#Polypropylene strapping machine

Text

What is the use of Polypropylene strapping machine?

A Polypropylene strapping machine, also known as a PP strapping machine, is a device used to automate the process of applying polypropylene strapping bands to packages or products. These machines are designed to increase efficiency, consistency, and safety in the strapping process, especially in environments where there's a high volume of packaging or bundling operations. Here are some of the key uses and benefits of Polypropylene strapping machines:

1. Speed and Efficiency:

Automated Operation: Strapping machines can significantly speed up the strapping process compared to manual methods.

Consistent Tensioning: Machines ensure consistent tensioning of the strapping bands, resulting in uniform and secure bundling of packages.

2. Increased Productivity:

Higher Throughput: By automating the strapping process, these machines can handle a larger volume of packages in a shorter amount of time.

Reduced Labor Costs: With less reliance on manual labor, companies can save on labor costs and allocate resources more efficiently.

3. Improved Safety:

Reduced Risk of Injury: Automation reduces the need for manual handling of heavy strapping tools, minimizing the risk of repetitive strain injuries and accidents.

Safer Working Environment: By removing the need for manual tensioning and sealing of strapping bands, these machines contribute to a safer workplace.

4. Consistency and Quality:

Uniform Strapping: Machines ensure consistent tensioning and sealing of strapping bands, resulting in uniformly secured packages.

Reduced Material Waste: Precise control over strapping tension helps minimize material waste by avoiding over-tensioning or under-tensioning of the strapping bands.

5. Versatility:

Adjustable Settings: Many strapping machines offer adjustable settings for strap tension, sealing temperature (if applicable), and other parameters to accommodate various package sizes and types.

Compatibility: Polypropylene strapping machines are compatible with different widths and thicknesses of PP strapping bands, allowing flexibility in packaging applications.

6. Integration and Automation:

Integration with Packaging Lines: These machines can be integrated into existing packaging lines for seamless automation of the strapping process.

Advanced Features: Some models may offer advanced features such as automatic strap feeding, tension adjustment, and seal initiation, further streamlining the packaging workflow.

In summary, Polypropylene strapping machines offer significant advantages in terms of speed, efficiency, safety, and consistency in the packaging and bundling process. They are essential tools for businesses looking to streamline their packaging operations and improve overall productivity.

0 notes

Text

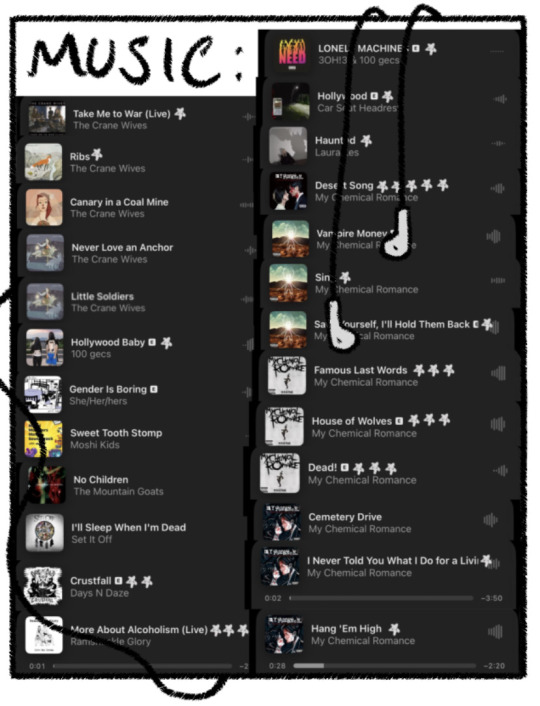

tadaaaaa a post

edit so u can read the music if u want to

[IMAGE DESCRIPTION:

starting in the top left corner it says "SCARYBOOCAT" in all caps. below that is a line of flags. the progress pride flag, the gay mlm flag, the aroace flag, the trans flag with blahaj on it, and the american flag. the american flag is on fire. below that is a little sign saying im 5'2". under that, taking up most of the space, is a drawing of me. im leaning forwards slightly, lifting one hand in a wave. my other hand is clutching the strap of my messanger bag. it has gir from invader zim on the front, multicolored pins down the strap, and a red voltron keychain. my hair is shaggy and red, and im smiling. im wearing a button-up, a crop top, cargo pants with cutouts in the thighs and shins, a choker, kandi, and boots. all my clothes are black. at my feet is a plush humanoid rabbit with one eye and horns. theres an arrow pointing at him labeling him "richard". theres an uncolored doodle of my waterbottle, and a handful of stars filling the empty space around me.

to the right is a group of five boxes. above that it says "meet the artist!". the boxes are labeled likes, dislikes, music, pets, and things i have on me.

the likes are on a bullet point list. the bullets are hearts. it reads: monster high, supernatural, the magnus archives, music, art, lps, photography, dolls, my chem, red, black, pink, night at the museum, invader zim, my pets.

