#Polyacrylamide Powder Manufacturer

Explore tagged Tumblr posts

Text

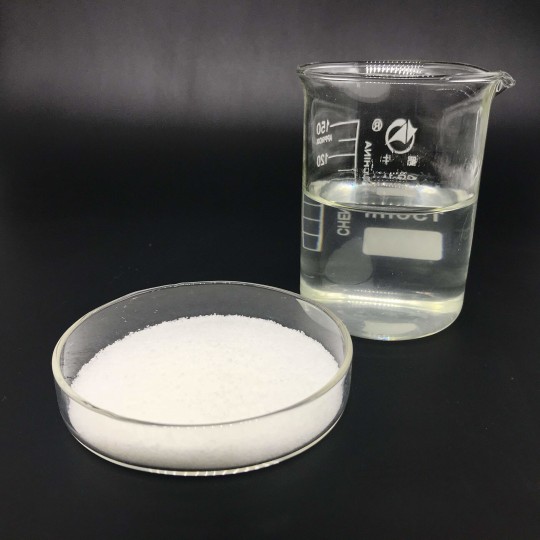

Polyacrylamide | Polyacrylamide Supplier In India - Chem Fert Chemicals

Polyacrylamide Supplier In India - Get Polyacrylamide in India! Chem Fert Chemicals, a leading Polyacrylamide Supplier In India, Polyacrylamide Supplier In India, offers high-quality Polyacrylamide for various applications.

Polyacrylamide Supplier In India, PAM Supplier In India, Polyacrylamide, Polyacrylamide (PAM) Powder Supplier In India, Polyacrylamide Powder Supplier In India, Polyacrylamide Manufacturers & Suppliers in India, Polyacrylamide Latest Price in India, Buy Polyacrylamide Powder Online in India, Polyacrylamide Powder Manufacturer, Supplier, Exporter, Poly Electrolyte Polyacrylamide Supplier In India, Polyacrylamide 9004-05-8 Supplier In India, Anionic Polyacrylamide Supplier In India, Polyacrylamide Manufacturers in India, www.chemfertchemicals.com, www.chemfertchemicals.com/polyacrylamide-supplier-india.php, Chem Fert Chemicals

#Polyacrylamide Supplier In India#PAM Supplier In India#Polyacrylamide#Polyacrylamide (PAM) Powder Supplier In India#Polyacrylamide Powder Supplier In India#Polyacrylamide Manufacturers & Suppliers in India#Polyacrylamide Latest Price in India#Buy Polyacrylamide Powder Online in India#Polyacrylamide Powder Manufacturer#Supplier#Exporter#Poly Electrolyte Polyacrylamide Supplier In India#Polyacrylamide 9004-05-8 Supplier In India#Anionic Polyacrylamide Supplier In India#Polyacrylamide Manufacturers in India#www.chemfertchemicals.com#www.chemfertchemicals.com/polyacrylamide-supplier-india.php#Chem Fert Chemicals

0 notes

Text

Anionic Polyacrylamide Powder

Anionic polyacrylamide powder(APAM) could be used in petroleum,metallurgy, electricity, chemical, coal, papermaking, dyeing, leather, pharmaceutical, food and stone industries. Mainly for separation of solid and liquid, treatment of industrial wastewater and the recycling of wasted water.

- Provide consultant to all kinds of inquiries; - provide serivces of lab test, pilot test and scaled up test; - we could send technican to your site and provide a complete solution; - We could analyze the sample you send and provide the test report. - Professional Anionic Polyacrylamide Powder Manufacturers.

+86-13951412113

0 notes

Text

Sustainable Packaging Solutions in the Polyacrylamide Market

Polyacrylamide: A Versatile Synthetic Polymer Used in Various Industries and Applications What is PAMs?

PAMs is a water-soluble non-ionic polymer made from acrylamide subunits through free-radical polymerization. It comes as a white water-soluble powder and has a chemical formula of (C3H5NO)n. Simply put, PAMs is a long-chain synthetic molecule made up by the polymerization of acrylamide monomers. PAMs is a highly water-absorbent substance and can retain up to 200-600 times its mass in water. Uses of Polyacrylamide in Flocculation

One of the main uses of PAMs is in waste water treatment and mining via a process called flocculation. In flocculation, PAMs polymers are added to suspensions containing small suspended particles like sediments, algae, heavy metals etc. The long molecular chains of PAMs bind to the particles and form larger, easily settleable clumps called flocs. This allows for faster and more efficient solid-liquid separation processes like sedimentation and filtration. PAMs flocculants are commonly used in water treatment plants and mining operations to purify water and recover valuable minerals. Applications in Paper Manufacturing

PAMs finds applications in paper manufacturing processes as well. It is added to pulp and paper mill wastewater streams during treatment to remove suspended fibers and fillers. This improves the drainage rate by coagulating fine particles and increasing the consolidation rate when dewatering paper sludge. PAMs is also used as a binder and strength agent in the wet end of paper making to increase physical properties like tensile strength, burst strength and fold endurance of paper products. Uses in Enhanced Oil Recovery

Due to its ability to increase viscosity, PAMs is used extensively in enhanced oil recovery (EOR) techniques. In EOR processes like polymer flooding, a dilute solution of PAMs is injected into oil reservoirs after conventional methods to increase the mobility of the displacing fluid. The high molecular weight PAMs solutions form a polymer bank that sweeps through the reservoir and tends to drive more oil toward the production well by improving microscopic displacement efficiency. This technique can extract 10-15% additional oil from mature oilfields. Applications in Agriculture

PAMs also has beneficial uses in agriculture. It is used as a soil conditioner to help retain moisture and nutrients in soil. When applied to soil, PAMs absorbs water and prevents runoff, thereby conserving water. It also seals micro cracks in soil to reduce loss of moisture and small fertilizer particles. This leads to better water efficiency and increased crop yields. In hydroponics systems and greenhouse soils, PAMs acts as a water retaining agent that allows for controlled release of water to plant roots. Role in ConstructionDue to its moisture absorbing property, polyacrylamide plays a key role in construction. It is added to concrete mixtures as a superplasticizer or water reducing admixture to improve workability. PAMs allows concrete to be mixed at lower water-cement ratios without compromising on slump or flow properties. This leads to stronger, more durable concrete structures. It is also used to manufacture grouts and floor leveling compounds with self-leveling and self-curing properties. PAMs based compounds fill cracks, level floors and bond building surfaces. Uses as a Thickening Agent

Because of its high molecular weight and hydrophilic nature, PAMs has superb thickening properties. It is widely used as a thickening agent in various industrial and consumer products like paints, coatings, adhesives, cosmetics, pharmaceuticals and foods. PAMs helps increase viscosity without significantly affecting other product properties. It provides stable viscosity even under low shear/high stress conditions. Some common applications as a thickener include its use in low-fat foods, shampoos, lotions, syrups, soups and metalworking fluids. Applications in Biotechnology

Due to biocompatibility, PAMs also finds applications in biotechnology and biochemical engineering processes. It is often used to prepare gels and beads for electrophoresis, isoelectric focusing and chromatography techniques in laboratories. PAMs gels serve as excellent media for separation, isolation and purification of biomolecules like proteins, nucleic acids and enzymes. In medicine, hydrogels made of PAMs are being researched for use in tissue engineering, artificial skin, soft contact lenses and drug delivery. In summary, polyacrylamide is a versatile synthetic polymer with wide applications across industries owing to its water solubility and moisture absorption properties. It acts as an efficient flocculant, thickening agent, soil conditioner, plasticizer, strengthening additive and supports various biochemical separation processes. With continued innovation, new uses of PAMs will likely be discovered, cementing its important role in science, engineering and technology.

