#Pre-Printed label manufacturers

Explore tagged Tumblr posts

Text

Discover the Best Label Manufacturers for Your Business Needs with Barspell Technology

In today's fast-paced business environment, the demand for high-quality labels is at an all-time high. Whether you're looking for pre-printed label manufacturers or a barcode label manufacturer, finding the right supplier can make all the difference in ensuring your products are well-branded and easily identifiable. At Barspell Technology, we specialize in providing top-tier label solutions that cater to various business needs, enhancing both efficiency and branding. This article delves into the importance of labels, the different types of label manufacturers, and how Barspell Technology can help you choose the best supplier for your specific requirements.

Why Labels Matter: An Overview

Labels are not just for identification; they play a vital role in marketing, branding, and logistics. From barcode labels used for inventory tracking to pre-printed labels that showcase your brand, choosing the right label manufacturer can enhance product presentation, improve supply chain management, and streamline operations. Whether you are in retail, manufacturing, or e-commerce, the quality and design of your labels can influence both customer perception and operational efficiency. Barspell Technology is committed to delivering high-quality, durable labels that help businesses like yours thrive.

What to Look for in Label Manufacturers

When searching for the best label manufacturers, several factors should be taken into consideration. Quality, durability, customization options, and cost-effectiveness are crucial for any business, regardless of industry. A reliable label manufacturer, such as Barspell Technology, will offer:

1. Customization Options: Labels can be tailored to fit the specific needs of your products, whether it’s pre-printed or featuring barcode technology.

2. Durability: High-quality labels that withstand various environmental conditions, from heat to moisture, are essential for long-term product labeling.

3. Fast Turnaround Times: Depending on the urgency of your business needs, Barspell Technology provides quick and efficient label production services.

4. Competitive Pricing: Choose manufacturers that offer a good balance of quality and cost, providing you with value for money.

Pre-Printed Label Manufacturers: Streamlining the Process with Barspell Technology

For many businesses, pre-printed label manufacturers offer a simple solution for efficient labeling. These labels come with your design already printed, which can save time in your production process. Pre-printed labels are ideal for products that have fixed information, such as barcodes, ingredients, or brand logos.

By working with experienced pre-printed label manufacturers like Barspell Technology, you ensure that each label is consistent, professionally designed, and printed with high-quality materials that can withstand wear and tear.

Barcode Label Manufacturers: Essential for Inventory and Logistics

Barcode labels are essential for inventory control, shipping logistics, and point-of-sale systems. A barcode label manufacturer such as Barspell Technology can provide you with high-quality labels that are scannable, durable, and customized to fit your product's needs. These labels enable fast, accurate tracking of products throughout the supply chain, which can significantly reduce human error and improve efficiency.

Whether you need standard 1D or advanced 2D barcode labels, Barspell Technology ensures that your barcodes are printed, scannable, and resistant to fading, ensuring smooth operations.

Choosing the Right Label Manufacturer for Your Business

With so many options available, choosing the right label manufacturer can feel overwhelming. Here are a few tips to help you make an informed decision:

1. Reputation and Reviews: Look for manufacturers with a proven track record of delivering high-quality labels. Barspell Technology has earned a reputation for quality and customer satisfaction in the labeling industry.

2. Industry Experience: A manufacturer experienced in your industry will understand your unique labeling needs and offer expert advice.

3. Technological Capabilities: Ensure the manufacturer uses the latest printing technology to deliver precise, high-quality labels. At Barspell Technology, we leverage cutting-edge technology to provide labels that meet your exact specifications.

Conclusion: Find Your Perfect Label Manufacturer with Barspell Technology

Whether you're looking for barcode label manufacturers or pre-printed label manufacturers, it’s important to work with a company that understands the nuances of labeling and meets your business’s unique requirements. By considering factors such as customization options, quality, and industry experience, you can find a label supplier to support your product labeling needs and help streamline your operations.

Labels are more than just a necessity they are an essential part of your brand’s identity and functionality. Partnering with Barspell Technology ensures you get the best labels to elevate your brand and optimize your business processes.

1 note

·

View note

Text

#label manufacturer#pre-printed label manufacturer#custom labels#printed labels#barcode labels#product labels#compliance labels#adhesive labels#high-volume label printing#label printing services#label solutions India#Barspell Technology#labels in Pune#label Manufacturer#label Manufacturer in Pune#label Manufacturer in Chakan#label Manufacturer in Mumbai#label Manufacturer in Nashik#label Manufacturer in Aurangabad#label Manufacturer in Kolhapur#label Manufacturer in Bangalore#label Manufacturer in Chennai#label Manufacturer in Gujarat#label Manufacturer in Vapi#label Manufacturer in Sarona#label Manufacturer in Hyderabad#label Manufacturer in Kanpur#label Manufacturer in Jaipur#label Manufacturer in Lucknow#label Manufacturer in Patna

0 notes

Text

Label Manufacturer & Pre-Printed Label Manufacturer | Barspell Technology

0 notes

Note

I love your art so much!!! I've also been starting to paint with gouache, and I'd love to know a little more about your process! What kind of paints do you use, do you sketch first or start with paint, do you paint in layers over several day or all at once?

Hi and thank you! I hope you don't mind me answering this publicly and apologies for length, but:

MY ART PROCESS!

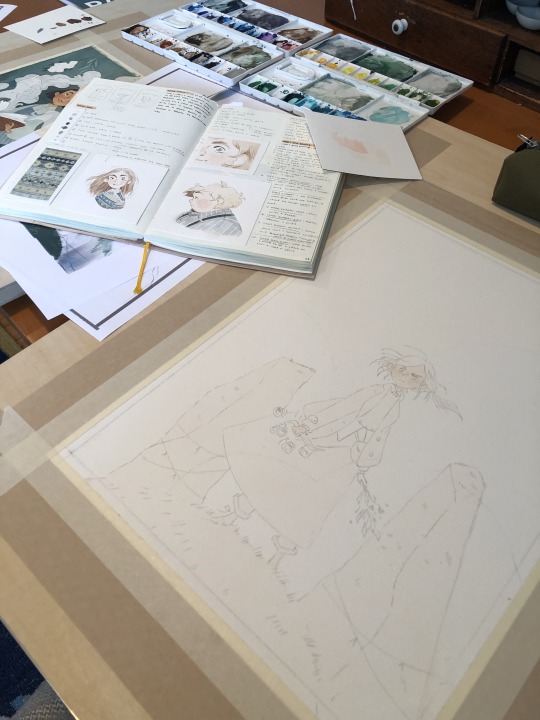

Supplies: I use winsor and newton gouache and arches cold press paper blocks, usually 140 lbs (the lime green ones) and sometimes 300 lbs (the teal green ones). Even though this paper comes pre-stretched in blocks, I actually take the sheets off and stretch them myself because I've found arches' glue isn't as strong as it used to be. This is how you get watercolor paper to lay flat! I recommend youtubing some videos on how to do it -- there's a lot of great tutorials out there. Also, I use princeton brushes, and kraft paper tape and these boards to stretch my paper. (these aren't affiliate links, I just shop at blick)

A word about art supplies: these are the exact tools I use but everyone uses supplies differently and two people with the exact same supplies might get different results! A lot of it is about what works for you and what you like, so I always suggest that gouache/watercolor beginners just buy a few tubes from a couple of different paint companies and some small pieces of paper from different manufacturers to see what you like. Just changing one ingredient in the above has created massively different results for me, but maybe that'll end up being something you'd like! The first step in learning a new medium imo is to play. Just have fun!

