#Polyimide Price

Explore tagged Tumblr posts

Text

Polyimide Prices | Pricing | Trend | News | Database | Chart | Forecast

Polyimide is a versatile polymer that has garnered significant attention across various industries due to its unique properties, including thermal stability, chemical resistance, and excellent mechanical strength. As a result, the demand for polyimide materials has surged, leading to fluctuations in prices influenced by several factors. Understanding the pricing dynamics of polyimide can provide insights for manufacturers, suppliers, and consumers alike, helping them make informed decisions.

The price of polyimide is primarily influenced by raw material costs, production methods, and market demand. Raw materials, such as anhydrides and diamines, are critical components in polyimide production. Variations in the prices of these materials can lead to corresponding changes in the overall cost of polyimide. For instance, geopolitical factors affecting the supply chains of these raw materials can create volatility in pricing. Additionally, energy costs play a crucial role, as the production process is energy-intensive, and fluctuations in energy prices can impact the final cost of polyimide products.

Get Real Time Prices for Polyimide: https://www.chemanalyst.com/Pricing-data/polyimide-1579Production methods also contribute to the pricing landscape of polyimide. There are various manufacturing processes, including solution casting, film extrusion, and coating techniques, each with its cost implications. Advanced production techniques, such as using high-performance solvents or specialized equipment, can lead to higher quality polyimide products but may also elevate production costs. These costs are often passed down to consumers, affecting the pricing strategy adopted by manufacturers. In competitive markets, producers may need to balance quality and cost to maintain their market position.

Market demand is another critical factor influencing polyimide prices. The growth of industries such as electronics, aerospace, automotive, and telecommunications has significantly increased the demand for high-performance materials like polyimide. As more applications for polyimide are identified, such as in flexible electronics and insulating films, the competition for these materials has intensified, driving prices upward. Moreover, the shift towards sustainability and the development of eco-friendly polyimide variants can also influence pricing, as these products often require additional research and development investment.

Global economic conditions and trends can further impact polyimide prices. Economic downturns may reduce demand for certain applications, leading to decreased prices as suppliers attempt to maintain sales volume. Conversely, during periods of economic growth, increased manufacturing activity can elevate demand and push prices higher. Additionally, international trade policies and tariffs can affect the import and export of polyimide products, leading to price variations based on regional supply and demand dynamics.

Technological advancements also play a pivotal role in shaping the pricing of polyimide. Innovations in production techniques can enhance efficiency, reduce waste, and lower costs, potentially leading to more competitive pricing. Conversely, the introduction of new, specialized polyimide formulations may come at a premium due to the added research and development costs involved. The balance between innovation and cost-effectiveness is crucial for manufacturers as they navigate the complexities of the polyimide market.

Sustainability is becoming an increasingly important consideration in the pricing of polyimide materials. As industries move toward greener practices, the development of sustainable polyimide options may command higher prices due to the costs associated with sourcing environmentally friendly raw materials and adhering to strict regulatory standards. Companies that prioritize sustainability may also invest in certifications and eco-labeling, which can further influence pricing strategies.

The geographical distribution of polyimide production and consumption also affects prices. Regions with a high concentration of polyimide manufacturers may experience lower prices due to increased competition. Conversely, areas reliant on imports may face higher costs, influenced by shipping expenses and tariffs. Understanding regional dynamics is essential for businesses seeking to source polyimide materials cost-effectively.

The interplay of supply and demand continues to shape the pricing landscape of polyimide. In periods of high demand coupled with constrained supply, prices are likely to increase. Manufacturers may respond by increasing production capacity or optimizing existing processes to meet market needs. However, sudden shifts in demand, such as those caused by economic downturns or technological disruptions, can lead to rapid changes in pricing, requiring agility from producers and consumers alike.

In conclusion, polyimide prices are influenced by a myriad of factors, including raw material costs, production methods, market demand, economic conditions, technological advancements, and sustainability considerations. As industries increasingly rely on polyimide for innovative applications, understanding the nuances of its pricing dynamics becomes crucial for all stakeholders. By staying informed about these trends and developments, manufacturers and consumers can better navigate the complex landscape of polyimide materials, ensuring they make sound purchasing decisions that align with their operational needs and budget constraints. As the market evolves, the ability to adapt to pricing fluctuations will be vital for maintaining competitiveness in a rapidly changing environment.

Get Real Time Prices for Polyimide: https://www.chemanalyst.com/Pricing-data/polyimide-1579

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

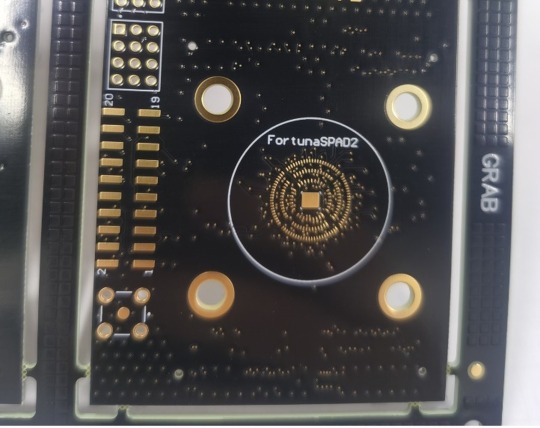

How do PCBs automatically help power with conductive pathways for non-conductive substrates?

HDI 12-layer PCBs automatically powered to help are called PWB (Printed wiring boards), PCBs (Printed Circuit Boards) come accessible to automatically help and electrically be part of electric powered-powered utilization of conductive pathways, signal strains etched from copper sheets laminated onto a non-conductive substrate. Apart from being much less high priced and reliable, PCBs are used for immoderate-volume production, even though their price is higher than wire-wrapped circuits. Generally, a Printed Circuit Board’s format is ready vaguely. Important characteristic internal PCB circuit format this is carried out to define the functionality further of mechanical and electric-powered products. This microwave PCB Prototype plays a crucial element characteristic within the format and introduction of found-out circuit boards. The technique of the PCB prototype goes via immoderate situations the whole thing is checked on the equal time because the manufacturing is in a technique including the strains and leads. However, underneath any kind of failure within the prototype, a present-day modified prototype needs to be built.

How are PCB prototypes to scrutinize efficiencies?

The prototype is saved under scrutiny until it performs as required. In case of the unavailability of a prototype of the Printed Circuit Boards, there are various uncertain risks and inefficiencies worried about the mass production of circuit boards. These revisions additionally may be time-ingesting in complex systems and may include immoderate expenses. Also, if something is determined incorrectly with a circuit, it takes a while to localize it. Different ENEPIG PCB materials are used for sort of PCB specifications and techniques in PCB prototyping and production.

What are the power outputs of rigid-flex PCB?

To get wonderful consequences and outputs, you will be capable of creating or formatting a PCB with the utilization of

Using Polyimide for flexibility – Polyimide can keep a heat temperature, which makes it most suitable for use in electric insulation applications.

Arlon for Longer Life at Higher Temperatures – Arlon materials are useful for the PCB fabrication of immoderate ordinary overall performance and frequency-mounted found-out circuit production.

Isola Range for PCB prototype – Isola range is an immoderate ordinary overall performance pre-peg system.

UTILITIES AND FUNCTIONS

Its low dielectric consistency and dissipation element permit the growth of an appropriate cloth for designing broadband circuits.

Last phrase and conclusion Storm pcb.com are expert in digital layout and PCB assembly. They remodel your circuit concept into reality, seamlessly, economically, and successfully for exceptional circuit manufacturing for men or woman demand.

#HDI PCB#RF PCB#High frequencypcb#rigid-flexpcb#Large PCB#Metalcore PCB#ENEPIG PCB#Microwave PCB#10 layer PCB#12 layer PCB

7 notes

·

View notes

Text

PA6 Prices shift in Mumbai

A sharp rise in the Polyimide (PA6), grade M28RC prices can be witnessed in the Mumbai market today as per the recent report from Indian Petrochem analysts. The sources revealed that prices have surged to Rs 203/kg on November 4, 2024 from Rs 199/kg on November 2, 2024. Industry analysts suggest that the price surge is attributed to fluctuations in supply and demand, along with rising raw material costs impacting production. Indian PA6 Prices, PA6 Prices In India, Indian Prices PA6, Indianpetrochem.

0 notes

Text

Copper-Clad Laminates Market Growth Trends By Forecast Period 2024-2032

The global copper-clad laminates market was valued at USD 16.60 billion in 2023. It is estimated to reach USD 26.64 billion by 2032, growing at a CAGR of 5.4% during the forecast period (2024–2032).

