#Polyacrylate

Explore tagged Tumblr posts

Text

Use of Acrylic Polymer and Polyacrylate as Antiscalant & Antifoulant

Scaling and fouling provide substantial difficulties in a variety of industrial processes and water treatment applications. Scaling, in general, means accumulation and precipitation of mineral deposits whereas fouling refers to organic or inorganic substance accumulation. Normally these are countered by the use of an organic acid and a dispersant, which are significantly corrosive and may degrade the metal surface. What if said, the same result or in fact a better result can be expected, if polymerized formulations are used. Yes. There are polymerized acids and phosphonates like Polyacrylic Acid (PAA), Polymaleic Acid (PMA), Polyphosphates, Polyphosphonates, PAPEMP, etc., which inhibits formation of carbonates, sulphates & silicates of Calcium, Barium, Magnesium, Strontium, over the surface, manifesting optimum efficacy in scale prevention and antifouling. These polymers functions by binding to the crystal surfaces of scale-forming minerals, preventing their growth and deposition. Moreover, these polymers also exhibit strong sequestration properties, keeping scale forming compounds away due to their ability to inhibit crystallization and precipitation of scale-forming minerals.

Polymer chemistry is the future for utility and industrial applications for its diverse applications such as Material Science Advancements, Sustainable Solutions, Energy Storage, Biomedical Applications, Electronics and Chemical Additive Manufacturing.

Acrylic Polymers as a versatile antiscalant and antifoulant manages to gain popularity from various industries. Why? Because the ability of the acrylic polymer to prevent scale formation by securing and distributing metal ions in solution is one of its primary benefits. Acrylic polymer aids in preserving the effectiveness and integrity of industrial equipment by avoiding the precipitation and deposition of minerals on surfaces. Additionally, acrylic polymer has potent antifouling qualities since it repels organic compounds. Its hydrophobic characteristic prevents fouling agents like algae, bacteria, and biofilms from adhering to and growing on it. With regard to applications in cooling towers, reverse osmosis systems, desalination plants, and other industrial processes where fouling is a concern, acrylic polymer is the best choice due to this property. The distinct structure of polyacrylate molecules enables them to sequester and disperse metal ions in water. Thus, the ions are kept apart and unable to combine to create the insoluble compounds that cause scale deposition. Some primary functions of Polymeric antiscalants and Polyacrylates are

High impact resistance

Transparency and Clarity

Weatherability

Chemical Resistance

Ease of processing

Wide color range and versatility

Easy maintenance and cleaning

Scale divergence

Threshold inhibition

Easy handling

Chemtex’s polyacrylate based antiscalant and antifoulants have remarkable scale inhibition properties. Their special compositions effectively scatter and stop the growth of chemicals that cause scale, protecting equipment surfaces from buildup and reducing downtime. The improved stability, solubility, and compatibility of these solutions make them appropriate for a variety of water treatment applications. These formulations are meticulously developed to provide superior scale inhibition and fouling resistance. Their products, fortified with advanced technology, effectively disperse and sequester metal ions, ensuring optimal performance of industrial equipment. Chemtex's expertise in polymer chemistry enables them to tailor solutions to specific water conditions and industry requirements, enhancing system efficiency and longevity.

For more information visit: https://www.chemtexltd.com/products-and-solutions/performance-chemicals/phosphonates-polymers/polymers/

0 notes

Text

After two days, it's here

The Pascal mini figure is here. Would write the alien child support thing on his shirt if he wasn't so small

Look how small he is in my hand

He's even shorter than my Tycho charm lol

Bonus:

When Pascal sleeps in his bed

#my bullshit#the sims 2#ts2#strangetown#pascal curious#papa manlet#Mini figure#Biblically accurate Pascal#What would you do with your Pascal?#I painted him last night#I was going to put polyacrylic on him but the lid was stuck#So this morning I put a hole in it so this man can shine

121 notes

·

View notes

Text

I was inspired by this post to tell the story of how I also grossed out male students with a pad during my phd!

I'm (currently, still) getting my PhD in chemistry. I'm working on how ions affect materials formation in solutions. The system I'm currently working on sometimes forms a gel and sometimes doesn't depending on which ions are present in the solution.

