#Polyacrylamide (PAM)

Explore tagged Tumblr posts

Text

Why Choose Chem Fert Chemicals As Your Polyacrylamide Supplier in India?

Polyacrylamide Suppliers in India – Polyacrylamide (PAM), a versatile water-soluble polymer, plays a crucial role in various industrial applications.

If you’re an industrial buyer in India seeking a reliable Polyacrylamide supplier, this guide by Chem Fert Chemicals is here to assist you.

Polyacrylamide Supplier In India, Best Polyacrylamide Supplier In India, Top Polyacrylamide Supplier In India, No 1 Polyacrylamide Supplier In India, Polyacrylamide (PAM), Chem Fert Chemicals

#Polyacrylamide Supplier In India#Best Polyacrylamide Supplier In India#Top Polyacrylamide Supplier In India#No 1 Polyacrylamide Supplier In India#Polyacrylamide (PAM)#Chem Fert Chemicals

0 notes

Text

https://www.tianrun.com.cn/en/

1 note

·

View note

Text

ポリアクリルアミド (Polyacrylamide) 価格動向: 詳細なチャート、市場分析、将来の見通し

ポリアクリルアミド (Polyacrylamide) は、水処理、石油抽出、製紙、繊維など、さまざまな業界で広く使用されている水溶性ポリマーです。コストを効果的に管理し、サプライ チェーンの効率性を維持したい企業にとって、ポリアクリルアミドの価格動向を監視することは不可欠です。

ポリアクリルアミドの価格に影響を与える主な要因

原材料費

ポリアクリルアミドを製造するための主な原料には、石油由来の化学物質から��られるアクリルアミドとアクリル酸が含まれます。原油価格の変動は、ポリアクリルアミドの価格に大きな影響を与えます。

エンドユーザー産業からの需要

水処理:効果的な凝集剤として、ポリアクリルアミドは廃水処理において重要な役割を果たします。

石油産業: PAM は石油増進回収 (EOR) プロセスに広く使用されています。

製紙および繊維産業:ポリアクリルアミドは紙の品質向上や繊維の保持剤として役立ちます。

生産コストと環境規制

化学製品の製造に関連する厳格な環境基準は、生産費用と入手可能性に影響を及ぼす可能性があります。

サプライチェーンのダイナミクス

世界的な海上輸送ルートの混乱、エネルギーコストの上昇、物流のボトルネックなどが価格変動の一因となる可能性があります。

地域市場動向

アジア太平洋

中国は、その広範な水処理および工業部門の牽引により、ポリアクリルアミドの生産と消費の両方において依然として主要なプレーヤーです。

北米

廃水処理施設や石油事業への投資増加が安定した需要を支えています。

ヨーロッパ

環境規制と持続可能な産業慣行への重点は、ポリアクリルアミド市場の動向に影響を与えます。

リアルタイムで ポリアクリルアミド (Polyacrylamide)価格: https://www.analystjapan.com/Pricing-data/polyacrylamide-pam-85

現在の市場シナリオ

原材料価格の上昇

アクリルアミドのコストとエネルギー投入の増加により、ポリアクリルアミドの価格が上昇しました。

環境コンプライアンスコスト

排出規制の遵守により、一部のメーカーはコストが高く、より環境に優しい生産方法を採用するようになりました。

パンデミック後の需要回復

産業が回復するにつれ、特に水処理と石油の分野でポリアクリルアミドの需要が増加し続けています。

ポリアクリルアミド価格の将来見通し

技術革新

効率性の向上と環境への影響の削減を目的とした新しい生産技術は、価格の安定に役立つ可能性があります。

廃水処理事業の拡大

持続可能な水管理への政府の投資は長期的な需要を押し上げる可能性が高い。

持続可能な実践

バイオベースの代替品の採用により、今後数年間で市場の状況が変化する可能性があります。

結論

ポリアクリルアミドの価格は、原材料費、産業需要、規制上の課題によって左右されます。市場動向を常に把握しておくことで、企業はコストを管理し、変化する状況��効果的に適応することができます。

アナリストジャパン

電話 +1 (332) 258-6602 〒215-0004 川崎市麻生区万福寺1-2-3

ウェブサイト: https: //www.analystjapan.com

メールアドレス: [email protected]

0 notes

Text

0 notes

Text

Flocculant & Coagulant Market - Forecast(2024 - 2030)

Overview

Flocculant & Coagulant Market size is forecast to reach around $7 billion by 2025, after growing at a CAGR of 6% during 2020-2025. Flocculant & coagulants are chemicals that aggregate the colloids and other suspended particles of high molecular weights in the liquid, thereby clean the water. Use of coagulation-flocculation method for removing harmful substances from wastewater is driving the growth of flocculant & coagulant market. Moreover, surging demand of poly aluminium chloride (PACl) and cationic polyacrylamide (C-PAM) for the removal of chemical oxygen demand (COD) and turbidity from paper recycling wastewater is aiding the growth of the market. Flocculant & coagulants are also used in oilfields for mud dewatering, oil/water separation and flow back water recycling.

Report Coverage

The report: “Flocculant & Coagulant Market – Forecast (2020-2025)”, by IndustryARC, covers an in-depth analysis of the following segments of the Flocculant & Coagulant Industry.