0 notes

Text

Dive Deep into Acrylamide: Unveiling Applications, Producing Techniques, and Revolutionary Technologies

Let's chat about a fascinating little compound called Acrylamide. But here's where it gets really interesting: Acrylamide isn't just your average chemical – oh no! It's a monomer, which means it's the building block for all sorts of cool polymers. We're talking about stuff like Polyacrylamide– sounds nice, right?

Now, hold onto your hats because here's the fun part: these polymers are everywhere! From keeping our water squeaky clean in water treatment plants to helping drill for oil and gas, making paper, and even weaving textiles, Acrylamide-based wonders are hard at work in all sorts of industrial and commercial gigs. But wait, there's more! Acrylamide also plays a role in cosmetics, as well as lending a hand in adhesives and grouts.

Introduction

Acrylamide, a versatile building block, acts as a thickener in cosmetics, printing inks, and adhesives. It also helps purify water by attracting impurities and strengthens fabrics. Polyacrylamides, the polymerized form of Acrylamide, take things a step further. In the paper industry, they bind fibers and improve pigment retention. In construction, they add strength to cement and regulate water loss. They also find uses in paints, coatings, and durable applications like car parts and appliances. From thickening lotions to strengthening buildings, Acrylamides and polyacrylamides are key materials across many industries. Beyond its major applications, Acrylamide finds uses in various specialized areas. It acts as a thickener for latex products, stabilizes emulsions in printing inks, and gels explosives for controlled detonation. Acrylamide also serves as a binder in adhesives and tapes and plays a role in the production of diazo compounds used in some dyes. Additionally, scientists utilize Acrylamide in specialized techniques like gel chromatography and electrophoresis for separating molecules in research settings.

Manufacturing Process

Synthetic Process

Acrylamide Production Process: The process typically starts with acrylonitrile, often made by reacting propylene with ammonia and oxygen (ammoxidation). Varieties of copper-based catalysts employed in this process are:

(A) a blend of a copper ion and metallic copper in the guise of copper wire or powder,

(B) reduced copper acquired through the reduction of a copper compound via a reducing agent,

(C) decomposed copper derived from the breakdown of a copper compound through heat, among other means, and

(D) Raney copper obtained by treating a Raney copper alloy with an alkali, among other methods. Reduced copper is yielded through these processes.

Preferably, it is advisable to prevent exposure of these copper-based catalysts to oxygen and oxygen-containing gases both prior to and during their utilization. Oxygen has a detrimental effect on their catalytic efficacy and leads to an increase in by-products such as ethylene cyanohydrin.

Typically, acrylonitrile derived from the ammoxidation of propylene serves as the initial acrylonitrile in the hydration reaction outlined in this invention. This acrylonitrile typically contains impurities like acetone, acrolein, oxazole, acetonitrile, propionitrile, methacrylonitrile, as well as cis- and trans-crotonitriles, with hydroquinone monomethyl ether utilized as a stabilizer.

The catalytic hydration reaction uses acrylonitrile in conjunction with the specified copper-based catalyst. The reaction occurs either in a suspended or fixed catalyst bed within the liquid phase, achieved by passing the reactants through the catalyst bed using either a flowing or batchwise approach. The weight ratio of acrylonitrile to water employed in the hydration reaction is largely flexible. Ideally, the preferred weight ratio of acrylonitrile to water ranges from 60:40 to 5:95, particularly falling within the range of 50:50 to 10:90. The reaction temperature for the hydration process is preferably maintained within the range of 70°C to 150°C, with a preference for temperatures between 90°C to 140°C. Acrylonitrile conversion rates are preferably targeted between 10% to 98%, with a particular emphasis on achieving rates ranging from 30% to 95%.

Typically, the pressure in this process ranges from atmospheric pressure to 10 atmospheres. However, since dissolved oxygen present in the catalyst, acrylonitrile, water, and Acrylamide (used as a co-solvent) can diminish the catalyst's activity and elevate the formation of undesirable by-products, it is preferable to completely eliminate oxygen prior to introducing these materials into the reactor.

The resulting reaction solution extracted from the reactor subsequent to the hydration reaction comprises unreacted acrylonitrile, unreacted water and Acrylamide, alongside trace amounts of copper and by-products like ethylene cyanohydrin.

The reaction solution derived from the aforementioned reaction undergoes a conventional evaporation or distillation process to yield a concentrated aqueous solution of Acrylamide while reclaiming nearly all of the unreacted acrylonitrile and a portion of the water. The reclaimed acrylonitrile and water are typically reused as starting materials, although they may find application in other processes.

In the described process for producing Acrylamide through the hydration of acrylonitrile with a copper-based catalyst, acetone, present as an impurity in the initial acrylonitrile, experiences minor loss during the reaction process. Nonetheless, the majority is recuperated through distillation alongside the unreacted nitrile and subsequently recycled back into the reaction system. With continued operation, however, the concentration of acetone within the reaction system gradually rises.

Biological process

Isolation of Nitrile-utilizing microorganisms

Nitrile-consuming microorganisms are isolated from soil samples using an enrichment culture method, employing a medium containing 0.2% (v/v) nitrile, with or without 0.5% (w/v) glycerol in the basal medium. These microorganisms are capable of utilizing various nitriles including acetonitrile, propionitrile, acrylonitrile, isobutyronitrile, succinonitrile, glutaronitrile, adiponitrile, and triacrylonitrile as their sole source of carbon.

Screening and Assay Method for Acrylamide Producing Strains

The isolated strains are cultured aerobically at 28°C for 3 days on the isolation medium. Subsequently, the cells were centrifuged, washed with physiological saline, and suspended in 0.1 M potassium phosphate buffer at pH 7.0. To screen for Acrylamide-producing strains, the reaction mixture consists of 100 µmol of potassium phosphate buffer at pH 7.0, 300 µmol of acrylonitrile as substrate, and wash cells from 3 ml of culture broth, in a total volume of 1.0 ml. The reaction proceeds at 30°C for 1 hour with moderate shaking and stopped by adding HCl. The amount of Acrylamide formed in the reaction mixture is quantified using a Shimadzu gas-liquid chromatograph, equipped with a flame ionization detector. A glass column, packed with Porapack Q are used. Operational parameters are set as follows: column temperature at 210°C; injection and detector temperature at 240°C. Nitrogen is used as the carrier gas.

Preparation of cell-free extract and enzyme assay

The suspended cells obtained as described above are disrupted for 10 minutes on ice with a Kaijo-denki 19kHz ultrasonic oscillator. After disruption, the cells are centrifuged at 17,000 x g for 20 minutes at 5°C. The resulting supernatant solution is dialyzed overnight against 0.01 M potassium phosphate buffer, pH 7.0, containing 1 mM 2-mercaptoethanol.

