#Polyurethane wheels

Explore tagged Tumblr posts

Text

Polyurethane wheels in india We take pride in introducing ourselves as a leading organization with rich industry experience, engaged in offering Polyurethane Wheels. These are manufactured using premium quality plastics according to the defined industry standards.We are a Noted Manufacturer and Supplier of all type wheel.

For More Detail :- https://www.proniercastorwheel.com/caster-wheels.html

0 notes

Text

Additionally, polyurethane wheels are non-marking, so work well on both hard and soft surfaces (think tile, wood, laminate, and concrete flooring), while still being able to support exceptionally heavy loads.

0 notes

Text

#PU Castors#Nylon Castors#Polyurethane Castors#castors wheels#PU Wheel Castors#Nylon Wheel Castors#castors and wheels#Which is a Better Castors

0 notes

Text

Polyurethane wheel in forklift

View On WordPress

0 notes

Text

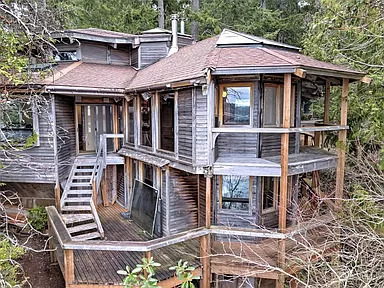

This 1975 fixer upper in Shelton, WA used to be an art/pottery studio & home on Harstine Island in the middle of Puget Sound, so it's a great location. Has 2bds, 2ba, and lots of potential. Asking $595K. I like it, see what you think.

So, it's a little weather beaten on the exterior. I wonder if that's some of the pottery they made.

If you're a wood lover, you'll be into this house. The carpet isn't bad, but that wallpaper would have to go. It's too dull for my taste.

Very unusual architecture. The interior really isn't that bad. This wood looks to be in good shape.

Large living room with a modern fireplace. The walls and ceiling look new with lovely skylights. Big windows provide a beautiful view of the sound.

Look at this fabulous feature. Love this.

I like the kitchen, it's different and has a great work triangle setup. I would just give the cabinets a light sanding and a couple of coats of polyurethane. The floor needs some TLC, too.

How cool is this? Look at that stove. The floor is worn so it looks like they spent a lot of time here. I don't blame them, it's cozy AF. All it needs is some new cushions and covers.

The back door- the hall has a lof of space for coats and stuff.

How gorgeous is this 2 story library? All it needs is a new set of cushion covers.

Cute little wood stove by the stairs.

Primary bedroom has built-ins and a big window w/a great view.

Nice closet/dressing area.

Large en-suite has vintage double sinks. This house is not bad inside, you could give it a good cleaning and live here while you do the work.

Sunken tub and shower. Look at the little door above the tub.

Check this out, a water closet with a marble top sink and interesting toilet.

There are decks all around the house, and here's a large one over the carport. Now let's have a look at the studio.

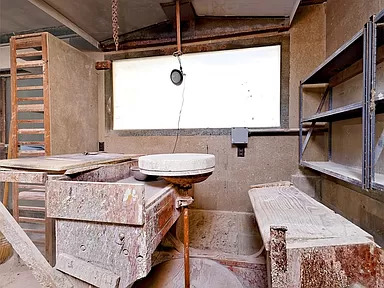

Oh, wow, this is huge.

This is fabulous.

Look, they left the pottery wheel and the area where they do the clay. So cool.

Upstairs in the loft. This has potential. It could be made into an apt. for an artist.

The banks of the Puget Sound.

This is how close it is to the water.

2.13 acre lot. Does this mean that you own part of the water in the sound?

https://www.zillow.com/homedetails/970-E-Maples-Rd-Shelton-WA-98584/60923977_zpid/?

390 notes

·

View notes

Text

no one will feed you anymore...

oh, y’all know what time it is by now, don’t you? 😈🥺😈 i stretched the definition of this delightful prompt - @whumpmasinjuly day 12: caught - and it really stirred my creativity! so it's time for morja to sufferrrrrrrrrr...😭😭😭

(sidenote: this training scenario was heavily insp. by this incredible art by @elgrajaz cause it gives such whumperflies 😍)

title insp. by this concept art quote by jenny holzer - "if you're considered useless, no on will feed you anymore."

