#Plastic Pallets Market Share

Explore tagged Tumblr posts

Text

What is strapping material and types of strapping material?

Strapping is securing and bundling packages and loads for storage and shipment. Different types of strapping materials are used to secure these cartons and other items. Various types of strapping materials are available in the market for different strapping and packaging needs. The strapping materials are made using different polymers, steel, and composite materials according to the need and demand. One should connect with the PET or PP Strap manufacturers in India according to their needs.

You will find strapping materials of various lengths, widths, and thicknesses to cater to different applications. The flexibility and tensile strength of the strapping materials also vary. All these qualities of strapping materials help in securely bundling several types of loads. Before buying the strapping materials from PP or PET Strap manufacturers in India, ask them about these qualities. Some of the most common applications of strapping materials are securing building or construction materials, securing products during shipping and transportation, securing finished goods for storage and supply, securing items at warehouses, and a few others.

Now that you know what strapping materials are and where they can be used, let’s know their types. After knowing the types of strapping material, you can choose the right strapping material for several applications. It will help you know which strapping material is used for which purpose, so let’s discover them.

Types of Strapping Materials

This blog shares the most common types of strapping materials used for multiple applications. They are:

Polypropylene Strap or PP Strap

Polyester Strap or PET Strap

Steel Strap

These three strapping materials are available with most PP strap manufacturers in India.

Polypropylene Strapping (PP Strap)

PP Strap is one of the most widely used straps for various applications. For applications that require light or medium strapping strength, polypropylene strapping is best for them. It is available in varied thicknesses, tensile strengths, widths, and colours. PP Straps are light in weight, making them suitable for bundling and sealing loads that are light in weight. They have several properties, like corrosion resistance, no deformation, and breaking strength. These qualities of PP Straps make them the perfect strapping material for holding products and items for a long time. Polypropylene Strapping material is mainly used in several applications like postal service, bailing hay, flooring, millwork, merchandise foods, and packing of frozen foods & meats.

Polyester Strapping (PET Strap)

PET Strap is the most common and highly durable strapping material among the multiple strapping materials. It is considered the best alternative to steel strapping because it is one of the strongest strapping materials with high tension. It is used to handle medium or heavy loads due to its several properties. It comes with several properties, like being resistant to UV rays, resistant to shocks, resistant to high temperatures, lightweight, and excellent stretch recovery.

Most PET straps are available in green colour as they are made using plastic bottles. But they are available in other colours too. You can ask the PET Strap manufacturers in India if they offer customized straps or not to get the desired colour. Most often, the PET straps are made using recycled materials only. Industries also use Polyester strapping because of their impact absorbing quality during the shipment. Some uses of polyester strapping material are in stabilizing heavy loads, palletizing heavy loads, and handling metals, bricks, tiles, pallets of bottles, and cans.

Steel Strap

It is one of those strapping materials used for a long time. We currently have several alternatives to steel strapping available in the market. Steel straps are mainly used for heavy loads or loads that require less stretching but high strength. Due to the zero stretchability, steel straps offer high tension, which is suitable for heavy materials. Like the above two strapping materials, steel straps are also available in different sizes, thicknesses, and widths. They come with different finishes like zinc-coated, glued, galvanized, and painted. Steel strapping is mainly used for several heavy-duty applications, like bundling metals, construction materials, securing metal containers, steel coins, railroad shipping, and packaging other heavy industrial equipment.

All these three strapping materials are widely used for packaging or bundling loads and items. If you need any of these strapping materials, go for OM Pack Strap. Being one of the best PET strap manufacturers in India, they offer heavy-duty, reliable pack straps at reasonable prices for several applications.

#PP Transparent Box Strapping#White Strap Roll#PP Strap Manufacturers in India#PET Strap Manufacturers in India#PP Box Strap Virgin

2 notes

·

View notes

Text

Returnable Packaging Market Growth: Key Trends Driving the Future of the Industry

The global returnable packaging market size is expected to reach USD 173.05 billion by 2030, according to a new report by Grand View Research, Inc., expanding at a CAGR of 6.0% over the forecast period. This is attributed to the expanding key end-use industries such as food & beverages, healthcare, and others.

Returnable packaging products offer numerous benefits to end-use companies, in comparison to single-use or expendable packaging products. Even though the procurement cost of returnable packaging is significantly higher than that of single-use packaging, it is reused multiple times, unlike single-use packaging, which will eliminate the recurring costs of packaging production. Besides, using similar containers for longer duration reduces the cost per trip and thus, returnable packaging proves to be cost-efficient in the longer term.

Food & beverages, pharmaceuticals, and automobiles are among the major end-use industries for returnable packaging. In these sectors, returnable packaging products such as pallets, crates, IBCs, dunnage, and others are mainly utilized for internal handling (within the manufacturing plant) of raw materials, semi-finished, and finished goods, as well as for the transportation of finished goods from the manufacturing plant to distribution and retail center. Therefore, expanding manufacturing and distribution activities within the food & beverages, pharmaceutical, and automobile industries is expected to directly fuel the demand for returnable packaging products.

Furthermore, the global pharmaceutical industry is expected to witness strong growth in the coming years. Growing aging population, especially in developed countries such as Japan, France, Germany, and others; increasing health consciousness among consumers; improving healthcare infrastructure, particularly in developing countries such as India, Brazil, and China; and high emphasis on the strengthening of the healthcare sector, coupled with the introduction of various healthcare insurance schemes by governments globally, are primarily driving the pharmaceutical industry.

Gather more insights about the market drivers, restrains and growth of the Returnable Packaging Market

Returnable Packaging Market Report Highlights

• Plastic has emerged as a dominating material in the market for returnable packaging with a majority share in 2022 and is expected to maintain a leading position by 2030, owing to its wide application in the food & beverage and healthcare industries, due to its unique properties such as anti-shock during shipping the products

• Pallets recorded the largest market share in 2022 in the products segment, due to their higher compatibility, structural integrity, and easy cleaning properties. However, the lack of international standards and uniformity in the sizes of pallets is expected to challenge material handling and transportation corporations

• The healthcare segment is expected to expand at a substantial CAGR of 6.9% during the forecast period. The pharmaceutical industry requires packing products like pallets, containers, FIBCs, drums, and barrels for the transportation of chemicals, medicines, drugs, and vaccines in bulk quantities

• The increasing aging population in countries like Japan, Germany, Italy, Portugal, and other European economies are expected to increase the demand for pharmaceutical products and healthcare equipment, which is expected to drive demand for returnable packaging from the healthcare end-use industry

• However, the growing adoption of single-use flexible packaging and several shortcomings of returnable packaging, such as expensiveness in comparison to other single-trip products, restrains the market growth to some extent

• New product developments, coupled with mergers & acquisitions and capacity expansions, are some of the strategies adopted by industry players. For instance, during the 2022 Plastics Caps & Closures conference in September, the Orbis Corporation showcased its reusable packaging solutions designed to address the unique requirements of the primary packaging supply chain that includes bulk containers, pallets, and boxes

Returnable Packaging Market Segmentation

Grand View Research has segmented the global returnable packaging market based on material, product, end-use, and region:

Returnable Packaging Material Outlook (Revenue, USD Billion, 2018 - 2030)

• Plastic

• Metal

• Wood

Returnable Packaging Product Outlook (Revenue, USD Billion, 2018 - 2030)

• Pallets

• Crates

• IBCs

• Drums & Barrels

• Dunnage

• Others

Returnable Packaging End-use Outlook (Revenue, USD Billion, 2018 - 2030)

• Food & Beverage

• Automotive

• Consumer Durables

• Healthcare

• Others

Returnable Packaging Regional Outlook (Revenue, USD Billion, 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o France

o U.K.

o Italy

o Spain

• Asia Pacific

o China

o India

o Japan

o South Korea

o Australia

• Central & South America

o Brazil

• Middle East & Africa

o South Africa

Order a free sample PDF of the Returnable Packaging Market Intelligence Study, published by Grand View Research.

