#Printed Electronic Materials Industry

Explore tagged Tumblr posts

Text

#Printed Electronic Materials Market#Printed Electronic Materials Report#Printed Electronic Materials Industry#Advanced Material#Bisresearch

0 notes

Text

The Future of Electronic Industrial Finishing: What You Need to Know

Explore the latest trends in electronic industrial finishing, from miniaturisation to environmentally friendly processes. Discover how automation and advanced surface treatments are revolutionising the industry. Contact A-Gas Electronic Materials to stay ahead with innovative finishing solutions for your electronic products.

#electronic industrial finishing#advanced surface treatments UK#nanocoatings#graphene-based coatings UK#3D printing finishing UK#electronic components finishing UK#electroless plating UK#A-Gas Electronic Materials

0 notes

Text

3D Printing Materials Market - Global Opportunity Analysis and Industry Forecast (2021-2028)

Meticulous Research®— a leading global market research company, published a research report titled “3D Printing Materials Market by Type (Polymer, Metal, Ceramics & Composites), Form (Filament, Liquid, Powder), Technology (FDM, SLA, Polyjet, Multijet, Binder Jetting, EBM), Application - Global Forecast to 2028”.

The 3D printing materials market is expected to grow at a CAGR of 26.7% by value from 2021 to reach $9.86 billion by 2028. The growth of this market is majorly attributed to factors such as growing demand for polymers in 3D printing, mass customization of various functional parts for industrial equipment, jewelry and consumer goods, and government initiatives to support the adoption of 3D printing. However, the high costs of 3D printing materials obstruct the growth of this market to some extent. Lack of awareness of 3D printing technology among supplies, buyers, users, and lack of skilled laborers to perform 3D printing operations is a major challenge for the growth of the 3D printing materials market.

Download Sample Report Here : https://www.meticulousresearch.com/download-sample-report/cp_id=5083

Scope of the Report

3D Printing Materials Market, by Type

· Polymer

o Photopolymer

o Polylactic Acid

o Acrylic Styrene

o Polyamide

o Polycarbonates

o Polypropylene

o Thermoplastic Elastomers

o Other Polymers

· Metal

o Steel

o Titanium

o Nickel

o Aluminum

o Copper

o Cobalt Chrome

o Other Metals

· Ceramics & Composites

3D Printing Materials Market, by Form

· Filament

· Liquid

· Powder

3D Printing Materials Market, by Technology

· Fused Deposition Modeling (FDM)

· Selective Laser Sintering (SLS)

· Stereolithography (SLA)

· Direct Metal Laser Sintering (DMLS)

· PolyJet

· Multi Jet Fusion

· Digital Light Processing (DLP)

· Binder Jetting

· Electron-beam Melting (EBM)

· Other Technologies

3D Printing Materials Market, by Application

· Consumer Products

o Electronic appliances

o Jewelry, Artistic Items, and Other Products

· Automotive Parts

· Industrial Application

o Equipment & Machines

o Goods & Materials

· Healthcare

· Aerospace & Defense

o Prototype Weapon

o Body & Spare parts

· Other Applications

3D Printing Materials Market, by Geography

· North America

o U.S.

o Canada

· Asia-Pacific (APAC)

o China

o Japan

o India

o South Korea

o Rest of APAC (RoAPAC)

· Europe

o Germany

o U.K.

o Italy

o France

o Russia

o Spain

o Rest of Europe

· Latin America

· Middle East & Africa (MEA)

Access full Report Description, TOC, Table of Figure, Chart, etc: https://www.meticulousresearch.com/product/3d-printing-materials-market-5083

The market is segmented based on type, form, technology, application, and geography. The study also evaluates industry competitors and analyzes the market at the country level.

Based on type, the 3D printing materials market is mainly segmented into polymers, metals, and ceramics & composites. By value, in 2021, the polymers segment is expected to account for the largest share of the 3D printing materials market. The large share of this segment is mainly attributed to its properties such as lightweight, corrosion resistance, toughness, and high strength, increasing demand for 3D-printed retainers made from nylon (PA66) or other polymers to reduce bearing weight, and the use of polymers to manufacture live saving equipment during COVID-19 pandemic. However, the ceramics & composites segment is expected to grow at the highest CAGR during the forecast period.

Based on form, the 3D printing materials market is segmented into powders, filaments, and liquids. In 2021, the powders segment is expected to account for the largest share of the 3D printing materials market. The large share of this segment is mainly attributed to the high demand for designing animal prosthetics, increasing demand for processing various industrial metals by using powder-based additive manufacturing, and manufacturing of three-dimensional lithium-iron batteries. However, the filaments segment is expected to grow at the highest CAGR during the forecast period.

Based on technology, the 3D printing materials market is segmented into fused deposition modeling (FDM), selective laser sintering (SLS), stereolithography (SLA), direct metal laser sintering (DMLS), polyjet, multijet fusion, digital light processing (DLP), binder jetting, and electron-beam melting (EBM). The fused deposition modeling (FDM) segment is expected to account for the largest share of the 3D printing materials market in 2021. The large share of this segment is mainly attributed to the ability to adjust several process parameters, such as both nozzle and build platform temperatures, and growing demand for using high-performance thermoplastics in FDM technology to manufacture customized parts and prototypes. However, the EBM segment is expected to grow at the highest CAGR during the forecast period.

Speak with Our Analyst: https://www.meticulousresearch.com/speak-to-analyst/cp_id=5083 Based on application, the 3D printing materials market is segmented into consumer products, automotive parts, industrial applications, healthcare, and aerospace & defense. The consumer products segment is expected to account for the largest share of the 3D printing materials market in 2021. The large share of this segment is mainly attributed to factors such as growing demand for customized 3D printed consumer goods, high adoption of 3D printing technology by industrial designers, mechanical engineers, packaging designers, and graphic artists to understand the aesthetics and functional appeal of the products.

Geographically, North America is expected to account for the largest share of 3D printing materials in 2021. The large share of this market is mainly attributed to the presence of major 3D printing materials companies, namely 3D Systems Corporation (U.S.), Proto Labs, Ltd., (U.S.), The ExOne Company (US), HP INC. (U.S.), EnvisionTEC, Inc. (U.S.), Markforged, Inc. (U.S.), and Tethon 3D (U.S.) for high adoption of 3D printing technology for making orthopedic and cranial implants, surgical instruments, dental restorations such as crowns, and external prosthetics in the healthcare industry.

