#Pressure safety Valve Manufacturer and Supplier in China

Explore tagged Tumblr posts

Text

#Pressure safety Valve Manufacturer and Supplier in China#Pressure safety Valve Manufacturer in China#Pressure safety Valve Supplier in China#Safety Relief valve Supplier#Safety Relief Valve#Breather Valve China#Breather Valve

0 notes

Text

Evolution of Pressure Safety Valves that Shaping Industrial Safety

Industrial safety in such high-pressure scenarios speaks volumes regarding oil refineries, chemical plants, and power generation facilities. PSV has been the most important safety factor that has helped avoid horrible failures of equipment due to overpressure. As the evolutions in industrial processes take place, so do PSVs evolve with smart technology. These PSVs by Pressure Safety Valve Manufacturers are changing the way they work and taking safety further than ever before.

Traditional Role of Pressure Safety Valves

Their function has been simple yet vital: attempting to automatically release excess pressure as it reaches unsafe levels to cause no damage or even explosions. PSVs have long been protecting systems, but traditional designs of the valves had limited real-time monitoring and predictive capabilities.

The Rise of Smart PSVs

Smart PSVs are fully upgraded with IoT and AI. It is built into the design. Let's dive into some of the many advantages offered by these smart PSVs by safety valve manufacturers:

Real-Time Monitoring

Smart PSVs provide real-time data about pressure levels. It permits the operator to constantly observe the system. It allows them to mitigate overpressure conditions before they get out of hand, which makes operations safer and more effective due to minimum downtime and other types of disruptions.

Predictive Maintenance

Whereas traditional PSVs would require periodic inspection cycles to determine the right timing for maintenance, these smart PSVs apply AI to predict when their maintenance will be required. By analyzing performance data, these systems offer early signs of wear and enable proactive maintenance to avoid costly system failures, reducing downtime.

Remote Operation

Another huge advantage is related to the possibility of remote control in locations. These are hazardous or unreachable. The operators can turn on the valve from a safe distance, which is highly effective in places like the oil and gas industry, where the systems may be remotely located or hazardous to reach.

Integration with Industrial Systems

With Industry 4.0, smart PSVs were able to communicate well with other industrial systems to enhance automated safety and overall operational efficiency. Connectivity signifies that varied parts of the system will work in harmony to prevent dangerous pressure buildups.

Advanced Materials and Designs

Not only the smart technology but also the improved materials used and the advanced manufacturing method have contributed to the durability and reliability of PSVs. Modern valves also possess resistance to extreme temperatures, corrosive atmospheres, and high pressures that can be used in industries dealing with chemical processing and the generation of power.

Multi-blister technology is designed to make superior pressure regulation. It allows them to improve their performance against contingency conditions.

Future of Pressure Safety Valves

The future holds smarter valves that, besides responding to changes in pressure, may automatically adjust themselves according to data input from other parts of the system. Such next-generation valves will contribute a great deal to making industrial processes safer by reducing the element of human error and enhancing the reliability of pressure regulation.

Conclusion

The evolution of pressure safety valves acts as a testimonial to how traditional engineering melts into modern technology. Smart PSVs have come to provide more reliable means of protection for the systems in each industry. Further evolution of these valves will go on to play an even more crucial role in safety and success in more complex industrial processes. Get them now with the top Switching safety valve.

#Switching safety valve#pressure safety#Safety Valves#Industrial Systems#021pv#safety valve manufacturers#safety relief valve supplier#safety valve manufacturer#high pressure magnetic drive pump#safety relief valve#pressure safety valve#safety valve#safety valve china

1 note

·

View note

Text

Tire Pressure Monitoring System Market - Industry Analysis, Market - Forecast(2025 - 2031)

Tire Pressure Monitoring System Market Overview

Request Sample :

Major trends in the TPM market include the growing adoption of wireless and sensor-based monitoring systems, which offer real-time data on tire pressure and temperature. These systems provide drivers with instant alerts in case of underinflated or overinflated tires, helping to prevent accidents and improve fuel efficiency.

Another key trend is the integration of TPM systems into advanced driver-assistance systems (ADAS) and connected car platforms. This allows for more seamless monitoring and control of tire pressure across a fleet of vehicles, enabling proactive maintenance and reducing downtime. Additionally, there is a rising demand for aftermarket TPM solutions, as vehicle owners seek to retrofit older vehicles with monitoring capabilities. This presents opportunities for aftermarket suppliers and service providers to cater to this growing market segment. Overall, the TPM market is expected to continue its growth trajectory, driven by technological advancements, regulatory mandates, and increasing awareness of the importance of tire safety among consumers and fleet operators.

Market Snapshot :-

Tire Pressure Monitoring System Market Report Coverage

The report: “Tire Pressure Monitoring System Market Forecast (2024–2030)”, by Industry ARC, covers an in-depth analysis of the following segments of the Tire Pressure Monitoring System Market. By Type: Direct TPMS, Indirect TPMS. By Vehicle Type: PC, LCV, and HCV. By Sales Channel: OEM, After Market. By Geography: North America (U.S., Canada, Mexico), Europe (Germany, U.K., France, Italy, Spain, Russia and Rest of Europe), Asia Pacific (China, Japan, India, South Korea, Australia & New Zealand, and Rest of Asia Pacific), South America (Brazil, Argentina and Rest of South America), and Rest of the World (Middle East and Africa).