~

Your job today is to run.

Until, anotèros?

There’s a blister on his ankle already. The friction of the shoe against skin, the rub-rub-rub, burn, burn, heat, sore, heat, foot falling flat against the ground, push off, spring forward, burn.

Until you catch up.

Morja blinks wet into his eyes and it stings, blurs, his feet pound their rhythm still. Can’t wipe it away. Keep going. He knows where he’s going and he doesn’t need to see. Just run.

Chase the buggy. The small white cart and the whine of the wheels as it speeds ahead, the anotèros driving, the anotèros with the stopwatch in his hand, the black glasses, don’t watch his face, just run.

He has caught the buggy before. Dog with rabbit in his teeth. Grab the bar, swing himself into the backseat, stopwatch clicking stop.

But it is so hot.

What is this track made of, anotèros?

His trainer’s eyes had squinted, slitted sideways down at Morja, and the skin of his palms itched.

The burn is all over. Heat. Heat in the legs, the thighs, the feet, the pulse of fire through each foot.

Raw, sharp, prick of fire, as the blister peels. Heat. Blood. Blood in the sock. Bad. Wash later. Run.

Keep going.

Keep going.

The heat is inescapable. It’s the worst part, really, of anything. He’s lived in heat. Used to heat. Born in it, raised in it, put in it day after day and still, it is the most inescapable.

Polyurethane, mostly. Does that answer your question, diathèsimòs?

Morja’s palms itched harder and he squeezed them into balls behind his back.

Yes, sir. Thank you, sir.

Good. Now get out there and run.

Fire jars through his chest with each breath, breath dragging sharp across his lungs, filling up with knives, throat a razor trap, chest a dozen blade tips. Breathing out is an ache but better, better than swallowing the fire of air.

Back straight. Drag air through the nose. Thick, rubber-scented, hot. It’s so hot in the building, foggy, every window had fog on it when he walked in today.

Polly-your-a-thane. Rubber. That’s the smell. Mixed with latex. The stuff that sticks to skin. Poured over asphalt. Bouncy over solid.

Knowing why your shoes stick to the track in the rain, in the heat, in the cold, doesn’t make you faster. It doesn’t help.

Morja sees sweat gleam on his trainer’s head, wrist swiping it away, the stopwatch gleaming bright, pinpoint-sharp, and the lights are bright. Big bulbs in the ceiling that hum against his skin they’re so blue-bright-sharp.

Keep up.

His sides pulse. The pulse has started now and the stabbing will only get stronger. Stitch. A needle pulling air through his body on a barbed thread. Poke. Drag. Poke. Drag.

They haven’t told you to stop.

Morja always has to remind himself his throat isn’t bleeding. It feels like it is. It isn’t. Not like his feet. Those are bleeding.

He can’t even hear the clink of his cuffs, thick leather slick and sticking to his flesh in an itching snick-snick-snick at every jostle. The piston of his elbows at his sides is short and doesn’t yank the chains trailing behind the buggy.

The slow whir of wheels-on-rubber is just a buzz now. Everything is a buzz, ears full of static, only the thudthudthud of blood rushing, water, past his ears, like his head is under the water, don’t think just run.

He won’t catch up to the buggy if he doesn’t run.

(It will outrun him anyway. That’s the point. It has to. Of course it will. It’s a buggy and Morja is on foot. There is no point.)

No. He can catch the buggy. He was told to and he can.

Keep the pace. This track doesn’t end. Run.

Inescapable.

Run.

He is a diathèsimòs and he must keep running.

The thud of his shoes against the track, the springing-then-solid, the reaching out with one hand, no, not close enough to reach and sweat blinds him again. Fuck.

He should have caught them already.

He must catch them.

Every step burns. Every breath burns. The lights burn. The track is a circle and he rounds a corner into a corner into a corner in pursuit.