#Returnable Packaging Market#Returnable Packaging Market Size#Returnable Packaging Market Share#Returnable Packaging Market Analysis#Returnable Packaging Market Growth

0 notes

Text

The global Plastic Pallets Market is projected to grow from USD 7,924.67 million in 2023 to USD 13,219.01 million by 2032, registering a CAGR of 5.85% during the forecast period.The global Plastic Pallets Market is experiencing significant growth, driven by the rising demand for sustainable and efficient material handling solutions across various industries. Plastic pallets have become an essential component in supply chain operations, offering durability, reusability, and superior hygiene compared to traditional wooden pallets.

Browse the full report at https://www.credenceresearch.com/report/plastic-pallets-market

Market Overview and Growth Drivers

The plastic pallets market is projected to grow significantly, with a compound annual growth rate (CAGR) of over 5% during the forecast period (2024–2032). The global shift towards sustainable logistics practices and stringent hygiene regulations, particularly in the food, beverage, and pharmaceutical sectors, are among the primary growth drivers. Unlike wooden pallets, plastic pallets are resistant to moisture, insects, and bacteria, making them a preferred choice in environments where contamination control is critical.

Additionally, industries are increasingly adopting returnable and reusable packaging solutions to reduce operational costs and minimize environmental impact. The durability and lightweight properties of plastic pallets make them ideal for repeated use, contributing to their popularity in sectors like automotive, retail, and manufacturing. Furthermore, technological advancements, such as the integration of RFID tags in pallets for tracking and inventory management, are further propelling the market growth.

Key Trends Shaping the Market

Sustainability Initiatives As environmental concerns grow, businesses are prioritizing eco-friendly solutions. Recycled plastic pallets, which are both cost-effective and sustainable, are gaining traction. These pallets are made from post-consumer or industrial waste, reducing the demand for virgin plastic and supporting circular economy practices.

Customization and Innovation Manufacturers are introducing customized pallets tailored to specific industry needs. For instance, pallets designed for automated warehouse systems ensure compatibility with robotic handling equipment. Similarly, stackable and nestable designs optimize storage and transport efficiency.

Digital Transformation Smart pallets equipped with IoT-enabled tracking devices are becoming a market trend. These devices provide real-time data on location, temperature, and load conditions, enhancing supply chain transparency and operational efficiency.

Growth in E-commerce The rapid expansion of the e-commerce sector has led to a surge in demand for efficient and lightweight pallets for fast and secure delivery. Plastic pallets are increasingly used in warehouses and distribution centers due to their ability to withstand heavy loads and automated processes.

Challenges in the Plastic Pallets Market

Despite its advantages, the plastic pallets market faces certain challenges. The high initial cost compared to wooden pallets remains a barrier for small and medium-sized enterprises (SMEs). Furthermore, the environmental impact of non-recyclable plastic pallets poses a concern, prompting regulatory bodies to enforce stricter guidelines on plastic usage. Manufacturers are addressing these issues by investing in advanced recycling technologies and developing biodegradable alternatives.

Key Player Analysis

Brambles Limited

Schoeller Allibert

Loscam

ORBIS Corporation

Craemer Group

CABKA Group

Greystone Logistics

Rehrig Pacific Company

Buckhorn Inc.

Plastic Pallet & Container, Inc.

TranPak Inc.

IPL Inc.

Material Handling Systems, Inc.

Litco International, Inc.

Premier Handling Solutions

Beecraft UK Ltd.

Cherry’s Industrial Equipment Corp.

TranPak (Australia) Pty Ltd.

PalletOne, Inc.

PDQ Plastics, Inc.

Segments:

Based on Type:

Nestable

Rackable

Stackable

Others

Based on Application:

Food & Beverages

Chemicals

Pharmaceuticals

Petroleum & Lubricants

Others

Based on Material:

High-Density Polyethylene

Low-Density Polyethylene

Polypropylene (PP)

Others

Based on the Geography:

North America

U.S.

Canada

Mexico

Europe

UK

France

Germany

Italy

Spain

Russia

Belgium

Netherlands

Austria

Sweden

Poland

Denmark

Switzerland

Rest of Europe

Asia Pacific

China

Japan

South Korea

India

Australia

Thailand

Indonesia

Vietnam

Malaysia

Philippines

Taiwan

Rest of Asia Pacific

Latin America

Brazil

Argentina

Peru

Chile

Colombia

Rest of Latin America

Middle East

UAE

KSA

Israel

Turkey

Iran

Rest of Middle East

Africa

Egypt

Nigeria

Algeria

Morocco

Rest of Africa

Browse the full report at https://www.credenceresearch.com/report/plastic-pallets-market

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

Wood Packaging Market

Wood Packaging Materials Market Size, Share, Trends: Brambles Limited Leads

Shift towards sustainable packaging solutions drives market growth.

Market Overview:

The global Wood Packaging Materials Market is expected to grow at a CAGR of 5.2% from 2024 to 2031, reaching a value of USD 86.4 billion by 2031. Asia-Pacific is the dominant region, accounting for 35% of the market share in 2024. The market is driven by factors such as increasing international trade, growing demand for sustainable packaging solutions, and the versatility of wood packaging materials.

Businesses are increasingly looking for environmentally responsible alternatives to plastic packaging. Wood packaging materials, which are biodegradable and recyclable, are becoming popular as a sustainable option.

DOWNLOAD FREE SAMPLE

Market Trends:

Wooden packing materials provide tremendous customisation and branding opportunities. Businesses are harnessing wood's natural aesthetics to develop unique and premium package designs that increase product appeal and brand identification.

Advances in wood processing technology enable the development of high-quality, long-lasting, and cost-effective wood packing materials. Wood packaging's application breadth is expanding because to innovations like engineered wood and composite materials.

Market Segmentation:

Pallets dominate the wood packaging materials industry, accounting for YY% of the market share in 2024. The segment is likely to remain dominant throughout the forecast period, driven by rising demand for efficient and standardised logistics solutions.

Recent pallet-related news includes the development of smart pallets with RFID technology for real-time tracking and inventory management. Furthermore, the use of pooled pallet systems is gaining traction, allowing organisations to cut costs while improving supply chain efficiency.

Market Key Players:

Brambles Limited

Greif, Inc.

Mondi Group

Universal Forest Products, Inc.

Nefab Group

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

Post-consumer Recycled Plastics Industry Revenue, Opportunity, Forecast Report 2030

The global market for post-consumer recycled (PCR) plastics was valued at approximately USD 10.66 billion in 2023, and it is projected to grow at a compound annual growth rate (CAGR) of 10.7% from 2024 to 2030. This market expansion is primarily driven by increasing sustainability initiatives from food & beverage and packaging companies, which are actively incorporating recycled plastic materials to reduce their environmental footprint. Additionally, the shift towards a circular economy where resources are reused and recycled rather than discarded is boosting the demand for PCR plastics across industries like packaging, textiles, and construction. Advanced recycling technologies that allow for high-quality recycled plastic production have further accelerated market growth.

