#Plastic bottle manufacturers in Andhra Pradesh

Explore tagged Tumblr posts

Text

Pet Bottle Scrap Plastic Washing and Recycling Plant in Vijayawada

R Mech Machines LLP is a leading provider of advanced Pet Bottle Scrap Plastic Washing and Recycling Plants in Vijayawada. Our Manufacturing Unit is located in Ahmedabad, Gujarat, India. R Mech Machines LLP PET washing and recycling plants utilize advanced technology to ensure high efficiency in processing plastic waste. The process involves cleaning, sorting, and transforming PET bottles into high-quality, reusable plastic flakes. The recycled plastic flakes produced through our washing and recycling process are of the highest quality, suitable for reuse in the manufacturing of new bottles, packaging, textiles, and other products. R Mech Machines LLP provide tailored solutions based on your capacity, requirements, and budget, ensuring maximum efficiency and profitability. We design our plants to be energy-efficient and cost-effective, helping businesses reduce operational costs while improving production efficiency and output. Why R Mech Machines LLP is Your Ideal Partner in Vijayawada: Proven Expertise: R Mech Machines LLP is committed to providing the best solutions for your PET recycling needs. Our engineers and technical team bring vast expertise to each project. Comprehensive Support: We offer full support from plant design, installation, training, to after-sales service, ensuring smooth operations and long-term success for your business. Affordable Solutions: We price our Pet Bottle Scrap Plastic Washing and Recycling Plants competitively, offering high returns on investment while reducing operational costs. Application: Packaging Industry Textile Industry Construction Consumer Goods R Mech Machines LLP Offers Pet Bottle Scrap Plastic Washing and Recycling Plant in Vijayawada, Andhra Pradesh and including locations Visakhapatnam, Vijayawada, Guntur, Nellore, Kurnool, Kakinada, Rajamahendravaram, Kadapa, Mangalagiri-Tadepalli, Tirupati, Anantapuram, Ongole, Vizianagaram, Eluru, Proddatur, Nandyal, Adoni, Madanapalle, Machilipatnam, Tenali, Chittoor, Hindupur, Srikakulam, Bhimavaram, Tadepalligudem, Guntakal, Dharmavaram, Gudivada, Narasaraopet, Kadiri, Tadipatri, Chilakaluripet. Contact us today for more information or to request a quote. View Product: Click Here Read the full article

#Ahmedabad#AndhraPradesh#Exporter#ExporterofPETBottleScrapPlasticWashingandRecyclingPlant#Gujarat#India#Manufacturer#ManufacturerofPetBottleScrapPlasticWashingandRecyclingPlant#PetBottleScrapPlasticWashing#PetBottleScrapPlasticWashingandRecyclingPlant#PetBottleScrapPlasticWashingandRecyclingPlantExporter#PetBottleScrapPlasticWashingandRecyclingPlantin#PetBottleScrapPlasticWashingandRecyclingPlantinAhmedabad#PetBottleScrapPlasticWashingandRecyclingPlantinGujarat#PetBottleScrapPlasticWashingandRecyclingPlantinIndia#PetBottleScrapPlasticWashingandRecyclingPlantinVijayawada#PetBottleScrapPlasticWashingandRecyclingPlantManufacturer#PetBottleScrapPlasticWashingandRecyclingPlantSupplier#RMechMachinesLLP#RecyclingPlantinVijayawada#Supplier#SupplierofPetBottleScrapPlasticWashingandRecyclingPlant#Vijayawada

0 notes

Text

Double Side Labeling Machine for House Cleaning Product

Shiv Shakti Machtech is a Manufacturer, Exporter and Supplier of Double Side Labeling Machine for House Cleaning Product in Ahmedabad, Gujarat, India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. A Double Side Labeling Machine for house cleaning products is a high-performance, automated system designed to apply labels on both sides of bottles, containers, or any other packaging used in the cleaning product industry. These machines are engineered to handle a wide range of containers and ensure precise, consistent, and high-speed labeling, making them an essential component for packaging lines in the cleaning industry. Other Similar Technology: Double-Sided Labeling Machine, Dual-Side Label Applicator, Front and Back Labeling System, Two-Side Labeler, Double-Side Sticker Labeling Machine, Automatic Two-Side Labeling Machine, Dual-Sided Labeling Equipment, Front and Rear Label Applicator, Double-Faced Labeling Machine, Dual-Panel Labeling System. Features and Specifications: Model Name/Number: SSM-DSL-120 Brand: Shiv Shakti Machtech Usage/Application: Labeling of house cleaning products such as surface cleaners, disinfectants, liquid detergents, glass cleaners, floor cleaners, toilet cleaners, etc. Country of Origin: Made in India Automation Grade: Automatic Electrical Load: 3 KW Control System: HMI (Human-Machine Interface) Dispensing Motor: Servo motor for precise label application Conveyor Height: 850 mm Labeling Speed: 100 labels per minute (depending on label size and container dimensions) Bottle Diameter Capacity: Up to 90 mm Gap Between Two Labels: Maximum 3 mm Direction of Movement: Left to Right Label Roll Diameter: Maximum 3 mm Capacity: Up to 100 bottles per minute (depending on the size and shape of the container) Ideal For: New products only FAQS: Can the machine be used for different bottle sizes? You can easily adjust the Double Side Labeling Machine to accommodate a wide range of bottle sizes, from small bottles to large containers. What type of labels can the machine apply? The machine can handle front and back labels of various types, including paper, plastic, and metallic labels, making it versatile for different packaging designs. Shiv Shakti Machtech is a Supplier of Double Side Labeling Machine for House Cleaning Product in Ahmedabad, Gujarat, India Including Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi, Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune, Rajasthan, Jaipur, Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatna, Hyderabad, Guntur, Chittoor, Kurnool, Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bengaluru, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamil Nadu, Kerala, Kochi, Thiruvananthapuram, Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar, and Chhachhrauli. For more information or to request a quote, please reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Ajmer#Alappuzha#Alwar#Amaravati#Amravati#Amreli#Andheri#AndhraPradesh#Ankleshwar#Asansol#Assam#Aurangabad#Baddi#Ballari#Bangalore#Barshi#Bengaluru#Bharatpur#Bharuch#Bhavnagar#Bhilwara#Bhopal#Bhubaneswar#Bhusawal#Bikaner#Brahmapur#Changodar#Chennai#Chitradurga

0 notes

Text

Supplier of Plastic Recycling Machine in Andhra Pradesh

Adroit Extrusion is a Manufacturer, Exporter, and Supplier of Plastic Recycling Machine in Andhra Pradesh. Adroit Extrusion is an ISO 9001:2015 certified company, in Ahmedabad, Gujarat, India. Blown Film Plant Accessories: Vertical Granule Mixer With Dryer Extrusion Process Control Gusset Board Assembly Trim Recycling Machine Hopper Loader Plastic Granule and Powder Mixer Plastic Recycling Machine Bubble Slit Assembly We excel in crafting cutting-edge machines that convert plastic waste into valuable resources. Our technology boasts advanced features ensuring high yields, low energy consumption, and minimal environmental footprint. From PET bottle recycling lines to HDPE and LDPE processing units, our machines optimize productivity and longevity. We customize our machinery to address Bengaluru's plastic recycling industry needs, adeptly navigating its unique challenges. Driven by innovation, we continuously upgrade our technology to elevate performance and respond to evolving market dynamics. Why Choose Our Plastic Recycling Machines? Advanced Technology: Our machines incorporate advanced technologies for efficient plastic recycling, ensuring high-quality output. Customized Solutions: Tailored to meet diverse recycling needs, our machines offer flexibility and scalability. Environmental Impact: Contribute to sustainability goals by reducing plastic waste and promoting circular economy practices. Comprehensive Support: From installation to maintenance, our dedicated team provides comprehensive support throughout the lifecycle of your machine. Adroit Extrusion is a Supplier of Plastic Recycling Machine in Andhra Pradesh including locations like Visakhapatnam, Vijayawada, Guntur, Nellore, Kurnool, Rajahmundry, Tirupati, Kadapa, Kakinada, Anantapur, Vizianagaram, Eluru, Ongole, Nandyal, Machilipatnam, Adoni, Tenali, Proddatur, Chittoor, Hindupur. For further information, feel free to contact us. View Product: Plastic Recycling Machine Read the full article

0 notes

Text

Post # 124

The economics, humanities and politics of "Sarai"...

