#Pressure Sensitive Adhesives market price

Explore tagged Tumblr posts

Text

Pressure Sensitive Adhesives Market Overview

Pressure Sensitive Adhesives Market size is forecast to reach US$ 9.5 billion by 2026, after growing at a CAGR of 6.5% during 2021-2026. Globally, the rising demand for pressure-sensitive adhesives (PSA) owing to its thin, flexible material with single or double-sided coating in various end-use industries such as packaging, automotive, and electronics is estimated to drive the market growth. The increasing usage of resins such as silicone polymers, polyisobutene, and elastomers, generally synthetic rubber as the base polymer owing to its functionality and durability, in various end-use sectors will also substantially drive the demand for PSAs. Nitrocellulose adhesive, hydrogenated hydrocarbon resins, and ethylene-vinyl acetate are the thermoplastic resins generally employed in pressure-sensitive adhesives. Moreover, the increasing usage of bio-based pressure-sensitive adhesives and advancements in pressure-sensitive adhesive tapes is expected to offer enormous market expansion opportunities and boost the pressure-sensitive adhesives (PSA) industry in the projected time frame.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐑𝐞𝐩𝐨𝐫𝐭 𝐒𝐚𝐦𝐩𝐥𝐞

Impact of Covid-19

The COVID-19 pandemic and its disruption to several manufacturing activities declined the growth of the pressure sensitive adhesives market in the year 2020. Due to the supply chain disruption and insufficient labor, the manufacturing activities of the packaging, automotive, and electrical and electronic industries were set at a pause which affected the market growth. Furthermore, considering the new government norms and reopening of several industries, it is presumed that the market for pressure sensitive adhesives will return to normal conditions.

Report Coverage

The: “Pressure Sensitive Adhesives Market Report – Forecast (2021-2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the pressure sensitive adhesives Market.

By Formulation: Water-based, Solvent-based, Hot Melt, Others

By Resin Type: Elastomer (Natural and Synthetic), Acrylic, Silicone, Ethylene-Vinyl Acetate, Polyvinyl Ether, Polyisobutene, Polybutadiene, and Others

By Application: Tapes, Labels, Graphics, and Others

By End Use Industry: Construction, Automotive, Electronics, Medical and Healthcare, Paper, Furniture, Renewable Energy, Wood Working, and Others

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, Italy, France, Spain, Netherlands, Russia, Belgium, and Rest of Europe), Asia Pacific (China, Japan, India, South Korea, Australia and New Zealand, Taiwan, Indonesia, Malaysia, and Rest of Asia Pacific),South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), and RoW (Middle East and Africa)

Key Takeaways

Asia-pacific region dominated the pressure sensitive adhesives Market due to the rising government investments in the healthcare, electronics, and construction and infrastructure segments in countries such as China, India, South Korea, and Australia.

Current product innovations to improve modulus of elasticity and rigidity are expected to broaden the application range of pressure sensitive adhesives in structural applications and drive the growth of the market in the projected period.

Rising demand for silicone polymers based pressure sensitive adhesive (PSA) in the electronic and medical industry will further drive the growth of the pressure sensitive adhesives market.

Low adhesive strength provided by the pressure-sensitive adhesives (PSA) would further affect the growth of the market over the forecast period.

#Pressure Sensitive Adhesives market price#Pressure Sensitive Adhesives market size#Pressure Sensitive Adhesives market share

0 notes

Text

Methyl Meth Acrylate (MMA) Prices: Trends and Market Dynamics

Methyl Methacrylate (MMA) is a critical chemical compound widely used in the production of acrylic sheets, coatings, adhesives, and other high-performance materials. The price of MMA is a significant determinant of cost structures in industries such as automotive, construction, and electronics. This article explores the recent trends, factors influencing MMA prices, and the market outlook.

Recent Trends in MMA Prices

In 2023 and 2024, MMA prices have exhibited notable fluctuations due to global economic conditions and changes in supply and demand dynamics. During the early months of 2023, MMA prices were relatively stable, with moderate growth driven by steady demand from the construction and automotive sectors. However, the latter half of the year saw increased price volatility as a result of raw material shortages and geopolitical tensions.

One significant trend was the impact of rising crude oil prices on MMA production costs. MMA is derived from acetone cyanohydrin or isobutylene, both of which are petrochemical derivatives. Increases in crude oil prices tend to ripple through the supply chain, raising production costs for MMA. Additionally, disruptions in the global supply chain, particularly in Asia, which is a significant producer of MMA, contributed to pricing challenges.

Get Real time Prices for Methyl Methacrylate (MMA): https://www.chemanalyst.com/Pricing-data/methyl-methacrylate-1288

Key Factors Influencing MMA Prices

Raw Material Costs The price of raw materials such as acetone and methanol directly affects MMA production costs. Fluctuations in these inputs, often linked to crude oil price trends, are a primary driver of MMA prices.

Supply and Demand Imbalance The MMA market is sensitive to shifts in supply and demand. Increased demand from the automotive sector for lightweight materials and the construction industry for durable coatings has supported price increases. On the other hand, oversupply or weak demand due to economic slowdowns can lead to price declines.

Geopolitical Factors Trade restrictions, tariffs, and geopolitical tensions have disrupted the MMA supply chain. For instance, production halts in key exporting countries have tightened global supply, exerting upward pressure on prices.

Environmental Regulations Stricter environmental regulations have increased compliance costs for MMA producers. Companies are investing in sustainable production methods, which could marginally raise costs and prices over the long term.

Market Outlook for MMA Prices

The outlook for MMA prices in the near term is mixed, influenced by economic uncertainties and evolving market conditions. As the global economy recovers, demand from end-use industries is expected to strengthen, supporting price stability or modest growth.

The Asia-Pacific region, particularly China and India, will likely remain pivotal in shaping MMA price trends due to their significant production and consumption capacities. However, macroeconomic factors such as interest rate hikes, currency fluctuations, and potential recessions in key markets may temper price growth.

Sustainability will also play an increasingly important role in the MMA market. Producers adopting bio-based feedstocks and energy-efficient processes may gain a competitive edge, potentially affecting pricing dynamics.

Conclusion

Methyl Methacrylate prices are influenced by a complex interplay of factors, including raw material costs, demand-supply balance, and external economic conditions. While challenges such as supply chain disruptions and regulatory pressures persist, the long-term outlook remains positive, supported by growing demand from diverse industrial applications. Stakeholders must closely monitor market trends to navigate the volatile MMA pricing landscape effectively.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Methyl Methacrylate News#Methyl Methacrylate Price Monitor#Methyl Methacrylate Database#Methyl Methacrylate Price Chart

0 notes

Text

The Ultimate Guide to Choosing the Best PVC Electrical Tape in Delhi

When it comes to ensuring electrical safety and durability, selecting the right materials is crucial. One of the most essential items in any electrician's toolkit is the PVC electrical tape. Whether you're working on a complex industrial project or a simple home repair, the quality of the PVC electrical insulation tape you choose can make all the difference. In this guide, we'll dive into everything you need to know about PVC tape, specifically focusing on the best options available in Delhi.

What is PVC Electrical Tape?

PVC electrical tape, often referred to as electric tape roll, is a type of pressure-sensitive tape used to insulate electrical wires and other materials that conduct electricity. Made from Polyvinyl Chloride (PVC), this tape is known for its durability, flexibility, and resistance to wear and tear. Its primary function is to prevent electrical currents from inadvertently flowing between wires, which could lead to short circuits, fires, or other dangerous situations.

Why PVC Electrical Tape is Essential

The use of PVC electrical insulation tape is vital in both residential and commercial electrical installations. Here are a few reasons why:

1. Electrical Insulation: PVC tape provides excellent insulation, reducing the risk of electrical shocks and fires.

2. Durability: The material is resistant to UV light, moisture, and most chemicals, ensuring long-lasting protection.

3. Flexibility: PVC tape can be easily stretched and wrapped around wires, making it ideal for use in tight spaces.

4. Cost-Effective: Compared to other insulation materials, PVC tape is affordable and readily available in various sizes and colors.

