#Press-tooling-manufacturers

Explore tagged Tumblr posts

Text

Mastering Precision Allows Unparallel Tool & Die Manufacturers

In the complicated sector of manufacturing, tool and die, manufacturers develop as the designers behind the scenes, defining the foundation of many industries. These artists specialize in fashioning precision tools and parts important for the mass production of varied goods. From the automotive sector to consumer electronics, the impact of tool and die manufacturers spread far and wide, contributing to the flawless creation of complicated components. This blog explains the knowledge of these craftsmen, digging into their role in manufacturing industrial tools, press tooling, and their importance in the art of manufacturing.

1. Industrial Tools Manufacturers Play a Pivotal Role in Supplying

Industrial tool manufacturers, a subsection of the bigger tool and die industry, are pivotal in supplying specific tools tailored for manufacturing applications. These gears, ranging from drills and saws to cutting and shaping implements, are crafted exactly to meet heavy-duty manufacturing processes’ demands. Industrial tools producers work together closely with many sectors, safeguarding that the tools they produce endure demanding use while preserving accuracy and durability. Their proficiency lies in creating strong tools and unceasingly innovating to meet growing industrial requirements, contributing to improved efficiency and production across manufacturing settings.

2. Press Tooling Manufacturers specialize in creating dies

Press tooling manufacturers focus on the making of dies and molds used in press types of machinery to shape and form supplies. This detailed and complicated process is vital for industries that necessitate mass production of components with consistency and exactness. Press tooling manufacturers work thoroughly with clients to design and produce dies that line up with precise manufacturing necessities. These dies find applications in many industries, such as automotive and appliance manufacturing, where the competence and precision of press tooling play a crucial role in the manufacture of stamped metal fragments. The association between tool and die manufacturers and press tooling experts safeguards the unified integration of precision tools into the manufacturing process.

3. Tool & Die Makers is done by skilled craftsmen

Tool and die makers are expert craftsmen who bring the plans of industrial tools and press tooling to life. Their professionalism lies in producing and preserving precision tools and dies that meet conditions. Tool & die makers combine old-style craftsmanship and contemporary technology, including Computer-Aided Design (CAD) and Computer Numerical Control (CNC) machining, to make intricate parts. Their role comprises not only the preliminary creation of tools but also the ongoing upkeep and repair, safeguarding that the tools endure in optimal condition for long periods. The attention to detail shown by tool & die makers is essential to the dependability and productivity of the manufacturing procedure.

4. Search Tool and Die Maker Near Me for convenient partnership

The search for a “tool and die maker near me” is a common exercise for industries looking for localized proficiency and convenient association. Nearness to a tool and die maker simplifies effective communication and safeguards that the manufacturing needs are understood correctly. This localized approach nurtures a sense of business, where businesses and tool and die, makers, work closely to talk about particular needs. The terrestrial proximity allows hands-on association, permitting for well-organized problem-solving and customization of tools based on the exclusive demands of the local manufacturing.

5. Machinists And Tool & Die Makers Have Common Goal

Machinists and tool and die makers are accomplished professionals with a common goal – meticulous machining. While technicians focus on functioning machine tools to manufacture precision parts, tool and die makers focus in creating the tools and dies used in the machining procedure. The partnership between these two professions is flawless, as machinists depend on the tools created by tool & die makers to accomplish precision in their work. The interdependent relationship between machinists and tool and die makers highpoints the interconnection of many roles in the manufacturing ecosystem, showcasing the importance of precision and teamwork in achieving extraordinary results.

The tool & die creators stand at the front of precision craftsmanship, contributing suggestively to the productivity and functionality of numerous industries. From the creation of engineering tools to press tooling that allows mass production, these craftspeople play an essential role in shaping the manufacturing process. The search for a tool and die maker in proximity highlights the importance of localized partnership, nurturing effective communication and problem-solving. As operators and tool and die, makers, work together; their collective efforts highlight the seamless integration of precision tools into the manufacturing process. In the complicated craftsmanship and technology, tool & die producers remain vital architects, making the tools that drive innovation and excellence in the manufacturing world.

The sector of tool & die manufacturing is constantly evolving, and the contemporary era has brought forth revolutions that blend old-style craftsmanship with cutting-edge technology. As businesses adapt to changing demands, tool & die manufacturers embrace developments such as computer-aided design (CAD) and computer numerical control (CNC) machining. These high-tech tools empower creators to create even more intricate and multifaceted components, pushing the boundaries of what is possible. The fusion of time-honored skills and latest technology makes sure that tool & die Companies continue to be at the forefront of precision engineering, constantly delivering solutions that meet the ever-rising needs of assorted manufacturing segments.

#Industrial-tool-manufacturers#Press-tooling-manufacturers#Tool-&-die-makers#tool-and-die-maker-near-me#Machinists-and-tool-and-die-makers#tool-&-die-Companies

0 notes

Text

Special Pharmaceutical Tooling Compression Machine– Buy Online from USA Supplier

The Special Pharmaceutical Tooling Compression Machine is designed for precision and efficiency in the pharmaceutical industry. offering enhanced performance, durability, and versatility for various pharmaceutical applications. Available from trusted USA suppliers

#"Pharmaceutical Tooling Compression Machine#Special Tooling Tablet Press#Pharmaceutical Tooling#Tablet Tooling in Pharma#Pharmaceutical Machinery In USA#Tablet Press Machine Manufacturers In USA#Pharmaceutical Tooling Compression Machine in USA#Special Tooling Tablet Press supplier In USA

0 notes

Text

Press Tools Manufacturers for Quality Tooling Solutions| CMD PPL

CMD Precision Products offers top press tools and press components. Get reliable, high-quality manufacturing solutions for all your precision needs.