Isolation of Acrylamide

The reaction mixture, which contains Acrylamide, undergoes centrifugation to separate the cells. Following centrifugation, the supernatant is lyophilized and subsequently treated with methanol for extraction. After centrifuging to remove insoluble residue, the extract is evaporated under vacuum at room temperature. The resulting crude crystals are dissolved in warm methanol and then filtered. Recrystallization from warm methanol yields colorless crystals.\

Major Acrylamide Processes used by Leading Players.

SNF Flopam India Pvt. Ltd. is a subsidiary of SPCM SA France, the parent company of the SNF Floerger group, renowned for its expertise in producing and processing water-soluble polymers. In the process used by SNF FLOPAM, Acrylamide production involves four reaction vessels. Precise control is essential for both the amounts of ingredients (acrylonitrile, water, catalyst, and several sodium compounds) and the reaction environment (temperature and acidity). Acrylonitrile levels are critical to protect the catalyst. After the initial reaction, two additional tanks ensure all the starting material is converted to Acrylamide, keeping unwanted acrylonitrile below 100 ppm. To maintain the lifespan of both the catalyst and the product, they add specific sodium compounds and adjust acidity with sodium hydroxide solution. Safety measures include using nitrogen to smother any fires and strict temperature control to avoid unwanted clumping (polymerization) of the Acrylamide. Reactors have built-in cooling systems to aid in this precise temperature control.

MCI AAM Process is a process used by Mitsui Chemicals for the production of Acrylamide. This method offers several advantages. It utilizes a highly active biological catalyst, which significantly reduces the amount of raw materials and utilities needed. The reaction itself is very efficient, occurring at room temperature and normal pressure. The biocatalyst excels at converting the starting material (acrylonitrile) into the desired product (Acrylamide) with minimal waste. Following the reaction, a special filtration process effectively removes the biocatalyst from the product mixture. The final result is a 50% Acrylamide solution, conveniently obtained without any further concentration steps. This biocatalytic approach presents a highly efficient and environmentally friendly way to produce Acrylamide.

Applications of Acrylamide

Water Treatment

Acrylamide acts like a tiny magnet in wastewater treatment. It attracts and clumps together suspended dirt and tiny organic materials floating in the water. These clumps, called flocs, become heavy and sink to the bottom, leaving clean water behind. This process is essential for removing impurities from both municipal wastewater (from homes and businesses) and industrial wastewater (from factories).

Enhanced oil recovery:

Acrylamide isn't directly used in oil recovery, but its modified version, partially hydrolyzed polyacrylamide (HPAM), is essential in Enhanced Oil Recovery (EOR). HPAM boosts water viscosity, slowing its movement and enabling better oil pocket penetration in reservoirs. This enhances the efficiency of oil recovery.

Paper-making

Acrylamide is used to make Polyacrylamide which is used as a binder and retention aid in papermaking. It helps to bind the paper fibers together and to retain fillers and pigments in the paper.

Flocculating agent

Polyacrylamide, derived from Acrylamide, has the ability to absorb water and cause particles to clump together makes it useful in a variety of thickening and flocculation applications, such as sewage treatment, soil conditioning, and ore processing.

Market Outlook:

The Acrylamide market is driven by its crucial role in water and wastewater treatment across various industries. Since Acrylamide acts as a flocculant, efficiently removing impurities and particles from water, it's essential for municipal, industrial, and commercial sectors. This dominance is further amplified by the growing footprint of oil and gas, chemical, pharmaceutical, and food & beverage industries, all of which rely heavily on clean water processes. Secondly, Acrylamide's role as a building block, particularly for polyacrylamide in wastewater treatment, fuels market demand. Furthermore, the rising use of Acrylamide monomers in diverse sectors like gel electrophoresis, ore processing, and even dye and plastic synthesis strengthens the market.

Acrylamide Major Manufacturers

Significant companies in the Global Acrylamide market are Ashland Global Holding Inc., SNF, Kemira OYJ, BASF SE, EMCO Dyestuff, Mitsui Chemicals Global, Pvt. Ltd., Ineos AG, Solvay, Nuoer Group, Black Rose Industries Ltd., and Others.

Conclusion:

Acrylamide and its polymerized form, polyacrylamide, prove themselves to be surprisingly versatile across a wide range of industries. From thickening our favorite cosmetics to aiding in oil drilling efficiency, these chemicals play a behind-the-scenes role in many aspects of our daily lives. Acrylamide acts as a thickening and stabilizing agent in everything from shampoos and lotions to printing inks and adhesives. Meanwhile, polyacrylamides find use in water treatment, paper production, and construction materials, enhancing everything from wastewater treatment to textile goods.

0 notes

Text

Key Regulatory Frameworks Shaping the Polyacrylamide Market Landscape

Polyacrylamide: An Overview of its Wide Industrial Applications What is Polyacrylamide? Polyacrylamide is a polymer comprised of acrylamide monomer units. It exists as a white powder that is soluble in water. Its chemical formula is (C3H5NO)n, where "n" refers to the large number of repeat units that give the polymer its unique properties. Synthesis and Properties Polyacrylamide is produced through the polymerization of acrylamide monomers. This process involves subjecting acrylamide to free-radical polymerization, where acrylamide molecules join together in long chains through carbon-carbon bonds between their vinyl groups. The resulting polyacrylamide molecule is a non-ionic water-soluble polymer with high molecular weight. It has good film-forming capabilities and is capable of absorbing up to 200 times its dry weight in water. Usage in Enhanced Oil Recovery One major use of polyacrylamide is in enhanced oil recovery processes carried out by oil drilling companies. Polyacrylamide polymers are injected into oil reservoirs to increase the viscosity of injected water or gas. This helps to displace more oil from the reservoir pores and cracks. By modifying the properties of injection fluids, polyacrylamide improves the volume of oil that can be recovered from a reservoir using techniques like waterflooding. It is estimated that the use of polyacrylamides for enhanced oil recovery could potentially increase total recoverable reserves by 15-20%. Applications in Paper Manufacturing Polyacrylamide finds widespread application in the papermaking industry. It is used as an additive during the papermaking process to improve the strength, formation and brightness qualities of produced paper. Its adhesion tendencies help bind wood fibers together better. As a result, less virgin pulp is required to make paper of the same strength. This allows paper producers to reduce costs and improve productivity. Usage in Wastewater Treatment Wastewater treatment plants heavily depend on polyacrylamide to clarify and dewater sewage sludge. As sludge dewaters, polyacrylamide causes small particles to stick together, improving the filtration process. This helps treatment facilities meet discharge standards while reducing operating costs. Its flocculation properties lead to smaller, more efficient treatment lagoons. The polymer is also employed for sludge thickening and conditioning. Applications in Mining Within mining operations, polyacrylamide finds various applications centered around separation processes. It is used for dewatering mineral slurries in operations like gold mining through flocculation. This separates recoverable solids from liquids to improve downstream processing. Polyacrylamide is also valuable in conditioning clays to render them amenable to separation from mined ores using magnetic or flotation techniques. Functions in Construction The water-absorption ability of polyacrylamide makes it suitable as an additive in concrete, cement and gypsum-based building materials. It increases workability and prevents water separation within the mixture. This leads to stronger finished products with fewer cracks or alignment issues. Polyacrylamide is commonly added to soil to stabilize foundations and reduce water permeability prior to construction work. Concluding Thoughts With widespread commercial production since the 1950s, polyacrylamide has emerged as an important industrial polymer with applications across multiple sectors. Its water management and filtration related properties have generated substantial socio-economic benefits. While oil drilling, wastewater treatment and paper manufacturing dominate demand, new functions are continually being discovered. Polyacrylamide exemplifies how engineering polymeric materials can create value and efficiencies throughout supply chains. Its diverse industrial roles highlight the transformative impact that innovative chemicals can have.

