#Polycarbonate Composites Market Trends

Text

Medical Plastics: Industry Dynamics, Major Companies Analysis and Forecast- 2030

Medical Plastics Industry Overview

The global medical plastics market size was estimated at USD 52.9 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 7.4% from 2024 to 2030.

This growth can be attributed to the development of advanced plastics and plastic composites used in medical components such as catheters, surgical instrument handles, and syringes. The demand for medical device packaging is likely to be driven by a rise in demand for in-house and advanced medical devices. Plastics including polyethylene, polypropylene, and polycarbonate are increasingly being utilized for the manufacturing of medical devices. The growth of home healthcare due to its low costs compared to hospital care and intensive care has resulted in a rise in demand for medical devices.

Gather more insights about the market drivers, restrains and growth of the Medical Plastics Market

According to the latest U.S. census, 16.8% of the U.S. population is over the age of 65 years and this number is anticipated to reach 74 million by 2030. People aged over 85 need the most care and their population is growing rapidly. In March 2021, the U.S. President, Joe Biden, proposed spending USD 400 billion on Medicaid over eight years to fund at-home care for elderly and disabled people as well as increase the wages of caregivers.

In the U.S., the frequent increment in costs and reduced margins have severely impacted healthcare providers and health plans. This compelled the government to ensure a significant transformation of healthcare funding and insurance coverage segments in the country through the introduction of ACA and Medicaid.

The COVID-19 pandemic has made in-home care more appealing than nursing home facilities as home care reduces healthcare costs and is more convenient for patients. According to Medicaid and CHIP Payment and Access Commission (MACPAC), it costs about USD 26,000 a year for home care compared to USD 90,000 a year for a nursing home. Increasing investment in healthcare by the government and rising preference for home care are expected to drive the medical plastics market in the U.S. over the forecast period.

The presence of key manufacturers such as Dow, Inc., Eastman Chemical Co., and DuPont can be regarded as one of the major factors driving the market for medical plastics in the country.

Browse through Grand View Research's Plastics, Polymers & Resins Industry Research Reports.

• The global wood pallets market size was estimated to be USD 13.12 billion in 2023, growing at a CAGR of 4.5% from 2024 to 2030.

• The global food wrap market size was estimated at USD 5.15 billion in 2023 and is projected to grow at a CAGR of 7.5% from 2024 to 2030.

Global Medical Plastic Market Report Segmentation

This report forecasts volume & revenue growth at global, regional, and country levels and provides an analysis of latest industry trends in each of sub-segments from 2018 to 2030. For this study, Grand View Research has segmented the global medical plastic market report based on product, application, and region.

Product Outlook (Volume, Kilotons & Revenue, USD Million, 2018 - 2030)

Polyethylene (PE)

Polypropylene (PP)

Polycarbonate (PC)

Liquid Crystal Polymer (LCP)

Polyphenylsulfone (PPSU)

Polyethersulfone (PES)

Polyethylenimine (PEI)

Polymethyl Methacrylate (PMMA)

Others

Process Technology Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Extrusion

Injection Molding

Blow Molding

Other

Application Outlook (Volume, Kilotons & Revenue, USD Million, 2018 - 2030)

Medical Device Packaging

Medical Components

Orthopedic Implant Packaging

Orthopedic Soft Goods

Wound Care

Cleanroom Supplies

BioPharm Devices

Mobility Aids

Sterilization and Infection Prevention

Tooth Implants

Denture Base Material

Other Implants

Others

Region Outlook (Volume, Kilotons & Revenue, USD Million, 2018 - 2030)

North America

U.S.

Canada

Mexico

Europe

Germany

U.K.

France

Italy

Netherland

Asia Pacific

China

India

Japan

Central & South America

Brazil

Argentina

Middle East & Africa

Saudi Arabia

UAE

Key Medical Plastics Company Insights

Some key market players include BASF SE; Celanese Corporation; Evonik Industries AG; SABIC; Dow, Inc.; Solvay S.A.; Trinseo S.A.; and Eastman Chemical Company.

Key Medical Plastics Companies:

The following are the leading companies in the medical plastics market. These companies collectively hold the largest market share and dictate industry trends. Financials, strategy maps & products of these medical plastics companies are analyzed to map the supply network.

Röchling SE & Co. KG

Nolato AB

Saint-Gobain

SABIC

Orthoplastics Ltd

Eastman Chemical Company

Celanese Corporation

Dow, Inc.

Tekni-Plex, Inc.

Solvay S.A.

HMC Polymers Company Limited

ARAN BIOMEDICAL TEORANTA

Trelleborg Group

Avantor, Inc.

Trinseo

Evonik Industries AG

Recent Developments

Some key players operating in market include BASF SE; Celanese Corporation; Evonik Industries AG; SABIC; Dow, Inc.; Solvay S.A.; Trinseo S.A.; Eastman Chemical Company among others.

In February 2023, Cleanse Corporation announced the acquisition of DUPONT's mobility and mobility business for USD 11.00 billion. This strategic move enables Cleanse to expand its global reach and enhance its offerings in the environmental sector, particularly in sustainable transportation.

In June 2023, SABIC acquired Clariant's 50% stake in Scientific Design, a renowned catalysis leader. This acquisition bolstered the non-cyclical, technology-driven business and brought it closer to becoming a leading global specialist

Order a free sample PDF of the Medical Plastics Market Intelligence Study, published by Grand View Research.

0 notes

Text

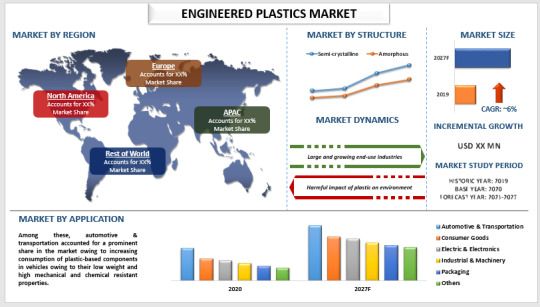

Analyzing the Engineered Plastics Market: Trends and Growth Potential

Engineered plastics, also known as engineering plastics market, are a group of plastic materials that have enhanced mechanical and thermal properties, making them suitable for more demanding applications than standard plastics. These materials are used in a wide range of industries, including automotive, aerospace, electronics, and healthcare. This article explores the current trends, driving forces, challenges, and future prospects of the engineered plastics market.

Understanding Engineered Plastics

Engineered plastics are polymers that exhibit superior strength, heat resistance, and durability compared to commodity plastics. Common types of engineered plastics include polycarbonate (PC), acrylonitrile butadiene styrene (ABS), polyamide (PA or nylon), polyoxymethylene (POM or acetal), and polyphenylene oxide (PPO). These materials are used in applications that require high performance and reliability.

Key Market Drivers

Growth in End-Use Industries: The expansion of industries such as automotive, aerospace, electronics, and healthcare is a major driver for the engineered plastics market. These industries demand materials that can withstand harsh environments, offer high precision, and contribute to lightweighting and energy efficiency.

Technological Advancements: Innovations in polymer science and manufacturing processes are enhancing the properties of engineered plastics. Advances such as reinforced composites, biodegradable polymers, and 3D printing materials are broadening the application scope of engineered plastics.

Environmental Regulations and Sustainability: Stringent environmental regulations and the growing emphasis on sustainability are driving the demand for engineered plastics. These materials are often recyclable, contribute to energy savings through lightweighting, and can replace metal parts, reducing the overall environmental impact.

Market Segmentation

The engineered plastics market can be segmented based on type, application, and region.

By Type:

Polycarbonate (PC): Known for its high impact resistance and transparency, used in automotive parts, electronics, and medical devices.

Acrylonitrile Butadiene Styrene (ABS): Offers good toughness and rigidity, used in automotive components, consumer electronics, and toys.

Polyamide (PA or Nylon): Known for its strength and wear resistance, used in automotive parts, textiles, and industrial applications.

Polyoxymethylene (POM or Acetal): Provides high stiffness and dimensional stability, used in precision parts like gears and bearings.

Polyphenylene Oxide (PPO): Offers high thermal stability and electrical insulation, used in electrical and electronic components.

By Application:

Automotive: Engineered plastics are used for components like fuel systems, interior and exterior parts, and under-the-hood applications.

Aerospace: These materials are used in lightweight structural components, interior parts, and insulation.

Electronics: Used in housings, connectors, and circuit boards.