0 notes

Video

youtube

Tool - L.A. Municipal Court (Salival)

Tool has the perfect song for my experience today with the local PD online reporting system.

(had to file a report for work because work equipment in my care got stolen)

(I tried calling a week ago to report it but they sent me to the online system. the online system said I wasn’t in their jurisdiction. it finally worked today.)

#legit headache warning#if you are calling from a secret spy-phone please press 5#do you know the make of the item? please go through this massive list of every manufacturer we could think to include 10 at a time#tool#music#ish

1 note

·

View note

Text

The Power of Software in Managing Fabricating Machine Tools

Software continues to evolve and spread its impact in the fabricating world. From Computer Numerical Control (CNC) machines to laser cutters and press brakes, software solutions are revolutionizing how manufacturers control and optimize their operations

CNC Machine Control and Programming: One of the primary applications of software in fabricating machine tools is CNC machine control and programming. Advanced CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software allows manufacturers to design intricate components and generate toolpaths with unparalleled precision. These toolpaths, when translated to CNC machines, guide the actions like cutting or bending processes, ensuring that the final product adheres precisely to the intended design. This level of automation not only reduces the risk of human error but also significantly accelerates the production process.

Optimized Production Scheduling: Fabrication software includes modules for production scheduling, enabling manufacturers to optimize the use of their machine tools. By considering factors such as machine availability, tooling requirements, and order priorities, the software generates efficient schedules that minimize downtime and maximize throughput. This results in a smoother workflow, reduced lead times, and enhanced overall efficiency in the fabrication process.

Real-Time Monitoring and Data Analytics: Modern fabricating software provides real-time monitoring capabilities, allowing manufacturers to track the performance of their machine tools on the shop floor. This includes monitoring parameters such as machine utilization, downtime, and error rates. By collecting and analyzing this data, manufacturers can identify bottlenecks, diagnose issues, and make informed decisions to optimize machine performance. Predictive maintenance algorithms can even anticipate potential equipment failures, minimizing unplanned downtime and maximizing the lifespan of the machinery.

Inventory and Material Management: Software solutions extend their influence to inventory and material management. By integrating with enterprise resource management (ERP) systems, fabricators can maintain real-time visibility into their material inventory. This leads to accurate demand forecasting, preventing out-of-stock or overstock situations. Additionally, software aids in material tracking, ensuring that the right materials are used for specific jobs, reducing waste, and optimizing costs.

Quality Assurance and Traceability: Software plays a pivotal role in ensuring product quality and traceability in fabricating machine tools. Quality control modules within these systems can monitor and enforce adherence to design specifications. Moreover, the software can include features for traceability, allowing manufacturers to trace the production history of each component, from raw material to finished product. This not only enhances quality assurance but also facilitates compliance with industry standards and regulations.

Integration with IoT (Internet of Things): The integration of fabricating machine tools with the Internet of Things (IoT) is another area where software is making a significant impact. Sensors on machines collect data in real-time, feeding it to the software for analysis. This connectivity enables remote monitoring, predictive maintenance, and the implementation of smart manufacturing practices. Manufacturers can make data-driven decisions (or feed them into decision-support software) to optimize production processes and respond promptly to changing conditions.

As the manufacturing landscape continues to evolve, the role of software in managing fabricating machine tools cannot be overstated. Embracing these technological advancements not only positions manufacturers at the forefront of innovation but also empowers them to meet the demands of a rapidly changing market while ensuring the highest standards of quality and performance.

#Software in Managing#Fabricating Machine Tools#Computer Numerical Control#(CNC)#laser cutters#press brakes#optimize operations#machine control programming#Advanced CAD/CAM#Computer-Aided Design#Computer-Aided Manufacturing#smoother workflow#reduced lead times

0 notes

Text

#leather clicker dies#custom clicker dies#Progressive tool drawing#leather product manufacturing#Clicker Press Canada

0 notes

Text

The Role of Punches and Dies in pharma industry

Overview of the Pharma Industry

The pharmaceutical industry is a business engaged in the manufacturing, marketing, and distribution of various medical products. In this, machinery and equipment like 'Tablet Press, Punches and Dies', 'Tablet Tooling', and 'Tablet Compression Machine' play an important role. These equipment are vital in the manufacturing of drugs, which are essential for pharmaceutical companies. Through this industry, significant contribution is made in the production of medical products, which improve the lives of people.

Understanding Punches and Dies

When it comes to manufacturing medical products, equipment such as 'tablet presses', 'punches and dies', 'tablet tooling', and 'tablet compression machines' are of utmost importance. Of these, 'Punches and Dies' are an important part. The die is actually made of a metal that is subjected to high pressure and strength. This dye creates how the new medicine will be made and look like. Punches, which are made into a variety of specific sizes and shapes, are used with dies. These punches enhance the potency of the dye and play an important role in the manufacturing of the medicine.

Importance of Punches and Dies in Pharma Manufacturing

When we talk about medical products, equipment prove to be of utmost importance. Of these, 'punches and dies' play an important role in pharma manufacturing.The die is actually made of a metal or metal, which is formed under high pressure and strength. This dye creates how the new medicine will be made and look like.Punches, which are made into specific sizes and shapes, are used with dies. These punches enhance the potency of the dye and play an important role in the manufacturing of the medicine. They help ensure the quality and compatibility of medical products.

Maintenance and Care of Punches and Dies

'Punches and dies' are vital in pharmaceutical manufacturing, and proper care of them is vital to their long and smooth life.

● Regular cleaning and maintenance: Punches and dies should be cleaned at regular intervals to avoid accumulation of debris. This will ensure that their work lasts and that they maintain their quality.

● Store in a cool and dry place: Punches and dies should be stored in a cool and dry place to avoid any cuts or damage.