Inquiry Before Buying :

Key Takeaways

North America dominated the Tire Pressure Monitoring System Market size with more than 38%. This is largely attributed to key automotive manufacturing hubs, rising vehicle production, strict safety regulations, increased consumer awareness, and demand for advanced automotive technologies, particularly in U.S.

The integration of tire-pressure monitoring systems (TPMS) as a crucial component of ADAS is increasing, driven by the growing demand for vehicle safety features.

For more details on this report — Request for Sample

By Type- Segment Analysis

Direct TPMS holds the majority market share in the Tire Pressure Monitoring System Market. Direct TPMS systems utilize sensors mounted on each tire’s valve stem to measure tire pressure and transmit real-time data to the vehicle’s onboard computer. This segment’s dominance is attributed to its accurate and reliable tire pressure monitoring capabilities, which help enhance vehicle safety and fuel efficiency. Additionally, advancements in direct TPMS technology, such as integration with advanced driver-assistance systems (ADAS), further drive its market share growth by offering comprehensive vehicle safety features.

By Vehicle Type — Segment Analysis

In the segmentation of the Tire Pressure Monitoring System Market by vehicle type, the Passenger Car (PC) segment holds the majority market share. This dominance is attributed to the widespread adoption of tire-pressure monitoring systems in passenger vehicles, driven by increasing concerns about road safety and regulatory mandates mandating the installation of such systems in new passenger vehicles. With a growing focus on vehicle safety features and the rising demand for advanced driver-assistance systems (ADAS), the passenger car segment is expected to continue leading the market in the foreseeable future.

By Geography — Segment Analysis

In 2023, North America dominated the Tire Pressure Monitoring System Market share with more than 38%. This dominance is driven by factors such as the presence of key automotive manufacturing hubs, increasing vehicle production, and stringent safety regulations mandating the installation of tire-pressure monitoring systems. Additionally, rising consumer awareness regarding vehicle safety and the adoption of advanced automotive technologies further contribute to the growth of the APAC market. With countries like U.S leading the demand for automotive safety features, the North America region is expected to maintain its market leadership in the tire-pressure monitoring industry.

Schedule A Call :

Drivers — Tire Pressure Monitoring System Market

Regulatory Mandates and Safety Standards

Regulatory mandates and safety standards play a pivotal role in driving the growth of the Tire-Pressure Monitoring (TPMS) Market. Across the globe, governmental bodies have enforced stringent regulations requiring the installation of TPMS in all new vehicles. These mandates aim to bolster road safety by ensuring that vehicles maintain optimal tire pressure levels, thereby reducing the risk of accidents due to underinflated tires. As automotive manufacturers strive to comply with these regulations, the demand for TPMS systems in both passenger and commercial vehicles continues to surge. This trend creates significant opportunities for TPMS manufacturers and suppliers to capitalize on the growing market demand. Moreover, as governments persist in prioritizing vehicle safety measures, the TPMS market is poised for further expansion, driven by the increasing need for compliance and enhanced road safety standards.

Increasing Vehicle Production and Sales

The expansion of the automotive industry, alongside escalating vehicle sales worldwide, serves as a pivotal catalyst for driving the Tire-Pressure Monitoring System (TPMS) market. Vehicle manufacturers are compelled to incorporate TPMS into their products to stand out in the competitive market landscape and adhere to stringent safety standards. This integration is prevalent across diverse vehicle segments, reflecting the industry’s commitment to enhancing road safety. Furthermore, the surging demand for advanced driver-assistance systems (ADAS) amplifies the adoption of TPMS, as it plays a crucial role in ensuring vehicle safety and preventing accidents. As a result, TPMS has evolved into an indispensable component of contemporary vehicle safety technology, positioning itself as a fundamental feature in modern vehicles worldwide. This trend is expected to persist and drive further growth in the TPMS market as automotive production and sales continue to rise globally.

Buy Now :

Challenges –Tire Pressure Monitoring System MarketComplexity of Integration

One significant challenge facing the Tire Pressure Monitoring System Market is the complexity of integrating TPMS into existing vehicle systems. Retrofitting older vehicles with TPMS or integrating it into new vehicle designs requires coordination between manufacturers, suppliers, and automotive engineers. This process involves ensuring compatibility with various vehicle models, electronic architectures, and sensor technologies, which can be time-consuming and costly. Additionally, the incorporation of TPMS into vehicles with different powertrain configurations and sensor placements poses technical challenges. Overcoming these integration complexities requires robust engineering solutions, close collaboration across the automotive supply chain, and adherence to strict regulatory standards, all of which contribute to the overall challenges faced by the TPMS industry.

Market Landscape

Technology launches, acquisitions, Partnerships and R&D activities are key strategies adopted by players in the Tire Pressure Monitoring System Market. In 2023, the market of Tire Pressure Monitoring System Market has been fragmented by several companies vying for top share. Tire-Pressure Monitoring top 10 companies include

ZF Friedrichshafen AG

Continental AG

Sensata Technologies, Inc.

Denso Corporation

Pacific Industrial Co., Ltd.

NXP Semiconductors

WABCO

NIRA Dynamics AB

Bendix Commercial Vehicles Systems LLC

DUNLOP TECH GmbH

Acquisitions/Technology Launches

In March 2022, Sensata Technologies and Nira Dynamics collaborate to develop a robust tire tread depth monitoring (TDM) solution. This partnership aims to enhance vehicle safety, efficiency, and uptime by providing accurate tread wear estimation. The TDM solution alerts vehicle OEMs, drivers, and fleets promptly, contributing to the Tire Pressure Monitoring System Market’s advancement.