One of my labmates remembered this stuff, it's a kids toy, where you add stuff to a bathtub to turn the water into a gel, but then you pour salt on it to make it go back to not a gel. We thought that could be relevant, so I wanted to test out that stuff to see if it's any salt, or if it's specifically NaCl that causes it to un-gel. The material in the bath toy is sodium polyacrylate, which is in lots of stuff, including diapers.

I didn't feel like waiting to order some, I just needed some for a quick experiment. I thought about going to the store and buying a diaper or orbeez or something, but then I realized I had pads in my backpack and those (sometimes) have sodium polyacrylate in them.

I took a pad to the lab and cut it open and did the experiment! One my my (male) labmates was completely grossed out but like... it's literally a clean pad? Why are guys like this? (to be fair, some of the other guys in the lab thought it was cool, it was just one guy that was grossed out. Also, my advisor, a woman, thought it was really cool)

Anyway, I cut up the pad, added water, turned it into a gel, then added salt, which made it un-gel (both salts I added, NaCl and NaNO3, caused it to un-gel, so it wasn't the smoking gun I was looking for, I'm assuming the salt causes the water to leave the gel due to osmosis)

#pads#chemistry#you can do this at home if you want!#literally cut open a pad (particularly the thin ones - thick ones usually have cotton as the absorbent material)#the one i cut up had the sodium polyacrylate infused into a paper-towel like thing#but when you add water it turns into a gel and you can squish it around#it looks like clear colorless jelly#but then if you add salt to it - the water leaves and you're left with just the paper towel stuff

3 notes

·

View notes

Text

Polyacrylic Acid Prices, News, Monitor, Demand & Analysis

North America

The North American Polyacrylic Acid market exhibited varied price movements during the fourth quarter of 2024, influenced by changes in feedstock dynamics, regional demand, and supply conditions. In October, the market experienced a price surge despite declining Acrylic Acid and Propylene costs. This was primarily driven by robust demand from the water treatment sector, which maintained strong offtake levels, and supply-side constraints due to production curtailments and logistical challenges. Demand from the textile industry, however, remained subdued as weaker economic activity persisted across the region.

In November, Polyacrylic Acid prices stabilized despite upward pressure from rising Acrylic Acid costs. Steady demand from downstream industries like construction and paints and coatings supported the market, but slower growth in these sectors, coupled with cautious pricing strategies by suppliers, prevented significant price changes.

By December, Polyacrylic Acid prices declined, driven by increased competition from imported materials and weakened feedstock cost support. Mixed demand from the construction sector, which faced challenges such as delays and cautious project spending, further contributed to the bearish market trend.

#Polyacrylic Acid#Polyacrylic Acid Market#Polyacrylic Acid Prices#Polyacrylic Acid Price Trends#Polyacrylic Acid News

0 notes

Text

Polyacrylic Acid Prices, News, Trend, Graph, Chart, Forecast and Historical

Polyacrylic Acid is a high-performance polymer with versatile applications across various industries, including water treatment, personal care, adhesives, and agriculture. As a crucial component in these sectors, the market for polyacrylic acid is shaped by its dynamic pricing trends, which are influenced by multiple factors such as raw material costs, demand fluctuations, and regional market dynamics. In recent years, the global polyacrylic acid market has experienced significant changes in pricing trends, driven by advancements in production technology, shifts in consumer preferences, and the growing emphasis on sustainability.

The cost of raw materials is one of the most critical determinants of polyacrylic acid prices. Typically derived from acrylic acid, polyacrylic acid production relies heavily on petrochemical feedstocks. Fluctuations in crude oil prices, supply chain disruptions, and geopolitical tensions often ripple through the acrylic acid market, subsequently impacting the cost of producing polyacrylic acid. For instance, during periods of rising crude oil prices, the production cost for acrylic acid increases, which translates to higher prices for polyacrylic acid. Conversely, when crude oil prices stabilize or decline, manufacturers may pass on these savings to consumers through reduced prices.