The key players operating in the 3D printing materials market are 3D Systems Corporation (U.S.), Proto Labs, Ltd., (U.S.), The ExOne Company (U.S.), HP INC. (U.S.), EnvisionTEC, Inc. (U.S.), Markforged, Inc. (U.S.), Tethon 3D (U.S.), Evonik Industries AG (Germany), Materialise NV (Belgium), EOS GmbH (Germany), Stratasys Ltd. (Israel), Zortrax (Poland), Sculpteo (France), Lithoz GmbH (Austria), and IC3D, LLC. (U.S.).

Download Free Research Sample @ https://www.meticulousresearch.com/download-sample-report/cp_id=5083

Key Questions Answered in the Report-

· Which are the high-growth market segments in terms of type, form, technology, application, and geography?

· What is the historical market size for 3D printing materials across the globe?

· What are the market forecasts and estimates for the period 2021-2028?

· What are the major drivers, restraints, opportunities, and challenges in the 3D printing materials market?

· Who are the major players in the market, and what are their market shares?

· Who are the major players in various countries?

· How is the competitive landscape for the 3D printing materials market?

· What are the recent developments in the 3D printing materials market?

· What are the different strategies adopted by the major players in the market?

· What are the key geographic trends, and which are the high-growth countries?

· Who are the local emerging players in the 3D printing materials market, and how do they compete with other players?

Contact Us:

Meticulous Research®

Email-

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn-

https://www.linkedin.com/company/meticulous-research

#3D Printing Materials Market#3D Printing Materials#3D Printing#Printing Materials Market#Chemicals and Materials#Chemicals#printing industry#printing#chemical industry#printing and packaging#automotive#electronics#consumer electronics#aerospace

0 notes

Text

Printed electronics material can store 1,000 times more charge than current forms

Imagine knowing your milk has gone bad without having to open your fridge. A technology called printed electronics could one day make innovations like this possible. Printed electronics refers to electronic circuits in sheets that are thin and bendable. The technology is already being used to make everything from solar cells for vehicle roofs to flexible displays on smart phones. Using the Canadian Light Source (CLS) at the University of Saskatchewan (USask), a team of researchers from Simon Fraser University (SFU) and USask developed a material that stores up to 1,000 times more charge than current forms of printed electronics. The group's work could move the concept of the Internet of Things another step closer to reality. The Internet of Things involves adding printed electronics to the everyday objects in our lives—for example, milk cartons and fridges—to enable communication between these objects and our smart phones and computers. Such an advance could open up a world of technological possibilities. For the food industry alone, this would help to minimize waste and spoilage at all levels of the supply chain.

Read more.

20 notes

·

View notes

Text

Role models: circular economy examples in manufacturing

Circular manufacturing or circular economy is a means of production, distribution, and consumption where producers bring materials from end-of-life goods back into the economy through reuse, recycling, and recovery instead of disposing of them as waste.

1. Stora Enso Sunila Mill: a pulp-based refinery plant

Stora Enso Sunila Mill in Finland was the first in the world to extract lignin in a pulp-based refinery plant. The pulp and paper industry is one of the largest manufacturing sectors in the world. It uses 12-15 percent of the wood from forests, which could double by 2050, according to the World Wildlife Fund (WWF).

To make the most of the wood they use, Stora Enso Sunila Mill, which owns one of the most extensive private forests in the world, has adopted the circular economy by reusing, recycling, and recovering materials at the mill.

The business sources pulp from their sustainably managed private forests to make paper and packaging to replace plastic. They also produce circular industrial products that are alternatives to fossil fuel-based non-renewable products

2. ReSolved Technologies: Closed-loop plastic recycling

A Dutch startup, ReSolved Technologies, has developed a closed-loop recycling solution for engineering plastics in electronic devices and automobiles.

Engineering plastics are complex and contain additives that make recycling difficult. 95 per cent of these plastics are downcycled, incinerated, or landfilled.

ReSolved Technologies’ solvent-based recycling technique removes additives like fillers, flame retardants, and colourants, and separates different types of plastics. The recycled plastics are good quality and they can be used to make engineering plastics again. This technology can be used to complement existing mechanical recycling facilities for plastics.

ReSolved Technologies closes the materials loop by turning electronic waste into new electronic devices. Their plastic recycling technology prevents the extraction of fossil fuels for new production and reduces plastic waste and pollution problems.

3. Batch.Works: Smart and circular manufacturing

Another Dutch startup, Batch.Works, offers 3D printing for “Circular Manufacturing as a Service (CmaaS)” using AI-driven factories.

The company uses circular materials like recycled plastics or agricultural waste from traceable sources to make new parts for the manufacturing industry. They offer smart 3D printing to meet on-demand digital production for just-in-time manufacturing, thus reducing overproduction and waste.

The company has a take-back policy for its products to recycle materials and leverages digital warehousing services from third parties for flexibility and scaling. Its novel manufacturing model creates short supply chains to reduce transportation costs and increase agility.

The short supply chain and digital warehousing cut transport pollution and emissions, and small-batch production makes manufacturing sustainable and cost-effective for client firms.

And many more examples in the link:

#solarpunk#solarpunk business#solarpunk business models#solar punk#startup#reculture#circular manufacturing#circular economy#industrial ecosystems

6 notes

·

View notes

Text

Why Poly Bags Are Essential for Retail and Industrial Packaging

In the world of packaging, few tools can compare to the versatility and utility of poly bags. From retail businesses to industrial sectors, these unassuming plastic sacks are essential for modern packaging solutions. But beyond their common use, poly bags offer a multitude of benefits across various industries. Whether you’re in retail, manufacturing, food, healthcare, agriculture, or event planning, understanding the importance of poly bags—and why they’re crucial—can optimize your operations and improve your bottom line.