In May 2022, Continental introduced ContiPressureCheck, an innovative tire monitoring system for CombineMaster and CombineMaster VF tires, aimed at monitoring tire pressure and temperature. This advancement caters to the growing demand for comprehensive tire monitoring solutions, enhancing safety and efficiency in the Tire Pressure Monitoring System Market.

For more Automotive Market reports, please click here

#TPMS#TirePressure#VehicleSafety#TireCare#SmartTires#CarMaintenance#SafeDriving

0 notes

Text

DNV GL Approved Buttweld Fittings Suppliers

Discover Excellence in Plumbing with Arvind Pipes Fittings Industries

In the bustling world of industrial and residential plumbing, the quality and reliability of materials can make all the difference. At Arvind Pipes Fittings Industries, we understand the critical role our products play in ensuring the safety and efficiency of plumbing systems across various sectors. With decades of expertise and a commitment to innovation, we are proud to be a trusted name in the industry.

About Us

Founded with a vision to redefine standards in plumbing solutions, Arvind Pipes Fittings Industries has grown to become a leading manufacturer and supplier of high-quality pipes and fittings. Our journey has been driven by a relentless pursuit of excellence, combined with a deep understanding of our customers' needs.

Our Products

At Arvind Pipes Fittings Industries, we offer a diverse range of products designed to meet the highest standards of quality and durability. Our product line includes:

Pipes: We provide an extensive selection of pipes made from premium materials such as PVC, CPVC, and PPR. Our pipes are designed to handle various pressures and temperatures, ensuring reliability in every application.

Fittings: Our fittings are engineered to provide leak-proof connections and seamless integration with existing plumbing systems. We offer a variety of shapes and sizes to accommodate any project requirement.

Valves and Accessories: We also supply a comprehensive range of valves and accessories that enhance the functionality and efficiency of plumbing systems.

Each product is meticulously crafted to adhere to stringent industry standards, ensuring that our clients receive only the best.

Why Choose Us?

Quality Assurance: We take pride in our rigorous quality control processes. Every product undergoes thorough testing to guarantee its performance and longevity.

Innovative Solutions: Our research and development team continually explores new technologies and materials to improve our products and meet evolving industry needs.

Customer-Centric Approach: We prioritize our customers' needs and provide tailored solutions to address specific challenges. Our dedicated support team is always ready to assist with technical advice and product recommendations.

Sustainability: We are committed to sustainable practices and work towards reducing our environmental footprint. Our products are designed to be both efficient and eco-friendly.

ARVIND PIPES FITTINGS INDUSTRIES is a leading DNV GL Approved Pipe Fittings, Socketweld Fittings, Buttweld Fittings, Flanges, Tee, Reducer, Elbow Manufactuers, Stockist & Exporters in India, Germany, UAE, Norway, Italy, China, Turkey, Korea, USA, France,Canada, Japan, Spain, Netherlands, dnv gl, dnv rules, mydnvgl, dnv norway, dnv gl rules, dnv standard, my dnvgl, dnv rules for ships, dnv rules and standards, dnv gl standards, dnv rules for lifting appliances, dnv gl rules for ships, dnvgl rules and standards, dnv gl offshore standards, dnv iso 9001 standards, DNV GL Rules For Marines.

Contact Us:-

022-66381372

0 notes

Text

An oil-free diesel air compressor is a type of air compressor that is powered by a diesel engine and does not use oil for lubrication in the compression chamber. Instead, this oil free air compressor uses pre-lubricated materials or special coatings to reduce friction. This design ensures the compressed air is free from oil contamination, making it suitable for applications where clean air is crucial, such as in medical, food processing, and electronics industries. Despite being diesel-powered, the oil free air compressor for sale is environmentally friendly due to the absence of oil vapor emissions.

What Is The Life Expectancy Of An Oil Free Diesel Air Compressor?

The life expectancy of an oil-free air compressor can vary greatly depending on several factors such as the quality of the oil free air compressor for sale, how often it’s used, and how well it’s maintained. On average, a well-maintained oil-free diesel air compressor can last between 10 to 15 years. However, it’s important to note that the oil free air compressor for sale tends to have a shorter lifespan than oil-lubricated models due to the increased wear and tear on their components. Regular maintenance, including cleaning and replacing parts as necessary, can significantly extend the life of an oil-free air compressor.

How Do You Maintain An Oil Free Air Compressor?

Maintaining an oil-free air compressor involves several steps. Firstly, regularly clean the intake vents to ensure optimal airflow and prevent dust accumulation. Secondly, drain the air tank after each use to remove any condensation, as moisture can cause rust and damage over time. Thirdly, check and clean or replace air filters as needed to maintain efficiency and prevent damage to the motor. Fourthly, regularly inspect the safety release valve to ensure it’s functioning correctly. Lastly, keep the exterior of the oil free diesel air compressor clean and store it in a dry, clean environment to prevent dust accumulation and moisture damage. Regular maintenance can significantly extend the oil free high pressure air compressor’s lifespan.