Get Real time Prices for Polyacrylic Acid: https://www.chemanalyst.com/Pricing-data/polyacrylic-acid-1587

The demand-supply equilibrium also plays a pivotal role in determining polyacrylic acid prices. As industries such as water treatment and personal care continue to grow, the demand for polyacrylic acid has risen steadily. The polymer’s unique properties, such as its ability to function as a thickener, dispersant, or binder, make it indispensable in these applications. However, when demand outpaces supply, prices often surge due to the scarcity of available products. Conversely, during periods of oversupply or reduced demand, prices tend to soften, providing a more competitive market environment.

Regional disparities in the production and consumption of polyacrylic acid significantly influence its pricing structure. Asia-Pacific, particularly countries like China and India, dominates the market due to the presence of large-scale manufacturing facilities and robust end-user industries. The availability of low-cost labor and raw materials in these regions enables manufacturers to offer polyacrylic acid at competitive prices. In contrast, regions such as North America and Europe often witness higher production costs due to stringent environmental regulations, leading to relatively higher market prices. These regional differences highlight the importance of global trade and supply chain efficiency in stabilizing polyacrylic acid prices.

Technological advancements in production processes have also contributed to pricing fluctuations. Innovations aimed at improving production efficiency and reducing environmental impact have enabled manufacturers to optimize costs. For instance, the adoption of bio-based feedstocks or energy-efficient production technologies can lower the overall cost of manufacturing polyacrylic acid. While these advancements initially require significant investment, they often result in long-term cost benefits, which can positively influence pricing trends.

Sustainability has emerged as a key factor influencing the polyacrylic acid market, with increasing consumer awareness and regulatory pressures driving the demand for eco-friendly alternatives. This shift has prompted manufacturers to explore sustainable production methods, such as using renewable raw materials or developing biodegradable variants of polyacrylic acid. While these innovations often come at a premium price initially, they are expected to gain traction as economies of scale improve and regulatory incentives are introduced. This evolving landscape underscores the interplay between environmental considerations and market pricing dynamics.

The impact of global economic conditions cannot be overlooked when analyzing polyacrylic acid pricing trends. Economic downturns or periods of recession often lead to reduced industrial activity, dampening the demand for polyacrylic acid. Conversely, economic recovery or periods of growth can stimulate demand across end-user industries, contributing to price increases. Additionally, currency exchange rates and trade policies also affect the cost of imports and exports, adding another layer of complexity to pricing dynamics.

Looking ahead, the polyacrylic acid market is expected to witness continued growth, driven by the increasing adoption of sustainable practices and the expanding applications of the polymer in emerging industries. The rising demand for advanced water treatment solutions, coupled with the growth of the personal care and healthcare sectors, is likely to sustain the upward trajectory of polyacrylic acid prices. However, manufacturers must navigate challenges such as raw material price volatility and regulatory compliance to remain competitive in this evolving market.

In conclusion, polyacrylic acid prices are shaped by a complex interplay of factors, including raw material costs, demand-supply dynamics, regional market conditions, technological advancements, and sustainability trends. As industries continue to innovate and adapt to changing consumer preferences, the polyacrylic acid market will likely remain a vibrant and competitive space. Stakeholders across the value chain must stay attuned to these developments to capitalize on emerging opportunities and mitigate potential risks. With its wide-ranging applications and strategic importance in key industries, polyacrylic acid is poised to remain a critical component of the global chemical market for years to come.

Get Real time Prices for Polyacrylic Acid: https://www.chemanalyst.com/Pricing-data/polyacrylic-acid-1587

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Polyacrylic Acid#Polyacrylic Acid Prices#Polyacrylic Acid Price#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Top Qualities to Look for in a Reliable Polyacrylic Acid Manufacturer

When choosing a polyacrylic acid manufacturer, it’s essential to focus on a few key qualities to ensure you’re partnering with a reliable, reputable, and high-quality supplier. Polyacrylic Acid is widely used in industries such as water treatment, adhesives, detergents, and personal care products, so having a trustworthy manufacturer can make a big difference in the consistency and quality of your products.