The latest Global Copper-Clad Laminates Market by straits research provides an in-depth analysis of the Copper-Clad Laminates Market, including its future growth potential and key factors influencing its trajectory. This comprehensive report explores crucial elements driving market expansion, current challenges, competitive landscapes, and emerging opportunities. It delves into significant trends, competitive strategies, and the role of key industry players shaping the global Copper-Clad Laminates Market. Additionally, it provides insight into the regulatory environment, market dynamics, and regional performance, offering a holistic view of the global market’s landscape through 2032.

Competitive Landscape

Some of the prominent key players operating in the Copper-Clad Laminates Market are

Kingboard Holdings Ltd

Shengyi Technology (SYTECH)

ITEQ Corporation

Panasonic Corp

Isola Group

Nan Ya Plastics Corp

FINELINE Ltd

Doosan Corporation Electro-Materials (South Korea)

Grace Electron Corp (Wuxi city and Guangzhou city)

Taiwan Elite Material Co. Ltd

Taiwan TAIFLEX Scientific Co. Ltd

UBE Industries Ltd

Goldenmax International Technology Ltd

Guagndong Chaohua Technology Co

Get Free Request Sample Report @ https://straitsresearch.com/report/copper-clad-laminates-market/request-sample

The Copper-Clad Laminates Market Research report delivers comprehensive annual revenue forecasts alongside detailed analysis of sales growth within the market. These projections, developed by seasoned analysts, are grounded in a deep exploration of the latest industry trends. The forecasts offer valuable insights for investors, highlighting key growth opportunities and industry potential. Additionally, the report provides a concise dashboard overview of leading organizations, showcasing their effective marketing strategies, market share, and the most recent advancements in both historical and current market landscapes.Global Copper-Clad Laminates Market: Segmentation

The Copper-Clad Laminates Market segmentation divides the market into multiple sub-segments based on product type, application, and geographical region. This segmentation approach enables more precise regional and country-level forecasts, providing deeper insights into market dynamics and potential growth opportunities within each segment.

By Product

Paper Board

Composite Substrate

FR-4

Halogen-free Board

Others

By Type

Rigid

Flexible

By Application

Computers

Communication Systems

Consumer Appliances

Vehicle Electronics

Healthcare Devices

Defense Technology

By Reinforcement Fiber

Glass Fiber Base

Paper Base

Composite Base

By Resin

Epoxy

Phenolic

Polyimide

Polyester (PET)

Fluoropolymer/PTFE

Polyphenylene Ether (PPE)

Polyphenylene Oxide (PPO)

Others (Polyethylene Naphthalate [PEN], etc.)

By End Use

Automotive

Aerospace & Defense

Consumer Electronics

Healthcare

Industrial

Others

Stay ahead of the competition with our in-depth analysis of the market trends!

Buy Now @ https://straitsresearch.com/buy-now/copper-clad-laminates-market

Market Highlights:

A company's revenue and the applications market are used by market analysts, data analysts, and others in connected industries to assess product values and regional markets.

But not limited to: reports from corporations, international Organization, and governments; market surveys; relevant industry news.

Examining historical market patterns, making predictions for the year 2022, as well as looking forward to 2032, using CAGRs (compound annual growth rates)

Historical and anticipated data on demand, application, pricing, and market share by country are all included in the study, which focuses on major markets such the United States, Europe, and China.

Apart from that, it sheds light on the primary market forces at work as well as the obstacles, opportunities, and threats that suppliers face. In addition, the worldwide market's leading players are profiled, together with their respective market shares.

Goals of the Study

What is the overall size and scope of the Copper-Clad Laminates Market market?

What are the key trends currently influencing the market landscape?

Who are the primary competitors operating within the Copper-Clad Laminates Market market?

What are the potential growth opportunities for companies in this market?

What are the major challenges or obstacles the market is currently facing?

What demographic segments are primarily targeted in the Copper-Clad Laminates Market market?

What are the prevailing consumer preferences and behaviors within this market?

What are the key market segments, and how do they contribute to the overall market share?

What are the future growth projections for the Copper-Clad Laminates Market market over the next several years?

How do regulatory and legal frameworks influence the market?

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Copper-Clad Laminates Market Market#Copper-Clad Laminates Market Market Share#Copper-Clad Laminates Market Market Size#Copper-Clad Laminates Market Market Research#Copper-Clad Laminates Market Industry#What is Copper-Clad Laminates Market?

0 notes

Text

4 layers Flex PCB for LCM, Hitech Circuits - top manufacturer from China

It is simple and convenient for workers to hold, solder and other operations. Moreover, the price of flex pcb is relatively cheap, which can reduce production costs; it can play a better insulation effect and ensure the stable operation of 4 layers flexible PCB for LCM.

Technical Parameters

POLYIMIDE material with 4 layers flexible printed circuit board

Outer Copper is 1OZ and Inner Copper is 0.5OZ.

Finished Thickness is 0.2mm for flexible part and 0.4mm for stiffener.

Stiffener: steel

Surface finish: ENIG

Min. trace width/spacing: 0.075/0.075mm

Punching

If you have an inquiry for our service, please contact us, Cynthia<[email protected]>, thank you.

0 notes

Text

Global Market Trends for Colorless Polyimide Films: Forecasts and Predictions

Introduction to Colorless Polyimide Films Market

Colorless polyimide films are high-performance materials known for their excellent thermal stability, electrical insulation, and optical clarity. Used in various applications such as electronics, aerospace, and automotive industries, these films offer superior performance in demanding environments. The market for colorless polyimide films is driven by the increasing demand for advanced materials in technology sectors. As electronics become more compact and complex, the need for efficient, reliable insulation materials grows. Additionally, the aerospace industry’s focus on lightweight, durable materials further fuels market expansion. Key players in this market are investing in innovations to enhance film properties and applications.

Market overview

The Colorless Polyimide Films Market is Valued USD 152.8 billion by 2024 and projected to reach USD 10,037.2 Million by 2030, growing at a CAGR of CAGR of 59.20% During the Forecast period of 2024–2032.This growth is fueled by the expanding use of these films in flexible electronics, advanced packaging, and other high-tech applications.

Access Full Report : https://www.marketdigits.com/checkout/3504?lic=s

Major Classifications are as follows:

By Type:

50 m

31–50 m

21–30 m

20 m

By application:

Flexible Displays

Flexible Solar Cells

Flexible Printed Circuit Boards

Lighting Equipment

Others

By end-use industry:

Data Security

Electronics

Solar Energy

Medical

Others

Key Region/Countries are Classified as Follows: ◘ North America (United States, Canada, and Mexico) ◘ Europe (Germany, France, UK, Russia, and Italy) ◘ Asia-Pacific (China, Japan, Korea, India, and Southeast Asia) ◘ South America (Brazil, Argentina, Colombia, etc.) ◘ The Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, and South Africa)

Major players in Colorless Polyimide Films Market:

DuPont, Kaneka Corporation, Kolon Industries Inc., SK Innovation Co., Ltd., Sumitomo Chemical Company Ltd., Wuhan Imide New Materials Technology Co., Ltd., Industrial Summit Technology Corporation, NeXolve Holding Company, Wuxi Shunxuan New Materials Co., Ltd., Suzhou Kinyu Electronics Co., Ltd., Changchun Gao Qi Polyimide Material Co., Ltd., Zymergen Inc., Dr. Dietrich Muller GmbH and Others.

Market Drivers in Colorless Polyimide Films Market:

Technological Advancements: Continuous innovation in electronics, including flexible displays and wearable technology, requires materials with high thermal stability and electrical insulation, driving demand for colorless polyimide films markets.

Miniaturization of Electronics: The trend toward smaller, more compact electronic devices increases the need for efficient, thin, and durable insulating materials, boosting the demand for polyimide films.

Aerospace Industry Growth: The aerospace sector’s need for lightweight and high-strength materials for components and insulation supports the growth of polyimide films.

Market challenges in Colorless Polyimide Films Market:

High Production Costs: The manufacturing of polyimide films involves complex processes and high-quality raw materials, leading to elevated production costs. This can limit market growth, especially in cost-sensitive applications.

Raw Material Prices: Fluctuations in the prices of raw materials used in polyimide film production can impact overall costs and profitability.

