#Pressure Plate Springs in delhi

Explore tagged Tumblr posts

Text

The Leading Check Valve and SS Check Valve Manufacturer in India

India's industrial landscape is growing exponentially, and with this growth comes the increasing demand for high-quality industrial components such as check valves. Pedlock is a premier check valve and SS check valve manufacturer in Chennai, Ahmedabad, Mumbai, Bangalore, Rajasthan, Gujarat, Delhi and Ghaziabad in India, has carved a niche for itself in this competitive space by providing top-notch products that meet international standards. If you're looking for reliability, efficiency, and precision-engineered solutions, is the name to trust. This article delves into why Pedlock Valves is the best choice for check valves in India, detailing their offerings and industry expertise.

What Are Check Valves and Why Are They Important?

Check valve and ss check valve play a critical role in a wide range of industries, including oil & gas, petrochemicals, water treatment, and power generation. These one-way valves prevent reverse flow, ensuring that fluids move in a single direction through pipelines. Their primary function is to protect equipment from damage, maintain process efficiency, and prevent backflow contamination. Pedlock Valves specializes in manufacturing check valves that provide superior reliability, durability, and performance under the most demanding conditions.

Pedlock Valves: The Benchmark in Check Valve Manufacturing

Pedlock Valves has established itself as a leading check valve and ss check valve manufacturer in India, thanks to its focus on quality, innovation, and customer satisfaction. The company adheres to stringent quality standards and uses state-of-the-art manufacturing processes to deliver products that meet or exceed industry expectations.

Key Features of Pedlock Check Valves

Hydraulic Flow control valve: Pedlock is valves manufacturer, exporters and supplier of world class range of Hydraulic Flow Control Valves Manufacturer in Ahmedabad, Mumbai, Vadodara, Ghaziabad, Rajasthan, Chennai, Bangalore, Delhi, Gujarat in India.

Hydraulic Check valve: Pedlock is hydraulic ball valves and Hydraulic Check valves manufacturer in Ahmedabad, Mumbai, Delhi, Chennai, Bangalore, Rajasthan, Ghaziabad, Vadodara, Gujarat.

SS Needle valve: Pedlcok is a leading needle valves and ss needle valves manufacturer in Ahmedabad, Vadodara, Mumbai, Delhi, Chennai, Bangalore, Ghaziabad, Rajasthan, Gujarat India.

Types of Check Valves Offered by Pedlock

Pedlock offers a comprehensive range of check valve and ss check valve designed to meet the varied needs of different industries. Their product portfolio includes:

1. Check Valve

Check valves are ideal for systems where low-pressure drop and flow efficiency are essential. These valves feature a disc that swings on a hinge or shaft, allowing fluid to flow in one direction and preventing reverse flow. Swing check valves are designed to offer smooth operation and minimal maintenance.

2. SS Check Valve

SS check valve are compact and lightweight, making them a popular choice for industries where space is at a premium. These valves fit between two flanges, offering easy installation and cost-effective solutions for preventing backflow in pipeline systems.

3. Dual Plate Check Valve

Dual plate check valves are designed for high-pressure applications. These valves feature two spring-loaded plates that close automatically when flow reverses, offering enhanced durability and superior performance in challenging environments.

4. Lift Check Valve

Lift check valves are used in high-pressure and high-temperature applications. The valve disc lifts automatically with the flow of fluid and falls back into place when the flow stops, preventing reverse flow. These valves are ideal for steam, gas, and other high-pressure media.

5. Ball Check Valve

Ball check valves are a versatile and cost-effective solution for industries dealing with slurries and viscous fluids. Our company manufactures these valves with a focus on durability and efficient operation, ensuring reliable performance in the toughest industrial conditions.

Why Choose Pedlock Valves for Your Check Valve and SS Check Valve Needs?

Choosing the right check valve manufacturer is critical to ensuring the long-term success of your operations. This company offers a variety of benefits that make them the preferred choice for many industries in India and abroad:

1. Uncompromised Quality

Our places a strong emphasis on quality at every stage of the manufacturing process. From material selection to final inspection, each valve is subjected to strict quality controls to ensure it meets the highest standards.

2. Extensive Industry Experience

With decades of experience has a deep understanding of the challenges faced by industries that rely on check valves. Their expert team is dedicated to providing innovative solutions that cater to the specific needs of each sector.

3. Advanced Technology

Pedlock is committed to staying at the forefront of technological advancements. The company continually invests in research and development to improve the efficiency, performance, and reliability of its check valve products.

4. Competitive Pricing

We are focuses on delivering premium products, they also ensure that their pricing is competitive. This balance of quality and affordability makes them the go-to manufacturer for businesses looking for cost-effective solutions without compromising on performance.

5. Excellent Customer Support

We are is renowned for its customer-centric approach. The company provides comprehensive support throughout the entire purchasing process, from product selection to after-sales service, ensuring a seamless experience for its clients.

Conclusion

Pedlock stands out as a leader in the check valves & SS Check Valves Manufacturer in Mumbai, Delhi, Ahmedabad, Chennai, Vadodara, Gujarat, Rajasthan, Ghaziabad, Bangalore industry in India, providing solutions that meet the highest standards of quality, performance, and reliability. Whether you’re in the oil and gas sector, water treatment, or power generation, Our Company has the expertise and product range to cater to your specific needs. Their dedication to customer satisfaction, combined with advanced manufacturing techniques, makes them a trusted partner for businesses seeking durable and efficient check valve solutions.

#Check valve manufacturer in India#Mumbai#Chennnai#Ahmedabad#Vadodara#Gujarat#rajasthan#ghaziabad#bangalore#Delhi#SS Check valve manufacturer in India

0 notes

Text

Stainless Steel Washers Manufacturers in India

Stainless Steel Washers Manufacturers in India. Leading suppliers dealers in Mumbai Chennai Bangalore Ludhiana Delhi Coimbatore Pune Rajkot Ahmedabad Kolkata Hyderabad Gujarat and many more places. Sachiya Steel International manufacturing and exporting high quality Washers Fasteners worldwide. We are India's largest Washers Exporter, exporting to more than 85 countries. We are known as Stainless Steel Washers Manufacturers and Exporters due to exporting and manufacturing on a large scale.

Types of Washers -

Sachiya Steel International manufacture a wide variety of Washers. There is a different types of washer used for different needs. Washers are used with Nuts and Bolts to minimize the pressure. Our Washers are available in different sizes, grades and shapes. Sachiya Steel International manufactures and exports high-quality industrial Washers. We are Exporters of the following Washers -Spring Washers, Plain Washers, Internal Star Washers and External Star Washers.

About Washers Fasteners -

A washer is a thin plate (usually disk-shaped) with a hole (usually in the middle) that is normally used to distribute the load of a threaded fastener, such as a bolt or nut. Other uses are as a spacer, spring washer, wear pad, preload indicating device, locking device, and to reduce vibration (rubber washer). Washers often have an outer diameter (OD) about twice their inner diameter (ID), but this can vary quite widely. Washers are usually made of metal or plastic depending on the use.

For More Info Visit our Website: https://sachiyasteel.com/stainless-steel-washers-manufacturers-in-india.php

Email Us: [email protected]

Contact Us: 097690 56007

0 notes

Text

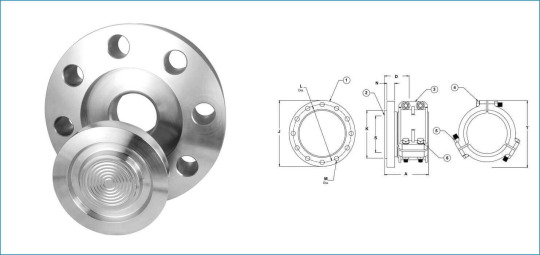

asme b16.5 flanges in uae

ASME B16.5 Flanges in UAE, ASME B16.5 Flanges Manufacturers, in UAE. We are making ANSI B16.5 Flanges, ASME B16.5 Wn Flanges, ASME B16.5 Weld Neck Flanges and ANSI B16.5 Flanges Material plausibly considering sensible expert hours in UAE and uncommon well spring of astonishing ASME B16.5 Class 150 Flanges, most very smart arrangement, cost open in Dubai, India.

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is all around acclaimed provider of ASME B16.5 Ring Joint Flanges got a handle on by Saudi Aramco. We keep up wide store of ANSI B16.5 Free Flanges, ANSI B16.5 Carbon Steel Flanges, ANSI B16.5 Diminishing Flanges, ASME B16.5 Decreasing Flanges, ASME B16.5 Slip On Flanges, ASME B16.5 Flanges Material and ASME B16.5 Blind Flanges. Meraki Star Metals Oil & Gas Equipment Trading L.L.C. stock total degree of ASME B16 5 Opening Flanges, ANSI B16.5 Expander Flanges in Stock in different sizes.

We can other than give free occasion of ASME B16.5 Rtj Flanges,Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is having our Vendor and Merchant in Bangalore, Karnataka, Chennai (Madras), Tamil Nadu, Ahmedabad, Gujarat, Delhi, Pune, Maharashtra, Rajkot, Ghaziabad, Uttar-Pradesh, Bhosari, Ludhiana, Punjab, Vadodara, Aurangabad, Faridabad, Gurgaon, Haryana, Indore, Madhya Pradesh, Jaipur, Rajasthan, Kolkata, West-Bengal, Khopoli, Karnataka, Kolhapur, Nagpur, Raipur, Chhattisgarh.. So in case you are looking for best expense of ASME B16 5 Flanges, ANSI B16.5 Ring Joint Spine near you with most short period of time improvement or free occasion of Flanges WNRF ASME B16.5.