Here are some of the top qualities to look for in a Polyacrylic Acid manufacturer:

Proven Track Record of Quality

One of the first things to look for in a manufacturer is a strong reputation for producing high-quality Polyacrylic Acid. A reliable manufacturer will have a proven track record and should be able to provide evidence of their quality standards. This could come in the form of certifications, such as ISO quality standards, or third-party testing that verifies the consistency and purity of their Polyacrylic Acid. Consistency in quality is essential, especially for industries where even minor variations can affect product performance.

Compliance with Safety and Environmental Standards

A responsible Polyacrylic Acid manufacturer will always prioritise safety and environmental standards. The manufacturing process of Polyacrylic Acid involves chemicals that require careful handling and disposal to prevent environmental damage. Look for manufacturers who follow local and international safety regulations and those who have environmental policies in place. This not only demonstrates responsibility but also helps your business meet its sustainability goals. A manufacturer that values compliance can be trusted to deliver products safely and ethically.

Strong Research and Development Capabilities

The chemical industry is constantly evolving, with new applications and improved formulations emerging all the time. Choosing a Polyacrylic Acid manufacturer with a strong focus on research and development can give your business an edge. A manufacturer who invests in R&D is likely to innovate continuously, providing you with the latest and most effective versions of Polyacrylic Acid. They may also be able to offer custom formulations to better meet the unique needs of your products, helping you stay competitive.

Clear and Transparent Communication

Good communication is essential in any business relationship. A reliable Polyacrylic Acid manufacturer will keep communication lines open and transparent. They should be responsive, clear, and proactive in providing information about their production processes, lead times, and any potential disruptions. Transparent communication helps you plan better, reduces the risk of misunderstandings, and builds trust over time. Whether you have questions about product specifications or delivery timelines, a reliable manufacturer should be quick to provide the information you need.

Flexible and Reliable Delivery

Timely delivery is crucial, especially if your production relies on a steady supply of Polyacrylic Acid. Look for a manufacturer known for their reliable delivery schedules and the flexibility to adapt to your business’s needs. This could mean adjusting quantities to meet changing demand or accommodating faster lead times when required.

Conclusion

Choosing the right polyacrylic acid manufacturer can have a lasting impact on your products and your business. By focusing on qualities such as a strong reputation, commitment to safety, R&D capabilities, transparent communication, reliable delivery, competitive pricing, and excellent customer support, you can find a manufacturer who meets your needs. Prioritising these factors will not only ensure a smooth supply chain but also help you deliver high-quality products to your customers.

0 notes

Text

I use one of these things, they are so much more efficient and you can put them inside easily if you have any floorspace left.

Ok, so something I've noticed that is utterly baffling to me is that all the Americans I know primarily dry their clothes using a machine called a dryer. I don't even own a dryer. So, I need to know:

#using a dryer is not only wasting resources in terms of electricity#but it is also just plain bad for your clothes#many shouldn't even go in the dryer especially polyester / polyacryl

30K notes

·

View notes

Text

Polyacrylate Crosspolymer 11: Hướng Dẫn Toàn Diện

Polyacrylate Crosspolymer-11, còn được biết đến với tên gọi Carbomer, là một thành phần quan trọng trong ngành công nghiệp mỹ phẩm và chăm sóc da. Bài viết này sẽ cung cấp cho bạn một cái nhìn tổng quan và chi tiết về Polyacrylate Crosspolymer-11, từ định nghĩa, công dụng, cách sử dụng cho đến những thông tin cần thiết về độ an toàn. Chúng ta sẽ khám phá cách thức hoạt động của nó trên da, cách…

0 notes

Text

Sharpies Creative Markers Review

#acrylic paint#art#colors#Creative Color Markers#design#heart#paint#Photo#photography#polyacrylic#puzzle#sharpies#tree

0 notes

Text

The hidden parts of my personality are banging on the glass really loud tonight

1 note

·

View note

Photo

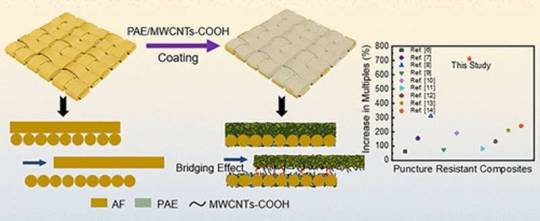

Stab-resistant fabric gains strength from carbon nanotubes, polyacrylate

Fabrics that resist knife cuts can help prevent injuries and save lives. But a sharp enough knife or a very forceful jab can get through some of these materials. Now, researchers report in ACS Applied Nano Materials that carbon nanotubes and polyacrylate strengthen conventional aramid to produce lightweight, soft fabrics that provide better protection. Applications include anti-stabbing clothing, helmets and insoles, as well as cut-resistant packaging.