Understanding Poly Bags

Poly bags, short for polyethylene bags, are made from a type of plastic known for its durability and flexibility. They come in various sizes, thicknesses, and designs, including open flat bags, gusseted bags, zipper bags, and more. Their adaptability to different packaging needs makes them an ideal choice for a wide range of applications.

The Benefits of Using Poly Bags

1. Versatility Across Industries

Poly bags cater to diverse needs, making them a staple in industries like retail, food, and healthcare. In retail, they serve as an economical packaging option for clothes, electronics, and hardware. In the food sector, their food-safe properties make them ideal for storing perishables safely. Healthcare sectors utilize them for sterile packaging of medical supplies, ensuring contamination-free storage.

2. Cost-Effective Solution

One of the main advantages of poly bags is their cost-effectiveness. Their lightweight nature reduces shipping costs, while their affordability makes them a budget-friendly option for businesses looking to optimize their packaging expenses without compromising quality.

3. Durability and Protection

Poly bags provide an unsurpassed level of protection for products against dirt, moisture, and damage during transportation and storage. The InfinitePack 1 Mil Clear Plastic Flat Open Poly Bags, for instance, boast extra strength and durability. Their 1 mil thickness ensures that even delicate items remain intact and protected.

4. Customization Options

Businesses can customize poly bags with logos, designs, and branding, offering a unique marketing opportunity. Custom-printed poly bags help reinforce brand identity and enhance the customer experience by adding a professional touch to packaging.

5. Eco-Friendly Options

In response to growing environmental concerns, many manufacturers now offer eco-friendly poly bag options made from biodegradable or recyclable materials. These alternatives allow businesses to maintain their commitment to sustainability while still enjoying the benefits of traditional poly bags.

Applications of Poly Bags in Key Industries

Retail Businesses

Retailers benefit from poly bags' affordability and convenience, using them for packaging clothing, accessories, and other merchandise. Their transparency allows customers to view products easily, enhancing the shopping experience.

Manufacturers and Distributors

For manufacturers and distributors, poly bags streamline the packaging process with their versatile application in bulk storage, transportation, and protection against environmental elements.

Food Industry

Poly bags play a critical role in the food industry, meeting all food safety requirements. The food-grade quality of bags like the InfinitePack ensures safe storage of perishables, snacks, or prepared meals.

Healthcare and Pharmaceutical Industry

In healthcare, sterile packaging is crucial. Poly bags provide a hygienic solution for storing medical instruments, supplies, and pharmaceuticals, reducing the risk of contamination.

Agriculture and Landscaping

Farmers and landscapers use poly bags for seed storage, plant protection, and packaging fertilizers. Their durability withstands the rigors of outdoor conditions, ensuring the integrity of agricultural products.

Event Planners and Marketers

For event planners and marketers, poly bags offer a convenient way to package promotional materials, giveaways, and event supplies. Customizable options also allow for branded packaging that enhances event visibility.

Highlighting InfinitePack 1 Mil Clear Plastic Flat Open Poly Bags

The InfinitePack 1 Mil Clear Plastic Flat Open Poly Bags serve as an excellent example of the versatility and efficiency of poly bags. Here are some key features and benefits:

Exceptional Value & Quality: Made from high-quality materials, providing extra strength and durability.

Stock Up for Any Occasion: Perfect for a variety of uses, from holiday treats to small item storage.

Perfectly Sized & Durable: Measuring 18" x 24" with a sturdy 1 mil thickness, they cater to multiple needs.

Food-Grade & Safe: Certified food-safe to meet all storage requirements, with options for heat sealing or twist tie closure.

Multi-Purpose Utility: Suitable for storing food, organizing supplies, and protecting items from dust and damage.

2 notes

·

View notes

Text

The Benefits of Ordering Printed Circuit Boards Online: A Guide to Choosing the Right PCB Manufacturer

In today's rapidly advancing technological landscape, printed circuit boards (PCBs) play a crucial role in various electronic devices, from smartphones to industrial machinery. As demand for these essential components grows, businesses and hobbyists alike seek efficient and cost-effective solutions for obtaining high-quality PCBs. One of the most convenient methods is to order printed circuit boards online. In this article, we will explore the advantages of ordering PCBs online and provide insights into selecting a reputable PCB manufacturer.

Why Order Printed Circuit Boards Online?

Ordering printed circuit boards online offers several benefits, making it an attractive option for many businesses and individuals:

Convenience: The ability to order PCBs from the comfort of your home or office eliminates the need for in-person visits to manufacturers or suppliers. This convenience saves time and effort, allowing you to focus on your projects or business operations.

Wide Range of Options: Online PCB manufacturers offer a variety of options in terms of materials, layer counts, finishes, and more. This flexibility allows you to customize your PCBs according to your specific requirements and budget.

Cost-Effectiveness: Many online PCB manufacturers provide competitive pricing, especially for bulk orders. Additionally, you can easily compare prices and services from different providers, ensuring you get the best value for your money.

Quick Turnaround Times: Online ordering often comes with expedited production and shipping options, allowing you to receive your PCBs faster. This is particularly beneficial for projects with tight deadlines or when you need quick prototypes.

Access to Advanced Technologies: Many online PCB manufacturers offer advanced technologies such as high-frequency PCBs, flexible PCBs, and more. This access to cutting-edge technology ensures your designs are compatible with the latest industry standards.

Choosing the Right PCB Manufacturer

Selecting the right PCB manufacturer is crucial to ensuring the quality and reliability of your printed circuit boards. Here are some key factors to consider when choosing a PCB manufacturer:

Experience and Reputation: Look for a manufacturer with a solid track record and positive reviews from previous customers. Experienced manufacturers are more likely to produce high-quality PCBs and provide reliable service.

Quality Assurance: Ensure the manufacturer follows strict quality control measures, such as ISO certification and regular testing. High-quality PCBs are essential for the proper functioning and longevity of your electronic devices.

Customer Support: Good customer support is vital, especially if you encounter issues during the ordering process or with the final product. Choose a manufacturer that offers responsive and helpful customer service.

Manufacturing Capabilities: Check the manufacturer’s capabilities, including the types of PCBs they can produce, their layer count capacity, and the materials they use. Make sure they can meet your specific design requirements.