Specification of ASME B16.5 Class 150 Flanges

ASME B16 5 FLANGE SIZE CHART1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000ANSI B16.5 FLANGE STANDARDSANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flange, ASME Flange, BS Flange, DIN Flange, EN Flange, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092ANSI B16.5 FLANGE PRESSURE RATING ANSIClass 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBSANSI B16.5 FLANGE PRESSURE CALCULATION IN DIN6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64JIS5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 KUNI6Bar 10Bar 16Bar 25Bar 40BarEN6Bar 10Bar 16Bar 25Bar 40BarCOATINGOil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip GalvanizedMOST COMMON TYPES OF ANSI B16.5Forged / Threaded / Screwed / PlateTEST CERTIFICATESEN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc

1 note

·

View note

Text

Compression Springs in Delhi | Compression Springs Manufacturers in Delhi

Compression is compacted by means of a load acting upon their endings are compacted, the plan of the wire tries to return it back into the first shape thus pushing back the load. They're designed and utilized to withstand applied compressive forces to keep energy in the drive mode. Typically they're cylindrical helical made out around the cord. However, they are sometimes produced with conical, oblong, barrel or any other form. The cable may also be round, rectangular or square. This really is the most typical configuration and are utilized in several applications like automotive, aerospace and consumer products. One can control the activities of compression springs in Delhi by They're designed. The width of the coil, the number of coils, the fashion of the finishes even the diameter and length and shape of the cable can make unique layouts. That is the reason it's essential to have all of the ideal measurements when purchasing so its functionality will fulfill the requirements of this program. Ace has been designing and manufacturing custom springs Because of 1939 and has assisted tens of thousands of businesses to fill a demand for your job but also offer you many different manufacturing and design solutions. We're big enough to give ability and repeatability yet small enough to still provide custom design and manufacturing runs for particular requirements. Searching for an American maker, Ace will be delighted to demonstrate our abilities and caliber for you.

1. Conical compression springs

2. Concave compression springs

3. Convex compression springs

All these are utilized separately or in conjunction with every other. Round cable is overriding in compression springs since it's easily available and flexible to conventional coiler tooling.

Compression springs ought to be stress relieved to eliminate Based on space and design constraints, compression springs might be categorized based on stress level.

Without permanent setup, to ensure an excess operation for eliminating set isn't required. These springs are created with torsional pressure levels when compacted solid plus they don't exceed about 40% of the minimum tensile strength of their substance.

Another Kind of compression spring would be those that are compacted solid with no additional permanent setup set has been eliminated. These might be pre-set from the spring maker as an extra operation. All these are springs equipped with torsional pressure levels when compacted solid which typically do not exceed 60% of the minimum tensile strength of this substance.

Finally, there are springs that Can't Be compacted strong without some additional permanent set occurring because the place cannot be fully removed beforehand. These springs demand torsional pressure levels that exceed 60% of their minimal, tensile strength of this substance. When compression springs were created, It's that the Distance between the coils which modulates the dimensional limitations. These limitations determine the anxiety level.

#Torsion Springs#Extension Springs#Down Light Springs#Door Closer Springs#Clutch Plate Springs#Engine Valve Springs#Pressure Plate Springs#manufacturing of springs and wireforms#Wire forms manufacturing company in India#spring manufacturers in delhi#Wireforms manufacturing company in India#downlight spring#DownLight Springs in india#manufacturing of Brake Parts Springs in delhi#Wireforms in delhi#Pressure Plate Springs in delhi#Manufactures of springs and Wireforms#Extension Springs Manufacturers in Delhi#combine springs manufacturers in delhi#extension springs supplier in delhi#springs manufacturers in delhi#Manufacturers of springs and Wireforms

0 notes

Text

Wire forms Manufacturers in Delhi | Manufactures of springs and Wire forms

Kalyani Springs we custom design and Fabricate High-quality wire forms in several of various shapes and sizes. To create our semi-automatic cable types, the pros in Keats use a huge array of cutting-edge manufacturing procedures like drawing, cutting, drawing edge, flattening, extending and straightening.

Wire types have many purposes, but one of the most common Uses that we create are for cans, and computer brace parts, but we also fabricate them. For small volume orders, we create our cable forms, however for bigger orders, wire types are created automatically in highly innovative machines, and we're pleased to state that there are virtually no limitations on design criteria of pins. By employing the most recent CNC automatic spring coilers and wire forming equipment, Western Springs and Pressings can quickly produce a vast assortment of cable forms. Besides this and other states of the art technologies, we could even use manual procedures to present expert hand cooling.

Wire forms are made for a wide Selection of end applications and may be made to almost any shape, dimensions, and substance. Detecting a wire form manufacturer with a comprehensive history of cable form production is essential.

With more than half a century of expertise, Plymouth Spring has made custom wire types for many businesses and applications. We use this expertise to help make reliable, economical custom wire forms and, frequently, this procedure starts with cable form layout.

Design and Sampling

We can help you attract your custom cable types to life with our layout and sampling solutions. Process. This may mean tiny tweaks or consulting with our engineers to ensure that your layout is prepared. Additionally, it may imply our engineers re-engineer the role to allow it to fulfill your wants. Regardless of the degree of layout help your component wants; our engineers are here to assist.

The next step of this process is prototyping and sampling your component. As opposed to wasting money and time doing a complete run simply to learn after that the component required to be changed, we've got the capabilities set up to conduct prototypes and sample components.

Nothing, serving as an excess pair of eyes searching the part over for defects in front of a complete production run starts.

Cable Form Material Type

We fabricate custom wire forms from all sorts of material. You are able to learn about the appropriate applications of each material type within our Properties of Materials graph.

1. Hard Drawn Wire

2. Alloy Steel Wire

3. Stainless Steel Wire

Pin using a diameter which equals 1.5X the cable diameter. So the interior radius of the bend will probably equivalent 0.75X the cable diameter. For more difficult spring tempered steel, then we’ll utilize a bending pin with a diameter which equals 2X the cable diameter. So the interior radius of the bend will probably equivalent 1X the cable diameter.

Wire Diameter

We've got a Wide Selection of CNC wire forming machines which may

Cable Form Material Type

We fabricate custom wire forms from all sorts of material. The most Frequent material types for cable forms are wrapped steel (1008 or even PH), audio wire, hard drawn and petroleum tempered. Uses of each material type within our Properties of Materials graph.

#springs manufacturers in delhi#extension springs supplier in delhi#combine springs manufacturers in delhi#Extension Springs Manufacturers in Delhi#Pressure Plate Springs in Delhi#Manufactures of springs and Wireforms#Wireforms in delhi#manufacturing of Brake Parts Springs in delhi#DownLight Springs in india#downlight springs#Wireforms manufacturing company in India#spring manufacturers in delhi#Wire forms manufacturing company in India#manufacturing of springs and wireforms#Pressure Plate Springs#Engine Valve Springs#Clutch Plate Springs#Door Closer Springs#Brake Parts Springs#Down Light Springs#Extension Springs#Torsion Springs#Compression Springs#Compression Springs in delhi#Engine Valve Springs in Delhi#precision springs#helical spring#wire forming#wire form manufacturers in delhi#wire forms

0 notes

Text

Specification of Check Valve or Non-Return Valve Manufacturers in India

Various industries use valves to help with the movement of gas, liquid, and loose material in bulk. The flow can be started, halted, or controlled by a moveable element that opens, closes, or partially obstructs. There are various valves present that perform various functions in a different industry. To meet the needs of diverse industries, valves assist in controlling the flow and pressure inside a piping system.

The Check valve manufacturer in Mumbai can be defined as “Non return Valve designed to prevent back-up of liquids or gases in the line. It's made of durable plastic and is incorporated into a hand grip. Simply adjust the valve to the desired setting and place it in the desired location. Once set, the valve will keep liquids or gases from flowing back into the tank. Check Valve Hand Grips are available in four sizes to accommodate a variety of containers. The dial hand-grip features a bright red band and clear indicators for easy viewing of the setting.”

A Non return valve manufacturer in Chennai is also a type of valve that helps to flow the liquid in one-way direction. A check valve is a valve that opens with a positive flow pressure and closes when the flow reverses. A check valve is often part of a domestic water supply piping system. Check valves or Non return valves are used to prevent backflow into the domestic water supply. Check valves are used in a wide variety of applications, including domestic water systems, fire sprinkler systems, sewage treatment plants, and irrigation systems.

Check valves are often used in household water systems to keep water flowing in the right direction. The device consists of a movable disc or plate that opens and closes to allow fluid to flow. Check valves are often used in water systems to prevent water from flowing back into the pump, and in sewer systems to prevent sewage from flowing back into the home. Check valve manufacturer in Kolkata also used in oil and gas pipelines to prevent oil or gas from flowing back into the pump.

Check valves or Non return valves are made up of numerous parts. These parts work together to open and close the valve as needed. The body of a check valve is the housing that contains all of the internal parts of the valve. The body is connected to the piping system and has ports that allow fluid to enter and exit the valve.

It consists of a ball or disc that is placed in the path of the liquid. A check valve's primary function in a system is to stop backflow, which could harm machinery or contaminate media upstream. Check valves help to direct gas and liquid flow in one direction, which automatically prevents backflow and protects against harm.

If a check valve is fast, like a spring-actuated check valve, it can help stop the water hammer. By doing this, pressure spikes that send shockwaves through the medium are avoided. Therefore, a Non return valve manufacturer in Ahmedabad, Gujarat can help to prevent water hammer.