By Type: Coagulant {Organic Coagulant (Polyamine, Chitosan, and others) and Inorganic Coagulant (Aluminium Sulfate, Aluminium Chloride, Sodium Aluminate, Ferric Sulfate, Others)} and Flocculant (Anionic, Cationic, Non-Ionic, and Others)

By Application: Municipal Water Treatment, Paper and Pulp, Textile, Oil and Gas, Mining, Chemical Processing, and Others

By Geography: North America, South America, Europe, APAC, and RoW

Request Sample

Key Takeaways

In APAC Flocculant & Coagulant market, China dominated the market throughout the forecast period owing to the large consumer base and increase in demand of flocculant & coagulant chemicals for treating paper and pulp wastewater.

Decline in manufacturing activities globally due to the outbreak of coronavirus has hampered the growth of flocculant & coagulant market.

Increasing adoption of UV technologies and RO filtration hinder the growth of flocculant & coagulant market.

Type - Segment Analysis

Coagulant segment holds the largest share of more than 55% in the flocculant & coagulant market in 2019. The use of coagulation offer various advantages like it reduces the time required to settle out suspended solids and is very effective in removing fine particles that are very difficult to remove. Moreover, the water treatment coagulants consists of positively charged molecules that, destabilizes negatively charged particulate and colloidal contaminants. The inorganic and organic coagulants are also used to treat water for the removal of suspended solids in oilfields and textile industries. The rise in production of oil and gas increases the use of coagulants for the separation of oil and water. For instance, according to International Energy Agency (IEA), the global oil production capacity is expected to rise by 5.9 mb/d by 2025 whereas Non-OPEC supply of crude and natural gas liquids will rise by 4.5 mb/d.

Inquiry Before Buying

Application - Segment Analysis

Based on the application, the paper and pulp segment held the largest share of more than 25% in the flocculant & coagulant market in 2019. The growing use of flocculant & coagulant chemicals in paper industry for the removal of suspended particles from water is driving the growth of flocculant & coagulant market. According to Environmental Paper Network (EPN), paper use is steadily increasing year on year and exceeded to 400 million tons per year in 2018. Furthermore, rising environmental concerns and strict government regulations to lower the use of polyethylene bags has escalated the demand of paper for packaging purposes, which in turn augments the growth of flocculant & coagulant chemicals. For instance, California government has introduced a regulation known as SB270 in July 2015 for prohibiting use of plastic bags at groceries, pharmacies, and other stores.

COVID-19 has badly impacted the flocculant & coagulant market. Coronavirus has disrupted the supply chain and e-commerce sector. Decrease in purchasing capital has direct impact on various industry growth, which in turn hampered the growth of flocculant & coagulant market. With the steep reduction in demand due to sudden stoppage of exports/imports and also domestic sales has hampered the growth of flocculant & coagulant market. The Confederation of Indian Textile Industry (CITI) has requested the government to announce relief packages for the textile and apparel sector to curb the crisis being faced by the textile industries. Hence, downfall of textile industry also reduces the demand of flocculant & coagulant chemicals.

Geography - Segment Analysis

Asia Pacific dominated the flocculation and coagulation market with a share of more than 35% in 2019 followed by North America and Europe. Rapid industrialization and treatment of wastewater generated from manufacturing plants is driving the growth of flocculant & coagulants market. India is the second-largest manufacturer and exporter of textiles and apparel with a share of 5% of global trade. Exports of textile and clothing products from India have increased from US$ 39.2 billion during 2017–18 to US$ 40.4 billion during the year 2018–19, registering a growth of 3%. According to National Investment Promotion and Facilitation Agency, exports in the textiles and apparel industry are expected to reach $300 Bn by 2024-25 resulting in a tripling of Indian market share from 5% to 15%. Thus, growth of textile industry has increased the use of flocculant & coagulant chemicals for the filtration and aggregation of suspended particles present in wastewater. Furthermore, Asia is one of the largest producer of paper and increase in demand of flocculation and coagulant chemicals from paper industries is boosting the growth of market. According to the Trade Map, global import of pulp of wood and cellulose fibers was valued around $ 53,084,971 while china alone imported pulp of $19,240,368 in 2019.

Schedule a Call

Drivers – Flocculant & Coagulant Market

Increasing health concerns and government policies for wastewater treatment

Strict government regulations for the direct disposal of contaminated water is escalating the use of flocculation and coagulant chemicals in manufacturing industries. For instance, the United States Environmental Protection Agency (EPA) regulates the discharge and treatment of wastewater under the Clean Water Act (CWA). The National Pollutant Discharge Elimination System (NPDES) issues permit to all wastewater dischargers and treatment facilities. Whereas, contaminated water also causes severe health problems including diarrhea, cholera, dysentery etc. Thus, increasing health concerns also boosts the growth of flocculation and coagulant market. Moreover, the Indian government policies such as “State Sewerage and Wastewater Policy” which frames guidelines for resource development and management, wastewater collection and treatment, onsite and offsite sanitation also aids the growth of flocculation and coagulants market.

Global increase in mining operations

Increase in mining operations for the extraction of ores, minerals, coals etc. has resulted in water pollution. According to the USGS National Minerals Information Center, the U.S mines production grew by 3% reaching $82.2 billion of raw mineral materials in 2018 as compared to $79.7 billion in 2017. Water is used in mining for mineral processing, dust suppression and slurry transportation. The United States Geological Survey (USGS) has estimated that 4 billion gallons of water were withdrawn for mining operations in the U.S. in 2015, up 1% from 2010. Thus increase in mining operation has increased the use of flocculant & coagulant chemicals for the removal of suspended colloidal particles. Furthermore, government’s act and regulation such as Clean Water Act (CWA) in the United States that regulates the mining operations in and discharges of pollutants to streams also augments the growth of flocculant & coagulant market.