How to Choose the Right PVC Electrical Tape in Delhi

When shopping for PVC electrical tape in Delhi, there are several factors you should consider to ensure you get the best product for your needs.

1. Thickness

The thickness of the PVC tape roll is a key factor in its effectiveness. Thicker tapes provide better insulation and are more durable, but they may be less flexible. For general electrical work, a tape thickness of 7-10 mils is typically sufficient.

2. Adhesion

The adhesive quality of the PVC tape is crucial for ensuring it stays in place. Look for tapes that offer strong adhesion without leaving a sticky residue when removed.

3. Temperature Resistance

Delhi experiences a wide range of temperatures, so it's important to choose a PVC electrical insulation tape that can withstand both high and low temperatures. Tapes with a temperature resistance range of -10°C to 80°C are generally suitable for most applications.

4. Flame Retardancy

For added safety, opt for a PVC tape that is flame retardant. This feature can prevent the tape from catching fire, even in the event of a short circuit.

5. Color Coding

Color-coded PVC tapes are not only visually appealing but also serve a functional purpose. Different colors can be used to identify different types of wiring or phases in a system, making it easier to troubleshoot problems later on.

Where to Buy PVC Electrical Tape in Delhi

Delhi is home to numerous suppliers and stores that offer high-quality PVC electrical tapes. Whether you prefer to shop online or visit a local hardware store, you'll find a wide range of options to suit your needs.

1. Online Marketplaces

Platforms like Amazon, Flipkart, and IndiaMART offer a vast selection of PVC tape rolls from various brands. Shopping online allows you to compare prices, read reviews, and have the products delivered straight to your door.

2. Local Electrical Shops

For those who prefer to see the product before purchasing, visiting a local electrical shop in Delhi can be a good option. Some of the popular areas for buying electrical supplies include Bhagirath Palace in Chandni Chowk and Nehru Place.

3. Wholesale Markets

If you're looking to purchase PVC tape in bulk, consider visiting a wholesale market in Delhi. These markets often offer significant discounts for large orders, making them ideal for contractors and businesses.

Top Brands of PVC Electrical Tape in Delhi

Several reputable brands offer high-quality PVC electrical insulation tapes in Delhi. Some of the most trusted names include:

1. 3M: Known for their premium quality and reliability, 3M tapes are a popular choice for both professionals and DIY enthusiasts.

2. Anchor: Offering a range of affordable yet durable tapes, Anchor is a go-to brand for many electricians in Delhi.

3. Steelgrip: This brand provides excellent adhesion and insulation properties, making it a top pick for industrial applications.

4. Wonder Tape: Known for its versatility, Wonder Tape offers tapes that are suitable for various electrical and automotive applications.

Conclusion

Choosing the right PVC electrical tape is essential for ensuring the safety and longevity of your electrical projects. By considering factors like thickness, adhesion, temperature resistance, and flame retardancy, you can find the perfect PVC tape roll for your needs. Whether you choose to buy your PVC electrical insulation tape online or from a local store in Delhi, make sure to opt for a trusted brand that offers high-quality products.

#pvc electrical tape#bijli electrical tape#electrical insulation tape#pvc insulation tape in delhi#pvc electrical insulation tape#PVC tape in Delhi

0 notes

Text

The global Epoxy Phenol Novolac (EPN) market, valued at USD 139.19 million in 2024, is witnessing significant growth, with an expected CAGR of 5.30% from 2024 to 2032. Epoxy Phenol Novolac Resin (EPNR) is a high-performance thermosetting resin renowned for its superior chemical resistance, thermal stability, and mechanical strength. This resin, synthesized through the reaction of phenol with formaldehyde and then with epoxy, finds extensive applications across various industries, including automotive, aerospace, electronics, and construction. As industries continue to evolve, the demand for EPNR is witnessing significant growth. This article delves into the current trends, market dynamics, and future outlook of the Epoxy Phenol Novolac Resin market.

Browse the full report at https://www.credenceresearch.com/report/epoxy-phenol-novolac-resin-market

Market Overview

The global EPNR market is experiencing robust growth driven by advancements in technology and increasing industrial applications. The resin's inherent properties make it ideal for applications requiring high durability and resistance to harsh environments. In particular, sectors like automotive and aerospace leverage EPNR for its ability to withstand extreme temperatures and corrosive conditions.

Key Drivers

1. Growing Automotive and Aerospace Industries: The automotive and aerospace sectors are major consumers of EPNR due to the resin’s ability to meet stringent performance requirements. The ongoing trend of lightweight and high-performance components in these industries boosts the demand for EPNR, as it provides excellent mechanical properties and resistance to high temperatures and chemicals.

2. Technological Advancements: Innovations in resin formulations and manufacturing processes are enhancing the performance and application scope of EPNR. Developments such as improved curing processes and formulations that offer better adhesion and flexibility contribute to the resin's growing popularity.

3. Infrastructure Development: The expansion of infrastructure projects, especially in emerging economies, is another significant driver of EPNR demand. The resin's use in coatings, adhesives, and composite materials supports the construction of durable and high-performance structures.

Challenges

1. High Costs: One of the primary challenges in the EPNR market is the high cost associated with its production and raw materials. This cost factor can limit the adoption of EPNR in price-sensitive applications, particularly in emerging markets where cost efficiency is crucial.

2. Environmental Concerns: The production of EPNR involves the use of formaldehyde, a substance that raises environmental and health concerns. Regulatory pressures and the need for sustainable practices are pushing the industry towards developing greener alternatives and more environmentally friendly processes.

3. Competition from Alternatives: The EPNR market faces competition from alternative resin systems such as epoxy phenolic resins and other thermosetting resins. These alternatives often offer similar properties at a lower cost or with fewer environmental impacts, posing a challenge to EPNR’s market share.

Regional Insights

1. North America: The North American market holds a significant share due to the strong presence of automotive and aerospace industries. The region’s focus on technological advancements and high-performance materials supports the demand for EPNR.

2. Europe: Europe, with its emphasis on stringent regulations and high-quality standards, also represents a substantial market for EPNR. The automotive and electronics industries, along with the push for sustainable materials, drive growth in this region.

3. Asia-Pacific: The Asia-Pacific region is witnessing rapid industrialization and infrastructure development, leading to increased demand for EPNR. Countries like China and India are emerging as key markets due to their expanding automotive and construction sectors.

Future Outlook

The Epoxy Phenol Novolac Resin market is poised for growth, driven by technological advancements, increasing industrial applications, and infrastructure development. The focus on high-performance materials in industries like automotive, aerospace, and construction will continue to propel the demand for EPNR. However, challenges related to cost and environmental concerns need to be addressed through innovation and sustainable practices.

Key players:

Huntsman,

GP Chemicals,

Aditya Birla Group,

DowDuPont,

Hexion Inc.,

DIC,

Momentive,

Emerald Performance Materials,

Kukdo Chemical Industry,

CORCHEM,

A&C Catalysts,

NanYa Plastics.

Recent Developments

Segmentation

Segment by Type

Phenol Type Epoxy Phenol Novolac

O-Cresol Type Epoxy Phenol Novolac

Bisphenol A Type Epoxy Phenol Novolac

Segment by Application

Adhesives

Protective Coatings

Composite Materials

Others

By Region

North America

The U.S.

Canada

Mexico

Europe

Germany

France

The U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/epoxy-phenol-novolac-resin-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Copper Foil Market - From Supply Chain Resilience to Technological Advancements

The global copper foil market size is anticipated to reach USD 22.00 billion by 2030 and is anticipated to expand at a CAGR of 11.9% during the forecast period, according to a new report by Grand View Research, Inc. Increasing adoption of renewable energy sources and electric vehicles (EVs), as a part of decarbonization efforts, is projected to fuel the growth of global market for copper foil. Copper foil functions as the electrical conductor of printed circuit board (PCB). Rising demand for PCBs, due to the aforementioned application of copper foil in them, is likely to play a crucial role in influencing demand for copper foil. PCBs are essential building blocks in electronics manufacturing. As electronic devices become more complex and intelligent, there is an ever-growing demand for PCBs. As a result, rising demand for smart devices is likely to propel growth of the industry.

