#Poly methyl methacrylate (PMMA) Market

Explore tagged Tumblr posts

Photo

Glasses: Acrylic glass

Both a glass and a polymer, thanks to its amorphous structure, acrylic glass is just another name for poly(methyl methacrylate), or PMMA. A thermoplastic, acrylic glass is marketed under numerous brand names, including Plexiglas, Crylux, Lucite, and Perspex, among numerous others. Because of its transparency and strength, it is often used in places where non-organic glasses are also used.

First produced in the late 1920s, today acrylic glass is produced in a variety of forms and using a variety of methods. In addition to strength and transparency, this plastic has high impact resistance, excellent chemical resistance, and good dimensional stability - it is both lightweight and durable, all of which are properties that lend themselves to its popularity. Its strength is less than that of traditional glass, however, so it cannot replace the latter in all applications, at least not without design changes (i.e., increased thickness of acrylic glass, as compared to traditional glass).

Applications of acrylic glass are too numerous to list here. Nearly any common mold processing methods can be used to shape the polymer, including injection molding and extrusion. Higher quality sheets of the material are made with cell casting, in which the polymerization step and molding step are carried out simultaneously.

Sources/Further reading: ( 1 - all images ) ( 2 ) ( 3 )

34 notes

·

View notes

Text

Poly Methyl Methacrylate (PMMA) Prices: Trends and Market Dynamics

Poly Methyl Methacrylate (PMMA), also known as acrylic or plexiglass, is a widely used thermoplastic polymer. Its versatility, excellent optical clarity, and resistance to impact and weathering make it a popular choice across various industries, including automotive, construction, electronics, and healthcare. However, like many other polymers, PMMA prices are influenced by a complex interplay of factors ranging from raw material costs to global market dynamics.

Key Factors Affecting PMMA Prices

Raw Material Costs: PMMA is primarily derived from methyl methacrylate (MMA) monomer. Fluctuations in the prices of MMA significantly impact PMMA prices. MMA prices, in turn, are influenced by the costs of petrochemical feedstocks like propylene and acetone. Any disruption in the supply chain or volatility in crude oil prices directly affects the cost of production.

Supply and Demand Dynamics: PMMA demand is driven by its diverse applications, particularly in high-growth sectors like automotive and electronics. For instance, PMMA is extensively used in LED screens, which have seen rising demand due to advancements in display technology. Conversely, oversupply in the market can lead to price reductions as manufacturers compete for buyers.

Energy Costs: The production of PMMA is energy-intensive. Rising energy costs, whether due to geopolitical tensions or seasonal demand fluctuations, can lead to increased production costs, which are often passed on to end-users.

Economic Conditions: Macroeconomic factors such as inflation, currency exchange rates, and global economic growth significantly influence PMMA prices. During periods of economic slowdown, reduced industrial activity can lead to lower demand, putting downward pressure on prices.

Regulatory and Environmental Policies: Stringent environmental regulations around the use of petrochemical derivatives and the push for sustainable alternatives can influence PMMA production costs and market dynamics. Additionally, initiatives to recycle PMMA are gaining traction, potentially altering the supply landscape.

Get Real time Prices for Poly Methyl Methacrylate (PMMA): https://www.chemanalyst.com/Pricing-data/polymethyl-methacrylate-50

Regional Trends in PMMA Pricing

Asia-Pacific: The Asia-Pacific region dominates the PMMA market, both in terms of production and consumption. China, in particular, is a significant player due to its vast manufacturing base. PMMA prices in this region are highly competitive but sensitive to shifts in demand from the electronics and automotive sectors.

North America and Europe: In developed markets like North America and Europe, PMMA prices are influenced by advanced applications, such as aerospace and medical devices. Additionally, stricter environmental regulations often lead to higher production costs.

Middle East and Africa: The Middle East benefits from proximity to petrochemical feedstocks, often resulting in more stable prices. However, limited domestic consumption means that exports play a critical role in price determination.

Recent Trends and Forecast

In 2023, PMMA prices experienced significant fluctuations due to disruptions in the global supply chain and energy market volatility. As of late 2024, prices are stabilizing, supported by improving economic conditions and steady demand recovery post-pandemic. Analysts forecast moderate growth in PMMA prices over the next five years, driven by sustained demand from key industries and ongoing innovations in PMMA recycling technologies.

Conclusion

Understanding PMMA price trends requires a thorough analysis of multiple factors, including raw material costs, market demand, and regional dynamics. As industries continue to innovate and adopt sustainable practices, the PMMA market will likely evolve, presenting new opportunities and challenges for stakeholders. Keeping an eye on these developments will be crucial for businesses aiming to navigate this complex market effectively.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Poly Methyl Methacrylate#Poly Methyl Methacrylate Price#Poly Methyl Methacrylate Prices#Poly Methyl Methacrylate Pricing#Poly Methyl Methacrylate News#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Commodity Plastics Market is expected to display a steady growth by 2028

According to a new report published by UnivDatos Markets Insights, the Commodity Plastics Market is expected to grow at a CAGR of around 6% from 2022-2028. The analysis has been segmented Type (Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC), Polystyrene (PS), Acrylonitrile Butadiene Styrene (ABS), Polyethylene Terephthalate (PET), Poly (Methyl Methacrylate) (PMMA)); End-User (Packaging, Automotive, Electronics, Consumer Goods, Construction, Textiles, Medical & Pharmaceutical, Others); Region/Country.

The Commodity Plastics market report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the Commodity Plastics market. The Commodity Plastics market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the Commodity Plastics market at the global and regional levels.

Market Overview

Commodity plastics are entire families of products made of a particular polymer. Commodity plastics are inexpensive and do not possess any exceptional mechanical properties. Such plastics are produced in large volumes for a wide spectrum of applications such as food packaging and storage, household products, and carry bags. In addition, they exhibit relatively weak mechanical properties. The most common examples of commodity plastics include polyethylene, polypropylene, polystyrene, polyvinyl chloride, and poly (methyl methacrylate).

Factors such as the growing demand use of plastics in the packaging industry as well as other end-use industries with multiple applications, such as packaging, photographic, electronics, and pharmaceuticals, and the increase in demand for consumer goods are positively influencing the market demand for commodity plastics. In addition, the rising need for specialized commodity plastics in the healthcare sector for manufacturing medical masks, gowns, and other safety kits is expected to boost the market growth in the coming years. However, rising consumer awareness regarding the harmful effects caused by improper disposable plastics is anticipated to hamper the market.

Some of the major players operating in the market include Exxon Mobil Corporation, The Dow Chemical Company, BASF SE, Reliance Industries, Sinopec, Mitsubishi Chemical, Nova Chemicals, Sumitomo Chemical, LyondellBasell, Chevron Phillips Chemical.