the dislikes have broken hearts as bullets. it reads: crowds, loud noises, silence, disk horse, drawing (jk), writing (jk), polypropylene doll hair (lets fight). there is an arrow through the list, pointing towards the likes list, and the bullets switch back to hearts. my friends, glow in the dark, primary colors, glitter, hanahaki, textured art brushes, lining pens.

the music box has a pair of wired headphones draped across it. all the songs inside are screenshots. some of them are starred. they read: take me to war (live), ribs, canary in a coal mine, never love an anchor, little soldiers, hollywood baby, gender is boring, sweet tooth stomp, no children, ill sleep when im dead, crustfall, more about alcoholism (live), lonely machines, hollywood, haunted, desert song, vampire money, sing, save yourself ill hold them back, famous last words, house of wolves, dead!, cemetery drive, i never told you what i do for a living, hang em high.

pets: uncolored doodle of a cat and a dog laying next to each other. the cats labeled flower, and the dogs labeled dexter.

things i have on me: my phone, my wallet, notebook, pens, hat, band aids, hermie. all of them are accompanied by uncolored doodles. hermie is an lps hamster.

END ID]

#its me#hey#thats wild#if ur here from somewhere else!! im active i promise. this isnt my main acc.#look i didnt even put vld in the likes column this year. wow.#okay. how do i tag this?#art#my art#meet the artist#speaks

5 notes

·

View notes

Text

The Essential Guide to Strapping Machine Spare Parts

The Essential Guide to Strapping Machine Spare Parts

In the world of packaging, strapping machines play a crucial role in securing products for shipping and storage. To ensure these machines operate at peak efficiency, it’s vital to maintain and replace their spare parts regularly. This blog post will explore the significance of strapping machine spare parts, common components, and tips for maintenance.

Why Spare Parts Matter

Strapping machines are subject to wear and tear due to continuous use. Without proper maintenance and timely replacement of spare parts, these machines can fail, leading to costly downtime and disrupted operations. Investing in high-quality spare parts not only enhances the machine’s performance but also extends its lifespan, ensuring your packaging process remains smooth and efficient.

Common Spare Parts for Strapping Machines

Strapping Heads

The heart of any strapping machine, strapping heads apply the tension and seal the strap. Over time, wear can affect performance, making replacement crucial for consistent results.

Sealing Components

Seals are essential for securing the strap around the package. Depending on the type of strapping used (e.g., polypropylene, polyester), you may need specific sealing elements to ensure a strong bond.

Feed Rollers

These components guide the strap through the machine. If they become damaged or worn, they can lead to misfeeds and product damage. Regular checks can help prevent this issue.

Tensioning Mechanism

This mechanism controls the tightness of the strap. A faulty tensioner can result in loose or overly tight strapping, which may compromise package integrity.

Control Panels

Modern strapping machines often feature digital control panels for ease of use. If the control panel malfunctions, it can disrupt the entire packaging process, making it essential to keep spare panels on hand.

Electrical Components

Wiring, fuses, and sensors are critical for the machine's operation. Regular inspections can help identify electrical issues before they lead to significant problems.

Tips for Maintenance

Regular Inspections

Schedule routine inspections of your strapping machine to identify worn or damaged parts early. This proactive approach can save time and money in the long run.

Keep a Spare Parts Inventory

Maintain an inventory of essential spare parts so that replacements can be made quickly when needed. This minimizes downtime and keeps your operations running smoothly.

Follow Manufacturer Guidelines

Always refer to the manufacturer’s recommendations for maintenance and replacement intervals. Adhering to these guidelines helps ensure optimal performance.

Train Your Staff

Ensure that your staff is trained in operating and maintaining the strapping machine. Knowledgeable employees can quickly identify issues and carry out necessary repairs or replacements.

Use Quality Parts

When replacing parts, always opt for high-quality or OEM (Original Equipment Manufacturer) components. This ensures compatibility and reliability, reducing the likelihood of future issues.

Conclusion

Strapping machine spare parts are vital for maintaining the efficiency and reliability of your packaging operations. By understanding the key components, implementing regular maintenance practices, and keeping an inventory of essential parts, you can minimize downtime and ensure your packaging process remains efficient. Investing in the right spare parts not only enhances performance but also contributes to a smoother, more productive workflow.

For further inquiries about strapping machine spare parts or to find reliable suppliers, feel free to reach out!

0 notes

Link

Check out this listing I just added to my Poshmark closet: Katy Perry heels nwot sz 8.

0 notes

Text

Tanishka Packaging Machines: Leading Strapping Machine Manufacturers in India

In the realm of industrial packaging solutions, Tanishka Packaging Machines stands out as a prominent name, renowned for its high-quality strapping machines. Based in India, Tanishka Packaging Machines has carved a niche for itself by consistently delivering reliable and efficient packaging solutions tailored to the diverse needs of businesses across various industries.