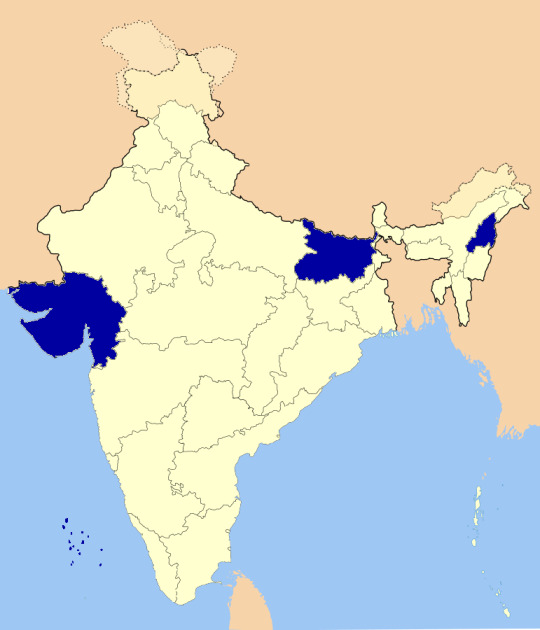

In February, 2014, the Andhra Pradesh Reorganization Bill was passed and Telangana broke away. The resultant state of Andhra now looks like this. :-)

In 2019, state general elections were held in A.P and YSR Congress won hands down. YS Jaganmohan Reddy became Chief Minister and set out to fulfill a unique electoral promise to his vote bank - Prohibition of Liquor in the state of A.P.

The new liquor policy, which includes a 40% reduction in bar licences, exorbitant hike of new license fees, closure of some 40000 illegal outlets, time restrictions and take over of bars by A.P State Beverages Corporation, aims to make Andhra Pradesh alcohol-free by 2024. A.P will then join Gujarat, Bihar, Mizoram, Nagaland and Lakshadweep as states/territories which have successfully implemented liquor prohibition.

But will Jagan be able to make this initiative a success in A.P? Because, this is not the first time such a thing has been tried in Andhra. In 1995, in a strange reversal of roles, Telugu Desam Party won the state elections, crushing Congress, and TDP Chief N T Rama Rao banned the sale of liquor in A.P. In 1995, his son-in-law, N. Chandrababu Naidu, staged a coup-of-sorts, toppled NTR, became Chief Minister and in 1997, reversed the decision.

But what was all that drama back then in 1990s? Therein lies a tale.

First of all, let's understand the economics of Liquor production and sale. Why is the state government so interested in it? It's very simple. Liquor fills the state government's revenue coffers in form of excise duty on its production. The state government also makes money from the issuance of licenses for its sale. Liquor boosts tourism and entertainment industries too.

The A.P state government discovered this golden hen sometime in the 1970s and since then, liquor has become a state policy. In 1970, the excise duty collected from liquor was INR 40 crores, which jumped to INR 800 crores in early 1990s and quantum leaped to INR 12000 crores in 2015. That's big money coming into the state revenue coffers.

In 1983, when NT Rama Rao came to power for the first time, he introduced a particularly aggressive liquor policy called Varuna Vahini (literally meaning Flood of Liquor), which delivered government-manufactured country liquor - Sarai, in Telugu, Arrack in English - to doorsteps, in easily affordable plastic sachets and bottles. He used some of this revenue to subsidise other populist schemes, like Rs 2 per kilo rice scheme.

Andhra Pradesh typically constitutes about 3-5% of sales of major liquor manufacturers like United Breweries and United Spirits. So, they usually have a word or two to say in this regard.

Oh! By the way, liquor contractors make a truck load of money too, which they invest in real estate, films, finance and construction projects, and make donations to cultural and religious institutions, thus strengthening their socio-political clout.

So, net-net, liquor manufacturing and sale is a well-oiled economic engine for any state, especially for Andhra Pradesh.

Now, let's understand the human aspects of state-promoted liquor sales.

I read a report that said, in 1991-92, the average annual income of a family in Andhra was, hold your breath, INR 1840. This was the total family income, for the entire year!

Out of this, the working male spent INR 830 on liquor. So, the man of the house spent 45% of his measly income on Sarai - Arrack. It was the norm. Every man, in every house, did it. And the government promoted it, supported it and benefited from it.

The logic was - the poor man had spent a miserable day, doing a miserable job, for a miserable pay. So it's ok, if he drowns his misery in a drink after sunset. Hmm. The problem was - the miserable man had a family - a wife, who slogged all day to make ends meet and feed her children. And god forbid, if there was an illness in the family, begging was the only way out.

On top of it, any body who has had a drink in their life knows, liquor is ok as a socializing drink. But it doesn't alleviate a man's misery. Infact, it compounds it.

This foul smelling man, in his foul mood, came home at midnight, in stupor, and sparks flew. Domestic violence, physical and mental abuse, were rampant. Suicides, rapes and murders were common.

Net-net, life in a village in Andhra Pradesh, which had a government-promoted arrack shop, was living hell, especially for the women folk. And because Arrack sale filled government coffers, there was an Arrack shop in every village. So life, in pretty much every village in Andhra Pradesh, was living hell for its women folk.

All of this was indicating an impending change. And change happened - in form of a massive, state level, Anti-Arrack movement, led by the women folk of Andhra Pradesh, which resulted in the prohibition of alcohol in the state!

In 1988, the Government of India launched the National Literacy Mission (NLM). In January 1990, the NLM was launched in Nellore district in Andhra Pradesh. The state-organised mass-literacy campaigns led to women getting together and discussing their problems. The awareness brought on by these group discussions resulted in the women discovering that the consumption of locally made, cheap Arrack was the main source of their unsettled domestic life. This awareness resulted in a spontaneous movement in the small village of Dubagunta in Nellore district of Andhra Pradesh.

The rural women of the village, who had no autonomy in any sphere of life, took it in their hands to fight against the production and sale of Arrack. They raided the Arrack shops with broomsticks and chili powder and cowered the owner into shutting the shop.

What started as an agitation in a single village, soon turned into a state-wide movement. In each village, women simply destroyed the ingredients used for the production of liquor. They also started policing the men in their individual households against consuming Arrack.

They then started speaking against the liquor contractors, local bureaucracy, police officials and even the Chief Minister. They started questioning the government on the availability of basic amenities like water, schools etc, which were in a dearth, as opposed to Arrack, which was always easily available. When the government insisted that the excise collected from the production of Arrack was used for welfare programmes, like the subsidy of rice, the women even agreed to contribute a day’s wages to help in the welfare schemes.

For them, it was clear. The cost-benefit equation of government-promoted liquor policies on human indices simply didn't match up to the economics. They put their foot down. Finally, when the movement had gained momentum in three districts, the government had to buckle under the pressure and ban Arrack in the state.

Now, let's go to the politics of the matter. Where there is a people's movement, there will be politics. And political parties.

It was 1994 - the election year in A.P. NT Rama Rao of TDP, the main opposition party, promised his electorate that, if they elected him to power, he would ban all forms of alcohol from the state (Toddy and IMFL - Indian made foreign liquor - were still available.) Ironically, it was his Varuna Vahini programme that was responsible for this situation. But, it was a powerful promise. So, he won a landslide election, came to power, and fulfilled his promise.

In 1995, Andhra Pradesh became alcohol free!

But this situation was shortlived. Within 9 months, NTR's son-in-law, N Chandrababu Naidu, staged a coup against his father-in-law, stating excessive interference of his second wife Parvathy Laxmi, in the party politics. Both NTR and Parvathy Laxmi were ousted from the party.

In 1997, Chandrababu Naidu, repealed the prohibition, stating that the exchequer has lost INR 1200 crores that year in excise revenue, illegal bootlegging had become unstoppable and that he was under pressure from all quarters to repeal the "dry rule." A few hushed and a few not-so-hushed voices say that there was no intent in the first place.

That's why there is some scepticism about Jaganmohan Reddy's latest initiative. Is there political will?

Post Script::

In 2016, 93 year old Dubagunta Rosamma, one of the early Anti-Arrack crusaders passed away, in Nellore.

Inspired by the story Seethamma kadha (the story of Seethamma) taught as part of the adult literacy programme in the night school in her village, the women of Dubagunta, led by Rosamma, destroyed the pots storing Arrack, after giving assurance to the families depending on the trade, thus sparking the first light of what would soon become a state-level agitation.

May this post be a small tribute to her!

4 notes

·

View notes

Text

Cap or Tap? - Bottled Water vs Tap Water

Water is covered two-third of the earth’s surface and the human body consists of 75 percent of it. Bottled water is no better than tap water, and it’s not any healthier for you. Purity, cost and environmental impact that you must consider before deciding between bottled water and tap water. Bottled water is more expensive than tap water, it also uses many more resources to package, ship and disposes of when the bottles become empty.