The main applications of the Check valves or Non-Return valves are as below:

To prevent downstream equipment from being damaged by backflow as if the flow of liquid flows backward then can cause losses.

Avoiding pollution brought on by reverse flow and flow in one direction.

To stop diverting the fluid or gas to divert in another direction and make sure that it flows in the required direction.

Check valve preserves the vacuum sea, so that bubble-tight sealing without high leak integrity.

In some systems, a common header may be used to exhaust a variety of gases.

It is advised that separate check valves be installed on each gas vent line to ensure that the gases can't combine inside the system.

Check valves should be regularly checked for proper operation because the parts inside are susceptible to deterioration.

Over the past ten years, Yakshita Engineering has established a solid reputation in the global market of India. As we are manufacturer of check valve manufacturer in Haryana, Delhi, Ghaziabad, Hyderabad etc. in major cities of India with the best quality.

#Check Valve Manufacturer#Check Valve Supplier#Check Valve Exporter#Non-Return Valve Manufacturer#Non-Return Valve Exporter

1 note

·

View note

Video

tumblr

Zimmer Pneumatic Clamping System and Braking Element with high performance, durable and innovative.

In this video we are seeing how Pneumatic Clamping Mechanism for Linear Technology (Rail Guides) works in order to get high durability, higher holding force and safe clamping in case of energy failure.

SEIMITSU is an authorized Zimmer Group Distributor in Pune. SEIMITSU has an 8 branch offices in Mumbai, Surat, Ahmedabad, Chennai, Hyderabad, Bangalore, Coimbatore and Delhi.

Following are the Benefits of Clamping and Braking Elements:

1. Profile rail guide: This Pneumatic clamps are available for all common profile rail guides

2. Wedge-type gear: Zimmer clamps is designed in order to transmission of power between piston and clamping jaw

3. Clamping Jaw: Pneumatic rail clamp has clamping jaw which is pressed at the free surfaces of the profile rail guide.

4. Housing: Housing material of Pneumatic clamping and braking element chemically nickel plated steel.

5. Pneumatic Piston: Inside piston of Pneumatic clamps moves the wedge-type gear longitudinally.

6. Spring-loaded energy storage: For non-pressurized closing of the clamping unit.

Contact us form link: https://www.seimitsu.in/contact-us.html

Referral link: https://www.seimitsu.in/Zimmer-Group-Linear-Technology.html

#pneumaticclamping#pneumaticclampingsystem#pneumaticclampingmechanism#zimmerclampingandbrakingelements#clampingandbrakingelements#pneumaticclamp#MKSseriespneumaticclamp#linearguides#linearmotion#automationcomponents#configurablecomponents#factoryautomation#assemblyautomation#railguides#zimmerclamps#zimmergroupdistributor#pneumaticrailclamp#zimmerlineartechnology#pneumaticclampingsupplierinpune#seimitsudistributorofzimmer#seimitsu#seimitsufactoryautomationpvtltd#industrialautomation

1 note

·

View note

Text

Plain Washer Manufacturers in India

PLAIN WASHER MANUFACTURERPLAIN WASHER EXPORTER

Plain Washer manufacturers in India. Leading suppliers dealers in Mumbai Chennai Bangalore Ludhiana Delhi Coimbatore Pune Rajkot Ahmedabad Kolkata Hyderabad Gujarat and many more places. Sachiya Steel International manufacturing and exporting high quality Plain Washer Fasteners worldwide. We are India's largest Plain Washer Exporter, exporting to more than 85 countries. We are known as Plain Washer Manufacturers and Exporters due to exporting and manufacturing on a large scale.

Plain Washer Manufacturers in India: Plain Washer Specifications -

We at Sachiya Steel International manufacture a wide variety of Washers. There is a different types of washer used for different needs. Washers are used with Nuts and Bolts to minimize the pressure. Our Washers are available in different sizes, grades and shapes. Sachiya Steel International manufactures and exports high-quality industrial Washers. We are Exporters of the following Washers -Plain Washer, Spring Washer, Internal Star Washer, and External Star Washer. We are a well known and India's leading Industrial Plain Washer Exporters in Mumbai.

Plain Washer Manufacturers in India: About Plain Washer Fasteners -

A Plain Washer is a thin plate (usually disk-shaped) with a hole (usually in the middle) that is normally used to distribute the load of a threaded fastener, such as a bolt or nut. Other uses are as a spacer, spring washer, wear pad, preload indicating device, locking device, and to reduce vibration (rubber washer). Washers often have an outer diameter (OD) about twice their inner diameter (ID), but this can vary quite widely. Washers are usually made of metal or plastic depending on the use.

Plain Washer Manufacturers in India: Industrial Plain Washer -

Oil & Gas Industries

Defence Industry

Petroleum Industries

Chemical Industry

Aerospace Industry

Nuclear Energy Sector

0 notes

Text

Tenders for Door Repair

Tender for Repair Maintenance Operation Lifts At Nirman Bhawan, Sh: Pdg Services For Cleaning Of Lift Control Room / Lift Car / Lift Machine Room/Landing Door And Lift Pit.

TRN : 10850962 | Central Government/Public Sector | Civil Work

New Delhi - Delhi | Last Date : 10 Apr, 2017 | Tender Value 2.68 Lacs

| Get Help | Liaison Service |

Tender for Special Repair To Dr Brairch –Sh :Changing Of Manually Operated Door To Sensor Door At Major Ot 6Th Floor And Bmt Ward 7 Th Floor

TRN : 10845459 | Central Government/Public Sector | Health Services/Equipments

New Delhi - Delhi | Last Date : 07 Apr, 2017 | Tender Value 42.05 Lacs

| Get Help | Liaison Service |

Tender for Tender For Repair And Painting Of Boundary Wall Ceiling, Tender For Making Aluminum Cabin, Painting Work Of Record, Construction Of Toilet, Guest House, Water Supply Service, Mat Work, Ceiling Repair Work, Door, Window With Replacement,

TRN : 10841256 | State Government | Civil Work

Jhansi - Uttar Pradesh | Last Date : 14 Apr, 2017 | Tender Value 25.00 Lacs

| Get Help | Liaison Service |

Tender for Repair Replacement Of Door Windows Flooring, Plumbing Joinery And Other Br Works At Aadc Officer Mess Single Offrs Living Accn Servant Qtrs Mh Aro Supply Depot, Ge Gos, Tcp 1, Tcp-4 And Periodical Services To Certain Bldgs

TRN : 10841977 | Central Government/Public Sector | Security Services

Jabalpur - Madhya Pradesh | Last Date : 06 Apr, 2017 | Tender Value 34.00 Lacs

| Get Help | Liaison Service |

Tender for Provision Of Galvalume Sheets On Both Hangers Door And Repair And Replacement Of Cable Tray In Both Hangersat At Icgae