The length of chain yanks, every step jolts his ribs against the inside of his skin, like every step jolts cuff against wrist, the chain growing tauter, the breaths shorter, harsher, dragging, razorwire, like the lungs being whipped.

The shredded grunt of each breath can’t be coming from him, he doesn’t think, but it must be. It’s so loud in his ears, like his heartbeat, as knife of breathing stabs, stabs, stabs.

The buggy is getting further away, inch by inch, and there is no way his lungs can bleed, like a horse. He is a diathèsimòs and his lungs don’t bleed.

Breathing and seeing are fire.

Hot rubber and hot copper and the itch of sweat is all he can think about. The sting of it in his open blisters. The crawl of it down the waistband of the pants, into the neck of the shirt, in his dry mouth like spit, in his dry eyes like tears.

The track is designed to help you not slip. That’s how running tracks are made. That’s why the rubber smells so strong.

But a stab, too-sharp, too-blinding, doubles him. He jerks against the cuffs and it’s done. The buggy keeps going and Morja doesn’t and his shoes fly out from under him and he hits the track.

Rubber. Asphalt. Body.

All the ragged breath is slammed from his lungs as his chest hits the ground, chin tucked against the fall, and the track burns across every inch, shoulders sharp and shocking at the jarring pull, pull, pull, dragged behind the buggy-

“Stop! Time.”

The burning stops and Morja lays there, heaving, light pulsing with every sharp heartbeat behind his eyelids, and he’s curled up on the ground, arms stretching out with their chains behind the buggy.

Get up.

He can’t.

Then kneel.

Rolling, belly first, then dragging one leg, burning, stabbing, shaking, up beneath him. Another. He does kneel up and his lids, bleary, blink open as the shape of his anotèros floats from the buggy. The squeak of leather as the shape bends to crouch in front of him, a rolling smell as sharp and bright and cold as the overhead bulbs swallows him up, clean scent and sharp corners, holding up a gleaming pinpoint in Morja’s face.

The stopwatch.

The only cold Morja’s felt today stabs into the hollow of his stomach as numbers, bright electric lines, become clear.

Slow.

Fuck.

I was slow.

“Gonna have to work on your speed, diathèsimòs. Guess you didn’t manage to catch up. You know the drill - don’t stop running until we’re caught.”

Morja tastes blood in his mouth. Not from his lungs. Of course not. He takes his teeth out of his cheek and the smell of rubber fills his nose as he bows his head to the ground.

Polyurethane, soft against his skin.

“…Yes, anotèros.”

~ oooh, a little glimpse into morja's training regimen, which is very fair and achievable!! 🥺🥺🥺

taglist: @much-ado-about-whumping @haro-whumps @whump-tr0pes @whumpthisway @i-eat-worlds

@wolfeyedwitch @whumpzone @whumping-every-day @redwingedwhump @straight-to-the-pain

@stoic-whumpee @liliability @whatgoeswhumpinthenight @thingsthatgo-whump-inthenight @whumpster-draganies

@whump-me-all-night-long @suspicious-whumping-egg @scoundrelwithboba @kixngiggles @tears-and-lilies

i hope everyone has a very merry @whumpmasinjuly! 💖💖💖

@whumpmasinjuly-archive

#this prompt was a lot of fun to play around with creatively!! 💖#so sorry to morja for making you suffer so much but...listen...it's for character....#morja#morja and company#my writing#whump#whumpee#whumper#exhaustion#slavery#conditioned whumpee#conditioning#environmental whump#training#wij24day12#whumpmasinjuly2024

31 notes

·

View notes

Text

More dye adventures with Zonda Journey, Zephyr Slip alt deco

Okay, this is going to be a bit text heavy and process oriented, and there's no snazzy new design to show off, just sharing my process a bit as it develops.

April wanted her copy of Zephyr Slip in custom colors, so following Transformers redeco tradition, Zephyr now has a sister, Zonda Journey. (The Zonda is a wind from the mountains in Argentina, though far to the west of the locale where Austroraptor was discovered.)

The build was a mixed success but a learning experience in my pursuit of a dying process that results in uniform, predictable, and durable color.