Advanced Technology and Innovation

At the core of Tanishka Packaging Machines’ success lies its commitment to leveraging advanced technology and continuous innovation. The company integrates state-of-the-art components and cutting-edge manufacturing processes to develop strapping machines that ensure secure and efficient packaging operations. Whether for bundling boxes, pallets, or heavy-duty goods, Tanishka’s machines are engineered to meet stringent performance standards.

Product Range

Tanishka Packaging Machines offers a comprehensive range of strapping machines, catering to both manual and automated packaging requirements. Their product lineup includes:

1. Automatic Strapping Machines: Ideal for high-volume packaging lines, these machines automate the strapping process, enhancing productivity while maintaining consistency and reliability.

2. Semi-Automatic Strapping Machines: Designed for versatility and ease of use, these machines are suitable for medium to large-scale packaging operations, providing efficient strapping solutions.

3. Battery Operated Strapping Tools: Offering mobility and flexibility, these tools are perfect for applications where portability and ease of handling are paramount.

4. Polyester and Polypropylene Strapping: Tanishka also provides a range of strapping materials tailored to different packaging needs, ensuring secure and durable bundling of products.

Quality Assurance

Tanishka Packaging Machines places a strong emphasis on quality assurance at every stage of manufacturing. Each strapping machine undergoes rigorous testing to ensure it meets the highest standards of performance, durability, and safety. This commitment to quality has earned Tanishka Packaging Machines the trust of countless businesses across India and beyond.

Customer-Centric Approach

Apart from manufacturing top strapping machines, Tanishka is recognized for its customer-centric approach. The company collaborates closely with clients to understand their specific packaging challenges and provides customized solutions that align with their operational requirements. This personalized service has established long-term partnerships with a wide array of industries, including logistics, manufacturing, food and beverage, and more.

Conclusion

In summary, Tanishka Packaging Machines exemplifies excellence in the realm of strapping machine manufacturing in India. With a blend of technological innovation, product diversity, stringent quality control, and customer-centric service, Tanishka continues to be a preferred choice for businesses seeking reliable and efficient packaging solutions. Whether for securing packages in transit or streamlining warehouse operations, Tanishka Packaging Machines stands ready to meet the evolving needs of the modern industrial landscape.

0 notes

Text

Unveiling the Benefits of Carton Strapping Machines

In the world of packaging, efficiency and security are paramount. Businesses that rely on palletized shipments understand the importance of securing their goods for safe and damage-free transportation. While traditional methods like strapping by hand have served their purpose, carton strapping machines have emerged as a game-changer.

These innovative machines offer a multitude of advantages, streamlining the packaging process and ensuring optimal protection for your palletized goods.

Understanding Carton Strapping Machines:

Carton strapping machines automate the process of applying straps around cartons or pallets. This eliminates the need for manual strapping, enhancing efficiency and worker safety. Here's a breakdown of the basic operation:

Pallet Loading and Positioning: The pallet loaded with cartons is positioned within the designated area of the machine.

Strap Feeding: The machine feeds the strapping material (usually polypropylene or polyester) from a dispenser.

Strap Tensioning: The machine automatically tensions the strap to the desired level of tightness, ensuring secure hold on the cartons.

Sealing and Cutting: The machine seals the ends of the strap using heat sealing or friction welding, depending on the machine type.

Strap Discharge: The completed, strapped pallet is ejected from the machine for further handling or wrapping.

The Advantages of Utilizing Carton Strapping Machines:

Carton strapping machines offer a multitude of benefits for businesses that rely on palletized shipments:

Enhanced Efficiency: Automating the strapping process significantly reduces manual labor requirements. This translates to faster packaging times, allowing you to process more pallets per hour and fulfill orders more efficiently.

Improved Worker Safety: Manual strapping can lead to repetitive strain injuries and back problems. Carton strapping machines eliminate the need for manual exertion, promoting a safer work environment for your employees.

Increased Consistency: Machines apply straps with consistent tension every time, ensuring a secure and reliable hold on your palletized goods. This reduces the risk of damage during transportation due to loose or uneven strapping.

Reduced Costs: While there's an initial investment in the machine itself, carton strapping machines can lead to long-term cost savings. Increased efficiency translates to reduced labor costs. Additionally, consistent strapping minimizes product damage, leading to fewer returns and lower replacement costs.

Improved Inventory Management: Faster and more efficient packaging allows for better control over inventory and order fulfillment. This can enhance customer satisfaction by ensuring timely deliveries.

Versatility: Carton strapping machines can handle a wide range of pallet sizes and configurations, making them suitable for various packaging needs.

Choosing the Right Carton Strapping Machine:

With various carton strapping machines available, selecting the right one for your business requires careful consideration:

Volume of Pallets: Consider the average number of pallets you strap per day or week. High-volume operations might benefit from heavy-duty, automatic machines.

Pallet Size and Weight: Ensure the machine can accommodate your typical pallet sizes and weight capacity.

Strap Material: Machines can handle different strapping materials like polypropylene or polyester. Choose the material best suited for your specific application.