Challenges – Flocculant & Coagulant Market

Presence of substitutes for water treatment

The adoption of U.V technologies and RO water filtration whose purification efficiency is higher than flocculation and coagulant chemicals hampers the growth of flocculant & coagulant market. U.V and RO filters not only eliminates the suspended particles but also remove the harmful bacteria and pathogens. Although flocculant & coagulants are widely used in industries for effluent water treatment processes in solids removal, water clarification, lime softening, sludge thickening, and solids dewatering, but the cost and the need for accurate dosing of coagulants and frequent monitoring is a major challenge. Coagulants need accurate dosing equipment to function efficiently and the dose required depends on raw water quality that varies rapidly.

Buy Now

Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the flocculant & coagulant market report. In 2019, the market of flocculant & coagulant has been consolidated by the top 10 companies accounting for xx% of the share. Major players in the flocculant and coagulation market industry outlook are, BASF SE, Ecolab Inc., Solenis LLC, Solvay SA, Kemira Oyj, Buckman Laboratories International, Inc., Kurita Water Industries Ltd., Suez S.A., Feralco AB and Hengyang Jianheng Industry Development Co., Ltd., among others.

Acquisitions/Technology Launches

In January 2019, BASF SE merged its wet-end Paper and Water Chemicals business with Solenis. With this merger the company has expanded its chemical offerings for customers in the pulp, paper, oil and gas, chemical processing, mining, biorefining, and power industries. BASF SE would have a 49% stake in the merged entity, while 51% shares would be owned by Solenis.

In April 2017, Kemira Oyj launched a new high-performance cationic flocculant Kemira Superfloc® XD-7600 polymer. It was designed to help customers decrease their Total Cost of Ownership through more efficient sludge handling, including freight and disposal costs.

#Flocculant & Coagulant Market#Flocculant & Coagulant Market Share#Flocculant & Coagulant Market Size#Flocculant & Coagulant Market Forecast#Flocculant & Coagulant Market Report#Flocculant & Coagulant Market Growth

0 notes

Text

Polyacrylamide (PAM) Prices | Pricing | Price | News | Database | Chart | Forecast

Polyacrylamide (PAM) prices is a versatile and widely used synthetic polymer that has gained significant attention across various industries. Its application ranges from water treatment to enhanced oil recovery, and agriculture to paper production, making it a critical component in several sectors. The demand for polyacrylamide has been on the rise due to its effectiveness in improving processes such as flocculation, thickening, and lubrication. This increasing demand has naturally influenced PAM prices, which fluctuate based on several key factors, including raw material costs, production capacity, market demand, and global economic trends. Understanding these factors and their influence on the pricing of polyacrylamide is crucial for businesses relying on this polymer.

One of the primary factors that affect polyacrylamide prices is the cost of raw materials, particularly acrylonitrile and acrylic acid. These materials are petroleum derivatives, and their prices tend to fluctuate with the global oil market. When crude oil prices increase, the cost of producing polyacrylamide often rises as well, leading to higher market prices for the polymer. Conversely, a drop in oil prices can sometimes result in lower production costs, providing an opportunity for more competitive pricing. However, the relationship between crude oil and PAM prices is not always direct, as other factors also play a role, such as supply chain dynamics and production efficiency.

Another significant factor that drives polyacrylamide prices is the global supply and demand balance. The increasing use of PAM in water treatment facilities, particularly in emerging markets, has significantly boosted demand. Clean water and wastewater treatment have become pressing issues globally, especially in regions experiencing rapid industrialization and urbanization. PAM is highly effective in treating wastewater by helping remove suspended solids and organic contaminants through flocculation and coagulation processes. As more countries invest in water treatment infrastructure, the demand for PAM continues to grow, putting upward pressure on prices.

In addition to water treatment, polyacrylamide is used extensively in the oil and gas industry, particularly in enhanced oil recovery (EOR) techniques. EOR involves injecting water, polymers, or gases into oil reservoirs to increase the amount of recoverable oil. PAM is used as a thickening agent in these processes, helping to improve the efficiency of oil recovery. The volatility of the oil market can influence PAM prices, as fluctuations in oil production and exploration activities can impact demand. When oil prices are high, exploration and production activities typically increase, driving up demand for PAM and consequently its price. Conversely, a slump in oil prices can lead to reduced demand and lower prices for polyacrylamide.

Get Real Time Prices for Polyacrylamide (PAM): https://www.chemanalyst.com/Pricing-data/polyacrylamide-pam-1202

Environmental regulations also play a role in shaping PAM prices. In many countries, strict environmental regulations have been implemented to reduce pollution and improve water quality. These regulations often mandate the use of chemicals like polyacrylamide in industrial and municipal wastewater treatment. As a result, industries are required to invest in treatment solutions, increasing the demand for PAM. However, these regulations can also impact production costs. For instance, environmental standards may necessitate the adoption of cleaner production processes or technologies, which can drive up the cost of manufacturing polyacrylamide. These costs are typically passed on to the end consumer in the form of higher prices.

China is a major producer and consumer of polyacrylamide, accounting for a significant portion of global production capacity. As such, developments in the Chinese market can have a considerable impact on global PAM prices. For instance, environmental policies in China have led to stricter controls on chemical manufacturing, including the production of polyacrylamide. These regulations have forced some manufacturers to upgrade their facilities or even shut down temporarily, leading to supply constraints and price increases. Additionally, China’s role as a key exporter means that any disruptions in its supply chain can affect the availability of polyacrylamide in international markets, further influencing prices.