Tap water:

Many people argue that the overall quality of water is not good and cannot drink straight from the tap. But actually, it is possible to convert the same source of water into a clean and pure tasting. Here, water is delivered through a system of pipes, pumps and other purification systems to home and building in the developing world.

Bottled water:

Water has gone through a purification process and is then bottled and distributed through retail stores. While using bottled water you must aware of the purity of water inside the bottle and disadvantage of constantly purchasing cap of bottled water. The bottled water is mainly consumed by offices and residences in most of the areas.

Why bottled water become popular?

Bottled water becomes more and more popular over the last few decades. Today making bottled water is nearly as popular as carbonated soft drinks. Bottled water doesn’t have any calories, no sugar, and no artificial sweeteners. Sometimes it will be the reason for choosing bottled water by most of the consumers. Bottled water is always different in taste, health, convenience, fashion, etc.

The bottled water has a healthy and pure image within the customers. While tap water is stored inside reservoirs and it can be carried into homes or offices.

Bottled water vs Tap water

We cannot say bottled water is more accurate than tap water. In most of the places, tap water is safe as bottled water. The bottled water and tap water is always varied with cost, taste, safety, sustainability.

Bottled water is typically safer than tap water, more than half of all bottled water comes from tap water.

Currently, water bottles are a major source of pollution

Usages of reusable bottles are an easy way to save money and help the environment.

The bottled water contains chlorine but tap water doesn’t.

The bottled water sometimes contains added minerals or flavors. The tap water uses various types of natural but relatively harmless contaminants.

If you are building tap water you won’t worry about the below-mentioned inconvenience that occurred due to bottled water.

Running out of water

Lifting those heavy bottles

Difficult to find a place to store

Interruption of the busy workday for water delivery

Is the tap water is safe:

We can say that tap water is not “safer” than tap water. The tap water is tested more frequently than bottled water. If the tap water tastes bad, doesn’t necessarily mean that it is unhealthy or contaminated. The taste may be resulting from chlorination or the mineral content in the water. The filter can be used to keep water tasting great. It is much less expensive than bottled water.

Conclusion:

Sometimes bottled water is thought to be a necessity to get clean, purified, water at home and office. By using your purified tap water instead of bottled water you contribute to being eco- friendly and save your money.

Smart packaging is one of the well-known Plastic BottleManufacturers popular in the field of plastic containers, bottles, PET bottles, etc. Their team is established with a focus on promoting a wide variety of innovative and cost-effective plastic bottles using high-quality polymers.

As a market leader in the plastic bottle industry, smart packaging provides a product such as Flip Top Cap Bottles, Spray Bottles, Chemical Plastic Bottles, Oil Bottles, Tablet Bottles, Dish Wash BottlesPlastic, etc.

For more details please visit:

www.smartpackaging.co.in

PLASTIC BOTTLE MANUFACTURERS

PLASTIC BOTTLE MANUFACTURERS IN KARNATAKA

PLASTIC BOTTLE MANUFACTURERS IN KERALA

PLASTIC BOTTLE MANUFACTURERS IN TAMILNADU

#PLASTIC BOTTLE MANUFACTURERS#plastic bottle manufacturers in Karnataka#plastic bottle manufacturers in tamilnadu#plastic bottle manufacturers in kerala#Plastic bottle manufacturers in Andhra Pradesh

0 notes

Photo

Overview: Mold-Tek Packaging limited (MTPL) operates in Plastics sector.It is a Small Cap company with a market capital of Rs 714.53 Crore. About the company: Mold-Tek Packaging limited was established at Hyderabad, Andhra Pradesh and became a publicly listed enterprise 1993. MTPL is engaged in the manufacturing of Plastic Packaging Products such as Containers for Pharma & Cosmetics, Child Resistant Caps & Bottles, Pharma Pack Pouches and Blow moulded shampoo and medicine packs. MTPL also specializes in standard and made-to-order packaging solutions for leading brands of Paints, Lubricants, Pharmaceuticals, Cosmetics and FMCGs etc. With 25% market share, Mold-Tek Packaging Limited is the leader in rigid plastic packaging in India... Read more with recommendation login website largecapindia.co.in (at India) https://www.instagram.com/p/CHZyX5CHgCn/?igshid=peayltj9wouo

0 notes

Text

Vizag gas leak: LG Chem plant operated with state permits since 1997 despite lacking environmental clearance from Centre

New Delhi: A plastic factory in India where a chemical gas leak killed 12 people and sickened hundreds more last week lacked federal environmental clearance but had been issued state permits to operate anyway, exposing a potentially dangerous enforcement gap in the country's laws.

The owner of the LG Polymers plant in Andhra Pradesh state, South Korean chemicals giant LG Chem, said in a May 2019 affidavit that formed part of an application for the clearance that the company “doesn’t have a valid environmental clearance substantiating the produced quantity, issued by the competent authority, for continuing operations.”

LG Chem spokesman Choi Sang-kyu told The Associated Press that the company had always followed Indian law and had operated the plant based on the guidance of Indian officials, both at the state and federal level. He said the affidavit was a pledge to comply with the law in the future and not an admission of any violations.

Interviews with officials and legal experts indicate that the plant was likely operating in a legal grey area, with the environmental clearance required under federal regulations but the enforcement of those requirements left up to states. While there has been no indication that the lack of such a clearance played a role in the 7 May disaster, experts say the fact that the plant operated for years without one shows how weak environmental laws can be in a nation with many of the world's most polluted cities.

“There are many such industries operating without an EC," environmental lawyer Mahesh Chandra Mehta said, adding that it showed authorities were “toothless.”

LG Polymers is facing charges following the disaster, which involved styrene gas, a neurotoxin, leaking from a storage tank as workers prepared to restart operations idled during India’s coronavirus lockdown. In addition to the dead, more than 1,000 people were sent to hospitals.

Police have charged LG Polymers with culpable homicide, including negligence in handling toxic substances. lndia’s top environmental court has also asked the company to pay a $6.6 million penalty because of “damage to life, public health and environment.”

The court is also considering a plea filed by an environmental activist and former federal bureaucrat that raises questions about how state authorities allowed the company to function without federal clearance.

Choi said the company couldn’t comment on an ongoing investigation but would cooperate with Indian authorities.

LG Chem bought the plant in 1997 and between then and 2006 it is clear that it needed only state permits to operate, which it had.

Things get murkier after that, however, due to new federal rules that came into force requiring companies in industries including petrochemicals to obtain a federal environmental clearance every time they expanded a plant or changed what they manufactured.

LG Chem expanded its operations at LG Polymers plant five times between 2006 and 2018, but it never received an environmental clearance, according to the May 2019 affidavit.

Choi said when the federal rules changed in 2006, the company consulted with the ministry and was told that no environmental clearance was required. “We have been operating the company while abiding environmental regulations even before the laws on environment clearances were made,” Choi said.

Environment Secretary CK Mishra told the AP that LG Polymers would not have needed a clearance in 2006, but would have had to apply for environmental clearances going forward to change what they were making or expand capacity.

LG Polymers appears to have never been asked for a federal clearance until 2017, when it approached the Andhra Pradesh Pollution Control Board with plans to start producing engineering plastics at its plant, according to meeting minutes reviewed by AP.

The request was denied and the company was told it would need the federal clearance.

There are no indications, however, that the state told the company to stop operating the plant. T Rajendra Reddy, a member of the state pollution board, said he “had no information” about any such order.

In 2018, when LG Polymers wanted to expand its manufacturing capacity of polystyrene, a plastic used to make bottles and lids, the company finally applied for its first environmental clearance, documents show. The Environment Ministry flagged the application for review, noting that the company didn’t have a clearance for the chemicals it was already manufacturing.

LG Polymers then withdrew the application and instead applied for a retroactive clearance that the Environment Ministry offered companies in 2018 as a one-time amnesty. That application remained pending when the deadly leak occurred.

“While we were not required to retroactively apply for an EC, we did apply for the EC under the central government policies and the application is currently under review,” Choi said.

Choi said each of the times the company expanded the plant it did so under approval granted by its state permits.

State authorities issue two permits in India -- the first to start a new business and another to run it -- that are required for all industries that could potentially pollute the air or water. The operational permits are renewed every five years.

Mehta, the environmental lawyer, said that each time LG Polymers renewed that permit, the state pollution board, the authority charged with enforcing federal environmental law, had the power to fine the company or deny it a permit until it received federal clearance.

It never did so.