Competition from Alternative Materials: The development of alternative materials with comparable or superior properties, such as other high-performance polymers, can pose a threat to the market for polyimide films.

Regulatory Compliance: Adherence to stringent environmental and safety regulations can increase operational costs and affect market dynamics.

Market opportunities in Colorless Polyimide Films Market:

Growth in Flexible Electronics: The increasing use of flexible and wearable electronics creates a demand for colorless polyimide films market due to their excellent flexibility, thermal stability, and clarity.

Advancements in Aerospace Applications: Expanding aerospace and defense sectors require lightweight, durable materials for advanced applications, creating opportunities for polyimide films.

Expansion of Electric Vehicles (EVs): The rise of EVs and their need for high-performance insulation materials for batteries and electronic systems presents a growing market for colorless polyimide films.

Future trends in Colorless Polyimide Films Market:

Integration with Flexible Electronics: As flexible electronics and wearables continue toevolve, the demand for colorless polyimide films market with enhanced flexibility and durability is expected to grow. Innovations in film technology will likely cater to these advanced applications.

Advancements in Manufacturing Techniques: Improved manufacturing processes and technologies, such as roll-to-roll processing and advanced coating techniques, may reduce production costs and enhance film properties.

Increased Adoption in Automotive Sector: With the rise of electric and autonomous vehicles, there will be a growing need for high-performance insulation materials for batteries and electronic components, driving demand for polyimide films.

Conclusion:

In conclusion, the colorless polyimide films market is poised for significant growth driven by technological advancements, increasing demand for high-performance materials, and expanding applications across industries such as electronics, aerospace, and automotive. Despite facing challenges such as high production costs and competition from alternative materials, the market presents numerous opportunities through innovations in manufacturing, sustainability trends, and the development of new applications. Future trends indicate a continued evolution towards more flexible, durable, and eco-friendly films, which will further fuel market expansion. Overall, the colorless polyimide films market is set to thrive as industries seek advanced materials to meet the demands of modern technology and applications.

#colorless polyimide films market demand#colorless polyimide films market share#colorless polyimide films market size#colorless polyimide films market trend

0 notes

Text

ポリイミド (Polyimide) の価格: トレンド、データ分析、将来の予測

ポリイミド (Polyimide) は、優れた熱安定性、耐薬品性、機械的特性で知られる高性能ポリマーで、電子機器、航空宇宙、自動車、ヘルスケアなどの業界で不可欠な材料となっています。ポリイミドの価格は、原材料費、主要産業からの需要、技術の進歩、世界経済の状況など、さまざまな要因の影響を受けます。

ポリイミド価格の主な要因の 1 つは、その製造に使用される原材料のコストです。ポリイミドは通常、石油化学製品から得られる芳香族ジアミンと二無水物から合成されます。原油価格、地政学的緊張、サプライ チェーンの混乱などの要因によって引き起こされるこれらの石油化学原料の価格の変動は、ポリイミドの製造コストに直接影響を与える可能性があります。原材料費が上昇すると、メーカーはこれらの値上げを顧客に転嫁し、ポリイミドの価格上昇につながる可能性があります。

最終用途産業からの需要は、ポリイミドの価格に影響を与えるもう 1 つの重要な要因です。たとえば、エレクトロニクス業界は、特にフレキシブルプリント回路、絶縁膜、マイクロエレクトロニクスなどの用途でポリイミドの主な消費者です。技術が進歩し、よりコンパクトで効率的で耐久性のある電子機器の需要が高まるにつれて、ポリイミド材料の需要も増加します。同様に、航空宇宙産業と自動車産業は、燃料効率と高温環境での性能を向上させるために不可欠な軽量で耐熱性のあるポリイミドに依存しています。これらの産業の成長は、ポリイミドの需要の増加につながり、価格を押し上げる可能性があります。

ポリイミドの製造と処理における技術の進歩も価格に影響を与える可能性があります。熱伝導性の向上や機械的強度の向上など、ポリイミドの性能を向上させるイノベーションは、新しい用途を生み出し、需要を促進する可能性があります。ただし、これらの技術の開発と実装には多額の投資が必要になることが多く、生産コストの上昇、ひいてはポリイミド製品の価格上昇につながる可能性があります。逆に、製造効率の向上や廃棄物の削減などの進歩はコスト削減に役立ち、より競争力のある価格設定につながる可能性があります。

世界的な経済状況は、ポリイミドの価格形成に大きな役割を果たします。景気後退や不況により主要産業の需要が減退し、メーカーが販売量を維持しようとする中で価格が下がる可能性があります。一方、経済成長や産業活動の活発化によりポリイミドの需要が高まり、価格が上昇する可能性があります。さらに、為替レートの変動は、特に国際的な買い手と売り手にとってポリイミドの価格に影響を与える可能性があります。たとえば、米ドルが強くなると、他の通貨を使用する買い手にとってポリイミドの価格が高くなり、需要と価格の動向に影響を与える可能性があります。

リアルタイムでポリイミド (Polyimide)価格: https://www.analystjapan.com/Pricing-data/polyimide-3468

環境規制と持続可能性のトレンドは、ポリイミド市場にますます影響を与えています。政府と業界が二酸化炭素排出量の削減と環境への影響の最小化に注力するにつれて、より持続可能な生産プロセスと材料に対する需要が高まっています。環境規制への準拠により、ポリイミドメーカーの生産コストが上昇し、価格の上昇に反映される可能性があります。ただし、これらのコストは、より環境に優しい生産方法の開発や、環境に配慮した消費者や業界にアピールできるバイオベースのポリイミドの導入によって相殺される可能性があります。

サプライチェーンのダイナミクスも、ポリイミドの価格を決定する上で重要な役割を果たします。自然災害、地政学的緊張、物流上の問題など、主要な原材料の供給が途絶えると、不足や価格上昇につながる可能性があります。さらに、ポリイミドの生産が特定の地域や国に集中すると、サプライ チェーンが地域的な混乱に対して脆弱になり、価格にさらなる影響を与える可能性があります。供給源の多様化と現地生産能力への投資は、これらのリスクを軽減し、価格を安定させるのに役立つ可能性があります。

要約すると、ポリイミドの価格は、原材料費、主要産業からの需要、技術の進歩、世界経済の状況、環境規制、サプライ チェーンのダイナミクスなど、さまざまな要因の複雑な相互作用によって左右されます。産業が進化し続け、ポリイミドの新しい用途が出現するにつれて、利害関係者が市場をナビゲートし、情報に基づいた決定を下すには、これらの要因を理解することが不可欠です。業界のトレンド、技術開発、世界経済指標を常に把握しておくことで、将来のポリイミドの価格動向に関する貴重な洞察を得ることができます。

ANALYST JAPAN

Call +1 (332) 258- 6602 1-2-3 Manpukuji, Asao-ku, Kawasaki 215-0004 Japan

Website: https://www.analystjapan.com

Email: [email protected]

0 notes

Text

The global demand for polyethylene naphthalate (PEN) was valued at USD 1124.5 Million in 2022 and is expected to reach USD 2081.4 Million in 2030, growing at a CAGR of 8% between 2023 and 2030.Polyethylene Naphthalate (PEN) is an advanced polymer known for its superior properties compared to conventional plastics like polyethylene terephthalate (PET). Its unique characteristics make it an attractive material for a variety of high-performance applications, driving growth in the global PEN market. This article explores the current trends, market drivers, and future outlook for the PEN market.

Browse the full report at https://www.credenceresearch.com/report/polyethylene-naphthalate-market

Overview of Polyethylene Naphthalate

PEN is a high-performance thermoplastic resin derived from the polymerization of naphthalene and ethylene glycol. It boasts a range of beneficial properties, including high thermal stability, chemical resistance, and superior mechanical strength. These attributes make PEN suitable for applications in demanding environments where traditional polymers might fail.

Market Drivers

1. Growing Demand in Electronics and Electrical Industries: The electronics and electrical sectors are major consumers of PEN due to its excellent dielectric properties and thermal stability. PEN is used in manufacturing components like insulating films, connectors, and substrates for circuit boards. As electronics become more advanced and miniaturized, the demand for high-performance materials like PEN is expected to rise.

2. Advancements in Packaging: PEN’s high barrier properties against gases and moisture make it a valuable material for packaging applications. It is increasingly used in food and beverage packaging to extend shelf life and maintain product quality. As the demand for high-quality and durable packaging materials grows, so will the need for PEN.