TRN : 10836308 | Central Government/Public Sector | Security Services

Porbander - Gujarat | Last Date : 15 Apr, 2017 | Tender Value 13.00 Lacs

| Get Help | Liaison Service |

Tender for Supply Of Spare Parts For Vehicles And, , Miscellaneous Stores - A.C Pump Filter Mgp, A.C Pump Repair Kit, A.C Block Telco, A.C. Piston Ring Goetze, A.C Pump Assembly, Ucal/Mgp/Mico, Alternator Auto Lec, Arm Clutch Release, Alternator Rectivifire, Autolec, Delax/Katrina/Kwc, Alternator Cut Out, Autolec Delax/, Katrina/Kwc, Arial Right, Air Cleaner Assembly, Air Pressure Meter V3, Air Pressure Horn Pipe, Air Compression, Connection Bush, Air Compression Repair, Kit, Air Cleaner Filter, Alternator Starter Coil, Ana Bond 01 Tube, Air Cline Hose. Neepon, Air Compress Her Repair, Kit, Air Cleaner Element, Mgp, Acm Complete Assembly,, Axle Cone,, Air Cleaner Inner,, Air Cliner Filter,, Mgp/Lumex/Fualgard, Air Cleaner Assembly, Air Governor Assembly, Tvs/Kbx, Air Pressure Horn, Set.Roots, Air Cleane, R To Carburetor Hose Pipe, Air Protection Valve, Repair Kit Tvs, Air Pressure Point, Air Pressure Swi, Tch Deluxe/Roots, Armature Paper, Per Pot Armature Paper, Emer, Y Paper Water Proof Emery Cloth, Armature Wire, Armature Taping Cotton, Alternator Armatu, Re Delux Autolec, Alternator Carbon Brash, Autolec, Alternator Carbon, Holder Delax/Autolec, Alternator Coil Filed, Autolec, Alternator Re-Winding, Alternator, Rectifiersdelax, Autolec, Alternator Voltage, Regulatordelax, Autolec, Alternator, Rulerautolec, Alternator Rooter, Coilautolec, Alternator Assembly, A/Lac/Bgautolec, Alternator, Carbonautolec, Alternator Bearing, Alternator, Regulatorautolec, Alternator Fan,, Alternator Fan Pulley,, Alternator Commentator,, End, Alter Motor Pulley, Axle Shim Marco, Axle Assembly, Ino/Sky/D/D/Marco, Axle Pinion Teethmarco, Axle Thapa Pacing Cover, Marco, Axle Gasket Neepon, Axle Nut Marco, Axle Cross Frontmarco, Axle Oil Seal Rear, A/Lac/Bq, / Ngk Neepon, Axle Oil Seal Fron, T A/Lac/Bq, / Ngk Neepon, Axle Oil Seal Rear Inner, Ngk Neepon, Axle Bearing R Outer, Ngk/Yik, I/Mtm Marco, Axle Bearing R Inner, Ngk Marco, Axle Bearing F Inner, Ngk Marco, Axle Bearing F Outer, Ngk Marco, Axle Right Side Rear, Sky Marco, Axle Left Sid, E Rear Sky Marco, Axle Cone R, Innermarco, Axle Bearing Rear Ngk, Marco, Axle Lock Rear Marco, Axle L/R Sky Marco, Accelerator Cable, Mirai/Impex/Impect, Accelerator Rodmarco, Body Nut Bolt Marco, Back Light Assy, Kkk/Raz/Automax, Back Light,, Bulbautomax,, Back Light Cover,, Kkk/Raz/Automax,, Baby Filterneepon, Baby Filter Washer, Neepon, Black Tip, Black Light, Holderautomax, Break Shape With Rivets, Front Anl/Tvs, Break Shoe Lock Bolt, B. T Clip, Banjo Bolt, Break Steel Pipe, Break, Shape Spring F/R, Bearing Needle, Ball Crank Repair Kit, Ball Crank Bearing, Break Drum/ Break, Discf, Valve Crank Repair Kit, Half, Valve Crank Repair Kit, Full, Valve Crank Bearing, Break Flexible Pipe F/R, Shani, B.T Head, Bible Gear Assy / Spider, Gear Assy, Break Steel Pipe, Break Shape Spring, F/R, Break Shape With Rivets, Rear, Bonnet Clip, Big End Bearing, Bushing Kit Set, Brake Shoe Lining, Mgp/Tvs/Neepon, Brake Shoe Disc M/G, Neepon, Banjo Washer, Brake Faxable Pipe F, Neepon, Bible Gear, Battery Terminal Wire, Clip,, Battery Terminal Assy,, Copper,, Battery Terminal Wire, Brake Pedal Spring, Bonnet Kabza, Brake Pedal Bush, Ball Join,, Bonnet L, Ock,, Bonnet Lock Cable, Break Adjusting, Complete, Back Gear Bearingkkk, Back Gear Pinion Kkk, Back Gear Shaft, Back Gear Bearing, Ventilator Glass, Bumper Front, Bumper Rear, Butting Lock Shim, Break Drum F/ Break, Discf Ndc/Kilaska, Break Drum R/ Break, Discr Ndc/Kilaska, Big & Bearing No.10, Ndc/Kilaska, Big & Bearing No. 20, Ndc/Kilaska, Big End Bearing Std, Clutch Release Bearing, Newson/Viki, Crown Thrust Washer, Counter Shaft, Counter Side Washer, Center Bolt R/F, Clutch Control Arm, Cabin Mounting, Chamber Bolt, Car Star, Cutout Assembly, Cam Bush Nippon, Cam Sh, Aft Assembly, Mgp, Cam Mounting Clutch Gutgha, Cam Oil Seal Nippon, Clutch Goti, Carburetor To Cover, Crown Side Bearing, Cross Coupling,, Center Bearing,, Coupling Oil,, Sealneepon, Cross Holder, Coiler Oil Sealneepon, Collar Bush 1St Gear, Neepon, Collar Bush 2Nd, Gearneepon, Collar Bush 3Rd, Gearneepon, Collar Bush 4Th, Gearneepon, Collar Bush 5Th, Gearneepon, Cam Bushneepon, Cam Oil Seal Neepon, Chassis Hang, Er F&Rmarco, Carburetor Repair Kit, Clutch Pressure Plate, Complete Valukowa, Clutch Pressure Bolt, Clutch Cable Mirai, Inpex, Clutch Housing, Clutch Cylinder Assy., Kbx/Tvs, Clutch Cylinder, Assembly Upper, Clutch Cylinder, Assembly Lower, Clutch Release Bearing, Viki, Calitar Kit, Calitar Assembly, Clutch Cablemirai/Inpex, Connecting Bush, Ananda, Cabin Light Tube Type, Automex, Crown Thrust Washer, Center Bearing, Cabin Mounting, Cam Shaft Lock Mgp, Cam Pinion Bolt, Conceding Bus, H Carburetor Kit, Carburetor Nodal Valve, Clutch Pressure Assy, Valukoria,, Cabin Light Assy Kkk,, Cross Holder Vri,, Clutch Rod, Cut Out L Point Kkk, Carburetor Butter Fly, Carburetor Fuel Injector, Carburetor, Gasketneepon, Clutch Plate Valukoria, Cross ‘ U ‘ Bolt, Cross Bolt With Nut, Clutch Frog, Cut Out Resistancekkk, Cut Out Pointkkk, Clutch Disc Plate, Clutch Kit Upper, Kbx/Tvs, Clutch Kit Lower, Kbx/Tvs, Condenser Locus,, Carburetor Repair Kit, Octorn, Chamber, Gasketneepon, Connecting Bearing, Ndc, Connecting Rod Mgp, Cut Out Point No.27, Kkk, Cut Out Point, No.28Kkk, Cam Pinion, Cam Shaft, Cam Shaft Housing, Crank Side Trash Washer, Clutch Pressure Repair, Kit, Crank Shaft Mgp, Crank Shaft Pinion, Crank Pinion Bolt, C.B Point, Counter 5 Gear, C.B Circuit, Counter Gear Pinion, Counter Bearing Viki, Clutch Presser Finger Kit, Ampro, Crank Oil Seal F/R,, Neepon,, Cross Half Yoke Vri,, Clutch Control Leaver,, Arm, Crank Pulley Lock, Cabin Light Assy, Automex, Carburetor Assy., Kpacco, Counter Shim, Crank Shaft Pulley, Crank Shaft Pinion, Clutch Cylinder Repair, Kit Half Kbx/Tvs, Clutch Cylinder Repair, Kit Full Kbx/Tvs, Diesel Filter With Washer, Mico/Lous, Diesel Filter Case, Diesel Filter Top Cover, Dynamo Carbon Brash, Delux, Dynamo Carbon, Dynamo Field Coil Set Of, Nos., Dynamo Bearing Small, Dynamo Body Post, Kkk, Dynamo Carbon Holder, Plate, Dynamo Bearing Big, Kkk, Dynamo Bush Neepon, Dynamo De Platekkk, Dynamo De Boltkkk, Dynamo Fankkk, Dynamo Commentator, End Kkk, Dynamo Housing Kkk, Dynamo Carbon Plate, Dynamo Through Bolt, Kkk, Dynamo Carbon Holder, Lockkkk, Dynamo Pulleykkk, Dynamo Cut Out Kkk, Dynamo Cut Out, Pointkkk, Dynamo Lockkkk,, Dynamo Rivetskkk,, Dynamo Pulleykkk, Dark Ling Repair Kit, Dark Ling Goti Complete, Dynamo Carbon Spring, Dynamo Switch, Dynamo Armature, Locus, Dynamo Armature, Liverkkk, Diesel Over Flow Pipe, Diesel Flexible Pipe, Diesel Filter Overflow, Valve Mico, Dual Break Valve Repair, Kit, Distributor Cap Lucas, Distributor Point Lucas, Distributor Assembly, Lucas, Door Lock With Handle, Door Glass Handles, Door Glass Bit Inner, Outer, Door Hang, Diesel Faxable Pipe, Differe, Ntial Oil Seal, S/Seel Diesel Filter Top Cover, Dynamo Field Coil, Differential Side Washer, Dynamo Bush Neepon, Diesel Tank Pipe Tank, Filter, Diesel Main Pipeneepon, Dale Cobja, Dynamo Commenter, Kkk, Drag Link Repair Kit, Drag Link Assembly, Lintorn, Double Horn Assy., Double Gear, Differential Oil, Sealneepon, Differential, Gasketneepon, Door Glass Machine, Dash Board Lock, Door Vaisor, Dash Board Channel, Doo, R Channel Door Glass Channel With, Door Glass, Door Pad, Engine Head, Gasketvictor Neepon, Engine Head Stack Bolt, Engine Switch With Key, Jusihin, Engine Liner Tiger, Power, Engine Head Bolt Tvs, Engine Gasket Sethalf, Victor/Neepon, Engine Gasket, Setfullvictor/Neepon, Engine Switch With Key, Jusin, Engine Fan, Engine Mounting F/R, Engine Valve, Evl/Kruvr, Engine Valve Evl, Engine Valve Oil Seal, Korao Neepon, Engine Valve, Sealneepon, Engine Valve Lock, Engine Oil Seal Kosars, Neepon, Engine Gasket Cement, Engine Valve Guide Evl, Engine Side Oil Presser, Assembly, Engine Valve Seat, Engine Crank Gear, Coned, Engine Housing Center, Plate, Engine Bottom, Assembly, Engine Bottom Kit,, Fan Vip,, Fog Light Assembly,, Fuel Pump Assembly,, Mgp,, Front Hubs Oil Seal,, Fuel Injector Assembly,, Fuel Presser Regulator, Front Axle Oil Seal, Front Glass Solex, Fuel Filter, Engine Valve Exhaust, Evl, Engine Valve Intake, Evl, Engine Piston Ring, No.10 Gotze, Engine Piston Ring, No.20 P/C, Engine Piston Ring Std, Rie, Engine Timing Cover, Gasket Gotze Neepon, Engine Piston With Pin, Mgp, Engine Piston Slive, Usha, Engine Crank Shaft Oil, Seal Neepon, Fan Belt, Front Hubs Bearing, Outer, Front Hubs Bearing, Inner, F.P. Filter Mgp, Front Axle, Fog Light Holder Kkk, Fog Light Bulb12 Volt, Halogen, Fuse No.10, Feed Pump Repair Kit, Feed Pump Assy, Mico/Rajmirh, Feed Pump Valve, Mico/Rajmirh, Feed Pump Spring, Mico/Rajmirh, Feed Pump Filter, Feed Pump Washer, Fuse No.20, Fuel Tank House, Pipeneepon, Fuel Meter Assembly, V3,, Fuel Line Flexible Pipe,, Neepon,, F.I.P Gasketneepon, Flasher Electrical, Deluxe, Flag Stand With Clamp, Fuse, Foot React Rubber, Fly Wheel Ring, Fly Wightrsv, Fly Wight Rqv, Fiver Washer, Fly Wheel Assembly, Fly Wheel Pilot Bearing, Foot Mat Rubber, Fly Wheel Bolt, Front Spindle, Fly Wheel Bush, Fuse Box Assembly, Front Window Glass, Sheilddouble, Fiver Washer, Fip Body Housing, Front Glass Cannel, First Gear Pinion, Forth Gear Pinion, Fifth Gear Pinion, , Gear Box Cover Assy., Tyco, Gear Box Assembly, Gear Box Top Repairing, Kit, Gear Box Housing, Gear Box Oil Seal S/Lac, Gear Leaver Assembly, Gear Box Mounting, Gear Shaft Yuck, Gasket Cement, Gear Box Gasket Half, Gear Box Gasket Full, Gear Box