0 notes

Text

A Comprehensive Guide to Chlorine Tablets, PAM Powder, and Filter Balls for Pools

Ensuring your pool stays crystal clear and hygienic involves the strategic use of various pool maintenance products. In this guide, we will delve into the practicalities and benefits of employing chlorine tablets, PAM powder, and filter balls in your pool maintenance routine, addressing common user queries and providing insights into the effective utilization of these products.

Chlorine Tablets: Chlorine tablets are a fundamental component of pool water treatment. Users often wonder about the optimal way to use these tablets. Here are some key points:

Proper Placement: To maximize efficiency, place chlorine tablets in a dedicated dispenser near the water return outlet rather than directly into the pool. This ensures even distribution throughout the pool.

Dosage Considerations: The quantity of tablets depends on factors such as pool size and current chlorine levels. It is crucial to follow the manufacturer's guidelines for accurate dosage.

Dissolution Time: Allowing sufficient time for the tablets to dissolve is essential. Factors like tablet composition and water temperature influence dissolution rates. Refer to the manufacturer's instructions for specific recommendations.

PAM Powder: Polyacrylamide (PAM) powder is known for its flocculant properties, aiding in the removal of suspended particles. Users often have questions about its application. Here's a guide:

pH Testing: Before applying PAM powder, check the pool's pH levels. PAM is most effective in a slightly alkaline environment, with a pH range between 7.5 and 8.5.

Dosage Precision: Adhering to recommended concentrations is crucial. Typically, a concentration of 5-10mg/L is advised. This ensures optimal performance without overuse.

Mixing and Settling: After applying PAM powder, thorough mixing is necessary for even distribution. Allowing the pool water to settle for at least six hours enhances the coagulation process.

Filter Balls for Pools: Filter balls are a modern alternative to traditional filter media like sand. Users often seek guidance on their usage. Here's what you need to know:

Installation: Replace sand with filter balls in your pool filter system. Follow the manufacturer's instructions for proper installation.

Filtration Efficiency: Filter balls provide excellent filtration and require less backwashing. Regularly check and clean the balls for optimal performance.

Maintenance Tips: Keep track of the condition of filter balls and replace them when needed. Rinse the balls periodically to remove accumulated debris.

Conclusion: By understanding the nuances of using chlorine tablets, PAM powder, and filter balls, pool owners can streamline their maintenance routines. Remember to follow recommended dosages, placement strategies, and maintenance practices to keep your pool water pristine and inviting. Regularly consulting manufacturer guidelines and staying informed about best practices ensures a safe, healthy, and enjoyable swimming environment.

0 notes

Text

How is coolant powder made & what are its ingredients?

Coolant powder is a common form of coolant that is widely used in various fields. This article will introduce the manufacturing process and main ingredients of coolant powder, and explore its applications in different fields.

Coolant powder is a granular form of coolant that has good heat dissipation properties. It is usually made from specific compounds or mixtures to meet the needs of different application areas.

Manufacturing process

The manufacturing process of coolant powder usually includes the following steps:

Raw material preparation: Select the corresponding raw materials according to the required coolant formula. These raw materials can be a single compound or a mixture of multiple compounds.

Mixing and grinding: Ingredients are mixed in specific proportions and ground to ensure uniformity and fineness of particles. The grinding method can be mechanical grinding or other appropriate processing methods.

Processing and granulation: The mixed and ground materials are processed to form the desired granular structure. This can be achieved by extrusion, spray drying, Cooling Agent crystallization or other corresponding granulation methods.

Drying and screening: The formed granules are dried to remove moisture and the size and distribution of the granules are controlled through a screening process.

Packaging and quality control: The coolant powder after drying and screening is packaged and subjected to necessary quality inspection and control to ensure that the product meets standards and specifications.

Main ingredients

The composition of coolant powder can vary depending on the application. Here are the main ingredients of some common coolant powders:

Organic compounds: such as amino acids, glucose, urea, etc. These organic compounds absorb large amounts of heat as they dissolve, thus acting as a Cooling Agent agent.

Inorganic salts: such as sodium chloride, calcium nitrate, boric acid, etc. These inorganic salts also release heat when dissolved, achieving a Cooling Agent effect.

High molecular polymers: such as polyacrylamide, sodium polyacrylate, etc. These high molecular polymers have high water absorption and moisture retention properties and can be used to make aqueous coolant powders.

Application areas

Coolant powder has a wide range of applications in various fields. Here are some of the main application areas:

Electronic equipment: Coolant powder can be used to dissipate heat from electronic equipment, helping to reduce device temperature and improve equipment performance and life.

Automotive industry: Coolant powder can be used in automobile engine Cooling Agent systems to maintain normal engine operating temperature and prevent overheating.

Industrial refrigeration: Coolant powder can be used to control the Cooling Agent of equipment and materials during industrial production to ensure the smooth progress of the process.

Cosmetics: Coolant powders can be added to cosmetics to provide a soothing feel and help regulate skin temperature.

Medical field: Coolant powder can be used for local anesthesia and skin Cooling Agent in some medical procedures to reduce pain and discomfort.

Coolant powder is a common form of coolant and its manufacturing process involves steps such as raw material selection, mixing, grinding, processing and drying. The main ingredients include organic compounds, inorganic salts and high molecular polymers. Coolant powders play an important role in various fields such as electronic equipment, automotive industry, industrial refrigeration, cosmetics and medical fields. Understanding its manufacture and composition helps to better understand and apply the performance and functionality of coolant powders.

Welcome to contact us to learn more about coolants!

0 notes

Text

Super Absorbent Polymers Market Expansion: An Overview of Key Trends and Opportunities | BASF SE, Nippon Shokubai Co. Ltd., Evonik Industries AG, LG Chem Ltd., Sumitomo Seika Chemicals Co. Ltd., SDP Global Co. Ltd.

Global “Super Absorbent Polymer Market” Research report is an in-depth study of the market Analysis. Along with the most recent patterns and figures that uncovers a wide examination of the market offer. This report provides exhaustive coverage on geographical segmentation, latest demand scope, growth rate analysis with industry revenue and CAGR status. While emphasizing the key driving and restraining forces for this market, the report also offers a complete study of the future trends and developments of the market.

This report on the Super Absorbent Polymer Market study considers important factors such as an analysis of the market, a definition of the market, segmentation, significant trends in the industry, an examination of the competitive landscape, and research methodology. The research provides an idea about various market inhibitors as well as market motivators in both a quantitative and qualitative approach with the purpose of providing users with accurate information.