Asked why the state kept renewing the plant's permits despite it not having the federal environmental clearance, Vivek Yadav, the state board’s second-in-command, told AP they were “examining the issue in detail.”

Compared with state permits, the federal environmental clearance takes a broader approach: assessing the potential impact of the project on people, their livelihoods and the environment while ensuring that precautions are built in to prevent accidents.

B Sengupta, the former head of India’s top anti-pollution agency, said that the state permits only consider pollution, not safety. The federal clearance “looks at those risks, how hazardous materials are being handled and stored, what plans are there to prevent and deal with disasters,” he said.

via Blogger https://ift.tt/3dHGEtS

0 notes

Text

Pharmaceutical injection tablets and capsules | Aster Pharma

Aster Pharma is one of the top 10 PCD pharma franchise companies offering a wide range of pharmaceutical injection, tablets, capsules and health supplements.

They offer PCD Pharma franchise of injections, critical care products, Pharmaceutical tablets, and capsules. Visit the website if you are looking for pharmaceutical manufacture or third party manufacturing of pharmaceutical injectable. Pharma injections are designed for the healthcare of people. We are the best Pharma Company in India as our manufacturers provide quality pharmaceutical injection. The Pharmaceutical Injections that we manufacture are prepared carefully in the controlled conditions in our laboratories. We are one of the well-known manufacturer, supplier, and exporter of Pharmaceutical Injections. We are wholesale Trader of Pharmaceutical Injections — Piperacillin & Tazobactam Injection, Meropenem 500 Mg/250mg/1mg Injection, and Anti Malaria Injection. Aster Pharma is a manufacturer of Pharmaceutical Tablets and Capsules. Paracetamol Tablet, Vitamin, and Mineral Capsule are offered by Aster Pharma, Panchkula/Chandigarh, and India. The pharmaceutical industry can be divided into the bulk drug and formulations segments. We are very much into the drug formulation segment. Aster Pharma is a Manufacturer, Distributor, Supplier, Trading Company of Pharmaceutical Tablets, and Capsules in India. Pharmaceutical Tablet and Capsule range are available for franchise business. Aster Pharma is known as top Formulation Pharma Companies in Panchkula/Chandigarh, India as a leading Manufacturer of Tablets & Capsules in India.

We are supplying pharmaceutical injection tablets and capsules in Chandigarh | Bihar | UP | Telangana | Kerala | Andhra Pradesh | Karnataka | Tamilnadu | Odisha | West Bengal and other states of India. Aster Pharma is offering pharmaceutical injection tablets and capsules In Maharashtra | Gujarat | Rajasthan | Madhya Pradesh |Punjab| Jammu, and Kashmir | Jharkhand | Chhattisgarh | Assam | Uttarakhand | Tripura | Puducherry | Mizoram, and Manipur. Find below the brand name of the medicine, drug brand name, price of the medicine, and list of pharmaceutical products manufactured by Aster Pharma.

