#Plastic Pallet Manufacturers

Explore tagged Tumblr posts

Text

Heavy Industrial Plastic Pallet Manufacturers from New Delhi

Introduction

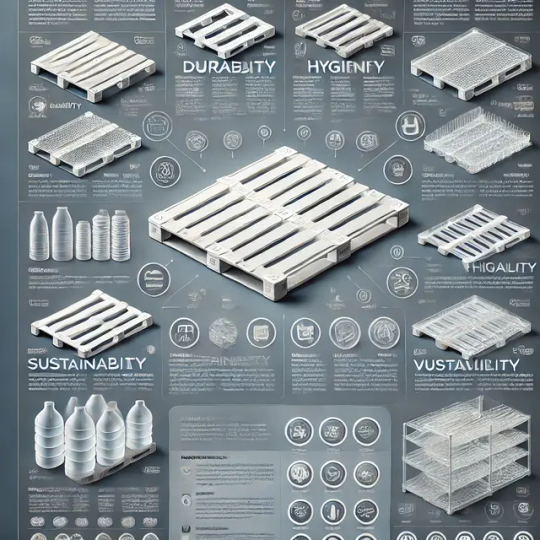

In the fast-paced world of industrial logistics, efficient storage and transportation solutions are critical.. These pallets provide durability, hygiene, and cost-effectiveness, making them a preferred choice across industries such as manufacturing, pharmaceuticals, food processing, and warehousing. In India, New Delhi has emerged as a hub for Top-tier Plastic Pallet Manufacturers, Offering High-Quality products that cater to both domestic and international Markets.

Why Choose Heavy Industrial Plastic Pallets?

Heavy industrial plastic pallets have gained prominence due to their superior advantages over traditional wooden or metal pallets. Here are some key reasons why businesses opt for plastic pallets:

Durability and Strength: Plastic Pallet Manufacturers are built to withstand high loads and rigorous industrial use without breaking or cracking.

Hygiene and Safety: Unlike wooden pallets, plastic pallets do not absorb moisture, making them resistant to bacteria, fungi, and pests.

Eco-Friendly and Recyclable: Many manufacturers in New Delhi focus on sustainable solutions, using recyclable materials to produce pallets.

Lightweight and Easy to Handle: Despite their strength, plastic pallets are lighter than metal or wooden alternatives, making them easier to transport.

Longer Lifespan: Plastic pallets outlast wooden ones, offering better returns on investment over time.

Weather and Chemical Resistance: These pallets can withstand extreme temperatures and exposure to chemicals without degrading.

The Growth of Plastic Pallet Manufacturing in - New Delhi

New Delhi has witnessed significant growth in the plastic pallet manufacturing industry, driven by rising demand from the logistics and supply chain sectors. The city is home to numerous established and emerging manufacturers that produce world-class plastic pallets using advanced molding techniques, automation, and high-grade raw materials.

Factors contributing to the expansion of the plastic pallet industry in New Delhi include:

Booming Industrial and E-Commerce Sectors: Increased warehousing and logistics needs have fueled demand for durable and reliable pallet solutions.

Government Support and Regulations: Policies promoting sustainability and bans on certain wooden packaging materials have led industries to switch to plastic pallets.

Technological Advancements: New Delhi manufacturers utilize injection molding and blow molding techniques to create high-quality, standardized pallets.

Export Opportunities: Many manufacturers export their products to the Middle East, Europe, and Southeast Asia, further boosting growth.

Leading Heavy Industrial Plastic Pallet Manufacturers in New Delhi

Several reputed manufacturers in New Delhi specialize in heavy industrial plastic pallets. These companies focus on innovation, quality, and customer satisfaction. Some of the key players include:

1. ABC Plastics Pvt. Ltd.

Known for durable, lightweight, and cost-effective plastic pallets.

Offers customized solutions for industries like food processing, pharmaceuticals, and retail.

Uses environmentally friendly materials and advanced manufacturing processes.

2. XYZ Polymer Solutions

Specializes in high-load-bearing plastic pallets suitable for industrial applications.

Provides options in different sizes, colors, and load capacities.

Adheres to international quality standards for safety and durability.

3. Delhi Poly Products

Offers a diverse range of plastic pallets, including rackable, nestable, and hygienic pallets.