Soft body armor is typically made from aramid, ultra-high-molecular-weight polyethylene, or carbon and glass fabrics. Their puncture resistance depends, in part, on the friction between yarn fibers within these materials. Up to a point, greater friction means greater protection. Manufacturers can boost friction by roughening the fiber surfaces, but that requires a complicated process, and product yield is low.

Alternatively, the bonding force between yarns can be enhanced by adding another component, such as a sheer thickening fluid (STF) or a polyurethane (PU) coating. But these composite fabrics can't simultaneously satisfy the requirements for thinness, flexibility and light weight. Ting-Ting Li, Xing-xiang Zhang and colleagues wanted to find another way to improve performance while satisfying these criteria.

Read more.

#Materials Science#Science#Polyacrylate#Acrylics#Aramids#Body armor#Composites#Fabrics#Carbon nanotubes#Nanotechnology#Carbon#Nanotubes

15 notes

·

View notes

Text

Ever wondered how are artificial snow formed in Christmas decor? It's the science of Sodium Polyacrylate

Choosing sodium polyacrylate for your festive decorations brings numerous benefits. Its lightweight nature and easy cleanup mean it's practical for both quick event setups and prolonged displays. Completely reusable, this faux snow can be dried out and used again, offering great value over the season. Additionally, it’s non-toxic and safe, ideal for environments frequented by children and pets.

At Chemtex, we pride ourselves on providing a high-quality sodium polyacrylate that stands out from the rest. Our product is not only effective but also eco-friendly, aligning with today’s environmental values. Whether you are decorating a small space or outfitting a large venue, our artificial snow promises superior performance and reliability. This efficiency not only proves cost-effective but also aligns with our commitment to sustainability. Each batch of our artificial snow is non-toxic and completely safe for use around children and pets, making it ideal for family-friendly events and public spaces. Moreover, we pride ourselves on the eco-friendly nature of our product, ensuring that you can enjoy the festive cheer without compromising environmental values. Whether decorating a small space or setting up large-scale displays, Chemtex’s sodium polyacrylate guarantees performance and reliability, making it the premier choice for your holiday decorating needs.

#artificial snow#fake snow#sodium polyacrylate#instant snow#super absorbent polymer#snow polymer#magic snow#water absorbing#SAP polymer#chemtex

0 notes

Photo

Tips to keep: when to use polyacrylic vs. paste wax finish on a furniture piece you've refinished yourself by Jennfer Rizzo.

#furniture#finishes#refinishing#DIY#paste wax#polyacrylic#comparisons#tutorials#tips#home dec#decorating#knowledge#furnishings#how-to

1 note

·

View note

Text

0 notes

Text

Polyacrylic Acid Prices | Pricing | Trend | News | Database | Chart | Forecast

Polyacrylic acid is a synthetic polymer widely used in various industries due to its excellent properties as a thickener, dispersant, and water retention agent. It is a key component in a range of applications such as detergents, coatings, adhesives, and personal care products. The pricing of polyacrylic acid is influenced by several factors, including the cost of raw materials, supply chain dynamics, demand fluctuations, and macroeconomic conditions. Recent trends in the market have shown that the prices of polyacrylic acid have been volatile due to the interplay of these factors. Understanding the drivers of these price changes is critical for businesses that rely on polyacrylic acid in their production processes.

One of the primary factors affecting polyacrylic acid prices is the cost of its main raw material, acrylic acid. Acrylic acid, derived from propylene, is subject to price fluctuations based on the availability of propylene, which is a petrochemical product. Any disruption in the global petrochemical supply chain, such as natural disasters, geopolitical tensions, or fluctuations in crude oil prices, can directly impact the cost of propylene and, consequently, acrylic acid. When acrylic acid prices rise, manufacturers of polyacrylic acid typically pass these costs on to buyers, resulting in higher prices for polyacrylic acid. Conversely, when acrylic acid prices drop, polyacrylic acid prices tend to follow suit.

