus, Powerlink and others. Different organizations use different networking protocols for their systems, which make the fieldbus-independent IO-Link more suitable for the companies, as it allows the businesses to connect their products to different systems and control level devices including Programmable Logic Controller (PLC), Supervisory control and data acquisition (SCADA) and others. This in turn, saves the investments that are already made by the manufacturers, plant operators, machine builders and others, on the systems. Even when the organizations decide to migrate from one technology to other technology, IO-Link makes the process cost effective, by reducing the overall cost. In January 2019, Korenix introduced a new cost-effective Profinet supported, Fieldbus gateway, JetLink 1302, which can transmit the data faster among the devices and provide seamless communication between fieldbus and industrial Ethernet communication protocol. Hence, the fieldbus independency of IO-Link is one of the major growth drivers of this market.

IO-link Market Challenges

Security Issues:

IO-link technology is vulnerable to various security threats such as cross site request forgery (CSRF), reflected cross-site scripting (XSS), blind command injection, denial-of-service (DoS) issues, spear phishing and others, which hinders the growth of this market. Furthermore, in February 2020, OTORIO security researchers discovered a security weakness in PROFINET-IO stack, which is responsible for handling the packets that being used in device management. If a device is overloaded with multiple diagnostic packets, it may create a security threat that allows the attackers to send the devices into a denial-of-service (DoS) condition, which can create disruption in operational processes. Many industrial devices such as devices produced by Siemens, MoxaEDS Ethernet switches and others; that rely on Siemens PROFINET-IO stack are highly being affected. Hence, the above mentioned factor creates security related issues that will hinder the growth of this market during 2021-2026.

Buy Now

IO-link Market Landscape

Partnerships and acquisitions along with product launches are the key strategies adopted by the players in the IO-link Market. As of 2020, IO-link Market top 10 companies includesSiemens AG, Hans Turck GmbH & Co. KG, Balluff GmbH, Rockwell Automation, Inc.,SICK AG, Omron Corporation, Pepperl+Fuchs SE,Schneider Electric, General Electric,B&R Industrial Automation GmbH among others.

Acquisitions/Technology Launches

In March 2020, Harting Americas had launched Single Pair Ethernet (SPE) technology, thatutilizes Power over Data Line (PoDL) technology to bring communication to the devices and also the voltage and amperage needed to power the device. SPE communication protocols are available for Ethernet/IP, Profinet, EtherCat and others.

In February 2020, European company, SICK had launched a sensor integrated PROFINET gateway, which is the first product that can act as both IO-Link Masters and control system.

For more Electronics related reports, please click here

#IO-link Market price#IO-link Market share#io link market#IO-link Market trends#IO-link Market report#IO-link Market analysis#IO-link Market forecast#IO-link

0 notes

Text

Automated Blinds In Coquitlam: Top 3 Things To Consider

With the increasing popularity of home Automated Blinds in Coquitlam and the number of Smart gadgets such as speakers, sensors, etc., in-home automation of window coverings has become a typical question for customers. Consider these 3 things before making a decision.

Home Automation and the advancement of various devices like speakers, sensors, and so on have triggered a surge of interest in automated window coverings. Many customers prefer automated blinds for the ease of voice-control, remote access, hassle-free operation etc.

Generally, there are three factors to consider when choosing a custom automated window blinds setup:

1. Automation need

2. Choice of window covering

3. Integrating the system

1. Automation need

While it can be amazing to presume that I can have full control of all the shades and draperies in my home by lifting apart a wall-mounted remote control or hailing my smart speaker with my simple name, this is not a practical solution in the long run, as I will discover after purchasing several sets of custom-made drapery control for each pane of glass.

Instead of focusing on windows that they ought to automate, you could instead focus on windows which represent the maximum benefit.

Common things to consider :

• Can the window be opened?

Is the window too narrow, such as, for example, large windows that require them to be pulled back by levers or rods somewhat? Or tall windows.

• Are there scheduling times that describe how you need to operate the window treatments? For example, is it necessary to close the shades before leaving for work?

• Am I going to need to oversee multiple windows in a room to achieve the desired atmosphere?

• Do my home automation system include controls to control shades drapery?