Focuses on sustainable and recyclable materials.

Serves logistics companies, warehouses, and cold storage facilities.

4. IndoPlast Industries

Manufactures heavy-duty plastic pallets designed for automated warehouses.

Ensures compliance with international packaging and shipping regulations.

Provides innovative design solutions for bulk material handling.

5. Reliance Pallet Solutions

Produces impact-resistant, anti-slip, and UV-resistant plastic pallets.

Works with customized designs to suit industry-specific requirements.

Offers cost-effective bulk purchase options.

Key Features of High-Quality Plastic Pallets

Manufacturers in New Delhi prioritize the following features in their heavy industrial plastic pallets:

Material Quality: High-density polyethylene (HDPE) or polypropylene (PP) ensures robustness and longevity.

Load Capacity: Industrial plastic pallets can support static loads up to 6000 kg and dynamic loads of around 1500 kg.

Structural Design: Pallets come in different configurations such as single-deck, double-deck, and reinforced designs for various applications.

Ease of Handling: Compatible with forklifts and pallet jacks for seamless operations.

Safety Compliance: Products adhere to global safety standards, ensuring worker and product safety.

Applications of Heavy Industrial Plastic Pallets

Plastic pallets manufactured in New Delhi are used across a wide range of industries, including:

Logistics & Warehousing: Ensuring safe and efficient transportation of goods.

Food & Beverage Industry: Maintaining hygiene and compliance with health regulations.

Pharmaceuticals: Preventing contamination and ensuring sterile storage.

Automotive & Engineering: Handling heavy parts and components with ease.

Retail & E-Commerce: Streamlining storage and order fulfillment processes.

Customization and Innovation in Plastic Pallet Manufacturing

Manufacturers in New Delhi understand that different industries have unique needs. Many companies offer customization options such as:

Size and Dimensions: Tailored to fit specific racking systems or storage spaces.

Color Coding: Helps in inventory management and segregation of goods.

Branding & Logos: Companies can print logos or barcodes for tracking purposes.

Anti-Static & Fire-Resistant Pallets: Specially designed for industries handling sensitive materials.

Hygienic & Non-Porous Surfaces: Ideal for food and pharmaceutical applications.

Sustainability in Plastic Pallet Manufacturing

Sustainability is a crucial factor in modern manufacturing. Many manufacturers in New Delhi are adopting eco-friendly practices, such as:

Using recycled plastic to minimize environmental impact.

Implementing energy-efficient production techniques.

Designing reusable and repairable pallets to extend lifespan.

Promoting buy-back programs to encourage responsible disposal.

Conclusion

The demand for heavy industrial plastic pallets is on the rise, and New Delhi has positioned itself as a major manufacturing hub for these essential products. With leading manufacturers offering durable, cost-effective, and eco-friendly solutions, Businesses across various sectors can benefit from high-quality plastic pallets. Whether for logistics, warehousing, or specialized industrial applications, New Delhi’s Plastic Pallets or Warehouse Manufacturers continue to innovate and provide exceptional products that meet the.

By investing in plastic pallets from reputable manufacturers in New Delhi, businesse can improve efficiency, reduce costs, and contribute to sustainable industrial practices. If you are looking for a reliable plastic pallet supplier, exploring New Delhi’s top manufacturers will undoubtedly provide you with the best solutions tailored to your industry needs.

1 note

·

View note

Text

Plastic Pallet Manufacturers and Suppliers Near me - Beecraft

Beecraft is a prominent supplier and manufacturer of plastic pallets, serving various industries with high-quality, durable solutions. Located near several major urban centers, including London, Birmingham, and Manchester, Beecraft offers a wide range of pallet types tailored to specific needs such as export, stacking, and hygiene. Their pallets are known for their reliability, longevity, and compliance with industry standards, making Beecraft a trusted choice for businesses seeking efficient and sustainable logistics solutions. With a commitment to innovation and customer satisfaction, Beecraft continues to set benchmarks in the plastic pallet industry.