● Regular checking and updating: Along with 'Tablet Press' and 'Tablet Compression Machine', regular checking and updating of these is necessary. This will ensure that they are working properly and that they have a better experience.

● Reputable and Expert Service: It is better for Punches and Dies to provide reputable and expert service. They should be regularly checked and updated by experts.

As such, proper care and maintenance of 'Punches and Dies' play a vital role in the smooth running of 'Tablet Press', 'Tablet Compression Machine', and 'Tablet Tooling' and increase their importance in pharma manufacturing.

The contribution of 'punches and dies' to the medical industry is extremely important. These equipments are essential in 'Tablet Press', 'Tablet Compression Machine', 'Tablet Tooling', and 'Tablet Manufacturing' and without them this industry cannot run smoothly.

Proper design and composition of dies and punches ensure that the drug is manufactured accurately and meets therapeutic standards. Their proper use and care ensures that they function properly and the quality of the products does not suffer.

In the manufacturing of medical products, 'punches and dies' have an important contribution. This special equipment are used in 'Tablet Press' and 'Tablet Compression Machine', which play an important role in manufacturing various medical products. Singhania Tableting specializes in new technologies and updating them.

#punches and dies manufacturers#tablet press manufacturers#tablet tooling#tablet compression machines#singhania tableting

0 notes

Text

Sheet Metal Press Brake

Sheetmetal Tooling Tech is the world's leading manufacturer of turret punch, press brake & stamping tooling.

0 notes

Text

Canada’s ground-breaking, hamstrung repair and interop laws

If you'd like an essay-formatted version of this post to read or share, here's a link to it on pluralistic.net, my surveillance-free, ad-free, tracker-free blog:

https://pluralistic.net/2024/11/15/radical-extremists/#sex-pest

When the GOP trifecta assumes power in just a few months, they will pass laws, and those laws will be terrible, and they will cast long, long shadows.

This is the story of how another far-right conservative government used its bulletproof majority to pass a wildly unpopular law that continues to stymie progress to this day. It's the story of Canada's Harper Conservative government, and two of its key ministers: Tony Clement and James Moore.

Starting in 1998, the US Trade Rep embarked on a long campaign to force every country in the world to enact a new kind of IP law: an "anticircumvention" law that would criminalize the production and use of tools that allowed people to use their own property in ways that the manufacturer disliked.

This first entered the US statute books with the 1998 passage of the Digital Millennium Copyright Act (DMCA), whose Section 1201 established a new felony for circumventing an "access control." Crucially, DMCA 1201's prohibition on circumvention did not confine itself to protecting copyright.

Circumventing an access control is a felony, even if you never violate copyright law. For example, if you circumvent the access control on your own printer to disable the processes that check to make sure you're using an official HP cartridge, HP can come after you.

You haven't violated any copyright, but the ink-checking code is a copyrighted work, and you had to circumvent a block in order to reach it. Thus, if I provide you a tool to escape HP's ink racket, I commit a felony with penalties of five years in prison and a $500k fine, for a first offense. So it is that HP ink costs more per ounce than the semen of a Kentucky Derby-winning stallion.

This was clearly a bad idea in 1998, though it wasn't clear how bad an idea it was at the time. In 1998, chips were expensive and underpowered. By 2010, a chip that cost less than a dollar could easily implement a DMCA-triggering access control, and manufacturers of all kinds were adding superfluous chips to everything from engine parts to smart lightbulbs whose sole purpose was to transform modification into felonies. This is what Jay Freeman calls "felony contempt of business-model."

So when the Harper government set out to import US-style anticircumvention law to Canada, Canadians were furious. A consultation on the proposal received 6,138 responses opposing the law, and 54 in support:

https://www.michaelgeist.ca/2010/04/copycon-final-numbers/

And yet, James Moore and Tony Clement pressed on. When asked how they could advance such an unpopular bill, opposed by experts and the general public alike, Moore told the International Chamber of Commerce that every objector who responded to his consultation was a "radical extremist" with a "babyish" approach to copyright:

https://www.cbc.ca/news/science/copyright-debate-turns-ugly-1.898216

As is so often the case, history vindicated the babyish radical extremists. The DMCA actually has an official way to keep score on this one. Every three years, the US Copyright Office invites public submissions for exemptions to DMCA 1201, creating a detailed, evidence-backed record of all the legitimate activities that anticircumvention law interferes with.

Unfortunately, "a record" is all we get out of this proceeding. Even though the Copyright Office is allowed to grant "exemptions," these don't mean what you think they mean. The statute is very clear on this: the US Copyright Office is required to grant exemptions for the act of circumvention, but is forbidden from granting exemptions for tools needed to carry out these acts.

This is headspinningly and deliberately obscure, but there's one anecdote from my long crusade against this stupid law that lays it bare. As I mentioned, the US Trade Rep has made the passage of DMCA-like laws in other countries a top priority since the Clinton years. In 2001, the EU adopted the EU Copyright Directive, whose Article 6 copy-pastes the provisions of DMCA 1201.

In 2003, I found myself in Oslo, debating the minister who'd just completed Norway's EUCD implementation. The minister was very proud of his law, boasting that he'd researched the flaws in other countries' anticircumvention laws and addressed them in Norway's law. For example, Norway's law explicitly allowed blind people to bypass access controls on ebooks in order to feed them into text-to-speech engines, Braille printers and other accessibility tools.

I knew where this was going. I asked the minister how this would work in practice. Could someone sell a blind person a tool to break the DRM on their ebooks? Of course not, that's totally illegal. Could a nonprofit blind rights group make such a tool and give it away to blind people? No, that's illegal too. What about hobbyists, could they make the tool for their blind friends? No, not that either.

OK, so how do blind people exercise their right to bypass access controls on ebooks they own so they can actually read them?