Copper Foil Market Report Highlights

Based on product, rolled foil held a maximum revenue share of over 55.0% in 2023 and is expected to grow at a significant CAGR over the forecast period due to its high consumption in batteries, solar panels, and IoT-enabled services, among others

Based on application, batteries segment is expected to grow at a lucrative pace over the forecast period owing to the growing EV industry

In solar & alternative energy, tin-plated copper foils in combination with acrylic-based pressure-sensitive adhesive tapes, are used in thin-film solar applications. These are solderable, and their usage provides stable electrical performance and is also easy to work with during the solar panel production process

Asia Pacific dominated the market owing to several countries in region focusing on reducing their carbon emissions by shifting their attention toward the adoption of renewable energy. For instance, according to the International Trade Administration, Taiwan plans to cater to 20% of its energy requirements from renewable sources by 2025. It is expected to harness 20 GW of solar energy by 2025

In January 2024, Hungary-based Volta Energy Solutions announced its geographic expansion into North American market by building a new battery copper foils plant in Quebec, Canada to cater to a fast-growing EV segment. It is a developer of world's first electrodeposited copper foils for batteries

For More Details or Sample Copy please visit link @: Copper Foil Market Report

Use of copper results in reduced carbon emissions and cuts down amount of energy required to generate electricity. There is six times more copper in renewable energy systems than in traditional systems. Hence, growing adoption and transition towards green energy in infrastructure development, such as electric vehicles (EVs) and electricity generation is anticipated to benefit market growth. According to the IEA, the global sales of EVs reached 10.3 million units in 2022 compared to 6.7 million units in 2021 and 3.2 million units in 2020. Global sales are expected to have touched 14.1 million units in 2023; however, actual statistics are yet to be published.

Copper is a commodity that has historically witnessed high price volatility during the historic period of 2018-2022. Fluctuations in prices of copper cathode are expected to have a bearing on the profitability of the producer. Further, hikes in energy prices, supply constraints, and high demand from end-use industries are expected to put pricing pressure on the global market and affect smelter profitability and revenue performances of foil producers over the forecast period. Hence, price volatility of copper is expected to be a significant restraint to the revenue performance of the market.

The market is very competitive, with a strong presence of several large-sized players, such as Nippon Denkai, Ltd., SKC, and Lotte Energy Materials Corporation. Due to growth of end-use applications, players have been investing in increasing their capacities through greenfield projects. For instance, in August 2023, Lotte Energy Materials Corporation announced that it would build a new foil plant in Spain and would be operational in 2025.

#CopperFoilMarket#Electronics#ConductiveMaterials#Manufacturing#Technology#RenewableEnergy#ElectricVehicles#Semiconductors#SupplyChain#Sustainability

0 notes

Text

India Butyl Acrylate Market Outlook, Report 2023-2030

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the India Butyl Acrylate Market size by value at USD 432.99 million in 2023. During the forecast period between 2024 and 2030, BlueWeave expects the India Butyl Acrylate Market size to expand at a CAGR of 7.85% reaching a value of USD 534.03 million by 2030. The Butyl Acrylate market in India is propelled by the increasing application as a solvent in the paints and coatings, as well as adhesive and sealants sectors, predominantly within the expanding construction and automotive industries. India has witnessed a rising trend in residential and commercial development in recent years, driven by increasing investments and evolving lifestyles. Also, butyl acrylate plays a crucial role as an ingredient in pressure-sensitive adhesives, widely employed by the textile and construction sectors. Its presence in PVC modifiers and molding or extrusion additives further enhances its application in the plastics sector. With the upswing in construction activities and infrastructure development, there is an anticipated surge in demand for commodities like paints & coatings and plastics, consequently boosting the overall demand for butyl acrylate over the forecast period.

By volume, BlueWeave estimated the India Butyl Acrylate Market size at 261.66 thousand tons in 2023. During the forecast period between 2024 and 2030, BlueWeave expects the India Butyl Acrylate Market size by volume is projected to grow at a CAGR of 7.01% reaching the volume of 301.09 thousand tons by 2030. The increasing use of butyl acrylate in the production of thermoplastic ethylene acrylate copolymers (EAC), containing up to 35% butyl acrylate, stands out as pivotal factor contributing to market expansion. The combination of butyl acrylate with other monomers, such as vinyl acetate, methyl methacrylate, acrylic acid, styrene, and other acrylate ester monomers, opens up possibilities for diverse copolymer compositions.

Sample Request @ https://www.blueweaveconsulting.com/report/india-butyl-acrylate-market/report-sample

Opportunity – Expanding automotive industry

The expanding automotive industry in India is anticipated to drive the need for butyl acrylate. The compound plays a crucial role in polymer manufacturing, specifically contributing to the production of car dashboards and leather seats. Additionally, butyl acrylate serves as a key component in the production of sealants, utilized in various automotive applications such as within the trunk, hood, doors, front dash, and on both the interior and exterior metal joints of vehicles. The global surge in motor vehicle production stands as a significant factor contributing to the anticipated growth of the butyl acrylate market in the coming years.

Impact of Escalating Geopolitical Tensions on India Butyl Acrylate Market

Increasing geopolitical tensions can have a multifaceted impact on the India Butyl Acrylate Market. The surge in upstream values, particularly crude oil, is exerting pressure on downstream derivatives, thereby elevating inflationary concerns for consumers. Butyl acrylate prices in the domestic market have responded with buoyancy, driven by multiple elements contributing to these fluctuations. A substantial driver for this upward trajectory is the notable increase in crude oil values, impacting critical feedstocks like n-Butanol and Acrylic Acid. The exponential rise in crude oil prices is a consequence of global uncertainties, with low inventories in the USA driving up spot prices of Brent. Simultaneously, geopolitical tensions between Russia and Ukraine have further heightened global contract purchases. Additionally, increased consumption in China, post-easing of the dual energy policy and winter Olympics-related restrictions, has influenced the overall pricing dynamics for crude oil globally. Also, heightened demand fundamentals for Butyl Acrylate in the downstream derivative segment contribute to the overall upward price trend in the Indian market.

India Butyl Acrylate Market

Segmental Information

India Butyl Acrylate Market – By Application

On the basis of application, the India Butyl Acrylate Market is divided into Paints & Coatings, Adhesives & Sealants, Chemical Synthesis, Plastic Additives, and Textiles segments. The paints & coatings segment holds the highest share in the India Butyl Acrylate Market by application closely followed by the adhesive & sealants segment. It is primarily due to their growing applications in the construction and automotive industries. Additionally, the rising trend of substituting old coatings with water-based alternatives in combination with the increased usage of adhesives further contributes to the sustained leadership of these industries in the market.

India Butyl Acrylate Market – By Region

Geographically, the India Butyl Acrylate Market is divided into North India, South India, East India, and West India regions. West India holds the highest market share and is expected to maintain its dominance during the forecast period. Its dominance is attributed to key consumption in states like Gujarat and Maharashtra, driven by prominent companies, such as Asian Paints. Until FY2022, India relied on imports to meet the demand for butyl acrylate.