For instance, in October 2023, Repsol S.A. collaborated with Signode Industrial Group LLC to launch a durable polypropylene (PP) strap containing 30% recycled content, designed for high-strength applications. Such innovations underscore the growing demand for PCR plastics across diverse sectors, including building & construction, packaging, electronics, textiles, and automotive, where PCR plastics are increasingly used as eco-friendly alternatives to conventional virgin plastics. The demand for PCR plastics is particularly high in construction activities within regions like China, India, the U.S., and Saudi Arabia, where various development projects, including residential and commercial buildings, affordable housing, and healthcare infrastructure, are on the rise.

Gather more insights about the market drivers, restrains and growth of the Post-consumer Recycled Plastics Market

One of the primary challenges for the PCR plastics market lies in managing waste and advancing plastic recycling technologies. High-income countries often export plastic waste to lower-income nations due to environmental and economic reasons, creating complex waste management issues. However, increasing governmental regulations targeting plastic waste reduction and disposal are positively impacting market growth. Many countries have banned single-use plastics, while others have introduced extended producer responsibility (EPR) programs, which require manufacturers to manage the end-of-life disposal of their products.

The stringent regulations governing the plastics industry encourage companies to invest in recycling technology advancements and quality control measures to ensure that the recycled materials meet safety and sustainability standards. By adhering to these regulatory frameworks, companies can not only reduce their environmental impact but also enhance customer trust and support sustainable innovation.

Source Segmentation Insights:

In terms of source material, the plastic bottles segment led the market in 2023, capturing a substantial revenue share. Plastic bottles are among the most common sources of PCR plastics, as they are widely used in packaging for beverages, cleaning products, cosmetics, and other goods. Due to the large volume of discarded plastic bottles, they serve as a readily available raw material for recycling processes. Additionally, heightened awareness about sustainability and the need to reduce plastic waste is expected to drive further growth in this segment.

Government regulations promoting plastic recycling worldwide also contribute to the adoption of plastic bottle recycling, thereby increasing PCR plastic production from this source. As a result, the demand for recycling plastic bottles is likely to remain strong.

The non-bottle rigid plastics segment is anticipated to grow at a CAGR of 10.4% during the forecast period. This category includes durable and non-durable plastic items such as pallets, crates, carts, 5-gallon buckets, electronic housings, dairy and deli containers, lids, yogurt cups, jars, and other similar food packaging. The diversity and wide use of non-bottle rigid plastics in various industries make them a valuable source for recycling, further supporting the growth of the PCR plastics market.

Order a free sample PDF of the Post-consumer Recycled Plastics Market Intelligence Study, published by Grand View Research.

0 notes

Text

Post-consumer Recycled Plastics Market 2030 Size, Share, Business Growth, Demand and Applications

The global market for post-consumer recycled (PCR) plastics was valued at approximately USD 10.66 billion in 2023, and it is projected to grow at a compound annual growth rate (CAGR) of 10.7% from 2024 to 2030. This market expansion is primarily driven by increasing sustainability initiatives from food & beverage and packaging companies, which are actively incorporating recycled plastic materials to reduce their environmental footprint. Additionally, the shift towards a circular economy where resources are reused and recycled rather than discarded is boosting the demand for PCR plastics across industries like packaging, textiles, and construction. Advanced recycling technologies that allow for high-quality recycled plastic production have further accelerated market growth.

For instance, in October 2023, Repsol S.A. collaborated with Signode Industrial Group LLC to launch a durable polypropylene (PP) strap containing 30% recycled content, designed for high-strength applications. Such innovations underscore the growing demand for PCR plastics across diverse sectors, including building & construction, packaging, electronics, textiles, and automotive, where PCR plastics are increasingly used as eco-friendly alternatives to conventional virgin plastics. The demand for PCR plastics is particularly high in construction activities within regions like China, India, the U.S., and Saudi Arabia, where various development projects, including residential and commercial buildings, affordable housing, and healthcare infrastructure, are on the rise.

Gather more insights about the market drivers, restrains and growth of the Post-consumer Recycled Plastics Market

One of the primary challenges for the PCR plastics market lies in managing waste and advancing plastic recycling technologies. High-income countries often export plastic waste to lower-income nations due to environmental and economic reasons, creating complex waste management issues. However, increasing governmental regulations targeting plastic waste reduction and disposal are positively impacting market growth. Many countries have banned single-use plastics, while others have introduced extended producer responsibility (EPR) programs, which require manufacturers to manage the end-of-life disposal of their products.

The stringent regulations governing the plastics industry encourage companies to invest in recycling technology advancements and quality control measures to ensure that the recycled materials meet safety and sustainability standards. By adhering to these regulatory frameworks, companies can not only reduce their environmental impact but also enhance customer trust and support sustainable innovation.

Source Segmentation Insights:

In terms of source material, the plastic bottles segment led the market in 2023, capturing a substantial revenue share. Plastic bottles are among the most common sources of PCR plastics, as they are widely used in packaging for beverages, cleaning products, cosmetics, and other goods. Due to the large volume of discarded plastic bottles, they serve as a readily available raw material for recycling processes. Additionally, heightened awareness about sustainability and the need to reduce plastic waste is expected to drive further growth in this segment.

Government regulations promoting plastic recycling worldwide also contribute to the adoption of plastic bottle recycling, thereby increasing PCR plastic production from this source. As a result, the demand for recycling plastic bottles is likely to remain strong.

The non-bottle rigid plastics segment is anticipated to grow at a CAGR of 10.4% during the forecast period. This category includes durable and non-durable plastic items such as pallets, crates, carts, 5-gallon buckets, electronic housings, dairy and deli containers, lids, yogurt cups, jars, and other similar food packaging. The diversity and wide use of non-bottle rigid plastics in various industries make them a valuable source for recycling, further supporting the growth of the PCR plastics market.

Order a free sample PDF of the Post-consumer Recycled Plastics Market Intelligence Study, published by Grand View Research.

0 notes

Text

Automotive Parts Packaging Market Size, Share, Trends, Growth Opportunities and Competitive Outlook

"Global Automotive Parts Packaging Market – Industry Trends and Forecast to 2028

Global Automotive Parts Packaging Market, By Product Type (Bags and Pouches, Corrugated Boxes, Crates, Folding Carton, Pallets, Reusable Containers and Cases, Trays and Protective Packaging), Packaging Type (Reusable, Disposable), Component (Electrical Components, Automotive Filter, Battery, Cooling System, Engine Components, Lighting Component and Underbody Component), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

**Segments**

- Packaging Type: The Automotive Parts Packaging market can be segmented based on packaging type, including folding cartons, plastic containers, bubble bags, corrugated boxes, and others. Different automotive parts require specific packaging types to ensure safe transportation and storage.

- Material: Segmentation based on material includes options such as paper & paperboard, plastic, metal, and others. Each material type offers specific properties that cater to the diverse packaging requirements of different automotive parts.

- Vehicle Type: Another crucial segmentation factor is the vehicle type, which categorizes packaging solutions based on applications in passenger vehicles, commercial vehicles, and others. Each vehicle type has distinct packaging needs that influence the market's dynamics.

**Market Players**

- DS Smith - Mondi - Sonoco Products Company - Schur Flexibles Group - Deufol SE - Goodpack Limited - Nefab Group

The global Automotive Parts Packaging market is witnessing significant growth fueled by the increasing demand for efficient packaging solutions in the automotive industry. With a focus on ensuring the safe and secure transportation of automotive parts, the market is segmented based on packaging type, materials, and vehicle types. Packaging types such as folding cartons, plastic containers, bubble bags, and corrugated boxes cater to different automotive part requirements. Material segmentation includes paper & paperboard, plastic, metal, and others, offering diverse properties to meet specific packaging needs. Vehicle types such as passenger vehicles and commercial vehicles further influence the packaging market dynamics by necessitating tailored packaging solutions.