COVID-19 Impact

The advent of global pandemic resulted in creating a global crisis in the FMCG industry. Impacting over 195 countries across the globe, the pandemic has already created an economic backdrop the globe. social distancing has made a drastic negative impact on the FMCG industry. Logistic issues, lack of adequate labor force, and operations limiting the production of only essential items are some of the few examples most FMCG companies are facing across the globe. Moreover, the usage of plastic decreased in most sectors as demand and output dropped, especially in large-scale plastics-using sectors including motor vehicles, trade, and construction which significantly impacted the market growth of commodity plastics.

The global Commodity Plastics market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

· Based on type, the commodity plastics market is segmented into polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), acrylonitrile butadiene styrene (ABS), polyethylene terephthalate (PET), poly (methyl methacrylate) (PMMA). Polypropylene (PP) caters substantial share of the market. As It is one of the cheapest thermoplastics and caters to a considerable share of global plastics materials consumption. Also, owing to its low price, ease of processing, chemically inertness, and many other attractive properties, it has replaced metals, glass, wood, cellophane, and paper in countless applications.

· Based on end-user, the commodity plastics market is classified into oil & gas, manufacturing, healthcare/ pharmaceutical, food & beverages, energy & utility, consumer goods, metal & mining, transportation, and others. Among these, the packaging segment to hold a significant share in the market in 2020. Increasing demand for packaged food and beverages and growing demand for flexible packaging are some major factors driving revenue growth of this segment. Furthermore, the development in packaging materials technology and the increasing use of renewable plastics for packaging are anticipated to propel the segment growth in the coming years.

Commodity Plastics Market Geographical Segmentation Includes:

North America (United States, Canada, and Rest of North America)

Europe (Germany, United Kingdom, Spain, Italy, France, and the Rest of Europe)

Asia-Pacific (China, Japan, India, Australia, and the Rest of Asia-Pacific)

Rest of the World

Asia Pacific is anticipated to grow at a substantial CAGR during the forecast period. This is mainly attributed to the rapid growth in the e-commerce sector coupled with the increasing population and growing demand for packaged foods contributing to the growth of the market.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=25603

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the Commodity Plastics market. The major players have been analyzed by using research methodologies for getting insight views on global competition.

Key questions resolved through this analytical market research report include:

• What are the latest trends, new patterns, and technological advancements in the Commodity Plastics market?

• Which factors are influencing the Commodity Plastics market over the forecast period?

• What are the global challenges, threats, and risks in the Commodity Plastics market?

• Which factors are propelling and restraining the Commodity Plastics market?

• What are the demanding global regions of the Commodity Plastics market?

• What will be the global market size in the upcoming years?

• What are the crucial market acquisition strategies and policies applied by global companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature and geography. Please let us know If you have any custom needs.

Browse Related Newsletter from UnivDatos Market Insights

Manganese Alloys Market: SWOT Analysis [2023-2028]

Green Methanol Market: SWOT Analysis [2023-2028]

About Us:

UnivDatos Market Insights: Your Partner in Data-Driven Market Strategies. Unlock growth opportunities and make smart decisions with our expert research and insights.

Contact us:

UnivDatos Market Insights (UMI)

Email: [email protected]

Web: https://univdatos.com

LinkedIn: www.linkedin.com/company/univ-datos-market-insight/

Ph: +91 7838604911

0 notes

Text

Global Top 13 Companies Accounted for 82% of total Poly Methyl Methacrylate (PMMA) market (QYResearch, 2021)

Polymethyl Methacrylate (PMMA) is a thermoplastic polymer of Methyl Methacrylate (MMA). It is a clear, strong and lightweight plastic generally used as a substitute to glass due to its energy efficiency and weather resistance.

According to the new market research report “Global Poly Methyl Methacrylate (PMMA) Market Report 2023-2029”, published by QYResearch, the global Poly Methyl Methacrylate (PMMA) market size is projected to reach USD 6.08 billion by 2029, at a CAGR of 7.4% during the forecast period.

Figure. Global Poly Methyl Methacrylate (PMMA) Market Size (US$ Million), 2018-2029

Figure. Global Poly Methyl Methacrylate (PMMA) Top 13 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Poly Methyl Methacrylate (PMMA) include Röhm, Trinseo, Mitsubishi Chemical, Sumitomo Chemical, LX MMA, Lotte MCC, Chi Mei, Double Elephant Optical Material, Wanhua Chemical, Kuraray, etc. In 2021, the global top 10 players had a share approximately 82.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Methyl Methacrylate Market Trends: Insights and Analysis

Overview Methyl methacrylate (MMA) is an organic compound with the formula C5H8O2. It is a colorless, volatile liquid that is slightly soluble in water but very soluble in most organic solvents. MMA's main uses are in the production of poly(methyl methacrylate) (PMMA), which is better known by trade names like Plexiglas or Acrylic glass, and as a chemical intermediate in the production of other substances and industrial chemicals. Production and synthesis Commercially, MMA is produced via the hydrolysis of methacrylic anhydride which itself is produced from acetone cyanohydrin or via the acid-catalyzed esterification of methacrylic acid with methanol. In laboratory settings, it can also be prepared by the condensation of acetone with malonic acid followed by decarboxylation. Globally, over 3 million tons of MMA are produced annually. It is one of the 150 most commonly produced chemicals and a valuable petrochemical product. The key manufacturers are located in Asia, North America and Western Europe. Uses and applications of PMMA Polymerization of MMA yields poly(methyl methacrylate) or PMMA, which is a transparent thermoplastic often used as a lightweight or shatter-resistant alternative to glass in applications such as aircraft canopies or windows and aquariums. It is easily worked, molded or thermoformed due to its low melting point. Some common uses of PMMA include: - Signage and displays: Thin PMMA sheets are often used as an alternative to acrylic glass in illuminated signage due to its light weight and shatter resistance. It is also used as the glazing material on bus/taxi stop shelters. - Construction: PMMA finds use in architectural applications like skylight domes, greenhouse glazing and translucent wall panels. It can also be used to produce bathtubs or sanitary fittings needing high durability and an aesthetically pleasing finish. - Medical and dental: Clear and impact-resistant PMMA sheets are commonly used as the material for orthodontic appliances and in medical devices like inhalers or eyeglass frames. It is also employed as an insulator in bone cements used for joint replacements. - Electronics: Various consumer electronic devices, especially mobile phones and PDAs, employ PMMA for touchscreens and display lenses owing to its durability and optical clarity. Conclusion In summary, methyl methacrylate is an essential building block in modern materials production. As the monomer for PMMA plastic sheet and specialist polymers, it delivers technical advantages of strength, clarity and formability paired with economical processability. Its versatility as an intermediate also means that by controlled reaction with many different molecules, it enables the cost-effective synthesis of various industrial chemicals in demand. With growing applications across markets, MMA's global output and relevance will likely remain substantial for the foreseeable future. Care must continue to be taken regarding the associated human health and environmental impacts through prudent handling and process design.