Bolt, Gear Leaver Repair Kit, Gear Frog, Gear Box Bearing Viki, Gear Frog Bolt Spring, Gear Box Cup Lank, Gear Box Fuel Washer, Gear Changing Shaft, Grinding Past,, Grinding Stick,, Grease Gun Big,, Grease Gun Nipple Pipe, Grease Gun Small, Gear Box Bearing, Aux/36/96, Gear Box Bearing, Aux/62/22, Gear Leaver Kit, Gear Box Konkan, Bearing,, Gear Box Mounting Spl. Box, Gear Box Oil, Sealneepon, Gear Box Housing Bolt, Glass Handle, Glass Machine Bharat, Governor Housing, Gear Box Top Cover Tyco, Gear Lever Cap, Gear Frog Shaft, Gear Box Cupping, Gear Lever Lock, Grease Gun 01 Kg, Gauge Water, Temperature, Gear Leaver Assembly, Tyco, Head Light Bulb 12 Volt, Normal Automex, Head Light Bulb 12 Volt, Halogen Platinam, Automex, Head Light Holder 12, Volt Halogen Automex, Head Light Glass, Head Light Bulb 24 Volt, Halogen Roots, Automex, Head Light Bulb, Automex, Horn Cut Out Anupam, Deluxe, Head Gasketneepon, Horn Tt Double Hela, Horn Singleanupam,, Horn T.Thela,, Anupam,, Horn Pressureroots,, Anupam,, Head Light Switch Kkk, Head Light Assy., Hemen/Automex, Head Light Round, Heman, Head Gasket, Singleneepon, Head Light Holder Kkk, Heat Meter Socket, Heat Meter Assy V3, Head Light Knuckle, Yes, Heat Meter Normal V3, Heat Meter Electric V3, Hubs Front, Hubs Rear, Horn Point, Hub Cap Rear, Hub Stack Nut Bolt, Hose Pipe Set Radiator, Hubs Stack Nut Bolt, Hub Cap Front, Hubs Bearing Rear, Indicator Bulb, Indicator Light Assembly, Ignition Switch, Ignition Coil Kkk, Indicator Light Holder, Kkk, Indicator Light Glass, Impute Shift Bearing, Insulation Tap Pin Stick, Jum Nut, Julna Bush, Julna Hanger F&R, Judgment Rod, H/Truck, Kilometer Cable, V3/Nirai/Inpex, Kilo Meter Box Assembly, Kilo Meter Pinionouter, Kilo Meter Pinioninner, Kin Pin Shim,, King Pin Bush,, King Pin Bearing Viki,, King Pin,, Knuckle Oil Seal Keycee,, Kanga Bearing,, Kin Pin Bush Bearing, Leaf Front 2Nd Spring, L&R, Tiger/Rajduni/Indo, Japan, Leaf Rear 2Nd Indo, Japan, Leaf Front Main Indo, Japan/Tyco, Leaf Front 3Rd Indo, Japan, Leaf Rear 3Rd Indo, Japan, Leaf Rear 4Th Indo, Japan, Leaf Front Fortindo, Japan, Leaf Front 5Th Indo, Japan, Leaf Rear 5Th Indo, Japan, Leaf Front 6Thindo,, Japan, Leaf Rear 6Th Indo, Japan, Leaf Front 7Thindo, Japan, Leaf Rear 7Th Indo, Japan, Looking Glass, Pencil Bulb, L.T. Weir 4Mm, Shanco, L.T. Weir 5Mm, Shanco, L.T. Weir 6Mm, Shanco, Mobile Filter Mico, Master Cylinder Assy., Kbx/Tvs,, Master Cylinder Repair,, Half Kbx/Tvs,, Master Cylinder Repair,, Full Kbx/Tvs,, Main Shaft Bearing Viki,, Main Bearing Ndc,, Main Bearing Oil Seal,, Korus/Neepon,, Mudguard Flaps,, Main Shaft Shim,, Main Shaft Gazra, Main Counter Shaft, Manifold Gasket, Neepon, Master Cly Switch, Mobil Filter Top Cover, Mico, Mobil Housing, Pipeneepon, Main Baring Collar, Pipeneepon, Nozzle Pipe Neepon, Nozzle Over Fiow, Pipeneepon, Nut & Bolt All Type, Nozzle Washer, Oil Presser Switch, Oil Seal S/Kac, Oil Pump, Assemblymgp, Over Flow Valve, Over Flow Main Pipe, Piston, Piston Pin, Petrol Tank Tyco, Piston Ring, Petrol Tank Cap Hold, On, Popular Shaft Yolk, Kalfla, Popular Shaft Teeth, Kalfla, Popular Shaft Center, Bearing, Popular Shaft Center, Rubber, Popular Shaft Nut & Bolt, Popular Shaft Copling Nut W/ Washer, Push Pull Switch, Push Rod, Petrol Pipeneepon, Pull Push Switch Delux, Radiator Assy., Radiator Mounten, Radiator Rod, Radiator Hose Pipe,, Release Bearing Assy,, Newson/Viki,, Release Bearing Viki, Rubber Bushing, Kitmgp/Kbs/Nippon, Rubber Bush, Release Bearing Housing, Radiator Thermos, Bulbautomex, Rocker Shaft Mgp, Radiator Cap Holdon, Self Starter Carbon, Dulax, Self Starter Bandex, Dulax, Self Starter, Bushneepon, Self Starter Housing, Bush, Self Starter Carbon, Spring, Self Starter Coil Set Of 2, Nos. Self Starter Pinion, Self Starter Clutch Assy., Self Starter Sealing, Switch Dulax, Self Starter Sealing, Switch Contract Point, Spring Set Bushneepon, Silence Tail Pipe, Neepon, Self Starter Kale Bush, Neepon, Self Starter Planer Rod, Self Starter Carbon Cover, Spring, Self Starter Carbon Cover, Self Starter Holder Plate, Self Starter Field Oil, Solenoids Switch Dulex, Sparking Plug, Mico/Denso, Shackle Pin Assy. F, Shackle Pin Assy. I, Shackle Pin, Shackle Pin,, Bushneepon,, Steering Cross Holder,, Steering Oil Seal S/Seel,, Steering Box Bearing,, Viki, Steering Column Teeth, Steering Armed, Steering Wheel, Starting Combination, Switch Delux, Steering Colum Shft, Steering Box Gasket, Nippon, Steering Box Assy., Himda, Steering Pull & Push, Assembly, Steering Horn Point, Steering Inner Column, Steering Armed Nut, Steering Cone, Steering Column Bush, Silencer Box Assy Rear, Shock Observer, Bushneepon, Shock Observer Assy., Loyalax, Steering Wheel Cover, Steering Communication, Switch Kkk, Steering Cover, Star Pinion, Star Pinion Cross, Second Gear Pinion, Servo Repair Kit, Tvs/Kbx, Servo Assembly, Tvs/Kbs, Steering Cross, Mgp/Atulac, Taming Kit, Taming Oil Seal, Neepon, Tappet Cover Gasket, Rinco, Timing Cover Repair, Kitrinco, Top Gear Bearing Viki, Top Gear Oil Seal S/Lac, Top Gear Chilam, Tie Road End Goti,, Lintorn,, Top Gear Cuplink,, Tail Oil Seal S/Lac, Tie Rod End Assy., Lintorn, Tank Cap With Key, Tail Pinion, Tail Light Assembly, Third Gear Pinion, Turbo Rip Kit, Turbo Compt, Turbo Pipe Steel, Turbo Rubber Pipe, Tail Crown Assy., Wheel Cylinder, Assy.Front Kbx/Tvs, Wheel Cylinder, Assy.Rear Kbx/Tvs, Wheel Cylinder Repair Kit, Full, Wheel Cylinder Repair Kit, Half, W.C Bucket, Pbr.Kbx/Tvs/Mgp, Wiper Blade Assy, Wiper Motor Assy, U.J. Cross, Tyco/Kaffala/Autolac, U Bolt, U.J. Cross Holder Vri, Valve Spring Plate, V.I.P Light Magnetive, Type, Valve Oil Seal Koras, Ventilator Rubber, V.I.P Light Red, Coil Kkk, Ignition Coil, A/Lac/Lucas/Kkk, Hopper Meter Assy., Water Pump Repair Kit, Full Tvs, Water Pump Repair Kit, Half Tvs, Water Pump Bearing, Viki, Water Pump Ampair, Water Pump Ampair, Shaft,, Water Pump,, Gasketneepon,, Water Pump Fan, Water Pump Pully, Water P, Ump Assy Basto, Water Pump Fan Pully, Wiper Assy., Window Glass Channel,, Wiper Blade, Window Glass/ Door, Hand Primer Mico, Element Mico, Delivery Valve Mico, Nozzle Mico, Governor Repair Kit, Tvs, Feed Pump Assy., Rajanir, Feed Pump Repair Kit, Half Mico, Feed Pump Valve, Feed Pump Valve Washer, Fip Opening And Fitting, Fip Over Holing, Feed Pump Over Hulling, Nozzle Grinding &, Pressure Sating, Nozzle Body, Crank Shaft Grindi, Ng Valve Shed Fitting, Cam Bush Opening &, Fitting, Fly Wheel Grinding, Fip Taming Pinion, Gear Box Opening &, Fitting, Clutch Plate Opening &, Fitting, Four Wheel Hubs, Grassing, Tail Crown Opening &, Fitting, Timing Setting, Engine Over Holing, Engine Block Boring, Complete Engine,, Machine Job Work,, Without Head,, Complete Engin, E Over, Holding Charge,, Gear Box Over Holing, Bra, Ke Over Holing Kin Pin Opening & Fitting, Complete Wiring Checking, Charge, Radiator Washing, Self Starter Opening &, Fitting, Dynamo Opening &, Fitting, Rear & Front Deferential, Opening, Checking & Refitting, Charge., Radiator Soldering, Vehicle Wiring, Dynamo Armature Rewinding, Self Starter Armature Rewinding, Self Starter Armature, Lucas, S.S. Bush Bottom Switch, Self Starter Over Holing, Charge, Alternator Over Holing, Charge, Hopper Alternator Rewinding, Electric Work Full, Alternator Re-Winding, Wire, Rexin For Seat Cover, Bullbat Cloth For Seat, Cover, Paint Dico, Paint Milo, Putin Victor, Primer Victor, Engine Piston Ring, No.10Gotze, Fuse No.10, Cut Out Point, Cut Out Point, No.27Kkk, Cut Out Point, No.28Kkk,, Collar Bush 1St Gear,, Nippon,, Grease Gun 01 Kg,, Collar Bush 2Nd Gear,, Nippon, Dynamo Field Coil Set Of, 2 Nos, Leaf Rear 2Nd Indo, Japan, Leaf Front 2Nd Spring, L&R, Tiger/Rajduni/Indo, Japan, Self Starter Coil Set Of 02, Nos, Collar Bush 3Rd Gear, Nippon, Gear Change Shaft Land, Leaf Fr, Ont 3Rd Indo Japan, Leaf Rear 3Rd Indo, Japan, Collar Bush 4Th Gear, Nippon, Leaf Rear 4Th Indo, Japan, Collar Bush 5Th Gear, Nippon, Counter 5 Gear, Gear Change Shaft 5 And, Back Gear, Leaf Front 5Th Indo, Japan, Leaf Rear 5Th Indo, Japan, L.T Wire 5Mm Shanco, Car Fan Automatic 6 Fen, Joint Pinion 1St, 2Nd & 3Rd, L.T Wire 4Mm Shanco, 4 Wheel Hubs Greasing, And Brake Shoe Changing, Charge, Leaf Front 6Th Indo, Japan, Leaf Rear 6Th Indo, Japan, L.T Wire 6Mm Shanco, Gear Change Shaft 3 And, 4, Leaf Front 7Th Indo,, Japan,, Leaf Rear 7Th Indo,, Japan,, Big & Bearing No.10,, Ndc/Kilaska, Battery Post Dig Jeep 12, Volt N/P, Battery Post Dig Gypsy 12, Volt N/P, Fog Light Bulb 12 Volt, Halogen, Head Light Bulb 12 Volt, Normal Automex, Head Light Bulb 12 Volt, Halogen Platinum, Automex, Head Light Holder 12, Volt Halogen Platinum, Automex, Big & Bearing No.20, Ndc/Kilaska, Head Light Bulb 24 Volt, Halogen Roots Automex, , Welding Stick 10, No., Iron Sheet 4X6, 16Gz, 18 Gz, 20Gz, Iron Patti, Iron Angle1”, 1.5”, 2”, Inch., Batteries Recondition 12, Volts 09 Plt, Batteries Recondition 12, Volts 11 Plt, Batteries Recondition 12, Volts 13 Plt, Batteries Recondition 12, Volts 17 Plt, Batteries Recondition 12, Volts 19 Plt, Batteries Recondition 12, Volts 21 Plt, Batteries Recondition 12, Volts 23 Plt, Batteries Recondition 12, Volts 25 Plt, Tyre Retreading Size No, F.78X15, Tyre Retreading Size, No.600X16, Tyre Retreading Size, No.700X16, Tyre Retreading Size, No.750X16, Tyre Retreading Size, No.825X16, Tyre Retreading Size, No.1000X20, Tyre Retreading Size, No.920X20, Tyre Retreading Size, No.215/75 R 15-1005, Best Quality Hood Cotton, Clothes/Rexine, Welding Machine, Diplomat, Compressor Machine, Sheet Cutter, Hand Drilling Machine, Hand Grinding Machine, Ring Spanner 6.7 To, 20.22 Tapparia, Double End Spanner 6.7, To 20.22 Tapparia, Socket Set Tapparia, Bench Wise,