Lead Times and Shipping: Consider the manufacturer’s production lead times and shipping options. Quick turnaround times are crucial for meeting project deadlines, so choose a manufacturer that can deliver within your required timeframe.

Pricing and Payment Terms: While cost is an important factor, it should not be the sole consideration. Ensure the manufacturer offers transparent pricing and flexible payment terms that suit your budget.

Conclusion

Ordering printed circuit boards online is a convenient and cost-effective way to obtain high-quality PCBs for your projects. By choosing a reputable PCB manufacturer, you can ensure the reliability and performance of your electronic devices. Whether you are a business looking to streamline your supply chain or a hobbyist working on a personal project, ordering PCBs online provides a seamless and efficient solution.

For those ready to place a printed circuit board order online, consider the factors outlined above to select the right PCB manufacturer for your needs. With the right partner, you can bring your electronic designs to life with precision and quality.

#printed circuit board#pcb manufacturer#pcb supplier#printed circuit board order online#pcb design & manufacturing services#pcb circuit manufacturer in ahmedabad#electronic circuit design company

2 notes

·

View notes

Text

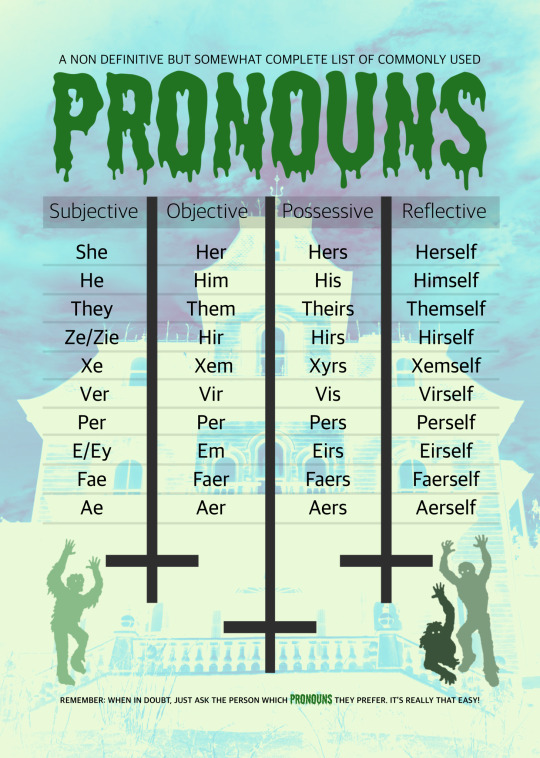

FANE MASTER POST

youtube

[Status December 1st 2023. Issue 1 now available in digital and print-on-demand formats! www.FANEmag.com | Currently accepting submissions of all kinds for Issue 2.]

{Contributors/contributions per category for next issue: Art (0), Photography (0), Interviews (0), Music Reviews (0), Print (0), Articles (0), Random (0), Letters (0)}

FANE is a digital & print zine with the intent to lift up artists of all kinds and expose them to new audiences. In every issue I hope to feature Musicians, Photographers, Illustrators, Poets, Painters, etc., along with life testimonials from marginalized peoples (are you a gender non conforming POC in the Crust Punk scene? I wanna know what that’s like. Are you transitioning in a rural area and want to share your experience? I want to help you do that. Do you love transgressive writing and like picking it apart? I wanna read those book reviews.). I am actively seeking out creatives in the LGBTQIA+ community who make the kinds of works that don’t get the attention or respect of mainstream queer culture. That said, FANE is all encompassing and we welcome submissions from peoples of all different walks of life (from CisHet to TransQueer, and everything before, in between, and after).

FANE is 100% volunteer. Everyone involved is donating their time and content. The digital version of the zine is available completely free. The print version will full color A4 Print-on-Demand by Lulu.com Any kind of profits made or donations received will go towards building an online presence, securing future hosting/domain related fees, etc.

Examples of what we’re looking for:

Music Reviews, Live Show Reports, Photography, Painting, interviews (both interviewers and those willing to be interviewed), indie film makers, queer activists/artists, anything that defies convention, short stories, poetry, anyone willing to share honestly their struggles with mental health or other health issues, anyone into body modification, anyone with an unconventional body structure comfortable showing their body and discussing it, anyone willing to share terrifying personal experiences they’ve overcome, comedic works as prose or illustration, sex workers willing to share what their lives are like. Anything & anyone who deserves their “15 minutes” currently denied by surface culture. Contributions don’t have to be small, and you don’t have to do any page layout/framing (we can set up the pages from your content/files). Aesthetic: glitchy, dark, dusty, ash, noise, industrial, goth, experimental electronics, metal, punk, esoterica…

Examples of what we’re NOT looking for:

Pornography, edgelord shit for the sake of edgelord shit, right wing/conservative bullshit, Racists, animal cruelty, white nationalist propaganda, Nazi sympathizers, homophobes, transphobes, sexists, and other generally shitty human garbage. This doesn’t mean journalistic articles about such things can’t find inclusion, just that I don’t want to print the actual things themselves. For legal reasons, we’re also not accepting fandom art, fan fiction, etc. We respect those of you who create such things, it’s just they’re not a good fit for us.

All submissions to FANE must be your original work or works you have the legal right to use. When submitting, you give FANE the right to reproduce your material in perpetuity within the context of magazine print runs, website/blog postings, publishing collected editions of the zine, etc. (we’re not going to sell your works as prints or shirts or mugs or any kind of similar shenanigans). You are NOT giving us exclusive rights to anything, and your works will always be yours to do with as you wish outside of the zine.

No matter what you’re submitting, we ask everyone for a photo of themselves in the portrait orientation. If you are uncomfortable sharing a photo of yourself, we can go with an artistic interpretation or simply a “No Photo Available” generic pic. There’s also a short questionnaire. Any question you don’t want to answer, you can put “No Comment” or something sassy, etc. The Bio bit should only be about a paragraph (2-5 sentences).

Name:

Age:

Pronouns:

Gender:

Location:

Primary Medium:

Other Mediums:

Bio:

Links:

For each visual artist that has contributed so far, I’ve created a Bio page for the issue. I don’t know how that will translate to written works (would make sense for poetry submissions, or long journalistic works, but probably not for short reviews, know what I mean?), but better to have the info/pic and not need it than the other way around.