2. Window covering choices

When researching which windows to have automated shades or drapes installed, consider the type of product you'd like for the windows.

Products are specified for shading, privacy, outside appearance, and design to create a variety of light environments in a room with multiple windows. You may need to address multiple window coverings at once to control the quantity of light inside the room appropriately. In some cases, a window shading or drapery may require a 3rd position besides full open or fully close.

Manual guidance of 1 or 2 shades can be a better option in many instances, however, in rooms with several windows, centralized control of shades may be more beneficial. With a motorization update from a specialist like us, you can get the results you want at a sensible rate with long-term quality in mind.

3. Integrating systems

With new competing products in the market, there are no front standards. The technology used in automated window coverings (blinds and curtains) must remain future-proof, trading standard apps for home automation that control light, music, security, garage door, and window covering can be used if the home has this degree of automation and lights, curtains, and accessories can be controlled by a single app.

Integrating Technologies

Our products fully integrate with a variety of different third-party technologies.

Radio Technology Somfy® (RTS): Programmable motorized systems can be controlled via a wireless radio via the RTS family of controls.

Somfy Digital NetworkTM (SDN) A control method that uses a two-wire bus is RS485.

Z-Wave R: It is a wireless, 2-way RF networking technology used in both residential and office automation applications.

Zigbee Protocol: An RF mesh networking technology that relies on 2.4GHz nodes is used for commercial and residential applications.

Third-Party Automation Systems

Our expert technicians can mount your home automation system of choice, whether it be Crestron, Control4, or Amazon Alexa. We can also ensure that your motorized window coverings work with your system of choice.

Whether it's high-end home automation systems such as Crestron or Control4 or the latest consumer-grade wireless solutions such as Amazon Alexa, we can assure you that contemporary mechanized window treatment product integration can occur using the system of your choosing.

Conclusion

Each protocol and communication standard has its proponents and supporters. The reality is that there’s no way of knowing which technology or standard will prevail.

Even if you are inclined to use a skeleton-like controller with switches and remote controls to control safety concerns in your window coverings, you need to learn of the broader products that may make your motorized window treatments more stable. When you are choosing motor brands that are large enough for your blinds, shades or draperies, you should seek out motor manufacturers that are standard brands. Famous companies use proprietary processing techniques that do not work out across multiple platforms. This article was originally posted on: https://sunblinds.ca/vancouver/automating-your-blinds/

0 notes

Text

Industrial IoT Devices | Programmable Ethernet IoT Device | Industrial ESP32 | NORVI

Ready for the Future - NORVI IIOT

Programmable IoT Devices - Our Arduino based PLC s make it easy to automate processes, connect sensors, and create sophisticated automation systems. Get the most out of your IoT projects with programmable ESP32 Ethernet device. Our MQTT end device is designed to be easy to setup, while providing powerful performance.

Industrial Arduino Mega - Get reliable, secure, and customizable control of your industrial processes with Arduino Mega PLCs. Get the best out of your system. Industrial Arduino for Automation Applications which control industrial processes with Arduino based hardware and software. Programmable with Arduino IDE.

Modbus MQTT Device - NORVI Agent Industrial IoT Node. Ready to use IoT Node. Ready for industrial applications. WiFi LoRa NB-IoT. Wall mount IoT node is designed for industrial applications and boasts a range of features including WiFi, GSM, LTE and LoRa connectivity. Battery Powered IoT node with WiFi GSM LTE LoRa connectivity for industrial applications. Our programmable nodes are designed for powering your IoT solutions.

ModBus RTU ESP32 - MODBUS Communication on ESP32 NORVI IIOT via RS-485. ModBus RTU with ESP32 based industrial controller. MQTT over Ethernet devices - Norvi offers programmable MQTT devices come with a variety of features that make them suitable for industrial automation and IoT solutions. As a leading industrial IoT device manufacturer, NORVI Offers Industrial Controllers for IoT applications, ESP32 based Industrial Controllers, Industrial IoT Devices. Changing IOT One Device At A Time (4 - 20mA, 0 - 10V DC Analog inputs and Outputs). Programmable controllers with flexibility and open source software.