Key market players driving the Automotive Parts Packaging market forward include DS Smith, Mondi, Sonoco Products Company, Schur Flexibles Group, Deufol SE, Goodpack Limited, and Nefab Group. These companies offer a range of packaging solutions tailored to the automotive industry's unique requirements, contributing to the market's overall growth and innovation. With a focus on sustainability, durability, and cost-effectiveness, these market players play a crucial role inThe global Automotive Parts Packaging market is experiencing substantial growth driven by the rising need for efficient packaging solutions in the automotive sector. The market segmentation based on packaging type allows for customized solutions to meet the unique requirements of various automotive parts. Folding cartons, plastic containers, bubble bags, and corrugated boxes are utilized based on the specific transportation and storage needs of different automotive components. The segmentation by material further enhances the market's flexibility, with options such as paper & paperboard, plastic, metal, and others providing distinct properties to cater to diverse packaging demands. This versatility ensures that automotive parts are adequately protected during transit and storage, contributing to the overall efficiency of the supply chain within the automotive industry.

The segmentation based on vehicle type is another crucial aspect shaping the Automotive Parts Packaging market. By categorizing packaging solutions according to their applications in passenger vehicles, commercial vehicles, and other vehicle types, manufacturers can tailor their offerings to suit the specific requirements of each segment. Passenger vehicles may require packaging solutions that focus on aesthetics and branding, while commercial vehicles may prioritize durability and stackability. Understanding these distinctions allows market players to develop targeted packaging solutions that effectively address the needs of different vehicle types, thereby driving market growth and innovation.

Key market players such as DS Smith, Mondi, Sonoco Products Company, Schur Flexibles Group, Deufol SE, Goodpack Limited, and Nefab Group are instrumental in advancing the Automotive Parts Packaging market. These companies bring a wealth of experience and expertise to the table, offering a wide range of packaging solutions designed to meet the automotive industry's stringent requirements. By focusing on sustainability, durability, and cost-effectiveness, these market players are driving innovation and setting new benchmarks in the automotive packaging sector. Their commitment to delivering high-quality solutions that provide both protection and efficiency further solidifies their position as market leaders, influencing trends and shaping the future of automotive parts packaging.

In conclusion, the Automotive Parts Packaging market is poised for continued growth, driven by the increasing demand for tailored**Segments**

- **Packaging Type**: The Automotive Parts Packaging market's segmentation based on packaging type plays a crucial role in meeting the diverse needs of the automotive industry. By offering options such as folding cartons, plastic containers, bubble bags, and corrugated boxes, the market can cater to specific transportation and storage requirements of various automotive parts.

- **Material**: The segmentation based on material type further enhances the market's flexibility and adaptability to different packaging needs. With options such as paper & paperboard, plastic, metal, and others, the market can provide tailored solutions that offer specific properties to ensure the safe and secure packaging of automotive components.

- **Vehicle Type**: Categorizing packaging solutions based on vehicle type, including passenger vehicles, commercial vehicles, and others, allows for the customization of packaging materials to meet the unique requirements of each segment. This segmentation ensures that packaging solutions align with the varied needs of different vehicle types, influencing market dynamics and driving innovation.

Global Automotive Parts Packaging Market, By Product Type (Bags and Pouches, Corrugated Boxes, Crates, Folding Carton, Pallets, Reusable Containers and Cases, Trays and Protective Packaging), Packaging Type (Reusable, Disposable), Component (Electrical Components, Automotive Filter, Battery, Cooling System, Engine Components, Lighting Component and Underbody Component), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium,

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Core Objective of Automotive Parts Packaging Market:

Every firm in the Automotive Parts Packaging Market has objectives but this market research report focus on the crucial objectives, so you can analysis about competition, future market, new products, and informative data that can raise your sales volume exponentially.

Size of the Automotive Parts Packaging Market and growth rate factors.

Important changes in the future Automotive Parts Packaging Market.

Top worldwide competitors of the Market.

Scope and product outlook of Automotive Parts Packaging Market.

Developing regions with potential growth in the future.

Tough Challenges and risk faced in Market.

Global Automotive Parts Packaging top manufacturers profile and sales statistics.

Browse Trending Reports:

Regenerated Fiber Market Cardiac Resynchronization Therapy Crt Devices Market Electronic Trial Master File Etmf Systems Market Starch Processing Market Acute Myeloid Testing Market Food Inclusions Market Industrial Dryers Market Neurosurgery Market Viral Hepatitis Market Glass Bottle Market Reclaimed Rubber Market Modified Wheat Starch Market Plant Genomics Market Digital Pump Controller Market Tofu And Tempeh Market Non Gmo Certification Market Linear Low Density Polyethylene Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

Carbon Credits Market Size, Share, Volume, Trends, Demand, Growth and Forecast Report 2024-2032

Carbon Credits Market provides in-depth analysis of the market state of Carbon Credits manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Carbon Credits in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Carbon Credits Market Report:

The report offers a comprehensive and broad perspective on the global Carbon Credits Market.

The market statistics represented in different Carbon Credits segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Carbon Credits are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Carbon Credits.

Major stakeholders, key companies Carbon Credits, investment feasibility and new market entrants study is offered.

Development scope of Carbon Credits in each market segment is covered in this report. The macro and micro-economic factors affecting the Carbon Credits Market

Advancement is elaborated in this report. The upstream and downstream components of Carbon Credits and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/carbon-credits-market-100582

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Plastic Bucket MarketMarket Analysis

Segmented Ball Valves MarketMarket Size

Global Massive Multiplayer Online (MMO) Games MarketMarket Share

Global Residential Interior Door MarketMarket Growth

Boron Doped Diamond Electrode (BDD) MarketMarket

Optical Character Recognition MarketMarket Share

Retail Banking MarketMarket Growth Rate

Rare Disease Treatment MarketMarket Forecast

Global MEMS Microphone MarketMarket Size

Electronic Logging Device MarketMarket Growth

Real Time Payments MarketMarket Analysis

Ion Exchange Resins MarketMarket Size

Global E-Learning Services MarketMarket Share

Global Enterprise Social Networking (ESN) MarketMarket Growth

Iron and Steel MarketMarket

Direct Drive (Gearless) Wind Turbine MarketMarket Share

LVT Flooring MarketMarket Growth Rate

AI in Education MarketMarket Forecast

Global Note Taking App MarketMarket Size

Aluminum Powder in Additive Manufacturing MarketMarket Growth

Free Space Optics Communication Technology MarketMarket Analysis

Curved Televisions MarketMarket Size

Global Laser Communication Terminal MarketMarket Share

Global Unified Communication as a Service (UCaaS) MarketMarket Growth

Produce Wash MarketMarket

Biaxially Oriented Polyamide (Nylon) Film (BOPA) MarketMarket Share

Transaction Monitoring MarketMarket Growth Rate

Wedding Dress MarketMarket Forecast

Global Dry Construction Material MarketMarket Size

Voltage Controlled Crystal Oscillator (VCXO) MarketMarket Growth

Electro Hydraulic Servo Valve MarketMarket Analysis

B2B Publishing MarketMarket Size

Global Rubber Shoe Sole MarketMarket Share

Global Intelligent Virtual Assistant MarketMarket Growth

D-Luciferin Substrate Market Market

Pendant Stations MarketMarket Share

Curved Guide Rail MarketMarket Growth Rate

Insulin Injection Related Product MarketMarket Forecast

Global Selective Wave Solder Pallet MarketMarket Size

Medical Grade Silicone Rubber MarketMarket Growth

0 notes

Text

Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Market - Forecast(2024 - 2030)