Budget: Carton strapping machines come in various price ranges. Consider your budget and the long-term cost savings associated with increased efficiency.

Additional Features: Some machines offer additional features like automatic strap feeding, corner protection, or integration with conveyor systems. Choose features that align with your specific packaging needs.

The Future of Carton Strapping Machines:

The future of carton strapping machines is likely to see advancements in areas like:

Increased Automation: Further automation of the strapping process, potentially with robotic arm integration for improved efficiency and flexibility.

Smart Technology Integration: Machines with built-in sensors and connectivity for real-time monitoring of strap tension, machine performance, and potential maintenance needs.

Sustainable Materials: Increased use of eco-friendly strapping materials made from recycled plastics or bio-based alternatives.

Conclusion:

Carton strapping machines are no longer just an alternative; they are becoming an essential tool for businesses that prioritize efficient and secure palletized shipments. By automating the strapping process, these machines offer a multitude of benefits, including increased efficiency, improved worker safety, and reduced costs. As technology continues to evolve, carton strapping machines are poised to play an even greater role in the future of streamlined and sustainable packaging solutions.

0 notes

Text

Small Make Up Bag, Ecofriendly Colorful Money and ID Wallet, Planet Earth Friendly Handmade Small Reusable Bag

These bags are a modified version of traditional bags used in Turkiye. Determined not to use disposable plastic shopping bags, these small makeup bags were hand made to be comfortable, fashionable, and fun. These bags are great to use for make up, personal items and keeping money safe and are machine washable. These bags are made by women to gain financial freedom. Since each bag is handmade, each one is unique. These reusable bags are great for placing small items in like money, credit cards and ID, jewelry and travel items.

Product Description:

Each bag is unique and handmade

Elastic closure strap

Interior is cotton lined

Reusable and Planet Earth Friendly

Material is FDA Approved for food contact

Product Details:

Made of polypropylene

Machine washable

Lay flat to dry

1 3/4"W 6 1/2"L 8"H

Made in Turkiye

Price- $19.99

0 notes

Text

Pallet Strapping Systems

The Quick Pak High Performance Advantage. Utilizing the latest in strapping head technology the new 733 series comes in a variety of configurations designed to handle a broad range of applications.

With its modular arch system and ability to handle a variety of sizes of both Polyester and Polypropylene strapping, the new PSS733 is extremely versatile. The PSS733 series consists of vertical, horizontal and the latest, top seal pallet strapping applications and is easy to integrate into any conveying system.

This new strapping head can pull over 720 pounds of tension and allows both polyester and polypropylene in the recommended working range to keep pallets secure, improve production efficiency, and lower packaging costs.

As with all packaging equipment, Quick Pak Inc stock a large inventory of spare parts, and factory-trained technicians keep your machines running for years.

-Large Carton Strapping Systems.

-Light Duty Pallet Strapping Systems.

-Stock Pallet Strapping Solutions.

-Custom Strapping Solutions.

Standard Features of all PSS733 Pallet Strapper:

-Powerful 733 Strapping Head.

-Friction welded joints produce 80% + seal joint efficiency

-Siemens PLC Control

-Touch pad accessibility to all functions on board diagnostics

-Standard Automation Interface

-Modular Arch System

-Custom arch sizes can be constructed with shorter lead times

-Several Models Available

Using the basic platform The PSS733 can strap vertically, horizontally and through pallet voids.

Models Available:

PSS733V – Fixed track, fixed strapping head, side seal for vertical strapping.

PSS733VM – Fixed track, side seal, indexing head for vertical strapping.

PSS733VLM – Fixed track, side seal, indexing head, with lance system for vertical strapping through pallets.

PSS733H – For applying horizontal straps. An indexing head is standard on the PSS733H.

PSS733TSM – OUR NEWEST MODEL

Let’s discuss your pallet strapping application. Call us 813 242 6995 or [email protected]

#quickpakinc#pricing news#stretch film pricing#stretch film#quick pak inc#coreless film#resin pricing#free pallet wrapper#youtube#free machine#pac strapping#automated strapping system#pallet strapping machine#transpak pallet strapping machine

0 notes

Text

Types Of Strapping Material And Their Uses

You know that strapping can be used to bundle products together, reinforce cartons, and to secure items to pallets for shipment. These strapping materials come in a variety of options, but how do you know which is best for your application? Your options can be filtered down into three primary categories: polypropylene(PP), polyester(PET), and steel.

Strapping materials are used primarily for bundling products together and securing pallet loads during transport and storage. When used for palletizing, it is often complemented with the additional security of stretch wrap. Being a market leader in supplying strapping materials to companies of all sizes, we've been able to help many brands overcome the challenges of securing your products from shipment to shelf.

You might find yourself with a lot of questions when trying to find the best strapping material for you.

Which type of strapping material is ideal for your application, and how does it function?

What is the difference between virgin and recycled strapping?

Find out how these materials work and which will be the best fit to optimize the security and unitizing of your products..