Healthcare: Employed in medical devices, surgical instruments, and diagnostic equipment.

Industrial: Used in machinery parts, gears, bearings, and conveyor systems.

By Region:

North America: Driven by advancements in technology and the presence of key end-use industries.

Europe: Emphasis on sustainability and high-performance materials.

Asia-Pacific: Rapid industrialization and growth in automotive and electronics industries.

Latin America and Middle East & Africa: Emerging markets with increasing demand for high-performance materials.

Challenges in the Market

Despite the positive growth outlook, the engineered plastics market faces several challenges:

High Costs: The production and raw material costs for engineered plastics are higher than for commodity plastics, which can limit their adoption in cost-sensitive applications.

Regulatory Compliance: Meeting stringent environmental and safety regulations requires continuous innovation and investment in research and development.

Market Competition: The market is highly competitive, with numerous players offering a wide range of products. Differentiating based on quality, performance, and sustainability is crucial for gaining a competitive edge.

Request for a sample of the report browse through- https://univdatos.com/get-a-free-sample-form-php/?product_id=23691

Future Prospects

The future of the engineered plastics market is promising, with several growth opportunities on the horizon:

Advancements in Composite Materials: The development of reinforced composites and hybrid materials will enhance the performance characteristics of engineered plastics, expanding their application range.

Growth in Emerging Markets: Emerging economies in Asia-Pacific, Latin America, and Africa present significant growth opportunities. Increasing industrialization and infrastructure development in these regions will drive the demand for engineered plastics.

Sustainability Initiatives: The push for sustainability will continue to drive innovations in biodegradable and recyclable engineered plastics. These materials will play a crucial role in reducing the environmental impact of various industries.

Conclusion

The engineered plastics market is set for robust growth, driven by the expansion of end-use industries, technological advancements, and sustainability trends. While challenges such as high costs and regulatory compliance persist, innovations in composite materials and the growth of emerging markets offer substantial opportunities. As industries evolve, engineered plastics will continue to play a vital role in delivering high-performance, durable, and sustainable solutions.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

Global Bio-based Polycarbonate Market Assessment, Opportunities and Forecast, 2030

Bio-based Polycarbonate Market size was valued at USD 75.28 million in 2022, expected to reach USD 145.65 million in 2030 with a CAGR of 8.6% for the forecast period between 2023 and 2030. Conventional polycarbonate resins are made from bisphenol A, which raises the concerns of sustainable goals and innovation shifted to derive alternate polycarbonate from bio or natural resources. Polycarbonates have many applications used alone or blended for numerous sectors like electronics, automotive, housewares, etc. Being produced from natural resources, the features of polycarbonates got enhanced, like delivering excellent optical properties, chemical & UV resistance, higher surface resistance, etc.

Sample report- https://www.marketsandata.com/industry-reports/bio-based-polycarbonate-market/sample-request

Electronics Industry is Augmenting the Bio-based Polycarbonate Market While Concerning the Sustainable Goals

Bio-based polycarbonate copolymer drives the electronics industry by providing sustainable materials and achieving net-zero carbon emissions. It is successively used as a smartphone battery cover, which should be certified by prominent certifications. The bio-based polycarbonate is made of a minimum composition of natural polymers and a maximum content of post-consumer products. Such effective polycarbonates assist in thin-wall injection molding for numerous applications, including electrical housings or health care. SABIC has developed high-performance bio-based polycarbonate that comprises around 21% natural polymers (like vegetable oils) and over 50% post-consumer recycled resin, along with pre-consumer recycled carbon fibers. Substantially the product is halogen free and PIN flame retarded and progressively used for electronics packaging.

Data released by the Static PIB states that the global market industry in 2020 is dominantly estimated at around USD 2.9 trillion, which is almost equivalent to India’s economy. India is growing exponentially, creating a huge production potential of around USD 25 billion in the electronics industry, around 12% of global investment. A survey data published by the Japan Electronics and Information Technology Industries Association JEITA states that the global electronics and IT industries are estimated to rise 5% in 2022, total to USD 3,536.6 billion.

Automotive Industry is Propelling Exceptionally using Bio-based Polycarbonates

Bio-based polycarbonate possesses unique features like incredible optical properties, high transparency, and phenomenal scratch resistance. These properties are substantially important in the perspective of automotive vehicles. Plant-derived polycarbonates are contributing to developing enhanced vehicle features and appearance with extended durability. These polymer formulations develop additional sustainable benefits supporting the economy and reducing product carbon footprint. Mitsubishi Chemical has developed excellent plant-based bicarbonate resin extensively used for automotive exterior and interior parts. Plant-based isosorbide polycarbonates have excellent optical properties and retain high surface hardness and transparency characteristics, imparting vivid colors in the transparent panels.

The demand for cars in South America has increased by 1.8%, accounting for 2.8 million units sold in 2022, where Brazil is contributing majorly to such a segment. In 2022, Indian passenger car sales rose by 23.1%, achieving 3.8 million units due to effective measures taken by the Indian government like lower interest rates. Taking account of 2023, the outlook for the European market is convincingly showing positive trends to create huge growth for the automotive industry.

Roofing Solutions has Effectively Improved by Incorporating Bio-based Polycarbonates

Bio-based Polycarbonate have successively enhanced the roofing and sliding solution from huge malls to large stadiums. The selection of high-strength and durable panels that enable varying heat and light intensity can lead to the proper architecture of such massive constructions. Palram Industries Ltd. is successfully manufacturing polycarbonate flat and corrugated panels for a wide range of applications. Its unique roofing and sliding solutions use proprietary SolarSmart technology which effectively facilitates light penetration selectively. From building huge malls to advancing world-class Olympic stadiums, they have numerous accountings of such projects that provide thermal insulation, heat blocking, chemical resistance, light transmission, and diffusion.

Annual report published by Stadiums Queensland (SQ) stated that during 2021-2022, Stadiums Queensland (SQ) hosted more than 3.4 million patrons across entire venues that substantially contributed more than USD 646 million in economic benefit to the Queensland economy and created around 5,717 FTE jobs for various event-related industries including cleaning, catering, and security.

Impact of COVID-19

The outbreak of COVID-19 has severely impacted numerous sectors and human livelihoods, where every person was vulnerable to infectious disease. The fight against COVID-19 was a challenging operation that evolved every sector to contribute their practices and eradicate the impact. Bio-based polycarbonates are important for developing effective solutions in numerous applications, especially automotive and construction. The pandemic impact was extended to these significant sectors, leading to a complete shutdown of manufacturing units and the delivery of new cars. But after the pandemic, companies invested more to recover the loss during a pandemic, and construction practices also resumed. Therefore, the market for bio-based polycarbonates is on the verge of growing exponentially with such enormous applications.

Bio-based Polycarbonate Chemical Market: Report Scope

“Bio-based Polycarbonate Market Assessment, Opportunities and Forecast, 2016-2030F”, is a comprehensive report by Markets and data, providing in-depth analysis and qualitative & quantitative assessment of the current state of the Bio-based Polycarbonate Market, industry dynamics and challenges. The report includes market size, segmental shares, growth trends, COVID-19 and Russia-Ukraine war impact, opportunities and forecast between 2023 and 2030. Additionally, the report profiles the leading players in the industry mentioning their respective market share, business model, competitive intelligence, etc.

Click here for full report- https://www.marketsandata.com/industry-reports/bio-based-polycarbonate-market

Contact

Mr. Vivek Gupta

5741 Cleveland street,

Suite 120, VA beach, VA, USA 23462

Tel: +1 (757) 343–3258

Email: [email protected]

Website: https://www.marketsandata.com

0 notes

Text

Resin Market: Long-Term Value & Growth Seen Ahead

Market Research Forecast added research publication document on Worldwide Resin Market breaking major business segments and highlighting wider level geographies to get deep dive analysis on market data. The study is a perfect balance bridging both qualitative and quantitative information of Worldwide Resin Market. The study provides valuable market size data for historical (Volume** & Value) from 2019 to 2023 which is estimated and forecasted till 2032*. Some are the key & emerging players that are part of coverage and have being profiled are DuPont (U.S.),Arkema (France),BASF SE (Germany),INEOS Holdings Ltd. (U.K.),Hexion (U.S.),Invista (U.S.),LyondellBasell (Netherlands),Mitsubishi Engineering-Plastics Corporation (Japan),Mitsui Chemicals (Japan),Nova Chemicals (Canada),Qenos (Australia),Radici Group (Italy),SABIC (Saudi Arabia),Repsol (Spain),Sumitomo Chemical Co. Ltd. (Japan),Teijin Limited (Japan),Tosoh Corporation (Japan),Toray Group (Japan).