AI in Cobots Market Overview

The global AI in cobots market in 2021 reached $118.2 million and is estimated to grow at a CAGR of 34.22% during the forecast period to reach $616.3 million by 2027. The entire robotics industry is witnessing the effects of Covid-19 pandemic, with strain felt on the supply chain restricting parts of imports and equipment exports in H1 2021 especially. The overall economic uncertainty also pushed majority of customers to defer purchases in order to conserve capital. Recent advancements in Machine Learning and human robot interaction have enabled collaborative robots to precisely execute tasks in dynamically changing workspaces, enabling operations and material handling to run more smoothly, efficiently and productively. AI is now intelligently powering cobots by leveraging billions of hours of iterative machine learned practices in manufacturing, production and engineering. Collaborative robots (cobots) represent a variant of industrial robots and is currently considered to be one of the fastest growing segments in industrial automation driven by improved technology such as virtual assistants, cloud computing, internet of things. A cobot is a type of robot that is designed to operate alongside humans in shared workspaces. These machines are easy to program and deploy, can increase productivity manifold, and offer high returns on investment.

Report Coverage

The report: “AI in Cobots Market – Forecast (2022-2027)”, by IndustryARC covers an in-depth analysis of the following segments of the AI in Cobots market

By Payload: Up to 5 Kg, 5 to 10 Kg, Above 10 Kg. By Application: Handling, Assembling/Disassembling, Welding and Soldering, Dispensing, Packaging and Others. By End User: Automotive, Electronics, Semiconductor, Plastics and Polymer, Food and Beverage, Healthcare, Metals and Machining and others. By Geography: North America (U.S, Canada, Mexico), South America (Brazil, Argentina and others), Europe (Germany, UK, France, Italy, Spain, Russia and Others), APAC (China, Japan India, SK, Aus and Others), and RoW (Middle east and Africa).

Request Sample

Key Takeaways

Group PSA’s Sochaux plant in France has chosen Universal Robots UR10 for its "Plant of the Future" Project. Two UR10 cobots have been implemented at the Sochaux plant in screw driving applications on body-in-white assembly lines to increase performance and reduce production costs at the factory.

In 2019, Walmart has planned to invest $2.7 billion to add new robots totaling almost 4,000 robots in its stores and facilities in order to shift human workforce to customer service roles. The robots are majorly used for scanning, sorting goods from delivery trucks. This is set to create opportunities for AI in cobots in retail sector.

AI in Cobots Market Segment Analysis – By Application

Material Handling had a major share in the AI in Cobots Market with a value share of approximately 22.3% in 2021. Material handling is one of the major applications of industrial robots. Robots in material handling segment are used in applications such as movement of goods, protection, storage and control of products throughout manufacturing as well as warehousing of the products. Any industries that need to store, receive, dispatch or ship its products always entail industrial robot. Manufacturing and Warehouse operations involving handling of goods becomes complex when it takes place at a larger scale. This is made easy and efficient with the aid of industrial robots. Material handling robots are majorly used in warehousing applications as compared to its counterpart. Material handling applications that benefit from the incorporation of AI cobots encompass picking, packing, palletizing, sorting, and more. The wide-ranging use of these applications makes them a more site-specific solution for safety implementation. Operators and other workers are often moving or transporting other materials around the AI cobot, requiring additional planning to avoid hazardous contact. Safety-rated grippers are rare in the market at the present time. Currently, manufacturers typically use pneumatic grippers, which require safety considerations for impacts and the loss of power or suction. Uses of bar code, RFID, voice-activated receiving and packaging, pick-to-light technology, transportation management system is some of the drifts observed by material handling robots. Cycle counting, annual, physical and perpetual are few approaches of keeping a track of inventory.

Inquiry Before Buying

AI in Cobots Market Segment Analysis – By End User

Among industries, automotive held the largest share in 2021 at 23.2%. The industry development of AI cobots is ongoing in several different areas. Faster reaction time, more exact movement patterns, orientation capabilities, capabilities in imitating humans – all these aspects contribute to advancements in AI driven cobot development. In addition, brain-computer interfaces is an exciting area that has made significant progress recently. In recent developments in technologies such as linked data, parallel processing, edge computing and distributed artificial intelligence allow for efficient decision making by cobots, making execution robust and efficient. A challenge with the market deployment of AI cobots is that insufficient technology maturity hinders the market deployment of cobots. AI Cobot technology includes hardware design, sensors and actuators, efficient information processing, video processing, planning and multiple of fields from artificial intelligence landscapes, along with technologies that ensure safety, predictability and security of the solution. There is currently a need for high amount of signaling, bandwidth, low latency, and fast decision-making capabilities through efficient computing for AI driven cobots in safety-critical environments, wherein the facilities do not need human intervention. While the automation industry was affected during the pandemic, the longterm outlook for automation is positive, as end users evaluate their reliance on overseas supply chains and reevaluate their operations in a world where a pandemic can stop production cold. Automation is hence being looked upon as a valuable bulwark against the risks laid bare during the pandemic, and this can act as a strong growth driver for AI driven cobots and robots in industrial automation end user verticals.

AI in Cobots Market Segment Analysis – By Geography

Geographically, APAC held major share of 37% of AI in cobots market share in 2021, owing to high adoption of automation technologies in industrial and automotive warehouses and increasing investments and funding. North America is the next largest market with 33% revenue share in 2021. South America is witnessing the fastest growth rate with a CAGR of around 46.6% during the forecast period 2022 – 2027 owing to high investments and growing deployment of automation technology mainly in the countries such as Brazil, Argentina and Colombia. Portuguese company MOV.AI has announced in October, 2020 that it has raised $4m in funding. The company has designed its ROS for manufacturers of cobots, as well as academics and automation integrators. It also contributes to the ROS community. Some of the robots with AI enabled are YuMi from ABB, Franka Emika Panda, APAS from Bosch, Aura, Aubo, NEXTAGE and CORO etc.

Schedule a Call

AI in Cobots Market Drivers

Growing demand for automation and technological advancements set to drive the AI In Collaborative Robotics Market

There has been significant growth in AI driven collaborative robotics market owing to the increased demand for automation, high competition in the e-commerce industry, and the advancement in technologies such as Internet of Things (IoT) and Artificial Intelligence (AI). The use of robots reduces the risk of injury to workforce has also witnessed growth. Integration of robots with artificial intelligence (AI) and machine vision technology has been assisting companies in obstacle detection, navigation, movement of the goods. This has been attracting vendors in automating the warehouses and installing the robots in warehouse, thereby driving the collaborative robotics market. In 2019, Geek Plus Robotics, an intelligent logistics robot solution provider had launched the world’s first interweaving sorting robot, which could be an alternative to conveyor systems. Mobile Industrial Robots (MiR), a leading manufacturer of collaborative mobile robots launched a new warehouse robot to automate the transportation of pallets and heavy goods across warehouses. Development of new robots for various applications of warehouses set to boost the demand of collaborative robotics market.