Logistics and transportation costs also influence the pricing of polyacrylamide. Given that PAM is a bulk chemical, its distribution involves significant transportation expenses. Changes in fuel prices, shipping costs, and logistical challenges can all impact the final price of PAM in different regions. Geopolitical factors, such as trade restrictions and tariffs, can further complicate the global distribution of polyacrylamide, potentially leading to regional price disparities. For example, increased tariffs on Chinese chemical products could raise the price of PAM in countries that rely heavily on Chinese imports.

Technological advancements in polyacrylamide production and application are another factor affecting prices. Innovations in production methods can lead to improved efficiency, reducing the cost of manufacturing PAM. Additionally, advancements in the formulation of PAM can enhance its performance, making it more effective in smaller quantities. This can provide cost savings for end-users, even if the price per unit of PAM remains stable or increases. On the other hand, the development of new technologies and applications for PAM can create new demand, driving up prices as industries compete for limited supply.

The competitive landscape of the polyacrylamide market also plays a role in determining prices. With numerous manufacturers and suppliers vying for market share, price competition can be fierce. In regions with a high concentration of PAM producers, prices may be lower due to increased competition. However, in areas with limited production capacity or fewer suppliers, prices tend to be higher. The ability of manufacturers to differentiate their products based on quality, performance, and customer service can also influence pricing dynamics.

In conclusion, polyacrylamide prices are influenced by a complex interplay of factors, including raw material costs, supply and demand dynamics, environmental regulations, global economic conditions, and technological advancements. As industries continue to rely on PAM for various applications, from water treatment to oil recovery, understanding these factors becomes essential for businesses seeking to manage costs and optimize their supply chains. Despite the challenges posed by fluctuating prices, the growing demand for polyacrylamide in critical sectors suggests that it will remain a vital commodity for the foreseeable future.

Get Real Time Prices for Polyacrylamide (PAM): https://www.chemanalyst.com/Pricing-data/polyacrylamide-pam-1202

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Polyacrylamide#Polyacrylamide Price#Polyacrylamide Prices#Polyacrylamide Pricing#Polyacrylamide News#Polyacrylamide Price Monitor

0 notes

Text

Mumbai market sees a gain in Polyacrylamide prices

POM prices have witnessed a substantial rise in Mumbai today. On July 18, 2024, PAM prices in imported tanker loads at Mumbai were quoted higher from Rs.157/Kg to Rs.161/Kg a hike of Rs 4/kg. Any disruptions in the supply chain, such as logistical issues, transport constraints, or interruptions in production facilities, can lead to decreased supply and thus higher prices. POM chemical compounds are used to flocculate and coagulate suspended solids in water, wastewater, and soil. They assist in management of the Earth's soil and water. In the straight-chain form, it is also used as a thickener and suspending agent. Soluble in water, forming a transparent gel when mixed with water. Used mainly for water treatment and mineral processing. Commonly used in wastewater treatment, enhanced oil recovery, and paper-making industries. Effective in sludge dewatering, sewage treatment, and papermaking. India POM Prices, POM Orices In Indian, Indian Prices POM, Indianpetrochem.

0 notes

Text

Sustainable Packaging Solutions in the Polyacrylamide Market

Polyacrylamide: A Versatile Synthetic Polymer Used in Various Industries and Applications What is PAMs?

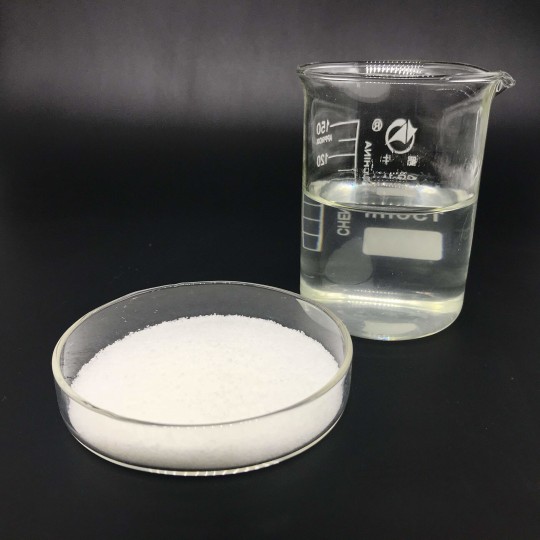

PAMs is a water-soluble non-ionic polymer made from acrylamide subunits through free-radical polymerization. It comes as a white water-soluble powder and has a chemical formula of (C3H5NO)n. Simply put, PAMs is a long-chain synthetic molecule made up by the polymerization of acrylamide monomers. PAMs is a highly water-absorbent substance and can retain up to 200-600 times its mass in water. Uses of Polyacrylamide in Flocculation

One of the main uses of PAMs is in waste water treatment and mining via a process called flocculation. In flocculation, PAMs polymers are added to suspensions containing small suspended particles like sediments, algae, heavy metals etc. The long molecular chains of PAMs bind to the particles and form larger, easily settleable clumps called flocs. This allows for faster and more efficient solid-liquid separation processes like sedimentation and filtration. PAMs flocculants are commonly used in water treatment plants and mining operations to purify water and recover valuable minerals. Applications in Paper Manufacturing

PAMs finds applications in paper manufacturing processes as well. It is added to pulp and paper mill wastewater streams during treatment to remove suspended fibers and fillers. This improves the drainage rate by coagulating fine particles and increasing the consolidation rate when dewatering paper sludge. PAMs is also used as a binder and strength agent in the wet end of paper making to increase physical properties like tensile strength, burst strength and fold endurance of paper products. Uses in Enhanced Oil Recovery