Here's how. Each blind person, all by themself, is expected to decompile and reverse-engineer Adobe Reader, locate a vulnerability in the code and write a new program that exploits that vulnerability to extract their ebooks. While blind people are individually empowered to undertake this otherwise prohibited activity, they must do so on their own: they can't share notes with one another on the process. They certainly can't give each other the circumvention program they write in this way:

https://pluralistic.net/2024/10/28/mcbroken/#my-milkshake-brings-all-the-lawyers-to-the-yard

That's what a use-only exemption is: the right to individually put a locked down device up on your own workbench, and, laboring in perfect secrecy, figure out how it works and then defeat the locks that stop you from changing those workings so they benefit you instead of the manufacturer. Without a "tools" exemption, a use exemption is basically a decorative ornament.

So the many use exemptions that the US Copyright Office has granted since 1998 really amount to nothing more than a list of defects in the DMCA that the Copyright Office has painstaking verified but is powerless to fix. We could probably save everyone a lot of time by scrapping the triennial exemptions process and replacing it with an permanent sign over the doors of the Library of Congress reading "Abandon hope, all ye who enter here."

All of this was well understood by 2010, when Moore and Clement were working on the Canadian version of the DMCA. All of this was explained in eye-watering detail to Moore and Clement, but was roundly ignored. I even had a go at it, publicly picking a fight with Moore on Twitter:

https://web.archive.org/web/20130407101911if_/http://eaves.ca/wp-content/uploads/2010/Conversations%20between%20@doctorow%20and%[email protected]

Moore and Clement rammed their proposal through in the next session of Parliament, passing it as Bill C-11 in 2012:

https://en.wikipedia.org/wiki/Copyright_Modernization_Act

This was something of a grand finale for the pair. Today, Moore is a faceless corporate lawyer, while Clement was last seen grifting covid PPE (Clement's political career ended abruptly when he sent dick pics to a young woman who turned out to be a pair of sextortionists from Cote D'Ivoire, and was revealed as a serial sex-pest in the ensuing scandal:)

https://globalnews.ca/news/4646287/tony-clement-instagram-women/

Even though Moore and Clement are long gone from public life, their signature achievement remains a Canadian disgrace, an anchor chain tied around the Canadian economy's throat, and an impediment to Canadian progress.

This week, two excellent new Canadian laws received royal assent: Bill C-244 is a broad, national Right to Repair law; and Bill C-294 is a broad, national interoperability law. Both laws establish the right to circumvent access controls for the purpose of fixing and improving things, something Canadians deserve and need.

But neither law contains a tools exemption. Like the blind people of Norway, a Canadian farmer who wants to attach a made-in-Canada Honeybee tool to their John Deere tractor is required to personally, individually reverse-engineer the John Deere tractor and modify it to talk to the Honeybee accessory, laboring in total secrecy:

https://www.theregister.com/2024/11/12/canada_right_to_repair/

Likewise the Canadian repair tech who fixes a smart speaker or a busted smartphone – they are legally permitted to circumvent in order to torture the device's repair codes out of it or force it to recognize a replacement part, but each technician must personally figure out how to get the device firmware to do this, without discussing it with anyone else.

Thus do Moore and Clement stand athwart Canadian self-reliance and economic development, shouting "STOP!" though both men have been out of politics for years.

There has never been a better time to hit Clement and Moore's political legacy over the head with a shovel and bury it in a shallow grave. Canadian technologists could be making a fortune creating circumvention devices that repair and improve devices marketed by foreign companies.

They could make circumvention tools to allow owners of consoles to play games by Canadian studios that are directly sold to Canadian gamers, bypassing the stores operated by Microsoft, Sony and Nintendo and the 30% commissions they charge. Canadian technologists could be making diagnostic tools that allow every auto-mechanic in Canada to fix any car manufactured anywhere in the world.

Canadian cloud servers could power devices long after their US-based manufacturers discontinue support for them, providing income to Canadian cloud companies and continued enjoyment for Canadian owners of these otherwise bricked gadgets.

Canada's gigantic auto-parts sector could clone the security chips that foreign auto manufacturers use to block the use of third party parts, and every Canadian could enjoy a steep discount every time they fix their cars. Every farmer could avail themselves of third party parts for their tractors, which they could install themselves, bypassing the $200 service call from a John Deere technician who does nothing more than look over the farmer's own repair and then types an unlock code into the tractor's console.

Every Canadian who prints out a shopping list or their kid's homework could use third party ink that sells for pennies per liter, rather than HP's official colored water that cost more than vintage Veuve Cliquot.

A Canadian e-waste dump generates five low-paid jobs per ton of waste, and that waste itself will poison the land and water for centuries to come. A circumvention-enabled Canadian repair sector could generate 150 skilled, high-paid community jobs that saves gadgets and the Earth, all while saving Canadians millions.

Canadians could enjoy the resliency that comes of having a domestic tech and repair sector, and could count on it through pandemics and Trumpian trade-war.

All of that and more could be ours, except for the cowardice and greed of Tony Clement and James Moore and the Harper Tories who voted C-11 into law in 2012.

Everything the "radical extremists" warned them of has come true. It's long past time Canadians tore up anticircumvention law and put the interests of the Canadian public and Canadian tech businesses ahead of the rent-seeking enshittification of American Big Tech.

Until we do that, we can keep on passing all the repair and interop laws we want, but each one will be hamstrung by Moore and Clement's "felony contempt of business model" law, and the contempt it showed for the Canadian people.