0 notes

Text

Innovation in Clarity: Exploring the Applications of Poly Methyl Methacrylate (PMMA) (2023-2034)

Ever heard of Polymethyl methacrylate (PMMA)? PMMA is a transparent and rigid thermoplastic, crafted from the monomer methyl methacrylate, holding impressive resistance to UV light and weathering. With its crystal-clear clarity, PMMA finds its way into a myriad of applications, from sleek car windows and durable smartphone screens. Read more about the versatility and manufacturing of PMMA in this blog! The global Poly Methyl Methacrylate (PMMA) market is likely to flourish at a CAGR of 4.05% by the year 2034.

Introduction

A scientific term, Poly (methyl methacrylate), refers to the clear and lightweight plastic commonly called acrylic or plexiglass. In its natural state, it's easily broken, but it can be colored, textured, and shaped in many ways. Crystal-clear plastic, known as Polymethyl methacrylate (PMMA) or acrylic, stands out for its toughness. Unlike glass, it won't shatter, making it a popular choice as a substitute. PMMA boasts several advantages over other clear plastics like polycarbonate (PC) and polystyrene (PS). These include superior resistance to sun damage and weather, exceptional light transmission, and the ability to be colored in any shade imaginable.

Scientific Properties: PMMA is scratch resistant and remains unaffected by aqueous solutions. However, exposure to certain chemicals like aromatic or chlorinated hydrocarbons, esters, or ketones can compromise its surface.

Sound and Break-Resistance: PMMA acts as a sound-resistant material, reducing the transmission of external sound waves. This quality makes it ideal for constructing spaces that require internal sound insulation, such as audio studios, libraries, quiet rooms, and vehicles.

Environmental Sustainability: PMMA exhibits excellent outdoor durability, resisting corrosion, ultraviolet light, and various environmental factors. Furthermore, it is both recyclable and BPA-free, making it one of the safer plastics in terms of environmental impact. These characteristics contribute to PMMA's sustainability profile, aligning with eco-conscious practices and initiatives.

Manufacturing Process

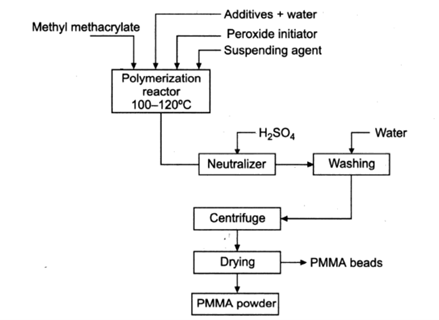

PMMA, derived from methacrylic acid (CH2=C[CH3]CO2H), is a significant member of the acrylic resin family. Its production primarily involves propylene, obtained from the lighter fractions of crude oil, and benzene, reacting to form cumene or isopropylbenzene. The resulting cumene undergoes oxidation to cumene hydroperoxide, then acid treatment to yield acetone. Subsequently, acetone undergoes a three-step process to produce methyl methacrylate (CH2=C[CH3]CO2CH3), a flammable liquid. Methyl methacrylate is polymerized, either in bulk liquid form or as fine droplets suspended in water, using free-radical initiators to form solid PMMA. This polymerization process links the molecules together, resulting in the formation of PMMA with a repeating unit structure.

The polymerization reactor receives a feed mixture consisting of a monomer, water acting as the reaction medium, suspending agents, and a monomer-soluble initiator. To adjust the density of the aqueous medium, decrease the monomer's water solubility, and increase interfacial tension, an inorganic salt is added. Polymerization occurs at around 100°C. After polymerization, the resulting slurry is neutralized with sulfuric acid before undergoing filtration or centrifugation. The material is then dried. This method ensures the controlled production of the desired polymer, achieved through the precise interaction of monomers, reaction medium, initiators, and additives within the polymerization reactor.

Applications of Poly Methyl Methacrylate (PMMA)

Construction

PMMA is very useful in building. It is commonly used for shatterproof skylights. It may also be found in many shower and bath systems, and many people prefer acrylic over ceramic tiles. As previously said, acrylic may be found in many sound-proof rooms, audio studios, and automobiles.

Automotive

PMMA sheets are utilized in automobile windows, motorbike windshields, interior and exterior panels, fenders, and other vehicle components. Colored acrylic sheets are also utilized in automotive indication light covers and interior light covers, among other applications. It is also utilized for ship windows (salt resistance) and aviation applications.

Electronics

Because of its superior optical clarity, high light transmission, and scratch resistance, PMMA is widely utilized in LCD/LED television screens, computers, smartphone displays, and electrical equipment. PMMA is also utilized as a cover material in solar panels due to its strong UV resistance and light transmission properties, which allow for high energy conversion efficiencies.

Furniture

PMMA provides exceptional features like transparency, hardness, and attractiveness to make chairs, tables, kitchen cabinets, bowls, and table mats in any shape, color, or finish.

Market Outlook:

The PMMA market is embracing sustainability. As environmental concerns grow, manufacturers are seeking eco-friendly solutions for PMMA, either through bio-based materials, improved recycling, or circular economy approaches. This aligns with the global push for sustainability and positions PMMA to meet evolving consumer and regulatory demands. Additionally, PMMA's clear optics, biocompatibility, and easy sterilization make it ideal for healthcare applications like lenses, instruments, and dental materials. As healthcare technology advances, PMMA's properties are well-suited for these demanding medical uses, creating exciting opportunities for market growth and diversification.

Poly Methyl Methacrylate (PMMA) Major Players

Significant companies in the Global Poly Methyl Methacrylate (PMMA) market are Mitsubishi Rayon Co., Ltd., Evonik, Chi Mei Corporation, Sumitomo Chemical, LX MMA, Wanhua Chemical, Suzhou Double Elephant Optical Materials, and Kuraray Co., Ltd., Lotte MCC, and Others.

Poly Methyl Methacrylate (PMMA) market restraints

The Poly Methyl Methacrylate (PMMA) market faces several restraints as well. These are as follows:

Fluctuating Raw Material Prices: Poly Methyl Methacrylate (PMMA) production relies on raw materials like bisphenol A and phosgene, the prices of which are subject to market volatility. Fluctuations in raw material costs can affect the overall production costs and profit margins for Poly Methyl Methacrylate (PMMA) manufacturers.