Growth in E-Commerce Sector

E-Commerce industry is rising at global level of retail and logistics. As a result, growing number of e-commerce companies look forward to automate warehouses. Warehouse robots play a key role in e-commerce industry for various applications such as automated storage and retrieval, picking and placing, order fulfillment operations and many others. Adoption of warehouse cobots by e-commerce companies helps in reducing operational and logistical costs and save on delivery time. This has been increasing automation in warehouses in order to deliver goods to shoppers in faster and more efficient ways by increasing productivity of supply chain. In developed countries such as the U.S., and Canada, Grocery retailers are focusing on deploying robots that bring the shelf stacks to human workers, who pick out the right products and package them up to be sent out. These robots travel with high speed, faster than humans, thereby increasing efficiency of the work. In 2019, Amazon had introduced new warehouse cobots in several of its U.S. warehouses that scan and pack items to be sent to customers. It has started using robots in warehouses, which scans goods coming down a conveyor belt raising the scope of adoption. In 2020 Covariant.ai launched its AI robots and solutions through its warehouse bin-picking robots which is being used by companies such as Knapp, a warehouse logistics company and Obeta, a German electronics retailer. As per estimates, around 2,000 AI powered robots have been deployed across warehouses globally.

AI in Cobots Market Challenges

High Initial Investment

The initial cost of AI driven collaborative robots that are used in factories are high as the cost of automation is much higher in comparison with labor costs. This prevents most companies from completely automating their operations with robots. The average selling prices of cobots vary from $25,000 to $50,000 and does not include the installation costs. In addition to this, there is a training cost associated with the robots that further restricts the operators’ likeability for integrating robots into their operating lines. Slow deployment of collaborative robotic systems by smaller and medium enterprises hampers the robotics market. However, high labor costs are set to drive the collaborative robot market during forecast period.

Buy Now

AI in Cobots Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the AI in Cobots market. In 2021, the market of AI in Cobots market has been consolidated by the top players

Fanuc

Techman Robots

Rethink Robots

AUBA Robots

ABB

Kawasaki

KUKA

Yaskawa

Staubli

Universal Robots

Recent Developments

In May 2019, the government of Saudi Arabia announced an investment of $30 billion to upgrade warehousing facilities by adoption of the advanced autonomous robots in the newly built warehouses across Saudi Arabia, thereby contributing towards the growth of the cobots market during forecast period in this region.

In October 2019, the South Korean government announced an investment $150 million to develop the intelligent robots for various industrial application which includes warehousing and logistics, thereby enhancing the growth of the cobots market.

#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Market#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Market size#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Industry#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Market share#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems top 10 companies#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Market Report#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Industry outlook

0 notes

Text

0 notes

Text

How to chose the stretch film for YUPACK pallet wrapper

Stretch film is the film used in pallet wrapper. This plastic film, with unique stretching and adhesive properties, can be very good for packaging items. However, for the first time contact with the winding film, how to identify its advantages and disadvantages, and buy the right product is a difficult problem. Today, YUPACK will share with you some tips on how to choose and buy stretch film.

Most of the stretch films in the market are made of PE material, which relies on glue in order to adhere, while

YUPACK's stretch film is made of brand new LLDPE material, which has electrostatic self-adhesive property with just

one pull. It is ultra-thin, strong, transparent and at the same time has excellent adhesive properties, both

single-sided and double-sided, to meet your different needs.

of course, all this jargon may confuse you. Don't worry, we can also compare them from other angles.

For example, thickness, width and ductility. The thickness of the film is usually measured in filaments,

and you may think that for the same price, the thicker the better. But YUPACK would like to remind you that

our film is priced by kilo, so for the same price, the thicker the film, the shorter the metre may be!

After these comparisons, I believe you have been able to buy the right stretch film for yourself.

For more information about the supporting products of winding machine, please call YUPACK's sales

department. YUPACK is willing to provide the best protection for each of your goods.

1 note

·

View note

Text

Returnable Packaging Market Share 2024 Trends, Growth, and Forecast by 2031

Returnable Packaging Market Scope & Overview

The fundamental purpose of the Returnable Packaging Market research is to help readers better understand the market in terms of definition, segmentation, market potential, noteworthy trends, and the challenges that major regions and emerging countries face. This study will help readers obtain a comprehensive grasp of the market. Statistics and market data have been acquired from trustworthy sources such as websites, annual reports, newspapers, and other publications, and have been reviewed and validated by industry experts.

During the creation of the Returnable Packaging market report, extensive research and analysis were conducted. In the report, facts and data are represented using diagrams, graphs, pie diagrams, and other drawings. This improves the visual representation of the data and helps people grasp it better. The report's goal is to assist players in gaining a competitive advantage and improving their market positioning.

Get a Sample Report https://www.snsinsider.com/sample-request/3033

Market Key Players:

Schoeller Allibert, CHEP, NEFAB GROUP, Celina, RPP Containers, Amatech Inc, UBEECO Packaging Solutions, PPS Midlands Limited, RPR Inc, Tri-pack Packaging Systems Ltd

Market Segmentation

Each market region and country are profiled in the report. Production, use, import and export, sales volume, and income estimates are all identified. The study looks at the bulk of the industry's product types, as well as product specifications for each key player and sales volume and value. The market is further segmented into numerous principal applications of its sector based on the Returnable Packaging market and its applications. For each segment, it provides market size, CAGR, and predictions. The research provides a complete PEST analysis for all five regions: North America, Europe, APAC, MEA, and South America, after examining political, economic, social, and technological elements affecting the Returnable Packaging market in various areas.

By Raw Material

Wood

Metal

Plastic

By Product Type

Crates

IBCs

Dunnage

Pallets

Barrels & Drums

Others

By Application

Food & Beverage

Healthcare

Automotive

Others

Russia-Ukraine War Impact Analysis

The influence of the Russia-Ukraine war on global and domestic markets is also discussed in the Returnable Packaging market study. The report is a valuable source of guidance and information for businesses and consumers interested in the industry. It contains vital information as well as the current state of the markets of the main manufacturers.

Competitive Scenario

The report includes information on production, cost, gross margin, sales volume, sales, consumption, growth rates, imports, exports, supply, future strategies, and technological advancements. Market trends, as well as organic and inorganic growth approaches, are discussed in the study. A number of companies are prioritizing new launches, product approvals, and other organic growth techniques including patents and events. These efforts have cleared the way for market participants to expand their client base and revenue. Market payers are projected to gain from lucrative growth opportunities in the future as the global Returnable Packaging market grows.

Buy the Research Report Now https://www.snsinsider.com/checkout/3033

0 notes

Text

Exploring Emerging Trends in Shrink Films Procurement Intelligence

The shrink films category is anticipated to grow at a CAGR of 6% from 2023 to 2030. Three primary types of films are used in shrink wrapping or packaging: polyvinyl chloride (PVC), polyolefin (POF), and polyethylene (PE). Shrink films can be converted into bags, flattened roll stock, overwrap, tubing, and banding. Shrink films can also be segregated into centerfold and single-wound films. These are mainly made from POFs and PE. PVC shrink films are extensively used for non-food goods such as CD and DVD packaging, game and software boxes, and other packaging. This is because PVC is banned in many countries due to its chemical composition and the hazardous by products that are generated during its synthesis and decay. Hence, companies such as Walmart take extra precautions and ensure the highest standards for use and disposal when certain manufacturers use this chemical in their packaging.

In the plastics packaging industry, the key trend is the increasing focus on sustainability. Considering the increasing momentum of the anti-plastic movement, there are significant concerns about the usage of shrink wrap/films in the packaging industry. However, most of the films are produced using LDPE, the production of which does not emit polluting agents and is recyclable in most cases. As a result, companies are increasingly trying to implement environmental-friendly plastics or recycled content while manufacturing films or wraps. One such instance is the use of green polyolefin film, which can help companies achieve more than 25% in annual savings.