Competitive Landscape

The India Butyl Acrylate Market is fragmented, with numerous players serving the market. The key players dominating the India Butyl Acrylate Market include Bharat Petroleum Corporation Limited, BASF, Vizag Chemical, Dhalop Chemicals, Dow, Arkema, Otto Chemie Pvt Ltd, KR Chemicals, and LG Chem. The key marketing strategies adopted by the players are facility expansion, product diversification, alliances, collaborations, partnerships, and acquisitions to expand their customer reach and gain a competitive edge in the overall market.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

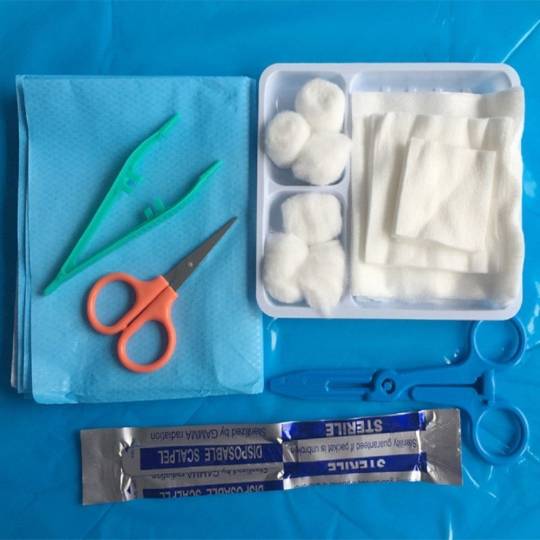

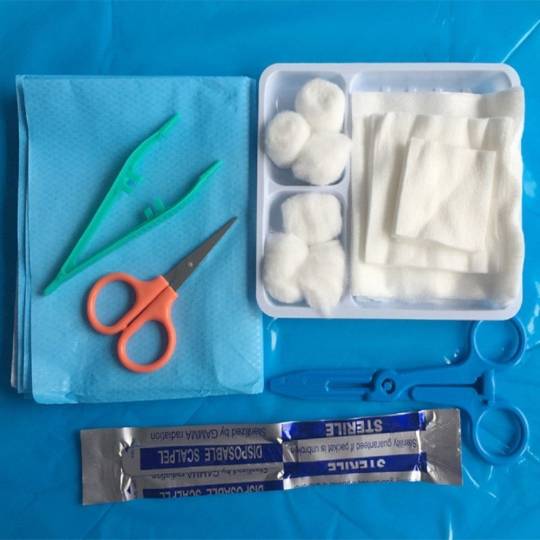

The Unfiltered Truth Behind the Surgical Dressing Market Boom

Hey there, wound care enthusiasts and market trend aficionados! Today, let’s take a deep dive into the not-so-glamorous yet utterly essential world of surgical dressings. Spoiler alert: no decoding or navigating needed, just plain talk about a market worth billions.

Setting the Stage: A Glimpse of the Surgical Dressing Market

So, we’ve got a market worth a staggering USD 3.80 billion in 2022, with predictions skyrocketing to USD 6.18 billion by 2031. Who would have thought bandages and gauze could be such big business, right?

The Cast of Characters: Key Players in the Dressing Drama

Picture this: Johnson & Johnson, 3M Healthcare, Smith & Nephew, Mölnlycke Health Care, and B. Braun Melsungen AG �� the rockstars of the surgical dressing world. These players are not just making band-aids; they’re crafting the future of wound care, one hydrocolloid dressing at a time.

The Plot Thickens: What’s Driving the Surgical Dressing Saga?

The Surge of Surgical Procedures: As surgeries become as common as a morning coffee, the need for surgical dressings shoots up. Apparently, wounds are still a thing in the age of advanced medicine.

Wound Care 101: People suddenly care about wound management — who knew? Thanks to advancements in healthcare infrastructure and a growing geriatric population, surgical dressings are having their moment in the spotlight.

Innovation and Techno-Magic: Materials science meets manufacturing prowess, giving birth to surgical dressings with powers like moisture management, antimicrobial activity, and ease of application. Move over, Hogwarts — the magic is in the bandage.

The COVID-19 Twist: The pandemic threw a curveball, emphasizing infection prevention. With elective surgeries on hold, surgical dressings are gearing up for a post-pandemic resurgence.

Behind the Scenes: Challenges and Opportunities

As we celebrate the growth, let’s not forget the hurdles. Pricing pressures, reimbursement woes, and regulatory red tape are the villains here. But wait, the heroes emerge — the trend toward outpatient care and home-based wound management opens new doors for innovation.

The Market in Numbers: A Rollercoaster of Growth

Drumroll, please! The growth rate: 5.56% CAGR.

The big shot: Hydrocolloid Dressings.

The rising star: Adhesive Bandages.

Regional blockbusters: North America stealing the spotlight, closely followed by Europe.

Segmental Showdown: A Closer Look

Connector Type Battle:

Hydrocolloid Dressings leading the pack with their versatile, moist goodness.

Adhesive Bandages emerging as the crowd-pleaser for minor injuries.

Application Face-Off:

Wound Care taking the crown, but Ostomy Care stealing the spotlight with its rapid growth. Ostomy, the dark horse!

Lights, Camera, Action: Global Surgical Dressing Market Dynamics

The Driving Forces:

Chronic wounds are having a moment, pushing the demand for effective wound care solutions.

Technological advancements — because who doesn’t want their bandage to be cutting-edge?

The Showstoppers:

Regulatory challenges playing party pooper, causing delays in the production and distribution of these medical superheroes.

Allergic reactions and skin sensitivity — not everyone is a fan of band-aids, it seems.

For More Information: https://www.skyquestt.com/report/surgical-dressing-market

The Grand Finale: Competitive Landscape

The stage is set, and the competition is fierce. Smith & Nephew, Mölnlycke Health Care, and friends are not just players; they’re conducting an orchestra of innovation. Strategic alliances, product development, and global reach expansion — the dressing game is serious.

Epilogue: The Unfiltered Truth

In a world obsessed with the latest tech and flashy gadgets, the surgical dressing market might seem like the unsung hero. But hey, when life throws you a cut, surgical dressings are there to save the day — no capes needed.

So, here’s to the silent champions of wound care, the unsung heroes in bandages, and the market that’s stitching it all together, one surgical dressing at a time.

And that’s a wrap, folks! Until next time, stay wound-erful!

About Us-

SkyQuest Technology Group is a Global Market Intelligence, Innovation Management & Commercialization organization that connects innovation to new markets, networks & collaborators for achieving Sustainable Development Goals.

Contact Us-

SkyQuest Technology Consulting Pvt. Ltd.

1 Apache Way,

Westford,

Massachusetts 01886

USA (+1) 617–230–0741

Email- [email protected]

Website: https://www.skyquestt.com

0 notes

Text

The Unfiltered Truth Behind the Surgical Dressing Market Boom

Setting the Stage: A Glimpse of the Surgical Dressing Market

So, we’ve got a market worth a staggering USD 3.80 billion in 2022, with predictions skyrocketing to USD 6.18 billion by 2031. Who would have thought bandages and gauze could be such big business, right?

The Cast of Characters: Key Players in the Dressing Drama

Picture this: Johnson & Johnson, 3M Healthcare, Smith & Nephew, Mölnlycke Health Care, and B. Braun Melsungen AG — the rockstars of the surgical dressing world. These players are not just making band-aids; they’re crafting the future of wound care, one hydrocolloid dressing at a time.

The Plot Thickens: What’s Driving the Surgical Dressing Saga?

The Surge of Surgical Procedures: As surgeries become as common as a morning coffee, the need for surgical dressings shoots up. Apparently, wounds are still a thing in the age of advanced medicine.

Wound Care 101: People suddenly care about wound management — who knew? Thanks to advancements in healthcare infrastructure and a growing geriatric population, surgical dressings are having their moment in the spotlight.

Innovation and Techno-Magic: Materials science meets manufacturing prowess, giving birth to surgical dressings with powers like moisture management, antimicrobial activity, and ease of application. Move over, Hogwarts — the magic is in the bandage.

The COVID-19 Twist: The pandemic threw a curveball, emphasizing infection prevention. With elective surgeries on hold, surgical dressings are gearing up for a post-pandemic resurgence.

Behind the Scenes: Challenges and Opportunities

As we celebrate the growth, let’s not forget the hurdles. Pricing pressures, reimbursement woes, and regulatory red tape are the villains here. But wait, the heroes emerge — the trend toward outpatient care and home-based wound management opens new doors for innovation.

The Market in Numbers: A Rollercoaster of Growth

Drumroll, please! The growth rate: 5.56% CAGR.

The big shot: Hydrocolloid Dressings.

The rising star: Adhesive Bandages.

Regional blockbusters: North America stealing the spotlight, closely followed by Europe.

Segmental Showdown: A Closer Look

Connector Type Battle:

Hydrocolloid Dressings leading the pack with their versatile, moist goodness.

Adhesive Bandages emerging as the crowd-pleaser for minor injuries.

Application Face-Off:

Wound Care taking the crown, but Ostomy Care stealing the spotlight with its rapid growth. Ostomy, the dark horse!

Lights, Camera, Action: Global Surgical Dressing Market Dynamics

The Driving Forces:

Chronic wounds are having a moment, pushing the demand for effective wound care solutions.