Image: JeffJ (modified) https://en.wikipedia.org/wiki/File:Tony_Clement_-_2007-06-30_in_Kearney,_Ontario.JPG

CC BY-SA 3.0 https://creativecommons.org/licenses/by-sa/3.0/

--

Jorge Franganillo (modified) https://commons.wikimedia.org/wiki/File:Duga_radar_system-_wreckage_of_electronic_devices_(37885984654).jpg

CC BY 2.0 https://creativecommons.org/licenses/by/2.0/deed.en

#pluralistic#o canada#canada#cdnpoli#bill c32#anticircumvention#interoperability#trumpism#technological self-determination#c32#bill c244#bill c294#c244#c294#interop#repair#r2r#right to repair#tools exemptions#use exemptions#trade war#economic development

532 notes

·

View notes

Text

i've got one more wall of text in me for today. i'm sorry, but hopefully this helps more people than it annoys.

i understand the concerns people have about social media being captured to technofascist oligarchs and i share them.

however, and you can call me a boomer for this if you'd like, i am way more worried about the fact that we are watching a scarier replay of the 2016 hyper-normalization of Donald Trump already being carried out in mainstream/establishment news outlets.

Some political operatives on the right, who saw mainstream media coverage of Trump’s first term as overly hostile, say the way the press covered Trump’s first term unwittingly did him a favor. “I do expect that the media coverage will be a little different in tone,” one national Republican strategist told The Hill this week. “Not because the media is all of a sudden planning on being more objective and less biased, but because they probably finally recognize that their over-the-top hysterical coverage has done nothing but help Trump politically.”

there are many reason this freaks me out worse, but i can sum up a couple of them.

the rhetoric this time is a magnitude more insane and suddenly alarmingly expansionist. logic would suggest this would justify an even more critical evaluation from the media that they are seemingly neglecting to provide.

the public, thanks to total dereliction of duty by the Democrats, are far more geared up for fascist shit than ever, but are totally ignorant to how this is going to happen (concentration camps)

speaking of the Democratic party: following a series of humiliating, high profile L's, the party finds themselves leaderless and less popular than they've been in 30 years at the worst time. when asked to name the leader of the Democratic Party, 49% of registered voters couldn’t name a person or said “nobody.”

before i continue, i know that there has been a dramatic decrease in people who get their news from traditional media and instead rely on social media, podcasts and the like. that makes sense. people aren't watching cable news anymore, chiefly because fewer and fewer people under the age of 30 even have cable TV and they definitely aren't paying for a New York Times subscription.

but what people fail to consider is that the "news" people consume via social media is often rehashed or half-baked, word of mouth versions of reporting conducted by the mainstream media or the journalists who work for them. there are still journalists working for these publications who take advantage of the increased exposure podcasts provide and go on them to talk about their writing.

people hear the same stories at the end of the day, but the way the issue is initially framed when the story first "breaks" and how it is approached by other outlets who follow up on it is significant. it's a lot less work to have to clean up and suppress news on your platform when the news is already favorable to your cause.

think along the lines of a massive disinformation campaign emerging from one outlet, social media being thrown into a complete frenzy and the only journalist who knows the truth from another outlet hesitating to speak out because of threats from his publisher to keep outrage revenue high or, perhaps more ominously, to directly serve the interest of the fascists in charge.

the US media has always been servile to whims of corporate interests because... well... they are owned by the corporate interests.

but up until today, i was holding out some sliver of hope that even if the NYT, for example, wasn't taking up antifascist actions, they would hold onto a tiny bit of reliability as a further watered down version of itself. an increasingly rare, delicate weapon against misinformation on social media, as opposed to being another tool wielded by fascists on aforementioned social media to grow legitimacy and manufacture consent.

then i saw this. my feeling is now that if the New York Times can't even write a headline - with THAT photograph underneath it - that says in plain English "Elon Musk Makes Nazi Salute Twice at Trump Inauguration," then there is going to be a frightening decrease in quality journalism being funded by mainstream outlets coming.

if you are not sure what to do and you want to be well informed, i have two suggestions. the first and most important, most difficult one that is a skill hard to master, is to develop decent media literacy and an ability to derive context from history.

the second is to build a network of trustworthy local, national and global sources that you can count on. ideally, they would be completely independent and free from editorial oversight or corporate control.

here are some of my recommendations. all of them are flawed. never rely on one source. do not immediately accept something as the truth from any single source. everyone is capable of accidentally getting a detail wrong, or even deliberately misleading.

Dropsite News - ran by Ryan Grim, Jeremy Scahill

The Intercept - sadly running out of money, alleged CIA ties

Democracy Now! - more center-left, better domestically

Jacobin - wide variety, sometimes shitty takes, Alex Press is great

The Grayzone - this one is controversial (mainly just to liberals) and they make no qualms about being committed to reporting from an anti-imperialist view of the world

Black Agenda Report - perspective from Black leftists. founded by Glen Ford (RIP), a Black Panther and accomplished investigative journalist

Hasan Piker - hate him, love him, neutral, doesn't matter. he's the largest independent political commentator on the left (by far), covering news and misinformation 9 hours a day. you can think he has shit takes, but he's still a reliable source and has been insanely accurate with his opinions

The Majority Report - been around forever, Sam Seder & Emma Vigeland are amazing, once home to the incredible Michael Jamal Brooks (RIP)

Breakthrough News

Labor Notes

Ben Norton @ Global Political Economy

Caitlin Johnstone (AUS)

these are just what i could come up with but there are many more if you do a little bit of digging using these as a baseline. just remember that the source ultimately is irrelevant and will have it's own biases. it is up to you to separate fact and fiction.

#long post#media#resources#united states#us politics#media literacy#misinformation#journalism#us news#trying to be better about ableist terms#but i definitely left a few in#i'm working on it#i can grow

233 notes

·

View notes

Text

He’s a f—king madman who has no idea what he’s doing or what kind of harm he’s going to cause. Coffee prices will soar and it won’t’t just be Columbian coffee because it will create a greater demand for coffee from other nations. Then you can expect all the importers and retailers to price gouge on top of that. Pressed flowers will become unaffordable as well. Then gas prices will rise because their cheap crude oil will suddenly cost 25% more and again everyone else in the business will see increased demand and raise their prices and price gouge on top of that. Worse, he’s threatening to Jack the tariffs up to 50% for countries that won’t now to his demands.