0 notes

Text

Unleashing Power and Durability: Shanghai Agile Valves' High-Pressure Stainless Steel Ball Valve

In the realm of industrial valves, Shanghai Agile Valves stands out as a prominent brand, known for its commitment to quality, precision engineering, and reliable performance. With a comprehensive range of valve solutions, including high-pressure ball valves and stainless steel ball valves, Shanghai Agile Valves caters to diverse industries seeking robust and durable valve options. In this article, we will explore the exceptional features and benefits of Shanghai Agile Valves' high-pressure stainless steel ball valve, emphasizing its suitability for demanding applications.

China Valve: Shanghai Agile Valves, a renowned manufacturer and supplier, proudly represents the excellence of China's valve industry. Their commitment to innovation, rigorous quality control, and cutting-edge technology has solidified their reputation as a trusted provider of high-quality valves. By embracing advanced manufacturing processes, Shanghai Agile Valves ensures that their valves meet international standards, delivering superior performance and reliability.

High-Pressure Ball Valve: When it comes to applications requiring robust and dependable valves, Shanghai Agile Valves' high-pressure ball valve rises to the challenge. Designed to withstand extreme pressure conditions, these valves are engineered with precision and durability in mind. Constructed from high-grade materials, such as stainless steel, these valves exhibit exceptional strength, corrosion resistance, and longevity. Shanghai Agile Valves' high-pressure ball valves are meticulously crafted to offer reliable shut-off capabilities, ensuring optimal flow control and system safety even in high-pressure environments.

Stainless Steel Ball Valve: For industries requiring valves that can withstand harsh environments and corrosive fluids, Shanghai Agile Valves' stainless steel ball valve is an ideal choice. These valves are crafted from high-quality stainless steel, renowned for its resistance to corrosion and chemical damage. Shanghai Agile Valves' stainless steel ball valves provide excellent sealing properties, ensuring leak-free operations and minimizing downtime. With their robust construction and smooth operation, these valves offer long-lasting performance and reliable fluid control.

SS Ball Valve: Shanghai Agile Valves' SS ball valve is a testament to their dedication to precision and quality. SS ball valves, made from high-quality stainless steel, offer exceptional resistance to corrosion, making them suitable for a wide range of industries and applications. These valves provide reliable shut-off capabilities, ensuring efficient flow control and preventing leakage. Shanghai Agile Valves' SS ball valves are designed to withstand demanding conditions while maintaining their performance over an extended lifespan.

Shanghai Agile Valves: Shanghai Agile Valves has established itself as a trusted and reliable provider of high-quality valves. Their commitment to customer satisfaction, technical expertise, and stringent quality control has earned them a reputable position in the market. Shanghai Agile Valves' dedication to continuous improvement and innovation enables them to deliver valves that meet the specific needs of industries across the globe.

Conclusion: Shanghai Agile Valves' high-pressure stainless steel ball valve exemplifies their commitment to delivering robust, durable, and high-performance valve solutions. With their precision engineering, corrosion-resistant materials, and reliable shut-off capabilities, these valves ensure optimal flow control and system safety in demanding industrial applications. As a leading brand in China's valve industry, Shanghai Agile Valves continues to provide exceptional value to customers seeking reliable and long-lasting valve solutions. Whether it's a high-pressure ball valve, stainless steel ball valve, or SS ball valve, Shanghai Agile Valves stands ready to meet the needs of industries worldwide.

0 notes

Text

Enhancing Efficiency and Reliability: The Power of Automation Valve Technology in China Valve Couplings

In today's rapidly evolving industrial landscape, maximizing efficiency and ensuring reliable operations are top priorities for businesses worldwide. One of the key factors contributing to this success lies in leveraging cutting-edge technologies, such as automation valves, in conjunction with high-quality China valve couplings. This blog explores the significance of automation valve technology and its role in optimizing operations, particularly when integrated with China valve couplings, to enhance productivity and drive growth.

Understanding Automation Valve Technology: Automation valves, also known as control valves, are crucial components that regulate the flow, pressure, temperature, or level of a fluid within a system. These valves are designed to automatically respond to signals from external devices, ensuring precise control and consistent performance. Leveraging advanced features like electric, pneumatic, or hydraulic actuators, automation valves offer seamless integration with process control systems, enabling remote monitoring and operation.

China Valve Couplings: A Mark of Quality and Reliability: China has emerged as a leading player in valve manufacturing, with numerous reputable companies producing high-quality valve couplings. China valve couplings, renowned for their durability and precision, provide secure and leak-free connections between various components within a system. These couplings are designed to withstand demanding industrial environments and offer enhanced resistance to corrosion, ensuring prolonged service life and reduced maintenance costs.

The Synergy of Automation Valve Technology and China Valve Couplings: When automation valve technology is paired with China valve couplings, it creates a formidable combination that unlocks numerous benefits for industrial applications. Let's delve into some key advantages:

Enhanced Efficiency: Automation valves enable precise and real-time control over fluid flow, optimizing process efficiency and minimizing wastage. Combined with China valve couplings' reliability, operations can run smoothly with minimal downtime and improved productivity.

Improved Safety: With the integration of automation valves, operators can remotely control valve operations, reducing the need for manual intervention in potentially hazardous environments. The robustness of China valve couplings ensures secure connections, mitigating the risk of leaks or accidents.

Streamlined Maintenance: Automation valves equipped with diagnostic capabilities provide valuable insights into performance and maintenance requirements. Combined with the durability of China valve couplings, maintenance schedules can be optimized, minimizing downtime and maximizing equipment lifespan.