INJECTABLES

S.NO. PRODUCT NAME COMPOSITION SIZE PACKING MRP

1 ASMIKA-100 Amikacin 100mg Injection 2ml Vial 35

2 ASMIKA-250 Amikacin 250mg Injection 2ml Vial 48

3 ASMIKA-500 Amikacin 500mg Injection 2ml Vial 90

4 ASCLAV-1.200MG Amoxycillin 1gm + Potassium Clavulanate 200mg Single vial 132

5 ASUNATE-60MG Artesunate 60mg Single vial 222.12

6 ASZONE-1GM Cefoperazone 500mg + Sulbactum 500 mg Injection vial vial 295

7 ASZONE-1.5GM Cefoperozone 1000 mg + Sulbactum 500 mg Injection vial vail 375

8 TRAZIM-TM-1.125MG Ceftazidime-1gm + Tazobactam 125mg Single vial 480

9 TRAZIM 1GM Ceftazidime-1gm inj. Single vial 290

10 CEFASTER-1 GM Ceftriaxone 1000mg Injection Single Vial 56.5

11 CEFASTER-S 1.5GM Ceftriaxone 1gm + Sulbactun 500mg Injection Single Vial 110

12 CEFASTER-T 1.125GM Ceftriaxone 1gm + Tazobactum 125mg Injection Single Vial 126

13 ASIME -1.5 Cefuroxime 1500mg Single vial 340

14 ASCOLIN -2ML Citicoline 250mg/2ml inj. Single amp 215

15 ASCOLIN -4ML Citicoline 500mg/4ml inj. Single vial 340

15 ASCALI- 500 MG Clarithromycin 500mg Injection Single vial 955

16 ASCLIN -4ML Clindamycin 600 mg inj. Single amp 340

17 ASDEC-75 INJ Diclofenac Sodium 75mg Injection 5x1 1ml amp 14.5

18 ASCORTISONE 100 MG Hydrocortisone Sodium Succinate Injection IP Single vial 38

19 ASLASTIM -1GM Imipenem 500mg+ Cliastatin 500mg Single vial 2100

20 ASCROS -2.5ML Iron Sucrose 2.5ml Single amp 230

21 ASCROS -5ML Iron Sucrose 5ml Single amp 260

22 EPILEVET -5ML Levetiracetam 5ml Single vial 172

23 ASPINEM-1GM Meropenem -1000mg Single vial 2800

24 ASPINEM-500GM Meropenem -500mg Single vial 1250

25 ASTHIN-10ml L-Ornithine L-Aspartate Infusion Single vial 318

26 MIRAJ PLUS Methylcobalamin, Vitamin B6 & Niacinamide Injection 2ml Dispo 65

27 ADSOLE -40MG Methylprednisolone Sodium Succinate 40mg Inj Single vial 178

28 ADSOLE -125MG Methylprednisolone Sodium Succinate 125mg Inj Single vial 228.44

29 ADSOLE -500MG Methylprednisolone Sodium Succinate 500mg Inj Single vial 675

30 ADSOLE -1 GM Methylprednisolone Sodium Succinate 1 gm Inj Single vial 1075

31 ASCOJA -1500 MG Mecobalamin 1500mcg Injection with syringe 2ml Dispo 55

32 ASCOJA -2500 MG Mecobalamin 2500mcg Injection with syringe Dispo 120

33 ASDECA-25 Nandrolone Decanoate 25mg Injection Single Amp 80

34 ASDECA-50 Nandrolone Decanoate 50mg Injection Single Amp 130

35 ASAMOL -100ML Paracetamol Iv 100Ml Single

36 ASPEN-40 MG Pantoprazole 40mg Injection Single Vial 46

37 ASPIPTAZO-1.125GM Piperacillin 1gm +Tazobactum 0.12mg Injection Single vial 220

38 ASPIPTAZO-2.25GM Piperacillin 2gm +Tazobactum 0.25mg Injection Single vial 430

39 ASPIPTAZO-4.54GM Piperacillin 4gm +Tazobactum 500mg Injection Single Vial 461

40 ASPIRA 15ML Piracetam 15ml Single vial 160

41 ASPIRA 60ML Piracetam 60ml Single vial 465

42 ASPIROX -2ML Piroxicam 2ml Single amp 18

43 ASIZOLE-20MG Rabeprazole 20mg inj. Single vial 130

44 ASANEX -5ML Tranexamic Acid 5ml Single amp 78.5

TABLETS

S.NO. PRODUCT NAME COMPOSITION SIZE PACKING MRP

45 ASNAC-SP Aceclofenac 100mg + Paracetamol 325mg + Serratiopeptidase 15mg 10*10 Alu/Alu 720

46 ASNAC Aceclofenac 100mg + Paracetamol 325 mg 10*10 Alu/Alu 320

47 ASNAC-CL Aceclofenac 100mg + Paracetamol 325mg +Chlorzoxazone 250mg 10*10 Alu/Alu 750

48 ASNAC-A Aceclofenac 200mg Sustained Release 10*10 Alu/Alu 650

49 ASCLAV Amoxycillin 500mg + Potassium Clavulanate 125mg 10*6 Alu/Alu 1015.4

50 ASZITH-250 Azithromycin 250mg 10*6 Blister 600

51 ASZITH-500 Azithromycin 500mg 10*3 Blister 600

52 ASCAL-D3 Calcium Carbonate 500mg + Vitamine D3 250 i.u. 10*15 Blister 650

53 AXIME-200 Cefixime 200mg tab 10*10 Alu/Alu 920

54 AXIME Cefixime 50mg Dispersible 10*10 Alu/Alu 485

55 ASDEC-P Diclofenac Potassium 50 mg +Paracetamol 325 mg 20*10 Blister 250

56 ASDEC-PC Diclofenac potassium 50mg+Paracetamol 325 mg + Chlorzoxazone 250mg 10*10 Alu/Alu 700

57 ASDEC-SP Diclofenac Potassium 50mg+Paracetamol 325 mg + Serratiopeptidase 10mg 10*10 Blister 760

58 ANAZOLE Fluconazole 150 mg 5*6 Blister 230

59 ASURE XT Ferrous Ascorbate 100 mg, Folic Acid 1.5 Mg & Zinc 22.5 mg 10*10 Alu/Alu 950

60 EPILEVET 250 Levetiracetam - 250mg 10*10 Alu/Alu 600

61 EPILEVET 500 Levetiracetam - 500mg 10*10 Alu/Alu 1200

62 ASLEVAST Montelukast Sodium 10mg + Levocetirizine 5mg 10*10 Alu/Alu 960

63 ASNIM Nimesulide 100mg + Paracetamol 325mg 10*10 Blister 320

64 ASTIN Nitrazepam 10 mg 10*10 Blister 430

65 ASLOXA-200 Ofloxacin 200mg 10*10 Alu/Alu 560

66 ASLOXA-OD Ofloxacin 200mg + Ornidazole 500mg 10*10 Alu/Alu 750

67 ASPENTA-40 Pantoprazole 40mg 10*10 Alu/Alu 550

68 ASPENTA-D Pantoprazole 40mg + Domperidone 10mg 10*10 Alu/Alu 580

69 ASCOLD-CP Paracetamol, phenylephrine HCL ,caffeine &Diphenhydramine HCL tablets 10*10 Blister 550

70 PENTOLOX_CT Pantoprazole 40mg + Clintapride 3 mg SR Capsules 10*10 Alu/Alu 1190

71 ASIZOLE 20 Rabeprazole 20 mg 10*10 Alu/Alu 460

72 AXIME - O Cefixime 200mg + Ofloxacin 200mg 10*10 Alu/Alu 1750

73 ASIZOLE-D Rabeprazole 20 mg + Domperidone 10 mg 10*10 Alu/Alu 750

SOFT GEL CAPSULES

74 ASCOJA OD Methylcobamin with vitamins,Alpha Lipoic Acid & Folic Acid Capsules 10*10 Blister 1580

75 ASMEGA omega 3,6,9 fatty acids soft gelatin Capsule 10*10 Blister 2500

76 BONEMEL-CT Calcitriol 0.25mg+Calcium Carbonate 500mg + Zinc Sulphate7.5mg Softgel 10*10 Blister 1300

75 ASCOD-E Vitamin E & Cod Liver Oil 10*10 Blister 2500

CAPSULES

76 ASPRA-OD Omeprazole capsules 20mg+Domperidone10mg 10*10 Alu/Alu 450

77 ASGEN Ginseng, Multivitamin, Multimineral, Antioxidants with Lactic acid Bacillus Capsules 10*10 Alu/Alu 850

78 ASPENTA-DSR Pantoprazole 40mg + Domperidone 30mgSR 10*10 Alu/Alu 860

79 ASIZOLE-DSR Rabeprazole 20 mg + Domperidone 30mgSR 10*10 Alu/Alu 760

SYRUPS

80 ASOVIT Multivitamins + Multiminerals Syrup 200ml Pet bottle 98

81 JOYVIT Multivitamins + Multiminerals + Antioxidant B complex Syrup with monocarton 200ml Pet bottle 87

82 ASKOFF-A Ambroxol 15 mg , Guaiphenesin 50 mg, Salbutamol 1 mg & Menthol 1 Mg Syrup 100ml Pet bottle 58

83 ASCRAN Cranberry, D- Mannose & Potassium Magnesium Citrate Syrup 200ml Syrup 250

84 ASTHIN "L-Ornithine L-Aspartate Nicotinamide Plus Riboflavin

Syrup" 200ml Syrup 300

85 ASKOFF-D "Dextromethorphan 10mg+Chlorpheniramine 4mg+

Menthol 2.5mg Syrup" 100 ml Pet bottle 60

86 ASCOSET Lycopene, Multivitamin & Multimineral Syrup 200ml Syrup 170

87 ASPRO-L Protein Hydrolysate + Niacinamide + Iron chollhe citrate + Manganese Chloride + Zinc Sulphate + L Lysine HCl Syrup 201 ml Syrup 198