Get free access to Sample Report in PDF Version along with Graphs and Figures @ https://marketresearchforecast.com/report/reports/resin-market-1341/sample-report

The Resin Marketsize was valued at USD 533.55 USD Billion in 2023 and is projected to reach USD 750.76 USD Billion by 2032, exhibiting a CAGR of 5.0 % during the forecast period.resins can be formulated from either organic or synthetic compounds that convert from the liquid state to a solid, homogeneous structure. Resin is a very tough material which can be used even in such harshest conditions as impact of the water and other environmental factors. Annealing makes wire unbreakable when it is restored to its original properties by cooling. This feature enhances its multi-purpose characteristics for use indoors in settings like bathrooms, kitchens, and living rooms. They might be the products of natural materials or be manufactured using other chemicals. Resins are remarkably resistant to all types of chemicals and therefore a perfect choice for application in a large pool of industrial and commercial utilities. The resins are heat-resistant, therefore, they will not melt nor get stuck to the hot wheels of cars when a garage is being entered. Tackifiers samples are unlike any other clear resins, the fact if they are of a good quality and professional makes them ideal for decorative and aesthetic use.

Keep yourself up-to-date with latest market trends and changing dynamics due to COVID Impact and Economic Slowdown globally. Maintain a competitive edge by sizing up with available business opportunity in Resin Market various segments and emerging territory.

Influencing Market Trend

Rising demand for flexible packaging in the food & beverage industry

Increased adoption of lightweight materials in transportation sectors

Growing use of resins in construction for insulation and reinforcement

Challenges:

Volatile Raw Material Costs: Price fluctuations of crude oil and natural gas impact resin production costs.

Competition from Alternative Materials: Growing adoption of metals, ceramics, and composites in various applications.

Environmental Concerns: Conce

Have Any Questions Regarding Global Resin Market Report, Ask Our Experts@ https://marketresearchforecast.com/report/reports/resin-market-1341/enquiry-before-buy Analysis by Type (Polyethylene, Polypropylene, Polyethylene Terephthalate, Polyvinyl Chloride, Acrylonitrile Butadiene Styrene, Polyamide, Polycarbonate, Polyurethane, Polystyrene, and Others), by End-use Industry (Packaging, Automotive & Transportation, Building & Construction, Consumer Goods/Lifestyle, Electrical & Electronics, Agriculture, and Others), by North America (U.S., Canada), by Europe (Germany, U.K., France, Italy, Spain, Rest of Europe), by Asia Pacific (China, Japan, India, South Korea, Rest of Asia Pacific), by Latin America (Brazil, Argentina, Mexico, Rest of Latin America), by Middle East & Africa (Saudi Arabia, South Africa, Rest of Middle East & Africa) Forecast 2024-2032

Competitive landscape highlighting important parameters that players are gaining along with the Market Development/evolution

• % Market Share, Segment Revenue, Swot Analysis for each profiled company [DuPont (U.S.),Arkema (France),BASF SE (Germany),INEOS Holdings Ltd. (U.K.),Hexion (U.S.),Invista (U.S.),LyondellBasell (Netherlands),Mitsubishi Engineering-Plastics Corporation (Japan),Mitsui Chemicals (Japan),Nova Chemicals (Canada),Qenos (Australia),Radici Group (Italy),SABIC (Saudi Arabia),Repsol (Spain),Sumitomo Chemical Co. Ltd. (Japan),Teijin Limited (Japan),Tosoh Corporation (Japan),Toray Group (Japan)]

• Business overview and Product/Service classification

• Product/Service Matrix [Players by Product/Service comparative analysis]

• Recent Developments (Technology advancement, Product Launch or Expansion plan, Manufacturing and R&D etc)

• Consumption, Capacity & Production by Players

The regional analysis of Global Resin Market is considered for the key regions such as Asia Pacific, North America, Europe, Latin America and Rest of the World. North America is the leading region across the world. Whereas, owing to rising no. of research activities in countries such as China, India, and Japan, Asia Pacific region is also expected to exhibit higher growth rate the forecast period 2023-2028.

Table of Content

Chapter One: Industry Overview

Chapter Two: Major Segmentation (Classification, Application and etc.) Analysis

Chapter Three: Production Market Analysis

Chapter Four: Sales Market Analysis

Chapter Five: Consumption Market Analysis

Chapter Six: Production, Sales and Consumption Market Comparison Analysis

Chapter Seven: Major Manufacturers Production and Sales Market Comparison Analysis

Chapter Eight: Competition Analysis by Players

Chapter Nine: Marketing Channel Analysis

Chapter Ten: New Project Investment Feasibility Analysis

Chapter Eleven: Manufacturing Cost Analysis

Chapter Twelve: Industrial Chain, Sourcing Strategy and Downstream Buyers

Read Executive Summary and Detailed Index of full Research Study @ https://marketresearchforecast.com/reports/reports/resin-market-1341

Highlights of the Report

• The future prospects of the global Resin Market during the forecast period 2023-2028 are given in the report.

• The major developmental strategies integrated by the leading players to sustain a competitive market position in the market are included in the report.

• The emerging technologies that are driving the growth of the market are highlighted in the report.

• The market value of the segments that are leading the market and the sub-segments are mentioned in the report.

• The report studies the leading manufacturers and other players entering the global Resin Market. Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Middle East, Africa, Europe or LATAM, Southeast Asia.

Contact US :

Craig Francis (PR & Marketing Manager)

Market Research Forecast

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

Phone: +1 201 565 3262, +44 161 818 8166

[email protected]

#Global Resin Market#Resin Market Demand#Resin Market Trends#Resin Market Analysis#Resin Market Growth#Resin Market Share#Resin Market Forecast#Resin Market Challenges

0 notes

Text

Phenol Market Analysis: Assessing Growth Opportunities

Phenol, a vital aromatic compound, serves as a foundational building block in the chemical industry, finding extensive applications across various sectors. This blog aims to delve into the dynamics of the global phenol market, exploring its demand drivers, key applications, emerging trends, and future growth prospects.

Understanding Phenol:

The Phenol Market, also known as carbolic acid, is an aromatic organic compound with the chemical formula C6H5OH. It is a white crystalline solid at room temperature with a distinct, sweet odor. Phenol is widely used in the production of phenolic resins, bisphenol-A (BPA), caprolactam, and various other chemicals.

Market Dynamics:

Resilient Chemical Industry Demand: Phenol serves as a key intermediate in the production of numerous chemicals, including phenolic resins used in adhesives, coatings, and molded products, contributing to its steady demand in the chemical industry.

Polycarbonate and Epoxy Resins: Phenol is a crucial raw material in the production of polycarbonate and epoxy resins, which find extensive use in automotive, electronics, construction, and aerospace industries due to their strength, durability, and heat resistance properties.

Bisphenol-A (BPA) Production: Phenol is a primary component in the synthesis of Bisphenol-A (BPA), which is utilized in the manufacturing of polycarbonate plastics, epoxy resins, and thermal paper coatings, among other applications.

Nylon Production: Caprolactam, demand from phenol, is a key intermediate in nylon-6 production, which is used in textiles, automotive components, engineering plastics, and industrial applications.

Applications Across Industries:

Chemical Industry: Phenolic resins, polycarbonate, epoxy resins, caprolactam.

Automotive and Aerospace: Composite materials, coatings, automotive components.

Electronics: Circuit boards, electrical components.

Construction: Adhesives, coatings, insulation materials.

Market Trends:

Sustainability and Environmental Concerns: The phenol market is witnessing a shift towards sustainable production methods, including bio-based phenol derived from renewable sources, to address environmental concerns and meet regulatory requirements.

Technological Advancements: Ongoing research focuses on developing novel production processes, improving phenol derivatives' properties, and exploring new applications to enhance market competitiveness.

Emerging Applications: Phenol and its derivatives are finding new applications in areas such as healthcare, renewable energy, and specialty materials, expanding the market's scope and driving innovation.

Future Prospects:

The global Phenol market is poised for continued growth, driven by its versatile applications, technological advancements, and evolving consumer preferences towards sustainable products. As industries prioritize performance, sustainability, and regulatory compliance, Phenol and its derivatives remain integral to diverse sectors, fueling innovation and economic growth.