TRN : 10836986 | State Government | Security Services

Agartala - Tripura | Last Date : 12 Apr, 2017 | Tender Value NA

| Get Help | Liaison Service |

Tender for Repair And Maintenance Of Furniture And Fixture- Steel Almirah, Steel Revolving Chair, Door Lock, Foot Rest, Spirit, Stamp And Name Plate, Rubber Stamp, Banners, Calculator, Wall Clock Of Ministry Of Coal

TRN : 10833954 | Central Government/Public Sector | Coal And Lignite

New Delhi - Delhi | Last Date : 24 Apr, 2017 | Tender Value NA

| Get Help | Liaison Service |

Tender for Special Repair To Ceiling, Cladding, Flooring, Roofing, Door, Window, Wiring And Connected Items In Para Drying Shed Bldg No T-Twg-02 And Bldg No T-Ts-18, 20 And 21 Under Various Units

TRN : 10832484 | Central Government/Public Sector | Security Services

Tawang - Arunachal Pradesh | Last Date : 13 Apr, 2017 | Tender Value 70.56 Lacs

| Get Help | Liaison Service |

For More Information About Door Repair Tenders Just Click Here

0 notes

Text

Extension Springs Supplier in Delhi | Extension Springs | Springs

Extension springs are springs which attach to the ends of other bits. They save power and apply a pulling force. What's more, extension springs really loosen up and house energy, to make a resistance to a different pulling energy? It is the first tension that finally decides how closely together the expansion spring is wound. In India, we've got our recognition since the maximum metal Kalyani springs maker. We offer manmade high excellent pressure springs. The springs are made from premium excellent steel, making the product highly trustworthy and powerful. Its capability is far better to pull a load.

1. Square wire around 20 Millimeter cable diameter

2. Stainless Steel 0.15 to 60 Millimeter cable diameter

3. We offer to customize substance According to customer's requirement

Extension springs fluctuate in conclusion contours for garage Doors, automotive businesses. Drawbar spring can also be expansion spring. You will find an assortment of extension springs are all observed. The springs are closely wounded with no load. The springs hold the pins, eyes and other port design in the end to link the load. The expansion springs are of various kinds depending upon their finish design. The drawbar spring can also be the 1 kind of extension springs that are also called loops based upon its design. The load may employ in the one ends of stainless loops that pass via the springs middle and therefore are hooked around another finish that is the way that it simplifies the spring upon loading. The drawbar springs are all great for its possible overload scenarios and offer a definite stop which will continue to take a static load after attaining the maximum long length. The drawbar expansion spring is principally used when encouraging a porch swing.

Knowing the Fundamentals

A tension spring Might Be the Specific opposite of the generally A very simple type of the expansion spring could be observed at the workings of a rubber ring, as this efficiently works on the exact same principle of employing a rotational power. Tension springs can also be utilized to keep form and structural integrity inside substances. The load on the spring is produced by stretching instead of compression and thus extension springs frequently have small loops or hooks at either end, which can be utilized to attach the spring right into place.

1. boiled in attachments

2. Extended hooks

3. Screw in connectors

4. Negative loops

5. Half hooks

6. German loops

7. Negative hooks

8. English loops

But, Together with the many variants of expansion spring which exist, they All function in the exact same basic method of capturing and redirecting an employed force.