Get Real Time Prices for Polyacrylic Acid: https://www.chemanalyst.com/Pricing-data/polyacrylic-acid-1587

The supply chain for polyacrylic acid is another critical factor in determining its price. Global supply chain disruptions, such as those caused by the COVID-19 pandemic, have led to challenges in the transportation and distribution of raw materials and finished products. Ports' congestion, labor shortages, and restrictions on movement have all contributed to longer lead times and increased shipping costs. As a result, manufacturers have faced higher costs, which have been reflected in the price of polyacrylic acid. Additionally, the concentration of production facilities in certain regions, such as Asia and Europe, means that any localized disruption can have a global impact on supply and pricing.

Demand fluctuations also play a significant role in determining polyacrylic acid prices. The demand for polyacrylic acid is closely linked to the industries it serves, such as personal care, water treatment, and industrial manufacturing. For example, during periods of economic growth, there is typically an increase in industrial production, leading to higher demand for polyacrylic acid as a key ingredient in coatings, adhesives, and other products. Conversely, during economic downturns, demand for these products decreases, leading to lower demand for polyacrylic acid and, subsequently, lower prices. In recent years, the personal care industry has become a significant driver of demand for polyacrylic acid due to its use in products such as shampoos, lotions, and creams. As consumer preferences shift toward products that offer better performance and environmental sustainability, the demand for polyacrylic acid-based products is expected to grow, potentially putting upward pressure on prices.

Another factor contributing to polyacrylic acid price fluctuations is environmental regulations. As governments worldwide continue to implement stricter regulations on the production and disposal of chemicals, manufacturers of polyacrylic acid face increased compliance costs. These costs are often passed on to consumers in the form of higher prices. For example, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has led to increased scrutiny of chemical manufacturing processes, resulting in higher production costs for polyacrylic acid. In addition, the shift towards more sustainable and environmentally friendly production processes has led to investments in new technologies, which can also drive up production costs.

Geopolitical factors also influence polyacrylic acid prices. Tensions between major economies can lead to trade barriers, tariffs, or sanctions, which can disrupt the flow of raw materials and finished goods across borders. For instance, trade disputes between the United States and China have had significant repercussions on the global chemical industry, including the polyacrylic acid market. Tariffs on acrylic acid and other petrochemical products have led to increased costs for manufacturers, which in turn has pushed up the prices of polyacrylic acid. Additionally, political instability in key regions such as the Middle East, where a significant portion of the world's petrochemical production takes place, can lead to supply disruptions and price volatility.

The global economic environment also has a profound impact on polyacrylic acid prices. Inflation, currency fluctuations, and interest rates all affect the cost of raw materials, production, and distribution. For example, when inflation rises, the cost of producing polyacrylic acid typically increases as the prices of raw materials, energy, and labor rise. Currency fluctuations can also affect the cost of importing raw materials, particularly for manufacturers that rely on international suppliers. Additionally, changes in interest rates can impact the cost of financing for manufacturers, which can be passed on to consumers in the form of higher prices for polyacrylic acid.

In conclusion, polyacrylic acid prices are subject to a variety of factors, including the cost of raw materials, supply chain dynamics, demand fluctuations, environmental regulations, geopolitical influences, and the broader economic environment. Businesses that rely on polyacrylic acid must carefully monitor these factors to manage their costs effectively and remain competitive in the market. As the global economy continues to evolve, it is likely that the pricing of polyacrylic acid will remain volatile, requiring businesses to stay agile and adapt to changing market conditions. With the increasing focus on sustainability and environmental regulations, manufacturers may also need to invest in new technologies and processes to remain compliant and competitive, further influencing the price of polyacrylic acid in the years to come.

Get Real Time Prices for Polyacrylic Acid: https://www.chemanalyst.com/Pricing-data/polyacrylic-acid-1587

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Polyacrylic Acid#Polyacrylic Acid Prices#Polyacrylic Acid Price#Polyacrylic Acid News#Polyacrylic Acid Monitor

0 notes