ESP32 Data Logger - NORVI can build a WiFi Data Logger using SD card, Combining few libraries of Arduino you can access or view the Temperature & Humidity via WiFi. NORVI's Analog Input ESP32 is designed for industrial applications, allowing you to measure and monitor 0-10V or 4-20mA signals using an ESP32 controller.

NORVI Controllers

Our Address :

ICONIC DEVICES PVT LTD

Phone : +94 41 226 1776 Phone : +94 77 111 1776

E-mail : [email protected] / [email protected]

Web : www.icd.lk

Distributors

USA

Harnesses Motion LLC

1660 Bramble Rd. Tecumseh, MI

49286, United States

Phone : +1 (734) 347-9115

E-mail : [email protected]

EUROPE

CarTFT.com e.K.

Hauffstraße 7

72762 Reutlingen

Deutschland

Phone : +49 7121 3878264

E-mail : [email protected]

Products :

ESP32 Ethernet Device

Industrial Arduino Mega

ESP32 Modbus device

Programmable sensor node

Battery Powered Programmable Sensor node

4 - 20mA ESP32

Know More About:

WiFi Datalogger

4 - 20mA Arduino device

Industrial IoT Devices

Modbus MQTT gateway

Arduino based Industrial Controller

#Programmable IoT Devices#Industrial IoT Devices#Industrial Arduino#Arduino PLC#ESP32 Ethernet Device#Programmable Ethernet IoT Device#MQTT End Device#Industrial Arduino Mega#Arduino Mega PLC#Arduino based Industrial Controller#Programmable MQTT Device#Modbus MQTT Device#ESP32 Modbus device#Wall mount IoT Node#Wall mount sensor node#Programmable sensor node#Wireless sensor#Battery Powered IoT Node#Battery Powered Programmable Sensor node#Solar powered sensor node#MODBUS RTU ESP32#Modbus to IoT gateway#Modbus MQTT gateway#Programmable MQTT devices#MQTT over WIFI devices#MQTT over Ethernet devices#Industrial IoT device manufacturer#0 - 10V Arduino device#4 - 20mA Arduino device#ESP32 data logger

0 notes

Text

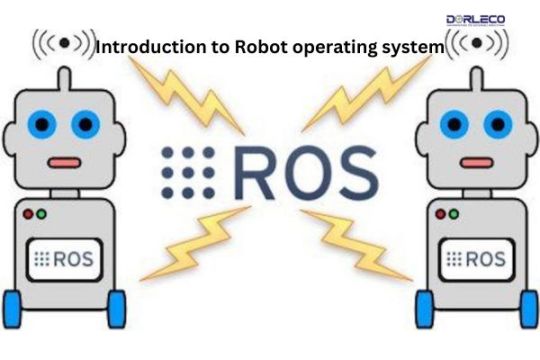

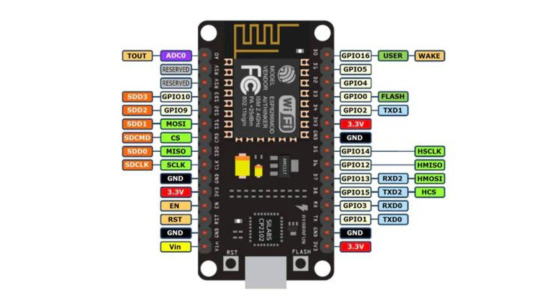

All About ESP32 Development Board with Wi-fi & Bluetooth and AMICA Node MCU ESP8266 Module

The ESP32 Development Board with Wifi and Bluetooth is a low-footprint, minimal system development board powered by the latest ESP-WROOM-32 module and can be easily inserted into a solderless breadboard.

It includes the ESP-entire WROOM-32's basic support circuitry, including the USB-UART bridge, reset and boot-mode buttons, an LDO regulator, and a micro-USB connector. The developer has access to every important GPIO.

Projects That You Can Do With The ESP32 Development Board With Wifi And Bluetooth:-

Universal low-power IoT sensor hub

Home automation.

Mesh network.

Industrial wireless control.

Sensor networks.

Smart Socket.

Wi-Fi speech recognition device.

AMICA Node MCU ESP8266 Module:-

The AMICA Node MCU is an excellent Wi-Fi chip that can be used in a variety of wireless applications. Arduino-style hardware io that is interactive and programmable. The board's Micro USB slot can be directly connected to a computer or other USB host devices. It is a great way to add internet connectivity to any embedded project.