0 notes

Text

youtube

#Plastic Pallet Manufacturers#Plastic Pallets in Delhi#Plastic Pallet in Delhi#Industrial Plastic Pallets in Delhi#Plastic Pallet Manufacturers in Delhi#Industrial Plastic Pallets Manufacturers in Delhi#Plastic Pallets Suppliers in Delhi#Plastic Pallet Suppliers in Delhi#Plastic Pallets Wholesalers in Delhi#Plastic Pallet Wholesalers in Delhi#Youtube

0 notes

Text

How Pallet Manufacturers Are Innovating With Stackable Plastic Pallets

In the dynamic world of logistics and warehousing, the demand for smarter, more durable, and eco-friendly solutions is at an all-time high. Pallet manufacturers are rising to the occasion, developing innovative designs and materials to meet these evolving needs. One standout innovation in recent years has been the widespread adoption and advancement of stackable plastic pallets. These pallets are revolutionizing how goods are stored, transported, and managed across global supply chains.

In this article, we explore how pallet manufacturers are pushing boundaries with stackable plastic pallets, the benefits they offer, and what the future holds for this essential component of modern logistics.

The Rise of Stackable Plastic Pallets

A Shift From Wood to Plastic

Traditionally, wood pallets dominated the logistics industry due to their low cost and wide availability. However, concerns over hygiene, durability, and environmental impact have led many businesses to seek alternatives. Stackable plastic pallets have emerged as a superior option for many applications, offering long-term durability, easy sanitization, and better return on investment.

Demand Driven by Efficiency

Pallet manufacturers are increasingly focusing on stackable designs to optimize storage space and improve operational efficiency. Stackable plastic pallets can be nested or stacked uniformly, allowing for more products to be stored or shipped using the same footprint.

How Pallet Manufacturers Are Driving Innovation

Advanced Material Engineering

Leading pallet manufacturers are investing in high-performance plastics such as HDPE (High-Density Polyethylene) and PP (Polypropylene). These materials are resistant to moisture, chemicals, and extreme temperatures, making them ideal for industries like pharmaceuticals, food and beverage, and chemicals.

Modular and Custom Designs

Modern pallet manufacturers are creating modular stackable plastic pallets that can be tailored to specific industry requirements. Whether it’s for heavy-duty machinery or lightweight retail goods, manufacturers offer customized solutions that meet exact load and handling specifications.

Integration With Smart Technology

Some forward-thinking manufacturers are embedding RFID tags, QR codes, and IoT sensors into stackable plastic pallets. These smart features enable real-time tracking, inventory management, and asset recovery, significantly reducing losses and improving supply chain visibility.

Benefits of Stackable Plastic Pallets

Improved Durability and Longevity

Unlike wooden pallets that splinter and degrade over time, plastic pallets are more resilient and can last for years with minimal maintenance. This durability translates into lower long-term costs for businesses.

Enhanced Sanitation and Compliance

Plastic pallets are easier to clean and sanitize, making them suitable for hygiene-sensitive industries. Many stackable plastic pallets meet FDA and other international standards, helping companies stay compliant with health regulations.

Sustainable and Eco-Friendly Options

Pallet manufacturers are increasingly using recycled plastics and designing pallets for full recyclability at end-of-life. This circular approach supports sustainability goals and reduces waste in landfills.

Industry Use Cases and Examples

Food and Beverage Industry

In food logistics, stackable plastic pallets are favored for their cleanliness and resistance to contaminants. Companies can stack multiple loaded pallets efficiently in cold storage or shipping containers, reducing space and energy consumption.

Pharmaceutical Sector

Pharmaceutical companies benefit from the traceability and hygienic properties of plastic pallets. Smart stackable plastic pallets with RFID help track drug shipments from factory to pharmacy.

Retail and E-commerce

Retailers and e-commerce companies use stackable pallets to streamline storage and delivery operations. The uniformity of stackable plastic pallets improves automation compatibility in warehouses.

Challenges and Considerations

Initial Investment Costs

Plastic pallets typically have a higher upfront cost than wood. However, their longevity and reusability often offset the initial investment over time.

Recycling and Lifecycle Management

While many pallets are made from recyclable materials, not all facilities are equipped to handle plastic pallet recycling. Manufacturers are working on developing take-back programs and easier disassembly methods to address this issue.

Future Trends in Stackable Plastic Pallets

Sustainable Manufacturing Practices

Expect to see more pallet manufacturers using bio-based plastics and renewable energy in production. This shift aims to further reduce the carbon footprint of pallet manufacturing.