Polypropylene Strapping And Its Uses

Polypropylene (PP) strapping is one of the most common types of strapping and comes in a variety of tensile strengths, widths, and core sizes depending on your application.

It’s almost always embossed, giving it additional strength and texture for better friction. Embossing also significantly reduces dust created during the strapping process.

Polypropylene strapping can be applied manually with buckles or hand tools up to fully automated strapping machines.

PP strapping stretches around 25% when applying, however, it recovers about 10% back shortly after. As a package or pallet settles, the strap will retain some tension. Polyester and steel will not recover as your package/pallet settles.

Unless otherwise formulated, plain PP strap can be sensitive to UV light degradation and is sometimes negatively impacted by elevated temperatures. By selecting the proper formulation of PP strapping with your supplier, you won't have to worry about these downsides.

Some new formulations negate most of these issues. Dynaric/PolyChem's Ultraband polyester strapping can handle weighty loads, up to 2000 lbs of tensile strength! But it does have a higher price point. Most alternative PP strapping materials are generally less expensive than Polyester (PET), making them very economical.

Best Uses For Polypropylene Strapping

Polypropylene strapping is exceptionally versatile and can be used on various applications including:

Printed Materials (Newspapers, Magazines)

Direct mail

Millwork (moldings, banisters, etc.)

Flooring (hardwoods, laminates)

Appliances

Clothing

Foods (Distribution centers that supply grocery stores)

Meats, produce, and other fresh and frozen food packers

Pharmaceutical and Drug Store Distribution Centers

Hay baling

The list above should give you the overall idea. Polypropylene can be used in almost any strapping application! In one of our customer applications, a 2,000 pound cradled load is easily secured with four straps!

Polyester Strapping

Polyester (PET) strapping is generally smooth in texture, but can also be embossed. Most Polyester strapping is created from recycled materials.

Fun Fact: You will notice that most PET strapping is green. This color is due to being created from plastic bottles. Most ginger-ale bottles and 7-UP® are green, and these significantly impact the color!

Heavy-duty polyester strapping has a higher tensile strength than steel and has decent thermal tolerance. It also has a lesser amount of tension decay over PP, which means it holds the tension for a longer period of time. This is important to keep in mind for cross-country hauls from one destination to another, or multiple stops along the path to the load's final destination.

There is also a polyester corded strapping, which is easily tied by hand with a wire buckle. It is a cloth material glued together, so there is no stretch available, but it is very flexible.

There are new formulations available as well such as Dynaric/PolyChem's Ultraband polyester strapping which can handle weighty loads, up to 2000 lbs of tensile strength. This strapping does have a higher price point though.

Best Uses For Polyester Strapping

Polyester strapping is best used for rigid loads and helps to absorb impact during transit. It's also a better alternative when you need higher initial tension to contain loads when compared to PP strapping.

Metals

Lumber

Pallets of Bottles and Cans

Bricks

Tiles

Excellent for stabilizing and palletizing heavy loads

Steel Strapping

Steel strapping is becoming a lesser-used option, but has historically been utilized in mostly railroad-shipped applications. It is required by the government (Association of American Railroads) for railroad transport where the load is not held within a container.

There are a few AAR-approved PP or PET strapping options available, so if you prefer one of these, inquire with us about your options! Few places use steel for packaging that cannot use PP or PET strapping. Most steel strapping is made of stainless steel.

When bent at a right angle, like wrapping around the edges of a pallet, for example, steel strapping loses half of its strength.

Best Uses For Steel Strapping

Steel strapping is the oldest and most heavy-duty of the top 3 strapping material options. It is best used in heavy-duty applications. Steel does not expand or contract with the load, once it is secured, it stays!

Heavy manufacturing and industrial equipment

Steel coils

Construction Materials

Bundling metals

Baling wire

Secure Closure of Metal Containers

Railroad Shipping

What Factors Should I Consider When Choosing Strapping Material?

Product Dimensions

The most important factors to consider when selecting your strapping material will be the size, weight, and oddly enough awkwardness of your product. An example of a product that’s very awkward to package would be a refrigerator.

When shipped, refrigerators are usually strapped to a pallet that is the same width of the base. With fridges being top-heavy, you will want to make sure you have enough strength in your strapping to maintain stability in transit.

Some businesses want to over-strap for added security. However, with the right-sized, proper material, you can reduce wasted material and secure your loads properly.

Shipping Distance

If your product is shipping long distances, you will want a more sturdy strap to resist the transport movement. Consider the width of strapping when considering shipment as well. For a long haul carrying a heavy load, you will not want to use 1/4" wide strap. The thinner strap will not have the strength to manage the load, so you will want something with more width and strength.

The more likely your products are to shift during travel, the wider the strapping you will want to use. If your products tend to settle during shipment (printed materials, for example), polypropylene is an excellent option because it can stretch and maintain integrity. Polyester is less likely to stretch.