3. Automotive Industry Growth: The automotive industry’s shift towards lightweight and high-strength materials is driving the adoption of PEN. The polymer’s strength and durability make it suitable for use in various automotive components, from interior parts to under-the-hood applications. With the automotive industry’s focus on improving fuel efficiency and vehicle performance, PEN’s role is expected to expand.

4. Sustainable Alternatives: As sustainability becomes a critical focus across industries, PEN offers an advantage due to its recyclability and lower environmental impact compared to some traditional plastics. This shift towards more sustainable materials is likely to bolster PEN’s market growth.

Challenges Facing the PEN Market

Despite its advantages, the PEN market faces several challenges:

1. High Production Costs: PEN production involves complex processes and higher costs compared to other polymers. These costs can impact its adoption in price-sensitive applications. Manufacturers are continually working on improving production techniques and reducing costs to make PEN more competitive.

2. Limited Awareness and Application: PEN is still relatively niche compared to more widely used polymers. Limited awareness and understanding of its benefits may restrict its adoption across various industries. Increasing educational efforts and demonstrating PEN’s advantages could help expand its market presence.

3. Competition from Alternatives: Other high-performance polymers and materials, such as polyimides and PEEK, also offer similar benefits and may compete with PEN in certain applications. The PEN market must continuously innovate to maintain its competitive edge.

Market Trends

1. Technological Innovations: Ongoing research and development in polymer technology are leading to innovations in PEN production and applications. Advances in processing techniques, such as improved polymerization methods, are expected to enhance PEN’s performance and reduce production costs.

2. Emerging Applications: New and emerging applications for PEN, including advanced medical devices, aerospace components, and renewable energy technologies, are driving market growth. As industries continue to seek materials with superior properties, PEN is likely to find new and expanding applications.

3. Regional Insights: The PEN market is experiencing growth in various regions, with significant developments in North America, Europe, and Asia-Pacific. The expanding electronics and automotive industries in these regions are contributing to the increased demand for PEN.

Future Outlook

The future of the Polyethylene Naphthalate (PEN) market looks promising, driven by technological advancements and increasing demand across various sectors. While challenges remain, ongoing innovations and a growing emphasis on sustainability are expected to enhance PEN’s market position. As industries continue to seek high-performance materials, PEN’s unique properties will likely play a crucial role in shaping the future of advanced polymer applications.

Key Players

Teijin DuPont Films

Toray Monofilament Co. Ltd

Sumitomo Chemical Co. Ltd

DuraFiber Technologies Inc

SKC Inc

SASA Polyester Sanayi A.S.

DuPont

Seiwa Inc

Others

Segmentation

By Applications

Films

Bottles and Containers

Automotive Parts

Electrical and Electronic Parts

Textiles

Other Industrial Applications

By End-Use Industry

Packaging Industry

Automotive Industry

Electrical and Electronics Industry

Textile Industry

Aerospace Industry

Healthcare and Medical Industry

Other Industries

By Processing Methods

Extrusion

Injection Molding

By Grade Types

Standard PEN

Modified PEN

Reinforced PEN

By Environmental and Sustainability Aspects

Recycled PEN (r-PEN)

Biodegradable PEN

By Region

North America

The U.S.

Canada

Mexico

Europe

Germany

France

The U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/polyethylene-naphthalate-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Colorless Polyimide Films Market worth $1,102 million by 2027

The report "Colorless Polyimide Films Market by Application (Flexible Displays, Flexible Solar Cells, Flexible Printed Circuit Boards, Lighting Equipment), End-Use Industry (Electronics, Solar, Medical), and Region - Global Forecast to 2027", is expected to grow from USD 96 million in 2022 to USD 1,102 million by 2027, at a CAGR of 60.0% during the forecast period. The key factor driving the colorless polyimide market include increasing demand from applications such as flexible displays, flexible solar cells, and flexible printed circuit boards owing to its excellent heat resistance and light transmittance properties.

Download pdf-https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=16252223

Excellent light transmittance of colorless polyimide films leading to its application in flexible displays

The colorless polyimide market has been segmented into flexible displays, flexible solar cells, flexible printed circuit boards, lighting equipment, and others, on the basis of application. Amongst these, the flexible displays segment accounted for the largest share of the market in 2021. With digitalization, a significant amount of information is being consumed through electronic media such as mobiles and laptops and hence, consumers have presented demand for high-quality, convenient, and portable digital devices with advanced display designs. Designers are also looking for greater freedom in developing them and are moving away from traditional display designs to next-generation displays that are larger, thinner, lightweight, and flexible or foldable. As colorless polyimide combines the thermal resistance properties of polyimide resin with the optical performance of polymer products, it is a the forefront for making of flexible display cover windows.

Product innovation in the electronics industry presenting growth opportunities for the colorless polyimide films market

The colorless polyimide films market is segmented on the basis of end-use industry into electronics, solar, medical, and others. Out of them, the electronics segment is projected to dominate the demand for these films through the forecast period. Colorless polyimides provide excellent thermo-mechanical properties, have high chemical resistance, and are also optically transparent. These properties are suitable for manufacturing electronic components such as flexible displays and flexible printed circuit boards. With electronics companies constantly developing new products to attract potential customers, including the likes of foldable smartphones, flexible screen for laptops, and curved displays in televisions, the demand for colorless polyimides films is expected to grow during the forecast period.

Sample Request- https://www.marketsandmarkets.com/requestsampleNew.asp?id=16252223

Asia Pacific is projected to register the fastest growth between 2022 to 2027

Asia Pacific is the dominant market for colorless polyimide films. Innovation, price deflation, and rising household incomes, especially in emerging markets in Asia Pacific, have resulted in high demand for consumer electronics products in the region. Electronics companies including Oneplus, Xiaomi, Samsung, and LG, present in Asia Pacific, are well-positioned in the field of flexible electronics and dominate their commercial applications. These companies have been at the forefront in the development of electronics with flexible design using colorless polyimide films in their components. With the demand for flexible electronics gaining traction, these companies are expected to boost the production of such devices. For instance, according to OMDIA, the shipment of flexible OLED panels is expected to grow by 10 times between 2022 and 2028. Owing to these factors, the market of these films is expected to be concentrated in the Asia Pacific region through the forecast period.

DuPont (US), Kaneka Corporation (Japan), Kolon Industries Inc. (South Korea), SK Innovation Co., Ltd. (South Korea), and Sumitomo Chemical Company Ltd. (Japan) are the key players in this market. These players have adopted strategies such as expansions and new product development to enhance their position in the market.

#ColorlessPolyimideFilms#PolyimideFilms#FlexibleElectronics#TransparentPolymers#HighPerformanceMaterials#FlexibleDisplays#Optoelectronics#PolymerScience#AdvancedMaterials#ElectronicMaterials#InnovativeMaterials#PolyimideTechnology#HighTemperaturePolymers#EngineeringPlastics#FlexibleCircuits

0 notes

Text

Polyimide Prices Trend, Database, Index, News, Chart, Forecast

Polyimide prices have been subject to fluctuations in recent years due to various factors impacting the supply chain and market dynamics. Polyimides are high-performance polymers known for their exceptional thermal stability, mechanical strength, and chemical resistance, making them indispensable in industries such as electronics, aerospace, automotive, and healthcare. The cost of polyimides is influenced by several key factors, including raw material prices, manufacturing processes, demand-supply dynamics, and technological advancements.

One significant factor affecting polyimide prices is the cost of raw materials. Polyimides are typically derived from aromatic dianhydrides and aromatic diamines, which are themselves derived from petroleum or other chemical feedstocks. Fluctuations in crude oil prices, geopolitical tensions, and supply chain disruptions can all impact the cost of these raw materials, thereby affecting the overall price of polyimides. Additionally, the availability of raw materials can be influenced by factors such as natural disasters, regulatory changes, and shifts in global trade patterns, further contributing to price volatility.

Get Real Time Prices of Polyimide: https://www.chemanalyst.com/Pricing-data/polyimide-1579

Manufacturing processes also play a crucial role in determining polyimide prices. The production of polyimides involves several complex steps, including polymerization, curing, and post-treatment processes. Energy costs, labor expenses, and capital investments required for equipment and infrastructure all factor into the manufacturing cost of polyimides. Innovations in process efficiency, automation, and recycling technologies can help manufacturers optimize their operations and reduce production costs, ultimately influencing the market price of polyimides.