Expansion of Smart Pallets

The integration of technology will continue, with stackable plastic pallets becoming a crucial part of digital supply chains. Real-time data will inform smarter logistics decisions, reduce waste, and optimize inventory levels.

Increased Global Standardization

With international trade increasing, there is a push toward standardizing pallet sizes and specifications. Stackable plastic pallets are well-suited for this, thanks to their precision engineering and uniformity.

Conclusion

The innovations introduced by pallet manufacturers in the realm of stackable plastic pallets are transforming logistics and warehousing operations worldwide. From improved hygiene and durability to smart tracking and sustainability, these pallets are far more than just platforms for cargo—they’re strategic assets in modern supply chains.

As industries continue to evolve, so too will the pallets that support them. Businesses that invest in innovative pallet solutions today will reap operational efficiencies and environmental benefits for years to come.

FAQs

1. What are stackable plastic pallets made of?Most are made from HDPE or PP plastics, which are durable, lightweight, and resistant to chemicals.

2. Are stackable plastic pallets suitable for heavy loads?Yes, many models are designed for high load-bearing capacity and can be customized based on industry needs.

3. How do plastic pallets compare to wooden pallets in terms of cost?While plastic pallets have a higher upfront cost, they offer greater longevity and lower maintenance, resulting in long-term savings.

4. Can stackable plastic pallets be recycled?Yes, most are fully recyclable, and many manufacturers offer take-back programs to facilitate recycling.5. Do stackable plastic pallets comply with international shipping regulations?Yes, many comply with ISPM 15 and FDA standards, making them ideal for international and hygiene-sensitive shipping.

0 notes

Text

Industrial Plastic Crates

Star Corporation offers high-quality Industrial Plastic Crates designed for durable and efficient storage and transportation. Made from premium-grade plastic, these crates are lightweight, sturdy, and resistant to chemicals and impact.

0 notes

Text

Why Plastic Pallets Are in High Demand Across Industries in India

In today’s fast-paced and competitive industry environment, efficient logistics and safe product handling are critical to success. One such invention that has made a significant difference is Plastic pallets.

For businesses across India, where diverse industries operate in varying climates and conditions, plastic pallets are proving to be the ultimate choice. Here’s why:

1. Durability That Outlasts Traditional Options

Plastic pallets are designed to withstand significant weight and rigidity. Though classic pallets are susceptible to splitting, decaying or breaking completely, plastic pallets keep their basic shape and changes storage structure for years at a time.

For instance, Swift’s Roto Molded Plastic Pallets, made from 100% virgin material, provide superior strength and longevity, making them an ideal solution for heavy-duty applications.

2. Hygiene and Cleanliness: Perfect for Food and Pharma

High hygiene selectivity is imperative for the Food, Pharmaceutical and Chemical industries. Being non-porous, moisture resistant and easy to clean plastic pallets are an ideal choice where hygiene is the utmost concern. Swift’s Food-Grade Pallets, specifically designed for these industries, not only guarantee that hygiene requirements are fulfilled but also provide durability.

3. Weather-Resistant for India’s Diverse Climates

From the humid shores of Kerala to arid Rajasthan, India’s varied climates can be punishing on traditional pallets. On the other hand, plastic pallets are significantly impervious to climatic conditions ensuring reliability while sending products through ruthless summers or monsoon showers.

4. Lightweight Yet Strong

Plastic pallets are much lighter than traditional pallets, even though they are quite popular. Plastic pallets offer the best strength against breakage. Not only does this reduce shipping costs, but it’s also easier and safer for workers to handle. For Industries managing high volumes of logistics across India, Swift’s Rackable Pallets offer a perfect combination of lightweight design and heavy load-bearing capacity.

5. Eco-Friendly and Sustainable

As sustainability becomes more significant, plastic pallets are also a responsible choice. Most are created with recyclable materials to limit the environmental footprint. Plus their longevity also means fewer replacements, leading to less landfill waste. Swift’s Recyclable Pallets help Industries align with their green goals without compromising on quality.

6. Safety First

Plastic pallets do not have nails protruding at any point, making them safe to use; there are no sharp edges or splinters. This becomes particularly important in high handling applications like warehousing and distribution centers. Swift’s Safety Pallets, for instance, are designed with smooth edges and robust construction to prevent workplace injuries.