Get a Sample PDF of the report @ https://www.themarketinsights.com/request-sample/289433

What is New Additions in 2023?

Detailed industry outlook

Additional information on company players

Customized report and analyst support on request

Recent market developments and it’s futuristic growth opportunities

Customized regional/country reports as per request

The list of Key Players Profiled in the study includes:- BASF SE, Nippon Shokubai Co., Ltd., Evonik Industries AG,LG Chem Ltd., Sumitomo Seika Chemicals Co., Ltd., SDP Global Co., Ltd., Songwon Industrial Co., Ltd., KAO Corporation, Formosa Plastics Corporation, Yixing Danson Technology

Cataloging the Competitive Terrain of the Super Absorbent Polymer Market:

The report provides an overview of every manufacturers and the products developed by each manufacturer along with the application scope of every product.

Data regarding the market share of every company, as well as sales figures concerning each firm, is stated in the report.

Details regarding the profit margins and price patterns have been inculcated in the report.

IN THE NEWS

➤ Increasing Demand from Agriculture Industry

➤Focus on Sustainability

➤Rising Applications in the Healthcare Sector

➤Advancements in Technology

➤Growing Investments

Super Absorbent Polymer Market Dynamics:

This section deals with understanding the market drivers, advantages, opportunities, restraints and challenges. All of this is discussed in detail as below:

Growth Drivers:

Increasing Demand from Hygiene Industry

Agriculture Industry

Rising Demand for Environmentally Friendly Products

Advancements in Manufacturing Technology

Increasing Applications in Healthcare

Growing Investments in Research and Development

Get a Discount on Research Report @ https://www.themarketinsights.com/check-discount/289433

Segmentation Analysis of the Market:

Global Super Absorbent Polymer Market forecast report provides a holistic evaluation of the market. The report offers a comprehensive analysis of key segments, trends, drivers, restraints, competitive landscape, and factors that are playing a substantial role in the market. Global Super Absorbent Polymer Market segments and Market Data Break Down are illuminated.

Application: The market can be segmented based on the application of super absorbent polymers, such as hygiene products, agriculture, medical, and industrial applications.

Type: Super absorbent polymers can be segmented based on their type, such as sodium polyacrylate, polyacrylamide copolymer, and others.

Form: Super absorbent polymers can be in different forms, including powders, granules, and gels.

End-User: The market can be segmented based on end-user, including diaper manufacturers, feminine hygiene product manufacturers, adult incontinence product manufacturers, and others.

Source: Super absorbent polymers can be derived from natural or synthetic sources, and this can be another segmentation factor.

About us Delivering foresights along with statistical analysis of the operational business industry impacts has been our foremost priority. With the constant developments in the research & development industry, we have always challenged the conventional research methodologies and discovered new research tactics to evolve the growing B2B requirements.

Direct Contact Jessica Joyal +1(213)338-8279 | +1(877)3769989 Email– [email protected] Website – https://www.themarketinsights.com/

0 notes

Text

Polyacrylamide Market Size 2020, Statistics, Trends, Regional Analysis by Key Players

Polyacrylamide Market Size 2020, Statistics, Trends, Regional Analysis by Key Players

Increasing Use in Water and Wastewater Treatment and Pulp & Paper Manufacturing Industry Contributes to Polyacrylamide Market According to our latest market study, titled “Polyacrylamide Market Forecast to 2028 – COVID-19 Impact and Regional Analysis – by Type (Anionic, Cationic, Non-Ionic), by Form (Powdered, Liquid) and End Use (Water and Wastewater Treatment; Industrial Wastewater; Pulp and…

View On WordPress

0 notes

Text

What Is The Purpose Of The Binder Within Tablets?

Binders are substances that bind tablets of powder. Fillers do not have to be good binders because of their low binding power. Tablet Binders are added to a dry mix prior to granulating. They can be used to form the matrix. These ingredients act as a glue, binding the powders together. Binders are classified as solid or wet, according to whether they are water soluble or insoluble.

Starch

In tablet production, starch is usually an important ingredient. Apart from providing the space between the tablet and the drug surface, starch can be an extremely powerful tablet coloring. Starch's flexibility makes it an ideal binder for pharmaceuticals. However, it does have some drawbacks. Granular starch is water insoluble and, requires heating to activate its polymer. This could cause several problems.

The composition of tablet-binding starsches depends on their properties. Compressible starch powder is usually comprised of between 15 and 85% of dry granulated starch, and a significant amount of wet binder that granulates. The resultant powder contains modified granules that are better compacted and disrupted than normal. It's a great binder, particularly when compressed. We will discuss a variety of starches that can be used for capsule and tablet manufacturing.

Medicinal tablet formulations usually contain an emulsifier made of starch. Starch is employed in the pharmaceutical industry as a disintegrant and to act as a diluent. Tablet production is largely by using fresh starch paste in amounts of 5 to 15 percent. Starch is also used in other innovative applications that include periodontal and nasal system for drug delivery. These may require changes to existing starches or the creation and development of new sources.

Povidone

An artificial polymer, the povidone is a nonionic water soluble binder used in tablet formulations. Povidone is found in various concentrations in tablet formulations. It is commonly used as an adhesive in tablets in 0.5 percent to 5.5% weight-to-weight. The solubility of povidone in water varies from 1 to 2 percent, and different concentrations give various molecular weights.

Researchers looked into the kinetics and release rates of raloxifene within tablets that contained various binding agents. Researchers found that raloxifene released more quickly from tablets that had different levels of povidone (including lactose and PEG-PVA). The highest povidone concentration K30 LP was 30ppm, whereas PEG-PVA binders contained 17 peroxides per milliliter.

The choice of binders is essential when it comes to ensuring the stability of pharmaceutical dosage forms. Innovative packaging and the use of antioxidants can alleviate this problem. PEG-PVA is completely free of residual peroxides that can cause oxidative decay. When you choose a tablet binder make sure to consider the stability of the medication is crucial.

Okra fruit mucilage

There are many applications for Okra fruit mucilage within the pharmaceutical industry. Apart from being an affordable raw material it is an excellent technological resource for manufacturers of food and beverages. The mucilage, also known as gel-forming material, can be used as an tablet coloring and is an excellent alternative for oral delivery. Further, okra mucilage may also be used in the production of a wide range of other products.

Polyacrylamides, for example, can be made into pharmaceutical-grade products. But, polysaccharides are not biodegradable. They are usually added to polysaccharides to boost their biodegradability. One example of such a polymer is Okra fruit muclage. And when combined with polyacrylamide it may improve tablet-binding properties, as shown by the results of a recent study.

Natural polymers

Aqueous solutions can be altered by using synthetic as well as natural polymers. They generally comprise repeating units or blocks, as well as hydrophilic groups which can be anionic, cationic or nonionic. Synthetic polymers can enhance tablet hardness, however they also reduce dissolution efficiency. They also cost a lot and may have a negative impact on stability of the product.

Numerous benefits are attributed to polymers made from plants. They can act as a binder in tablets, as a diluent or a superdisintegrant. They are biodegradable, safe and easy to utilize, making the perfect pharmaceutical material. They can also improve the bioavailability and absorption capacity of added drugs. These advantages have caused the pharmaceutical industry to employ more natural polymers in its formulations.