Technological advancements — because who doesn’t want their bandage to be cutting-edge?

The Showstoppers:

Regulatory challenges playing party pooper, causing delays in the production and distribution of these medical superheroes.

Allergic reactions and skin sensitivity — not everyone is a fan of band-aids, it seems.

For More Information: https://www.skyquestt.com/report/surgical-dressing-market

The Grand Finale: Competitive Landscape

The stage is set, and the competition is fierce. Smith & Nephew, Mölnlycke Health Care, and friends are not just players; they’re conducting an orchestra of innovation. Strategic alliances, product development, and global reach expansion — the dressing game is serious.

Epilogue: The Unfiltered Truth

In a world obsessed with the latest tech and flashy gadgets, the surgical dressing market might seem like the unsung hero. But hey, when life throws you a cut, surgical dressings are there to save the day — no capes needed.

So, here’s to the silent champions of wound care, the unsung heroes in bandages, and the market that’s stitching it all together, one surgical dressing at a time.

And that’s a wrap, folks! Until next time, stay wound-erful!

About Us-

SkyQuest Technology Group is a Global Market Intelligence, Innovation Management & Commercialization organization that connects innovation to new markets, networks & collaborators for achieving Sustainable Development Goals.

Contact Us-

SkyQuest Technology Consulting Pvt. Ltd.

1 Apache Way,

Westford,

Massachusetts 01886

USA (+1) 617–230–0741

Email- [email protected]

Website: https://www.skyquestt.com

0 notes

Text

Automatic Labelling Machines Market Size | Industry Growth, And Trends

the global Automatic Labelling Machines Market growth is a cornerstone of economic development, influencing the prosperity of nations and shaping the lives of individuals. research proides a diverse array of sectors, each with its unique characteristics and contributing in distinct ways to the overall economic landscape. The growth of Automatic Labelling Machines Market is driven by a multitude of factors, including technological advancements, shifts in consumer preferences, government policies, and the global economic climate.

An extensive overview of the global Automatic Labelling Machines Market Size is provided by the Growth, Share, Price, Trends, Report and Forecast 2027, which evaluates the market based on segments such as types, applications, structural designs, and major regions.

Request for Free Sample PDF - https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/101967

Automatic Labelling Machines Market Segmentated By:

By Type

Self-Adhesive/Pressure Sensitive

Shrink Sleeves

Glue Based

By Configuration

Stand Alone

Integrated

By Industry

Food & Beverage

Healthcare & Pharmaceuticals

Consumer Goods

Other (Automotive, etc.)

The report examines the most recent market updates and their effects on the whole market. In addition, it analyzes price and demand indicators as well as market demand. Additionally, the report uses Porter's Five Forces and the SWOT models to track the market.

List of Top Key Players in Automatic Labelling Machines Market:

Krones AG (Bavaria, Germany)

Sidel (Tetra Lavel International S.A.) (Emilia-Romagna, Italy)

Sacmi Imola S. C. (Emilia-Romagna, Italy)

Herma (Baden-Württemberg, Germany)

Fuji Seal International Inc. (Kansai, Japan)

Marchesini Group S. P. A. (Emilia-Romagna, Italy)

I. M. A. Industria Macchine Automatiche S. P. A. (Emilia-Romagna, Italy)

KHS GmbH (Salzgitter AG Consolidation Group) (North Rhine-Westphalia, Germany)

Barry – Wehmiller Companies (Missouri, U.S.)

ProMach (Ohio, U.S.)

Novexx Solutions GmbH (Bavaria, Germany)

Accutek Packaging (California, U.S.)

Wuxi Sici Auto Co., Ltd. (Jiangsu, China)

Worldpack Automation Systems (Maharashtra, India)

Weber Marking Systems GmbH (Rhineland-Palatinate, Germany)

Kunshan Bojin Trading Co., Ltd. (Jiangsu, China)

CECLE Machine (Zhejiang, China)

PDC International Corp. (Connecticut, U.S.)

Newman Labelling Systems Ltd (London, England)

Quadrel (Ohio, U.S.)

The global Automatic Labelling Machines Market is divided up according to the type, application, country, company, etc. As they utilize the report as a potent resource, players, stakeholders, and other participants in the global Automatic Labelling Machines Market will be able to gain the upper hand. Sales, revenue, and forecasts by type, application, and region (country) are the main topics of the segmental analysis.

COVID-19 Impact on this Market:

The COVID-19 pandemic significantly affected both short- and long-term trends in the Automatic Labelling Machines Market. Though the precise impacts might differ depending on the area and sector.the COVID-19 pandemic affected the Automatic Labelling Machines Market in a variety of ways, including supply chain disruptions, shifts in the demand for necessities, price fluctuations, and a renewed emphasis on supply chain sustainability and resilience. The Automatic Labelling Machines Market in the post-pandemic era will probably continue to be shaped by these changes' long-term effects.

The emergence of COVID-19 has brought the world to a standstill. We understand that this health crisis has brought an unprecedented impact on businesses across industries. However, this too shall pass. Rising support from governments and several companies can help in the fight against this highly contagious disease. There are some industries that are struggling and some are thriving. Overall, almost every sector is anticipated to be impacted by the pandemic.

We are making continuous efforts to help your business sustain and grow during COVID-19 pandemics. Based on our experience and expertise, we will offer you an impact analysis of coronavirus outbreaks across industries to help you prepare for the future.

Report Highlights:

A thorough rundown of Automatic Labelling Machines Market Size and the current developments influencing the sector, Provide information on past and anticipated growth rates.

Important elements supporting, limiting, challenging, and offering the market a chance.

Significant industry advancements and important insights.

Prominent entities operating within Automatic Labelling Machines Market Size.

Players' major tactics include launching new products to increase revenue generation, collaborating with other businesses, and others.

Some other market trends.

Regional Analysis for Automatic Labelling Machines Market:

North America (the USA and Canada)

Europe (UK, Germany, France, Italy, Spain, Scandinavia and Rest of Europe)

Asia Pacific (Japan, China, India, Australia, Southeast Asia and Rest of Asia Pacific)

Latin America (Brazil, Mexico and Rest of Latin America)

The Automatic Labelling Machines Market Size research report provides a thorough evaluation of the sector. The report's estimates were developed based on well-established research philosophies and hypotheses.

0 notes

Text

Pressure Sensitive Adhesives Market Growth: Trends and Opportunities

Pressure Sensitive Adhesives Market: Driving the Bond for Innovation and Growth

Pressure-sensitive adhesives (PSAs) are a class of adhesives that form a bond when pressure is applied to join two surfaces. These versatile adhesives are integral to various industries and have experienced significant growth in recent years. The Pressure Sensitive Adhesives Market has witnessed remarkable developments, driven by advancements in technology, changes in consumer preferences, and increasing demand across diverse sectors. In this comprehensive analysis, we will delve into the key factors shaping the pressure-sensitive adhesives market, its applications, trends, and future prospects.

Market Overview

The pressure-sensitive adhesives market has undergone substantial expansion in recent years, with a compound annual growth rate (CAGR) exceeding 4% over the past decade. The market is expected to continue its growth trajectory in the coming years, driven by several factors.

Key Drivers

Increasing Demand in Packaging Industry: The packaging industry is a major consumer of pressure-sensitive adhesives. With the rise in e-commerce and online shopping, the demand for innovative packaging solutions has surged. Pressure-sensitive adhesives are preferred for their ease of use and versatility in packaging applications.

Automotive Sector Growth: The automotive industry has seen a growing need for pressure-sensitive adhesives in applications like interior trim, exterior parts, and safety-related components. These adhesives contribute to weight reduction and improved aesthetics.

Electronics and Electrical Equipment: As electronic devices become smaller and more complex, the demand for miniaturized components and adhesive solutions that provide reliable bonding without damaging sensitive electronics has increased.

Healthcare and Medical Devices: The healthcare sector relies on pressure-sensitive adhesives for applications such as medical tapes, wound care products, and wearable medical devices. With the aging global population, the demand for these products is on the rise.