Tensile Strength

Tensile strength is the amount of force required to break a strap. The break strength is dependent upon the method of strapping, the number of straps used per load, the size of the strapping, and the overall weight of the products being strapped. It's essential to speak with your supplier about optimal strap sizing to eliminate breaking.

Method of Strapping

How you strap your products is very important in selecting the ideal strapping material. If you are only strapping ten shoe-box- sized products a day, manual strapping tools are a perfect option. If you are strapping 100 shoe-sized boxes per day, you will want to consider a semiautomatic or automatic machine.

There are TONS of options available in machinery to find the ideal match for your application. Automatic machinery can handle around three straps per minute and up to 1,000 per day.

Most heavy-duty applications are strapped manually with strapping tools

Virgin vs Recycled Strapping

When considering machine strapping, you will be best-suited with virgin strapping material. Virgin strapping differs from recycled strapping in how it's created and how it can be used. Virgin strapping is produced purely from new polymers and practically eliminates camber. Virgin strap also reduces the amount of dust created by semi and automatic machines, reducing downtime and maintenance costs. Using machinery, a recycled strap will often have irregularities, or camber.

Camber is the amount of curve or irregularity in strapping. When using machinery, it's essential to have as little camber as possible to reduce machinery issues during the strapping process. If you are strapping manually, the camber is not as much of a problem. Too much camber can cause the strap to come out of place, causing damage to the machinery and create safety hazards.

Although recycled strap is around half the cost of virgin strapping material, its important to consider consistency over initial expense. Machinery damaged from recycled strapping will cost more in the long haul for repairs than sticking with the ideal virgin strapping solution.

Most white strapping is virgin material and machine-grade. Black strapping is almost always going to have some re-processed materials within it.

Choosing The Right Strapping Material

With all of the information provided above, you should be in an excellent place to start your strapping selection! Our years in business and knowledge will give you a step ahead, so get in touch with our team. We can discuss your project and determine the ultimate sizing, pricing, and tools to set you up to strapping with ease.

Strapping is an excellent material for protecting your products in transit and storage. If it sounds like the right option for you, let's start a conversation!

0 notes

Link

Check out this listing I just added to my Poshmark closet: The Sak Bright Multicolor Purse Striped Crochet lightweight Shoulder bag EUC.

0 notes

Text

Electric Bag Sewing Machine Equipment suppliers in Uganda

Electric Bag Sewing Closer Machines in Kampala Uganda

Bag closer machines, also known as bag sewing machines or portable bag closers, are specialized machines used to close and seal bags of various materials, such as woven polypropylene, jute, paper, or plastic. These machines provide efficient and reliable closure solutions for bags in industries such as agriculture, packaging, food processing, and construction.

details about bag closer machines in Kampala

Portable Design: Bag closer machines are designed to be portable and easy to maneuver. They are typically lightweight and equipped with handles or straps for convenient transportation. This portability allows operators to move the machine to different locations or work in areas where mobility is required.

Sewing Mechanism: Bag closer machines use a sewing mechanism, often a single-thread chain stitch or a two-thread double chain stitch, to close and seal bags. The machine feeds the bag through the sewing head, and the stitching process secures the opening, creating a tight closure.

Versatile Applications: Bag closer machines can be used with various types of bags, including woven sacks, paper bags, plastic bags, and burlap sacks. They are suitable for closing bags filled with products such as grains, seeds, fertilizers, animal feed, cement, chemicals, and more.

Speed and Efficiency: Bag closer machines offer high sewing speeds, enabling operators to close bags quickly and efficiently. The speed can be adjusted to match the specific requirements of the bag and the desired closure strength. This allows for increased productivity in bag sealing operations.

Manual or Electric Operation: Bag closer machines are available in manual and electric models. Manual machines are operated by hand, requiring the operator to guide the bag through the sewing head. Electric machines, on the other hand, are powered by an electric motor, which automates the feeding and sewing process for greater ease of use and speed.

Durability and Maintenance: Bag closer machines are constructed with sturdy materials to withstand continuous use in industrial environments. They are designed for durability and require minimal maintenance. Regular cleaning and oiling of the machine are typically recommended to ensure optimal performance and prolong the machine's lifespan.

Optional Features: Bag closer machines may come with additional features and accessories to enhance functionality. These can include built-in cutters to trim excess bag material, variable stitch length adjustment, thread break sensors, thread lubrication systems, and thread cone holders for efficient thread management.

Bag closer machines are widely used in various industries where bag sealing is necessary. They provide a reliable and efficient solution for closing bags securely, preventing product spillage, protecting contents from contamination, and facilitating transportation and storage.

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance.

For inquiries on deliveries contact us

Office +256 705 577 823, +256 775 259 917

Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036

Email: [email protected]

https://barcodescalesuganda.wordpress.com/about-us-2/

https://barcodescalesuganda.wordpress.com/clients/

https://weighingscalesineastafrica.wordpress.com/about-us/

0 notes

Text

🚀 Unlock the Power of Secure Packaging with PP Strapping! 🚀

Are you looking for a reliable, cost-effective solution for your packaging needs? Look no further than PP strapping! Here’s why polypropylene strapping should be your go-to choice:

🔹 High Strength and Durability: PP strapping is known for its exceptional tensile strength, making it perfect for securing heavy loads and ensuring safe transportation.