Difficulty in Recycling: While clear acrylic sheets can be recycled, the process is complex. Breaking down large pieces and using specialized methods like perspex recycling are just the first steps. This difficulty contributes to a global problem of acrylic waste harming ecosystems. In some areas, acrylic buildup disrupts the natural balance of CO2 and O2 exchange, hindering plant growth.

Conclusion:

The Polymethyl Methacrylate (PMMA) market has boomed in recent years, driven by its use in key industries like electronics, automotive, and construction. PMMA's unique properties, such as high durability and chemical resistance, suggest continued growth in the coming years. Rising urbanization, increasing demand for modern electronics, and projected growth in vehicle sales are all expected to fuel PMMA demand by 2034.

#PMMA#PMMAprices#PMMAmarket#PMMApricetrend#PMMApriceforecast#PMMAmarketprice#priceofPMMA#PMMAdemand#PMMASupply

1 note

·

View note

Text

Global Commodity Plastics Market Overview – Market Growth Analysis And Key Drivers

The Commodity Plastics Global Market Report 2023, provides comprehensive information on the commodity plastics market across 60+ geographies in the seven regions - Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa for the 27 major global industries. The report covers a ten year historic period – 2010-2021, and a ten year forecast period – 2023-2032.

Learn More On The Commodity Plastics Market’s Growth:

As per The Business Research Company’s Commodity Plastics Global Market Report 2023, the market size is expected to grow from $465.38 billion in 2022 to $498.49 billion in 2023 at a compound annual growth rate (CAGR) of 7.1%. The Russia-Ukraine war disrupted the chances of global economic recovery from the COVID-19 pandemic, at least in the short term. The war between these two countries has led to economic sanctions on multiple countries, a surge in commodity prices, and supply chain disruptions, causing inflation across goods and services and affecting many markets across the globe. The market size of commodity plastics is expected to grow to $637.15 billion in 2027 at a CAGR of 6.3%.

Get A Free Sample Of The Report (Includes Graphs And Tables):

Product advancement is a key trend gaining popularity in the commodity plastics market. Major market players are focusing on technological advancements to sustain their position in the commodity plastics market. For instance, in August 2021, Krehalon, a Netherlands based packaging company, launched the KreCycleTM to meet the demand for more sustainable packaging options, as well as a portfolio of conveniently recyclable high barrier flexible films for fresh food applications. The KreCycleTM product line includes polyester (PET), polyethylene (PE), and polypropylene (PP) based solutions with customized barrier qualities to meet the needs of specific applications. It is perfect for packaging fresh protein products such as red meat, poultry, processed meat, fish, and hard cheese. Flexible thermoforming films, flowrap films with a high barrier option, lidding films, and vacuum pouches are among the products available. For the convenience of the consumer, there are additional lock and peel seal options.

The commodity plastics market is segmented:

1) By Type: Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC), Polystyrene (PS), Acrylonitrile Butadiene Styrene (ABS), Polyethylene Terephthalate (PET), Poly (Methyl Methacrylate) (PMMA)

2) By Plastic Type: Reusable, Recyclable

3) By End-User: Packaging, Construction, Consumer Goods, Automotive, Electronics, Textiles, Medical and Pharmaceutical, Other End Use Industry

Asia-Pacific was the largest region in the commodity plastics market in 2022.

The table of contents in TBRC’s commodity plastics market report includes:

1. Executive Summary

2. Market Characteristics

3. Market Trends And Strategies

4. Impact Of COVID-19

5. Market Size And Growth

6. Segmentation

7. Regional And Country Analysis

.

.

.

27. Competitive Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

Learn About Us:�� The Business Research Company is a market intelligence firm that pioneers in market, company, and consumer research. TBRC’s specialist consultants are located globally and are experts in a wide range of industries that include healthcare, manufacturing, financial services, chemicals, and technology. The firm has offices located in the UK, the US, and India, along with a network of proficient researchers in 28 countries. Through the report businesses can gain a thorough understanding of the market’s size, growth rate, major drivers and leading players.

Contact Us: The Business Research Company Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

0 notes

Text

0 notes

Text

Photoresist Chemicals Market Size, Share, Demand, Growth & Trends by 2032

The market for photoresist chemicals is expanding due to the inherent properties of photoresist chemicals and the lack of any viable substitutes. Between 2022 and 2032, overall demand for photoresist chemicals is expected to expand at a CAGR of 3.6%, totaling roughly US$ 4,537.2 Million. Photoresist chemicals are used in the fabrication of µm- and sub-µm structures, prominently in the micro-electronics industry. These are speciality chemical which changes its chemical structure when exposed to ultraviolet (UV) light, this unique property makes them ideal for photolithography and photoengraving processes which in turn are commonly used in semiconductor manufacturing industry.

Get a Sample Copy of Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-2334 Henceforth, photoresist chemicals are considered as an essential component for making high-performance circuit boards and semiconductor chips. Various chemical are used for this purpose, to achieve the desired properties, such as, poly methyl methacrylate (PMMA), poly methyl glutarimide (PMGI), phenol formaldehyde resin (DNQ), SU-8 and OSTE polymers. Further, there are two basic classification of photoresists, positive and negative, both works on different principals, but cater to similar needs. However, with increasing smaller geometry designs in micro-electronics industry, positives are becoming more popular, as they offer process controllability. With inevitable features offered by Photoresist chemicals and absence of any other feasible alternatives, market for photoresist chemical is ever growing Photoresist Chemicals Market: Drivers and Restraints The global photoresist chemicals market is projected to grow at a moderate growth rate as the demand for micro-electronics continue to steadily grow, amid rising demand from electronic products in developing nations, and increasing penetrations of IoT across the globe. Furthermore, rising demand for dynamic display technology is expected to be another prominent factor fuelling growth in photoresists chemicals market. Excessive R&D in the photoresist chemicals and its end use industry, is expected to drive innovations, further shaping newer demand arenas, and fuelling more revenues in the global photoresist chemicals market. Photoresist chemicals are prominently made from crude oil; thus rising prices of crude oil is expected to increase costs, this coupled with continued pricing pressure from end use industries, shall affect margins in the market. Furthermore rising environmental concerns regarding derogatory effects of these chemicals is also expected to affect the market in long term.