Projects That You Can Do With The AMICA Node MCU ESP8266 Module:-

Internet Smoked Alarm

VR Tracker

Octopod

Serial Port Monitor

ESP Lamp

Incubator Controller

IoT home automation

Security Alarms

1 note

·

View note

Text

Webots for nao

WEBOTS FOR NAO SIMULATOR

We use the naoqi_bridge_msgs package to publish the FSRs sensors within a FloatArrayStamped message. We also run a supervisor node that publishes the ground truth torso pose.

WEBOTS FOR NAO SIMULATOR

terms, our results show that Webots is the simulator with the lowest use of resources. Particularly, we launch a controller node to publish NAO sensor data within ROS, as well as providing a simple control scheme based on a Webots example, using precomputed movements. 20 times a robotic scenario composed by a NAO robot that must. The webots_run package will allow you to execute Webots within ROS, and automatically will use the controller set in the world file passed as argument to Webots( nao_demo.wbt by default). It is highly recommended to use a launch file, you can use run.launch as an example. ( This was fixed temporarily in the CmakeLists file, but in a not elegant way ) Running the nodes NAO (pronounced now) is an autonomous, programmable humanoid robot developed by Aldebaran Robotics. Particularly, you must copy the executable to $WEBOTS_HOME/projects/robots/aldebaran/controllers/nao_webots_node in order to let Webots to find the controller. Nao robots in a Webots RoboCup soccer simulation. nao_webots_node) into the Webots controller folder. However, you must copy the executable generated by catkin (i.e. Since everything is catkinized, catkin_make is enough to build everything. One walking behavior is the Move To box in Choregraphe the other is a walkin. Set WEBOTS_HOME to the folder where you put Webots. This video demonstrates 2 different walking behaviors on a simulated NAO robot.NAOqi enabled controller for simulated NAO robots in Webots. We must set some environment variables before: Browse The Most Popular 29 Nao Robot Open Source Projects. An interface between ROS and Webots for the NAO robot Requirements

0 notes

Text

Use click plc as modbus server

#Use click plc as modbus server code

#Use click plc as modbus server code

This must be imported into the code to be used. In an Allen Bradley PLC, such as the Compact or ControlLogix series, an Add-On Instruction (AOI) for Modbus is available from Rockwell Automation for Modbus TCP transactions. No explanation is complete without a couple of examples as to how this might look. She or he must know: the device address (not called a node anymore, but the same thing), the function code, the starting address, and the length (if multiple). The IP address is usually able to be changed with external software, or sometimes by means of DIP switches embedded in the device. It can even be on the same network as the rest of the Ethernet devices, as long as the network parameters can be configured properly (the IP address, subnet mask, etc). This means that an Ethernet port can be used as the physical connection for a Modbus TCP device. However, in the TCP structure, the network communication is handled using industry-standard industrial Ethernet messaging. Not to sound redundant, but the programmer once again only needs to know those same basic elements as before. In summary, all the programmer needs to know for both RTU and ASCII is the node #, function code, starting address, and length (if multiple). In the Modbus ASCII system, the same data is provided as for the Modbus RTU, except rather than using binary equivalents of the function codes, it uses the ASCII equivalents.Īgain, the good news is that all the programmer needs to understand is whether the device is programmed for Modbus RTU or ASCII, and choose the appropriate format from a list. When you press buttons on a keyboard, each letter, number, and character is given a special standardized code. In RTU, all data is formatted as binary equivalents of the decimal codes, but the good news is that the programmer usually doesn’t need to know or care about how it does this. Node # (since RS-232 and 485 networks are defined by nodes), the function code, the starting address, and the ending address. Modbus for remote terminal units (RTU) is a method of structuring a data packet so that the data transmission includes the following pieces: This provides a lot of flexibility and customization over which terminals are accessible easily from other devices. Some controllers allow you to choose the Modbus address for each I/O terminal manually. The same goes for writing or reading, and for discrete and word information. Function code 15, starting address 0, now with a length of 3.If you wish to turn on the first three digital outputs, the structure would look like this: Therefore, if you wish to energize that output, you must use the following structure: When a Modbus device is manufactured, each terminal or task (for example, the first digital output of a remote I/O terminal, or maybe the stop command for a VFD) will have the built-in address of 0. The only other factor that must be identified in order to share information is the address of a contact, coil, or register. The complete list of available function codes for Modbus I/O commands is the following: Description Note that you cannot write to an input contact - only the real-world device (button, sensor) has the ability to write itself. So the slightly elaborated list of possible Modbus functions includes: In slightly longer detail, those words are called ‘registers’, and those ‘bits’ may be output coils or input contacts. Read words (usually words are 16-bit integers).In short, there are 4 things we can do with Modbus: There is a small selection of codes used to identify what type of information we want to use, and what task we wish to perform. Therefore, if we wish to share information with I/O devices, it would seem logical to assume that all we must determine is whether the information is discrete or analog, and whether we are reading or writing the information. I/O and data exist as either discrete (boolean) or multi-bit words (as integers or floating-point values). Modbus TCP takes advantage of common standards, while still maintaining a simplified code function code and address structure. On the other hand, perhaps it is useful to adopt standardized protocols to some limited extent in order to take advantage of the many sockets and plugs that exist in modern equipment, such as Ethernet ports.įigure 1. It is neither necessary nor beneficial to rely on protocols that require massive packets of configuration data when only simple data transmissions are requested. Modbus is a communication protocol commonly used with input/output (I/O) data to share information at this simple device network level.