Natural binders are found in plant fibers. Cellulose, an insoluble natural polymer, is one of the most frequently used pill binding agents. Gelatin is a cow product, is a high bacterial count and is not suggested to use. Natural polymers are a more secure, more cost-effective alternative. So, what are the benefits from using natural polymers for tablet binder?

0 notes

Text

What's The Function Of The Binder Within Tablets?

Binder is the material which holds together the powders within tablets. Fillers do not have to be good binders due of their low binding power. Tablet binding agents are added to dry mixes before granulating. They can be used to form the matrix. They function as glue by binding powders. Binders are classified as either solid or wet, depending on whether they are water soluble or insoluble.

Starch

In tablet manufacturing, starch is often a key ingredient. Starch is a crucial ingredient in tablet production. It can fill the gap between drug and tablet surface. Starch's versatility makes it an excellent binder for pharmaceuticals. However, it's not without disadvantages. Granular starch is water insoluble and requires a heating process to activate its polymer, which causes several problems.

The composition of tablet-binding starsches depends on the properties they possess. Compressible starch is generally comprised of between 15 and 85% of dry granulated starch as well as a substantial amount of wet binder for granulation. The result is altered granules which are more compacted and dispersed than regular. It is a good binder, particularly when compressed. We will be discussing several starches that could be used to make tablets and capsules.

The majority of medicinal tablet formulations contain the starch-based binder. Starch is used in the pharmaceutical industry to disintegrate and as an diluent. Tablet manufacturing is done largely with fresh starch paste at concentrations of 5 to 15%. Starch is also used in other innovative applications that include nasal and periodontal system for drug delivery. These applications may require modifications to existing starches, or the creation and development of novel sources.

Povidone

Povidone is a synthetic polymer. is a water-soluble, nonionic binder, which is employed in tablet formulations. Povidone is used in varying concentrations in tablet formulations, and is commonly used in tablets as binders with 0.5% to 5% w/w strength. The solubility of povidone within water is ranging from 1 to 2 percent, and different concentrations provide different molecular weights.

In the course of their research, scientists examined the kinetics of a model substance called raloxifene inside a tablet that contained different binding agents. They discovered that raloxifene released more quickly from tablets with various levels of povidone such as PEG-PVA and lactose. PEG-PVA bindings had 17ppm peroxides. K30 LP contained a maximum concentration of 30 ppm.

When it comes to the stability of dosage forms for pharmaceuticals it is essential to select the appropriate binders. Smart packaging and the use of antioxidants can help alleviate this issue. PEG-PVA is free of residual peroxides which reduces raloxifene oxidative decay. When selecting a binder for tablets, remember that the stability of the medication is of utmost importance.

Okra fruit mucilage

Okra fruit mucilage can be used for a variety of potential uses for the pharmaceutical industry. In addition to being an affordable raw material it is an excellent technological resource for beverage and food manufacturers. Mucilage, a gel-forming substance, can also be used to create Tablet Binder and is the ideal choice to deliver oral medication. Okra mucilage is also utilized to create a range of other items.

Polyacrylamides, for instance, can be used in the production of pharmaceutical grade products. Polysaccharides are, however, not biodegradable. They are often combined with polysaccharides to increase their biodegradability. One example of such a polymer is Okra fruit mucilage. A recent study has revealed that it has the ability to improve tablet-binding properties when mixed with polyacrylamide.

Natural polymers

Synthetic and natural polymers may be used to bond and modify the physical properties of aqueous solutions. They typically comprise repeating units, blocks and hydrophilic group that can be anionic, nonionic, or the cationic. However, synthetic polymers tend to increase the hardness of tablets and reduce dissolution efficiency. They also cost a lot and may have a negative effect on the stability of the tablet.

Polymers derived from plants have many benefits. They are able to act as an adhesive to tablets, a diluent, or a superdisintegrant. They are biodegradable and safe and therefore suitable for use in pharmaceutical applications. These compounds also improve the bioavailability and absorption of added drugs. This has led to the pharmaceutical industry use natural polymers in their formulations.

Plant fibres are an excellent example of natural binders. Cellulose is an insoluble natural polymer is the most frequently used tablet binders. However, gelatin, which is a product of the cow has high bacterial counts and is not thought of as a healthy option. Natural polymers are a more secure, more cost-effective alternative. What are the advantages of using natural polymers as tablet binding agents?

0 notes

Text

Chem Fert Chemicals: Your Leading Polyacrylamide (PAM) Supplier in India

Polyacrylamide Supplier In India – Chem Fert Chemicals offers high-quality Polyacrylamide (PAM) powder for various industries in India. Explore anionic, cationic & non-ionic PAM for water treatment, oil & gas, and more. Contact us today! Polyacrylamide Supplier In India.

Polyacrylamide Supplier In India – Polyacrylamide (PAM), also known as Polyacrylamide Powder, is a versatile water-soluble polymer with applications across numerous industries.

Polyacrylamide Supplier In India, PAM Supplier In India, Polyacrylamide, Polyacrylamide (PAM) Powder Supplier In India, Polyacrylamide Powder Supplier In India, Polyacrylamide Manufacturers & Suppliers in India, Polyacrylamide Latest Price in India, Buy Polyacrylamide Powder Online in India, Polyacrylamide Powder Manufacturer, Supplier, Exporter, Poly Electrolyte Polyacrylamide Supplier In India, Polyacrylamide 9004-05-8 Supplier In India, Anionic Polyacrylamide Supplier In India, Polyacrylamide Manufacturers in India, www.chemfertchemicals.com, www.chemfertchemicals.com/polyacrylamide-supplier-india.php, Chem Fert Chemicals

#Polyacrylamide Supplier In India#PAM Supplier In India#Polyacrylamide#Polyacrylamide (PAM) Powder Supplier In India#Polyacrylamide Powder Supplier In India#Polyacrylamide Manufacturers & Suppliers in India#Polyacrylamide Latest Price in India#Buy Polyacrylamide Powder Online in India#Polyacrylamide Powder Manufacturer#Supplier#Exporter#Poly Electrolyte Polyacrylamide Supplier In India#Polyacrylamide 9004-05-8 Supplier In India#Anionic Polyacrylamide Supplier In India#Polyacrylamide Manufacturers in India#www.chemfertchemicals.com#www.chemfertchemicals.com/polyacrylamide-supplier-india.php#Chem Fert Chemicals

0 notes

Text

What's The Point Of The Tablet Binder?

Binder is the material that holds powders together in a tablet. It's not required for fillers to be excellent binding agents, as their own binding capacity is not as effective. To create a matrix, tablet binding ingredients are able to be added to dry mixtures before they are made into granules. These ingredients act like a glue by binding the powders together. The water-soluble and insoluble characteristics of binders determine if they can be classified as either liquid or solid.

Starch

In tablet manufacturing, starch is typically an important ingredient. Starch is an essential ingredient in tablet manufacturing. It can fill the gap between the drug and tablet surfaces. Starch's versatility makes it an excellent binder for pharmaceuticals. But, it's not without its drawbacks. Granular starch, which is water insoluble, requires heating to activate the polymer. This can cause several problems.