Aside from a more stable kickstand, Zonda's design didn't change much from Zephyr's. For ease of dying and painting, the scooter floor, wing insets, and nasal / maxilla area were all separate pieces this time and glued into place with two-part epoxy, but not much else has changed in the model.

The build does differ from Zephyr Slip in that several of Zonda's joints use clear polyurethane rods in place of ABS ones, most importantly in the feet and tail. These have to be threaded into place and cut, but they're compliant, so while posing is a little spongy, they support more weight with more stability and absorb some shock, making the figure less likely to tip over from bumping the shelf.

But back to the dyes. Details like the inside of Zonda's headlights and taillights, and her claw emblem, pinstripes, face details, and rims are painted, and as usual she has paper decals for her eyes and console. But the bulk of her color, everything magenta, purple, or black, is dyed. I'm going to work through those in reverse order here, black, purple, magenta.

Some of the black parts were printed in stock black resin, like the wheels, but I've had difficulty with failed prints using it, and elements like the black sections of the tail and head where I've used white resin and dyed it black end up with a uniform, more satin finish, so I think that I'm going to prefer that method from now on.

Using black ink for brushed-in details like the shoe treads works, but it's risky, because the ink can sometimes find the grain of the printed surface and wick away where I don't want it. Anywhere I intend to do this on future models will require a deep trench in the model to capture the ink, similar to the grooves used for Zonda's pinstriping seen on the part above.

Zonda's darker purple elements could have been more uniform with a couple more tries. Brushing the ink on with any color but black leaves a patchy, cloudy surface, and dying in a bath requires far too much ink. Workbenchmaniac suggested using an airbrush to apply the ink, and that seems to work very well, with a lot less waste than a bath and much more uniform results than brushing, so with a bit more practice, that might be my go-to method for dying parts, especially with a layer of clearcoat on top as here.

Zonda's magenta parts were simply printed in color, but I ran into a novel problem right away that I didn't solve at all: she was never intended to be magenta in the first place. The dyed liquid resin was lavender.

I already knew from working on Nova that dying liquid resin would really only work for pastel colors, and that the color after curing wouldn't quite match the liquid form. Nova's pink was also a little less punchy and fluorescent after printing. But I wasn't prepared for the wild swing around the color wheel this dye underwent with printing and curing.

I've read that alcohol dyes are ironically susceptible to UV photodegradation, but I'm not convinced that's what's at work here. In fact, all of Zonda's headlights and taillights have clear UV resin poured in and cured in place after painting, which means that areas of both the magenta and the surface-dyed purple have been exposed to much longer UV blasting with no visible effect.

So I've learned some things from this process. I think the most reliable tools in my kit in relation to dye are brushed black dye and airbrushed everything else. Airbrushing gives me bright and predictable colors, and with practice I can make them pretty uniform. Black dye, which is always uniform and can go over any other color, is a handy tool for detailing as long as the model is prepared with grooves to control the spread. And breaking elements down into parts that can be dyed separately continues to be a reliable and useful step that saves much more workbench time than it takes in Blender time.

As for Zonda Journey, I have a lot of things to improve on for next time, but I'm reasonably happy with the result for now, and April is happy with her, which is what counts.

7 notes

·

View notes

Text

What Are the Important Parts of an Electric Skateboard?

The following are the crucial parts of an electric skateboard. Without these, most e-boards would work. We’ll go over each of these parts now so you have a better idea of their materials.

Deck: The deck is the “board” in “skateboard”. Usually, it’s a single piece made from one or more materials, like maple, bamboo, fiberglass, or carbon fiber. The deck is then covered in grip tape to provide traction for the rider.

Battery: Most electric skateboard batteries are made of lithium-ion. Lithium polymer and LiPro4 batteries are possible but less common. Lithium batteries do need to be treated a certain way both for the sake of extending their lifespan and for safety.

Motor & Controller & Remote Control & Trucks: These accessories for most electric skateboards are made of metal.

Battery box and ESC case: plastic. The ESC shell of some electric skateboards is equipped with metal sheets, which can dissipate heat better than all plastic shells

Skateboard wheels and straps: Electric skateboard and longboard wheels aren’t any different than the usual kind. Most wheels and straps are made of polyurethane material.