ALSO: gouache isn't super light permanent, check your tubes for which ones hold up to sunlight. Here is winsor and newton's color chart explaining which ones will fade when exposed to sunlight -- all manufacturers will give you this. I only use the colors rated A and AA, and I still frame my pieces with UV glass just to be safe. Not all gouache is re-wettable, but winsor and newton is. I just put it in my palettes and refill my palettes if it runs low. AND SOME PAINT IS TOXIC. A lot of paints have cadmium and cobalt in them. I don't use any of the toxic colors, but if you do, make sure you don't eat while working and wash your hands thoroughly afterwards. This information is also usually available on manufacturer's websites. As more people are rejecting cadmium paint, you'll see more tubes labeled things like cadmium-free yellow. This is why. More artists should be aware that their tools can be dangerous. You don't need that many tubes of paint to begin, just a warm and cool red, warm and cool yellow, warm and cool blue, white and black. I have around 50 colors and use 20 regularly. I always mix all my colors myself, and never use straight tube paint. Most of my colors have about 5-6 different tube colors mixed together. If you use re-wettable paint a tube of paint will last you years; even as a professional I only buy new paints every 5 years or so.

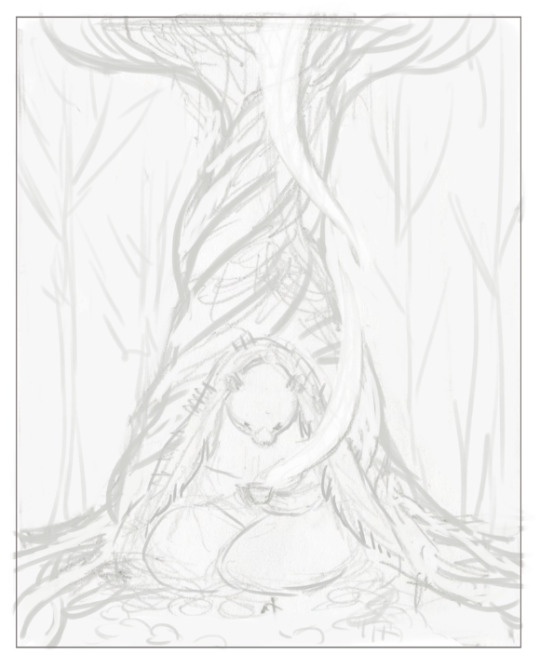

Process: I ALWAYS start with a sketch first. Not everyone has to, but because I do illustration work -- where sometimes a client gets input on a drawing -- I always do a lot of preliminary work before I even begin to paint. At this point, even my personal work usually involves the exact same process:

I start with a 3" or so thumbnail that I scan (left; I traced it quickly digtally for clarity to myself here) and then either clean up digitally or print out and clean up traditionally with tracing paper (right):

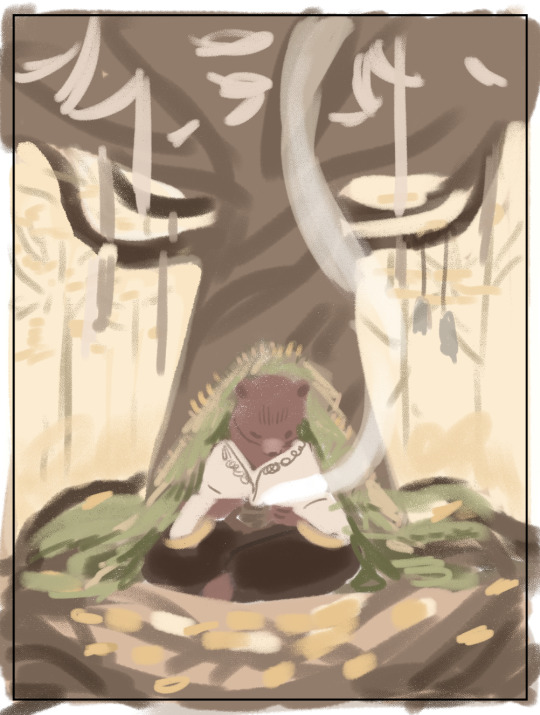

Then I scan the cleaned sketch in and color rough it digitally (left, this was for a gallery show, so no one had to approve my color roughs, so it's messy!) then I transfer my sketch to my paper (with either carbon transfer paper or a light table), stretch my paper, and paint (right):

I obviously changed my mind about the color of the ribbon in the trees, ha, and made everything a lot more vibrant. The benefit again of gallery work is no pre-approval!

You are correct, I paint in a series of washes, going from lightest to darkest, where I apply the same color beneath all shapes that are the same warmth (cools under all upcoming cools, warms under all upcoming warms). I paint a piece usually in one or two days, depending on complexity. I didn't take pictures of the above painting, but here's a different painting to show you a little bit what I mean:

I painted the peach color under everything (and twice for skin tones), and the gray color of the sky under everything that would be grayish (the rocks, trees, her pants, her skirt, and coat). I do this to stop me from getting darker lines where two different colors butt up against each other, and also for color harmony. I have step by step photos of this in my process stories highlight on my instagram; also check my FAQ and tip highlights for more info on all this stuff. Most pieces take around 25-30 washes before I start adding in the details (sometimes I add in face details early though because if I mess those up it's not worth finishing the rest of the painting! 😅)

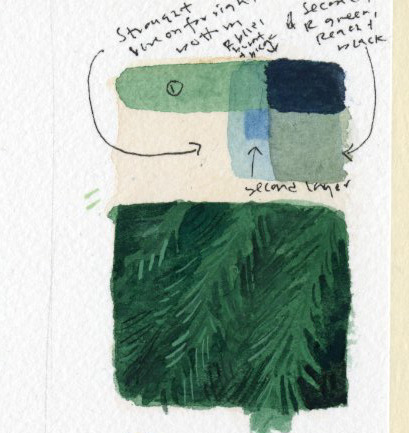

All this might seem like a lot of work (...it is) but I do it so that I can show clients previews of the final piece and so I don't have to repaint the finals. I also used to pre-test all of my washes on scrap paper like this:

I still recommend doing this if you're just beginning! But at this point I only do it when testing techniques because I know my paints really well. (the above was my test for the pine boughs in this piece)

Painting by far is the longest part of the process, so I do more work up front to not have to do it twice. Every piece takes about 6-24 hrs of actual work time to produce. Stretching watercolor paper takes about 24 hrs to dry, and because I sell most of my originals in galleries, they need to be flawless, so planning ahead is useful and in the end saves me time.

And to conclude this novel of an explanation, don't be overwhelmed by all the information I've given you! I put it here so that people at various stages of their artistic journey can maybe find something useful in it. But seriously, the first step to learning how to paint whether it's traditionally or digitally is just to have fun. Try it out, see what's working and what isn't, and then try to solve specific issues that you're struggling with. I've been doing this for a loooooong time at this point, but here's my first watercolor piece from when I was re-teaching myself how to paint traditionally nine years ago:

Obviously, I was destined for greatness. Ha, yeah, no. If you scroll back through my tumblr archive, you can see me learning how to use these paints in real time. And keep in mind that I'd been working digitally for years before then, and years before that where I didn't post my work online at all.

So for anyone who needs to hear it: there's no such thing as talent, just hard work, patience, and trying again and again and again...and sometimes again. What I do is a skill and anyone can learn it. Sometimes, progress is slow. I'm 38. I only really feel like my art was half-way decent starting a few years ago, but I've been making art my entire life, and I went to art school at 18. 20 years later I'm kind of figuring it out.

The best advice I can give, whether it's about art or not, is find the thing you love so much that you'll keep at it even when you suck at it, because most skills you'll suck at to begin with -- and perhaps for a long time. I sucked at art for yeeeaaaaarrrrs. On top of the usual learning curve, I struggled with fine motor control and dexterity. But I loved it so much I kept trying every time I failed. If I can do it, so can all of you, no matter what stage of art you're at now, and no matter how old you are.