Tariffs are meant to be used sparingly to stimulate domestic industry instead of relying on foreign producers. They were never intended to be used across the board on every item from a country. The foreign producers aren’t going to absorb a 25% loss in revenue, that’s never happened and likely never will. Prices for American consumers will rise by 25% plus inconvenience fees and price gouging.

Tariffs aren’t a weapon if you think they are you’re just shooting your own citizens in the foot. This is pretty basic stuff. Most people learned this when studying early American history in elementary school. American leaders in the post-revolutionary years imposed tariffs on European manufactured goods such as tools, guns, furniture, machines, etc to end reliance on imported goods while stimulating American manufacturing and turning us into an exporting nation.

Trump’s sole college degree is a bachelor’s in economics. This dumb ass should know how this works. He the densest mother f—ker alive and is completely incapable of being taught anything. Further he’s suffering cognitive decline due to mental illness and is a raging drug addict on top of that. Coke as an upper and Adderall to come down. His shadow president, Elon Musk, ironically only has a bachelor’s degree as well and surprise it’s also in economics. He should know better but also is suffering from mental illness and the consumption of mass quantities of Ketamine. Two moronic drug addicts.

The Republicants who should be advising Trump aren’t the best and brightest either. Nearly all of them haven’t gone beyond a bachelor’s degree and they certainly didn’t major in anything that would be useful in managing a large country with the largest economy on the planet. They are trying to run a government based on sound bites and talking points they picked up from the uneducated hosts of Fox News and Fox Business.

Once countries get burned by Trump’s tariffs they will seek out trading partners in Russia, Asia, the Middle East, and Africa. Once a trading partner leaves they almost never return. We’ll be forced to seek out more expensive trading partners who will be very cautious dealing with an unreliable USA. Further Columbia will stop cooperating and sharing intelligence in the war against the narco terrorists. Politically all these nations Trump alienates will realign their political goals with BRICS which is growing as an alternative trade and policy for nations not aligned with the Western and first world states. This is an economic and foreign policy disaster that will ripple through the world for decades to come. Trump isn’t just going to crash our economy but likely cause a worldwide depression, or at least recession. When the US catches a cold the rest of the world sneezes.

THIS IS NOT NORMAL AND ITS NOT EVEN RATIONAL.

#trump doesn’t understand tariffs#Trump’s advisers are not intelligent or well educated and certainly are not competent#tariffs are not tools#nobody wins a trade war#an unsuccessful NYC realtor is not qualified to be president#this is self destructive#the US and world economies will suffer#republican assholes#maga morons#traitor trump#crooked donald#traitor#resist#republican values#republican hypocrisy#republican family values

96 notes

·

View notes

Text

#industrial-tools-manufacturers#Press-tooling-manufacturers#Tool-&-die-makers#Metal-Stamping-Dies#tool-and-die-maker-near-you#machinists-and-tool-and-die-makers

0 notes

Text

Special Pharmaceutical Tooling Compression Machine– Buy Online from Global Supplier

The Special Pharmaceutical Tooling Compression Machine is designed for precision and efficiency in the pharmaceutical industry. offering enhanced performance, durability, and versatility for various pharmaceutical applications. Available from trusted global suppliers

#"Pharmaceutical Tooling Compression Machine#Special Tooling Tablet Press#Pharmaceutical Tooling#Tablet Tooling in Pharma#Pharmaceutical Machinery In USA#Tablet Press Machine Manufacturers In USA Global#Pharmaceutical Tooling Compression Machine in USA Global#Special Tooling Tablet Press supplier In USA Global

0 notes

Text

"The Biden era has normalized illness and demonized mitigations for the sake of “back to normal”. We now live in a country where educated liberals genuinely think it’s okay-and in fact good- that their kids are constantly ill (to be expected given the immune system-damaging nature of COVID). Where leftists argue that killing old people is less harmful than wearing masks. Where concern for community health is painted as cowardly and using the modern scientific tools we are lucky enough to have is portrayed as rude and stupid. And terribly, this liberal political project under Joe Biden has come down like a hammer on community solidarity, leaving “the vulnerable” squabbling with their mocking former comrades. It’s hard to overstate just how much damage the normalization of COVID has done to the very concepts of public health and community.

My beliefs throughout the pandemic have never changed: that vulnerable people deserve access to society, that mitigation must be prioritized, that great progress is possible with great effort, that community care is most critical in times of state abandonment. It’s hard to know where to go from here, at the nadir of a COVID response that vilifies and mocks any gesture toward prevention and care. But for those of us who are still here, education must start from a place of unpacking several years-worth of propaganda, while learning from disability justice activists who have reckoned with their social marginalization for decades.

Despite the multitude of falsehoods that continue to be poured over the heads of our comrades by outlets that can’t or won’t reckon with Biden’s failure, the truth has the advantage of being obvious, and patient. So we’ll continue to repeat it, until the people are ready to hear it: COVID is not mild. COVID is not harmless. COVID is not inevitable. COVID is not over. Stay safe out there."