Demand-supply dynamics significantly impact polyimide prices, as these polymers are used in a wide range of high-performance applications. Rapid industrialization, urbanization, and technological advancements drive demand for polyimides in sectors such as electronics (e.g., flexible printed circuits, display films), aerospace (e.g., lightweight composites, thermal insulation), automotive (e.g., engine components, electrical insulation), and healthcare (e.g., medical devices, implants). Fluctuations in end-user demand, market trends, and competitive dynamics can lead to shifts in supply and demand equilibrium, thereby affecting polyimide prices.

Technological advancements and innovation also influence polyimide prices by enabling the development of new grades, formulations, and applications. Research and development efforts focused on enhancing the performance, durability, and sustainability of polyimides can lead to the introduction of advanced materials with superior properties. However, the adoption of novel technologies and materials may initially entail higher production costs, which can impact the pricing of these innovative polyimide products. Over time, economies of scale, process optimization, and market acceptance can help mitigate these cost implications.

In conclusion, polyimide prices are subject to various factors, including raw material prices, manufacturing processes, demand-supply dynamics, and technological advancements. Fluctuations in crude oil prices, manufacturing costs, end-user demand, and innovation all contribute to the volatility and pricing trends observed in the polyimide market. As industries continue to evolve and demand for high-performance materials grows, stakeholders across the value chain must closely monitor these factors to make informed decisions and navigate the complexities of the polyimide market.

Get Real Time Prices of Polyimide: https://www.chemanalyst.com/Pricing-data/polyimide-1579

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Understanding Single-Sided PCBs with PCB TRACE Technologies Inc.

At PCB TRACE Technologies Inc., we are a leading manufacturer of Single-Sided Printed Circuit Boards (PCBs), designed for simple and non-complicated circuit applications. These boards have a printed circuit on one side only and are available in three classes:

Class 1: Consumer electronics.

Class 2: Highly reliable devices.

Class 3: Critical devices, such as those in aviation.

We produce three types of single-sided PCBs: rigid, flexible, and metal-core. Rigid PCBs, made from materials like FR-4, are the most common. Flexible PCBs use Polyimide and offer bending capabilities. Metal Core PCBs, ideal for heat dissipation, use a special insulating layer to separate the copper circuit from the metal core.

Single-sided PCBs support through-hole and surface mount components, making them versatile for various applications. Contact PCB TRACE Technologies Inc. for competitive pricing and quick turnaround times for all your single-sided PCB needs.

1 note

·

View note

Text

Kapton Film Manufacturers In Delhi

Bansal Insulation and Mica House, a leading name among Kapton Film Manufacturers in Delhi, specializes in high-quality polyimide films known for their thermal stability, chemical resistance, and excellent dielectric properties. Catering to various industrial applications, their Kapton films are ideal for electronics, aerospace, and automotive sectors. With a commitment to innovation and customer satisfaction, Bansal Insulation and Mica House stands out for its precision, reliability, and competitive pricing.

#Transformers Accessories Dealers In Delhi#Bakelite Sheet Manufacturer In Delhi#Fiberglass Sheets Dealers In Faridabad#Insulation Tape Dealers In Delhi

0 notes

Text

Europe Medical Tubing Market Forecast Size Estimated to Observe Significant Growth by 2028

Business Market Insights recently announced the release of the market research titled Europe Medical Tubing Market Outlook to 2028 | Share, Size, and Growth. The report is a stop solution for companies operating in the Europe Medical Tubing market. The report involves details on key segments, market players, precise market revenue statistics, and a roadmap that assists companies in advancing their offerings and preparing for the upcoming decade. Listing out the opportunities in the market, this report intends to prepare businesses for the market dynamics in an estimated period.

Is Investing in the Market Research Worth It?

Some businesses are just lucky to manage their performance without opting for market research, but these incidences are rare. Having information on longer sample sizes helps companies to eliminate bias and assumptions. As a result, entrepreneurs can make better decisions from the outset. Europe Medical Tubing Market report allows business to reduce their risks by offering a closer picture of consumer behavior, competition landscape, leading tactics, and risk management.

A trusted market researcher can guide you to not only avoid pitfalls but also help you devise production, marketing, and distribution tactics. With the right research methodologies, Business Market Insights is helping brands unlock revenue opportunities in the Europe Medical Tubing market.

If your business falls under any of these categories – Manufacturer, Supplier, Retailer, or Distributor, this syndicated Europe Medical Tubing market research has all that you need.

What are Key Offerings Under this Europe Medical Tubing Market Research?

Global Europe Medical Tubing market summary, current and future Europe Medical Tubing market size

Market Competition in Terms of Key Market Players, their Revenue, and their Share

Economic Impact on the Industry

Europe Medical Tubing Market Analysis by Application

Production, Revenue (value), Price Trend

Cost Investigation and Consumer Insights

Industrial Chain, Raw Material Sourcing Strategy, and Downstream Buyers

Production, Revenue (Value) by Geographical Segmentation

Marketing Strategy Comprehension, Distributors and Traders

Global Europe Medical Tubing Market Forecast

Study on Market Research Factors

Who are the Major Market Players in the Europe Medical Tubing Market?

Europe Medical Tubing market is all set to accommodate more companies and is foreseen to intensify market competition in coming years. Companies focus on consistent new launches and regional expansion can be outlined as dominant tactics. Europe Medical Tubing market giants have widespread reach which has favored them with a wide consumer base and subsequently increased their Europe Medical Tubing market share.

Report Attributes

Details

Segmental Coverage

Material

Polyvinyl Chloride (PVC)

Polyimide/Nylons

PTFE/Thermoplastic Elastomers (TPES)

Thermoplastic Polyurethanes (TPUS)

Polyvinylidene Fluoride (PVDF)

Polypropylene and Polyethylene

Silicon

and Other

Others

Structure

Single-Lumen

Multi-Lumen

Multi-Layer Extruded Tubing

Tapered or Bump Tubing

Braided Tubing

Balloon Tubing

Corrugated Tubing

Heat Shrink Tubing

and Others

Others

Application

Bulk Disposable Tubing

Catheter & Cannula

Drug Delivery System

and Others

Others

End User

Hospitals and Clinics

Ambulatory Care Centres

Medical Device Companies

Laboratories

and Others

Others

Regional and Country Coverage

North America

US

Canada

Mexico

Europe

UK

Germany

France

Russia

Italy

Rest of Europe

Asia Pacific

China

India

Japan

Australia

Rest of APAC

South / South & Central America

Brazil

Argentina

Rest of South/South & Central America

Middle East & Africa

South Africa

Saudi Arabia

UAE

Rest of MEA

Market Leaders and Key Company Profiles

Compagnie de Saint Gobain SA, Nordson Corp, Optinova AB, Spectrum Plastics Group Inc, TE Connectivity Ltd, Trelleborg AB , and other key companies

What are Perks for Buyers?

The research will guide you in decisions and technology trends to adopt in the projected period.

Take effective Europe Medical Tubing market growth decisions and stay ahead of competitors

Improve product/services and marketing strategies.

Unlock suitable market entry tactics and ways to sustain in the market

Knowing market players can help you in planning future mergers and acquisitions

Visual representation of data by our team makes it easier to interpret and present the data further to investors, and your other stakeholders.

Do We Offer Customized Insights? Yes, We Do!

Business Market Insights offer customized insights based on the client’s requirements. The following are some customizations our clients frequently ask for:

The Europe Medical Tubing market report can be customized based on specific regions/countries as per the intention of the business

The report production was facilitated as per the need and following the expected time frame

Insights and chapters tailored as per your requirements.

Depending on the preferences we may also accommodate changes in the current scope.

Author’s Bio: Bhavesh Shinde Senior Market Research Expert at Business Market Insights

0 notes

Text

Polyimide Films Market Size, Share, Trends, Key Drivers, Growth and Opportunity Analysis

Global Polyimide Films Market' the new research report adds in Data Bridge Market Research's reports database. This Research Report spread across 329 Page, 53 No of Tables, And 244 No of Figures with summarizing Top companies, with tables and figures. The Polyimide Films market research report presents a comprehensive study on production capacity, consumption, import and export for all the major regions across the world. By keeping in mind the end user's point of view, a team of researchers, forecasters, analysts and industry expert's work in-depth to formulate this Polyimide Films market research report.