Browse Full Report: https://www.futuremarketinsights.com/reports/photoresist-chemicals-market Photoresist Chemicals Market: Region Wise Outlook The global photoresist chemicals market is segmented into the seven key regions: North America, Latin America, Western Europe, and Eastern Europe, Asia Pacific Excluding Japan (APEJ), Japan and Middle East and Africa (MEA). APEJ and Japan together leads the Global Photoresist Chemicals Market in terms of demand, followed by North America and Western Europe. Furthermore, owing to rapidly rising electronics industry in India and China, the APEJ region is anticipated to remain its dominance and grew steadily over the forecast period. Along with, rising economies of Latin America, demand for microelectronics is expected to significantly rise in the region, translating into rising demand for photoresist chemicals. In terms of production, photoresist market has been a forte of Japan and Korea based companies, and with many new upcoming companies in the region, competition in the APEJ market is expected to further intensify. Photoresist Chemicals Market: Key Players

The Dow Chemical Company

Fujifilm Electronic Materials Co. Ltd

Tokyo Ohka Kogyo Co. Ltd.

E.I. DuPont de Nemours

Mitsui Chemicals America Inc

JSR Corporation

LG Chem

Shin-Etsu Chemical

TOK America

Honsou Chemical Industry

Key Segments Covered in the Photoresist Chemicals Industry Analysis

By Product Type:

Positive

Negative

By Spectral Line Size:

g-line

i-line

KrF

ArF Immersion

ArF Dry

By End Use Application:

Microelectronics

Sand Carving

Fabrication of Printed Circuit Boards

Others

By Region:

North America

Latin America

Europe

Asia Pacific

Middle East & Africa

0 notes

Text

Poly Methyl Methacrylate (PMMA) Price | Prices | Pricing | News | Database | Chart

Poly Methyl Methacrylate (PMMA), often referred to as acrylic or plexiglass, is a versatile thermoplastic with various applications across industries. PMMA is widely used in the automotive, construction, electronics, and medical sectors due to its excellent transparency, durability, and weather resistance. Given its importance, understanding the pricing dynamics of PMMA is essential for manufacturers, suppliers, and end-users alike. PMMA prices are influenced by several factors, ranging from raw material costs and supply-demand dynamics to market trends and regional variations. Like many other polymer materials, PMMA prices tend to fluctuate based on feedstock availability, especially the key monomer methyl methacrylate (MMA). The production process involves the polymerization of MMA, and the availability and pricing of this monomer directly impact the overall cost of PMMA.

Global market demand is a crucial determinant of PMMA prices. PMMA is used in various applications, including automotive lighting, LCD screens, signage, and medical devices. The increasing demand for lightweight and durable materials in the automotive and electronics industries has propelled the demand for PMMA. However, shifts in global economic conditions, such as economic slowdowns or trade disruptions, can lead to fluctuations in demand and, consequently, PMMA prices. For instance, during economic downturns, the reduced demand from key industries can lead to lower PMMA prices as suppliers adjust to the lower demand. Conversely, in periods of economic growth, rising demand can push prices upward as supply tightens.

Get Real Time Prices for Poly Methyl Methacrylate (PMMA): https://www.chemanalyst.com/Pricing-data/polymethyl-methacrylate-50

Regional variations in PMMA prices also play a significant role in the global market. Asia-Pacific, especially China and Japan, is one of the largest consumers of PMMA due to the booming automotive and electronics sectors. In this region, PMMA prices tend to be influenced by local supply and demand dynamics, government policies, and the availability of raw materials. In contrast, in Europe and North America, factors such as stricter environmental regulations and higher production costs can contribute to slightly higher PMMA prices. Moreover, transportation costs and trade tariffs between regions can lead to price disparities across different markets.

The cost of energy and labor also impacts PMMA prices. Since the production of PMMA is energy-intensive, fluctuations in energy prices, particularly oil and natural gas, can have a direct effect on the cost of production. Rising energy costs lead to higher production expenses, which are often passed on to the end consumers in the form of increased PMMA prices. Labor costs, especially in regions with high wages, can also add to the overall production costs. In countries where labor is more affordable, such as in parts of Asia, the production of PMMA can be more cost-effective, leading to lower prices compared to regions with higher labor costs.

Technological advancements and innovations in the production process can also affect PMMA prices. Improved manufacturing techniques and the development of new grades of PMMA that offer enhanced properties, such as increased impact resistance or UV protection, can influence the market. For example, specialty grades of PMMA that cater to specific industries, such as medical or aerospace, tend to command higher prices due to their specialized nature and the additional costs involved in their production. On the other hand, innovations that reduce production costs, such as more efficient polymerization processes or the use of alternative raw materials, can lead to lower PMMA prices over time.

Supply chain disruptions are another factor that can cause volatility in PMMA prices. Disruptions in the supply of raw materials, logistical challenges, or political instability in key manufacturing regions can lead to supply shortages, driving up PMMA prices. For instance, natural disasters, geopolitical tensions, or pandemics can impact the availability of methyl methacrylate and other essential inputs, leading to production delays and price increases. In addition, the COVID-19 pandemic had a significant impact on the global supply chain, leading to price fluctuations in many materials, including PMMA. As industries around the world experienced shutdowns and reduced production capacities, the demand for PMMA in sectors like automotive and electronics temporarily declined, causing prices to dip. However, as the global economy began to recover, demand surged, and PMMA prices experienced a corresponding increase due to supply chain constraints.

Sustainability concerns and environmental regulations are increasingly shaping the PMMA market and its pricing. As industries and governments worldwide focus on reducing carbon footprints and promoting sustainable practices, the demand for eco-friendly alternatives to conventional plastics has grown. PMMA, being recyclable and less harmful than some other polymers, is benefiting from this trend. However, stricter environmental regulations, especially in regions like Europe, can lead to increased production costs due to compliance requirements, thereby influencing PMMA prices. Producers may have to invest in cleaner production technologies or adopt more expensive processes to meet environmental standards, which can result in higher prices for PMMA.

In conclusion, the price of Poly Methyl Methacrylate is influenced by a multitude of factors, including the availability and cost of raw materials like methyl methacrylate, global and regional demand, energy and labor costs, technological advancements, supply chain disruptions, and environmental regulations. Understanding these factors is crucial for stakeholders in industries that rely on PMMA, as price fluctuations can significantly impact production costs and profit margins. As the global economy continues to evolve, with new challenges and opportunities emerging in various industries, the pricing of PMMA is likely to remain dynamic, reflecting the changing landscape of the materials market. Those involved in the supply chain of PMMA must stay attuned to these factors to navigate the market effectively and ensure cost-efficiency in their operations.