Sustainability and Environmental Concerns: Pressure-sensitive adhesives are increasingly chosen for their eco-friendly properties. Manufacturers are focusing on developing bio-based and recyclable PSA formulations to meet the growing demand for sustainable adhesive solutions.

Market Challenges

While the pressure-sensitive adhesives market holds immense promise, it also faces certain challenges:

Price Volatility: Fluctuations in raw material prices, especially petroleum-based feedstocks, can impact the cost of producing pressure-sensitive adhesives, affecting profit margins.

Regulatory Compliance: Stringent environmental regulations and health standards require adhesive manufacturers to invest in research and development to meet compliance requirements, which can be costly and time-consuming.

Intense Competition: The pressure-sensitive adhesives market is highly competitive, with several established and emerging players vying for market share. This competition can lead to pricing pressures.

Market Segmentation

The pressure-sensitive adhesives market can be segmented based on several factors:

By Product Type:

Acrylic PSA Rubber PSA Silicone PSA Others

By Application:

Packaging Automotive Electronics Healthcare Construction Others

By Region:

North America Europe Asia-Pacific Latin America Middle East and Africa

Market Trends

Several notable trends are shaping the pressure-sensitive adhesives market demand:

Smart Labels and Packaging: The integration of smart technology into labels and packaging has created a demand for pressure-sensitive adhesives that can adhere to a wide range of surfaces and withstand various environmental conditions.

Customization and Specialty Formulations: Customers are seeking customized adhesive solutions to meet specific application requirements. This has led to the development of specialty formulations tailored to unique needs.

Digital Printing: The growth of digital printing has influenced the choice of pressure-sensitive adhesives, with adhesives that cater to digital printing technology gaining popularity.

Sustainability Initiatives: Adhesive manufacturers are increasingly investing in sustainable product lines, including bio-based adhesives and recycling programs.

Mergers and Acquisitions: Consolidation within the industry is common, with larger companies acquiring smaller players to expand their product portfolios and global reach.

Future Outlook

The pressure-sensitive adhesives market is poised for continued growth. As industries evolve and innovate, the demand for these versatile adhesives is expected to rise. Advancements in formulation technology, sustainability efforts, and expanding applications will likely fuel the market's expansion.

In conclusion, the pressure-sensitive adhesives market plays a vital role in various industries, from packaging to electronics and healthcare. While it faces challenges such as price volatility and regulatory compliance, the market's growth prospects are strong, driven by evolving consumer preferences and the need for innovative adhesive solutions. As the world continues to change, pressure-sensitive adhesives will remain a crucial component in bonding materials, products, and innovations together.

#Pressure Sensitive Adhesives Market Share#Pressure Sensitive Adhesives Market Growth#Pressure Sensitive Adhesives Market Demand#Pressure Sensitive Adhesives Market Trend

0 notes

Text

Petroleum Resin Prices: Trend | Pricing | News | Price | Database

Petroleum Resin Prices have become a focal point in the global market, influenced by a complex interplay of supply-demand dynamics, raw material availability, geopolitical factors, and downstream industry performance. These versatile resins, derived primarily from cracking petroleum hydrocarbons, are essential components in various applications such as adhesives, paints, coatings, rubber, and printing inks. The pricing trends of petroleum resin are inherently linked to the crude oil market, as fluctuations in crude oil prices directly impact the cost of feedstock materials like C5, C9, and DCPD (dicyclopentadiene). In recent years, the petroleum resin market has witnessed significant volatility, driven by global economic uncertainties, disruptions in supply chains, and shifting demand patterns across key end-use sectors.

One of the critical drivers of petroleum resin prices is the raw material supply chain. Any disruption in the availability of feedstock, such as naphtha or ethylene, directly affects production costs. Geopolitical tensions, natural disasters, or unplanned refinery shutdowns often lead to constrained supply, thereby pushing prices higher. For instance, periods of heightened geopolitical tension in oil-producing regions often result in reduced crude oil output, which cascades down to increased feedstock costs for petroleum resin manufacturers. On the demand side, growth in industries such as construction, automotive, and packaging significantly influences the market. Adhesives and sealants, which are major consumers of petroleum resins, have shown consistent growth, particularly in developing regions where urbanization and infrastructure development are accelerating. This rising demand exerts upward pressure on prices, especially when supply fails to keep pace.

Get Real time Prices for Petroleum Resin: https://www.chemanalyst.com/Pricing-data/petroleum-resins-1128

Environmental regulations and sustainability concerns have added another layer of complexity to the petroleum resin market. With a growing emphasis on reducing carbon footprints and adopting eco-friendly alternatives, some industries are exploring bio-based resins or other substitutes. However, these alternatives are often more expensive and less versatile, ensuring that petroleum resins remain in demand, albeit with rising costs associated with compliance and innovation. The push for sustainability has also led manufacturers to invest in cleaner production technologies, which, while reducing environmental impact, often result in higher production costs passed on to consumers.

Another significant factor influencing petroleum resin prices is the global trade landscape. Tariffs, trade restrictions, and changing international relations can alter the flow of raw materials and finished products. For example, trade wars or sanctions can disrupt supply chains, creating shortages or surpluses that affect prices. Export-oriented markets, particularly in Asia, are highly sensitive to such disruptions. In addition, freight and logistics costs, which have been particularly volatile in recent years, play a crucial role in determining the final price of petroleum resins in different regions. Any increase in transportation costs, whether due to rising fuel prices, container shortages, or port congestions, inevitably translates to higher prices for end-users.

Technological advancements in resin production have also impacted pricing dynamics. Innovations that improve yield, quality, or energy efficiency can help mitigate rising costs, offering competitive pricing in a market driven by cost-sensitive applications. Companies investing in research and development to create high-performance resins are positioning themselves to cater to premium segments while also managing cost pressures. However, the initial capital investment for such advancements often reflects in the pricing structure, especially for new or specialized resin grades.

Seasonality and market speculation further contribute to price fluctuations. During peak construction or manufacturing seasons, demand for petroleum resins tends to spike, leading to temporary price increases. Speculative activities in commodity markets can also drive short-term volatility, as traders react to news related to crude oil prices, geopolitical events, or economic data releases. These speculative factors can amplify the impact of supply-demand imbalances, making pricing more unpredictable.

In the long term, the petroleum resin market is expected to grow steadily, driven by increasing industrialization, urbanization, and technological advancements. However, the pricing environment will likely remain dynamic, influenced by macroeconomic trends, regional developments, and the broader push for sustainability. Companies in this space need to adopt strategies that balance cost-efficiency with innovation to remain competitive in a challenging market landscape. By closely monitoring raw material trends, investing in advanced production technologies, and diversifying supply chains, market participants can better navigate the complexities of pricing while meeting the evolving needs of their customers. The petroleum resin market thus continues to be a vibrant and critical component of the global economy, with its pricing trends offering valuable insights into broader industrial and economic patterns.

Get Real time Prices for Petroleum Resin: https://www.chemanalyst.com/Pricing-data/petroleum-resins-1128

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Petroleum Resin#Petroleum Resin Price#Petroleum Resin Prices#Petroleum Resin Pricing#Petroleum Resin News#Petroleum Resin Database#Petroleum Resin Price Chart#crude oil prices

0 notes

Text

The latest developments in UV LED industry

During the three years of the epidemic, the UV LED industry has experienced ups and downs. Overall, the penetration of UV LEDs in terminal applications such as industrial curing and disinfection has accelerated significantly.

Market situation in terms of industrial curing In the field of industrial curing, the application of UVA LED started relatively early, and the technology is relatively mature. The performance of UVA LED curing equipment has been able to meet the market demand, and it is constantly accelerating the development of new subdivided application fields. At present, UVA LED has basically completely replaced mercury lamps in the fields of adhesive curing such as electronic components and medical consumables, as well as consumer curing represented by nail curing. Wide range of applications. In many fields such as offset printing, silk screen printing, optical fiber coating, wood curing, and automotive curing, there is a huge space for UV LEDs to replace them. However, the current curing equipment standards in the UV market are chaotic, and there are large information errors, which affect the further expansion and penetration of UV LEDs in the curing field.