Polyimide Films Market research report provides data and information about the scenario of industry which makes it easy to be ahead of the competition in today's speedily altering business environment. Analytical study of this market report aids in formulating growth strategies to augment sales and build brand image in the market. The report underlines historic data along with future forecast and detailed analysis on a global, local and regional level. The winning Polyimide Films Market report also takes into account an analysis of existing major challenges faced by the business and the probable future challenges that the business may have to face while operating in this market.

Access Full 350 Pages PDF Report @

Data Bridge Market Research analyses that the global polyimide films market which was USD 34,42,943.76 thousand in 2022, is expected to reach USD 60,41,829.48 thousand by 2030, growing at a CAGR of 7.4% during the forecast period of 2023 to 2030. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

Key points covered in the report: -

The pivotal aspect considered in the global Polyimide Films Market report consists of the major competitors functioning in the global market.

The report includes profiles of companies with prominent positions in the global market.

The sales, corporate strategies and technical capabilities of key manufacturers are also mentioned in the report.

The driving factors for the growth of the global Polyimide Films Market are thoroughly explained along with in-depth descriptions of the industry end users.

The report also elucidates important application segments of the global market to readers/users.

This report performs a SWOT analysis of the market. In the final section, the report recalls the sentiments and perspectives of industry-prepared and trained experts.

The experts also evaluate the export/import policies that might propel the growth of the Global Polyimide Films Market.

The Global Polyimide Films Market report provides valuable information for policymakers, investors, stakeholders, service providers, producers, suppliers, and organizations operating in the industry and looking to purchase this research document.

Table of Content:

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Global Polyimide Films Market Landscape

Part 04: Global Polyimide Films Market Sizing

Part 05: Global Polyimide Films Market Segmentation by Product

Part 06: Five Forces Analysis

Part 07: Customer Landscape

Part 08: Geographic Landscape

Part 09: Decision Framework

Part 10: Drivers and Challenges

Part 11: Market Trends

Part 12: Vendor Landscape

Part 13: Vendor Analysis

The investment made in the study would provide you access to information such as:

Polyimide Films Market [Global – Broken-down into regions]

Regional level split [North America, Europe, Asia Pacific, South America, Middle East & Africa]

Country-wise Market Size Split [of important countries with major market share]

Market Share and Revenue/Sales by leading players

Market Trends – Emerging Technologies/products/start-ups, PESTEL Analysis, SWOT Analysis, Porter’s Five Forces, etc.

Market Size

Market Size by application/industry verticals

Market Projections/Forecast

Some of the major players operating in the global polyimide films market are:

DuPont (U.S.)

Saint-Gobain (France)

UBE Industries, Ltd. (Japan)

Kaneka Corporation (Japan)

SKC Kolon PI, Inc. (South Korea)

CEN Electronic Material Co., Ltd. (China)

FLEXcon Company, Inc. (U.S.)

Dunmore Corporation (U.S.)

L&L Products, Inc. (U.S.)

Shinmax Technology Ltd. (China)

Everbrighten Technologies (China)

Jiangsu Yabao Insulation Material Inc. (China)

Taimide Tech. Inc. (Taiwan)

SABIC (Saudi Arabia)

Changchun Group (China)

Browse Trending Reports:

Extrusion Coating Market

Sulfur Hexafluoride Sf6 Market

Epoxidized Soybean Oil Market

Polyimide Film Market

Self Cleaning Glass Market

Floating Solar Panel Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 888 387 2818

UK: +44 208 089 1725

Hong Kong: +852 8192 7475

Email: [email protected]

#Polyimide Films Market Size#Share#Trends#Key Drivers#Growth and Opportunity Analysis#market report#market share#market size#market trends#market analysis#market research#marketresearch#markettrends

0 notes

Text

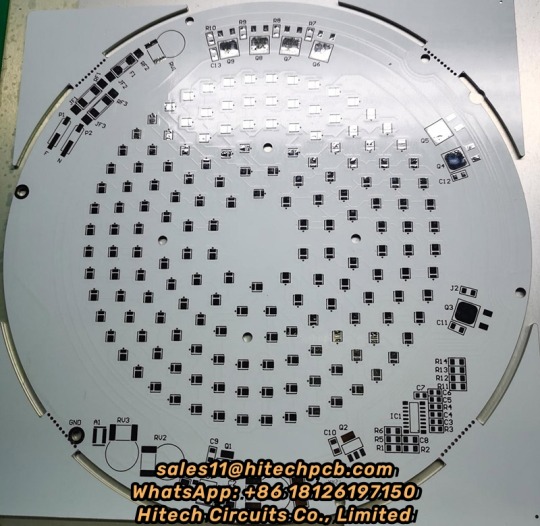

Aluminium PCB

1. What’s Aluminium LED PCB?

Aluminum LED PCB substrate is a metal - based copper-clad sheet with good heat dissipation. A single panel is generally composed of three layers of structure, namely the circuit layer (copper foil), insulation layer and metal base layer. It is commonly found in LED lighting products. There are two sides, the white side is used to weld the LED pins, and the other side is the natural color of aluminum, which is usually coated with heat-conducting gel and then in contact with the heat-conducting part. Among all metal core PCBS, Aluminum LED PCB is the most common type. The base material consists of an aluminum core and standard FR4. It features a thermal cladding that dissipates heat in an efficient manner while cooling components and improving the overall performance of the product. Currently, aluminum-backed PCBS are considered solutions for high power and tight tolerance applications.

2. Aluminum LED PCB with Copper Layer, Dielectric Layer & Aluminum Layer

Aluminum LED PCB has a similar layout to any other printed circuit boards with copper layer(s), solder mask layer(s) and silkscreen(s). Instead of having a fiberglass or plastic substrate, Aluminum LED PCB is made from metal core substrate, which consists of copper layer, dielectric layer and aluminum layer. This substrate is called as Aluminum based copper clad laminate (CCL). The glass reinforced and ceramic filled dielectric layer in-between copper layer and aluminum layer is very thin, but plays a very important role of electric insulation and thermal conductivity (because of minimum thermal resistance) from copper layer to aluminum base. The copper is etched into conductors and metal base is to withdraw thermal (/heat). The superior heat transfer capacity of Aluminum-based PCB helps cooling components while eliminating problems associated with managing fragile ceramics.

3. Thermal conductivity of Aluminium LED PCB

The general thermal conductivity of Aluminum LED PCB is 0.3, 0.6, 1.0, 1.5, 2.0, 3.0, 5.0, 122W/m.k, etc., among which 0.3-1.0w /m.k is the general conductive Aluminum LED PCB, 1.5W/m.k is the middle conductive Aluminum LED PCB, 2.0-3.0w /m.k is the high conductive Aluminum LED PCB. 5.0W/m.k is thin abasal substrate, and 122W/m.k is ultra-high conductivity Aluminum LED PCB, also known as ALC Aluminum LED PCB.

At present, the common Aluminum LED PCB on the market has a thermal conductivity of 1.0, 1.5, 2.0W/m.k high conductivity type Aluminium LED, wherein the thermal conductivity of 1.0W/m.k Aluminum LED PCB is called general Aluminum LED PCB, its insulation layer is composed of epoxy glass cloth bonded sheet; Aluminum LED PCB with thermal conductivity of 1.5W/m.k is called high heat dissipation Aluminum LED PCB, and its insulation layer is composed of epoxy resin or other resins with high thermal conductivity; The Aluminum LED PCB with a thermal conductivity of 2.0W/m.k is called the Aluminum LED PCB for high-frequency circuit, and the insulating layer is composed of polyolefin resin or Polyimide resin glass cloth bonded sheet. The thermal conductivity of Aluminum LED PCB varies according to the copper layer in the circuit. Different processes produce different levels of thermal conductivity.

We currently support Aluminum based CCLs from Ventec, GDM and BoYu with thermal conductivity from 1.0 ~ 7 W/m•K. The Aluminum LED PCB prices of Ventec is much higher than that with GDM and BOYU since material cost, and the prices of high thermal conductivity is higher than low thermal conductivity. Hitechpcb provides a wide range of electrical and thermally conductive interface pads, thermally conductive gap filler, thermal phase change materials and thermally conductive electrically insulating materials, as well as specialized equipment for high volume Aluminum LED PCB manufacturing. Choosing Hitech Circuits PCB as your Aluminum LED PCB supplier, just send your Gerber files and fabrication notes to us, we will deliver qualitied PCB boards to you on time.

4. Dielectric Constant of Aluminium LED PCB

The dielectric constant of Aluminum LED PCB substrate is a special detection method for Aluminum LED PCB. It is a variable Q value series resonance method through the measurement of dielectric constant and dielectric loss factor. The sample and tuning capacitor are connected in series to the high frequency circuit to measure the series circuit The principle of Q value.