Please make sure to include a direct link, or links, to your work. You can also send files via email, but keep in mind we’re not touching anything that looks shady (Archives, Executables, etc). Also be sure to tell us what it is we should be looking at, and what your contribution idea is (Example: Photographer who provides links to their photos and states they want to share new works for the zine.)

Questions? Suggestions? Contributions? You can contact me here on tumblr or use FANEmag at gmail. I’m working on other communication methods as well, but I’m an Elder Millennial so please be patient with me :)

Feel free to reblog/spread far & wide.

Here are some visuals from Issue 1 to give you an idea of what the overall “vibe” of the zine is. The full issue can be downloaded for free from FANEmag.com

Asked & Answered:

* Hey! What does the name FANE mean/stand for?

It’s a noun. It means a church or temple. I’m not a religious person, but the most spiritual I feel is when I’m submersed in the arts, hence the name choice. Major world religions aren’t exactly friendly to the LGBTQIA+ community, so the zine, in my head at least, is an alternate experience where people can find community, inspiration, and acceptance.

I’m a self deprecating sarcastic asshat too, so the fact it rhymes with “feign” as in “to feign interest in this boring zine” is absolutely intentional. As is the fact that it’s a four letter “F” word :)

* Who are you?

Hi, my name’s Rob, and I’m an alcoholic (recovering). I’m a married cisgendered gay white male who uses he/him pronouns living on the East Coast USA. I’m medicated for anxiety and depression, and I believe I may have undiagnosed ADHD and/or ASD. I’m an amateur creative that’s been doing the best I can for the last 30 or so years with zero professional training. I’ve put out a good chunk of experimental music, some of which is still available online (“Vermilion Sky” is my best if you go looking). I’ve also collaborated with other musicians, labels, etc. I’m currently working on histological and minimal photography, as well as graphic design and illustration (digital).

#Open Call#Submissions Wanted#FANE#LGBTQIA+#Transgender#Queer#Non-binary#Zine#Noise#Industrial#Experimental#Artists on Tumblr#Photographers on Tumblr#Writers on Tumblr#Musicians on Tumblr#POC#Mental Health#Reviews#Articles#Testimonials#Comic Strips#Gay#Illustators on Tumblr#Subculture#Outsider#Marginalized People#Youtube

12 notes

·

View notes

Text

Elevating Industry Standards: PVDF Materials by Petron Thermo Plast

In the dynamic landscape of industrial materials, Polyvinylidene Fluoride (PVDF) emerges as a standout choice, renowned for its exceptional properties and diverse applications. Petron Thermo Plast, a leading manufacturer in the field, specializes in delivering top-tier PVDF Materials crafted to surpass industry expectations. This blog meticulously explores the features, benefits, and applications of PVDF materials by Petron Thermo Plast, showcasing why they are the preferred solution for professionals worldwide.

Unveiling PVDF Materials

PVDF materials represent a pinnacle of innovation, characterized by their remarkable chemical resistance, thermal stability, and mechanical strength. Petron Thermo Plast’s PVDF materials are engineered with precision to offer unparalleled performance across a multitude of industrial settings.

Key Attributes of PVDF Materials

1. Chemical Resistance:

PVDF materials exhibit exceptional resistance to a wide spectrum of chemicals, including acids, bases, and solvents, making them ideal for corrosive environments.

2. Thermal Stability:

With a high melting point and remarkable heat resistance, PVDF materials maintain their integrity even under extreme temperatures, ensuring reliability in demanding conditions.

3. Mechanical Strength:

PVDF materials boast high tensile strength and durability, enabling them to withstand mechanical stress and pressure, thus guaranteeing longevity in challenging applications.

4. Low Permeability:

The low permeability of PVDF materials to gases and liquids prevents leakage, making them suitable for applications requiring excellent barrier properties.

5. Weatherability:

PVDF materials exhibit exceptional weather resistance, making them suitable for outdoor applications where exposure to UV radiation and harsh weather conditions is common.

6. Non-Toxicity:

PVDF materials are non-toxic and safe for use in applications involving potable water and food processing, adhering to stringent health and safety standards.

Applications of PVDF Materials

PVDF materials by Petron Thermo Plast find extensive applications across diverse industries:

Chemical Processing: Used for fabricating pipes, fittings, and linings in chemical plants due to their resistance to corrosive chemicals.

Construction: Employed in architectural cladding, roofing, and facades for their durability and weather resistance.

Electronics: Utilized in printed circuit boards and semiconductor manufacturing for their electrical insulation properties.

Transportation: Applied in aerospace and automotive industries for interior and exterior components due to their lightweight and high strength-to-weight ratio.

Medical: Used in medical equipment and devices requiring sterilizability and chemical resistance.

Advantages of Choosing Petron Thermo Plast

Advanced Manufacturing Techniques:

Petron Thermo Plast employs cutting-edge manufacturing processes and rigorous quality control measures to ensure PVDF materials meet the highest standards.

Customization Options:

The company offers PVDF materials in various formulations, sizes, and colors to meet specific customer requirements.

Expert Technical Support:

Comprehensive technical support and guidance are provided to assist customers in selecting the right PVDF materials and ensuring proper integration into their projects.

Sustainability Commitment:

Petron Thermo Plast is committed to sustainable manufacturing practices, ensuring their PVDF materials are environmentally friendly and compliant with global standards.

Why Choose PVDF Materials from Petron Thermo Plast?

Investing in PVDF materials from Petron Thermo Plast guarantees superior quality, reliability, and performance. Here are some compelling reasons to choose Petron Thermo Plast:

Unmatched Quality: PVDF materials from Petron Thermo Plast adhere to the highest quality standards, ensuring consistency and reliability.

Tailored Solutions: With a wide range of formulations and customization options available, you can find the perfect PVDF material for your specific application.

Technical Expertise: Petron Thermo Plast provides expert technical support to guide you through every stage, from material selection to project completion.

Sustainability: By choosing PVDF materials from Petron Thermo Plast, you are supporting environmentally friendly manufacturing practices and contributing to a greener future.