Due to its ability to increase viscosity, PAMs is used extensively in enhanced oil recovery (EOR) techniques. In EOR processes like polymer flooding, a dilute solution of PAMs is injected into oil reservoirs after conventional methods to increase the mobility of the displacing fluid. The high molecular weight PAMs solutions form a polymer bank that sweeps through the reservoir and tends to drive more oil toward the production well by improving microscopic displacement efficiency. This technique can extract 10-15% additional oil from mature oilfields. Applications in Agriculture

PAMs also has beneficial uses in agriculture. It is used as a soil conditioner to help retain moisture and nutrients in soil. When applied to soil, PAMs absorbs water and prevents runoff, thereby conserving water. It also seals micro cracks in soil to reduce loss of moisture and small fertilizer particles. This leads to better water efficiency and increased crop yields. In hydroponics systems and greenhouse soils, PAMs acts as a water retaining agent that allows for controlled release of water to plant roots. Role in ConstructionDue to its moisture absorbing property, polyacrylamide plays a key role in construction. It is added to concrete mixtures as a superplasticizer or water reducing admixture to improve workability. PAMs allows concrete to be mixed at lower water-cement ratios without compromising on slump or flow properties. This leads to stronger, more durable concrete structures. It is also used to manufacture grouts and floor leveling compounds with self-leveling and self-curing properties. PAMs based compounds fill cracks, level floors and bond building surfaces. Uses as a Thickening Agent

Because of its high molecular weight and hydrophilic nature, PAMs has superb thickening properties. It is widely used as a thickening agent in various industrial and consumer products like paints, coatings, adhesives, cosmetics, pharmaceuticals and foods. PAMs helps increase viscosity without significantly affecting other product properties. It provides stable viscosity even under low shear/high stress conditions. Some common applications as a thickener include its use in low-fat foods, shampoos, lotions, syrups, soups and metalworking fluids. Applications in Biotechnology

Due to biocompatibility, PAMs also finds applications in biotechnology and biochemical engineering processes. It is often used to prepare gels and beads for electrophoresis, isoelectric focusing and chromatography techniques in laboratories. PAMs gels serve as excellent media for separation, isolation and purification of biomolecules like proteins, nucleic acids and enzymes. In medicine, hydrogels made of PAMs are being researched for use in tissue engineering, artificial skin, soft contact lenses and drug delivery. In summary, polyacrylamide is a versatile synthetic polymer with wide applications across industries owing to its water solubility and moisture absorption properties. It acts as an efficient flocculant, thickening agent, soil conditioner, plasticizer, strengthening additive and supports various biochemical separation processes. With continued innovation, new uses of PAMs will likely be discovered, cementing its important role in science, engineering and technology.

0 notes

Text

Global Polyacrylamide (PAM) Market Analysis: Assessing Growth Opportunities

Polyacrylamide (PAM) stands as a versatile polymer with diverse applications across industries, playing a vital role in water treatment, petroleum, agriculture, and other sectors. This blog explores the dynamics of the global polyacrylamide market, analyzing key drivers, applications, emerging trends, and future growth opportunities.

Understanding the Polyacrylamide Market:

Polyacrylamide (PAM) is a synthetic polymer derived from acrylamide monomers. It exists in various forms including anionic, cationic, and non-ionic, each offering specific properties suitable for different applications. PAM finds extensive use as a flocculant, thickener, soil conditioner, and friction reducer, among other functions.

Market Dynamics:

Water Treatment Sector: PAM is a cornerstone in water treatment processes, facilitating solid-liquid separation, sedimentation, and clarification in municipal and industrial wastewater treatment plants.

Enhanced Oil Recovery (EOR): In the petroleum industry, PAM is used for EOR processes to improve oil displacement efficiency, reduce water consumption, and enhance oil production from reservoirs.

Agricultural Applications: PAM is employed in agriculture as a soil conditioner and erosion control agent, enhancing soil structure, water retention, and preventing soil erosion.

Paper and Textile Industries: PAM serves as a retention aid and drainage aid in papermaking, as well as a sizing agent and dye-fixing agent in textiles.

Applications Across Industries:

Water Treatment: Flocculation, coagulation, sludge dewatering.

Petroleum Industry: Enhanced Oil Recovery (EOR), drilling fluid additives.

Agriculture: Soil conditioning, erosion control, irrigation management.

Paper and Textiles: Retention aid, sizing agent, dye-fixing agent.

Market Trends:

Environmental Concerns and Regulations: Stringent regulations regarding wastewater discharge and environmental impact drive the demand for effective water treatment solutions, boosting the adoption of PAM in water and wastewater treatment processes.

Advanced Formulations: Innovations in polymer chemistry lead to the development of high-performance PAM formulations with improved efficiency, lower toxicity, and enhanced compatibility with various water chemistries.

Focus on Sustainable Agriculture: Growing awareness of sustainable farming practices fuels the use of PAM in agriculture for soil conservation, water management, and improving crop yields while minimizing environmental impact.

Future Prospects:

The global polyacrylamide market is poised for substantial growth, driven by increasing demand from water treatment, petroleum, agriculture, and other sectors. Innovations in PAM formulations, sustainable practices, and expanding applications will shape the market's evolution in the coming years.

Conclusion:

Polyacrylamide plays a pivotal role across multiple industries, offering versatile solutions for water treatment, petroleum extraction, agriculture, and manufacturing processes. Navigating the polyacrylamide market requires awareness of industry trends, regulatory landscapes, and technological advancements. With a focus on innovation, sustainability, and customized solutions, the PAM market presents significant growth opportunities and contributions to global industrial and environmental sustainability goals.