Anyway, thank you to those still reading this deep in. I wish you all the best on your artistic journey. Art can kick your butt sometimes, but it's also pretty dang rewarding 💛

542 notes

·

View notes

Note

If you don't mind me asking, what do you use to print and cut your sticker?

Or get your charms made?

They all look so cute!

it's no problem! for stickers, i print them on "online labels" sticker paper at home with my home printer, laminate them (for more waterproof protection and/or pretty effects, depending on what i use) with laminating sheets and/or glitter sheets, and then cut them out with my silhouette cameo 3 i got pre-owned from ebay bid snipping

as for charms, i use vograce; it's a very good manufacturer, especially for beginners. there's a lot of tutorials that can be watched online for help; that's what i did! just have to search what Specifically you want to know, like looking up shaker charm video guides for shaker charms you want to make, etc etc

overall it's a lot of diy stuff to have fun making stuff for yourself and others if you have the resources and drive to do, ty for asking!

7 notes

·

View notes

Note

I have a question about IRL merch — did their clothing used to be better quality and it has gotten worse, or is it just the calendars that were worse this year? I ask bc I just got a shirt and sweatshirt from another content creator for the Same Price as dnp merch and the difference between them is crazy. Like I don’t think the dnp clothing feels cheap or whatever but the other merch just has a much thicker fabric and the sweatshirt is much softer on the inside. I don’t buy a lot of content creator merch in general so I’m not sure which of these is the norm for clothing quality!

(everything i have pre-crafts merch is UK manufactured and shipped)

i'd say it got worse overall. i am biased, though. they switch from one t-shirt company to another all the time, the same with longsleeves and hoodies. sometimes the material quality is good, sometimes it's sooo thin 🥲

the printing quality is inconsistent now, but idk how it was before 2022, not because i don't have older merch (i do), but because i haven't asked anyone and weren't paying much attention back then.

i also wanna point out that sometime around WAD (could be earlier) they stopped making their own branded labels*. Dan's "don't talk to me" longsleeve has DH label, but then... WAD doesn't (which can be understandable; the marble ii shirt also doesn't, but ii longsleeve does have printed D&P "label"), and all merch after their comeback has the original label of the company where they bought it. it's not about quality, i understand that, i just wanted to point out that they stopped making their merch more unique (i guess, i could call it that). i get that it's cheaper for them to not touch labels, but like, some old merch is just... cute. the new one? basic. for the same price!

*WAD leather jacket has a customized label - the only item. but the jacket itself was custom-made, i guess, so i'm not surprised.

i remember when dnp were selling candles, the shipping wasn't organised well enough and i knew people who got their candles broken. and someone told me that there was a problem with Phil's hot chocolate at the customs in one of Latam countries. dare i say, it wasn't handled correctly by IRL Merch (no chocolate, no refund in the end). all of that was pre-WAD. again, not the merch quality, per se, sorry.

4 notes

·

View notes

Text

Top 10 Durable Courier Bags for Safe and Secure Shipping

In the fast-paced world of eCommerce, logistics, and document delivery, durable courier bags are essential for keeping items safe and professional. Whether you’re an online seller or a business handling sensitive deliveries like bank documents or gold loan packets, choosing the right packaging can make all the difference.

At Euphoria Packaging, a trusted Courier Bag Manufacturer, we understand the importance of secure, tamper-proof, and eco-conscious solutions. Here’s our list of the Top 10 Courier Bags for safe and secure shipping.

1. Tamper Proof Courier Bags

✅ Ultimate Security for Confidential Deliveries

These bags are designed with a permanent adhesive strip, making them impossible to open without visible signs of tampering. Perfect for banks and document deliveries, including Bank Deposit / Gold Loan Bags and Gold Loan Envelopes.

2. Bubble Courier Bags

✅ Lightweight Protection with Bubble Lining

Great for fragile items, Bubble Courier Bags offer an extra layer of cushioning with internal air bubbles to prevent damage. These are ideal for shipping gadgets, accessories, and delicate merchandise.

3. Kraft Paper Bubble Mailers

✅ Sustainable + Protective

Combining eco-friendliness with protection, Kraft Paper Bubble Mailers are recyclable, sturdy, and lined with bubbles. A go-to for environmentally-conscious businesses.

4. Poly Mailers

✅ Cost-Effective and Versatile

Lightweight and water-resistant, Poly Mailers are perfect for clothes, documents, and non-fragile items. Printed Courier Bags with logos are often made from this material for branding and professionalism.

5. Air Bubble Bags

✅ Extra Protection for Fragile Products

Designed solely for protection, Air Bubble Bags are used to wrap or cushion products inside outer courier packaging. Combine them with a Poly Bubble Mailer with Document Pouch for high-value shipments.

6. Peel and Seal Bags

✅ Quick and Secure Packing

Thanks to their easy-to-use adhesive strip, Peel and Seal Bags save time and ensure your packaging stays closed in transit. Suitable for retail and fashion brands.

7. Eco-Friendly Courier Bags

✅ Green Packaging for Modern Businesses

More companies are turning to Eco-Friendly Courier Bags to reduce plastic waste. These are often made from biodegradable or recyclable material, offering function with conscience.

8. Clear Wicketed Mailers

✅ Organized & Transparent

Clear Wicketed Mailers are ideal for industrial and retail packing lines. Their transparency ensures visibility, while the wicket allows easy handling during high-speed packing.

9. Suffocation Warning Bags

✅ Safety First for Packaging

Perfect for garments and textiles, Suffocation Warning Bags come pre-printed with compliance text. They’re available with Plastic Draw Strings for convenience.

10. Direct Thermal Shipping Labels

✅ Stick-On Simplicity

While not a bag, Direct Thermal Shipping Labels are essential for organizing and labeling your shipments quickly and clearly, especially for logistics teams.

Why Choose Euphoria Packaging?

Industry-Leading Courier Bag Manufacturer

At Euphoria Packaging, we offer a complete range of packaging solutions — from Air Bubble Rolls to custom-printed Courier Bags — tailored to your needs. Our focus is on durability, customization, and eco-friendly innovation.

Final Thoughts

Whether you’re shipping fragile electronics, important legal documents, or stylish fashion items, choosing the right courier bag ensures a professional and damage-free delivery experience.

For bulk orders, custom printing, or wholesale inquiries, contact Euphoria Packaging, your reliable Courier Bag Manufacturer.

Courier Bags, Poly Mailers, Bubble Courier Bags, Kraft Paper bubble Mailers, Bubble Lined Courier Bags, Tamper Proof Courier bags, Gold Loan Envelopes, Direct Thermal Shipping Labels, Air Bubble Bags, Printed Courier Bags

Euphoria Packaging Private Limited Founded in 2012 with a focus to serve the need of the packing industry Euphoria Packaging Private Limited is reckoned as the dominant Manufacturer firm of best quality.

Euphoria Packaging, Courier Bag Manufacturer, Air Bubble Roll, Eco-Friendly Courier Bags, Plastic Draw Strings, Peel and Seal Bags, Poly Bubble Mailer with Document Pouch, Clear Wicketed Mailers, Suffocation Warning Bags, Bank Deposit / Gold Loan Bags.

Factory Address: 305, Omkar The Summit, Level 3, Nr Western Express Highway, Vileparle (East) — Mumbai 400 057.