Conclusion:

Phenol's significance as a versatile chemical compound spans across multiple industries, underpinning the production of essential materials and products. Navigating the global Phenol market requires a deep understanding of market dynamics, emerging trends, and technological advancements. With a focus on sustainability, innovation, and diversified applications, the Phenol market is positioned for sustained growth and remains a pivotal player in the global chemical landscape.

0 notes

Text

"Diving Deep into the Specialty Polymers Market: Trends, Innovations, and Strategic Insights

Specialty Polymers: Harnessing the Power of Specialty Macromolecules for Next-Generation Technologies

Specialty Polymers Overview

Specialty macromolecules, also known as engineering macromolecules, are a class of macromolecules that are specially engineered to have targeted physical and chemical properties that make them suitable for advanced applications. Though they only represent a small fraction of the total macromolecules market, specialty macromolecules command a significant revenue share due to their higher value and more niche end uses.

Types of Specialty Macromolecules

There are several main types of specialty macromolecules classified based on their monomer makeup and resultant properties. Some of the major types include:

Polyamides (Nylons)

Polyamides, best known by the brand name Nylon, are a class of thermoplastic macromolecules containing amide linkages along their polymer chains. They are known for their high strength, toughness, and relative durability compared to other plastics. Engineering polyamides such as Nylon 46 and Nylon 610 can withstand higher temperatures than commodity nylons.

Fluoromacromolecules

Fluoromacromolecules contain strong carbon-fluorine covalent bonds which give them unique oil, chemical, heat and weather resistance properties. Popular fluoromacromolecules include polytetrafluoroethylene (PTFE or Teflon), fluorinated ethylene propylene (FEP), and polyvinylidene fluoride (PVDF). They are used in applications requiring non-stick, low friction surfaces.

Polyesters

Engineering polyesters such as liquid crystal macromolecules (LCP), polybutylene terephthalate (PBT), and polyethyleneterephthalate (PET) can be formulated with enhanced heat resistance, strength and rigidity over traditional polyesters. They are employed in automotive, electrical/electronic and consumer goods.

Liquid Silicone Rubbers

Liquid silicone rubbers (LSRs) are two-part addition-cure silicone elastomers that vulcanize at room temperature. Their biocompatibility, stability and flexibility make them well-suited for medical, food and microfluidic device applications. Low compression set LSRs retain shape over time.

Polyketones

Polyketones are a family of thermoplastics with high strength, heat resistance and chemical resistance derived from their ketone groups in the polymer backbone. They include comacromolecules like polyetheretherketone (PEEK) used in demanding mechanical and electrical end uses.

Markets and Applications

Specialty macromolecules are developing across diverse markets driven by the need for advanced material performance. Some of the major application areas include:

Automotive

In automotive, specialty macromolecules enable lightweighting through replacement of traditional metals. Nylons, PBT, polycarbonate and liquid silicone aid composites in vehicles. Use in engine components require heat resistance of PEEK and liquid crystal macromolecules.

Electronics

Electronics rely on specialty macromolecules for miniaturization and reliability. PTFE, FEP, PET and PVDF bring dielectric, insulating properties. PBT molding aids housings. Semiconductor uses benefit from high heat resistance of PEKK and LCP.

Medical

Biocompatible and non-leaching properties of silicones, nylons and PEEK suits medical industry. Implants, catheters, sensors and drug delivery use these. PEKK aids orthopedic devices. Silicones serve prosthetics, wound care and contact lenses.

Infrastructure

Resistance to chemical, heat and environmental stress qualifies many macromolecules for infrastructure. PVDF and silicones protect coatings and paints. Dams, tunnels utilize durability of PTFE and polyketones lining.

Other Developments

New technologies foster demand for high performance plastics. Renewable energy harvest requires specialty macromolecules in wind turbines, solar cells. Aerospace gravitates toward sturdy yet lightweight materials like PEKK, PEEK. Microfabrication leverages specialty silicones and fluoromacromolecules. As applications diversify, advanced macromolecules enable novel solutions.

Future Prospects

The specialty macromolecules market is forecast to sustain strong growth over the medium term supported by their rising penetration across major end-use industries. Polyketones, liquid silicone rubbers and high-temperature polyamides will be key winning product types. The Asia Pacific region is expected to lead future demand growth driven by its large manufacturing industries. Robust R&D focus on bio-based and high-tech specialty macromolecules will further fuel new product innovations and market opportunities going forward.

In Summary, specialty polymers represent a fascinating realm of materials science, offering tailored properties and applications beyond traditional macromolecules. These advanced materials are engineered to meet specific performance requirements, such as enhanced durability, conductivity, or biocompatibility. From aerospace components to medical devices, specialty macromolecules play a crucial role in a wide range of industries, driving innovation and pushing the boundaries of what's possible.

0 notes

Text

Thermoplastic Elastomers Market: Top 3 Industrial Applications

According to UNEP, energy accounts for approximately 60%of global greenhouse gas emissions, making energy efficiency a top priority across various industries. In this context, thermoplastic elastomers (TPEs) have emerged as a viable solution, reducing energy consumption by nearly 75%. They have gained recognition among product developers and designers as an advanced alternative to thermoset elastomers. Triton’s estimates suggest that the global thermoplastic elastomers market is expected to grow at a CAGR of 6.37% in revenue and 2.61% in volume during 2023-2030.

Another significant factor is the increasing trend of 3D printing. Due to their durable, flexible, chemically resistant, and user-friendly properties, TPEs serve as filaments in additive manufacturing methods like selective laser sintering (SLS) and fused deposition modeling (FDM). For instance, renowned companies such as New Balance, Under Armour, and Nike have adopted thermoplastic polyurethane-based 3D printing for robust and flexible midsoles.

In this blog, we’ll explore the wide-ranging applications of TPEs and their significant presence in the top three industries.

· Automotive:

In terms of industrial vertical, automotive leads with $9325.51 million

These high-performance polymers have gained significant traction in the automotive industry. Polystyrene TPE, for example, is used in multiple auto parts like instrument panels, wheel covers, dashboard elements, pillar trims, door liners, seat belt components, etc. These plastics, unlike metals, are cost-effective and improve vehicle energy efficiency by reducing weight.

Moreover, their lightweight quality boosts vehicle fuel efficiency, with a 10% weight reduction translating to 5-7% lower fuel consumption. This has prompted TPE manufacturers like Covestro AG to introduce new production lines for high-performance thermoplastic polyurethanes to produce paint production films.

Regional Focus: Asia-Pacific set to be the fastest-growing region at 6.46%

Asia-Pacific is the world’s largest automotive producer, with China, India, Japan, and Indonesia leading the way. Nations like India and Indonesia are attracting investments in locomotive and high-speed rail manufacturing, further bolstering the demand for TPE in the region. Additionally, China is actively boosting production, aiming for 7 million annually by 2025, constituting 20% of total new car production. This surge in EV production is set to drive demand for polyurethane and polystyrene in automotive applications, driving the Asia-Pacific thermoplastic elastomers market.

· Electrical & Electronics:

Thermoplastic elastomers are preferred for electrical insulation due to their strength, flexibility, and resistance to corrosive substances like acids. Besides this, TPE composites, including polycarbonate, enhance impact and flame resistance in electronic devices and household appliances. Given these benefits, several companies have entered into partnerships or acquisitions to expand their footing. For example,

- Arkema SA acquired Polytec PT in May 2023 to expand offerings and serve the electronics sector.

- Avient Corporation collaborated with BASF SE to offer colored grades of Ultrason® high-performance polymers to provide users in the electrical & electronics sector with comprehensive technical support.

Widely Employed Material Type:

Thermoplastic polyolefin serves multiple purposes in the sector, finding use in low-voltage wire and extruded hoses. TPOs are preferred over TPVs in wire and cable applications due to their cost-effectiveness, excellent electrical properties, and temperature versatility. As per Triton’s report, polyolefin is expected to register a CAGR of 6.30% during the forecast period 2023-2030 in terms of material type.

· Adhesives & Sealants:

Thermoplastic elastomers have gained popularity in providing strong bonds and flexibility without mixing or high-temperature curing. Since TPE adhesive grades offer durability, electrical insulation, and chemical and water resistance, companies strive to expand footing in the adhesives sector. Arkema SA, for instance, acquired Ashland’s performance adhesive branch in February 2022 to strengthen its adhesives solutions segment.