0 notes

Text

A Comprehensive Guide to Chlorine Tablets, PAM Powder, and Filter Balls for Pools

Ensuring your pool stays crystal clear and hygienic involves the strategic use of various pool maintenance products. In this guide, we will delve into the practicalities and benefits of employing chlorine tablets, PAM powder, and filter balls in your pool maintenance routine, addressing common user queries and providing insights into the effective utilization of these products.

Chlorine Tablets: Chlorine tablets are a fundamental component of pool water treatment. Users often wonder about the optimal way to use these tablets. Here are some key points:

Proper Placement: To maximize efficiency, place chlorine tablets in a dedicated dispenser near the water return outlet rather than directly into the pool. This ensures even distribution throughout the pool.

Dosage Considerations: The quantity of tablets depends on factors such as pool size and current chlorine levels. It is crucial to follow the manufacturer's guidelines for accurate dosage.

Dissolution Time: Allowing sufficient time for the tablets to dissolve is essential. Factors like tablet composition and water temperature influence dissolution rates. Refer to the manufacturer's instructions for specific recommendations.

PAM Powder: Polyacrylamide (PAM) powder is known for its flocculant properties, aiding in the removal of suspended particles. Users often have questions about its application. Here's a guide:

pH Testing: Before applying PAM powder, check the pool's pH levels. PAM is most effective in a slightly alkaline environment, with a pH range between 7.5 and 8.5.

Dosage Precision: Adhering to recommended concentrations is crucial. Typically, a concentration of 5-10mg/L is advised. This ensures optimal performance without overuse.

Mixing and Settling: After applying PAM powder, thorough mixing is necessary for even distribution. Allowing the pool water to settle for at least six hours enhances the coagulation process.

Filter Balls for Pools: Filter balls are a modern alternative to traditional filter media like sand. Users often seek guidance on their usage. Here's what you need to know:

Installation: Replace sand with filter balls in your pool filter system. Follow the manufacturer's instructions for proper installation.

Filtration Efficiency: Filter balls provide excellent filtration and require less backwashing. Regularly check and clean the balls for optimal performance.

Maintenance Tips: Keep track of the condition of filter balls and replace them when needed. Rinse the balls periodically to remove accumulated debris.

Conclusion: By understanding the nuances of using chlorine tablets, PAM powder, and filter balls, pool owners can streamline their maintenance routines. Remember to follow recommended dosages, placement strategies, and maintenance practices to keep your pool water pristine and inviting. Regularly consulting manufacturer guidelines and staying informed about best practices ensures a safe, healthy, and enjoyable swimming environment.

0 notes

Text

Polyacrylamide | Polyacrylamide Supplier In India - Chem Fert Chemicals

Polyacrylamide Supplier In India - Get Polyacrylamide in India! Chem Fert Chemicals, a leading Polyacrylamide Supplier In India, Polyacrylamide Supplier In India, offers high-quality Polyacrylamide for various applications.

Polyacrylamide Supplier In India, PAM Supplier In India, Polyacrylamide, Polyacrylamide (PAM) Powder Supplier In India, Polyacrylamide Powder Supplier In India, Polyacrylamide Manufacturers & Suppliers in India, Polyacrylamide Latest Price in India, Buy Polyacrylamide Powder Online in India, Polyacrylamide Powder Manufacturer, Supplier, Exporter, Poly Electrolyte Polyacrylamide Supplier In India, Polyacrylamide 9004-05-8 Supplier In India, Anionic Polyacrylamide Supplier In India, Polyacrylamide Manufacturers in India, www.chemfertchemicals.com, www.chemfertchemicals.com/polyacrylamide-supplier-india.php, Chem Fert Chemicals

#Polyacrylamide Supplier In India#PAM Supplier In India#Polyacrylamide#Polyacrylamide (PAM) Powder Supplier In India#Polyacrylamide Powder Supplier In India#Polyacrylamide Manufacturers & Suppliers in India#Polyacrylamide Latest Price in India#Buy Polyacrylamide Powder Online in India#Polyacrylamide Powder Manufacturer#Supplier#Exporter#Poly Electrolyte Polyacrylamide Supplier In India#Polyacrylamide 9004-05-8 Supplier In India#Anionic Polyacrylamide Supplier In India#Polyacrylamide Manufacturers in India#www.chemfertchemicals.com#www.chemfertchemicals.com/polyacrylamide-supplier-india.php#Chem Fert Chemicals

0 notes

Text

Polyacrylamide: A Versatile Polymer for Various Applications

Polyacrylamide, often abbreviated as PAM, is a synthetic polymer with a wide range of applications. It has gained significant attention due to its excellent performance and versatility. In this article, we will explore the uses, properties, and preparation of polyacrylamide while highlighting its significance in different industries.

Polyacrylamide is commonly used in water treatment processes. It acts as a flocculant, helping to separate solid particles from wastewater and improving the overall water quality. With its high molecular weight and charge density, polyacrylamide effectively aggregates suspended particles, facilitating their removal during sedimentation or filtration.

The water treatment industry extensively utilizes polyacrylamide to treat various types of wastewater. Whether it's municipal sewage, industrial effluents, or agricultural runoff, polyacrylamide proves to be an efficient solution for reducing pollutant levels and ensuring environmental compliance.

Furthermore, polyacrylamide finds applications in diverse fields such as medicine, food, and cosmetics. In medicine, it is utilized for drug delivery systems, tissue engineering, and wound healing. Its unique ability to form hydrogels makes it an ideal candidate for controlled release and targeted drug delivery.

In the food industry, polyacrylamide is employed as a thickening agent and stabilizer in processed foods, providing improved texture and shelf-life. Additionally, it finds use in cosmetics for its film-forming and moisturizing properties, making it valuable in skincare products.