0 notes

Text

Optimizing Product Protection and Presentation with Blister Packaging Machines

How Automation and Innovation in Packaging Are Elevating the Standards of the Pharmaceutical and Consumer Goods Industries

In today’s fast-paced manufacturing environment, product integrity and visual appeal are critical to success—especially in the pharmaceutical, nutraceutical, and consumer goods sectors. A reliable solution that addresses both these needs is the blister packaging machine, a vital piece of equipment that has become the gold standard for securely packaging individual items while enhancing shelf appeal.

As consumer expectations rise and regulatory standards tighten, manufacturers must rely on automated solutions that guarantee consistency, safety, and efficiency. The blister packaging machine plays a central role in achieving these objectives. Designed to seal products within a pre-formed plastic cavity, this machine ensures that items are protected from moisture, contamination, and physical damage while maintaining a professional, tamper-evident presentation.

One of the primary benefits of using a blister packaging machine is the preservation of product quality. Medications, vitamins, electronics, and even small tools are sensitive to environmental factors such as humidity, light, and air. Blister packaging offers an effective barrier, extending shelf life and ensuring that the product remains effective or functional until the moment it is used. For pharmaceuticals in particular, this can be critical to patient safety.

Efficiency is another area where a blister packaging machine shines. These machines can handle high-speed production lines, delivering hundreds of precisely packaged units per minute. By automating the process, manufacturers reduce labor costs, minimize human error, and maintain uniformity across every unit produced. Whether dealing with tablets, capsules, or other small items, the ability to produce at scale with precision gives companies a significant edge in a competitive marketplace.

In addition to protecting products, a blister packaging machine also enhances branding and user experience. The clear plastic casing allows consumers to see the product before purchase, while the printed backing offers space for branding, dosage information, usage instructions, or compliance labels. This makes blister packaging a dual-purpose solution—ensuring safety while communicating important product details directly to the end-user.

Modern blister packaging machine models come equipped with advanced features such as touch-screen controls, real-time monitoring, and automatic rejection of faulty units. These innovations not only improve efficiency but also facilitate regulatory compliance, particularly in industries where product traceability and safety are paramount. Operators can monitor performance metrics, adjust settings quickly, and perform maintenance with minimal downtime.

Customization is another key advantage of today’s blister packaging machine technology. Manufacturers can adapt their machines to accommodate various materials (like PVC, aluminum foil, or recyclable plastics), package configurations, and product shapes. This flexibility allows businesses to create tailored packaging solutions that align with both product needs and brand aesthetics.

For manufacturers aiming to boost production quality and meet growing market demands, investing in a high-performance blister packaging machine is a smart and scalable solution. It enhances packaging efficiency, safeguards product integrity, and delivers a sleek, consumer-friendly presentation that builds trust and loyalty.

In conclusion, as companies across industries seek ways to optimize their packaging processes, the blister packaging machine continues to prove its value through precision, reliability, and adaptability. For those seeking to elevate their operations with top-tier packaging solutions, Encap North America stands at the forefront—offering advanced technologies and expert guidance to help businesses succeed in a highly regulated and competitive landscape.

1 note

·

View note

Text

How to Purchase 750ml Glass Bottles: A Comprehensive Guide for B2B Buyers?

750ml glass bottles are widely used in industries such as food, wine, cosmetics, and chemicals due to their capacity, premium, and eco-friendly recyclability. This guide will walk you through the key steps of procuring 750ml glass bottles, helping you efficiently identify quality suppliers, clarify requirements, and streamline your purchase process.

1. Define Your Core Requirements: Start with Key Parameters

Before initiating the purchase, clarify the following essential elements:

1. Product Application

○ Determine the bottle's end-use (e.g., wine bottles, sauce containers, essential oil bottles). Different applications require specific mouth diameters, body thicknesses, and temperature resistance (e.g., high borosilicate glass vs. soda-lime glass for high-temperature sterilization or frozen storage).

2. Customization Needs

○ Do you need silk-screened logos, enamel decals, or unique shapes (e.g., curved shoulders, grooved designs)? Customization requires advanced mold development discussions with suppliers, including lead times and MOQs (Minimum Order Quantities).

○ Consider bundled purchases of caps (screw caps, press-on closures), gaskets, labels, etc.

3. Order Scale

○ Clarify your order volume (MOQ typically ranges from 1,000 to 5,000 units). Bulk orders may qualify for price discounts and expedited delivery.

○ Long-term buyers should consider framework agreements to ensure supply stability.

2. Supplier Selection: Evaluate Based on 4 Critical Dimensions

1. Qualifications & Certifications

○ Prioritize ISO 9001-certified factories with food-grade glass production licenses to ensure compliance.

○ Review their portfolio for relevant industry cases (e.g., wine, pharmaceuticals).

2. Product Quality Control

○ Confirm testing standards (e.g., bubble rate, stress resistance, vertical axis deviation) and request third-party inspection reports.

○ Inquire about defect handling policies (e.g., breakage rate guarantees, replacement mechanisms).

3. Cost & Efficiency

○ Compare prices, customization fees, logistics costs, and MOQs to avoid hidden charges.

○ Opt for suppliers with automated production lines to shorten lead times (typically 15-30 days for regular orders).

4. Service & Responsiveness

○ Evaluate pre-sales support (free sampling, 3D modeling), after-sales services (quick response to complaints), and technical assistance.

○ Clarify payment terms (e.g., 30% deposit + balance), shipping methods (full container vs. LCL), and return policies.

3. Execution & Risk Management: Streamline the Process

1. Sample Verification

○ Request samples to check dimensional tolerances, printing accuracy, and packaging integrity.

○ Conduct tests if necessary to verify mouth compatibility and sealing performance.

2. Contract Signing

○ Detail product specs, quantities, prices, delivery timelines, payment terms, and违约责任 clauses.

○ Attach design drafts and mold details for customized orders.

3. Logistics & Warehousing

○ Ensure’s fragile packaging solutions (bubble wrap + honeycomb cardboard + pallet reinforcement).

○ Purchase transportation insurance and sign damage compensation agreements with logistics partners.

4. Long-term Optimization: Build a Sustainable Supply Chain

1. Inventory Management

○ Develop rolling purchase plans based on sales forecasts to avoid overstocking or stockouts.

2. Cost Reduction

○ Regularly review supplier quotes and explore lightweight bottle designs or recycling initiatives.

3. Technology Upgrades

○ Stay updated on industry innovations (e.g., antibacterial coatings, smart labels) to enhance product competitiveness.

Recommended Resource: One-Stop Glass Bottle Procurement Platform

glass bottles manufacturer 15+ years in food-grade glass bottle manufacturing with ISO/BRC certifications Support 750ml bottle customization (MOQ as low as 500 units) with free sampling and full-chain QC reports Nationwide warehouses for urgent replenishment👉 [Get a Free Quote Today]750ml glass bottles

0 notes

Text

A prescription, often abbreviated ℞ or Rx, is a formal communication from physicians or other registered healthcare professionals to a pharmacist, authorizing them to dispense a specific prescription drug for a specific patient. Historically, it was a physician's instruction to an apothecary listing the materials to be compounded into a treatment—the symbol ℞ (a capital letter R, crossed to indicate abbreviation) comes from the first word of a medieval prescription, Latin recipe (lit. 'take thou'), that gave the list of the materials to be compounded.

Format and definition

℞

Medical prescription

In Unicode U+211E ℞ PRESCRIPTION TAKE (℞)

Related

The symbol "℞", sometimes transliterated as "Rx" or "Rx", is recorded in 16th century manuscripts as an abbreviation of the late Latin instruction recipe, meaning 'receive'.[a] Originally abbreviated Rc, the later convention of using a slash to indicate abbreviation resulted in an R with a straight stroke through its right "leg".[1][b][c] Medieval prescriptions invariably began with the instruction from the physician to the apothecary to "take" certain materials and compound them in specified ways.