Regional Analysis: Asia-Pacific dominates the market based on volume

In Asia-Pacific, China dominates paint and coating production, while India is experiencing robust growth due to rapid industrialization and construction activities. Besides this, thermoplastic elastomer manufacturers are expanding in ASEAN countries like Thailand. Hence, the region’s expanding position in adhesive and sealant production fuels the region’s market, spearheaded by China.

Regulations & Shortages Prompt Innovation

Due to increasingly stringent environmental regulations and sustainability goals, elastomer manufacturers are compelled to create more recyclable tire options. This has led to a noticeable shift towards sustainable TPE materials, including bio-based TPEs. Shortages in raw materials further exacerbate the need for recyclable products. Notably, China has witnessed a significant increase in recycled rubber production, capturing more than 80% of the global production landscape.

In summary, the growing demand for eco-friendly solutions, regulatory pressures, and raw material shortages have spurred the adoption of TPEs as an effective means to reduce costs associated with waste tire management. Looking ahead, the industrial commitment to resource efficiency is expected to create lucrative opportunities within the thermoplastic elastomers market.

FAQs:

Q1) How big is the thermoplastic elastomers market in terms of volume?

Based on volume, the thermoplastic elastomers market recorded 7298.81 kilotons in 2022, expected to advance with a CAGR of 2.61% during 2023-2030.

Q2) Which are the 5 key thermoplastic elastomers?

Five key TPEs are polystyrene, polyamide, polyolefin, polyurethane, and elastomeric alloy.

#ThermoplasticElastomersMarket#ThermoplasticElastomers#Thermoplastic#tritonmarketresearch#marketresearchreports

0 notes

Text

An In-Depth Analysis of Polycarbonate Sheet Market : Product Segments and Regional Outlook

Report Overview

Polaris Market Research announces the release of a new report Polycarbonate Sheet Market by Share, Size, Trends, Future Growth, and Demand Analysis 2032 Keyword. The research report conducts an in-depth market study to provide a comprehensive analysis of the current state and future potential of the Polycarbonate Sheet Market. It covers several aspects, including industry size, key players, growth drivers, key opportunities, and challenges. Besides, market segmentation, competitive landscape, and regional analysis are detailed in the report.

The research study aims to assist stakeholders, investors, and businesses in making more informed decisions and formulating effective strategies to stay ahead of the curve. In addition, the impact of technological advancements, changing consumer preferences, and rising demand for innovative services on the market is covered. The report is a must-read for anyone currently involved or interested in the industry.

Request Our Free Sample Report for Polycarbonate Sheet Market Insights and Emerging Trends @ https://www.polarismarketresearch.com/industry-analysis/polycarbonate-sheet-market/request-for-sample

According to the research report published by Polaris Market Research, the Global Polycarbonate Sheet Market Size Is Expected To Reach USD 2.42 Billion By 2028., at a CAGR of 5.3% during the forecast period.

Competitive Landscape

The research study analyzes the current competitive environment of the market by providing information regarding Polycarbonate Sheet Market key players. The competitive landscape section covers several aspects of industry players, including their sales volume, market share, price, and gross margin. Additionally, important information about strategic developments such as mergers, acquisitions, and collaborations is provided in the report.

Major Key Players

3A Composites GmbH

Arla Plast AB

Brett Martin Ltd

Chi Mei Corporation

Covestro AG

Evonik Industries AG

Excelite

Koscon Industrial S.A.

Mitsubishi Gas Chemical Company

Palram Industries Ltd

Plazit-Polygal Group

SABIC

Spartech

Suzhou Omay Optical Materials Co.

Teijin Limited

Trinseo.

Make an Enquiry before Buying: https://www.polarismarketresearch.com/industry-analysis/polycarbonate-sheet-market/inquire-before-buying

Growth Drivers

Key trends: The report identifies and analyzes the key trends and drivers that are shaping the growth trajectory of the Polycarbonate Sheet Market.

Technological advancements: Advances in technology and their overall impact on the industry have been covered in the report.

Regulatory landscape: The research study provides an in-depth examination of the regulatory environment to help stakeholders seize opportunities and mitigate potential challenges.

Buy this Premium Research Report: https://www.polarismarketresearch.com/buy/889/2

Segmental Analysis

The Polycarbonate Sheet Market segmentation is primarily based on type, application, end use, and region. A comprehensive analysis of each of these segments is detailed in the report. Besides, the study sheds light on all the major sub-segments in the market. That way, stakeholders can better understand the needs of their customers and align their business strategies accordingly.

Regional Overview

The study offers additional insight into the regional market distribution, covering industry trends, revenue sources, and potential opportunities. Also, it offers predictions for revenue growth at regional, national, and global levels. Other important factors like pricing, production capacity, supply and demand ratios, and projected Polycarbonate Sheet Market sales are detailed in the report.

The Geographical Analysis Covers Following Key Regions:

North America (United States, Canada, and Mexico)

Europe (Germany, France, United Kingdom, Russia, Italy, and the Rest of Europe)

Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia)

South America (Brazil, Argentina, Colombia, and the rest of South America)

The Middle East and Africa (Saudi Arabia, United Arab Emirates, Egypt, South Africa, and the Rest of the Middle East and Africa)

Key Highlights of the Report

A descriptive analysis of the demand-supply gap and forecast in the global market.

Bottom-up and top-down approaches for regional analysis.

Covers a SWOT analysis of key players and the overall Polycarbonate Sheet Market.

Includes both primary and secondary research methods to provide a thorough market understanding.

Porter’s Five Forces model provides an in-depth examination of industry vendors, substitutes, and competition among industry players.

Provides a detailed picture of the market by including value chain analysis.

The Report Answers Questions Such As

What is the current size and projected value for the market?

What are the key factors driving the Polycarbonate Sheet Market demand?

Which is the leading segment in the industry?

What are the potential attractive investment opportunities in the market?

At what CAGR is the market projected to grow over the forecast period?

Where will strategic developments take the Polycarbonate Sheet Market in the short to long term?

Read More Trending Report of "Polaris Market Research Exclusive": https://www.polarismarketresearch.com/industry-analysis/polycarbonate-sheet-market

About Us

Polaris Market Research is a worldwide market research and consulting organization. We give unmatched nature of offering to our customers present all around the globe across industry verticals. Polaris Market Research has expertise in giving deep-dive market insight along with market intelligence to our customers spread crosswise over various undertakings. We at Polaris are obliged to serve our different client base present over the enterprises of medicinal services, healthcare, innovation, next-gen technologies, semiconductors, chemicals, automotive, and aerospace & defense, among different ventures, present globally.

Contact Us:

Polaris Market Research

Email: [email protected]

Ph: +1-929 297-9727

0 notes

Text

Plastic Market: Development Trends, Competitive Analysis and Key Manufacturers Report by 2032

The global plastic market is set to witness an impressive growth rate of 3.7% over the forecasted years of 2022 to 2032. The plastic market size is anticipated to reach a valuation of around US$ 885 Billion by the end of the year 2032 from the current valuation of US$ 695 Billion in 2022.

The main causes of the increased sales of plastic in several economies are the expansion of the ensuing need for ultralight constituents to increase automobile load capacity and decrease the cost of semiconductor devices. Compared to other materials, corrugated plastic has a specific gravity that is 85% lower providing for weight reductions of around 80% and component cost reductions of 30% to 50% when employed in the construction and automotive sectors.

The demand for plastic in infrastructure and building applications would be driven by rising government construction spending, notably in China and India. Additionally, the expanding need for metal substitutes drives an expansion of the use of engineering plastic or composite polymers across a range of sectors.

The plastic market key trends supported by the building industries are projected to decline as a result of strict rules regulating the use and recyclability of traditional plastic materials. In comparison to metal or wood, polymer fittings are often considered sustainable and ecofriendly that got hold of a considerable amount of global plastic market opportunities in the recent past.