When it comes to the preparation of polyacrylamide, it can be synthesized through free radical polymerization of acrylamide monomers. Various factors such as temperature, initiator concentration, and reaction time influence the polymerization process and result in polyacrylamide with different molecular weights and structures.

It's important to note that polyacrylamide is non-biodegradable and thus requires cautious handling and disposal. However, its non-toxic nature at low concentrations ensures its safe usage in various applications.

The price of polyacrylamide varies depending on factors like grade, purity, and quantity. Generally, it is priced per ton or per kilogram. For specific pricing details, it is advisable to contact reliable polyacrylamide suppliers who can provide accurate information based on your requirements.

In conclusion, polyacrylamide offers numerous advantages and finds extensive use in various industries. Its water treatment capabilities, along with its significant role in medicine, food, and cosmetics, make it an indispensable polymer. By understanding the properties and uses of polyacrylamide, industries can harness its potential to address challenges and improve processes.

3 notes

·

View notes

Text

폴리아크릴아미드(PAM) 가격: 최신 동향, 데이터베이스 통찰력 및 예측

2024년 3월 분기 종료

APAC

APAC 폴리아크릴아미드(PAM) 시장은 2024년 1분기에 어려운 상황을 겪었으며, 3월 칭다오에서 MT FOB당 가격이 850달러로 하락했습니다. 이러한 감소는 지속적인 공급 과잉과 아크릴아미드와 같은 주요 공급원료의 비용 감소로 인해 발생했으며, 이로 인해 생산업체는 경쟁력을 유지하기 위해 공격적인 가격 전략을 채택해야 했습니다. 중국 섬유 부문의 급속한 성장에도 불구하고 PAM에 대한 수요는 증가하지 않았으며, 이는 부문 성장과 원자재 소비 간의 단절을 강조했습니다. 수처리, 제지 등 주요 전방산업은 수요가 예상대로 회복되지 않는 부진한 모습을 보였습니다. 글로벌 경제 압박으로 인해 전통적인 연휴 이후 수요 급증이 더욱 위축되었습니다. 또한 제조 부문의 부진한 성과로 인해 PAM이 비축되어 공급업체가 재고 균형을 맞추기 위해 상당한 할인을 제공하게 되었습니다. 분기 말까지 APAC PAM 시장은 산업 소비 감소와 공급원료 가격이 시장 역학에 미치는 영향을 강조했습니다.

북아메리카

북미 폴리아크릴아미드(PAM) 시장은 2024년 1분기에도 하락 추세를 이어갔으며, 가격은 3월 말까지 텍사스주 MT FOB당 2,375달러로 하락했습니다. 이 기간은 주로 수처리, 석유 및 가스와 같은 주요 전방 산업의 공급 과잉과 수요 약세로 인해 수요와 공급이 지속적으로 불일치하는 기간이었습니다. 생산자들 사이의 높은 재고 수준은 거래 활동을 위축시켜 시장을 약세 전망으로 몰아넣었습니다. 국내 제조업체의 정상적인 생산률과 구매관리자지수(PMI)의 소폭 상승 등 긍정적인 기업 활동에도 불구하고 이러한 요인들은 전반적인 시장 침체를 상쇄하기에는 역부족이었습니다. 섬유와 같은 주요 PAM 소비 부문의 어려움으로 인해 신중한 거래 환경이 더욱 악화되었으며, 이로 인해 많은 기업이 대규모의 전략적 재고 축적보다 즉각적이고 필요한 조달을 우선시하게 되었습니다. 경제적 불확실성이 만연한 가운데 이러한 보수적인 접근 방식으로 인해 3월 북미 PAM 시장에서 관찰된 가격 인하가 이루어졌습니다.

유럽

실시간 폴리아크릴아미드(PAM) 가격 확인: https://www.analystkorea.com/Pricing-data/polyacrylamide-pam-1027

유럽 폴리아크릴아미드(PAM) 시장은 2024년 1분기 동안 하락 추세를 유지했으며, 3월 독일에서는 가격이 MT당 3,340달러에 정착했습니다. 시장은 공급 과잉과 물, 석유, 가스 부문의 수요 약화로 인해 과잉 재고가 발생하고 가격 하락 압력을 받는 것이 특징이었습니다. 이러한 상황은 제조업 PMI의 위축과 이것이 노동 및 구매 활동에 미치는 영향에 반영된 제조업 부문의 약세로 인해 더욱 악화되었습니다. 풍부한 공급으로 인해 생산자들은 높은 재고를 보유하게 되었고, 시장 심리가 약한 가운데 판매를 장려하기 위해 가격 인하를 촉발했습니다. 이러한 어려움에도 불구하고 공급업체는 계속해서 문의를 받았으며 이는 조심스럽기는 하지만 어느 정도 시장 활동이 있음을 나타냅니다. 구매자가 대량 구매보다 즉각적인 수요를 우선시하면서 신규 재고 이동이 제한되었습니다. 이번 분기는 주요 다운스트림 산업의 제한된 수요를 탐색하는 동시에 재고 관리 요구 사항의 균형을 맞추는 민감한 상태의 유럽 PAM 시장으로 마무리되었습니다.