#covid#eugenics#genocide joe#blue maga#death to america#genocide#wear a mask#queer cripple#anarchism#anticapitalism#ableism#anarchotahdigism#antifascism

440 notes

·

View notes

Text

The federal government will be investing $2.4 billion to accelerate Canada’s artificial intelligence (AI) sector, Prime Minister Justin Trudeau announced Sunday. The investment will be divided between a number of measures meant to advance job growth in the AI and tech industry and boost businesses’ productivity. “This announcement is a major investment in our future, in the future of workers, in making sure that every industry, and every generation, has the tools to succeed and prosper in the economy of tomorrow,” Trudeau said in a press release Sunday. Majority of the funds, $2 billion, will go toward increasing access to computing and technological infrastructure. Another $200 million is being invested into AI start-ups to accelerate the technology in “critical sectors” such as health care, agriculture and manufacturing, the release says. Additional funds will be put toward helping small and medium-sized businesses incorporate AI, with another $50 million being committed to help train workers whose jobs may be disrupted by the technology.

Continue Reading.

Tagging: @politicsofcanada

305 notes

·

View notes

Note

I love your art so much!!! I've also been starting to paint with gouache, and I'd love to know a little more about your process! What kind of paints do you use, do you sketch first or start with paint, do you paint in layers over several day or all at once?

Hi and thank you! I hope you don't mind me answering this publicly and apologies for length, but:

MY ART PROCESS!

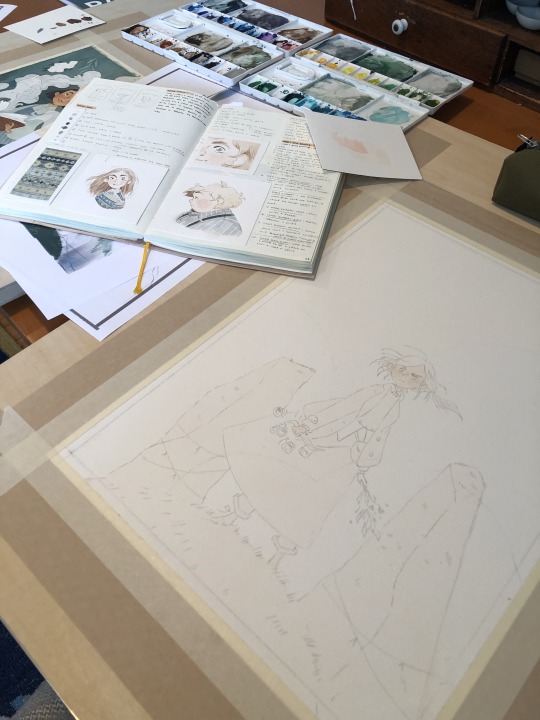

Supplies: I use winsor and newton gouache and arches cold press paper blocks, usually 140 lbs (the lime green ones) and sometimes 300 lbs (the teal green ones). Even though this paper comes pre-stretched in blocks, I actually take the sheets off and stretch them myself because I've found arches' glue isn't as strong as it used to be. This is how you get watercolor paper to lay flat! I recommend youtubing some videos on how to do it -- there's a lot of great tutorials out there. Also, I use princeton brushes, and kraft paper tape and these boards to stretch my paper. (these aren't affiliate links, I just shop at blick)

A word about art supplies: these are the exact tools I use but everyone uses supplies differently and two people with the exact same supplies might get different results! A lot of it is about what works for you and what you like, so I always suggest that gouache/watercolor beginners just buy a few tubes from a couple of different paint companies and some small pieces of paper from different manufacturers to see what you like. Just changing one ingredient in the above has created massively different results for me, but maybe that'll end up being something you'd like! The first step in learning a new medium imo is to play. Just have fun!

ALSO: gouache isn't super light permanent, check your tubes for which ones hold up to sunlight. Here is winsor and newton's color chart explaining which ones will fade when exposed to sunlight -- all manufacturers will give you this. I only use the colors rated A and AA, and I still frame my pieces with UV glass just to be safe. Not all gouache is re-wettable, but winsor and newton is. I just put it in my palettes and refill my palettes if it runs low. AND SOME PAINT IS TOXIC. A lot of paints have cadmium and cobalt in them. I don't use any of the toxic colors, but if you do, make sure you don't eat while working and wash your hands thoroughly afterwards. This information is also usually available on manufacturer's websites. As more people are rejecting cadmium paint, you'll see more tubes labeled things like cadmium-free yellow. This is why. More artists should be aware that their tools can be dangerous. You don't need that many tubes of paint to begin, just a warm and cool red, warm and cool yellow, warm and cool blue, white and black. I have around 50 colors and use 20 regularly. I always mix all my colors myself, and never use straight tube paint. Most of my colors have about 5-6 different tube colors mixed together. If you use re-wettable paint a tube of paint will last you years; even as a professional I only buy new paints every 5 years or so.

Process: I ALWAYS start with a sketch first. Not everyone has to, but because I do illustration work -- where sometimes a client gets input on a drawing -- I always do a lot of preliminary work before I even begin to paint. At this point, even my personal work usually involves the exact same process:

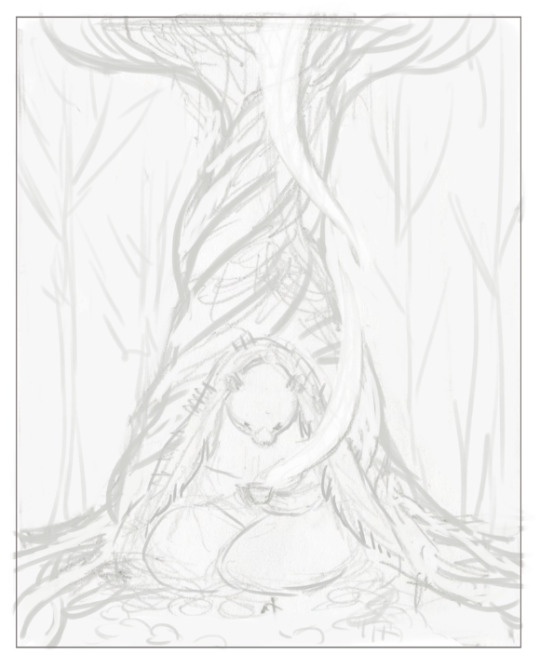

I start with a 3" or so thumbnail that I scan (left; I traced it quickly digtally for clarity to myself here) and then either clean up digitally or print out and clean up traditionally with tracing paper (right):