Get Real Time Prices for Poly Methyl Methacrylate (PMMA): https://www.chemanalyst.com/Pricing-data/polymethyl-methacrylate-50

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Poly Methyl Methacrylate#Poly Methyl Methacrylate Price#Poly Methyl Methacrylate Prices#Poly Methyl Methacrylate Pricing#Poly Methyl Methacrylate News

0 notes

Text

Global Poly Methyl Methacrylate (PMMA) Market Insights Report 2021-2026 : Mitsubishi Chemical, Evonik, Chi Mei, Arkema, Sumitomo Chemical, LG MMA

The Global Poly Methyl Methacrylate (PMMA) Market report focuses on market status, future forecast, growth opportunity, key market, and key players. The study objectives are to present Poly Methyl Methacrylate (PMMA) Market development worldwide. The report offers a precise evaluation of market size, share, demand, revenue, and growth rates. It presents current trends in the global market and projects the revenue and potential developments of key players. The report contains reviews of the final product, and the key factors affecting or hampering the market growth. The global Poly Methyl Methacrylate (PMMA) report detailed analysis with point-to-point structure and with flowcharts. The key competitors in the global Poly Methyl Methacrylate (PMMA) Market are Mitsubishi Chemical, Evonik, Chi Mei, Arkema, Sumitomo Chemical, LG MMA, Double Elephant Optical Material, Kuraray, Plaskolite, Asahi Kasei, PTTGM, Shanghai Jingqi, Zhongmeng Longxin.

Read Complete Report @ https://www.syndicatemarketresearch.com/market-analysis/poly-methyl-methacrylate-pmma-market.html

The Worldwide Poly Methyl Methacrylate (PMMA) Market research report delivers a comprehensive analysis of the newest market drivers. The competitive structure has been explained covering development activities related to products, advancements, technologies, and SWOT analysis are explored in this report. This information will help the businesses/clients penetrate or expand in the market. Additionally, this report researches the market in the worldwide market with production, benefits, usage, sales, import & export, market share, and growth rate in the projection period 20202026. The study contains all resourceful constraints, limitations, openings, challenges as well as outlines the historical data, current and future momentum of the Poly Methyl Methacrylate (PMMA) market. The report also offers extracts regarding statistics, market valuation, and revenue estimates, which further strengthens its status in the competitive spectrum and growth trends embraced by leading manufacturers in the business.

Request for Free Sample Report @ https://www.syndicatemarketresearch.com/sample/poly-methyl-methacrylate-pmma-market

The objective of the report is to present a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, industry-validated market data, and projections with a suitable set of assumptions and methodology. The report also helps in understanding Poly Methyl Methacrylate (PMMA) dynamics, structure by identifying and analyzing the market segments, and project the global market size. Further, the report also focuses on competitive analysis of key players by product, price, financial position, product portfolio, growth strategies, and regional presence. The report also provides PEST analysis, PORTER&rsquo's analysis, SWOT analysis to address questions of shareholders to prioritizing the efforts and investment in the near future to emerging segment in Poly Methyl Methacrylate (PMMA) market. The Poly Methyl Methacrylate (PMMA) market report helps the readers in understanding the development factors, industry plans, approaches, and advancement procedures actualized by key market players. The report has been prepared by keeping the clients perspective in mind.

Download Free Request Broucher PDF @ https://www.syndicatemarketresearch.com/inquiry/poly-methyl-methacrylate-pmma-market

The global version of this report with a geographical classification such as North America (the United States, Canada, and Mexico) Europe (Germany, UK, France, Italy, Russia, Spain, and Benelux) Asia Pacific (China, Japan, India, Southeast Asia, and Australia) Latin America (Brazil, Argentina, and Colombia) The Middle East and Africa

Key Developments in the Poly Methyl Methacrylate (PMMA) Market 1. To describe Poly Methyl Methacrylate (PMMA) Introduction, product type, and application, market overview, market analysis by countries, market opportunities, market risk, market driving force; 2. To analyze the manufacturers of Poly Methyl Methacrylate (PMMA), with profile, main business, news, sales, price, revenue, and market share in 2020 and 2026; 3. To display the competitive situation among the top manufacturers in Global, with sales, revenue, and market share in 2020 and 2026; 4. To show the market by type and application, with sales, price, revenue, market share, and growth rate by type and application, from 2020 to 2026; 5. To analyze the manufacturing cost, key raw materials and manufacturing process, etc. 6. To describe Poly Methyl Methacrylate (PMMA) Research Findings and Conclusion, Appendix, methodology and data source

Poly Methyl Methacrylate (PMMA) Market Report Structure at a Glance:

Macroeconomic factors and forecast factors.

Executive summary, market introduction, Poly Methyl Methacrylate (PMMA) definition.

Poly Methyl Methacrylate (PMMA) Market taxonomy segmentation on the basis of type, end-use, and region.

Pricing analysis, regulatory factors analysis, and value chain analysis.

Poly Methyl Methacrylate (PMMA) Market dynamics including key drivers, key restraints, recent trends, upcoming opportunities.

In-depth forecast analysis by type, end-use, region.

Poly Methyl Methacrylate (PMMA) Market structure and competition analysis.

In conclusion, it is a deep research report on the Global Poly Methyl Methacrylate (PMMA) industry. Here, we express our thanks for the support and assistance from Poly Methyl Methacrylate (PMMA) industry chain related technical experts and marketing engineers during Research Teams survey and interviews. This Poly Methyl Methacrylate (PMMA) report covers all the aspects of market vendors, product, its various applications, offer clients the scope to identify probable market opportunities and expand markets. In addition to this, the trends and revenue analysis of the global Poly Methyl Methacrylate (PMMA) has been mentioned in this report. This will give a clear perspective on how Poly Methyl Methacrylate (PMMA) will fare worldwide.

NOTE - TO PROVIDE A MORE ACCURATE MARKET FORECAST, ALL OUR REPORTS WILL BE UPDATED BEFORE DELIVERY, TAKING INTO ACCOUNT THE EFFECTS OF COVD-19. (* if you have any special needs, please let us know and we will report as you wish.)

Contact Us:

Email ID: [email protected]

#Poly Methyl Methacrylate (PMMA) Market#Poly Methyl Methacrylate (PMMA) Market 2021#Global Poly Methyl Methacrylate (PMMA) Market 2021#Poly Methyl Methacrylate (PMMA) Market Growth#Poly Methyl Methacrylate (PMMA) Market Demand#Poly Methyl Methacrylate (PMMA) Market Forecast#Poly Methyl Methacrylate (PMMA) Market Outlook#Poly Methyl Methacrylate (PMMA) Market Sale & Price#Poly Methyl Methacrylate (PMMA) Market Trend#Poly Methyl Methacrylate (PMMA) Market Size & Share#Poly Methyl Methacrylate (PMMA) Market with COVID-19 Impact Analysis

0 notes

Text

Poly Methyl Methacrylate (PMMA) Market Calculations Size, Share 2022 By Development Trend and Key Manufacturers | SMR

0 notes

Text

A view of acrylic

Acrylic plastic refers to a family of synthetic, or man-made, plastic materials containing one or more derivatives of acrylic products acid. The most common acrylic plastic is polymethyl methacrylate (PMMA), which is sold under the brand names of Plexiglas, Lucite, Perspex, and Crystallite. PMMA is a tough, highly transparent material with excellent resistance to ultraviolet radiation and weathering. It can be colored, molded, cut, drilled, and formed. These properties make it ideal for many applications including airplane windshields, skylights, automobile taillights, and outdoor signs. One notable application is the ceiling of the Houston Astrodome which is composed of hundreds of double-insulating panels of PMMA acrylic plastic.