Conclusion

PVDF materials by Petron Thermo Plast redefine excellence in the industrial sector. Their unparalleled properties, reliability, and versatility make them indispensable across various industries. Choose Petron Thermo Plast for PVDF materials that exceed your expectations and elevate your projects to new heights of success.

#pvdf material#engineering plastics#pvc ball valve#pvc butterfly valve#pvdf pipe#explore#union ball valve#hdpe pipe fittings

2 notes

·

View notes

Text

Learn About the Basics of Vacuum casting

Within the dynamic realm of production and prototyping, urethane casting is a unique technology that provides cost-effectiveness, accuracy, and diversity. Urethane casting has become the industry standard for a variety of applications, from complex prototypes to small-batch production runs, including consumer electronics, medical equipment, and the automotive and aerospace sectors.

Gratitude Casting of Urethane

The first step in the procedure is to create a master pattern, which is usually done via fast prototyping techniques like CNC machining or 3D printing. The silicone molds that are made from this master pattern are used to pour polyurethane resin into. The resin mimics the fine features of the master design once it has dried, producing pieces that are excellent and ready for manufacturing.

Flexibility throughout Sectors

The adaptability of urethane casting across sectors is one of its most noteworthy benefits. Urethane casting may be used for a variety of purposes, including the production of end-use components and prototypes for new product development. For instance, urethane casting makes it possible to quickly iterate ideas for dashboard panels, interior trim, and lighting fixtures in the car industry. Similar to this, urethane casting makes it easier and faster to produce unique medical device housings, surgical instruments, and prosthetic components in the medical profession. Vacuum casting also offers flexibility.

Benefits Compared to Conventional Approaches

When compared to conventional production techniques like CNC machining and injection molding, urethane casting has several significant benefits. The most important factor is cost-effectiveness. Because urethane casting requires less tooling up front, it's a great option for low-volume production runs if standard tooling costs are too high. Urethane casting also has a short turnaround time, which enables companies to quickly develop and refine ideas without having to wait for long lead periods.

Additionally, the design freedom provided by urethane casting makes it feasible to produce intricate surface details, undercuts, and complicated geometries that would be difficult or impossible to accomplish with alternative manufacturing processes. This versatility also applies to the choice of material, since a variety of polyurethane resins are available to satisfy certain performance needs, including those related to hardness, flexibility, and chemical resistance. You can Explore vacuum casting also.

Follow our Facebook and Twitter for more information about our product.

#vacuum casting#vacuum casting services#Urethane Casting#Explore vacuum casting#Custom Vacuum Casting Services

2 notes

·

View notes

Text

In the ever-evolving world of technology, terminology can be considered expendable for many tasks, including the use of facsimiles. Facsimiles are defined as "an exact copy, especially of written or printed material" and are used in a broad range of industries, including legal, medical, and government matters.

The need for facsimiles has grown over the last few decades, and the technology has advanced to the point that no technical terms are need to understand their use. The rise of digital imaging and scanning devices has simplified the process of securely transmitting long-distance documents. Even methods of retrieval and filing have become much simpler as cloud-based storage solutions become more and more popular.

Traditional facsimile machines were heavy and complicated, with their own set of user instructions and technical terms that needed to be understood. But with modern technology, the need to know these terms is no longer necessary. A user simply needs to scan the document and send it to its destination. The transmission of a facsimile is now very similar to the transmission of any other digital document.

Another development that makes specialized terminology expendable is the adaptations of the facsimile process that have been made for smartphone and other mobile devices. Mobile apps have become available that do what a facsimile machine once did. Documents such as contracts, forms, and other items can be read electronically and sent to their destination with a push of a button.

In short, the advances in technology have made the need for terminology unnecessary for facsimiles. Documents can now be sent safely and securely without any technical words or understandings. Processes have become simpler, more efficient, and with a much more user-friendly interface. It is likely that advances in technology will only continue to make the process of using a facsimile more streamlined and terminology-free in the future.

6 notes

·

View notes

Text

Become a Digital Marketing Pro: Learn the Basics NOW!

What is Digital Marketing?

Digital Marketing refers to the marketing of products and services of a company or business through digital channels such as search engines, websites, email, social media, mobile apps, etc. It involves the use of electronic devices and the internet. Digital marketing is often referred to as online marketing, internet marketing or web marketing.

Digital marketing mainly comprises Search Engine Optimization (SEO), Social Media Optimization (SMO), and Search Engine Marketing (SEM). We can say that it can be divided into three parts SEO, SMO, and SEM. However, Email Marketing and Affiliate Marketing have also become important components of digital marketing over the past few years. So, in digital marketing, we mainly deal with the following components:

SEO

SMO

SEM

Email Marketing

Affiliate Marketing

Why choose Digital Marketing?

Non-Digital Marketing, which is the traditional means of marketing, includes the usage of physical means of marketing. These are generally in the form of physical prints such as posters, flyers, newspaper advertisements, and billboards. Even at the first glance, it is quite apparent why almost every business is choosing to get into Digital Marketing.

The primary and the most fundamental reasoning for this is the amount of reach that is possible with it. There are smart devices everywhere, from televisions, laptops, computers, and tablets to smartphones. Even cars have smart systems enabled in them where you can access the Internet. All of these facilities present a blank canvas for advertising your brand.

How does Digital Marketing work?

There are two ways in which Digital Marketing is implemented by brands and businesses:

B2C (Business to Customer)

B2B (Business to Business)

B2C (Business to Customer):

When a brand or a company has to sell a product or service to individual customers. In fact, 95 percent of the time, the ads and marketing that you see online are examples of B2C campaigns, e.g., an ad for a candy bar, a promotional video for a safety razor, or a movie trailer. All of these marketing efforts are targeting individual consumers and not organizations.

B2B (Business to Business):

B2B is conducted for very specific products. You wouldn’t generally see B2B products being advertised on platforms with traffic from the everyday crowd. These marketing campaigns are low profile, professional, and in most cases, marketed directly (or pitched) to the client. This client can be a small business or a corporate giant. We can take heavy-duty cooking machinery used in big fast-food restaurants as an example. What would be the point of running a TV ad for an industry-level chimney? None. This sort of marketing is done through B2B-specialized salesmen who use custom-made marketing material, PowerPoint presentations, and word of mouth to pitch their product.