#springs manufacturers in delhi#extension springs supplier in delhi#combine springs manufacturers in delhi#Extension Springs Manufacturers in Delhi#Pressure Plate Springs in Delhi#Manufactures of springs and Wireforms#Wireforms in delhi#manufacturing of Brake Parts Springs in delhi#DownLight Springs in india#downlight spring#Wireforms manufacturing company in India#spring manufacturers in delhi#Wire forms manufacturing company in India#manufacturing of springs and wireforms#Pressure Plate Springs#Engine Valve Springs#Clutch Plate Springs#Door Closer Springs#Brake Parts Springs#Down Light Springs#Extension Springs#Torsion Springs#Compression Springs#Compression Springs in delhi#Engine Valve Springs in Delhi#precision springs#helical spring#wire form manufacturers in delhi#wire forming#metal spring

0 notes

Text

Clutch Plate Springs | Manufactures of Springs and Wireforms

Because of its shape this is described as a diaphragm spring, but in general engineering, it is perhaps better known as a Belleville spring, so named after the French civil engineer Julian Belleville who obtained a British patent for this form of spring as long ago as 1866. Basically, this spring comprises an annular disc initially dished to a conical shape. A compressive load applied to the disc tends to flatten it out, and a spring action is provided as the disc tries to regain its shape. Unlike a coil spring, the compressive load first increases with deflection of the disc and then, as the disc becomes more nearly flat, the load actually decreases with increased deflection, a characteristic unique to this type of spring.

In practice, it means that the load may be held constant over a considerable range of deflections. This is a particularly useful attribute as far as the motor vehicle clutch is concerned since it can be arranged for the clamping force on the Centre plate to be little affected as the liners wear thinner. The fact that this type of spring also possesses a high load carrying capacity for the space required makes it additionally attractive for application to motor vehicle clutches, which consequently can be of correspondingly shallower form.

The diaphragm spring is incorporated in the clutch in a manner which allows it to flex between a pair of fulcrum rings located on the inside face of the clutch cover. To supply the necessary clamping load on the center plate, the outer edge of the diaphragm spring bears against the rim of the pressure plate. The outer edge of the diaphragm spring is also embraced by retraction clips secured to the pressure plate so that the latter can be withdrawn from the center plate when the clutch is disengaged.

Parts in the clutch:-

The clutch assembly consists of many small parts but the following are the major parts

1. Flywheel – The flywheel, mounted on the crankshaft, keeps on running as long as the engine keeps running. The flywheel is equipped with friction surface OR a friction disc is bolted to the outer side of the flywheel.

2. Friction discs – Single OR multiple (as per requirement) discs lined with friction material having a high coefficient of friction are mounted on the drive shaft.

3. Pressure plate – Another friction disc is fast to the pressure plate. The pressure plate is mounted on the splined hub.

4. Spring levers – The spring used are diaphragm springs that move friction disc back & forth. The spring is backward with the assistance of levers.

How the clutch works

It transmits engine power to the gear case and permits the transmission to be interrupted whereas a gear is chosen to maneuver far from a stationary position, or once gears are modified whereas the automobile is moving.

Hydraulic clutch system

1. Most cars use a clutch operated either by fluid (hydraulic) or, additional ordinarily, by a cable.

2. When an automobile is moving below power, the clutch is engaged. A pressure plate fast to the regulator exerts constant force, by suggests that of a diaphragm spring, on the driven plate.

3. Earlier cars have a series of coil springs at the rear of the pressure plate, rather than a diaphragm spring.

4. The driven (or friction) plate runs on a splined input shaft, through that the ability is transmitted to the gear case. The plate has friction linings, the same as brake linings, on each its faces. this permits the drive to be haunted swimmingly once the clutch is engaged.

5. When the clutch is disengaged (pedal depressed), associate degree arm pushes a unharness bearing against the centre of the diaphragm spring that releases the clamping pressure.

6. The outer a part of the pressure plate, that features a giant friction surface, then not clamps the driven plate to the regulator, therefore the transmission of power is interrupted and gears will be modified.

7. When the treadle is discharged, the bearing is withdrawn and also the diaphragm-spring load once more clamps the driven plate to the regulator to resume the transmission of power.

8. Some cars have a hydraulically operated clutch. Pressure on the treadle within the automobile activates a piston in a very piston chamber that transmits the pressure through a fluid-filled pipe to a slave cylinder mounted on the clutch housing.

9. The slave-cylinder piston is connected to the clutch unharness arm.

For more information regarding spring custom manufactured parts, please call us at 9990044777 or e-mail us at [email protected] or visit www.kalyanisprings.com.

#Extension Springs in Delhi#Pressure Plate Springs in Delhi#Manufactures of springs and Wireforms#Wireforms in delhi#manufacturing of Brake Parts Springs in delhi#DownLight Springs in india#downlight springs#Wireforms manufacturing company in India#spring manufacturers in delhi#Wire forms manufacturing company in India#manufacturing of springs and wireforms#Pressure Plate Springs#Engine Valve Springs#Clutch Plate Springs#Door Closer Springs#Brake Parts Springs#Extension Springs#Torsion Springs#Compression Springs#Compression Springs in delhi#Extension Springs supplier in delhi#Engine Valve Springs in Delhi#precision springs#helical spring#wire form manufacturers in delhi#wire forming#metal spring#wire forms#Springs#sheet metal fabrication

0 notes

Text

Clutch Plate Springs | Engine Valve Springs | Pressure Plate Springs

#Kalyanisprings are capable of #producing more than 300 million springs annually as per the customer’s requirements and satisfaction with the latest CNC controlled coiling machine. We are here to supply the wide range of CNC and mechanical #Spring #Coiling #Machinery to our client’s. Spring Coiling Machines are highly appreciated for precise dimensions, great strength, and durability. Our CNC Coiling machines are provided with two finger systems are ideal for fully - automatic production of the left hand and right hand coiled #compression #springs with cylindrical, single or double conical spring bodies. Our #machines can produce high accuracy springs with optimum speed. Our product range is widely used in various #automobile #industries and #engineering machines. For more information regarding spring custom manufactured parts, please call us at 9990044777 or e-mail us at [email protected] or visit www.kalyanisprings.com

#steelspringinIndia

#WireFormssprings

#WireformsmanufacturingcompanyinIndia

#springmanufacturingcompanyinIndia

#springsteelwiremanufacturersinIndia

#Springs

#wireforms

#DownlightSpringsinIndia

#manufacturersofBrakePartsSpringsinDelhi

# wireformmanufacturersindelhi

# ExtensionSpringssupplierindelhi

# CompressionSpringsindelhi

# compressionsprings

#Extension Springs in Delhi#Pressure Plate Springs in Delhi#Combine Spring#Conical Spring#Wire Forms springs#associated spring#double torsion spring design#Down Light Spring#Brake Parts Spring#steel spring in india#conical spring design#spring manufacturing company in india#spring steel wire manufacturers in india#metal spring#wire forms#wire form manufacturers in delhi#Extension Springs supplier in delhi#Compression Springs in delhi#Compression Springs#Torsion Springs#Extension Springs#DownLight Springs#Brake Parts Springs#Door Closer Springs#Clutch Plate Springs#Engine Valve Springs#Pressure Plate Springs#manufacturing of springs and wireforms#Wire forms manufacturing company in India#spring manufacturers in delhi

0 notes

Text

Downlight Springs | Manufacturing of Springs and Wireforms

Kalyani Springs is manufactured and distributes company which manufactures a wide range if Downlight springs using the qualitative sourced from reliable vendors. We are an acclaimed firm in presenting a comprehensive array of LED Downlight Spring to the admired customers. These products are developed by our well-trained engineers who employing handpicked quality raw material keeping in mind the global quality norms and standards. Our engineers work on urbane machines and advanced technology to provide optimal gratifications. Furthermore to this, presented products are extremely sturdy and has even surface.

Integrated LED Downlights

I generally get asked by our customers that their electrician has suggested them that they must get LED downlights, so what can we recommend?

Firstly I would like to clarify some points, you can buy downlights that have the LED's fitted inside them (integrated) or as I prefer a standard downlight that you then fit an LED into. Nowadays, when you go to the market for purchasing downlights most of the integrated LED downlights are sealed and the LED's are not replaceable. Price does seriously dictate the quality of the fitting and often these downlights are sold in a term of 'they will last forever!' Sorry to say this but nothing lasts forever. Anything electronic has a chance of failure. The LED market is fast paced with new better models being released all the time.

We have several telephones calls a week into the office where people have had integrated LED downlights supplied and fitted by their electricians only to find a period of time late one or more has failed. They are then in a position that the model they have is no longer available and as the whole unit has to be replaced they cannot find one to match the rest in the ceiling. A customer just recently viewed a house on the market that was a very open plan with over 60 fittings, he saw that three were not working but assumed he could replace the lamps when he moved in. When he moved in he discovered they were integrated LED's, the model was no longer available and after a lot of searching came to the realization that all the downlights would have to be changed. If he'd known this before he would have made it a condition of the sale that they were all replaced.

I will always recommend standard mains rated downlight with a GU10 LED lamp to be fitted inside. Then if the LED fails it is really easy to change the Lamp (bulb) and all issues are averted. The LED lamps that we sell by Eglo all have a five-year guarantee on them, so if you do have a failure then you can get a free of charge replacement. Some of the best-LED lamps on the market the manufacturers still expect a 2 to 3 percent failure rate!

Now I am discussing the best process for actually fitting the Downlight Springs:-

1. Decide where you wish to place your chosen downlights measuring out the ceiling and marking the central point of the light. Now drill a small pilot hole through the ceiling.