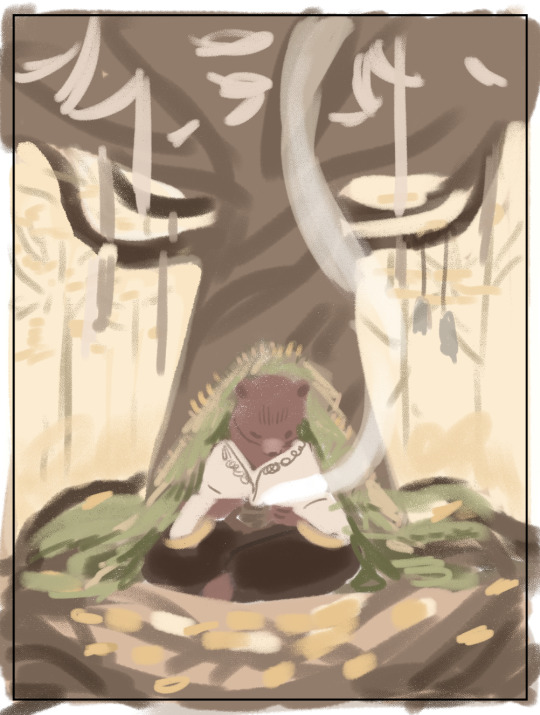

Then I scan the cleaned sketch in and color rough it digitally (left, this was for a gallery show, so no one had to approve my color roughs, so it's messy!) then I transfer my sketch to my paper (with either carbon transfer paper or a light table), stretch my paper, and paint (right):

I obviously changed my mind about the color of the ribbon in the trees, ha, and made everything a lot more vibrant. The benefit again of gallery work is no pre-approval!

You are correct, I paint in a series of washes, going from lightest to darkest, where I apply the same color beneath all shapes that are the same warmth (cools under all upcoming cools, warms under all upcoming warms). I paint a piece usually in one or two days, depending on complexity. I didn't take pictures of the above painting, but here's a different painting to show you a little bit what I mean:

I painted the peach color under everything (and twice for skin tones), and the gray color of the sky under everything that would be grayish (the rocks, trees, her pants, her skirt, and coat). I do this to stop me from getting darker lines where two different colors butt up against each other, and also for color harmony. I have step by step photos of this in my process stories highlight on my instagram; also check my FAQ and tip highlights for more info on all this stuff. Most pieces take around 25-30 washes before I start adding in the details (sometimes I add in face details early though because if I mess those up it's not worth finishing the rest of the painting! 😅)

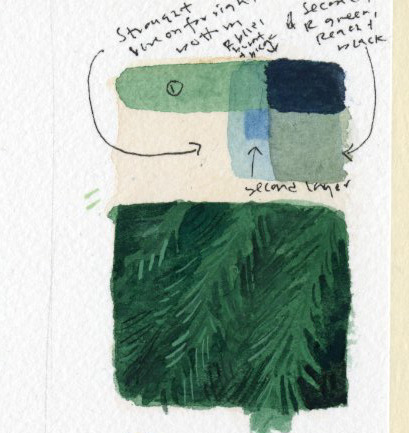

All this might seem like a lot of work (...it is) but I do it so that I can show clients previews of the final piece and so I don't have to repaint the finals. I also used to pre-test all of my washes on scrap paper like this:

I still recommend doing this if you're just beginning! But at this point I only do it when testing techniques because I know my paints really well. (the above was my test for the pine boughs in this piece)

Painting by far is the longest part of the process, so I do more work up front to not have to do it twice. Every piece takes about 6-24 hrs of actual work time to produce. Stretching watercolor paper takes about 24 hrs to dry, and because I sell most of my originals in galleries, they need to be flawless, so planning ahead is useful and in the end saves me time.

And to conclude this novel of an explanation, don't be overwhelmed by all the information I've given you! I put it here so that people at various stages of their artistic journey can maybe find something useful in it. But seriously, the first step to learning how to paint whether it's traditionally or digitally is just to have fun. Try it out, see what's working and what isn't, and then try to solve specific issues that you're struggling with. I've been doing this for a loooooong time at this point, but here's my first watercolor piece from when I was re-teaching myself how to paint traditionally nine years ago:

Obviously, I was destined for greatness. Ha, yeah, no. If you scroll back through my tumblr archive, you can see me learning how to use these paints in real time. And keep in mind that I'd been working digitally for years before then, and years before that where I didn't post my work online at all.

So for anyone who needs to hear it: there's no such thing as talent, just hard work, patience, and trying again and again and again...and sometimes again. What I do is a skill and anyone can learn it. Sometimes, progress is slow. I'm 38. I only really feel like my art was half-way decent starting a few years ago, but I've been making art my entire life, and I went to art school at 18. 20 years later I'm kind of figuring it out.

The best advice I can give, whether it's about art or not, is find the thing you love so much that you'll keep at it even when you suck at it, because most skills you'll suck at to begin with -- and perhaps for a long time. I sucked at art for yeeeaaaaarrrrs. On top of the usual learning curve, I struggled with fine motor control and dexterity. But I loved it so much I kept trying every time I failed. If I can do it, so can all of you, no matter what stage of art you're at now, and no matter how old you are.

Anyway, thank you to those still reading this deep in. I wish you all the best on your artistic journey. Art can kick your butt sometimes, but it's also pretty dang rewarding 💛

536 notes

·

View notes