Cost Savings: The synergy between automation valve technology and China valve couplings contributes to long-term cost savings. Improved process efficiency, reduced maintenance expenses, and enhanced reliability translate into a more profitable operation.

In the ever-evolving landscape of industrial automation, the integration of automation valve technology and high-quality China valve couplings serves as a powerful tool for businesses seeking to optimize their operations. The seamless synergy between these two components enables enhanced efficiency, improved safety, streamlined maintenance, and significant cost savings. By embracing this advanced technology and leveraging China's expertise in valve manufacturing, industries can elevate their productivity, reliability, and competitiveness in the global market.

Investing in automation valve technology and selecting trusted China valve coupling suppliers is a strategic decision that propels businesses towards a future of enhanced efficiency, reliability, and sustainable growth.

0 notes

Link

0 notes

Text

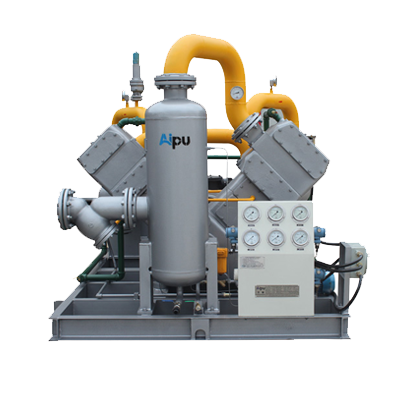

AIPU COMPRESSOR

Gas Compressor Manufacturer - Your professional supplier and reliable partner!

Bengbu Aipu Compressor Manufacturing Co., Ltd. is a professional manufacturer of gas compressors from China. Our main products include BOG compressors, LPG compressors, CNG compressors, and other gas compressors for CNG/LNG tank trucks, CNG filling station, LNG filling station, LNG gasification station, L-CNG filling station, LNG storage station, LNG peak regulation station, LNG receiving station, LPG filling station, chemical plant, oil and gas plant, etc. Each of Aipu piston reciprocating compressor is designed and manufactured professionally on the basis of the technical data and requirements from the end-users. We have different types of gas compressors such as industrial reciprocating compressor, natural gas booster compressor, reciprocating compressor, etc. We keep developing new technology and manufacturing processes to improve our different types of gas compressors and gas compression systems so that they could meet the market demand and the users' expectations.

BOG Compressor

BOG Compressor

BOG compressors also called boil-off gas compressors, are widely used to recover natural gas and boil-off gas left after the unloading of LNG cryogenic tanks and CNG tankers. The boil-off gas recovery system would be recovered and pressurized to CNG refilling station or pipeline network to achieve the dual purpose of maximum economic efficiency and environmental protection.

Z-type BOG Compressor

V-type BOG Recovery Compressor

More details

LPG Compressor

LPG Compressor

LPG compressors, one type of gas compressors for sale, are widely applied in liquefied petroleum gas stations, LPG car filling stations and mixed gas stations, and they are also an ideal equipment for chemical plants to pressurize the gases and benefit themselves from it, and popular in the areas of loading and unloading of LPG tank truck and vessel and bottle filling and tank decanting of LPG and similar media.

Z-type LPG Compressor

More details

CNG Compressor

CNG compressor is often used for medium size CNG filling stations, especially for CNG standard and daughter stations. It is a reciprocating (piston) gas compressor, which uses reciprocating compressor oil to operate and is mainly composed of the main compression,anti-explosive electric motor, cooling unit, lubrication unit, internal connection pipeline, safety valve, and the blow-down valve, the PLC control cabinet, etc. Currently, we have many natural gas compressors with reasonable prices for sale and they are widely used in the domestic and overseas markets.

D-type CNG Compressor

M-type CNG Compressor

More details

Other Compressors

There are different types of gas compressors, such as hydrogen gas compressor, ammonia gas compressor, electric gas compressor, gas booster compressor, etc. Generally, they pressurize the gas to some desired pressure to meet people's demands although the compressing mediums are different.

V-type Hydrogen Gas Compressor

Z-type Ammonia Gas Compressor

More details

Compressor Solutions

Aipu, one of the oil and gas compressor manufacturers in oil and gas industry can be widely seen in the field of gas recovery and storage, oil and gas plants, liquefied petroleum gas (LPG) filling stations, CNG filling stations, chemical areas, etc., its professional design and manufacture of oil and gas compressors with great prices meet the national standards and industrial requirements as well as the needs of users.

Compressor For LPG

Compressor For CNG

Recycle Compressor For BOG

https://www.aipucompressor.com/products/

1 note

·

View note

Text

Reasons to Love Henry Technologies Parts

Henry Technologies is a leading global manufacturer and supplier of air conditioning & refrigeration products, with an emphasis on refrigeration components and strengths in oil management controls and safety devices. Since 1914 Henry Technologies continues to lead in the design and fabrication of products for a wide range of commercial and industrial applications, offering superior quality standards and technical leadership. Through the consolidation of the Henry, AC&R and Heldon brands, Henry Technologies has one of the broadest component product portfolios in the commercial refrigeration industry, including refrigerant and oil flow control products, safety valves and system components. With manufacturing facilities and operating subsidiaries in the USA, UK, Australia, China & Singapore, Henry Technologies markets its products globally to leading OEM’s, wholesalers and contractors. Henry Technologies’ ability to serve their customers on a global basis is enhanced by their regional manufacturing operations and extensive sales and customer support.