🔹 Cost-Effective: Save on packaging costs without compromising on quality. PP strapping offers a high-performance solution at a fraction of the cost of other materials.

🔹 Eco-Friendly: Made from recyclable materials, polypropylene strapping is a sustainable choice for businesses looking to reduce their environmental impact.

🔹 Versatile Applications: Whether you’re in logistics, manufacturing, or retail, PP strapping is versatile enough to meet all your packaging needs.

🔹 Easy to Use: Our PP strapping is designed for both manual and automatic strapping machines, making it incredibly user-friendly.

💬 We Want to Hear From You!

Have questions or need advice on the best strapping solution for your business? Drop us a comment below or send us a direct message. Our team is here to help!

🔗 Shop Now: https://www.alibaba.com/product-detail/Yongsheng-factory-wholesale-custom-black-polypropylene_62430816768.html?spm=a2747.product_manager.0.0.9c0871d2RKZb8R

PackagingSolutions #PPStrapping #PolypropyleneStrapping #EcoFriendly #CostEffective #Logistics #Manufacturing

0 notes

Text

small size bag closure Sewing machine System in Kampala

Electric Bag Sewing Closer Machines in Kampala Uganda

Bag closer machines, also known as bag sewing machines or portable bag closers, are specialized machines used to close and seal bags of various materials, such as woven polypropylene, jute, paper, or plastic. These machines provide efficient and reliable closure solutions for bags in industries such as agriculture, packaging, food processing, and construction.

details about bag closer machines in Kampala

Portable Design: Bag closer machines are designed to be portable and easy to maneuver. They are typically lightweight and equipped with handles or straps for convenient transportation. This portability allows operators to move the machine to different locations or work in areas where mobility is required.

Sewing Mechanism: Bag closer machines use a sewing mechanism, often a single-thread chain stitch or a two-thread double chain stitch, to close and seal bags. The machine feeds the bag through the sewing head, and the stitching process secures the opening, creating a tight closure.

Versatile Applications: Bag closer machines can be used with various types of bags, including woven sacks, paper bags, plastic bags, and burlap sacks. They are suitable for closing bags filled with products such as grains, seeds, fertilizers, animal feed, cement, chemicals, and more.

Speed and Efficiency: Bag closer machines offer high sewing speeds, enabling operators to close bags quickly and efficiently. The speed can be adjusted to match the specific requirements of the bag and the desired closure strength. This allows for increased productivity in bag sealing operations.

Manual or Electric Operation: Bag closer machines are available in manual and electric models. Manual machines are operated by hand, requiring the operator to guide the bag through the sewing head. Electric machines, on the other hand, are powered by an electric motor, which automates the feeding and sewing process for greater ease of use and speed.

Durability and Maintenance: Bag closer machines are constructed with sturdy materials to withstand continuous use in industrial environments. They are designed for durability and require minimal maintenance. Regular cleaning and oiling of the machine are typically recommended to ensure optimal performance and prolong the machine's lifespan.

Optional Features: Bag closer machines may come with additional features and accessories to enhance functionality. These can include built-in cutters to trim excess bag material, variable stitch length adjustment, thread break sensors, thread lubrication systems, and thread cone holders for efficient thread management.

Bag closer machines are widely used in various industries where bag sealing is necessary. They provide a reliable and efficient solution for closing bags securely, preventing product spillage, protecting contents from contamination, and facilitating transportation and storage.

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance.

For inquiries on deliveries contact us

Office +256 705 577 823, +256 775 259 917

Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036

Email: [email protected]

https://barcodescalesuganda.wordpress.com/adam-weighing-equipment/

https://barcodescalesuganda.wordpress.com/hiweigh-weighing-balance/

https://barcodescalesuganda.wordpress.com/cardinal-weighing-equipment/

0 notes

Text

The Essential Guide to Strapping Machine Spare Parts

The Essential Guide to Strapping Machine Spare Parts

In the world of packaging, strapping machines play a crucial role in securing products for shipping and storage. To ensure these machines operate at peak efficiency, it’s vital to maintain and replace their spare parts regularly. This blog post will explore the significance of strapping machine spare parts, common components, and tips for maintenance.

Why Spare Parts Matter

Strapping machines are subject to wear and tear due to continuous use. Without proper maintenance and timely replacement of spare parts, these machines can fail, leading to costly downtime and disrupted operations. Investing in high-quality spare parts not only enhances the machine’s performance but also extends its lifespan, ensuring your packaging process remains smooth and efficient.

Common Spare Parts for Strapping Machines

Strapping Heads

The heart of any strapping machine, strapping heads apply the tension and seal the strap. Over time, wear can affect performance, making replacement crucial for consistent results.