Like all plastics, acrylic plastics are polymers. The word polymer comes from the Greek words poly, meaning many, and meros, meaning a part. A polymer, therefore, is a material made up of many molecules, or parts, linked together like a chain. Polymers may have hundreds, or even thousands, of molecules linked together. More importantly, a polymer is a material that has properties entirely different than its component parts. The process of making a polymer, known as polymerization, has been likened to shoveling scrap glass, copper, and other materials into a box, shaking the box, and coming back in an hour to find a working color television set. The glass, copper, and other component parts are still there, but they have been reassembled into something that looks and functions entirely differently.

The first plastic polymer, celluloid, a combination of cellulose nitrate and camphor, was developed in 1869. It was based on the natural polymer cellulose, which is present in plants. Celluloid was used to make many items including photographic film, combs, and men's shirt collars.

In 1909, Leo Baekeland developed the first commercially successful synthetic plastic polymer when he patented phenol formalde-hyde resin, which he named Bakelite. Bakelite was an immediate success. It could be machined and molded. It was an excellent electrical insulator and was resistant to heat, acids, and weather. It could also be colored and dyed for use in decorative objects. Bakelite plastic was used in radio, telephone, and electrical equipment, as well as counter tops, buttons, and knife handles.

Acrylic acid was first prepared in 1843. Methacrylic acid, which is a derivative of acrylic acid, was formulated in 1865. When methacrylic acid is reacted with methyl alcohol, it results in an ester known as methyl methacrylate. The polymerization process to turn methyl methacrylate into polymethyl methacrylate was discovered by the German chemists Fittig and Paul in 1877, but it wasn't until 1936 that the process was used to produce sheets of acrylic safety glass commercially. During World War II, acrylic glass was used for periscope ports on submarines and for windshields, canopies, and gun turrets on airplanes.

Acrylic plastic polymers are formed by reacting a monomer, such as methyl methacrylate, with a catalyst. A typical catalyst would be an organic peroxide. The catalyst starts the reaction and enters into it to keep it going, but does not become part of the resulting polymer.

Acrylic plastics are available in three forms: flat sheets, elongated shapes (rods and tubes), and molding powder. Molding powders are sometimes made by a process known as suspension polymerization in which the reaction takes place between tiny droplets of the monomer suspended in a solution of water and catalyst. This results in grains of polymer with tightly controlled molecular weight suitable for molding or extrusion.

Acrylic plastic sheets are formed by a process known as bulk polymerization. In this process, the monomer and catalyst are poured into a mold where the reaction takes place. Two methods of bulk polymerization may be used: batch cell or continuous. Batch cell is the most common because it is simple and is easily adapted for making diy acrylic key chain sheets in thicknesses from 0.06 to 6.0 inches (0.16-15 cm) and widths from 3 feet (0.9 m) up to several hundred feet. The batch cell method may also be used to form rods and tubes. The continuous method is quicker and involves less labor. It is used to make sheets of thinner thicknesses and smaller widths than those produced by the batch cell method.

We will describe both the batch cell and continuous bulk polymerization processes typically used to produce transparent polymethyl methacrylic (PMMA) sheets.

The mold for producing sheets is assembled from two plates of polished glass separated by a flexible "window-frame" spacer. The spacer sits along the outer perimeter of the surface of the glass plates and forms a sealed cavity between the plates. The fact that the spacer is flexible allows the mold cavity to shrink during the polymerization process to compensate for the volume contraction of the material as the reaction goes from individual molecules to linked polymers. In some production applications, polished metal plates are used instead of glass. Several plates may be stacked on top of each other with the upper surface of one plate becoming the bottom surface of the next higher mold cavity. The plates and spacers are clamped together with spring clamps.

An open comer of each mold cavity is filled with a pre-measured liquid syrup of methyl methacrylate monomer and catalyst. In some cases, a methyl methacrylate prepolymer is also added. A prepolymer is a material with partially formed polymer chains used to further help the polymerization process. The liquid syrup flows throughout the mold cavity to fill it.

The mold is then sealed and heat may be applied to help the catalyst start the reaction.

As the reaction proceeds, it may generate significant heat by itself. This heat is fanned off in air ovens or by placing the molds in a water bath. A programmed temperature cycle is followed to ensure proper cure time without additional vaporization of the monomer solution. This also prevents bubbles from forming. Thinner sheets may cure in 10 to 12 hours, but thicker sheets may require several days.

When the plastic is cured, the molds are cooled and opened. The glass or metal plates are cleaned and reassembled for the next batch.

The plastic sheets are either used as is or are annealed by heating them to 284-302°F (140-150°C) for several hours to reduce any residual stresses in the material that might cause warping or other dimensional instabilities.

Any excess material, or flash, is trimmed off the edges, and masking paper products or plastic film is applied to the surface of the finished sheets for protection during handling and shipping. The paper or film is often marked with the material's brand name, size, and handling instructions. Conformance with applicable safety or building code standards is also noted.

The storage, handling, and processing of the chemicals that make acrylic plastics are done under controlled environmental conditions to prevent contamination of the material or unsafe chemical reactions. The control of temperature is especially critical to the polymerization process. Even the initial temperatures of the monomer and catalyst are controlled before they are introduced into the mold. During the entire process, the temperature of the reacting material is monitored and controlled to ensure the heating and cooling cycles are the proper temperature and duration.

Samples of finished acrylic materials are also given periodic laboratory analysis to confirm physical, optical, and chemical properties.

Acrylic plastics manufacturing involves highly toxic substances which require careful storage, handling, and disposal. The polymerization process can result in an explosion if not monitored properly. It also produces toxic fumes. Recent legislation requires that the polymerization process be carried out in a closed environment and that the fumes be cleaned, captured, or otherwise neutralized before discharge to the atmosphere.