88 DIZASTO Fungal Diastase & Pepsin Syrup 200 ml Syrup 99

DENTAL PRODUCT

89 AXINE Cholohexadine mouth wash 100 ml Pet bottle 64

SUPPLIMENTS

90 ASPROD Protein Powder DHA - Chocolate Flavor 200 grm Plastic Tin 400

NEW PRODUCT

S.NO. PRODUCT NAME COMPOSITION SIZE PACKING MRP

91 ANCOMYCIN 1GM Vancomycin Hydrochloride for inj usp Single Vail 150

92 ASAMOL Paracetamol 100ml inj Single Vail 210

EYES DROP

94 BROADMOXI-D Moxifloxacin & Dexamethasone Eye Drop 5ml Drop 110

0 notes

Text

Daily Current Affairs Dated On 22-Aug-2019

Daily Current Affairs Dated On 22-Aug-2019 GS-1 Fossil find in kutch Why in news? The hot arid desert of Kutch was once a humid sub-tropical forest with a variety of birds, freshwater fish and possibly giraffes and rhinos, a team of Indian and French researchers has said. Their conclusions are based on the discovery of a tranche of vertebrate fossils from nearly 14 million years ago in a geological time period known as the Miocene. After the discovery, they took nearly 12 years for analysis. Details The fossils, consisting mostly of ribs, and parts of teeth and bones, were unearthed from Palasava village of Rapar taluk in Kutch, Gujarat. Overall, the fossil finds from Palasava suggest that a rich diversity of fauna and flora sustained in warm, humid/wet, tropical to sub-tropical environmental conditions during the Middle Miocene (about 14 Mya). The bulk of fossils unearthed in Kutch have so far been mainly marine organisms, due to their proximity to the Arabian Sea. Geological changes eventually closed off the salt-flats’ connection to the sea and the region turned into a large lake, eventually becoming salty wetlands. The findings point to clues on how mammals dispersed between Africa and the Indian subcontinent when part of India was in the Gondwanaland supercontinent that existed nearly 300 million years ago. Palaeontologist G.V.R. Prasad of Delhi University said that the finds were significant because they showed Kutch to be a potential treasure trove of mammal fossils with possible continuity to vertebrate fossils in the Siwalik, spanning Pakistan to Nepal. Daily Current Affairs Dated On 22-Aug-2019 GS-2 Oxytocin ban Why in news? The final decision on whether the government can block private pharmaceutical companies from manufacturing and selling vital pregnancy drug oxytocin in India has been deferred, with the Supreme Court deciding the issue needs further deliberation. While the apex court, hearing the government's appeal on the issue for several months, was expected to pronounce its judgment on the issue on August 22, a bench comprising Justices Abhay Manohar Sapre and Indu Malhotra has instead formulated seven “points” for consideration by a larger bench. What is oxytocin? Oxytocin, also known as the 'love hormone', is a hormone secreted by the pituitary glands of mammals during sex, childbirth, lactation or social bonding. However, it can also be chemically manufactured and is sold by pharma companies for use during childbirth. It is administered either as an injection or a nasal solution. Why is it vital? Oxytocin helps contract the uterus and induce delivery, control bleeding, and promote the release of breast milk. Its use is especially crucial to prevent new mothers from excessively bleeding after giving birth— a common cause of maternal deaths. According to an India sample registration scheme survey conducted in 2001-2003, postpartum hemorrhage accounted for 38 per cent of maternal deaths. Daily Current Affairs Dated On 22-Aug-2019 What is the case? The health ministry in April 2018 notified a ban on private firms from manufacturing and selling oxytocin, stating that it wanted to restrict the responsibility of supplying the drug to a Karnataka-based public sector manufacturer to avoid its misuse in the veterinary field. Following a case by drug makers like Mylan and Neon Laboratories and patient activist group All India Drug Action Network (AIDAN), the Delhi High Court in December quashed the ban on various grounds, including that it lacked scientific basis. The government has appealed the decision at the Supreme Court, arguing that the Karnataka PSU, Karnataka Antibiotics and Pharmaceuticals Ltd (KAPL), has built up the capacity to manufacture and supply the required quantity of the drug here. What happens now? The government and other parties in the case will have to place their arguments in front of the new bench on the seven points that the two judges have listed. These points are yet to be made public, as the court's latest order on this matter is not available yet. One nation one card Why in news? Last Friday, the government launched the pilot project for the inter-state portability of ration cards between Telangana and Andhra Pradesh, and between Maharashtra and Gujarat, as part of its 'One Nation, One Ration Card' scheme. Daily Current Affairs Dated On 22-Aug-2019 What is a ration card? A ration card is issued to the head of the family, depending on the number of members in a family and the financial status of the applicant. It is used by households to get essential food grains at subsidised prices from designated ration shops (also called fair price shops) under the Targeted Public Distribution System (TPDS). Over the years, different types of ration cards were issued depending on the level of deprivation. Later, in 2013, when the National Food Security Bill was passed, different ration cards were compressed to just two -- priority and Antyodaya (for the most poor). The responsibility of identifying eligible families and issuing ration cards to them rests with the state/UT government. What is a ration shop? Ration shops can be privately owned or owned by cooperative societies or by the government. Ownership licenses are issued by the concerned state government. Presently, commodities including wheat, sugar, rice and kerosene are being allocated as part of the TPDS. State governments have the discretion to provide additional commodities. What is the 'One Nation, One Ration card' scheme? Since ration cards are issued by state governments, this implied that beneficiaries could procure food grains only from the designated ration shops within the concerned state. If a beneficiary were to shift to another state, he/she would need to apply for a new ration card in the second state. There were other complications. For instance, after marriage, a woman needed to get her name removed from the ration card issued to her parents, and get it added to the ration card issued to her husband's family. The ONORC scheme attempts to address this gap in TPDS delivery. Essentially, the scheme has been launched keeping in mind the internal migration of our country, since people keep moving to different states in search of better job opportunities and higher standards of living. As per Census 2011, 4.1 crore people were inter-state migrants and 1.4 crore people migrated (inter and intra-state) for employment. Daily Current Affairs Dated On 22-Aug-2019 Benefits With the ONORC scheme being implemented in Telangana and Andhra Pradesh, the beneficiary can buy food grains from ration shops located in either of the states. The same is the case with Maharashtra and Gujarat. The government hopes to implement the scheme across India by June 1, 2020. GS-3 Illegal trade off tiger parts Why in news? While the latest census has put India’s tiger population at 2,967, the Traffic report uses the 2016 WWF estimate of 2,226, with India home to more than 56% of the global wild tiger population. A new report has quantified the illegal global trade in tigers and tiger parts over a 19-year period between 2000 and 2018. India has the world’s largest tiger population — 2,967 in the Tiger Census released last month — and the highest extent of tiger trade also happens in the country. About the report The new report has been compiled by Traffic, a NGO working in conservation and currently in partnership with the World Wildlife Fund (WWF) and the International Union for Conservation of Nature, according to the Traffic website. What it found, how? Overall, a conservative estimate of 2,359 tigers were seized from 2000 to 2018 across 32 countries and territories globally. These occurred from a total of 1,142 seizure incidents, the report said. Apart from live tigers and whole carcasses, tiger parts were seized in various forms such as skin, bones or claws. The report explains how the number of tigers was estimated from these diverse sets of seizures. Daily Current Affairs Dated On 22-Aug-2019 On average, 60 seizures were recorded annually, accounting for almost 124 tigers seized each year. The top three countries with the highest number of seizure incidents were India (463 or 40.5% of total seizures) and China (126 or 11.0%), closely followed by Indonesia (119 or 10.5%). The India findings While the latest census has put India’s tiger population at 2,967, the Traffic report uses the 2016 WWF estimate of 2,226, with India home to more than 56% of the global wild tiger population. India is the country with the highest number of seizure incidents (463, or 40% of all seizures) as well as tigers seized (625). In terms of various body parts seized, India had the highest share among countries for tiger skins (38%), bones (28%) and claws and teeth (42%). Microplastics Why in news? In its first report into the effects of microplastics on human health, WHO looked into the specific impact of microplastics in tap and bottled water. The World Health Organization (WHO) on Thursday said the level of microplastics in drinking-water is not yet dangerous for humans but called for more research into potential future risk. What are microplastics? Microplastics are very small pieces of plastic that pollute the environment. Microplastics are not a specific kind of plastic, but rather any type of plastic fragment that is less than 5 mm in length according to the U.S. National Oceanic and Atmospheric Administration (NOAA). They enter natural ecosystems from a variety of sources, including cosmetics, clothing, and industrial processes. Daily Current Affairs Dated On 22-Aug-2019 Salient points of report In its first report into the effects of microplastics on human health, WHO looked into the specific impact of microplastics in tap and bottled water. “The headline messages to reassure drinking water consumers around the world, that based on this assessment, our assessment of the risk is that it's low. WHO said that data on the presence of microplastics in drinking water is currently limited, with few reliable studies, making it difficult to analyse the results. The organisation has called on researchers to conduct a more in-depth evaluation into microplastics and the potential impact on human health. It has also urged a crackdown in plastic pollution to benefit the environment and reduce human exposure to microplastics. The report said that irrespective of human health risks caused by microplastics in drinking-water “measures should be taken by policymakers and the public to better manage plastics and reduce the use of plastics where possible”. WHO said that microplastics larger than 150 micrometres are not likely to be absorbed by the human body but said the chance of absorbing very small microplastic particles, including nanosized plastics, could be higher, although it said data is limited. Future issue and way ahead The report warns of other dangers ahead: if plastic emissions in the environment continue at the current rate, microplastics could present widespread risks for aquatic ecosystems in a century, which could in turn increase human exposure. Experts recommend wastewater treatment, which can remove more than 90% of microplastics in water by using treatments such as filtration. WHO said those measures would have a double advantage as it would also address the problem of faecally contaminated water by removing microbial pathogens and chemicals that can cause deadly diarrhoeal diseases.

0 notes

Text

Extruded Plastics Market Universal 2018 Expected to Grow at USD 280 Billion Dollar | at CAGR of 4.9% | Tendencies Currently Top Key Players | Inquiry Analysis Forecast to 2022

Extruded Plastics Market:

Extruded Plastics Market Abstract: Extruded Plastics Market is expected to grow at USD 280 billion in 2022 with the CAGR of 4.9% from 2016 to 2022.The drivers of this market are low feedstock and rise in energy price that tends to reduce the overall cost of extrudes. In-addition to this an innovation in extruded plastics to be utilized in medical and agriculture market will fuel this market. The polystyrene segment is expected to grow tremendously at the CAGR during the forecast period. Low thermal conductivity and poor resistance to oxygen and moisture make this resin a suitable material to be used in packaging of food products. In addition to this, polystyrene is an inexpensive thermoplastic resin to be used in, toys, construction and others. Polystyrene finds applications in food/non-food packaging, and in consumer products such as frames, cable ducts, tubes, sale displays/signage, containers, bottles, trays, tumblers, disposable cutlery and others.

Extruded Plastics Market Research is an intelligence report with meticulous efforts undertaken to study the right and valuable information. The data which has been looked upon is done considering both, the existing top players and the upcoming competitors. Business strategies of the key players and the new entering market industries are studied in detail. Well explained SWOT analysis, revenue share and contact information are shared in this report analysis.

Download free exclusive Sample of this report @ https://www.marketresearchfuture.com/sample_request/2100

Extruded Plastics Market Insight: Extruded Plastics Market has been evaluated to be rapidly growing and is expected to grow tremendously. Benefits like low thermal conductivity and poor resistance to oxygen and moisture make this resin a suitable material to be used in packaging of food products which has increased its market globally. With numerous usage of extruded plastics, the global extruded plastics market is expected to increase in future. Moreover, increasing demand in construction industry owing to the rising surge for plastics is another factor that drives the global extruded plastics market growth over the forecasted period 2022.

Data integration and capabilities are analyzed to support the findings and study the predicted geographical segmentations. Various key variables and regression models were considered to calculate the trajectory of extruded plastics market. Detailed analysis is explained and given importance to with best working models.

Geographically, the segmentation is done into several key regions like North America, Middle East & Africa, Asia Pacific, Europe and Latin America. The production, consumption, revenue, shares in mill UDS, growth rate of extruded plastics market during the forecast period of 2016 to 2022 is well explained.

The ongoing market trends of extruded plastics market and the key factors impacting the growth prospects are elucidated. With increase in the trend, the factors affecting the trend are mentioned with perfect reasons. Top manufactures, price, revenue, market share are explained to give a depth of idea on the competitive side.