Sealing Components

Seals are essential for securing the strap around the package. Depending on the type of strapping used (e.g., polypropylene, polyester), you may need specific sealing elements to ensure a strong bond.

Feed Rollers

These components guide the strap through the machine. If they become damaged or worn, they can lead to misfeeds and product damage. Regular checks can help prevent this issue.

Tensioning Mechanism

This mechanism controls the tightness of the strap. A faulty tensioner can result in loose or overly tight strapping, which may compromise package integrity.

Control Panels

Modern strapping machines often feature digital control panels for ease of use. If the control panel malfunctions, it can disrupt the entire packaging process, making it essential to keep spare panels on hand.

Electrical Components

Wiring, fuses, and sensors are critical for the machine's operation. Regular inspections can help identify electrical issues before they lead to significant problems.

Tips for Maintenance

Regular Inspections

Schedule routine inspections of your strapping machine to identify worn or damaged parts early. This proactive approach can save time and money in the long run.

Keep a Spare Parts Inventory

Maintain an inventory of essential spare parts so that replacements can be made quickly when needed. This minimizes downtime and keeps your operations running smoothly.

Follow Manufacturer Guidelines

Always refer to the manufacturer’s recommendations for maintenance and replacement intervals. Adhering to these guidelines helps ensure optimal performance.

Train Your Staff

Ensure that your staff is trained in operating and maintaining the strapping machine. Knowledgeable employees can quickly identify issues and carry out necessary repairs or replacements.

Use Quality Parts

When replacing parts, always opt for high-quality or OEM (Original Equipment Manufacturer) components. This ensures compatibility and reliability, reducing the likelihood of future issues.

Conclusion

Strapping machine spare parts are vital for maintaining the efficiency and reliability of your packaging operations. By understanding the key components, implementing regular maintenance practices, and keeping an inventory of essential parts, you can minimize downtime and ensure your packaging process remains efficient. Investing in the right spare parts not only enhances performance but also contributes to a smoother, more productive workflow.

For further inquiries about strapping machine spare parts or to find reliable suppliers, feel free to reach out!

0 notes

Link

Check out this listing I just added to my Poshmark closet: Katy Perry heels nwot sz 8.

0 notes

Text

small size bag closure Sewing machine System in Kampala

Electric Bag Sewing Closer Machines in Kampala Uganda

Bag closer machines, also known as bag sewing machines or portable bag closers, are specialized machines used to close and seal bags of various materials, such as woven polypropylene, jute, paper, or plastic. These machines provide efficient and reliable closure solutions for bags in industries such as agriculture, packaging, food processing, and construction.

details about bag closer machines in Kampala

Portable Design: Bag closer machines are designed to be portable and easy to maneuver. They are typically lightweight and equipped with handles or straps for convenient transportation. This portability allows operators to move the machine to different locations or work in areas where mobility is required.

Sewing Mechanism: Bag closer machines use a sewing mechanism, often a single-thread chain stitch or a two-thread double chain stitch, to close and seal bags. The machine feeds the bag through the sewing head, and the stitching process secures the opening, creating a tight closure.

Versatile Applications: Bag closer machines can be used with various types of bags, including woven sacks, paper bags, plastic bags, and burlap sacks. They are suitable for closing bags filled with products such as grains, seeds, fertilizers, animal feed, cement, chemicals, and more.

Speed and Efficiency: Bag closer machines offer high sewing speeds, enabling operators to close bags quickly and efficiently. The speed can be adjusted to match the specific requirements of the bag and the desired closure strength. This allows for increased productivity in bag sealing operations.

Manual or Electric Operation: Bag closer machines are available in manual and electric models. Manual machines are operated by hand, requiring the operator to guide the bag through the sewing head. Electric machines, on the other hand, are powered by an electric motor, which automates the feeding and sewing process for greater ease of use and speed.

Durability and Maintenance: Bag closer machines are constructed with sturdy materials to withstand continuous use in industrial environments. They are designed for durability and require minimal maintenance. Regular cleaning and oiling of the machine are typically recommended to ensure optimal performance and prolong the machine's lifespan.

Optional Features: Bag closer machines may come with additional features and accessories to enhance functionality. These can include built-in cutters to trim excess bag material, variable stitch length adjustment, thread break sensors, thread lubrication systems, and thread cone holders for efficient thread management.

Bag closer machines are widely used in various industries where bag sealing is necessary. They provide a reliable and efficient solution for closing bags securely, preventing product spillage, protecting contents from contamination, and facilitating transportation and storage.

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance.

For inquiries on deliveries contact us

Office +256 705 577 823, +256 775 259 917

Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036

Email: [email protected]

https://barcodescalesuganda.wordpress.com/weighing-scales-peripherals/

https://averyweighingscalesuganda.wordpress.com/services/

https://averyweighingscalesuganda.wordpress.com/weighing-scales-accessories/

0 notes