For a communication to be accepted as a legal medical prescription, it needs to be filed by a qualified dentist, advanced practice nurse, physician, or veterinarian, for whom the medication prescribed is within their scope of practice to prescribe.[citation needed] This is regardless of whether the prescription includes prescription drugs, controlled substances, or over-the-counter treatments.[citation needed]

Prescriptions may be entered into an electronic medical record system and transmitted electronically to a pharmacy. Alternatively, a prescription may be handwritten on preprinted prescription forms that have been assembled into pads, or printed onto similar forms using a computer printer or even on plain paper, according to the circumstances. In some cases, a prescription may be transmitted orally by telephone from the physician to the pharmacist. The content of a prescription includes the name and address of the prescribing provider and any other legal requirements, such as a registration number (e.g., a DEA number in the United States). Unique to each prescription is the name of the patient. In the United Kingdom and Ireland, the patient's name and address must also be recorded. Each prescription is dated, and some jurisdictions may place a time limit on the prescription. In the past, prescriptions contained instructions for the pharmacist to use for compounding the pharmaceutical product, but most prescriptions now specify pharmaceutical products that were manufactured and require little or no preparation by the pharmacist.[citation needed] Prescriptions also contain directions for the patient to follow when taking the drug. These directions are printed on the label of the pharmaceutical product.

The word prescription, from pre- ('before') and script ('writing, written'), refers to the fact that the prescription is an order that must be written down before a drug can be dispensed. Those within the industry will often call prescriptions simply "scripts".

Contents

Every prescription contains who prescribed the prescription, who the prescription is valid for, and what is prescribed. Some jurisdictions, drug types or patient groups require additional information as explained below.

Drug equivalence and non-substitution

Many brand name drugs have cheaper generic drug substitutes that are therapeutically and biochemically equivalent. Prescriptions will also contain instructions on whether the prescriber will allow the pharmacist to substitute a generic version of the drug. This instruction is communicated in a number of ways. In some jurisdictions, the preprinted prescription contains two signature lines: one line has "dispense as written" printed underneath; the other line has "substitution permitted" underneath. Some have a preprinted box "dispense as written" for the prescriber to check off (but this is easily checked off by anyone with access to the prescription). In other jurisdictions, the protocol is for the prescriber to handwrite one of the following phrases: "dispense as written", "DAW", "brand necessary", "do not substitute", "no substitution", "medically necessary", "do not interchange". In Britain's National Health Service, doctors are reminded that money spent on branded rather than generic drugs is consequently not available for more deserving cases.

Prescriptions for children

In some jurisdictions, it may be a legal requirement to include the age of child on the prescription. For pediatric prescriptions some[who?] advise the inclusion of the age of the child if the patient is less than twelve and the age and months if less than five. (In general, including the age on the prescription is helpful.) Adding the weight of the child is also helpful.

Label and instructions

Prescriptions in the US often have a "label" box. When checked, the pharmacist is instructed to label the medication and provide information about the prescription itself is given in addition to instructions on taking the medication. Otherwise, the patient is simply given the instructions. Some prescribers further inform the patient and pharmacist by providing the indication for the medication; i.e. what is being treated. This assists the pharmacist in checking for errors as many common medications can be used for multiple medical conditions. Some prescriptions will specify whether and how many "repeats" or "refills" are allowed; that is whether the patient may obtain more of the same medication without getting a new prescription from the medical practitioner. Regulations may restrict some types of drugs from being refilled.

Writing prescriptions

Globe icon.

The examples and perspective in this section deal primarily with the United States and the United Kingdom and do not represent a worldwide view of the subject. You may improve this section, discuss the issue on the talk page, or create a new section, as appropriate. (September 2017) (Learn how and when to remove this message)

Legal capacity to write prescriptions

National or local (e.g. US state or Canadian provincial) legislation governs who can write a prescription. In the United States, physicians (either M.D., D.O. or D.P.M.) have the broadest prescriptive authority. All 50 US states and the District of Columbia allow licensed certified Physician Assistants (PAs) prescription authority (with some states, limitations exist to controlled substances). All 50 US states and the District of Columbia, Puerto Rico and Guam allow registered certified nurse practitioners and other advanced practice registered nurses (such as certified nurse-midwives) prescription power (with some states including limitations to controlled substances). Many other healthcare professions also have prescriptive authority related to their area of practice. Veterinarians and dentists have prescribing power in all 50 US states and the District of Columbia. Clinical pharmacists are allowed to prescribe in some US states through the use of a drug formulary or collaboration agreements. Florida pharmacists can write prescriptions for a limited set of drugs. In all US states, optometrists prescribe medications to treat certain eye diseases, and also issue spectacle and contact lens prescriptions for corrective eyewear. Several US states have passed RxP legislation, allowing clinical psychologists who are registered as medical psychologists and have also undergone specialized training in script-writing, to prescribe drugs to treat emotional and mental disorders.

In August 2013, legislative changes in the UK allowed physiotherapists and podiatrists to have independent prescribing rights for licensed medicines that are used to treat conditions within their own area of expertise and competence. In 2018 this was extended to paramedics.

Standing orders

Some jurisdictions allow certain physicians (sometimes a government official like the state Secretary of Health, sometimes physicians in local clinics or pharmacies) to write "standing orders" that act like a prescription for everyone in the general public. These orders also provide a standard procedure for determining if administration is necessary and details of how it is to be performed safely. These are typically used to authorize certain people to perform preventive, low-risk, or emergency care that would be otherwise logistically cumbersome to authorize for individual patients, including vaccinations, prevention of cavities, birth control, treatment of infectious diseases, and reversal of drug overdoses.

Legibility of handwritten prescriptions

Doctors' handwriting is a reference to the stereotypically illegible handwriting of some medical practitioners, which sometimes causes errors in dispensing. In the US, illegible handwriting has been indirectly responsible for at least 7,000 deaths annually.

Some jurisdictions have legislatively required prescriptions to be legible—Florida specifies "legibly printed or typed"—and the Institute for Safe Medication Practices advocated the elimination of handwritten prescriptions altogether. There have been numerous devices designed to electronically read the handwriting of doctors, including electronic character recognition, keyword spotters, and "postprocessing approaches", though the gradual shift to electronic health records and electronic prescriptions may alleviate the need for handwritten prescriptions altogether. In Britain's NHS, remaining paper prescriptions are almost invariably computer printed, and electronic (rather than paper) communication between surgery and pharmacy is increasingly the norm.

Conventions for avoiding ambiguity

Over the years, prescribers have developed many conventions for prescription-writing, with the goal of avoiding ambiguities or misinterpretation. These include:

Careful use of decimal points to avoid ambiguity:

Avoiding unnecessary decimal points and trailing zeros, e.g. 5 mL rather than 5.0 mL, 0.5 rather than .50 or 0.50, to avoid possible misinterpretation as 50.

Always using leading zeros on decimal numbers less than 1: e.g. 0.5 rather than .5 to avoid misinterpretation as 5.

Directions written out in full in English (although some common Latin abbreviations are listed below).

Quantities given directly or implied by the frequency and duration of the directions.

Where the directions are "as needed", the quantity should always be specified.

Where possible, usage directions should specify times (7 am, 3 pm, 11 pm) rather than simply frequency (three times a day) and especially relationship to meals for orally consumed medication.

The use of permanent ink is encouraged.

Avoiding units such as "teaspoons" or "tablespoons".

Writing out numbers as words and numerals ("dispense #30 (thirty)") as in a bank draft or cheque.