In the year 1914, Henry Technologies was founded by Henry. It is a leading global manufacturer and supplier of refrigeration and air conditioning products. The fabrication of the products will be in high standards. Henry Parts like Discharge Line Mufflers, Henry Technologies Receivers, etc.

Henry Group manufactures Flow Controls, safety devices, fittings, compressor protection devices, pressure vessels, controls & tools, liquid management parts and so on. Henry Parts includes Pressure Relief Valves, Pressure Relief Valves – Transcritical CO2, Rupture Discs, Three Way Dual Shut Off Valves, Pressure Indicator Sentry, Safety Device Kits, Ball Valves, Check Valves, Magnetic Check Valves, Expansion Valves, Flange Unions, Packed Shut Off Valves, Packed Line Valves, Industrial Shut Off Valves, Rotalock Valves, Rotalock Connectors, Capped Line Valves, Service Valves, Solenoid Valves, Solenoid Coils, Reversing Valves, Flow Switches and much more.

Automatic controls which are designed by Henry Technologies having the ability to work without fail and without the need for constant manual monitoring. Henry components reliably control all critical functions based on preset parameters from managing the temperatures in cold rooms and refrigerators to maintain compressor levels. Henry Technologies Flow Controls are designed to be highly efficient by including functionality with a low-pressure drop. These flow controls will satisfy a wide variety of functions like remotely controlling flow direction, isolating the system parts for maintenance.

The main vision of Henry Technologies for making intelligent factory is to have the ability to learn new things from its environment and adjust processes automatically as per the requirement. In the factory, their production lines will identify the inventory replenish requirement, collect the components as needed for manufacturing the product. Henry Technologies doing hard work to make their products innovative and work for many years. Henry Discharge Line Mufflers should have the warranty.

1) 1 5/8" DISCHARGE LINE MUFFLER for Henry Technologies Part# S-6415:

S-6415 Henry Technologies Mufflers functionally used to reduce the noise in the discharge line of refrigeration and air conditioning system.

Product Specifications:

Name of the Part: S-6415 Henry Technologies Mufflers

Parts Number: S-6415

Manufacturer: Henry Technologies

Item Type: Discharge Line Mufflers

2) 1/4MPT X 1/4FPT SHUT OFF VALVE for Henry Technologies Part# 7771:

Henry Technologies 777 series Shut-Off Valves work efficiently. No more doubts at all to purchase shut off Valves.

Product Specifications:

Name of the Part: 777 series Shut-Off Valves

Parts Number: 7771

Manufacturer: Henry Technologies

Item Type: SHUT OFF VALVE

3) 3/8"Flr x 1/2"Flr Vertical Receiver for Henry Technologies Part# S-8066:

Henry Technologies manufactures and designs a complete line of both vertical as well as horizontal refrigerant receivers. If you want to make an order of S-8066-Henry Technologies Vertical Mount Receiver.

Product Specifications:

Name of the Part: S-8066-Henry Technologies Vertical Mount Receiver

Parts Number: S-8066

Manufacturer: Henry Technologies

Item Type: Receiver

1 note

·

View note

Text

Have an Idea about the Uses of PTFE Envelope Gasket

For the pipelines, containment, hygiene of tanks and safety, reactors, etc Gaskets are used widely. To produce high-quality tailor-made PTFE envelope gaskets, Leading PTFE sheet manufacturers are utilizing technology. Customizing them to suit a number of applications, this PTFE packing is easily available in various sizes.

Wherein PTFE is wrapped around a core insert material, Polytetrafluoroethylene or PTFE envelope gaskets are composite gaskets. Along with the properties of PTFE, it gives the characteristics and strength of the core material, which is the main benefit of envelope gaskets.

For making the gaskets, two or more insert materials can be used to enhance the properties.

Because of the chemical and physical properties of PTFE material, PTFE envelope gaskets by gasket manufacturers are in demand. It is widely used in the food, petrochemical, chemical, and pharmaceutical industries.

Using rubber elastomers, graphite, corrugated metals, non-asbestos fillers, etc, PTFE Sheet Manufacturers can provide custom-engineered products. On the basis of their following features, Applications of PTFE packing in China can be determined:

Due to the strong C-F bond of PTFE, they deliver high performance.

To most chemicals, these gaskets display greater resistance.

In environments with low to high corrosion, PTFE envelope gaskets are an ideal sealing solution as they are anti-corrosive in nature.

To running noise-free and vibration-free operations, PTFE gaskets also contribute.

To withstand temperatures of up to +250°C, The PTFE gaskets have the sturdiness depending on the gasket material used.

Without breaking, PTFE can stand the pressure in high-pressure environments.

Making it so popular across industries, Ultimate uses of PTFE envelope gaskets from, PTFE packing supplier is:

Pipelines

To the pipeline industry, Gasket manufacturers provide a number of sealant solutions. For gas and liquid inside the pipelines, PTFE envelopes gaskets are a highly useful sealant. Passing through the valves, flange joints, etc they help in preventing the leakage of the chemicals and acids.

Other Uses

PTFE gaskets are used with ceramic or steel, glass-lined or plastic flanges. With the dual purpose of ensuring the product quality, Gasket manufacturers design PTFE sealants while safeguarding the property and life on the site of the application.