0 notes

Text

Self Intro @ RCA DD

my website:

https://dimchen.com/

presentation (Google Slide):

https://docs.google.com/presentation/d/1QgjNRtCHKFAJ-dwIoH7Tg2SQJXjO03tLy3aBXmd6398/edit#slide=id.g13945637188_0_1233

So ...... Hello everyone I'm Chen Yang, I come from a computer science background and graduated from Beijing University of Posts and Telecommunications. As you can see, I use anime avatar (laughs) and I'm just a silent designer and developer. Next is my experience. Please don't be shocked by this photo - this is the person I used to be. I like to experiment with different hairstyles, so the next year could also be very different for me than it is now. So, while in college, I (the man!) worked on machine learning at CASIA, known as The Institute of Automation, Chinese Academy of Sciences. Then I worked on pattern recognition, human cognition, and data visualization at Microsoft Research Asia and Tencent PCG. Of course, for reasons I've mentioned before - if I could explain it again, I was tired of writing lots of apps that push spam and ad notifications to everyone's phone - I finally decided to study digital arts. By the way, my interests are mainly music games, MMORPGs, and synthesizers, and I learned that there are a lot of students in our program who are good at music, and I want to learn from you.

Next I'd like to start with a research project I'm working on. Please take a look at these three pictures: they are all buildings under construction by humans, but not built. As you know, programmers like to give their projects fancy names before they write code (laughs), so that's what the name means: great but unfinished intellectual achievements of human communities. As I said, I do a lot of data-related work: this is using sensors to collect physical simulations and hydrological information about rivers; this is using Internet data to restore human personalities and habits; this is using machines to understand and generate classical music; this is using sensors to reflect the relationship of the human organism to confront and adapt to its environment. In doing this work, I realized a question: do sensors and data now connect all living things to the world, and is there an abstract pattern in this that can decipher the relationship of our minds to the world? See the related work here: a series of big data devices, reflections on the origin of the universe, and some topological structures are included. These structures appear as Feynman diagrams in physics, nodes in the TouchDesigner we normally use, neural networks, and the pentagram of the sound network. So with this project I hope to investigate a new way of interaction and visualization that allows people to interact with the vast amount of data and the nature of the existence of the universe in an intuitive way. So this project is about our outward connection to this material world.