The use of the apothecaries' system or avoirdupois units and symbols of measure – pints (O), ounces (℥), drams (ℨ), scruples (℈), grains (gr), and minims (♏︎) – is discouraged given the potential for confusion. For example, the abbreviation for a grain ("gr") can be confused with the gram, abbreviated g, and the symbol for minims (♏︎), which looks almost identical to an 'm', can be confused with micrograms or metres. Also, the symbols for ounce (℥) and dram (ℨ) can easily be confused with the numeral '3' and the Latin letter ezh, 'Ʒ' and the symbol for pint (O) can be easily read as a '0'. Given the potential for errors, metric equivalents should always be used.

The degree symbol (°), which is commonly used as an abbreviation for hours (e.g., "q 2-4°" for every 2–4 hours), should not be used, since it can be confused with a '0' (zero). Further, the use of the degree symbol for primary, secondary, and tertiary (1°, 2°, and 3°) is discouraged, since the former could be confused with quantities (i.e. 10, 20 and 30, respectively).

Micrograms are abbreviated "mcg" rather than "μg" (which, if handwritten, could easily be mistaken for "mg" (milligrams). Even so, pharmacists must be on the alert for inadvertent over- or under-prescribing through a momentary lapse of concentration.

Abbreviations

Main article: List of abbreviations used in medical prescriptions

Many abbreviations are derived from Latin phrases. Hospital pharmacies have more abbreviations, some specific to the hospital. Different jurisdictions follow different conventions on what is abbreviated or not. Prescriptions that do not follow area conventions may be flagged as possible forgeries.

Some abbreviations that are ambiguous, or that in their written form might be confused with something else, are not recommended and should be avoided. These are flagged in the table in the main article. However, all abbreviations carry an increased risk for confusion and misinterpretation and should be used cautiously.

Non-prescription drug prescriptions

Over-the-counter medications and non-controlled medical supplies such as dressings, which do not require a prescription, may also be prescribed. Depending upon a jurisdiction's medical system, non-prescription drugs may be prescribed because drug benefit plans may reimburse the patient only if the over-the-counter medication is taken at the direction of a qualified medical practitioner. In the countries of the UK, National Health Service (NHS) prescriptions are either free or have a fixed price per item; a prescription may be issued so the patient does not have to purchase the item at commercial price.

Some medical software requires a prescription.

Legislation may define certain equipment as "prescription devices". Such prescription devices can only be used under the supervision of authorized personnel and such authorization is typically documented using a prescription. Examples of prescription devices include dental cement (for affixing braces to tooth surfaces), various prostheses, gut sutures, sickle cell tests, cervical cap and ultrasound monitor.[citation needed]

In some jurisdictions, hypodermic syringes are in a special class of their own, regulated as illicit drug use accessories[42] separate from regular medical legislation. Such legislation often allows syringes to be dispensed only with a prescription.[citation needed]

History

The idea of prescriptions dates back to the beginning of history. So long as there were medications and a writing system to capture directions for preparation and usage, there were prescriptions. The oldest known medical prescription text was found at Ebla, in modern Syria, and dates back to around 2500 BCE.

Modern prescriptions are actually extemporaneous prescriptions (from the Latin ex tempore, 'at/from the time'), meaning that the prescription is written on the spot for a specific patient with a specific ailment. This is distinguished from a non-extemporaneous prescription that is a generic recipe for a general ailment. Modern prescriptions evolved with the separation of the role of the pharmacists from that of the physician. Today the term extemporaneous prescriptions is reserved for compound prescriptions that requires the pharmacist to mix or compound the medication in the pharmacy for the specific needs of the patient.[citation needed]

Predating modern legal definitions of a prescription, a prescription traditionally is composed of four parts: a superscription, inscription, subscription, and signature.

The superscription section contains the date of the prescription and patient information (name, address, age, etc.). The symbol "℞" separates the superscription from the inscriptions sections. In this arrangement of the prescription, the "℞" is a symbol for recipe or literally the imperative "take!" This is an exhortation to the pharmacist by the medical practitioner, "I want the patient to have the following medication"[49] – in other words, "take the following components and compound this medication for the patient".

The inscription section defines what is the medication. The inscription section is further composed of one or more of:

a basis or chief ingredient intended to cure (curare)

an adjuvant to assist its action and make it cure quickly (cito)

a corrective to prevent or lessen any undesirable effect (tuto)

a vehicle or excipient to make it suitable for administration and pleasant to the patient (jucunde)

The subscription section contains dispensing directions to the pharmacist. This may be compounding instructions or quantities.

The signature section contains directions to the patient and is often abbreviated "Sig. or "Signa." It also obviously contains the signature of the prescribing medical practitioner though the word signature has two distinct meanings here and the abbreviations are sometimes used to avoid confusion.

Thus sample prescriptions in modern textbooks are often presented as:

Rx: medication

Disp.: dispensing instructions

Sig.: patient instructions

Use of technology

Further information: Electronic prescribing and electronic health record

As a prescription is nothing more than information among a prescriber, pharmacist and patient, information technology can be applied to it. Existing information technology is adequate to print out prescriptions. Hospital information systems in some hospitals do away with prescriptions within the hospital. There are proposals to securely transmit the prescription from the prescriber to the pharmacist using smartcard or the internet. In the UK a project called the Electronic Transfer of Prescriptions (ETP) within the National Programme for IT (NPfIT) is currently[when?] piloting such a scheme between prescribers and pharmacies.

Within computerized pharmacies, the information on paper prescriptions is recorded into a database. Afterwards, the paper prescription is archived for storage and legal reasons.

A pharmacy chain is often linked together through corporate headquarters with computer networking. A person who has a prescription filled at one branch can get a refill of that prescription at any other store in the chain, as well as have their information available for new prescriptions at any branch.

Some online pharmacies also offer services to customers over the internet, allowing users to specify the store that they will pick up the medicine from.

Many pharmacies now offer services to ship prescription refills right to the patient's home. They also offer mail service where you can mail in a new, original prescription and a signed document, and they will ship the filled prescription back to you.

Pharmacy information systems are a potential source of valuable information for pharmaceutical companies as it contains information about the prescriber's prescribing habits. Prescription data mining of such data is a developing, specialized field.

Many prescribers lack the digitized information systems that reduce prescribing errors. To reduce these errors, some investigators have developed modified prescription forms that prompt the prescriber to provide all the desired elements of a good prescription. The modified forms also contain predefined choices such as common quantities, units and frequencies that the prescriber may circle rather than write out. Such forms are thought to reduce errors, especially omission and handwriting errors and are actively under evaluation.

0 notes

Text

Flexo automation and the shift to digital and hybrid labels

The pressure-sensitive label industry in India continues to grow as packed and labeled products in numerous types of containers, formats, and sizes multiply. Every food and snack product is available in various exotic and localized flavors. You can now buy packs of Hershey’s chocolates filled with California almonds with guava and Mexican chilli flavor, or Hershey’s Exotic Dark blueberry and acai flavored centers. Also, you can find Mazan chocolate cubes filled with paan flavour and many other products in the market with a variety of localized flavors including Kurkure packs with ‘UP Taste.’ In short, the number of SKU’s of pouches and labeled containers have substantially multiplied.

It is no longer about flexo versus digital versus flexo. At the Labelexpo India in 2022, the European plate and roller manufacturers said that ‘digital is the death of flexo.’ To bolster their views they pointed to challenges such as print density, banding, and handling newer substances – a virtual laundry list of difficulties with digital label production.

Digital printing has found its place in various label applications, especially when personalization, variable data, and shorter print runs are required. Flexo holds significant advantages in terms of cost-effectiveness in large-volume production runs and printing on certain materials and increasingly for short-run flexible packaging, especially with the widespread availability of locally manufactured presses.