Strong robust demand from the F&B, electronics, pharmaceutical, and cosmetics sectors has contributed to the increasing requirement for shrink films. By consumption, the F&B sector accounts for the largest share, between 45 - 55% of the total. The rise in canned, packaged, and frozen food and the growing concerns about products during transit has led to the further expansion of shrink-wrap/film packaging. In addition, rising awareness among consumers about packaging is also positively impacting the industry. For instance, in 2022, it was found that 74% of customers are prepared to pay extra money for packaging that is fully recyclable or sustainable.

According to industry experts, as of April 2023, the PPWR proposal particularly in the European region could have a tremendous negative impact on the shrink films/wrap market. The proposed regulation intends to eliminate or drastically cut down on the usage of pallet wraps, shrink wraps, and stretch films made of polyethylene for transit packing. This poses a risk to all European Union producers and users of these wrapping products.

Order your copy of the Shrink Films Procurement Intelligence Report, 2023 - 2030, published by Grand View Research, to get more details regarding day one, quick wins, portfolio analysis, key negotiation strategies of key suppliers, and low-cost/best-cost sourcing analysis

The global shrink films category is fragmented. Regionally, plastics, polymers, and in turn, the shrink films industry is highly fragmented. As a result, the bargaining power for most of the suppliers is moderate to low. Large corporations having long-term agreements with their approved vendors may have higher negotiation power. Most of the manufacturers prefer using POFs due to their excellent durability and versatility properties. It is made of 100% recyclable material, which further helps companies contribute to sustainability. POFs have replaced PVC in many applications, and it also has received FDA certification for food packaging applications. In July 2023, Amcor announced the introduction of a new sustainable production line in its Swansea, U.K. “Flexibles” facility. The line is mainly for shrink films and bags for cheese and meat items. It is produced using thinner material with a formulation that is devoid of PVDC and has a high barrier.

Some of the key cost components associated with the category include raw materials, energy and equipment, labor, facilities and storage, transportation, and others. Other costs can include marketing, repairs, utilities and administrative expenses, tax, etc. The key raw materials for films include POF, PE, or PVC. POFs fall under the thermoplastics family and hence can utilize multiple raw materials such as ethylene, and propylene. These are again obtained from oil and natural gas. As a result, fluctuations in the prices of the raw material can have a significant impact on the cost of shrink film. For instance, price increases in the resin markets at the end of 2021 caused shrink wraps and film prices to increase by 8 - 12%. In the European region, the majority of polymers followed the increases in monomer prices, and polyolefin prices continued to grow in October 2023. Propylene C3 increased by EUR 60/ MT, while ethylene C2 increased by EUR 65 / MT.

The total cost is also impacted by certain variables such as the width and thickness of the film, package height, type of material used, etc. In addition to the unique formulations of the films, there is an increased cost when companies want printed designs. Printed shrink wraps/films are considered a premium option with branding, typography, logo, and graphic dynamics. It is more expensive than transparent or clear films. For instance, clear centerfold shrink films can cost on average between USD 100 - 250. Prices can vary based on roll orders. The cost of a printed pallet wrap order can easily range between USD 5,500 - 6,000, assuming the minimum order is 40 rolls (for machine pallet wrap).

According to Volza's October 2023 estimates, the top exporters of shrink films are China, India, and Vietnam, accounting for 38,769 shipments, 18,349 shipments, and 18,043 shipments respectively. The majority of the world's shrink films are exported to Vietnam, India, and the U.S. APAC dominated the shrink wraps and films category as it held 43% of the share in 2022. Most of the companies procure raw materials from China owing to its huge network of plastics and polymers supplier base coupled with manufacturing capacity. Under sourcing, most of the packaging companies such as Amcor, Mitsubishi Chemical Corporation, and Berry Global have their complete in-house plastics or dedicated flexibles manufacturing plants. Such corporations may have procured raw materials from their approved suppliers, however, film manufacturing from start to finish is done by the in-house team.

Shrink Films Procurement Intelligence Report Scope

• Shrink Films Category Growth Rate: CAGR of 6% from 2023 to 2030

• Pricing Growth Outlook: 10% - 15% (Annually)

• Pricing Models: Volume-based, contract-based pricing model

• Supplier Selection Scope: Cost and pricing, past engagements, productivity, geographical presence

• Supplier Selection Criteria: Material type (PVC, PE, or POF), application (food, bottles, sensitive products), features (tamper resistant, moisture and oxygen barrier), certifications, operational and functional capabilities, technology used, and others

• Report Coverage: Revenue forecast, supplier ranking, supplier positioning matrix, emerging technology, pricing models, cost structure, competitive landscape, growth factors, trends, engagement, and operating model

Browse through Grand View Research’s collection of procurement intelligence studies:

• Polyethylene (PE) Film Procurement Intelligence Report, 2024 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

• Conveyor Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

Key Companies Profiled

• Amcor Plc

• Berry Global Inc.

• Bolloré Group

• Sealed Air Corporation (SEE)

• The Dow Chemical Company

• Bonset America Corporation

• Allen Plastic Industries Co., Ltd

• Barbier Group

• Mitsubishi Chemical Corporation

• American Eagle Packaging

Brief about Pipeline by Grand View Research:

A smart and effective supply chain is essential for growth in any organization. Pipeline division at Grand View Research provides detailed insights on every aspect of supply chain, which helps in efficient procurement decisions.

Our services include (not limited to):

• Market Intelligence involving – market size and forecast, growth factors, and driving trends

• Price and Cost Intelligence – pricing models adopted for the category, total cost of ownerships

• Supplier Intelligence – rich insight on supplier landscape, and identifies suppliers who are dominating, emerging, lounging, and specializing

• Sourcing / Procurement Intelligence – best practices followed in the industry, identifying standard KPIs and SLAs, peer analysis, negotiation strategies to be utilized with the suppliers, and best suited countries for sourcing to minimize supply chain disruptions

#Shrink Films Procurement Intelligence#Shrink Films Procurement#Shrink Films Market#Shrink Films Industry

0 notes

Text

The global Plastic Pallets Market is projected to grow from USD 7,924.67 million in 2023 to USD 13,219.01 million by 2032, registering a CAGR of 5.85% during the forecast period.The global Plastic Pallets Market is experiencing significant growth, driven by the rising demand for sustainable and efficient material handling solutions across various industries. Plastic pallets have become an essential component in supply chain operations, offering durability, reusability, and superior hygiene compared to traditional wooden pallets.

Browse the full report at https://www.credenceresearch.com/report/plastic-pallets-market

Market Overview and Growth Drivers

The plastic pallets market is projected to grow significantly, with a compound annual growth rate (CAGR) of over 5% during the forecast period (2024–2032). The global shift towards sustainable logistics practices and stringent hygiene regulations, particularly in the food, beverage, and pharmaceutical sectors, are among the primary growth drivers. Unlike wooden pallets, plastic pallets are resistant to moisture, insects, and bacteria, making them a preferred choice in environments where contamination control is critical.

Additionally, industries are increasingly adopting returnable and reusable packaging solutions to reduce operational costs and minimize environmental impact. The durability and lightweight properties of plastic pallets make them ideal for repeated use, contributing to their popularity in sectors like automotive, retail, and manufacturing. Furthermore, technological advancements, such as the integration of RFID tags in pallets for tracking and inventory management, are further propelling the market growth.

Key Trends Shaping the Market

Sustainability Initiatives As environmental concerns grow, businesses are prioritizing eco-friendly solutions. Recycled plastic pallets, which are both cost-effective and sustainable, are gaining traction. These pallets are made from post-consumer or industrial waste, reducing the demand for virgin plastic and supporting circular economy practices.