2. Now you have marked out the positions of the downlights it is a good idea to check the ceiling to ensure that there are no joists/ wires/pipes in the way. Where you drilled the pilot holes you can able to see a small pinprick of light coming through the ceiling. If you are unable to view the ceiling from above, it gets trickier. The best way is to determine which way the joists run and what the spacing between them are. You could then use an old wire coat hanger bent at a 900 angle to the width of the downlight. Insert the wire through the hole until the 900 bend is through. Now twist the wire a full 3600 and hopefully, it will not bump into any obstructions. Remember that it is good practice to make sure there is more room around where the downlight is to be fitted so that the downlight is not positioned too close to a joist or other obstacle. A 6-inch gap should be maintained around the downlight to guarantee the fitting does not overheat.

3. In the instructions or on the box of the downlights it will say what the cut-out for that downlight will be. To get the best results, I will generally use a hole observed (a type of exercise bit) to the appropriate size of the downlight that can be purchased very inexpensively from most DIY stores. Alternatively, the use of a plasterboard saw (Pad Saw) can be used which eliminates the need for a drill and hole saw. For this method, you will need to draw a circle on the ceiling to the correct size as a guide for when you start to saw.

4. Hopefully, now you have produced a clean cut hole in the ceiling, got the plaster out of your eyes and shaken yourself outside to stop you looking like Casper the ghost!

Once the wiring has been pulled through the hole the downlight can be wired. To complement the downlight into the hole properly, hold the two springs back against the sides of the downlighter and push-up into the hole. The suspension system springs then lie firm on the side the ceiling holding it in place. For more information regarding spring custom manufactured parts, please call us at 9990044777 or e-mail us at [email protected] or visit www.kalyanisprings.com.

#downlight springs#pressure plate spring#Wireforms manufacturing company in India#spring manufacturers in delhi#Wire forms manufacturing company in India#manufacturing of springs and wireforms#Pressure Plate Springs#Engine Valve Springs#Clutch Plate Springs#Door Closer Springs#Brake Parts Springs#Wire Forms springs#Extension Springs#Torsion Springs#Compression Springs#spring manufacturing process#elevator companies in india#metal pressing companies#precision springs#helical spring#wire form manufacturers in delhi#wire forming#metal spring#wire forms#Springs#sheet metal fabrication#spring steel wire manufacturers in india#spring manufacturing company in india#conical spring design#steel spring in india

0 notes

Text

Wire form Manufacturers in Delhi | Wire Forms Springs | Wire Forms

forms. All these forms are fitted with different machine and equipment for their vibration free functioning. From our company you can avail the wide option of sizes, shapes, and finishes, these wire forms are manufactured from best quality of metals, sourced from the reputed market vendors. All these wire forms are manufactured by a team of skilled professionals, we have been satisfying in supplying wire forms such as custom wire forming springs, wire forming spring clip. This product is mostly used in numerous industrial components, which provide the vibration free and smooth operation. We also offer a different type of springs according to our customer requirement. With the most modern, state-of-the-art technology, a fully equipped manufacturing plant at Delhi and more than two decades of experience, we at Kalyani Springs are perfectly positioned to supply to the global markets. Our wide range of springs means we can deliver the springs you need fast, with stock orders generally shipping in one day. Kalyani Springs is the premier global source for stock catalog and custom designed mechanical springs and related products. Some of the main quality features are:

Features

1. The wire forms are tested strictly on their finish and strength

2. Manufactured in accordance with industry standards

3. Best known for their rust proof finish and high tensile strength

4. Ensures proper functioning of an assembly

5. High-grade metals are used in manufacturing the spring

6. Tested for its finish and quality

7. These springs exhibit high compression

8. Manufactured from high-grade metals, the springs are wide in demand

9. Ensure smooth movement and vibration free operations of machines

Kalyani springs always believe in supplying the best quality product at a reasonable price to their customers. Our main motive is customer's satisfaction. The appreciation of our customers will lead the company to become one of the reputed names in industrial spring manufacturer, exporter, and supplier. Our company products are completetly tested on several parameters such as resistance to corrosion, sturdiness, endurance, dimensional accuracy, resistance to torque and compression absorption. For more information regarding spring custom manufactured parts, please call us at 9990044777 or e-mail us at [email protected] or visit www.kalyanisprings.com.

#downlight springs#wireforms#torsion spring door closer#pressure plate spring#Wireforms manufacturing company in India#spring manufacturers in delhi#Wire forms manufacturing company in India#manufacturing of springs and wireforms#Pressure Plate Springs#Engine Valve Springs#Clutch Plate Springs#Door Closer Springs#Brake Parts Springs#Wire Forms springs#Extension Springs#Torsion Springs#Compression Springs#spring manufacturing process#elevator companies in india#metal pressing companies#precision springs#helical spring#wire form manufacturers in delhi#wire forming#metal spring#wire forms#Springs#sheet metal fabrication#spring steel wire manufacturers in india#spring manufacturing company in india

0 notes

Text

Spring Manufacturers in Delhi | Steel Spring in India | Wire Forming

Kalyani Springs is the best springs manufacturer and supplier of superior precision springs for different industrial requirements. Our Outstanding high-performance products are Extension Springs, Compression Springs, Torsion Springs, and Downlight Spring etc. Our commitment to supplying the best quality products in whole Delhi as we are highly concerned our customers’ requirements and complete satisfaction. The silent feature that distinguishes the company from the rest of the companies, we include the best available raw material used in production process, latest machinery and infrastructure available to produce upgraded and superior quality product Research and development lab in introducing and implementing latest technologies in the company's range.

Our Vision

Aiming at the bright future ahead, our main purpose to establish the in the field of springs and wire forms in National or International markets. We have started working with new production units and we will be able to deal with the requirements of our customers and fully satisfied our customers with our amazing services.

Our Strength

1. Vast industry experience and deep knowledge of the field

2. Rugged and sturdy infrastructure outfitted with latest machinery and equipment

3. Productive and experienced professionals comprising the workforce

4. Technology-driven manufacturing techniques and working methodologies

5. Strict and stringent quality control system

6. Gigantic warehouse to serve emergency demands and supply

7. Active transportation and packaging department

8. Quality products placed at competitive prices.

The springs offered by the Kalyani spring are basically famous for their durability, anti-corrosive nature, ability to hold off conflicting conditions and dimensional accuracy. These type of reliable springs are widely used in automotive products, medical devices, electronic items, toys, etc. We can produce as per requirements of the clients because we never run short of stocks in terms of resources. Count on us for all kinds of industrial springs requirements and no sooner you have lodged your order, we are already there on your doorsteps. For more information regarding spring custom manufactured parts, please call us at 9990044777 or e-mail us at [email protected] or visit www.kalyanisprings.com.

#spring manufacturing company in india#conical spring design#steel spring in india#Brake Parts Spring#Down Light Spring#double torsion spring design#associated spring#Wire Forms springs#Conical Spring#Combine Spring#downlight springs#wireforms#torsion spring door closer#pressure plate spring#Wireforms manufacturing company in India#spring manufacturers in delhi#Wire forms manufacturing company in India#manufacturing of springs and wireforms#Pressure Plate Springs#Engine Valve Springs#Clutch Plate Springs#Door Closer Springs#Brake Parts Springs#Extension Springs#Torsion Springs#Compression Springs#elevator companies in india

0 notes

Text

Spring Manufacturers in Delhi | Steel Spring in India | Wire Forming

Kalyani Springs is the best springs manufacturer and supplier of superior precision springs for different industrial requirements. Our Outstanding high-performance products are Extension Springs, Compression Springs, Torsion Springs, and Downlight Spring etc. Our commitment to supplying the best quality products in whole Delhi as we are highly concerned our customers’ requirements and complete satisfaction. The silent feature that distinguishes the company from the rest of the companies, we include the best available raw material used in production process, latest machinery and infrastructure available to produce upgraded and superior quality product Research and development lab in introducing and implementing latest technologies in the company's range.

Our Vision

Aiming at the bright future ahead, our main purpose to establish the in the field of springs and wire forms in National or International markets. We have started working with new production units and we will be able to deal with the requirements of our customers and fully satisfied our customers with our amazing services.

Our Strength

1. Vast industry experience and deep knowledge of the field

2. Rugged and sturdy infrastructure outfitted with latest machinery and equipment

3. Productive and experienced professionals comprising the workforce

4. Technology-driven manufacturing techniques and working methodologies

5. Strict and stringent quality control system

6. Gigantic warehouse to serve emergency demands and supply

7. Active transportation and packaging department

8. Quality products placed at competitive prices.

The springs offered by the Kalyani spring are basically famous for their durability, anti-corrosive nature, ability to hold off conflicting conditions and dimensional accuracy. These type of reliable springs are widely used in automotive products, medical devices, electronic items, toys, etc. We can produce as per requirements of the clients because we never run short of stocks in terms of resources. Count on us for all kinds of industrial springs requirements and no sooner you have lodged your order, we are already there on your doorsteps. For more information regarding spring custom manufactured parts, please call us at 9990044777 or e-mail us at [email protected] or visit www.kalyanisprings.com.

#downlight springs#wireforms#torsion spring door closer#pressure plate spring#Wireforms manufacturing company in India#spring manufacturers in delhi#Wire forms manufacturing company in India#manufacturing of springs and wireforms#Pressure Plate Springs#Engine Valve Springs#Clutch Plate Springs#Door Closer Springs#Brake Parts Springs#Wire Forms springs#Extension Springs#Torsion Springs#Compression Springs#spring manufacturing process#elevator companies in india#metal pressing companies#precision springs#helical spring#wire form manufacturers in delhi#wire forming#metal spring#wire forms#Springs#sheet metal fabrication#spring steel wire manufacturers in india

0 notes