Managing shorter print runs is challenging for flexo converters, considering the cost of creating printing plates, time-consuming press set-up, and set-up waste. Adding flexo units to a digital module in a hybrid configuration, or investing in a digital roll-to-roll press alongside established flexo lines has helped converters adopt a more sustainable ‘print-on-demand’ business model for shorter-run labels and packaging.

Hybrid printing can be a more sustainable and economical approach. “The flexo technologies being retrofitted with add-on features to a digital press are referred to as hybrid,” explained Ajit Bharadwaj of Vinsak. “Features such as variable data printing, foiling, stamping, die-cutting, and more automated features are increasingly in demand among converters. Reducing avoidable print waste saves both converters and brands money and reduces the need to handle excess printed stock,” he said.

Parwez Izhar, senior vice president of the printing cylinders business at UFlex shares that the Indian packaging industry is witnessing a surge in smart packaging that features technologies such as track-and-trace systems integrated into labels and packaging including RFID, NFC, QR codes, holograms, and more.

Izhar explains that approximately 20% of the gravure market share has shifted to flexo, primarily due to its cost-effectiveness and faster turnaround time. He says, “In the label industry, both flexo and digital are gaining ground, and with the increasing demand for short-run jobs, converters are also turning to digital.”

“However, converters are not focusing on just one approach, they are thinking about growth. Many opt for both technologies—if they have flexo, they add digital. Converters recognize the demand for a premium look and feel, so the future lies in hybrid technologies that can meet all the quality, volume, and variable data requirements,” Izhar adds.

The automated flexo presses that include hybrid LED UV systems, die-cut units, pre-register, auto-register, movable turn bar, lam and relam units, peal and seal kits, and foiling stations for labels, shrink sleeves, and flexible packaging are increasing in global demand. Faridabad-based Multitec’s mid-web flexo presses can print on various substrates including thin and extensible materials with capability ranging from 10 microns up to 450 microns at 200 meters a minute with impressive registration and low setup wastage.

Multitec generally leads the industry in new technology adoption and implementation with 40% of its manufacturing being exported. Amit Ahuja, managing director of Multitec explained, “The growing short-run demand is creating a market space for digital. This does not pose any threat to veteran flexo users – but the future is in the hybrid production of labels together with the increasing demand for more automation features and quicker and more precise make-ready solutions.”

0 notes

Text

NIICE Creative Media upgrades print quality with Canon

A creative designing agency working for clients from diverse market segments, businesses, and different walks of life, Chennai-based NIICE Creative Media is known for its bespoke designs and quality print solutions. The quality of its graphic prints has been redefined following the installation of a Canon imagePRESS V700, bought from Canon India.

Established in the year 2009, NIICE Creative Media has been a one-stop corner for complete designing and printing solutions. Narrating the company’s phases of development, Rajkumar, director of NIICE Creative Media, says, “After a brief run of a Canon press till 2011, we abruptly stopped our printing activity which we outsourced for some time.”

“Now, we have the imagePRESS V700, a machine with compact footprint and outsized performance, clicking all the boxes of our requirement,” adds Rajkumar. Certainly, imagePRESS V700 is packed with advanced features and capabilities that make the machine best among those in its class. It is designed and engineered to cater superior graphic prints in outstanding textures.

Talking about their expansive client base, Rajkumar says, “We have been a creative partner for many corporate biggies at pan-India level. Our client list consists of many businesses engaging in manufacture of home-made food and herbal products in Chennai city for which we provide complete labels and packaging prints. We design and print end products like labels, stickers, packaging boxes, cartons, etc. In this, imagePRESS V700 has been the key to overall printing of high-quality graphics.”

Capable of operating at the speed of 71 ppm (pages per minute), imagePRESS V700 is a marvel in delivering stunning graphic prints in resolution of 2400x2400 dpi, using the R-VCSEL imaging technology. Yet another advancement of this digital color production press is its flexible media handling capacity. It takes in a broad array of lightweight as well as heavyweight media ranging from 52 gsm up to 350 gsm. So efficiently, it adheres to special media such as covers, envelopes, synthetics, and long sheets.

Rajkumar mentions that they are now progressively expanding the client base which had been drastically squeezed during the Covid-19, like many in the market. “Before the pandemic, we had expanded our client base in the offshore markets too. What we are gearing up is to revive our pre-pandemic client base sooner or later. That’s why we are boosting our activities and reopened our production facility with the installation of the imagePRESS V700,” he concludes.

0 notes

Text

Best Private Label Tea Companies: Your Trusted Partner in Contract Manufacturing

Tea is one of the most consumed beverages worldwide, and businesses looking to enter the tea market have a fantastic opportunity with private label tea and contract manufacturing of tea. Whether you're a retailer, a startup, or a brand looking to expand, working with the best private label tea companies can help you create unique blends and packaging to establish your brand in the market.

Why Choose Private Label Tea?

Private label tea allows businesses to sell high-quality tea under their brand name without the need to manage production. This approach offers several benefits:

Customization: Choose your tea blends, flavors, and ingredients.

Branding Control: Design your packaging and create a unique identity.

Cost Efficiency: Avoid manufacturing setup costs and focus on marketing.

Scalability: Easily expand your product line with new tea variants.

Contract Manufacturing of Tea: How It Works

If you want to launch your tea brand without investing in production, contract manufacturing of tea is the perfect solution. The process involves:

Selection of Tea Blends – Choose from premium loose-leaf teas, herbal infusions, or flavored varieties.

Customization & Branding – Work with the manufacturer to develop your unique packaging and branding.

Production & Packaging – The manufacturer processes and packages the tea according to your specifications.

Quality Control & Delivery – Ensuring your product meets high-quality standards before shipping.

At Sugandh Tea, we specialize in private label tea packaging to help businesses launch their tea brands with ease.

Private Label Tea Packaging: Stand Out in the Market

One of the key elements of selling tea successfully is private label tea packaging. Packaging plays a vital role in attracting customers and maintaining the freshness of tea. We offer:

Custom Tea Bags & Loose Leaf Packaging – Choose from eco-friendly, resealable pouches, tins, or boxes.

Attractive Branding Options – Get your logo, tagline, and colors printed for a professional look.

FDA & FSSAI Compliance – Ensuring all packaging meets food safety regulations.

White Label Tea: Expand Your Brand Effortlessly

For businesses looking to sell pre-formulated, high-quality tea under their name, white label tea is an excellent option. This allows brands to:

Launch tea products faster without R&D costs.

Access premium tea blends already tested for quality.

Save time on product development and focus on marketing.

Choosing the Right White Label Tea Manufacturer

A reliable white label tea manufacturer can help you bring high-quality tea to market without the hassle of sourcing ingredients or manufacturing. Look for a manufacturer that:

Offers a Variety of Tea Blends – Green tea, black tea, herbal, and organic options.

Provides Custom Branding – Custom packaging and labeling services.

Meets Industry Standards – Quality certifications like ISO, GMP, or organic certifications.

At Sugandh Tea, we provide premium white label tea manufacturing and private label tea packaging, helping businesses grow their tea brands with high-quality products.

Conclusion

If you're looking for the best private label tea companies or a white label tea manufacturer, Sugandh Tea is your go-to partner. We offer premium contract manufacturing of tea, custom private label tea packaging, and high-quality blends to help your brand stand out.

📌 Visit us today: Sugandh Tea Private Label Services

Ready to launch your own tea brand? Contact us to start your private label tea journey!

0 notes

Text

How Does an Automatic Pouch Packaging Machine Work?