The performance of Aluminum LED PCB includes requirements such as peel strength, surface resistivity, minimum breakdown voltage, dielectric constant, flammability and thermal resistance.

5. Aluminum LED PCB with White Solder Mask

The retail price of Aluminum LED lights has dropped dramatically in recent years, while the energy efficiency and brightness of LED lights have improved. These technological advances have led some to predict annual growth of 45% over the next five years. With the development of the LED industry, the demand for LED PCBS and solder masks is also increasing. Solder shield is a protective coating applied to exposed printed circuit boards. The exposed PCB board is covered with a mask to prevent accidental solder bridging during PCB assembly and to protect the PCB from the environment. Solder masks are traditionally green, and are expected to withstand the high temperatures that occur in reflow soldering, as different colors such as blue, red, or black will occasionally appear. Increased production of Hitch Aluminum LED PCB requires increased whiteness and color stability of the mask. Aluminum LED PCB commonly used LPI welding color is white and black, of which white welding color is the most commonly used to achieve high brightness and perfect light reflection. White Aluminum LED PCB ensures no darkening and will not affect the color temperature of LED smd. At the same time, it also helps to increase the life of LED applications. Looking for reliable Aluminum LED PCB suppliers, Hitech is a good choice.

6. Classification of Aluminum LED PCB Substrate

Aluminum LED PCB-based copper clad plates are divided into three categories:

The first is the universal aluminum-based copper clad plate, the insulation layer is composed of epoxy glass cloth bonded sheet;

The second is the high heat dissipation aluminum-based copper-clad plate, the insulation layer is composed of high thermal conductivity epoxy resin or other resins;

Third, high frequency circuit aluminum base copper plate, insulation layer by polyolefin resin or Polyimide resin glass cloth bonded sheet.

The biggest difference between aluminum clad copper plate and conventional FR-4 clad copper plate is heat dissipation. Compared with 1.5mm thickness of FR-4 clad copper plate and aluminum clad copper plate, the former thermal resistance of 20 ~ 22 ℃, the latter thermal resistance of 1.0 ~ 2.0℃, the latter is much smaller.

7. Aluminum LED PCB Performance:

(1) Heat dissipation

Many double panel, multi - layer plate high density, power, heat distribution is difficult. Conventional printed board substrates such as FR4, CEM3 are bad conductors of heat, insulation between layers, heat does not escape. Local heating of electronic equipment is not excluded, leading to high temperature failure of electronic components, and Aluminum LED PCB can solve this problem of heat dissipation.

(2) Thermal Expansibility

Thermal expansion and cold contraction is the common nature of substances, and the coefficient of thermal expansion of different substances is different. Aluminum based printed board can effectively solve the problem of heat dissipation, so that the printed board components of different substances on the thermal expansion and contraction problem, improve the durability and reliability of the whole machine and electronic equipment. Especially solve SMT (surface mount technology) thermal expansion and shrinkage problems.

(3) Dimensional stability

Aluminum-based printed boards are obviously much more stable in size than those made of insulating materials. Aluminum base printed board, aluminum sandwich board, heating from 30℃ to 140~150℃, the size change is 2.5~3.0%.

(4) Other reasons

Aluminum based printed board, with shielding effect; Instead of brittle ceramic substrate; Safe use of surface mounting technology; Reducing the real effective area of the printed board; Instead of radiator and other components, improve the heat resistance and physical properties of products; Reduce production costs and labor.

8. Why choose Aluminum LED PCB from Hitechpcb? What are the advantages of Aluminum LED PCB?

(1) Good heat dissipation performance: Aluminum LED PCB can reduce the thermal resistance to the minimum, has a smaller thermal resistance, thermal expansion coefficient is closer to copper foil, so that Aluminum LED PCB has excellent thermal conductivity and heat dissipation performance, reduce the module operating temperature, prolong the service life.

High current load: Using the same thickness, the same line width, Aluminum LED PCB substrate can carry higher current.

(2) Good machinability: can replace ceramic substrate, better mechanical endurance. At the same time, high strength and toughness, can realize large area printed board manufacturing and component mounting.

(3) Good electromagnetic shielding: In order to ensure the performance of electronic circuits, some components of electronic products need to prevent electromagnetic radiation and interference. Aluminum LED PCB can act as a shield plate, play the role of shielding electromagnetic wave

(4) Environmental protection: The Aluminum LED PCB used in the raw material is non-toxic and can be recycled. Meet RoHs requirements.

(5)Light weight: Aluminum LED PCB has a surprisingly light weight with excellent strength and elasticity, which is very convenient.

Hitech Circuits can provide high quality and affordable Aluminum LED PCB products for you.

9. Technical requirements for Aluminum LED PCB

The main technical requirements are:

1. Dimensional requirements: including panel size and deviation, thickness and deviation, perpendicularity and warpage; Appearance, including cracks, scratches, burrs and delimitation, aluminum oxide film, etc.

2. Performance requirements, including peel strength, surface resistively, minimum breakdown voltage, dielectric constant, combustion and thermal resistance requirements.

10. Special test method for Aluminum-based copper clad plates

One is the measurement method of dielectric constant and dielectric loss factor. It is the series resonance method with variable Q value. The sample and tuned capacitor are connected to the high-frequency circuit in series to measure the Q value of the series circuit.

The other is the measurement method of thermal resistance, which is calculated by the ratio of temperature difference and heat conduction between different temperature measurement points.

11. The Aluminum LED PCB manufacturing process in Hitechpcba

(1)Substrate cutting

a. cutting process: material → cutting

b. Note: ① Check the size of the first piece; ② Pay attention to Aluminum surface scratching and copper surface scratching; ③ Pay attention to the layering of the board edge and the tip.

(2)Plate drilling

a, drilling process: pin → drilling → inspection plate

b, matters needing attention: ① check the number of drilling holes, the size of the empty chestnut chain; ② Check the plate burr, hole deviation; ③ Avoid scratching the substrate; ④ Check and replace the drill nozzle.

(3) Imaging transfer

a, graphic imaging process: grinding plate → film → exposure → development

b, precautions: ① Check whether there is an open circuit after development; ② Pay attention to the poor line caused by the board wipe; ③ There can be no air residual exposure to prevent poor exposure; ④ Whether there is deviation in developing counterpoint; ⑤ After exposure, the development should be done at rest for more than 15 minutes.

(4)Solder mask and Silkscreen process

a, kill row silk printing resistance welding, character process: screen printing → pre-baking → exposure → development → character

b, matters needing attention: ① Check whether there is foreign body on the board; ② Pay attention to the cleaning of the net board; ③ Pre-bake for more than 30 minutes after screen printing, to avoid bubbles in the line; ④ Pay attention to the thickness and uniformity of screen printing; ⑤ After the pre-baked plate to completely mutual cooling, avoid touching film or damage to the ink surface gloss.

(5)E-test or flying probe test

a, test process: line test → withstand voltage test

b, precautions: ① How to distinguish after the test how to store qualified and unqualified products.

(6)FQC, FQA, packaging, shipping

a. Process: FQC→FQA→ Packaging → shipping

b. Note: ① FQC should pay attention to the confirmation of the appearance of the finished Aluminum LED PCB in the process of eye inspection and make a reasonable distinction; ② FQA does spot check and verify the inspection standards of FQC; ③ We should confirm the number of packages to avoid mixed plates, wrong plates and package

12. Application of Aluminum LED PCB

1. Audio devices: input, output amplifier, balance amplifier, audio amplifier, preamplifier, power amplifier.

2. Power Supply: switching voltage regulator, DC/AC converter, SW voltage regulator, etc.

3. Communication electronic equipment: high frequency amplifier, filter, transmitter circuit

4. Office automation equipment: motor drive, etc

5. Automobile: electronic regulator, ignition device, power controller, etc.

6. Computer :CPU board, floppy disk drive, power equipment, etc.

7. Power module: converter, solid relay, rectifier bridge, etc

8. Lamps and lighting: A variety of colorful LED energy-saving lamps are well received by the market, and Aluminum LED PCB used in LED lights has also begun to be applied on a large scale.

13. Aluminum LED PCB Storage Conditions

Aluminum LED PCB are generally stored in a dark and dry environment. Most Aluminum LED tube lighting metal core pcb are prone to dampness, yellowing, and blackening. Generally, they should be used within 48 hours after opening the vacuum package.