Market situation in terms of disinfection and sterilization In terms of disinfection and sterilization, UVC LEDs have been widely used in the fields of air, water, and surface disinfection. However, due to the overall low radiation efficiency of UVC LEDs, air disinfection and flowing water treatment in small spaces or special areas are more popular in the market. Especially in the field of household appliances, the performance of disinfection and expansion is even better. At present, many brand disinfection machines, disinfection cabinets, refrigerators, air conditioners, washing machines, air purifiers, humidifiers and other products are equipped with UVC LED disinfection functions. (1) The market generally believes that the field of home appliances may be one of the application directions that can most stimulate the volume of UV LEDs

Zhongke Lu'an has designed and developed a series of supporting module products for white goods, small home appliances and other application scenarios, and has obtained long-term stable orders from leading white goods enterprises. In 2023, we will continue to deepen the market of white goods and small home appliances in terms of modules, develop more new applications and new concepts of UVC LEDs, and strive to achieve standard functions of home appliances.

The water purification company Angel revealed that about 50,000 to 100,000 sets of UVC LED modules will be used in 2022, a year-on-year increase of more than 60%. Angel believes that the application of UVC LED in water treatment is becoming more and more certain. The main problem at present is that based on the existing technical conditions, the overall cost of the sterilization module is relatively high. For household appliances, the cost pressure is very high. On the whole, home appliance terminals are quite sensitive to prices, and the current performance advantages of UVC LED products cannot support the cost premium brought by them, and the cost of modules is too high, among which the cost reduction and optimization of chips is particularly critical. If the chip technology achieves an effective breakthrough, it is believed that most home appliances are expected to be equipped with UVC LED technology, and the installed capacity of home appliances is bound to usher in a leapfrog growth. (2) In the field of public health and safety disinfection, UVC LED application scenarios have been further expanded

In 2022, Zhongke Luan developed a series of high-efficiency sterilization products, which are widely used in medical care, logistics cold chain, public transportation, schools, large venues, etc., such as vertical/wall-mounted air disinfection machines, cold chain package disinfection machines, disinfection robots , elevator sterilizer and other products, this series of products will shine in the Beijing Winter Olympics in early 2022.

Zhixin Semiconductor has a deep layout in the application field of high-power specialized intelligent products, and has designed and developed a variety of professional-grade disinfection equipment such as "Space Guard", which is suitable for the interior of closed spaces such as conference rooms, hospital wards, school classrooms, theater shopping malls, etc. .

Guangpu has successively launched a series of products such as electronic masks, health care machines, air disinfection machines, and elevator ultraviolet disinfection systems, which are widely used in public places and cold chain logistics disinfection applications. (3) Large-scale industrial sterilization or one of the application directions of UVC LED in the future, such as industrial water treatment, urban tap water treatment, aquaculture, etc. At present, foreign manufacturers including Metawater in Japan, Typhon in the UK and AquiSense Technologies in the United States have all demonstrated UVC LED municipal disinfection systems. Several units have been installed and more municipal and industrial systems are planned to be installed.

0 notes

Text

STMicroelectronics Introduces Industry's First MEMS Waterproof Pressure Sensor

【Lansheng Technology Information】STMicroelectronics has launched the first MEMS waterproof/liquid-proof absolute pressure sensor in the industrial market, which is included in the ten-year supply guarantee plan.

Simone Ferri, General Manager of the AMS MEMS Sub-Product Division at STMicroelectronics, said: "As the Industrial Internet of Things grows and spreads, companies are looking to collect data throughout their operations, often in challenging indoor and outdoor environments. Our latest The MEMS waterproof pressure sensor is weather-resistant enough to meet various industrial digital transformation requirements, and provides a long-term supply guarantee to protect customer designs."

The new ILPS28QSW sensor from STMicroelectronics is housed in a hermetically sealed cylindrical surface-mount package. The package protects the internal circuitry with a highly liquid impermeable ceramic substrate and a robust automotive potting compound. The lid is made of high-grade surgical steel, sealed with an O-ring and secured with epoxy adhesive. This unique package design ensures water resistance to IP58 rating, impermeability in more than one meter of water, and is IEC 60529 and ISO 20653 certified. In addition, the sensor can withstand overpressures up to 10 bar.

ILPS28QSW can measure absolute pressure with an accuracy of less than 0.5hPa, two ranges of 260-1260hPa and 260-4060hPa are optional, and the working temperature range is extended to -40°C to 105°C. High accuracy and excellent weather resistance make it suitable for applications such as gas meters, water meters, weather monitors, smart filters for air conditioners, and home appliances.

ILPS28QSW also features ST's unique Qvar® electrostatic charge sensing channel, developers can use this technology to create more value in practical applications, such as liquid leak detection and other functions. Combined with a pressure signal, the Qvar can monitor liquid levels and even detect the smallest leaks in household appliances and industrial processes.

With an operating current as low as 1.7µA, the ILPS28QSW can be used in power-sensitive applications, and the on-chip integrated digital functions simplify system design management. The sensor has built-in temperature compensation, FIFO memory and I2C/MIPI-I3C digital communication interface, and the output data rate is selectable in the range of 1Hz to 200Hz.

Lansheng Technology Limited, which is a spot stock distributor of many well-known brands, we have price advantage of the first-hand spot channel, and have technical supports.

Our main brands: STMicroelectronics, Toshiba, Microchip, Vishay, Marvell, ON Semiconductor, AOS, DIODES, Murata, Samsung, Hyundai/Hynix, Xilinx, Micron, Infinone, Texas Instruments, ADI, Maxim Integrated, NXP, etc

To learn more about our products, services, and capabilities, please visit our website at http://www.lanshengic.com

0 notes

Text

Best Spirulina Fish Foods Reviews in 2020

Are you currently raising aquatic creatures that are primarily vegetable eaters? If so, then you should understand that choosing the best Spirulina Fish Foods for your finned animals is essential. Indeed, you are probably wondering why it is essential to buy spirulina fish food, so we are going to explore what this fish food is all about in the rest of this article.

This article aims to help fish owners learn more about the importance of feeding your pet fish with Spirulina and the top rated products you can buy in the market these days. Many expert fish lovers prefer this fish food because it is known to be a highly nutritious food source.

The list of products reviewed here is considered to be one of the more premium options because they are designed to help keep your aquatic animal colors brighter and brighter; this is especially true if you are raising betta fish, cichlids, goldfish, koi, and tropheus, although these fish foods also work for various species of fish.

The buying and feeding tips discussed here will also serve as a very useful guide for you to take care of your most precious aquarium inhabitants.

The 9 Best Spirulina Fish Foods Buy and Guider

Sera Marine Spirulina Grazer

If you find it a bit difficult to decide which spirulina for goldfish to buy, you can drop your worries and go for this product instead. This is easy to use and contains superb ingredients that can ensure optimal health for your most precious fin friends.

These tablets are uniquely made and able to sink into the bottom of the tank, or they can also be attached to the aquarium glass with a light finger pressure. Many fish enthusiasts choose this product because it is designed to be a well-balanced food that encourages great fishy appearance, healthy development and supports the natural behavior of your aquatic animals.

Also, if you want the occupants of your aquarium to stay active, more alive, and to avoid various kinds of digestion issues, this food would help them achieve all of these goals. It even lets you see shy fish consuming their food right in front of you. If you need sticky tablets that might work well for large marine fish, this may be one of your best options.

Before purchasing this product, be sure to check out some of its downsides and these are its ability to break down very easily and it tends to leave a hard mark on the aquarium. Anyway, besides these weak points; this product is still reliable in many other aspects.

Pros

Adheres fairly well to glass

Certified premium adhesive tabs ideal for large saltwater fish

Formulated with 21% spirulina algae

Highly recommended fish food product for wrasses, angels and tans

Able to attract shy fish to eat them with enthusiasm

Cons

Tends to break down faster than expected

Can leave an extremely hard mark on the aquarium

Hikari Bio-Pure freeze-dried spirulina shrimp cubes

The quality of this product cannot be questioned as it is known to be a top-notch treat or daily diet for all saltwater and freshwater fish, various marine species and invertebrates. Besides, these are convenient options since you can also feed frogs and turtles with these foods.