In today’s fast-paced industrial landscape, packaging plays a crucial role in ensuring product safety, enhancing shelf appeal, and improving overall efficiency. Businesses across various industries rely on Automatic Pouch Packaging Machines to streamline their production lines and maintain product quality. But how do these machines function? Let’s explore the working process of an Automatic Pouch Packaging Machine and why choosing a reliable Automatic Pouch Packaging Machine Manufacturer like Ambika Packaging Solution is essential.

Understanding Automatic Pouch Packaging Machines

An Automatic Pouch Packaging Machine is a high-speed, precision-based equipment designed to fill and seal pouches efficiently. These machines are widely used in industries such as food & beverage, pharmaceuticals, chemicals, cosmetics, and more. By automating the packaging process, businesses can achieve greater consistency, reduce labor costs, and increase productivity.

Step-by-Step Working Process of an Automatic Pouch Packaging Machine

1. Pouch Loading and Feeding

The process starts with pouch loading, where pre-formed pouches are fed into the machine. Some machines come with an automatic feeding system that picks up the pouches from a stack and places them into the designated position for further processing.

2. Pouch Detection and Alignment

Once the pouches are fed into the system, sensors detect their presence and ensure proper alignment. This step is critical to avoid errors such as misaligned sealing or improper filling, which could compromise the packaging quality.

3. Pouch Opening

After alignment, the machine opens the pouch using vacuum suction or mechanical grippers. This step ensures that the pouch is fully open and ready to receive the product without any obstructions.

4. Product Filling

The filling station dispenses the pre-measured product into the open pouch. Different types of filling mechanisms are used depending on the nature of the product:

Auger Fillers – Used for powders like spices, flour, and coffee.

Liquid Fillers – Ideal for juices, oils, and sauces.

Weigh Fillers – Used for granular and solid products like snacks, nuts, and dry fruits.

5. Excess Air Removal (Optional)

In some packaging processes, excess air is removed from the pouch to increase product shelf life and maintain freshness. This is especially important in food packaging.

6. Pouch Sealing

Once the product is filled, the pouch moves to the sealing station. The machine applies heat and pressure to seal the pouch effectively. There are different sealing techniques, such as:

Heat Sealing – Commonly used for plastic and laminated pouches.

Ultrasonic Sealing – Used for delicate packaging materials and provides a strong seal without excessive heat.

7. Coding and Labeling (Optional)

Many Automatic Pouch Packaging Machines integrate a coding system to print batch numbers, manufacturing dates, expiration dates, and barcodes on the pouch. This step ensures compliance with industry regulations and enhances traceability.

8. Pouch Cutting and Discharge

After sealing, the machine cuts the pouch to separate it from the next one (if applicable) and then discharges the finished product onto a conveyor belt or collection area for final inspection and packaging.

9. Quality Check and Sorting

A final quality check ensures that the pouches are properly sealed, labeled, and free from defects. Any defective pouches are rejected automatically to maintain the highest packaging standards.

Benefits of Using an Automatic Pouch Packaging Machine

Increased Efficiency – Automating the packaging process significantly reduces downtime and improves production speed.

Consistent Quality – Ensures uniform filling, sealing, and packaging, eliminating human errors.

Reduced Labor Costs – Minimizes the need for manual intervention, cutting down labor expenses.

Versatility – Can handle a variety of pouch materials, shapes, and sizes.

Enhanced Product Shelf Life – Proper sealing techniques help prevent contamination and spoilage.

Customization Options – Machines can be tailored to suit specific industry requirements.

Choosing the Right Automatic Pouch Packaging Machine Manufacturer

Selecting a reliable Automatic Pouch Packaging Machine Manufacturer is crucial for ensuring durability, efficiency, and quality. Ambika Packaging Solution is a trusted name in the industry, offering state-of-the-art packaging machines tailored to various industrial needs. Here’s why you should choose Ambika Packaging Solution:

Advanced Technology – They use cutting-edge technology to manufacture high-performance packaging machines.

Customization – They provide tailored solutions to meet specific business requirements.

Quality Assurance – Machines undergo rigorous quality checks to ensure reliability and efficiency.

After-Sales Support – Dedicated customer support ensures seamless operation and minimal downtime.

Industry Expertise – Years of experience in the packaging industry make them a preferred choice among businesses.

Conclusion

An Automatic Pouch Packaging Machine is a game-changer for industries looking to enhance efficiency and maintain high packaging standards. By automating the pouch filling and sealing process, businesses can achieve consistent quality, reduce costs, and increase productivity. Choosing a reliable Automatic Pouch Packaging Machine Manufacturer, such as Ambika Packaging Solution, ensures that you get a high-quality machine tailored to your industry needs.

If you’re looking for a trusted partner in packaging automation, Ambika Packaging Solution offers cutting-edge solutions to streamline your packaging operations. Contact them today to learn more about their innovative packaging machines!

#Automatic Pouch Packaging Machine Manufacturer#Packaging Solutions Near Me#Packaging Machine Manufacturer in Haryana#Liquid Packaging Machines Manufacturer

0 notes

Text

How to Buy 500ml Glass Bottles in Bulk: A Smart B2B Guide

Whether you're a distillery, beverage brand, or packaging supplier, sourcing the right 500ml glass bottles requires balancing quality, cost, and reliability. This step-by-step guide helps you make the best purchasing decisions—without unnecessary risks.

Step 1: Define Your Needs

Before reaching out to suppliers, answer these key questions: ✔ Glass Type – Clear, amber, or green? (Affects UV protection & branding) ✔ Neck Size – Standard 28mm, 38mm, or custom? (Critical for cap compatibility) ✔ Design – Stock bottles, custom shapes, or pre-labeled options? ✔ Quantity – Small trial order (1,000–5,000) or bulk (10,000+ units)?

Pro Tip: If you're testing the market, start with stock bottles and add custom labels later—it’s cheaper than investing in a full mold.

Step 2: Choose a Supplier

Option 1: Local Manufacturers (Higher Cost, Faster Delivery)

✅ Pros: Quick turnaround, easier quality control ❌ Cons: More expensive (typically $1.50–$4.00/bottle) 📍 Best for: Urgent orders, small MOQs

Option 2: Overseas Wholesalers (Lower Cost, Longer Lead Times)

✅ Pros: Budget-friendly (as low as $0.40–$1.20/bottle from China/India) ❌ Cons: 6–10 week shipping, requires strict QC checks 📍 Best for: Large bulk orders

Where to Find Suppliers?

Alibaba (for global manufacturers)

ThomasNet (for US/EU-based suppliers)

Step 3: Compare Pricing & MOQs

What Affects Cost?

Customization (molds, embossing, colored glass)

Glass thickness (heavier = higher cost)

Shipping & import duties

Step 4: Ensure Quality Before Bulk Ordering

Avoid defective bottles by: 🔍 Requesting samples (check for bubbles, rough edges, uniformity) 📏 Measuring dimensions (especially neck finish and height) 🧪 Testing durability (drop test from 3 feet to check breakage resistance)

Red Flags in a Supplier: 🚩 No product certifications (FDA, LFGB, ISO) 🚩 Unwillingness to provide a sample 🚩 Vague answers about lead times

Step 5: Optimize Shipping & Logistics

For Large Orders: Use full container loads (FCL) for the lowest shipping cost

For Small Orders: Consider air freight (faster but expensive) or LCL (Less Container Load)

Storage Solutions: Some suppliers offer dropshipping to save warehousing fees

Where to Buy 500ml Glass Bottles?

Need reliable 500ml glass bottle suppliers? At glass bottles manufacturer, we connect businesses with trusted manufacturers, offering: ✅ Low MOQs (starting at 1,000 units) ✅ Custom branding options (screen printing, embossing, colored glass) ✅ Quality assurance (pre-shipment inspections available)

👉 [Get a Free Quote Today] 500ml glass bottle

0 notes