Bearings: Bearings generally have two types of metal bearings and ceramic bearings. At present, most electric skateboards use metal bearings.

2 notes

·

View notes

Text

Adding to this:

For my cars fanfic, I have researched all of the following:

-Mechanical engineering and classic car restoration practices including, but not limited to, chrome electroplating, sheet metal repair pre bondo, types of paint used in cars before the advent of acrylic polyurethane, the sorcery that is metallic paint, etc...

-How to rebuild the front shock and wheel assemblies for a 1949 Oldsmobile 88 Rocket. Someone was nice enough to scan in the contents of an old garage manual...and it's a fascinating read. http://edge-op.org/1949_Oldsmobile/index.php#contents

-Prohibition, and bootlegging in Dawsonville and Atlanta GA, during the 20s, 30s, and 40s

-How to make moonshine

-How to accurately convey, in writing, the fact that one of my OCs speaks with a heavy Appalacian accent (SE Kentucky sub-dialect)

-The origins of NASCAR and how it tied into bootlegging and prohibition

-Historical layouts of the Hudson Motorcar Company, Oldsmobile, and Cadillac factories in Detroit, MI

-Logging practices and logging machinery/equipment

-The size of a 51' Hudson Hornet's gas tank

-Classic stock car racing venues, especially Langhorne Speedway and all the crazy shit that went down there

This is why I read the reddit comments

#cars fandom#pixar cars#cars#cars pixar#disney pixar cars#doc hudson#cars 2006#cars fanfiction#disney cars

124K notes

·

View notes

Video

youtube

4.80/4.00-8 Electric Wheelbarrow Air Wheels, Wagon and Trolley Tire And ...

Provide polyurethane PU Solid and PU foaming equipment, processes, formulas and raw material services Web: www.modicasterwheels.com Email: [email protected] #Lawnmower #Tooltrolley #aerospacemanufacturing #equipment #Lawnmowertire #rollen #flatfreelawnmowertires #factories #productionengineering #flatfreetire #punctureprooftire #industrialsolutions #nhsengland #hospitalmanagement #castors #government #amazing #movingforward #aerospace #automation #gbmfg #innovationculture #innovation #quality #safety #automotiveindustry #engineering #supplychainsolutions #Trolley #manufacturingexcellence #automotive #manufacturinguk #industry #nhslongtermplan #ukmfg #wheels #engineeringuk #manufacturers #retweeet #protectthenhs #blickle #supportthenhs #nhs #supplychain #sourcing #industrial #b2b #industrialsupplies #casters #manufacturing #manufacturingindustry #materialhandling #Wheelbarrow #Dolly #Tools #garden #barrow #carts #caster #castor #cart #pu #Plastic #Solidtire #gardentools #tire #Tyre #weeder #Kart #gokart #shoppingcart #tractor #Handtruck #Handcart #toolcart #Toolbox #wheelchair #stroller #Constructiontools #manufacturer #manufacture #Factory #machine #production #plasticbox #wheelsandtires #casterwheels #wheelchairaccessories #solidtires #wheelchairwheels #wheelchairparts #mobilityscooteraccessories #solidtyres #solidtires #mobilityscooterparts

0 notes

Text

#castorskart#online castor#PU Castors#castors and wheels#top quality castors#industrial grade castors#buy castors online#industrial#india#manufacturer#castors#Polyurethane Castors#Casters#Casters and Wheels

0 notes

Text

PU Timing Belts Manufacturer

We are a professional PU Timing Belts Manufacturer and PU Timing Belts Factory, Our main products include rubber synchronous belts, double-sided belts, coated feeding belts, flat belts, ribbed belts, tooth-ribbed belts, polyurethane timing belts, conveyor belts and synchronous belt wheels, fish-separation belts, endless belts for high-speed packing and printing machines, nut-shell belt, vegetable-cutting belt and all kinds of special processing belt.