ANALYST KOREA

Call +1 (332) 258- 6602 55 Digital-ro 34-gil, Guro-gu, Seoul, KOREA - 08378

Website: https://www.analystkorea.com

Email: [email protected]

0 notes

Text

Polyacrylamide Market's Spectacular Ascent: 6.34% CAGR Anticipated

According to the ChemAnalyst report titled "Global Polyacrylamide (PAM) Market Analysis: Industry Market Size, Plant Capacity, Production, Operating Efficiency, Demand & Supply, End-User Industries, Sales Channel, Regional Demand, Company Share, 2015-2032," the Polyacrylamide (PAM) market is expected to expand and reach 4,200 thousand tonnes by 2032, with a healthy Compound Annual Growth Rate (CAGR) of 6.34% in the forecast period. In the coming years, the increasing awareness of wastewater treatment is anticipated to drive the market for coagulants and flocculants, subsequently boosting the demand for polyacrylamide.

Click Here To Read Full Report:

About Us:

ChemAnalyst is an online platform offering a comprehensive range of market analysis and pricing services, as well as up-to-date news and deals from the chemical and petrochemical industry, globally.

Being awarded ‘The Product Innovator of the Year, 2023’, ChemAnalyst is an indispensable tool for navigating the risks of today's ever-changing chemicals market.

The platform helps companies strategize and formulate their chemical procurement by tracking real time prices of more than 400 chemicals in more than 25 countries.

ChemAnalyst also provides market analysis for more than 1000 chemical commodities covering multifaceted parameters including Production,

Demand, Supply, Plant Operating Rate, Imports, Exports, and much more.

The users will not only be able to analyse historical data but will also get to inspect detailed forecasts for upto 10 years.

With access to local field teams, the company provides high-quality, reliable market analysis data for more than 40 countries.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße

15a Cologne, 50823, Germany

Tel: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com/

0 notes

Text

Reasons for sludge leakage of screw press

screw presss are widely used in different scenarios, some customers may find that sludge leaks from the ring on the screw shaft of the equipment, which greatly affects the working efficiency of the equipment. So, what could be the reason for it leaking mud?

1. The flocculation effect of the sludge is not good before it enters the dehydration main body. The ideal flocculation state can only be achieved after the sludge is in a suitable proportion of polyacrylamide (PAM). It will be filtered out from the gap between the dynamic and static rings. Of course, some sludge is not simply added with PAM. Some sludge has specific properties and needs to be added with PAC, caustic soda and other chemicals.

2. The design of the gap between the ring pieces of the screw press is too large. This is mainly because some manufacturers do not do a good enough leveling of the dynamic and static rings, and the flatness error is above 10 wires. The thickness of the gasket can be increased, and as a result, the gap between the dynamic and static rings becomes too large, and the sludge is filtered out.

1 note

·

View note

Text

Hydrogen Peroxide Prices Trend | Pricing | Database | Index | News | Chart

Hydrogen Peroxide Prices is a versatile chemical compound widely used across various industries and applications, from household cleaning to industrial processes. Its price can vary significantly based on factors such as concentration, volume, and regional market dynamics.

Regional differences also play a crucial role in determining hydrogen peroxide prices. In regions with higher production or supply chain efficiency, prices may be lower due to reduced transportation and logistics costs. Conversely, in areas where hydrogen peroxide needs to be imported or transported over long distances, prices can be higher. Additionally, fluctuations in raw material costs, such as those for the production of hydrogen peroxide or changes in energy prices, can impact overall pricing. For instance, changes in the cost of hydrogen or oxygen, which are key raw materials for producing hydrogen peroxide, can influence the final price.

Market demand and competition also affect hydrogen peroxide pricing. In sectors where hydrogen peroxide is used for specialized applications, such as in the textile industry for bleaching or in the pharmaceutical industry for sterilization, prices can vary based on demand and the specific requirements of the end users. Increased demand in one sector can lead to price increases if the supply does not keep pace. On the other hand, competitive market conditions can drive prices down if multiple suppliers offer similar products.

Economic factors, such as inflation or changes in currency exchange rates, also contribute to fluctuations in hydrogen peroxide prices. When inflation rates rise, the cost of production and transportation generally increases, leading to higher prices for consumers. Similarly, currency exchange rate fluctuations can impact the cost of imported hydrogen peroxide or raw materials, affecting pricing in various markets.

Get Real Time Prices for Polyacrylamide (PAM): https://www.chemanalyst.com/Pricing-data/polyacrylamide-pam-1202

Retailers and suppliers also play a role in determining the final price that consumers pay. Different suppliers may offer varying prices based on their sourcing, distribution costs, and profit margins. Bulk purchasing and long-term contracts can sometimes result in lower prices per unit, as suppliers offer discounts for larger orders or ongoing business relationships. For industrial and commercial buyers, negotiating bulk pricing or long-term supply agreements can be a cost-effective strategy.

Additionally, hydrogen peroxide's price can be influenced by regulatory factors and safety considerations. In regions with stringent safety regulations, the cost of compliance and the necessary safety equipment can impact the overall price of hydrogen peroxide. This is particularly relevant for higher concentrations of hydrogen peroxide, which require careful handling and storage due to their potential hazards.

In summary, hydrogen peroxide prices are subject to a variety of factors, including concentration, volume, regional market conditions, and economic influences. The cost of hydrogen peroxide can vary widely depending on these factors, with lower concentrations generally being more affordable for everyday use and higher concentrations or industrial-grade products commanding higher prices. Regional differences, market demand, competition, and economic conditions also play significant roles in shaping the pricing landscape. Understanding these factors can help consumers and businesses make informed decisions about purchasing hydrogen peroxide and managing associated costs.

Get Real Time Prices for Polyacrylamide (PAM): https://www.chemanalyst.com/Pricing-data/polyacrylamide-pam-1202

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Hydrogen Peroxide#Hydrogen Peroxide Price#Hydrogen Peroxide Prices#Hydrogen Peroxide Pricing#Hydrogen Peroxide News

0 notes