Get a 20% Discount! Request Sample @

https://www.futuremarketinsights.com/reports/sample/rep-gb-15157

Plastic Market by Segmentation

By Product :

Polyethylene (PE)

Polypropylene (PP)

Polyurethane (PU)

Polyvinyl chloride (PVC)

Polyethylene terephthalate (PET)

Polystyrene (PS)

Acrylonitrile butadiene styrene (ABS)

Polybutylene terephthalate (PBT)

Polyphenylene Oxide (PPO)

Epoxy Polymers

Liquid Crystal Polymers

Polyether ether ketone (PEEK)

Polycarbonate (PC)

Polyamide (PA)

Polysulfone (PSU)

Polyphenylsulfone (PPSU)

By Application :

Injection Moulding

Blow Moulding

Roto Moulding

Compression Moulding

Casting

Thermoforming

Extrusion

Calendering

By End-use:

Packaging

Construction

Electrical & Electronics

Automotive

Medical Devices

Competitive Landscape

Some of the well-known plastic market players are BASF SE, SABIC, Dow Inc, DuPont de Nemours, Inc, Evonik Industries, Sumitomo Chemical Co., Ltd., Arkema, Celanese Corporation, Eastman Chemical Company, Chevron Phillips Chemical Co., LLC, Lotte Chemical Corporation, Exxon Mobil Corporation, Formosa Plastic Corporation, Covestro AG, Toray Industries, Inc., and Mitsui & Co. Plastic Ltd. among others.

0 notes

Text

Bisphenol A (BPA) Market: Trends, Challenges, and Future Prospects

Bisphenol A (BPA) is a chemical compound primarily used in the production of polycarbonate plastics and epoxy resins. These materials are integral to various industries, including automotive, construction, electronics, and packaging. Despite its widespread use, BPA has faced scrutiny over potential health concerns, influencing market dynamics and regulatory frameworks. This article explores the current state of the BPA market, key trends, challenges, and future prospects.

Market Overview

As of 2023, the global Bisphenol A market is valued at approximately USD 7 billion, with an expected compound annual growth rate (CAGR) of around 4% over the next decade. The demand for BPA is driven by its extensive applications in manufacturing durable and high-performance materials. However, increasing regulatory restrictions and consumer awareness regarding BPA's health risks are prompting shifts towards alternative compounds.

Key Drivers of Growth

1. Demand in Polycarbonate Plastics:

Polycarbonate plastics, made using BPA, are valued for their transparency, high impact resistance, and thermal stability. These plastics are used in automotive parts, optical media (like CDs and DVDs), eyewear lenses, and various household items. The continued demand for high-performance materials in these sectors supports the growth of the BPA market.

2. Epoxy Resins in Construction and Electronics:

BPA-based epoxy resins are essential for coatings, adhesives, and composites. In the construction industry, these resins are used in flooring, coatings for steel structures, and concrete. In electronics, they are crucial for printed circuit boards and protective coatings. The growth of these industries, particularly in emerging economies, drives the demand for BPA.

3. Automotive Industry:

The automotive sector relies on BPA for producing lightweight and durable components, which contribute to fuel efficiency and vehicle performance. The shift towards electric vehicles (EVs) further enhances the demand for BPA-based materials due to their high thermal resistance and structural integrity.

Challenges and Regulatory Impact

1. Health Concerns and Regulatory Scrutiny:

BPA is an endocrine disruptor, and studies have linked it to various health issues, including reproductive disorders and developmental problems. This has led to stringent regulations in regions like the European Union, where BPA use in certain products, such as baby bottles and food containers, is restricted. In response, manufacturers are exploring BPA-free alternatives, which impacts the market demand.

2. Environmental Considerations:

The environmental impact of BPA, particularly its persistence and potential for bioaccumulation, has raised concerns. Regulatory bodies are increasingly focusing on the environmental footprint of BPA production and disposal, prompting stricter regulations and encouraging the development of more sustainable practices.

For a comprehensive analysis of the market drivers:- https://univdatos.com/report/bisphenol-a-market/

Market Segmentation

The BPA market can be segmented based on application and region.

- By Application:

- Polycarbonate Plastics: Widely used in automotive, electronics, and consumer goods.

- Epoxy Resins: Essential for construction, electronics, and protective coatings.

- **Others**: Including flame retardants, polyvinyl chloride (PVC) production, and thermal paper.

- By Region:

- North America: A mature market with significant regulatory oversight.

- Europe: Emphasis on regulatory compliance and sustainable alternatives.

- Asia-Pacific: The fastest-growing market, driven by industrialization and urbanization in countries like China and India.

- Latin America: Growing industrial activities and infrastructure development.

- Middle East & Africa: Emerging markets with increasing demand for high-performance materials.

Opportunities and Innovations

1. Development of BPA Alternatives:

The regulatory push and consumer demand for safer products have led to the development of BPA alternatives, such as Bisphenol S (BPS) and Bisphenol F (BPF). These alternatives aim to provide similar performance characteristics without the associated health risks, presenting opportunities for innovation and market growth.

2. Sustainable Production Practices:

The focus on reducing the environmental impact of BPA production is driving innovations in sustainable manufacturing processes. Companies are investing in green chemistry techniques and recycling technologies to minimize waste and improve the lifecycle management of BPA-based products.

For a sample report, visit:- https://univdatos.com/get-a-free-sample-form-php/?product_id=31300

3. Expansion in Emerging Markets:

The rapid industrialization and urbanization in emerging markets present significant opportunities for the BPA industry. Investments in infrastructure, automotive, and electronics sectors in regions like Asia-Pacific and Latin America are expected to drive the demand for BPA and its derivatives.

Future Outlook

The BPA market is at a crossroads, balancing the demand for high-performance materials with the need for health and environmental safety. While regulatory challenges and health concerns present hurdles, the market is poised for growth through innovation and adaptation. The development of BPA alternatives, coupled with sustainable production practices, will shape the future landscape of the industry.

In conclusion, the BPA market remains a vital component of the global chemicals industry, with significant applications across various sectors. By addressing regulatory challenges and embracing sustainable innovations, the market can continue to thrive and meet the evolving demands of consumers and industries worldwide.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

Construction Polymer Market Size, Share, Demand, Growth and Trends by 2026

The global construction polymer market is expected to grow at a robust pace by registering a CAGR of 6.8% over the projection period from 2022 to 2026. The global market is predicted to garner a valuation of around US$ 229,076 Mn in 2022 and reach a net worth of US$ 298,384 Mn by the end of 2026. The range of applications for construction polymers is widely spreading as a result of developments in civil engineering and construction technologies. Some latest trends observed in the market comprise a fair share of the revenue in research and development. Such trends are likely to bolster the construction of polymer demand.

According to FMI analysis, the variation between the BPS values observed in the construction polymers market in H1, 2022 - Outlook over H1, 2022 Projected reflects a decline of 10 units. However, compared to H1, 2021, the market is expected to again witness a decline of 30 BPS in H1 -2022. As per future Market Insight's historical estimations, the global market registered a 5.3% CAGR between 2012 and 2021. The emergence of new materials within the constriction polymers market is leading to the development of substantial potential.

Request a Sample @ http://bit.ly/3ZHkD6v

Key Takeaways

Structural polymers and plastic composites have been introduced as crucial materials in terms of their use in the construction industry. The design, technical and structural advantages of these constriction polymers have driven their application in building walls and flooring with maximum strength. Technological advancements within civil engineering and construction technologies are anticipated to propel the application purview of construction polymers.

Cost-effective production, feasible profit margins, and comparatively easy procurement of raw materials are inclining large chemical companies towards construction polymer businesses. The overall competitive landscape in the global construction polymer market remains densely populated by industry leaders from the chemicals and materials sector.

A major population of construction polymer manufacturers in the global market is based in countries such as China, India, and South Korea. As per the recent study projects through 2028, the Asia-Pacific excluding Japan (APEJ) region will represent the largest market for construction polymers. By the end of the forecast period, the APEJ construction polymer market will account for nearly half of the forecast global market value.

Prominent industry leaders from the chemicals & materials sectors are actively participating in the expansion of the global construction polymer market. These prominent companies are committed to testing new and advanced products along with creating advanced polymerized materials for the changing dynamics of the building & construction sector.

Prominent reasons for the change in growth rate accounted for the slow uptake of the market throughout the first half of the forecast period, owed to the strict environmental mandate implemented by the government in order to effectively curb the emission and shifting preferences in the favor of green materials and sustainable products. Further rise in the pricing of raw materials and lockdown in China have impacted the growth outlook.

Despite such challenges, some prospects lead the industry, which incorporates the increasing investment by the government in private sectors and utility infrastructure sectors, which is expected to provide a growth outlook to the market. A significant rise in building construction followed by urbanization is expected to influence market growth.