0 notes

Text

Caster wheels manufacturing involves the design, production, and assembly of wheels used for mobility and transportation in various applications. Manufacturers utilize materials like rubber, polyurethane, steel, or nylon to create durable and versatile caster wheels. The process includes material selection, precision engineering for the wheel and mounting components, and quality testing to ensure they can withstand varying loads and environments. Caster wheels are widely used in industries such as material handling, furniture, healthcare, and retail, offering mobility solutions for equipment, trolleys, and other load-bearing applications.

0 notes

Text

Why Car Paint Protection Film is a Must-Have for Your Vehicle

When you invest in a car, you’re not just buying a mode of transportation—you’re also investing in its appearance and resale value. Over time, exposure to the elements, road debris, and other hazards can significantly damage your vehicle’s paint. This is where Car Paint Protection Film (PPF) comes in as a game-changer for car owners looking to preserve their vehicle's aesthetics and longevity.

What is Car Paint Protection Film?

Car Paint Protection Film is a clear, durable, and self-healing material designed to protect your car’s paint from scratches, chips, stains, and other forms of damage. Made from a high-performance polyurethane material, PPF is applied to the exterior of the vehicle in areas that are most vulnerable to wear and tear, such as the hood, front bumper, side mirrors, and fenders.

Benefits of Car Paint Protection Film

Protection from Scratches and Chips One of the most significant advantages of PPF is its ability to safeguard your car’s paint from scratches, stone chips, and other physical abrasions. The film acts as a shield, absorbing the impact from road debris, gravel, and even minor brush-ups with branches or parking lot obstacles.

UV and Oxidation Protection UV rays can cause a car’s paint to fade and oxidize over time. PPF acts as a barrier, preventing harmful UV radiation from reaching the paint, thereby preserving its original color and shine for much longer.

Self-Healing Technology Some high-quality paint protection films come with a self-healing feature. This means that minor scratches or swirl marks that occur on the surface of the film can be "healed" by heat—either from the sun or a warm water rinse—restoring the film to its smooth, original state.

Enhanced Resale Value Maintaining your vehicle's paintwork with PPF can significantly boost its resale value. A car that looks well-maintained with minimal visible damage is far more appealing to potential buyers than one with faded or chipped paint.

Easier Cleaning and Maintenance PPF makes cleaning your car much easier. The surface of the film is hydrophobic, meaning it repels water and dirt. As a result, your car will stay cleaner for longer, and when it does get dirty, washing it is a breeze. Moreover, PPF helps prevent water spots, bird droppings, and tree sap from permanently staining your paint.

Invisible Protection One of the best features of Car Paint Protection Film is that it is virtually invisible once applied. It seamlessly blends with your car’s original paint, so you get all the benefits of protection without altering the look of your vehicle.

Areas of Your Car That Benefit from PPF

While PPF can be applied to the entire car, it’s most commonly used in the following areas:

Hood and Front Bumper: These areas are constantly exposed to road debris and insects, making them prime candidates for PPF protection.

Side Mirrors: Mirrors are highly vulnerable to scratches and chips.

Fenders and Wheel Arches: These areas often experience abrasions from gravel and other debris.

Door Edges and Handles: These high-contact areas are prone to scratches from keys and fingernails.

Rocker Panels and Rear Bumper: These areas often take the brunt of debris kicked up by the tires.

The Installation Process

Installing PPF is a meticulous process that requires skill and precision. While some people choose to apply the film themselves, professional installation is highly recommended to ensure optimal results. The process involves carefully cleaning the vehicle’s surface, applying the film using heat and water, and then smoothing it out to ensure there are no bubbles or imperfections. It typically takes a few hours to complete, depending on the size and complexity of the job.

Is PPF Worth the Investment?

The cost of Car Paint Protection Simulator can vary based on the quality of the product and the areas of the vehicle you choose to protect. However, given the long-term benefits—such as preserving your car’s appearance, reducing the need for expensive paint repairs, and enhancing its resale value—many car owners find PPF to be a worthwhile investment.

Conclusion

Car Paint Protection Film is more than just a trend; it’s an essential solution for car owners who want to keep their vehicle looking like new for years to come. With its ability to protect against scratches, UV rays, and everyday wear and tear, PPF is an investment that pays off in both aesthetics and value. If you’re looking to maintain the appearance of your vehicle and safeguard your investment, Car Paint Protection Film is definitely worth considering.