The composition of tablet-binding starches depends on the properties they possess. The composition of the compressible starch powder typically consists of between 15 and 85percent dry granulated steah and a small amount of wet-granulation binder. The resulting powder has altered granules that are more compacted and dispersed than regular. It's a great binder, especially when compressed. This article will explore a variety of ways starches can be used to make capsules and tablets.

The majority of medicinal tablet formulations contain an emulsifier made of starch. Apart from being an ingredient in tablets that binderizes them as well, it is also utilized as a diluent and disintegrant within the pharmaceutical sector. Tablet production is largely by using fresh starch paste in amounts of 5 to 15 percent. Nasal and periodontal drug delivery systems are also innovative applications of starch. But, these types of applications usually require modification of existing starches, or the discovery of novel sources.

Povidone

A synthetic polymer, the povidone is a nonionic water-soluble binder utilized in tablet formulations. Povidone is utilized in various concentrations in tablet formulations, and is commonly found in tablets as a binder in 0.5 percent to 5 w/w strength. The water solubility ranges from 1 to 2%, with different concentrations offering different molecular weights.

Researchers examined the release and kinetics of raloxifene inside a tablet containing various binding agents. They discovered that raloxifene is released faster from tablets with different levels of povidone such as PEG-PVA and lactose. The highest povidone concentration K30 LP was at 30 ppm, whereas PEG-PVA binders contained 17 ppm of peroxides.

When it comes to the stability of the dosage forms of pharmaceuticals it is essential that you choose the right binders. Smart packaging and the use of antioxidants can help alleviate this problem. PEG-PVA is free of residual peroxides, which can reduce raloxifene oxidative decay. When selecting a binder for tablets make sure to consider the stability of the drug is crucial.

Okra fruit mucilage

Okra fruit mucilage is a great source of applications in the pharmaceutical industry. Okra fruit mucilage is an ideal source of technological innovation for the food and beverage industry. Its mucilage or gel-forming material, can be used as a colored Pill Binder and can be a great alternative for oral delivery. Additionally, okra mucilage can also be used to make a wide range of other products.

Polyacrylamides, for example can be converted into pharmaceutical grade products. However, they aren't biodegradable. They are often mixed with polysaccharides in order to improve their biodegradability. Okra Mucilage from fruits is one such polymer. A recent study has shown that it has the ability to improve tablet-binding properties when it is combined with polyacrylamide.

Natural polymers

Aqueous solutions can be modified by using both synthetic and natural polymers. They often include repeating units, blocks and hydrophilic group that can be nonionic, anionic, or the cationic. Synthetic polymers can enhance tablet hardness, but they can also affect dissolution performance. They are also expensive and may have a negative impact on stability of the product.

Polymers that are derived from plants provide many advantages. They are able to act as an adhesive for tablets, as a diluent and superdisintegrant. Natural materials are biodegradable, safe and easy to use, which makes the perfect pharmaceutical material. They also enhance the bioavailability and absorption of incorporated drugs. These advantages have made pharmaceutical companies to use natural polymers in their formulations.

Plant fibres are a great example of natural binding agents. Cellulose is an insoluble natural polymer, is the most frequently used pill binding agents. Gelatin, however, a product from the cow, has high bacterial counts, and is not considered an option that is healthy. Natural polymers are a safer, more cost-effective alternative. So, what are the benefits of using natural polymers as tablet binder?

0 notes

Text

What Is The Function Of A Binder In Tablets?

A binder is the substance which holds together the powders within tablets. Fillers don't have to be good binders because of their low binding power. To create a matrix, tablet binding ingredients can be added to dry mix before being processed into granules. They act as a glue, gluing the powders. The water-soluble and insoluble characteristics of binders determine if they can be classified as either liquid or solid.

Starch

In tablet manufacturing, starch is typically an important ingredient. Starch is a key ingredient in tablet manufacturing. It is able to fill the gap between drug and tablet surfaces. Starch's versatility makes it an excellent binder for pharmaceuticals. However, it does have some drawbacks. Granular starch is water insoluble and requires heating to activate its polymer which leads to a number of issues.

The composition of tablet-binding starches is based on their properties. The composition of compressible starch powder is typically composed of between 15 and 85percent dry granulated the steah as well as a small amount of wet-granulation binder. The result is altered granules which are more compacted and dispersed than normal. It's a great binder, especially when compressed. We will be discussing several starches that could be used to make tablets and capsules.

The binder made of starch is commonly utilized in the manufacturing of tablets with medicinal properties. Starch is utilized in the pharmaceutical industry to disintegrate and as a diluting agent. Fresh starch paste in a concentration of 5-15% is extensively used in tablet production. Nasal and periodontal delivery system are other novel uses of starch. However, these applications often require modifications of existing starches or the discovery of new sources.

Povidone

Povidone is a synthetic polymer. It is a water-solubleand nonionic binder, which is utilized in tablet formulations. Povidone can be present in various amounts in tablet formulations. It is most commonly employed as an adhesive in tablets ranging from 0.5% to 5.5% w/w strength. The solubility of povidone within water is ranging between 1 and 2 percent, and different concentrations offer different molecular weights.

Researchers looked into the kinetics and release rates of raloxifene within a tablet containing various binders. They found that raloxifene was released more rapidly from tablets with different levels of povidone such as PEG-PVA and lactose. The highest amount of povidone K30 LP was 30 ppm and PEG-PVA binding agents contained 17 ppm of peroxides.

In the case of stability of the dosage forms of pharmaceuticals it is essential that you choose the right binding agents. Smart packaging and the use of antioxidants can alleviate this issue. PEG-PVA is free from residual peroxides that can cause oxidative decay. When choosing a tablet binder be aware that the stability of the drug is crucial.

Okra fruit mucilage

There are numerous uses for Okra mucilage from the fruit in the pharmaceutical industry. It is not only an affordable raw material it's a great technological resource for manufacturers of food and beverages. The mucilage, an ingredient that forms gels, can be utilized to create colored Pill Binder and is an ideal option to deliver oral medication. Furthermore, okra mucilage could also be used to produce many other products.

Polyacrylamides for instance, can be made into pharmaceutical-grade products. However, they aren't biodegradable. In order to improve their biodegradability, they can be combined with polysaccharides. One example of such a polymer is Okra fruit Mucilage. When combined with polyacrylamide, it can enhance the properties of tablet binding as evidenced by the results of a recent study.

Natural polymers

Synthetic and natural polymers may be used to bond and modify the physical properties of solutions in aqueous. They usually comprise repeating units or blocks as well as hydrophilic groupings that could be anionic, cationic, or nonionic. Synthetic polymers are known to increase the hardness of tablets and decrease dissolution performance. Additionally, they cost a lot and can have a negative impact on the stability of the product.

Polymers derived from plants have numerous advantages. They can serve as a binder within tablets, a diluent or a superdisintegrant. They are biodegradable and safe which makes them ideal for use in pharmaceutical applications. They can also improve the absorption and bioavailability of added drugs. These advantages have made pharmaceutical companies to use natural polymers to make their formulas.