Not surprisingly, billions of marketing dollars spent on traditional channels is already starting to shift to digital marketing campaigns and this will continue to increase as the Web matures.

#digital marketing#digital marketing from basics#Introduction to digital marketing#how to learn digital marketing#what is digital marketing#online marketing#affiliate marketing#Basics of digital marketing#Why choose digital marketing#How does digital marketing work#learn digital marketing#Email marketing#search engine optimisation#seo#seo marketing

13 notes

·

View notes

Photo

https://archive.org/details/hun-industrial-tech-04-2021/mode/2up

"HUN / INDUSTRIAL TECH is an art lab and content creation workshop founded in 2004 focusing on alternative, dark underground and industrial electronic music and subcultures. Its purpose is to follow, analyze and spread local and foreign dark electric- and body-music, philosophies infused into metallic and industrial soundscapes, cyberpunk and electronic social and life aspects; to connect the players and followers of the scene, and also to create and publish the industrial underground subcult zine HUN / INDUSTRIAL TECH (abbreviated as H.I.T)." This is what László Farkas "Crit" Farkas, one of the most prolific musicians of the local industrial scene (under the Empelde moniker), and also its archivist, who, in addition to the industrial music blog hunindustrialtech.hu, or being connected to it, keeps the scene's only real industrial music magazine alive, providing enough reading material for a year - the issues get released around the end of each Q1. The material is really powerful not only because it is uncompromising even in 2023 (only in Hungarian, only in PDF, hundreds of pages, a review sometimes runs twenty pages long), but it also brings the exact raw momentum, honesty and educated understanding that Második Látás (the most important local zine there is) brought to the younger generations after the regime change - if you weren't a member of the scene, you immediately felt that you were LEFT OUT, if you were a member, YOU STILL FELT THAT WAY. Print that large number of interviews (including many local ones), reviews (no, even more of them!) and articles and that heap of paper will stop a bullet. And that smartness, that stops the bullet, too. H.I.T. is at the forefront of the contemporary fanzines more or less approaching the underground-cyberpunk theme (Élő-halott, T+U, Rrriot Nerdz, Xenotopia), the latest copy is always available only on the fanzine's official website: https://hunindustrialtech.hu/magazin /

11 notes

·

View notes

Text

What is Upcycling? Is it the future of the Fashion Industry?

What is Upcycling in the Fashion Industry?

Upcycling is a process where we make some adjustment to the product which enhances the value of it. For example in t-shirt upcycling would be making some changes in the print of the t-shirt or adding some embroidery. In many industries upcycling has been adopted like furniture, electronics and automobiles. Companies have started adopting upcycling in the fashion industry.

Why Are Companies Gradually Adopting Upcycling?

There are 3 Things That Provoked Upcycling in the Fashion Industry.

Excessive Waste: In the fashion industry both pre and post consumption waste is very much. In the cutting table 15% of the raw material gets wasted. While making cotton and polyester water, chemical and other energies are wasted very much.

Make-Use-Throw: It is a new trend that has been followed by people nowadays. As per capital income is rising so people’s living standard is increasing due to which they buy more clothes and throw it away after using it for a few times.

Pandemic: This was the last and most powerful wave that provoked upcycling. As many brands had manufactured their stock at the time of pandemic but as we all know it did not come out to be sold, that made many brands to simply modify their stock and sell it once the market got open.

Will it Stagnant the Growth of Textile Companies?

The answer is a big no, the textile industry is growing at a CAGR of 8% year on year. So, the demand is there to cater by the brands. They can just shift a portion of their production to upcycling. Through upcycling also they would be able to earn profit. Brands will buy t-shirts in bulk, jeans in bulk and other garments.

Who Can Make Upcycling Possible?

Upcycling is a new challenge and opportunity for the brands to show their creativity. Designers are the ones who can make upcycling possible. They can add value to abandoned or damaged cloth which would be appealing in front of the eyes of customers. For example they can simply purchase bulk printed t-shirts and make some changes in the print and resell it in the market.

#textile#manufacturing#textiles#yarn#clothing#dyeing#knitting#business#fiber art#pattern#upcycling fashion#world cup#iccworldcup2023

2 notes

·

View notes

Text

New 3D printing technique integrates electronics into microchannels to create flexible, stretchable microfluidic devices

The transition from traditional 2D to 3D microfluidic structures is a significant advancement in microfluidics, offering benefits in scientific and industrial applications. These 3D systems improve throughput through parallel operation, and soft elastomeric networks, when filled with conductive materials like liquid metal, allowing for the integration of microfluidics and electronics. However, traditional methods such as soft lithography fabrication which requires cleanroom facilities have limitations in achieving fully automated 3D interconnected microchannels. The manual procedures involved in these methods, including polydimethylsiloxane (PDMS) molding and layer-to-layer alignment, hinder the automation potential of microfluidic device production. 3D printing is a promising alternative to traditional microfluidic fabrication methods. Photopolymerization techniques like stereolithography apparatus (SLA) and digital light processing (DLP) enable the creation of complex microchannels.

Read more.

11 notes

·

View notes

Text

Custom Hexagon Boxes: The New Trend in Packaging

In the world of packaging, innovation is the key to standing out. Custom Hexagon Boxes are the latest trend that has taken the market by storm. These boxes have unique shapes and make products noticeable on store shelves. Their six-sided design provides a unique aesthetic appeal that is hard to ignore.

Why Choose Custom Hexagon Boxes?

One main reason businesses opt for Custom Hexagon Boxes is their distinctive shape. Hexagon boxes have a modern and stylish look because of their geometric shape. They are different from square or rectangular boxes. This shape looks good and provides added protection to the products inside. A six-sided design protects The product from all angles, reducing damage during transit.

Another significant advantage of these boxes is the customization options they offer. With Custom Hexagon Boxes, businesses can add a touch of luxury to their packaging. The Hexagon closure keeps the box closed, making the products inside more secure. This feature is especially beneficial for high-end products requiring an extra protection layer. The Hexagon closure makes the packaging look classy and attractive to customers.