14. Specification for the manufacture of Aluminum LED PCB

a. Aluminum LED PCB is often used in power devices, power density is high, so the copper foil is thicker. If copper foils over 3oz are used, the etching of thick copper foils requires engineered line width compensation, otherwise the line width will be out of tolerance after etching.

b. The aluminum base surface of aluminum substrate must be protected by protective film in advance during PCB processing, otherwise, some chemicals will etch the aluminum base surface, resulting in appearance damage. And the protective film is easy to be hurt, resulting in gaps, which requires the whole PCB processing process must be inserted.

c. The hardness of the milling cutter used by the glass fiber board gong board is relatively small, and the hardness of the milling cutter used by the aluminum substrate is large. In the process of manufacturing glass fiber board milling cutter speed, while the production of aluminum substrate is at least two thirds slower.

d, computer milling glass fiber board is just the use of the machine's own cooling system, but the processing of aluminum substrate must be in addition to alcohol heat dissipation for the gong head.

15. Aluminum LED PCB circuit fabrication

(1) Mechanical processing: Drilling of aluminum substrate can be done, but no burr is allowed on the edge of the inner hole after drilling, which will affect the pressure test. Milling the shape is very difficult. And punching shape, need to use advanced mold, mold production is very skilled, as one of the difficulties of aluminum substrate. After shape punching, the edge should be very neat, without any burr, and do not hurt the welding resistance layer on the edge of the plate. Usually the use of soldier die, hole from the line, shape from the aluminum surface, circuit board punching force is cut down, and so on are skills. After punching the shape, the warpage of the board should be less than 0.5%.

(2) The whole production process is not allowed to wipe the aluminum base surface: aluminum base touch, or by a certain chemical will produce surface discoloration, blackening, which is absolutely unacceptable, re-polishing aluminum base some customers do not receive, so the whole process does not touch the aluminum base surface is one of the difficulties in the production of aluminum base plate. Some enterprises use passivation process, some in hot air leveling (spray tin) before and after each pasted protective film.

(3) Over-high voltage test: the aluminum base board of the communication power supply shall be tested at 100% high voltage. Some customers require direct current or alternating current. The voltage shall be 1500V or 1600V, and the time shall be 5 seconds or 10 seconds. Dirt on the board, holes and aluminum edge burr, line saw tooth, damage to any little insulation layer will lead to high voltage test fire, leakage, breakdown. Pressure test board stratification, foaming, are rejected.

1 note

·

View note

Text

What’s Aluminium LED PCB?

Aluminum LED PCB substrate is a metal - based copper-clad sheet with good heat dissipation. A single panel is generally composed of three layers of structure, namely the circuit layer (copper foil), insulation layer and metal base layer. It is commonly found in LED lighting products. There are two sides, the white side is used to weld the LED pins, and the other side is the natural color of aluminum, which is usually coated with heat-conducting gel and then in contact with the heat-conducting part. Among all metal core PCBS, Aluminum LED PCB is the most common type. The base material consists of an aluminum core and standard FR4. It features a thermal cladding that dissipates heat in an efficient manner while cooling components and improving the overall performance of the product. Currently, aluminum-backed PCBS are considered solutions for high power and tight tolerance applications.

2. Aluminum LED PCB with Copper Layer, Dielectric Layer & Aluminum Layer

Aluminum LED PCB has a similar layout to any other printed circuit boards with copper layer(s), solder mask layer(s) and silkscreen(s). Instead of having a fiberglass or plastic substrate, Aluminum LED PCB is made from metal core substrate, which consists of copper layer, dielectric layer and aluminum layer. This substrate is called as Aluminum based copper clad laminate (CCL). The glass reinforced and ceramic filled dielectric layer in-between copper layer and aluminum layer is very thin, but plays a very important role of electric insulation and thermal conductivity (because of minimum thermal resistance) from copper layer to aluminum base. The copper is etched into conductors and metal base is to withdraw thermal (/heat). The superior heat transfer capacity of Aluminum-based PCB helps cooling components while eliminating problems associated with managing fragile ceramics.

3. Thermal conductivity of Aluminium LED PCB

The general thermal conductivity of Aluminum LED PCB is 0.3, 0.6, 1.0, 1.5, 2.0, 3.0, 5.0, 122W/m.k, etc., among which 0.3-1.0w /m.k is the general conductive Aluminum LED PCB, 1.5W/m.k is the middle conductive Aluminum LED PCB, 2.0-3.0w /m.k is the high conductive Aluminum LED PCB. 5.0W/m.k is thin abasal substrate, and 122W/m.k is ultra-high conductivity Aluminum LED PCB, also known as ALC Aluminum LED PCB.

At present, the common Aluminum LED PCB on the market has a thermal conductivity of 1.0, 1.5, 2.0W/m.k high conductivity type Aluminium LED, wherein the thermal conductivity of 1.0W/m.k Aluminum LED PCB is called general Aluminum LED PCB, its insulation layer is composed of epoxy glass cloth bonded sheet; Aluminum LED PCB with thermal conductivity of 1.5W/m.k is called high heat dissipation Aluminum LED PCB, and its insulation layer is composed of epoxy resin or other resins with high thermal conductivity; The Aluminum LED PCB with a thermal conductivity of 2.0W/m.k is called the Aluminum LED PCB for high-frequency circuit, and the insulating layer is composed of polyolefin resin or Polyimide resin glass cloth bonded sheet. The thermal conductivity of Aluminum LED PCB varies according to the copper layer in the circuit. Different processes produce different levels of thermal conductivity.

We currently support Aluminum based CCLs from Ventec, GDM and BoYu with thermal conductivity from 1.0 ~ 7 W/m•K. The Aluminum LED PCB prices of Ventec is much higher than that with GDM and BOYU since material cost, and the prices of high thermal conductivity is higher than low thermal conductivity. Hitechpcb provides a wide range of electrical and thermally conductive interface pads, thermally conductive gap filler, thermal phase change materials and thermally conductive electrically insulating materials, as well as specialized equipment for high volume Aluminum LED PCB manufacturing. Choosing Hitech Circuits PCB as your Aluminum LED PCB supplier, just send your Gerber files and fabrication notes to us, we will deliver qualitied PCB boards to you on time.

4. Dielectric Constant of Aluminium LED PCB

The dielectric constant of Aluminum LED PCB substrate is a special detection method for Aluminum LED PCB. It is a variable Q value series resonance method through the measurement of dielectric constant and dielectric loss factor. The sample and tuning capacitor are connected in series to the high frequency circuit to measure the series circuit The principle of Q value.

The performance of Aluminum LED PCB includes requirements such as peel strength, surface resistivity, minimum breakdown voltage, dielectric constant, flammability and thermal resistance.

5. Classification of Aluminum LED PCB Substrate

Aluminum LED PCB-based copper clad plates are divided into three categories:

The first is the universal aluminum-based copper clad plate, the insulation layer is composed of epoxy glass cloth bonded sheet;

The second is the high heat dissipation aluminum-based copper-clad plate, the insulation layer is composed of high thermal conductivity epoxy resin or other resins;

Third, high frequency circuit aluminum base copper plate, insulation layer by polyolefin resin or Polyimide resin glass cloth bonded sheet.

The biggest difference between aluminum clad copper plate and conventional FR-4 clad copper plate is heat dissipation. Compared with 1.5mm thickness of FR-4 clad copper plate and aluminum clad copper plate, the former thermal resistance of 20 ~ 22 ℃, the latter thermal resistance of 1.0 ~ 2.0℃, the latter is much smaller.

6. Aluminum LED PCB Performance:

(1) Heat dissipation

Many double panel, multi - layer plate high density, power, heat distribution is difficult. Conventional printed board substrates such as FR4, CEM3 are bad conductors of heat, insulation between layers, heat does not escape. Local heating of electronic equipment is not excluded, leading to high temperature failure of electronic components, and Aluminum LED PCB can solve this problem of heat dissipation.

(2) Thermal Expansibility

Thermal expansion and cold contraction is the common nature of substances, and the coefficient of thermal expansion of different substances is different. Aluminum based printed board can effectively solve the problem of heat dissipation, so that the printed board components of different substances on the thermal expansion and contraction problem, improve the durability and reliability of the whole machine and electronic equipment. Especially solve SMT (surface mount technology) thermal expansion and shrinkage problems.

(3) Dimensional stability