The utilization of a wide range assortment of materials takes place in flooring, windows, cladding, pipes, membranes, seals, and insulation. Drastic advances are being made in the types of polymers including epoxy resins, polystyrene, polycarbonate, polyethylene, and polypropylene.

In addition, construction companies are known as the key users benefiting from the advances in properties such as flexibility, adhesion to substrates, durability, and water resistance. Overall, the demand for construction polymer is anticipated to rise at a CAGR of around 6.8% through 2026.

Competitive Landscape

The global construction polymer market is on a rise owing to the manufacturers who are investing in the research & development of new valves as per changing industry standards across multiple industry verticals.

Some key players are:

H.B Fuller Company

Momentive Performance Materials Inc.

Evonik Industries AG

Solvay SA

Arkema S.A.

E.I Dupont De Nemours and Company

SCG Chemicals Co., Ltd.

Croda International Plc

Henkel AG & Co. KGaA

Sika AG

3M Company

Polyone Corporation

BASF SE

Formosa Plastics Corp

Key Segments Covered in Construction Polymer Industry Survey

By Polymer Type:

Epoxy Resins Construction Polymer

Polystyrene Construction Polymer

Polycarbonate Construction Polymer

Polyethylene Construction Polymer

Polyisobutylene Construction Polymer

Polymethylmethacrylate Construction Polymer

Polypropylene Construction Polymer

Polyurethane Construction Polymer

Polyvinylchloride Construction Polymer

Other Construction Polymers

By Application:

Walls

Floorings

Piping

Windows

Roofs

Insulation and Sliding

Glazing

Cladding

Plastic Wraps

Other Applications

By End-User:

Commercial Real Estate Construction

Housing Real Estate Construction

Industrial Construction

Facility Infrastructure

Transportation Infrastructure

Utility Infrastructure

Other Infrastructure

By Construction Activity:

New Construction

Renovation

By Region:

North America

Latin America

Europe

East Asia

South Asia & Pacific

Middle East & Africa (MEA)

Browse Full Report: https://www.futuremarketinsights.com/reports/construction-polymer-market

0 notes

Text

Polycarbonate Sheets Market Demand, Status and Global Briefing 2022 to 2028 | SABIC, Covestro AG

Polycarbonate Sheets Market 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐑𝐞𝐩𝐨𝐫𝐭 𝟐𝟎𝟐𝟐 𝐢𝐬 𝐜𝐚𝐫𝐞𝐟𝐮𝐥𝐥𝐲 𝐜𝐨𝐧𝐝𝐮𝐜𝐭𝐞𝐝 𝐟𝐨𝐫 𝐭𝐡𝐞 𝐢𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐢𝐧 𝐚 𝐪𝐮𝐚𝐥𝐢𝐭𝐚𝐭𝐢𝐯𝐞 𝐚𝐧𝐝 quantitative 𝐰𝐚𝐲 𝐭𝐨 𝐞𝐧𝐬𝐮𝐫𝐞 𝐚 𝐬𝐮𝐜𝐜𝐞𝐬𝐬𝐟𝐮𝐥 𝐨𝐮𝐭𝐜𝐨𝐦𝐞 of the Polycarbonate SheetsMarket. In addition to identifying, analyzing, and estimating new trends, this research report also examines key industry drivers, challenges, and opportunities in addition to evaluating competitors, geographical areas, types, and applications. Understanding the competitive landscape is crucial for determining the product improvements that are needed. Industries can securely make decisions about their production and marketing strategy since they can obtain comprehensive insights from a Polycarbonate Sheetsreport.

𝐀 𝐬𝐚𝐦𝐩𝐥𝐞 𝐫𝐞𝐩𝐨𝐫𝐭 𝐜𝐚𝐧 𝐛𝐞 𝐯𝐢𝐞𝐰𝐞𝐝 𝐛𝐲 𝐯𝐢𝐬𝐢𝐭𝐢𝐧𝐠 (𝐔𝐬𝐞 𝐂𝐨𝐫𝐩𝐨𝐫𝐚𝐭𝐞 𝐞𝐌𝐚𝐢𝐥 𝐈𝐃 𝐭𝐨 𝐆𝐞𝐭 𝐇𝐢𝐠𝐡𝐞𝐫 𝐏𝐫𝐢𝐨𝐫𝐢𝐭𝐲) 𝐚𝐭:

𝐂𝐨𝐦𝐩𝐞𝐭𝐢𝐭𝐢𝐯𝐞 𝐥𝐚𝐧𝐝𝐬𝐜𝐚𝐩𝐞: SABIC, Covestro AG, Trinseo S.A., Teijin Limited, Mitsubishi Gas Chemical Company, Inc., Evonik Industries AG, Suzhou Omay Optical Materials Co., Ltd., Excelite, Plazit-Polygal Group, Arla Plast AB, 3A Composites GmbH, Palram Industries Ltd., Ug-oil-Plast Ltd., Gallina India, Koscon Industrial S.A., Isik Plastik, Brett Martin Ltd., and Spartech.

𝐌𝐚𝐫𝐤𝐞𝐭 𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐚𝐭𝐢𝐨𝐧: 𝐁𝐲 𝐓𝐲𝐩𝐞

Solid

Multiwall

Corrugated

Others

𝐌𝐚𝐫𝐤𝐞𝐭 𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐚𝐭𝐢𝐨𝐧: 𝐁𝐲 𝐀𝐩𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧

Building & Construction

Electrical & Electronics

Automotive & Transportation

Aerospace & Defense

Packaging

Others

By Region

North America, US, Canada, Latin America, Brazil, Mexico, Rest of Latin America, Western Europe, Germany, UK, France, Spain, Italy, Benelux, Nordic, Rest of Western Europe, Eastern Europe, Russia, Poland, Rest of Eastern Europe, Asia Pacific, China, Japan, India, South Korea, Australia, ASEAN (Indonesia, Vietnam, Malaysia, etc.), Rest of Asia Pacific, Middle East & Africa, GCC, South Africa, Turkey and Rest of the Middle East & Africa.

Key Highlights

• The report provides analysis of current global Polycarbonate Sheetsmarket landscape.

• The report explores the most likely scenarios of the pandemic that are going to impact the Polycarbonate Sheetsindustry in long-term.

• The report does a detailed analysis studying how the global market is changing.

• The report looks at how the global Polycarbonate Sheetsmarket is shifting, the target market which have biggest opportunities, and trends on horizon that may impact your business directly or indirectly.

• The report highlights the key challenges, risk that you may face in near term as well as highlights opportunities.

Explore Full Report with Detailed TOC Here:

𝐓𝐚𝐛𝐥𝐞 𝐎𝐟 𝐂𝐨𝐧𝐭𝐞𝐧𝐭:

1. Polycarbonate SheetsMarket Introduction

1.1. Definition

1.2. Research Scope

2. Executive Summary

2.1. Key Findings by Major Segments

2.2. Top strategies by Major Players

3. Global Polycarbonate SheetsMarket Overview

3.1. Polycarbonate SheetsMarket Dynamics

3.1.1. Drivers

3.1.2. Opportunities

3.1.3. Restraints

3.1.4. Challenges

3.2. COVID-19 Impact Analysis in Global Polycarbonate SheetsMarket

3.3. PESTLE Analysis

3.4. Opportunity Map Analysis

3.5. PORTER’S Five Forces Analysis

3.6. Market Competition Scenario Analysis

3.7. Product Life Cycle Analysis

3.8. Manufacturer Intensity Map

3.9. Major Companies sales by Value & Volume

𝐂𝐨𝐧𝐭𝐢𝐧𝐮𝐞.

Complete Growth Report Is Available (Including the Full TOC, Tables and Figures, Graphs as Well As Chart):

About Exactitude Consultancy

Exactitude Consultancy is a market research & consulting services firm which helps its client to address their most pressing strategic and business challenges. Our market research helps clients to address critical business challenges and also helps make optimized business decisions with our fact-based research insights, market intelligence, and accurate data. Contact us for your special interest research needs at [email protected] and we will get in touch with you within 24hrs and help you find the market research report you need.

Website: https://exactitudeconsultancy.com/

Irfan Tamboli

Contact: +91-7507-07-8687

0 notes

Link

The “ Polycarbonate Composites Market ” report provides a detailed analysis of global market size, regional and country-level market size, segmentation, market growth, market share, and competitive Landscape.