The Rise of Custom-Printed Hexagon Boxes

Custom Printed Hexagon Boxes are another trend gaining popularity in the packaging industry. These boxes come with a Hexagon closure, but what sets them apart is the custom printing option. Businesses can get their logo, brand name, or any other design printed on these boxes. However, The packaging looks better, and people recognize the brand more. Customers remember the brand better when they see a box with its logo. That makes them think of the brand more often.

Businesses can make their brand stand out by using packaging that has magnets and their logo. The logo on the box reminds customers about the brand, so they remember it. It can be helpful for new businesses trying to build their brand in the market.

Choosing the Right Hexagon Box Manufacturer

When choosing a Hexagon Box composer, businesses need to be careful. The quality of the boxes plays a crucial role in determining the success of the packaging. A low-quality box can damage the product inside, leading to customer dissatisfaction. So, choosing a manufacturer known for its quality products is essential.

If your business needs good boxes that have cost too much, try reasonably with the best quality Custom Boxes Wholesale. Buying in large quantities also guarantees a constant supply for businesses. That prevents any disruptions in the packaging process.

The Future of Packaging: Closure Boxes and More

Hexagon Closure Custom Boxes are the beginning. In the future, the packaging industry will see more innovations because of technology. Packaging is getting more elegant and sustainable, with options that interact with customers. The future looks promising.

Incorporating Sustainability with Custom Hexagon Boxes

As people become more conscious, they pressure businesses to adopt sustainable practices. Packaging plays a pivotal role in this transition. On the other hand, businesses can create unique hexagon boxes to prove their commitment to the environment.

Using recycled or sustainable materials, custom packaging with a logo benefits the environment. It also reduces carbon emissions. Consumers now want brands with similar values, and they focus on sustainability. Businesses can help the environment by using Custom Printed Hexagon Boxes. Customers like these boxes.

The Versatility of Custom Hexagon Boxes

One of the standout features of Custom Hexagon Boxes is its versatility. These boxes are not limited to a specific industry or product type. The hexagonal design fits cosmetics, electronics, jewelry, and gourmet foods. The Hexagon closure keeps things safe, so it's good for many things.

Custom Boxes allow businesses to experiment with different designs and finishes. The options are endless, whether a matte finish for a minimalist look or a glossy one for a touch of luxury. Businesses can customize their packaging to match their brand and attract desired customers.

Engaging Customers with Interactive Packaging

The future of packaging is more than looking good or keeping things safe. Technological advancements let Custom Hexagon Boxes include QR codes and augmented reality features. Customers can use a QR code to get special deals, learn about products, and connect with brands. Moreover, Customers feel more connected to the brand and find it easier to unpack products.

Custom Hexagon Packaging with a Logo can also incorporate these interactive elements. Imagine this: a customer scans the logo on the box it's transported to a virtual brand world. In this world, they can get insights, tutorials, or even try on virtual products. Such innovations can revolutionize the way customers perceive and interact with a brand.

Hexagon Custom Boxes: A Reflection of Brand Identity

Every brand wants to stand out from competitors by having a unique identity in the market. Hexagon Custom Boxes have a unique shape and many customization options, which helps a brand stand out. They are not containers; they are a reflection of what the brand stands for and the values it upholds.

For example, a luxury brand may choose Custom Hexagon Boxes with a velvet finish. A sustainable brand may prefer materials for its Custom Hexagon Packaging with Logo. How a brand packages its products says a lot about its values and goals.

Innovative Design Meets Functionality

It would be a mistake to overlook the enticing Hexagon Custom boxes because of their benefits. The hexagonal shape, apart from being striking, offers structural integrity. This design protects delicate items from outside pressures, keeping the contents safe.

Additionally, adding Hexagon closures to packaging with a custom logo provides security. However, Hexagon Closure Boxes ensure the contents remain intact, preventing accidental spillage or damage. Many businesses prefer these boxes because of their innovative design and functionality.

Customization: The Key to Brand Recognition

In today's competitive market, brand recognition is paramount. Brands can customize each box from Custom Boxes Wholesale to make them recognizable. Brand colors, logos, or design elements help people remember a brand.

Imagine a customer receiving a product in a Custom Hexagon Box. Opening the box feels incredible because of the Hexagon closure and one-of-a-kind design. However, It will leave a strong impression. Every time a similar box catches their eye, it reminds them of that experience and, in turn, the brand.

The Role of Hexagon Box Suppliers in Shaping Brand Image

Choosing the right Hexagon Box composer is crucial. If a manufacturer knows a brand's vision and values, they can make packaging that shows them. Hexagon Custom Boxes match the brand's identity and quality.

A trustworthy manufacturer keeps up with new trends and innovations in packaging. In Addition, this partnership helps brands provide customers with new and intriguing packaging options. That also helps brands strengthen their position in the market.

Final Thoughts: The Endless Possibilities with Custom Boxes

The world of packaging is ever-evolving, with new trends emerging. Hexagon Custom Boxes lead this change with their one-of-a-kind design and customization options. Brands can show who they are, interact with customers, and keep products safe. Moreover, Brands are discovering many possibilities with these boxes. Hexagon Custom Boxes are revolutionizing packaging and are here to stay.

Hexagon Boxes are the latest trend in the packaging industry. Their unique shape and customization options offer businesses a fresh perspective on packaging. Businesses can choose between Custom Boxes Wholesale or Custom Hexagon Boxes.

Businesses should select a reliable company to make Hexagon boxes. Therefore, this will boost sales and brand recognition. They can also make use of wholesale custom boxes.

The packaging does more than hold a product. It tells a story, creates an experience, and makes a statement. We design Custom Hexagon Boxes and offer various customization options. They provide businesses with a great opportunity to showcase their brand story. These boxes lead packaging with sustainability, versatility, and interactivity. For success, businesses should partner with a reliable manufacturer. This manufacturer should sell Hexagon boxes and provide wholesale custom boxes. Hexagon Custom Boxes help brands make a lasting first impression

#Custom Hexagon Boxes#Custom Hexagon Cardboard Boxes#Hexagon printed Boxes#Custom Boxes Wholesale#custom printed boxes

2 notes

·

View notes