Extruded Plastics Market Key Players: The major participants of this market are: Desku Group Inc, Halliburton Company, Excalibar Minerals LLC, P & S Extruded Plastics Mining Co. Ltd, Ashapura Minechem Ltd, Anglo Pacific Minerals, CIMBAR Performance Minerals, Kaomin Industries, Andhra Pradesh Mineral Development Corporation Limited, Mil-Spec Industries Corporation and others.

Make an inquiry for buying this report @ https://www.marketresearchfuture.com/check-discount/2100

Study Objectives of Extruded Plastics Market:

Studying market overview of extruded plastics

Estimating the market size by type and end-user

To provide insights about market drivers, restrains and opportunities

To provide geographic market analysis and future outlook with respect to North America, Europe, and Asia along with other parts of the world

To analyze the present status and future growth of global extruded plastics market based on various factors- supply chain analysis, Porters Five Force analysis etc.

To provide strategic profiling of key players in the market and broadly analyzing their core competencies

To evaluate competitive developments such as joint ventures, strategic alliances, mergers and acquisitions, new product developments along with research and developments in the global extruded plastics market

Table of Content:

1 Executive Summary

2 Scope of the Report

2.1 Market Definition

2.2 Scope of the Study

2.2.1 Research Objectives

2.2.2 Assumptions & Limitations

2.3 Markets Structure

3 Market Research Methodology

3.1 Research Process

3.2 Secondary Research

3.3 Primary Research

3.4 Forecast Model

4 Market Landscape

4.1 Five Forces Analysis

4.1.1 Threat of New Entrants

4.1.2 Bargaining Power of Buyers

4.1.3 Threat of Substitutes

4.1.4 Segment Rivalry

4.2 Value Chain/Supply Chain of Global Extruded Plastics Market

5 Industry Overview of Global Extruded Plastics Market

5.1 Introduction

5.2 Growth Drivers

5.3 Impact Analysis

5.4 Market Challenges

5.5 Impact Analysis

Table of Content from Continue………..

Complete table of content is available at @ https://www.marketresearchfuture.com/reports/extruded-plastics-market-2100

#Extruded Plastics#Extruded Plastics Market#Extruded Plastics Trends#Extruded Plastics Forecast#Extruded Plastics Analysis

0 notes

Text

global polyethylene terephthalate market to surpass us$ 60.73 billion by 2025, buoyed by rampant growth in food and beverage industry

The Global Polyethylene Terephthalate Market was valued at US$ 26.57 billion in 2016,according to a new report published by Coherent Market Insights. The increasing demand for bottled water and carbonated soft drinks are expected to dominate the market for PET during 2017-2025. PET bottles are gaining traction in food & beverages industry, due to its light weight, easy to handle, non-breakable and can be recycled into various products such as rain coats, door panel, fibers, industrial strapping among others. Favorable government regulations in Asia Pacific is expected to boost the market for PET during 2017-2025. For instance, in 2015, the Government of India allowed use of PET for pharmaceuticals packaging under Drugs & Cosmetics Act (1940), Schedule M, and Section 16.10. Major players in the market focus on new product development and integrating new technologies in existing product portfolio to meet rising demand of its customer base. For instance, in 2014, SIDEL introduced NEW RIGHTWEIGHT 0.5 liter bottle for still water weighs just 7.95 grams, yet offers a superior consumer experience and a top-load performance of 33 kilograms, without the need for nitrogen dosing, using standard 26/22 closures.

Petroleum derivatives are used as the primary feedstock in the manufacture of polyethylene terephthalate. Growing demand for PET packaging material from various food & beverages industries, is in turn propel the demand for PET. However, volatility of crude oil prices and growing GHG emission concerns has compelled the manufacturer to shift in focus towards bio based PET product, which in turn is expected to be the key challenges for petroleum based PET. Market leading food & beverages industry are continuously investing to develop environment friendly and bio based packaging material for food & beverages. For instance, in June 2012, The Coca Cola Company, Heinz & Co., Ford Motors, Nike Co. and Proctor & Gamble have signed Plant PET Technology Collaborative (PTC), intended for development and use of 100% bio-based PET in their product offerings. This development in bio based PET is expected to boost the market for PET during the forecast period.

Request Sample of Polyethylene Terephthalate Market: https://www.coherentmarketinsights.com/insight/request-sample/279

Key takeaways of the market:

Asia-Pacific is projected to be the largest region in global polyethylene terephthalate market. It accounted for around 59.8% of overall polyethylene terephthalate market revenue in 2016. The market in this region is expected to be primarily driven by rampant growth of end-use industries in China, India, and ASEAN countries. The growing food & beverages industries, rising economy, growing per capita income of middle class people are some of the key drivers for the growth of polyethylene terephthalate in the Asia-Pacific region.

The market in Latin America is expected to register a significant growth rate over the forecast period. Rise in discretionary income along with increasing ready to eat food are expected to create lucrative growth opportunities for the players in this region.

Automotive industry is one of the key industries for the use of polyethylene terephthalate. A strong automobile sales in Asia-Pacific and Europe is expected to enhance the growth of polyethylene terephthalate in the forecast period. The automotive applications such as headlamp retainer, wiper arm and gear housings, engine cover, connector housings are the key automotive application for the use of polyethylene terephthalate. According to India Brand Equity Foundation (IBEF), is a Trust established by the Department of Commerce, Ministry of Commerce and Industry, Government of India, South Korea’s Kia Motors Corp is close to finalizing a site for its first factory in India, slated to attract US$1 billion (Rs 6,700 crore) of investment. It is deciding between Andhra Pradesh and Maharashtra. The target for operationalizing the factory is the end of 2018 or early 2019.

Alpek S.A.B de C.V., RTP company, BASF SE, The Dow Chemicals Company, Jiangsu Sanfangxiang Group, Indorama Ventures, M&G Chemicals, Nan Ya Plastics Corporation, Far Eastern New Century and Quadrant AG. are few of the key players in global Polyethylene Terephthalate market.

There are various organic, and inorganic growth strategies which are being followed by the leading market players in the market. Technological advancement is leading to the key innovation in the new product launches. Companies are also investing in expansions, mergers & acquisitions, and joint ventures in the market.

To Get Discount On This Report:https://www.coherentmarketinsights.com/insight/request-discount/279

About Coherent Market Insights:

Coherent Market Insights is a prominent market research and consulting firm offering action-ready syndicated research reports, custom market analysis, consulting services, and competitive analysis through various recommendations related to emerging market trends, technologies, and potential absolute dollar opportunity.

Contact Us

Mr. Shah

Coherent Market Insights 1001 4th Ave,

#3200

Seattle, WA 98154

Tel: +1-206-701-6702

Email: [email protected]

Website: https://www.coherentmarketinsights.com/

Visit Blog : http://globalresearchtrends.blogspot.in/

#Polyethylene Terephthalate Market#Polyethylene Terephthalate Market Size#Polyethylene Terephthalate Market Share#Polyethylene Terephthalate Market Opportunity Analysis#Polyethylene Terephthalate Market Industry Forecast#Polyethylene Terephthalate Market PETP Market

0 notes

Text

Olive Oil Filling Machine

Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Olive Oil Filling Machine in Ahmedabad, Gujarat, India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. The Olive Oil Filling Machine – Servo-Based by Shiv Shakti Machtech is a high-performance, precision-oriented filling system designed specifically for packaging olive oil. The servo-based system ensures accurate, consistent, and fast filling, making it ideal for small to large-scale production in the food and beverage industry. This machine handles olive oil with care, filling it without spillage or wastage while maintaining its quality and integrity. Other Similar Technology: Servo-Driven Olive Oil Bottling, Automated Olive Oil Filling Equipment, High-Precision Olive Oil Filling, Olive Oil Packaging with Servo Technology, Servo-Controlled Olive Oil Filling System, Efficient Olive Oil Bottling Line, Servo-Based Dispenser Machine, Olive Oil Filling Machine for Glass and Plastic Bottles, Advanced Solution with Servo Mechanism, Olive Oil Filling and Capping (Servo Operated) Types of Olive Oil Filling Machine: Single Head Servo-Based Filling Machine Two Head Servo-Based Filling Machine Four Head Servo-Based Filling Machine Six Head Servo-Based Filling Machine Multi-Head Servo-Based Filling Machine Why Choose Shiv Shakti Machtech? Cutting-Edge Technology: Advanced servo-based control systems for precise and efficient filling. Customization: Tailored filling machines to meet the needs of both small and large-scale operations. Quality & Durability: Built for continuous operation, ensuring long-term reliability and productivity. Cost-Effective Solutions: Reduces waste and improves efficiency, offering great value for money. Excellent After-Sales Service: Ongoing support with timely servicing and maintenance to keep your machine running smoothly. What types of containers can be used with the Servo-Based Olive Oil Filling Machine? The machine is suitable for glass, plastic, and metal containers of various shapes and sizes. How accurate is the filling process? The filling accuracy is ±0.5%, ensuring consistent and precise filling with minimal waste. Can the machine be adjusted for different fill volumes? Yes, the filling volume is fully adjustable, allowing you to package olive oil in containers ranging from 50ml to 5L. Shiv Shakti Machtech is a Supplier of Olive Oil Filling Machine in Ahmedabad, Gujarat, India Including Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi, Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune, Rajasthan, Jaipur, Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatna, Hyderabad, Guntur, Chittoor, Kurnool, Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bengaluru, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamil Nadu, Kerala, Kochi, Thiruvananthapuram, Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar, Chhachhrauli. For more information or to request a quote, please reach out to us. View Product: Click Here Read the full article