The next project's is of interest to me in the midst of storytelling. Look at this graphic: this is the Buddhist Karma, a symbol that describes the connection between karma and things in one's reincarnation. Perhaps people with different beliefs will think of concepts within sin and punishment. I went through a period of anxiety and depression - something I'm sure many people here have felt (laughs) at a time when I realized that in modern society people are so atomized and isolated, and that the connections between us are false: not about political topics, preferences or clothing, but deeper emotional connections. ok. So at the time I was making all kinds of games, like platform-hopping action games, music games, and a pet companion to accompany you on your travels. I was trying to use all sorts of intuitive means to make the player experience storytelling and emotion. At this time I was also exposed to mythology as well as anthropology, and I became interested in the ability of artists to influence people's imperceptible subconscious as well as behavioral patterns like shamans. So this is my question: the possibility of story and emotional influence on our perceived connection to others and the world. Awareness of our bodies, cells and atoms, sharing the same atoms as all planets and creatures, and a shared responsibility for the future of the universe, and the inevitable entropy increase and thermal silence. So you'll see in the works I've referenced so far a series of video games that are designed to allow the viewer to interact intuitively with the world and the flow of emotions, and to reflect on the fragility and narcissism of their own lives.

OK. I'll end with this: I've done product design, studied machine learning and data visualization, and now I want to study 3D, music and illustration, but the most important thing I've learned is not to be limited by the way I present myself. Go and break down all the barriers (like color weakness (laughs)) and then find new means to present the subject you want to explore. That's why I'm here. Thank you all.

1 note

·

View note

Text

INTELLIGENT INDUSTRIAL REMOTE MONITORING APPLICATIONS

WHAT IS THE PROCESS FOR INDUSTRIAL REMOTE MONITORING?

Industrial Engineers and industrial supervisors can take remedial action at the right moment through remote monitoring utilising IoT features to gather data about the operations of any particular unit or machine and communicate that data back over the cloud.

IOT’S IMPACT ON IMPROVED AND IMPLEMENTED INDUSTRIAL MONITORING

IoT fully utilises the capabilities of intelligent equipment and uses real-time data analytics to extract insights that may be put to use. Here is further information on how industrial remote monitoring has been enhanced by IoT.

Smart machines include software and sensors that can track and gather data.

These data are stored and processed by cloud computing platforms.

high-end data analytics solutions that extract insightful information from the gathered data and communicate that information to engineers and industrial managers.

INDUSTRIAL REMOTE MONITORING ADVANTAGES

ENHANCE EFFICIENCY

The capacity for factories to automate, and thereby maximise their operational efficiency, is the major advantage of IIoT. Robotics and automated equipment may operate more precisely and productively, increasing output and assisting firms in streamlining their processes.

Manufacturers can increase operational efficiency through the use of IIoT-enabled data systems by:

automating manual processes and replacing them with digital ones

making judgments on all industrial functions based on data

Monitoring performance from anywhere, perhaps from thousands of kilometres distant or the production floor

REDUCE MISTAKES

Manufacturers may digitise almost every aspect of their operations thanks to industrial IoT. Manufacturers may lower the main risk associated with manual labour, human error, by minimising manual processes and entries.

LOWER COSTS

Knowing something gives you power, and IIoT solutions are offering manufacturers the knowledge they need to save costs and increase revenue. Businesses may be directed in a lucrative path by data-driven insights into operations, production, marketing, sales, and other areas.

THE FOLLOWING COMPONENTS ARE INCLUDED IN IOT MONITORING SOLUTIONS:

DEVICES AT THE FRONT-END EDGE

These are several sensor-based Internet of Things devices that gather data when a system needs to be monitored. These gadgets are in charge of gathering sensor data. They must be trustworthy and safe.

AUTHENTICATION TECHNOLOGIES

WI-FI IN SOLUTIONS FOR REMOTE MONITORING

Wi-Fi is a LAN that offers internet connectivity inside a constrained region, making it suitable for IIoT applications that operate locally. Being a star network, where all nodes or devices link to a single central hub, it is simple to add or remove devices without impacting the network as a whole.

THE CONNECTIVITY PROTOCOL FOR BLUETOOTH

Bluetooth is a low-cost, short-range technology, but it only functions when terminals are used in the same space as an access point. Bluetooth performs well in an industrial IoT environment if sensors are placed roughly equally (such as HVAC sensors and lighting) but less so for sporadic deployments (paper dispensers, power monitors, industrial monitors).

TELEPHONE NETWORKS FOR TRANSMITTING DATA

Cellular networks are a viable alternative for IoT connectivity since they are available almost everywhere and are controlled by cellular network operators. IoT devices employ two cellular networks: LTE-M and NB-IoT.

WIDE AREA LOW POWER NETWORKS