0 notes

Text

FSP New Zealand® takes workplace safety to the next level with its top-quality industrial chocks, including the 055 bracket.

These wheel chocks are essential for securely holding vehicles and preventing accidents. Made from high-density polyethylene and injected with polyurethane, they are lightweight, UV-resistant, and resistant to oil and water.

Designed with ease of use, the chocks are simple to maneuver and built to last.

Trust FSP New Zealand® for reliable safety solutions!

0 notes

Text

Ride Smart: Exploring the Benefits of Adult Scooters

Adult scooters are growing in popularity as a fun, efficient, and eco-friendly transportation option. Whether you're looking to navigate urban streets, commute to work, or enjoy a leisurely ride around your neighborhood, adult scooters offer an excellent blend of convenience and practicality. If you're considering making the switch, now is the perfect time to buy a scooter that fits your needs and lifestyle.

Why Choose an Adult Scooter?

Adult scooters have evolved far beyond their child-friendly counterparts. With durable construction, sleek designs, and advanced features, these scooters cater to a variety of needs:

Eco-Friendly Transportation Using an adult scooter reduces your carbon footprint by offering a greener alternative to cars or public transport. Perfect for short-distance commutes, scooters are energy-efficient and require no fuel or batteries for traditional models.

Portability and Convenience Most scooters for adults are lightweight and foldable, making them easy to carry and store. Whether you’re hopping on public transit or stowing it in your office, these scooters provide unmatched portability.

Health Benefits Riding a scooter engages your core muscles and improves balance. It’s a great way to stay active without putting too much strain on your joints, making it suitable for people of all fitness levels.

Cost-Effective Solution When you Buy Scooter, you’re investing in a one-time purchase that saves on fuel costs, parking fees, and maintenance expenses. Compared to other forms of transport, scooters are an affordable long-term option.

Key Features to Look for When Buying a Scooter

When shopping for an adult scooter, it’s important to prioritize features that align with your needs. Consider these aspects before making your purchase:

Weight Capacity: Ensure the scooter supports your weight comfortably for safe and smooth rides.

Wheel Size and Material: Larger wheels provide better stability, while high-quality rubber or polyurethane wheels enhance durability.

Adjustable Handlebar: Opt for a model with an adjustable handlebar to accommodate your height.

Suspension System: A good suspension minimizes shocks on uneven surfaces, ensuring a comfortable ride.

Braking Mechanism: Reliable brakes are essential for safe stopping, especially when riding at high speeds or on steep terrain.

Tips for Using Your Adult Scooter Safely

Once you’ve found the perfect scooter, it's important to ride responsibly. Here are some tips to ensure safety and enjoyment:

Wear Protective Gear Always wear a helmet, and consider additional protective equipment like knee and elbow pads if you’re new to scooting or riding in busy areas.

Be Mindful of Traffic Rules Respect road signs, ride in designated lanes, and signal when turning. Treat your scooter ride like any other vehicle on the road.

Practice in a Safe Space If you’re new to scooters, start practicing in an open, low-traffic area to get comfortable with balancing and maneuvering.

Perform Regular Maintenance Check your scooter’s wheels, brakes, and folding mechanisms regularly to ensure they’re in top condition.

Where to Buy Scooters for Adults

When it comes to purchasing a high-quality adult scooter, choosing a trusted retailer is essential. Mobileciti.com.au offers a range of reliable and affordable scooters to suit various preferences and budgets. With their commitment to quality and customer satisfaction, Mobileciti ensures that you’ll find the right scooter for your needs.

Conclusion

Adult scooters are not only a practical mode of transport but also a fun way to stay active and explore your surroundings. Whether you’re commuting or riding for leisure, investing in the right scooter can transform your daily routine. Don’t wait—buy a scooter today and enjoy the benefits of eco-friendly, efficient, and stylish mobility.

Find your ideal ride at Mobileciti and take the first step towards smarter, greener transportation.

0 notes