#AdvancedOliveOilFillingSolutionwithServoMechanism#Ahmedabad#Ajmer#Alappuzha#Alwar#Amaravati#Amravati#Amreli#Andheri#AndhraPradesh#Ankleshwar#Asansol#Assam#Aurangabad#AutomatedOliveOilFillingEquipment#Baddi#Ballari#Bangalore#Barshi#Bengaluru#Bharatpur#Bharuch#Bhavnagar#Bhilwara#Bhopal#Bhubaneswar#Bhusawal#Bikaner#Brahmapur#Changodar

0 notes

Link

Plastic Bottle Manufacturers Plastic Bottle Manufacturers in kerala Plastic Bottle Manufacturers in tamilnadu Plastic Bottle Manufacturers in karnataka

#Plastic Bottle Manufacturers in andhra pradesh#PET bottle manufacturers in kerala#PET bottle manufacturers in tamil nadu#PET containers in karnataka#PET containers in Andhra

0 notes

Text

Single Head Pneumatic Operated Chuck Capper Machine

Shiv Shakti Machtech is a Manufacturer, Exporter and Supplier of Single Head Pneumatic Operated Chuck Capper Machine in Ahmedabad, Gujarat, India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Shiv Shakti Machtech designs the Single Head Pneumatic Operated Chuck Capper Machine for efficient capping of bottles and containers in various industries. This advanced machine combines precision, speed, and durability, making it ideal for packaging lines in pharmaceutical, food and beverage, cosmetic, and chemical industries. The machine securely fastens caps onto bottles, ensuring no leakage and maintaining product integrity. Other Similar Technology: Servo Motor Single Head Chuck Capping Machine, Pneumatic Chuck Capper with Servo Motor Control, Single Head Servo Driven Bottle Capper, Servo Motor Operated Chuck Cap Sealing Machine, Automated Pneumatic Servo Chuck Capping Equipment, Single Head Servo Controlled Cap Tightening Machine, Servo Motor Chuck Capper for Plastic and Glass Bottles, Precision Pneumatic Chuck Capping Machine with Servo, Single Head Servo Capper for Screw Caps, Servo Motor Pneumatic Cap Tightening Machine Steps in the Process: Container Placement: The container is placed under the capping head using a conveyor belt. Chuck Gripping: The machine’s chuck mechanism securely holds the cap and aligns it with the bottle's neck. Cap Application: The pneumatic system applies controlled force to screw the cap onto the bottle. Release: The machine tightly fits the cap and then releases the capped bottle onto the next conveyor for further processing. Types of Single Head Pneumatic Operated Chuck Capper Machine: Manual Chuck Capping Machine Semi-Automatic Chuck Capping Machine Fully Automatic Chuck Capping Machine Advantages: The pneumatic operation enhances speed and accuracy, resulting in higher throughput. Reduced operational costs due to minimal power consumption and low maintenance needs. Provides consistent torque, ensuring uniform capping quality and preventing issues like over-tightening or under-tightening. Automated or semi-automated operation reduces the need for manual labor and speeds up the production process. Can be customized to accommodate different bottle sizes, shapes, and cap types. Built with durable materials and designed to last for years, ensuring long-term reliability. Shiv Shakti Machtech is a Supplier of Single Head Pneumatic Operated Chuck Capper Machine in Ahmedabad, Gujarat, India Including Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi, Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune, Rajasthan, Jaipur, Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatna, Hyderabad, Guntur, Chittoor, Kurnool, Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bengaluru, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamil Nadu, Kerala, Kochi, Thiruvananthapuram, Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar, Chhachhrauli. For more information or to request a quote, please reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Ajmer#Alappuzha#Alwar#Amaravati#Amravati#Amreli#Andheri#AndhraPradesh#Ankleshwar#Asansol#Assam#Aurangabad#Baddi#Ballari#Bangalore#Barshi#Bengaluru#Bharatpur#Bharuch#Bhavnagar#Bhilwara#Bhopal#Bhubaneswar#Bhusawal#Bikaner#Brahmapur#Changodar#Chennai#Chhachhrauli

0 notes

Text

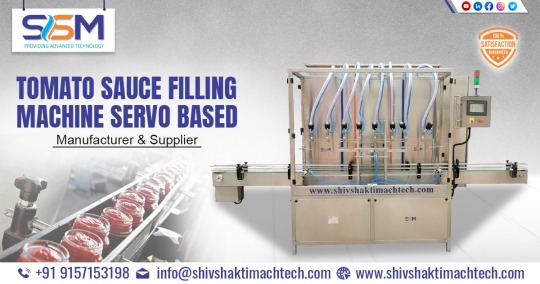

Tomato Sauce Filling Machine Servo Based

Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Tomato Sauce Filling Machine Servo Based across India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Shiv Shakti Machtech is a leading manufacturer and supplier of high-performance Servo-Based Tomato Sauce Filling Machines, designed to meet the precise filling requirements of the food processing industry. Our machines deliver accuracy, speed, and hygiene, making them ideal for small to large-scale production lines. Similar Sauce Bottle Filling Technology Machinery: Tomato Sauce Filling Machine, Ketchup Filling Machine, Automatic Tomato Sauce Servo Filling Machine, Automatic Sauce Tin Can Filling and Sealing Machine, Tomato Sauce Packing Machine, Automatic Liquid Filling Machine – Servo Based, Automatic Hot Tomato Sauce Filling Machine, Servo Automatic Sauce Filling Machin, Tomato Sauce Packaging Equipment, Tomato Sauce Bottling Machine Types of Tomato Sauce Filling Machines: Single-Head Servo Filling Machine Multi-Head Servo Filling Machine Automatic Servo-Based Filling Machine Semi-Automatic Filling Machine Custom Configurations Features: Servo Motor Technology: Ensures precision in filling volumes. Stainless Steel Construction: Durable and easy to clean, ensuring compliance with food-grade standards. Touchscreen Control Panel: Offers user-friendly operation and programmable settings. Adjustable Filling Nozzles: Accommodates various bottle sizes and shapes. Anti-Drip Mechanism: Prevents spillage and waste. High-Speed Operation: Enhances productivity for large-scale operations. What types of containers can this machine handle? Our machines can fill glass bottles, plastic jars, pouches, and even sachets. How accurate is the filling process? The servo-based design ensures high accuracy, typically within ±1% of the desired volume. Can this machine handle different viscosities? Yes, it is designed to handle various viscosities, from thin liquids to thick sauces. Is the machine suitable for small-scale production? We offer semi-automatic and single-head models that are perfect for small-scale operations. Shiv Shakti Machtech is a Supplier of Tomato Sauce Filling Machine Servo Based in Ahmedabad, Gujarat, India Including Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi, Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad, Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune, Rajasthan, Jaipur, Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan, Himachal Pradesh, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh, Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri, Durgapur, Bhubaneswar, Odisha, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatna, Hyderabad, Guntur, Chittoor, Kurnool, Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet, Telangana, Medak, Bengaluru, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi, Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode, Tirunelveli, Tamil Nadu, Kerala, Kochi, Thiruvananthapuram, Kozhikode, Thrissur, Kollam, Alappuzha, Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur, Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar, Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar, Chhachhrauli. For more information or to request a quote, please reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Ajmer#Alappuzha#Alwar#Amaravati#Amravati#Amreli#Andheri#AndhraPradesh#Ankleshwar#Asansol#Assam#Aurangabad#Baddi#Ballari#Bangalore#Barshi#Bengaluru#Bharatpur#Bharuch#Bhavnagar#Bhilwara#Bhopal#Bhubaneswar#Bhusawal#Bikaner#Brahmapur#Changodar#Chennai#Chitradurga

1 note

·

View note

Text

Square Bottle Labeling Machine