Additionally, this item is considered to be one of the cleanest freeze-dried fish food sold today. Note that you can expect a taste and texture that was not previously available in a freeze-dried food product.

This fish spirulina is a smart choice primarily because it is packed with nutritious ingredients that would provide many health benefits to the inhabitants of your aquarium. Since they’re fortified with essential vitamins, you can finally say goodbye to fish stress and other fish-related illnesses. It is so easy and convenient to use because it has been designed with a patented ratchet dispenser.

However, these foods are instantly crumbled and turn into a fine mixture, which should make the water in the tank whitish and look dirty. These are some of the issues that you would be slightly upset about once you start feeding your pets this fish food.

Pros

Not made with legumes or ground grains

Contains excellent levels of protein content

Formulated with multivitamins that help minimize fish stress and other related ailments

Serves as an appetizing treat for aquatic creatures

Designed with a ratchet dispenser top

Cons

Sensitive to crumbling in a fine mixture

Can create unwanted damage inside the tank

Fluval Hagen Vegetarian Flakes Fish Food

These Fish Spirulina Flakes are made with premium ingredients and a multi-plant formula that provides many health benefits for your finned animals. These are loaded with good amounts of spirulina, trace elements, and natural trace elements and are also a great source of protein and stabilized vitamin C which are all known to provide maximum daily nutrition. They are reliable for turning your finned friends into a more vibrant and energetic friend.

Additionally, these flakes contain highly nutritious kelp and four types of vegetables that are precisely formulated to improve the overall health of your aquarium buddies. They are enriched with omega 3, complex carbohydrates and polyunsaturated fatty acids which make them more important in providing good nutrition for the growth of your fish.

Some complaints when using these flake foods are that they are easily crumbled, making them too small to be used for feeding, and they seem to work best just for feeding fry, but not quite well. for big fish. Check these negative reviews first before you get one.

Pros

Contains several vegetarian formulas

Helps support the general well-being of your aquarium residents

Formulated with spirulina rich in trace elements and proteins

Can guarantee exceptional nutrition for the daily feeding of fish

Designed to be tasty to entice aquatic animals to eat with enthusiasm

Cons

Does not seem a practical choice for feeding large fish

Contains incredibly fragile flakes

Cobalt Aquatics Spirulina Fish Food Sinking Pellet

These Spirulina Fish Pellets are made with main ingredients such as spirulina, garlic, plankton, earthworm, salmon, kelp, krill and fish oil to ensure highly nutritious nutrition and tasty to your dearest aquarium settlers. What sets this product apart from other options is its triple vitamin boost formulation which works great in keeping fish healthy and strong.

Likewise, the green pellets dissolve well in the water column after a few minutes and the colonists in your aquarium appear to be swimming around the filter feed. It is nice to see your finned friends consuming their food with fondness and it is right to feed them fish food which comes with a complete formula to provide exceptional nutrition. The right amount of probiotics in this product helps promote healthier digestive system functions.

However, you should know that these pellets are larger in size which makes them a little hard to mix with other feed in the autoloader and the selling cost of this fish feed is not that affordable as people on a budget may feel unhappy about this.

Pros

Can ensure less production of fish waste inside the aquarium

Not inclined to make the tank water cloudy and moldy

Enriched with probiotics that promote healthy digestion

A convenient option for feeding saltwater and tropical fish

Formulated with a triple vitamin boost

Cons

Slightly large to mix with other foods in an automatic feeder

Sold at a slightly higher price

OSI Spirulina Flake Fish Food

Whether you are currently looking for premium spirulina for marine fish or freshwater aquatic creatures, these flake foods are perfect. They are made with a high amount of Spirulina which not only acts as a natural color enhancer but also does an exceptional job of vitalizing the immune system functions of the occupants of your aquarium.

Plus, you don’t have to worry about the general well-being of your pet fish as they become more hardy to fight bacteria, infections, and disease. These flakes are not uniform and paper thin like other options out there; although they are much more natural with the texture.

Please note that these foods tend to crumble into fine grains easily which makes them very messy to use and the water in the tank is expected to look dirty and cloudy. See for yourself if these inconveniences are a real problem for your aquarium.

Pros

Works great to naturally enhance the color of fish

Helps revitalize fish immunity to fight bacteria and disease

Makes fish brighter, healthier and more filling

Designed for saltwater and freshwater aquatic creatures

An ideal option for feeding sick and sensitive fish

Cons

May make tank water dark

Tends to be crumbled into a fine grain which becomes too dirty to use

Ocean Nutrition Spirulina Flakes

This spirulina aquarium fish food is a good catch. It is a nutrient-enriched food that could complement a regular diet. If you want to have colorful and energetic fish that play, roam and swim inside the aquarium; then these foods can help the colonists in your aquariums to become livelier and healthier artists for you, your loved ones and your guests.

If you have omnivorous and carnivorous pet fish inside the tank and want to make them more vibrant, healthy and hardy; so a great way to achieve your goal is to feed them these premium spirulina fish flakes.

These are reliable when it comes to providing the most exceptional nutrition to your finned animals. Without question, these foods can meet their dietary needs perfectly and you will be amazed at the noticeable difference if you feed them with these foods.

Take into account that these foods are not staple foods, which means you need to feed your finned friends varieties to meet their daily nutritional needs. Other than that, the price is a bit expensive considering that the size of the container will not last long.

Pros

Helps to intensify the colorings of fish, especially for omnivorous and carnivorous fish

A convenient option for feeding goldfish, angelfish and tangs

Uniquely formulated to provide the best nutrition

Can be used as a first choice food to supplement a regular diet

Helps preserve the beauty and life of your aquatic animal

Cons

Cannot be used as a staple food

A bit expensive for the container size

Sera Koi Professional Spirulina Color Pet Food

The many benefits of spirulina in aquaculture are immense. There’s no denying that spirulina-fed fish are getting healthier, more energetic, colorful, and more resistant to ailments. Fortunately, there are many options for purchasing fish products that contain a generous amount of spirulina.

These colorful foods are well accepted by various species of fish and you would love to see them actively swimming on the surface of the water. They are formulated with a high amount of protein so that your aquarium inhabitants can grow healthily, become more vigorous to fight disease and benefit from a highly nutritious diet.

All the same, two things that you will not find satisfactory about this product are its cheap quality container bucket which breaks instantly so that the freshness of the food is compromised and the cost of selling this product is always. expensive for anyone short on a budget.

Pros

Can be used as special food for koi and other essential pond fish

Recognized as a premium spirulina color food

Excellent food for ideal fish growth, vibrant fish colors and optimal health

Can be safely fed throughout the year if the temperature is above 46 degrees Fahrenheit

Easy to digest

Cons

Poor quality container bucket

No reasonable price

Zoo Med Spirulina 20 Flake Fish Food

For fish owners looking for high quality spirulina based fish food flakes, this product made by Zoo Med is worth a try. This is a great option that you can feed your finned friends because it is high in protein and can be safely given to goldfish, freshwater and marine fish, invertebrates, and other crustaceans. It contains 20% spirulina, so it is a highly nutritious certified fish diet.

Since it is enriched with spirulina content, you can rest assured that your fish colonists would become more energetic, grow faster, achieve a more elegant color, and live longer. In addition, if they are fed with spirulina, their reproduction, hatching and reproduction processes would be greatly improved. You will see a huge difference in your fish once you feed them this complete diet.

These flakes have an inconsistent flake size and they easily crumble into fine dust; as a result, they create more fish waste inside the tank, which means you will have to clean the water in the tank more often. Besides these little issues, these fish foods are great options to consider.

Pros

Manufactured to contain large amounts of protein source

Works best as a natural color enhancer

An ideal option for feeding saltwater and freshwater fish

Formulated with a full line of minerals, beta-carotene and color enhancing pigments

Does a good job of improving fish reproduction

Cons

Inconsistent flake size

Tends to produce more fish waste

Cobalt Aquatics Mysis Spirulina Fish

Buying the right spirulina fish food for cichlids is great because there are several options available that you can refer to. Just like this product, you can safely feed it with tropical fish, omnivores and marine herbivores. And, even if you have some very picky aquatic animals making the transition to prepared foods, this food would suit them well.