#Polycarbonate Composites Market trends#Polycarbonate Composites Market Size#Polycarbonate Composites Market Share

0 notes

Text

Polycarbonate Composites Market Segmentation, Industry trends and Development to 2028 | Chi Mei Corporation, Sabic Innovative Plastics, Mitsubishi Chemical Corporation.

QMI added to its vast collection of research reports most up-to-date research on global polycarbonate composites market to see worldwide growth by top companies- Chi Mei Corporation, Sabic Innovative Plastics, Mitsubishi Chemical Corporation, LG Chem, Covestro, Asahi Kasei Advance Co. Ltd., Teijin, Samyang Corporation, The Bond Laminates GmbH, Formosa Chemicals & Fibre Corporation, and Trinseo

Get Sample Copy of This Report @ https://www.quincemarketinsights.com/request-sample-58900?utm_source=Pooja/Offpage

In this study, the Quince Market insights provide a global polycarbonate composites market forecast. The global polycarbonate composites market is expected to reach USD 5.13 billion by 2028, growing at a CAGR of 8.0% during the forecast period.The study tells the market scenario of polycarbonate composites market in various segments based on geographical distribution along with analysis of the market for the current market situation and its potential to grow globally during the forecast period.

Report Description of this report analyzes the global polycarbonate composites market for the period 2016–2028. This report's primary objective (polycarbonate composites market) is to provide insights and key market developments relevant to the polycarbonate composites Tubes Industry that are slowly helping transform global businesses.

The global report on polycarbonate composites market begins with the executive summary for different categories and their share in the polycarbonate composites market. It is followed by the global polycarbonate composites market's market dynamics and overview, which includes analysis of market drivers, constraints, and trends that affect the polycarbonate composites market's growth. In addition, to understand the popularity of the polycarbonate composites market segment, the attractiveness index and BPS analysis will be provided with detailed insights into the same, showing the attractiveness of the market based on factors such as CAGR and incremental opportunities.

Make an Inquiry for purchasing this Report @ https://www.quincemarketinsights.com/enquiry-before-buying/enquiry-before-buying-58900?utm_source=Pooja/Offpage

The next segment of the report highlights segmentation by region of the polycarbonate composites market and gives the market forecast for 2016–2028. The report examines regional development as well as analyzes the factors affecting the regional polycarbonate composites market. North America, Western Europe, Eastern Europe, Asia Pacific, Middle East, and Rest of the World are the major regions evaluated in this study.

To assess the size of the market in terms of value and size, consideration is given to the revenues generated by the main manufacturers and their respective production capacity. The forecast presented here estimates the value-generated total revenue across the polycarbonate composites market. To provide a precise forecast, we have initiated by sizing up the current market, which forms the basis on how the future development of the polycarbonate composites market is predicted.

Market Segmentation:

By Reinforcement:

Glass Fiber Filled

Carbon Fiber Filled

Others

By End User:

Consumer Electronics

Medical Instruments

Automotive Plastics

Electrical Engineering

Packaging Plastics

Building & Construction

Others

By Region:

North America

By Country (US, Canada, Mexico)

By Reinforcement

By End User

Western Europe

By Country (Germany, UK, France, Spain, Rest of Western Europe)

By Reinforcement

By End User

Eastern Europe

By Country (Russia, Turkey, Rest of Eastern Europe)

By Reinforcement

By End User

Asia Pacific

By Country (China, Japan, India, Rest of Asia Pacific)

By Reinforcement

By End User

Middle East

By Country (UAE, Qatar, Iran, Saudi Arabia, Rest of Middle East)

By Reinforcement

By End User

Rest of the World

By Region (South America, Africa)

By Reinforcement

By End User

Reasons To Buy This Report:

· Market size estimation of the global polycarbonate composites market on a regional and global basis.

· Unique research design for market size estimation and forecast.

· Profiling of major companies operating in the polycarbonate compositesmarket with key developments.

· Broad scope to cover all the possible segments helping every stakeholder in the polycarbonate compositesmarket.

Customization:

We provide customization of the study to meet specific requirements:

· By Segment

· By Sub-segment

· By Region/Country

ABOUT US:

QMI has the most comprehensive collection of market research products and services available on the web. We deliver reports from virtually all major publications and refresh our list regularly to provide you with immediate online access to the world's most extensive and up-to-date archive of professional insights into global markets, companies, goods, and patterns.

Contact Us

Quince Market Insights

Ajay D. (Knowledge Partner)

Office No- A109,

Pune, Maharashtra 411028

Phone: +91 706 672 5858/+1 208 405 2835/+91 706 672 4848

Email:[email protected]

Web:www.quincemarketinsights.com

#Polycarbonate Composites Market#Polycarbonate Composites Market Size#Polycarbonate Composites Market Share#Polycarbonate Composites Market Growth#Polycarbonate Composites Market Trends#Polycarbonate Composites Market Outlook#Polycarbonate Composites Market Demand

0 notes

Text

Polycarbonate Sheets Market Global & Regional Industry Forecasts

Stratview Research, a global market research firm announces the release of the report titled – Polycarbonate Sheets Market which provides an in-depth analysis of the market dynamics, current and emerging trends, industry forecast, and competitive landscape.

Request a Free Sample here:

According to this report, the global Polycarbonate Sheets Market is estimated to growth at a healthy CAGR of 5% by 2027.

Market Segments Analysis

The market researchers have studied the Polycarbonate Sheets Market minutely for better understanding. The report consists of segment-wise details to assist the users in making suitable decisions for better growth opportunities. Below is the short piece of information -

Key Players

Sabic

Covestro AG

Trinseo S.A.

Teijin Limited

Mitsubishi Gas Chemical Company, Inc.,

Evonik Industries AG

Suzhou Omay Optical Materials Co., Ltd.

Plazit-Polygal Group

Arla Plast Ab

3A Composites GmbH

Growth drivers and Market Value:

This report, from Stratview Research, studies the Polycarbonate Sheets Market value and growth drivers over the trend period of 2022-27. According to the report -

Polycarbonate sheets market is likely to witness an impressive CAGR of 6.2% during the forecast period. The growing use of polycarbonate sheets by end-use industries, such as building & construction, electrical & electronics, and automotive & transportation influences the growth of the global polycarbonate sheets market

Segment Analysis:

Based on Type:

Based on the type, the market is segmented as solid, multiwall, corrugated, and others. The solid segment is estimated to have the highest growth in the coming five years. This growth can be attributed to the extensive adoption of polycarbonate sheets by end-use industries for various fabrication applications.

Based on Region:

In terms of regions, Asia-Pacific is expected to be the largest market for polycarbonate sheets in the coming five years. It is also estimated to have the highest growth during the forecast period. China and India are the growth engines of the region. Rapid urbanization and high demand from various end-use industries drive the market for polycarbonate sheets in the region. Europe and North America also offer sizeable growth opportunities in the coming five years.

Know more about the report, click here

What else are available in this report?

The answer lies in the TOC and other details. Take a sneak-peek into the TOCs of this report.

Report Scope

Report Objectives

Research Methodology

Market Segmentation

Secondary Research

Primary Research

Breakdown of Primary Interviews by Region, Designation, and Value Chain

Data Analysis and Triangulation

Custom Research:

Stratview research delivers custom research services across the sectors. In case of any custom research requirements, please send your inquiry to [email protected]. Or connect with our experts at +1-313-307-4176.

About Us Stratview Research is a global market research firm, offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients with insightful market data to aid strategic decision making. These exclusive reports are the result of exclusive research methodology and are available for key industries such as chemicals, composites, advanced materials, technology, renewable energy, and more.

0 notes

Text

Polycarbonate Sheets Market Size, Market Performance from 2020 To 2029

Based on past and recent market performance, the Polycarbonate Sheets market is estimated to reach USD 4.2 billion in size by 2029 at a CAGR of 5.1%.

Overview of the Polycarbonate Sheets Market

This report provides an evaluation of the most recent developments in the global Polycarbonate Sheets market. This report focuses on providing a broad perspective to the end-client and assisting them in developing market approaches and plans. The Polycarbonate Sheets market report investigates and provides a forecast for the period 2020 To 2029.

The research provides an outline and foundation for the Polycarbonate Sheets market, including section, arrangement, definition, item data, and the most recent turns of events and occasions associated with the market that might influence market activity.

The report addresses issues such as item order, item cost, and item developments. The information is centred on the global market's major drivers, limiting factors, obstacles, and opportunities.

Get the Report Sample Pages for Free@