Please Follow Us on Facebook and Twitter

1 note

·

View note

Text

#safety valve china#safety valve supplier#safety valve manufacturer#safety valve manufacturer in china#safety valve supplier in china#Pressure safety valve change over system#pressure safety valve manufacturer#pressure safety valve supplier#pressure safety valve china

0 notes

Text

#Pressure Safety Valves#Switching safety valve#Safety Valve#Safety Valve China#Pressure Safety Valve#Pressure Safety Valve Manufacturer#Pressure Safety Valve Supplier#B2B#Business services And Consultants#Industrial Machinery And Supplies#Logistics And Transportation#Industrial Supplies#Construction

0 notes

Text

Gas Treatment Market Size Is Estimated To Rise To USD 4.96 Billion By 2023: Report by MarketsandMarkets™

Global "Gas Treatment Market is estimated at USD 3.76 billion in 2018 and is projected to reach USD 4.96 billion by 2023, at a CAGR of 5.7% from 2018 to 2023. Major companies operating in this market such as DowDuPont Inc. (US), Huntsman International LLC (US), BASF SE (Germany), Ecolab Inc. (US), and Berryman Chemicals Inc. (US) have adopted both organic and inorganic growth strategies such as investments & expansions, new product launches, and agreements to serve their customers efficiently and increase their market shares.

Get PDF brochure of the report: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=167226464

Browse 79 market data Tables and 32 Figures spread through 109 Pages and in-depth TOC on "Gas Treatment Market.

The stakeholders in the gas treatment market are as follows:

Crude oil producers

Natural gas producers and processors

Amine manufacturers

Glycol manufacturers

Oil & gas associations

Distributors of amines and glycols

Suppliers of raw materials

Environment Support Agencies

Amines segment to lead the gas treatment market, during the forecast period, in terms of both value and volume

On the basis of type, the amines segment is projected to lead the gas treatment market, during the forecast period, in terms of both value and volume. The removal of acid contaminants from natural gas is necessary for the commercial industrial applications. Acid gases, such as hydrogen sulfide and carbon dioxide, need to be removed to meet the environmental and health and safety standards.

Acid gas removal segment is projected to lead the gas treatment market, during the forecast period, in terms of volume

On the basis of application, the acid gas removal segment is projected to lead the gas treatment market during the forecast period, in terms of both value and volume. Natural gas streams contain hydrogen sulfide and carbon dioxide. These gases are toxic and poisonous and need to be treated. These gases, in the presence of water, are extremely corrosive and can cause premature failure of pipeline, pressure vessels, and valves. Acid gases can also cause catalyst poisoning in refinery vessel and requires expensive precautionary measures. All these factors are responsible for the high growth of the gas treatment market.

https://www.prnewswire.com/news-releases/gas-treatment-market-worth-4-96-billion-by-2023-exclusive-report-by-marketsandmarkets--875081398.html

APAC gas treatment market is projected to register the highest CAGR, between 2018 and 2023, in terms of volume

The gas treatment market in APAC has immense growth potential. The discovery of new gas fields in the region is expected to fuel the demand for gas treatment during the forecast period. China, Australia, and Malaysia are some of the key countries in the region contributing significantly to the growth of the gas treatment market in the region.

Some of the key players in the gas treatment market are DowDuPont Inc. (US), Huntsman International LLC (US), BASF SE (Germany), Ecolab Inc., and Berryman Chemicals Inc. (US). Investments & expansions was the major growth strategy adopted by the market players, between 2015 and 2018, to enhance their regional foothold and meet the growing demand for gas treatment in the emerging economies.

Early buyers will receive 10% free customization on this report.

Don't miss out on business opportunities in Gas Treatment Market.

Speak to Our Analyst and gain crucial industry insights that will help your business grow.

https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=167226464

About MarketsandMarkets

MarketsandMarkets is the largest market research firm worldwide in terms of annually published premium market research reports. Serving 1700 global fortune enterprises with more than 1200 premium studies in a year, M&M is catering to a multitude of clients across 8 different industrial verticals. We specialize in consulting assignments and business research across high growth markets, cutting edge technologies and newer applications.

Contact: Mr. Ashish Mehra MarketsandMarkets™ INC. 630 Dundee Road Suite 430 Northbrook, IL 60062 USA: 1-888-600-6441 [email protected]

0 notes

Text

weigao Company Development

IN 1990

Yuyao High and Medium Pressure Standard Parts Factory was established and began to manufacture fasteners for valves.

IN 1995

began the production of American-made fasteners that fully comply with ASTM A193, A194, A320, A574, and A325 standards.

IN 1998

it passed the ISO9000 system certification, and in the same year, it provided supporting equipment for the US Crane Factory Group.

IN 2000

it supplied high-pressure fasteners to Japan's Beize Valve Co., Ltd., a globally renowned integrated valve man. in the same year, it became a supplier of WALWORTH COMPANY and IN DASTRIAL in Mexico and exported directly to Mexico.

IN 2005

it became a qualified supplier of TYCO fluid control in China. In the same year, it passed the audit of Shandong Cameron Petroleum Machinery Co., Ltd., a COMERON VALVES China plant in the United States, and became the company's fixed-point procurement supplier.

IN 2006

Yuyao Weigao Standard Parts Co., Ltd. was established. In the same year, it was awarded the "Special Equipment Manufacturing License" issued by the General Administration of Quality Supervision, Inspection and Quarantine of China.

IN 2015

it passed the SO14001 Environmental Management System and OHSAS18001 Occupational Health and Safety Management System Certification. In 2016, the company increased its capital to 35 million and changed its name to Zhejiang Weigao Standard Parts Co., Ltd.