Acrylic plastic is not easily recycled. It is considered a group 7 plastic among recycled plastics and is not collected for recycling in most communities. Large pieces can be reformed into other useful objects if they have not suffered too much stress, crazing, or cracking, but this accounts for only a very small portion of the acrylic display case boxes plastic waste. In a landfill, acrylic plastics, like many other plastics, are not readily biodegradable. Some acrylic plastics are highly flammable and must be protected from sources of combustion.

The average annual increase in the rate of consumption of acrylic plastics has been about 10%. A future annual growth rate of about 5% is predicted. Despite the fact that acrylic plastics are one of the oldest plastic materials in use today, they still hold the same advantages of optical clarity and resistance to the outdoor environment that make them the material of choice for many applications.

With so many options for clear plastic on the market, it is no surprise that lots of people misunderstand the differences between the types. Each type is made in a different way using different materials, which results in many different price points. We've put together this resource page to help sort out some of the most frequently asked questions, like "is acrylic a plastic or a glass?" and "what is the difference between acrylic and plastic?". While acrylic is a plastic, not all plastic is acrylic. The term "acrylic" represents a family of petroleum-based thermoplastics made from the derivation of natural gas. Another common name for acrylic is "polyacrylate" which is one of the most common types. This material is made from Methyl Methacrylate (MMA), Poly Methyl Methacrylate, or a combination of both.

Although the composition is pretty much the same, acrylic has many brand names. Plexiglas was the original trademark name when the Rohm and Haas Company first introduced the product to a mass market, but many others have established their own brand names including Lucite by du Pont and Acrylite by Evonik Cyro LLC. Some other common brands are Perspex, Oroglass, Optix, and Altuglass.Injection molded acrylic is manufactured by injecting acrylic or polymethyl methacrylate material into a mold. This transparent thermoplastic makes a great alternative to glass, which is why it is commonly used to manufacture bakery bins, sunglasses, and display risers. Unlike polystyrene, injection molded acrylic table number plate can be made without the issues of hazing or coloration. Additionally the material is much stronger and has minimal relief markings when removed from the mold. Injection molding takes less labor than hand-crafting, which results in a lower cost.

1 note

·

View note

Text

The global commodity plastics market size is projected to grow from USD 468.3 billion in 2020 to USD 596.1 billion by 2025, at a CAGR of 6.0% between 2020 and 2025. The major driving factors of the market include growing packaging industry, increased disposable income generating high demand for consumer goods, growing production of lightweight electric vehicles and increasing metal prices.

Packaging plays a vital role in keeping the product fresh, damage-proof, and acts as an efficient marketing tool. The most common commodity plastics are polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), and poly (methyl methacrylate) (PMMA). Acrylonitrile butadiene styrene (ABS) and polyethylene terephthalate (PET) are also considered commodity plastics. These plastics are increasingly replacing metals due to their high tensile strength, low cost, high availability, and easy processing properties.

The key players in the commodity plastics market are Exxon Mobil (US), LG Chem (South Korea), Sumitomo Chemical (Japan), The Dow Chemical Company (US), SABIC (Saudi Arabia), BASF SE (Germany), LyondellBasell (Netherlands), Sinopec (China), Ineos (Switzerland), Formosa Plastics (Taiwan), Mitsubishi Chemical (Japan), Borealis AG (Austria), Chevron Phillips Chemical (US), ENI SpA (Italy), Reliance Industries (India), Braskem (Brazil), Hanwha Chemical (South Korea), Lotte Chemical (South Korea), Indian Oil (India), Haldia Petrochemicals (India), Nova Chemicals (Canada), Qenos Pty (Australia), Qatar Petroleum (Qatar), Westlake Chemical (US), and PTT Global Chemical (Thailand).

#Commodity Plastics#Commodity Plastics market#COVID 19 Impact on Commodity Plastics market#Global Commodity Plastics market#Commodity Plastics Market Overview#Commodity Plastics Research Report#Commodity Plastics research insights#Commodity Plastics business research report#Commodity Plastics Industry Trends#Commodity Plastics market Share#Commodity Plastics market Analysis#Commodity Plastics market growth#Commodity Plastics Market Growth#Commodity Plastics Market Research#Commodity Plastics Market Revenue

0 notes

Text

Inyoric PMMA Yellow Aspheric intraocular lenses for the cataract surgery of the eye

The Inyoric is a premium PMMA IOL within the range. A UV-blocking polymer called Poly Methyl Methacrylate (PMMA) is used in their construction. These mono-focal, non-foldable Inyoric IOLs consistently provide excellent performance (workhorse like). Surgeons who perform cataract surgery using the conventional SICS technique prefer these IOLs.

The Inyoric IOL is a single piece design with biconvex aspheric optics. Most of the global population can benefit from the aspheric negative optic of Inyoric IOLs. Anteriorly, the optic has a sphere surface, while posteriorly, it has an aspheric negative surface. Inyoric IOLs come in a C Loop design. High quality UV blocking PMMA raw material is used in the manufacture of Inyoric IOLs.

We offer posterior chamber Inyoric IOLs in:

Yellow Aspheric with 360-degree square-edge (Model number 11323).

Inyoric IOLs are available in the optic diameter of 6.0 millimeters and overall diameter of 12.50 millimeters, and they possess two dialing holes. These dialing holes help in positioning of the IOL. The 360 degree square-edge reduces the chances of Posterior Capsule Opacification (PCO).

Our Inyoric IOLs have a refractive index of 1.49 at 20 degree Celsius in a dry state. Their “A-Constant” value is 118.2. Inyoric IOLs have a water content of up to 0.5%.

Being yellow, Inyoric offers better contrast sensitivity.

Diopter range for our Inyoric IOLs:

+5 D to +15 D are available with an increment of 1.0 D (+5, +6, +7 and so on).

+15 D to +27 D are available with an increment of 0.5 D (+15.5, +16, +16.5 and so on).

+27 D to +32 D are available with an increment of 1.0 D (+27, +28, +29 and so on).

Each Inyoric IOL comes packed in an acrylic lens case, which is then sealed in a medical grade pouch.

Our Inyoric IOLs are sterilized using the ETO sterilization process.

Inyoric IOL Market: We cater to the Indian domestic market and also export our PMMA IOLs to other countries.

#oms india#Ophthalmic#ophthalmic equipment#Ophthalmic Marketing And Services#Ophthalmic equipment manufacturing industry#Foldable hydrophilic IOLs#intra ocular lenses#Auto Claving Tray#metal handle#Occuphil IOLs#Occuphil#cannulas#Phaco Tip Wrenches#pva sponge#dental knives#Sharpedge dental knives#Inyoric#Inyoric IOLs#PMMA IOLs#premium IOL#biconvex aspheric optic#high quality imported UV blocking PMMA#posterior chamber Inyoric

0 notes