Customization and Innovation Manufacturers are introducing customized pallets tailored to specific industry needs. For instance, pallets designed for automated warehouse systems ensure compatibility with robotic handling equipment. Similarly, stackable and nestable designs optimize storage and transport efficiency.

Digital Transformation Smart pallets equipped with IoT-enabled tracking devices are becoming a market trend. These devices provide real-time data on location, temperature, and load conditions, enhancing supply chain transparency and operational efficiency.

Growth in E-commerce The rapid expansion of the e-commerce sector has led to a surge in demand for efficient and lightweight pallets for fast and secure delivery. Plastic pallets are increasingly used in warehouses and distribution centers due to their ability to withstand heavy loads and automated processes.

Challenges in the Plastic Pallets Market

Despite its advantages, the plastic pallets market faces certain challenges. The high initial cost compared to wooden pallets remains a barrier for small and medium-sized enterprises (SMEs). Furthermore, the environmental impact of non-recyclable plastic pallets poses a concern, prompting regulatory bodies to enforce stricter guidelines on plastic usage. Manufacturers are addressing these issues by investing in advanced recycling technologies and developing biodegradable alternatives.

Key Player Analysis

Brambles Limited

Schoeller Allibert

Loscam

ORBIS Corporation

Craemer Group

CABKA Group

Greystone Logistics

Rehrig Pacific Company

Buckhorn Inc.

Plastic Pallet & Container, Inc.

TranPak Inc.

IPL Inc.

Material Handling Systems, Inc.

Litco International, Inc.

Premier Handling Solutions

Beecraft UK Ltd.

Cherry’s Industrial Equipment Corp.

TranPak (Australia) Pty Ltd.

PalletOne, Inc.

PDQ Plastics, Inc.

Segments:

Based on Type:

Nestable

Rackable

Stackable

Others

Based on Application:

Food & Beverages

Chemicals

Pharmaceuticals

Petroleum & Lubricants

Others

Based on Material:

High-Density Polyethylene

Low-Density Polyethylene

Polypropylene (PP)

Others

Based on the Geography:

North America

U.S.

Canada

Mexico

Europe

UK

France

Germany

Italy

Spain

Russia

Belgium

Netherlands

Austria

Sweden

Poland

Denmark

Switzerland

Rest of Europe

Asia Pacific

China

Japan

South Korea

India

Australia

Thailand

Indonesia

Vietnam

Malaysia

Philippines

Taiwan

Rest of Asia Pacific

Latin America

Brazil

Argentina

Peru

Chile

Colombia

Rest of Latin America

Middle East

UAE

KSA

Israel

Turkey

Iran

Rest of Middle East

Africa

Egypt

Nigeria

Algeria

Morocco

Rest of Africa

Browse the full report at https://www.credenceresearch.com/report/plastic-pallets-market

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

The Essential Role of Food-Grade Plastic Pallets: Ensuring Safety Across Industries

Ever wonder what's up with those reliable platforms that store all our groceries? They may go overlooked, but they are important in preserving the safety and freshness of our food. We at Swift are very dedicated towards food safety, which is why we designed a special kind of pallet specifically for the food and pharmaceutical industry. We'll be sharing with you the inside scoop on these incredible pallets' uses, the reasons they've grown to be a favorite, and some easy maintenance tips in this post.

Where are Food Grade Plastic Pallets Used? Food-safe plastic pallets are essential in industries that focus on maintaining high levels of cleanliness and safety, especially in sectors handling food and pharmaceutical items.

Some of the industries where food grade plastic pallets are used include:

1. Food & Beverage Industry 2. Pharmaceutical Industry 3. Cosmetics Industry 4. Agriculture and Horticulture 5. Retail and Distribution 6. Hospitality Industry 7. Healthcare and Hospitals

Why are Food Grade Plastic Pallets Used in Various Industries?

The use of food grade plastic pallets offers several notable benefits:

1. Hygiene and Food Safety: Food-grade plastic pallets are designed to be non-porous, making them easy to clean and are resistant to pests, moisture, and almost all type bacteria. They prioritize the safety and quality of food products, meeting all the necessary regulations and standards for food safety.

2. Durability and Strength: Plastic pallets are like the strong, reliable guardians of the food industry, built for the roughest handling, stacking, and transportation challenges. They're crafted in such a way that our goods reach their destinations unscathed, thanks to their incredible strength, resilience against impacts, and ability to carry hefty loads.

3. Consistency and Standardization: Food-grade plastic pallets are carefully crafted and tailored to meet exact specifications, ensuring uniformity in weight, shape, and size. This attention to detail streamlines operational processes across the food supply chain, enhancing efficiency in handling, storage, and transportation.

4. Environmental Sustainability: Food grade plastic pallets play an essential role in nurturing environmental sustainability. By embracing recyclability and reusability, They become heroes by fighting waste and promoting conservation of natural resources.

How to Maintain Food Grade Plastic Pallets?

For food grade plastic pallets to last longer and maintain food safety regulations, proper maintenance is necessary. Here are some maintenance tips:

1. Regular Cleaning: Regularly clean food-grade plastic pallets with care, using either a soft brush or a pressure washer, along with water and mild soap. Make sure to remove any dirt, stains, for complete cleanliness.

2. Sanitization: Regularly clean plastic pallets with approved cleaning solutions to remove bacteria, mold, and other health risks. Always follow the manufacturer's instructions and industry standards for cleaning to ensure they are completely clean and safe.

3. Inspection: Take a closer look at plastic pallets, inspect, check and identify any signs of wear and tear like cracks, splits, or warping. If you spot any damage to the pallets, it's crucial to replace those pallets immediately. This ensures food safety and prevents any risk of contamination during handling.

4. Storage:When your plastic pallets aren't busy, give them a cozy spot in a clean, dry area with good airflow. Treat them kindly by shielding them from harsh sunlight, extreme heat, and any potent chemicals to maintain their quality. By not doing so it could damage the pallet.

Conclusion In conclusion, food grade plastic pallets are important to the various industries where food related items are handled, Swift Technoplast has been in the market putting efforts to preserve food safety, effectiveness, and compliance. Businesses could optimise their food handling procedures and maintain the highest standards of quality and hygiene by knowing their uses, advantages, and appropriate maintenance strategies.

#swifttechnoplast#plastic industry#plasticmanufacturer#plasticpallets#plasticproducts#foodgradeplasticpallet

0 notes

Text

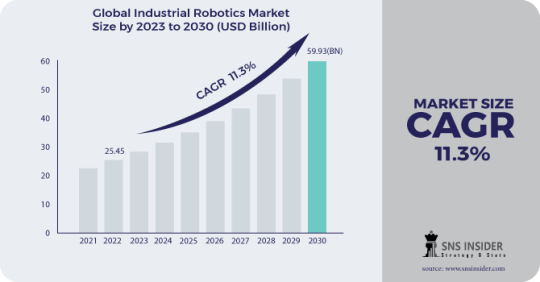

New Research Report On Industrial Robotics Market is Going to Boom by Size, Share, Scope and Forecast-2030

Industrial Robotics Market is going to reach USD 59.93 billion by 2030 and grow at a CAGR of 11.3% over the forecast period 2023-2030.

The most recent Industrial Robotics study evaluates global and regional market estimates and forecasts for all research segments. This study examines market trends, leading companies, supply chain trends, technological advances, key breakthroughs, and future strategies. Market figures were compiled using a combination of primary and secondary sources. Sales revenue from all of the study's specified segments and sub-segments are used to calculate market size. The market sizing analysis employs both top-down and bottom-up approaches for data validation and accuracy checks.