IN 2017

the company was awarded the American Petroleum Association API-20E, 20F Double-consultant Certificate.

0 notes

Text

Significant COVID-19 Impact on Industrial Valves | Semiconductors & Electronics Industry

COVID-19 Impact on Industrial Valves in Semiconductors and Electronics Industry

COVID-19 is a pandemic disease which has created a severe outbreak in the world starting from China to almost in every country. It has major impact almost on everything including human life, world economy, automotive sector, industrial sector and others as a result demand and consumption rate gets lowered. Unavailability of vaccine to cure or prevent the disease from spreading is major reason due to which lockdown has been initiated for prevention and to lower the COVID-19 spread.

To control the disease spread, lockdown is so far is considered to be the better solution observed in the many countries but it also has an adverse effect on the economy. As a consequence of COVID-19, much of the world is facing rather typical living conditions today. Under any form of quarantine, more than 2 billion people were at the height of the pandemic and 91 per cent of the world’s population, or 7.1 billion citizens, reside in countries with border controls or travel restrictions due to the outbreak.

As the pandemic hit globally, employees are advised to work from home. There is strict action by government to lockdown the countries till the time virus infected patients are controlled. The key players in industrial valves market such as Emerson Electric Co, The Weir Group PLC, Flowserve Corporation, Schlumberger Limited and IMI PLC, among others are continuing their operations by taking necessary precautions. The main focus of the companies is to keep employees healthy, while supporting their customers in the best way possible. The production of the industrial valves are stable, the sales and distribution channels of the market players are functioning normally which is driving the market in the pandemic situation.

IMPACT ON DEMAND

The COVID-19 pandemic has had tangible implications for the global economy. Traveling restrictions and social distancing steps on a wide scale cause a sharp decline in company and consumer spending due to the quarantine situation. The demand for industrial valves expected to improve gradually due to the plants in china resumed their production from March. Companies that need resources to connect remote workstations to employees, businesses that urgently need to go online to work with consumers or retailers, and delivery services. So the above reasons are directly impacting the demand for industrial valves in positive way.

IMPACT ON SUPPLY CHAIN

Could COVID-19 be the unpredictable event that finally forces many industries and companies, to re-think and transform their supply chain models? Due to the lockdowns, companies are facing severe problems for raw materials or finished products transport, this is directly impacting the growth of the company. To overcome this situation, companies must closely monitor long-term and short-term demand and maintain inventory to reduce production loss in the economic slowdown situation.

IMPACT ON THE MANUFACTURING INDUSTRY AND GOVERNMENT INITIATIVES TO BOOST THE MARKET

COVID-19 has created a major impact on the manufacturing industry as almost every country has opted for the shutdown option for every production facility except the ones who are dealing in producing the essential goods. To prevent the spread of coronavirus disease, the government has taken some strict actions such as the shutdown of production and sale of non-essential goods, blocked international trade, and many more. The only business which is dealing in this pandemic situation is the essential services that are only allowed to open and run the processes. Companies such as pharmaceutical and chemical, among others are allowed for facilities operation but with certain safety rules.

Now at the current period where almost half a year is ended the government is taking the initiative to support the economy by allowing the manufacturing operations by following physical distancing practices. The manufacturing facilities are getting started now with a limited workforce creating major demand for the market. Adjusting production volume and increases in production for products that are in demand will help the key players to sustain in the market. The demand for maintenance, the repair will remain the same but the capital investments by the end-users may change.

STRATEGIC DECISIONS FOR MANUFACTURERS AFTER COVID-19 TO GAIN COMPETITIVE MARKET SHARE

As the COVID-19 crisis continues to expand, makers would possible face challenges on varied fronts. Producing firms would be searching for immediate measures to stay their workforces safe and their businesses solvent. Makers would conjointly have to be compelled to look on the far side their economic viability. Because the COVID-19 pandemic intensifies, makers would possible face continued downward pressure on demand, production, and revenues. They’d continuously face cash-flow liquidity challenges and difficulties in managing debt obligations.

There is both positive as well as negative impact of the COVID-19 disease on market as it has lowered its demand and at the same time, several strategies which can help the market players to increase their presence and market share in the industry.

IMI PLC, which is engaged in the design and implementation of innovative, designed solutions for new plant constructions and also providing full plant life cycle service support planned to remain in close touch with our suppliers to monitor the supply chain, equipping their service technicians with additional personal protective equipment as required.

On 17th February 2020, before the global release of COVID-19, Flowserve issued its guidance on certain financial indicators for the full year 2020. Due to the rapidly changing effects of COVID-19, and end-market volatility, Flowserve is withdrawing its financial outlook for 2020 at this time. This strategic decision helps to help the business work, and is committed to making them run safely and efficiently.

CONCLUSION

COVID-19 has forced the workers to stay at home and take their workloads in their home, the sales and distribution channels of the market players are functioning normally which is driving the market in the pandemic situation. The global economy slowdown is directly impacting the consumption of industrial valve solutions which is acting as a restrain in the COVID-19 crisis. The strategic decisions such as close touch with our suppliers to monitor the supply chain and working closely with their component suppliers and monitoring the demand by the key players are opening lucrative opportunities for the market.

#Industrial Valves Market#Industrial Valves Market Analysis#Industrial Valves Market Forcast#Industrial Valves Market Future Innovation

0 notes