Natural binders can be found in plant fibres. Cellulose, an insoluble natural polymer, is the most frequently used tablet binding agents. However, gelatin, a product from the cow, has high levels of bacterial count, and is not considered to be a safe option. Natural polymers are safer and more economical as compared to other alternatives. What are the benefits of using natural polymers as tablet binding agents?

0 notes

Text

Polyacrylamide Market Global Industry Insights, Trends, Outlook, and Opportunity Analysis, 2018-2026

Polyacrylamide is made up of acrylamide monomer and is water-soluble. It increases the viscosity of water and facilitates the flocculation of particles present in water.Polyacrylamide is used for water treatment and sludge dewatering of municipal wastewater, industrial wastewater, potable water treatment, air flotation, and primary settling. The wide use of polyacrylamide in wastewater treatment has fueled growth of polyacrylamide market globally. Polyacrylamide supports are usually gelatinous in appearance and soft in nature. They also exhibit low nonspecific binding character toward biomolecules, buffer stability, and good pH, owing to totally synthetic nature, are resistant to microbial growth.In mineral processing, polyacrylamide is used for settlement/clarification of fine coal slurry in the thickening vessels, enhancement of solid-liquid separation coal with the help of filtration/centrifugation, settlement/clarification of the waste slurry and enhancement of solid-liquid separation of the tailings. In the paper and pulp industry, polyacrylamide is used as retention agent, dry strength agents and for filter aid. This has resulted in improved paper quality, enhanced physical strength of paper and reduced fiber loss. Drilling fluid additives, waste mud dewatering, enhanced oil recovery, oily water clarification, scale inhibition and as a drag reduced agent

Polyacrylamide Market Taxonomy

On the basis of type of material, the global market is classified into:

Anionic

Cationic

Non-ionic

On the basis of end-use industry, the global market is segmented into:

Mineral Processing

Wastewater treatment

Pulp and Paper

Oil recovery

Market Outlook –

Excellent flocculating and coagulating properties has rapidly increased consumption of polyacrylamide in wastewater treatment. Asia Pacific is expected to be the most potential market for polyacrylamide manufacturers. This is attributed to booming mining industry in emerging economies such as India and China. According to IBEF, in 2015, India produced 91.46 million tons (MT) of finished steel and is the third-largest steel producer in the world. Rapidly increasing urbanization and allied sectors have caused a surge in mining activities and boosted the growth of polyacrylamide market. India Brand Equity Foundation (IBEF) is a Trust founded by the Ministry of Commerce and Industry, Department of Commerce in collaboration with the Government of India with the aim of promoting and creating international awareness of goods manufactured in India.

Request Copy Of This Business Report: https://www.coherentmarketinsights.com/market-insight/polyacrylamide-market-305

Top Keyplayers : Shandong Shuiheng Chemical Co., Ltd., The Dow Chemical Company, Kemira, Ashland Inc., BASF SE, Beijing Heng- Chemical Group Co., Ltd., Shandong Zibo East Polymer Co., Ltd., Group, and Xitao Polymer Co., Ltd.

Key Developments

Key companies in the market are focused on adopting various growth strategies such as capacity expansion, in order to gain competitive edge in the market. For instance, in April 2019, BASF SE, the German chemicals company, expanded its commercial production of polyacrylamide powder at its site in Nanjing, China. This expansion would add 20,000 metric ton per year to capacity of polyacrylamide.

Major market players are focused on various business strategies such as capacity expansion, in order to enhance their product portfolio. For instance, in August 2019, SNF invested US$ 1.2 billion to expand its polyacrylamide production capacity. This expansion was done in the wake to meet increasing demand of polyacrylamide.

About Us:

Coherent Market Insights is a global market intelligence and consulting organization that provides syndicated research reports, customized research reports, and consulting services. We are known for our actionable insights and authentic reports in various domains including aerospace and defense, agriculture, food and beverages, automotive, chemicals and materials, and virtually all domains and an exhaustive list of sub-domains under the sun. We create value for clients through our highly reliable and accurate reports. We are also committed in playing a leading role in offering insights in various sectors post-COVID-19 and continue to deliver measurable, sustainable results for our clients.

Contact:

Coherent Market Insights 1001 4th Ave, #3200 Seattle, WA 98154, U.S. Email: [email protected] United States of America: +1-206-701-6702 United Kingdom: +44-020-8133-4027 Japan: +050-5539-1737 India: +91-848-285-0837

0 notes

Text

Polyacrylamide Emulsion

https://www.sinofloc.com/news/polyacrylamide-emulsion.html

Polyacrylamide emulsion is prepared by dispersion or inverse emulsion polymerization, which is a form of polyacrylamide liquid present. Besides the characteristics of solid polyacrylamide flocculants, through the molecular chain of polar groups to adsorb suspended solids in the water particles, the emulsion could formats the large flocs through bridge between the particles or electricity.

Polyacrylamide emulsion is divided into two types, water-in-oil, and water-in-water. Unlike polyacrylamide powder, the drying process is not required in the emulsion type polyacrylamide manufacturing process. Therefore, the polyacrylamide emulsions molecular weight and water solubility than the same powder polyacrylamide molecular weight is higher. Water-in-oil emulsions are usually water-insoluble. Therefore, in the emulsion-type polyacrylamide manufacturing process, or in the use of emulsion before the dissolution of the dilution process, the need to add a hydrophilic surfactant, so that when the emulsion type of water reverse phase, so that the emulsion can be dissolved in the water. But the water-in-water emulsion is very easy to dissolve, and also the synthesis process is more advanced. Dissolve the emulsion with water to use high-speed shear when the way, so that the emulsion of polyacrylamide hydrogel in full contact with water and quickly dispersed in water. If the emulsion and water can fully contact with the dispersion, its dissolution time is generally only 3-15 minutes. The storage temperature of the emulsion is preferably between 0 and 30 ° C, and the average emulsion is stored for 6 months. The temperature of the emulsion freezing is lower than that of the water. Frozen emulsion can continue to use after melting, its performance will not be significantly changed. Granular polyacrylamide is made by the AM (acrylamide) monomer polymerization colloid, crushing and drying and then obtained. There are too many disadvantages for polyacrylamide powder, such as the production of too much dust, crushing damage molecular chain, drying, the use of stirring to be dissolved (waste a lot of time and energy consumption), but the largest particle polyacrylamide is easy to transport and storage.

In addition to the advantages of solid polyacrylamide, the emulsion flocculants also have own advantages like a large charge density options, dissolution speed, low energy consumption, storage and easy to use and so on. Compared with the traditional cationic polyacrylamide products, polyacrylamide emulsion for a wider range of PH value, higher charge stability, flocculation effect is better, less dosage and a series of advantages. Also suitable for construction sites that do not have a large dissolution device installed.

Polyacrylamide emulsion is widely used in a variety of domestic sewage, chemical wastewater, oil field sewage, sludge dewatering, paper and other fields. Polyacrylamide water-in-oil emulsion is also widely used in urban sewage treatment, brewery, starch factory, food Processing plants and other sewage treatment. Disposal of flocculation of organic suspended solids in acidic or acidic effluents is particularly applicable. In the paper industry, it could be used as a retention aid filter, papermaking sewage treatment. Oil industry can be used as drilling emulsion coating agent or degreasing agent.

0 notes