7. Customization for Specific Needs

Indian industries are as diverse, and their logistics requirements vary correspondingly. Plastic pallets can be customized for specific requirements whether it is for printed materials, electronic products or agricultural produce. For instance, Swift’s Printing and Packaging Pallets are designed specifically to meet the specialized needs of the printing industry.

8. Compliance with Global Standards

You have to fall in line with international shipping laws if your industry deals with export. Plastic pallets also comply with these standards, for example ISPM-15 legislation prohibits untreated conventional pallets in international trade. Swift’s Export Pallets are developed as per these regulations hence are a no-hassles choice for industries that seek to go global.

Case Study: A Leading Indian FMCG Company

A renowned FMCG company in India recently switched to Swift’s Food-Grade Plastic Pallets for transporting its packaged food products. The result? A significant reduction in product damage during transit and improved warehouse efficiency. The lightweight yet sturdy design of the pallets also led to a 15% decrease in shipping costs.

Conclusion

Plastic pallets have started revolutionizing the manner in which Indian industries operate their logistics and warehousing. They offer several benefits, including resistivity, cleanliness and sustainability as well as cost efficiency; things that are needed in varying degrees by various sectors of the Indian industry. Ultimately, transitioning to plastic pallets is investing in durability and future strength no matter your industry, whether manufacturing, warehousing or retail.

Upgrade your operations today with Swift’s Plastic Pallets—India’s choice for smarter, safer, and more sustainable industry solutions!

#plastic pallets manufacturers in india#plastic pallets#plastic pallets supplier#roto molded pallets#plastic pallet near me#cost of plastic pallets#blue plastic pallets#swifttechnoplast

0 notes

Text

The Benefits of Investing in MS Slotted Angle Racks

Looking for reliable and versatile storage solutions? Discover the benefits of MS Slotted Angle Rack Manufacturers

Why Choose MS Slotted Angle Racks?

Customizable Design: Tailor the size and layout to fit your specific needs, whether for offices, warehouses, or retail spaces.

High Load Capacity: With load capacities ranging from 50 kg to over 400 kg per layer, these racks can handle heavy items efficiently.

Durable Material: Made from high-grade mild steel, these racks are built to last and withstand rough usage.

Versatile Applications: Ideal for storing tools, equipment, and supplies, they are perfect for various settings including industrial, commercial, and residential.

Easy Assembly: Designed for quick and straightforward assembly, making them user-friendly for all.

Key Features

Adjustable Shelves: Easily modify the height and number of shelves to accommodate different items.

Corrosion Resistance: Many manufacturers offer paint-coated or powder-coated finishes to enhance durability and aesthetics.

Space Efficient: Helps maximize storage space while keeping your environment organized.

Leading Manufacturers

Rolex India Engineering: Offers customizable racks with a load capacity of up to 100 kg per layer, perfect for office use.

Neelkamal Steel: Known for their six-shelf racks, designed for heavy-duty storage in warehouses.

Jaashvi Storage Solutions: Provides a range of display and storage racks, ensuring high quality and reliability.

Metal Storage Rack: Specializes in mobile shelving systems with a capacity of up to 1000 kg per layer.

Conclusion

Investing in MS Slotted Angle Racks is a smart choice for anyone looking to enhance their storage solutions. With their durability, customization options, and high load capacities, these racks are designed to meet diverse storage needs.Contact leading manufacturers today to find the perfect MS Slotted Angle Rack for your space!

#Mezzanine Floor Manufacturers#Fabric Storage Rack Manufacturers#Industrial Plastic Pallet Manufacturers#Storage Rack Manufacturers#Mobile Compactor Storage System Manufacturers#Storage Systems Manufacturers#Slotted Angle Racks Manufacturers#MS Slotted Angle Rack Manufacturers#Slotted Angle Storage Rack Manufacturers#Supermarket Display Rack Manufacturers#Mobile Compactor Manufacturers#Grocery Display Rack Manufacturers

0 notes

Text

Nilkamalbubbleguard is a trusted manufacturer of high-quality pallets designed for various applications. Explore our durable, cost-effective selection, including honeycomb and 4-way pallets.

#Pallet Manufacturers#Pallets#Wooden Pallets#Plastic Pallets#Industrial Pallets#Material Handling#Shipping Pallets#Honeycomb Pallets#4-Way Pallets#Nilkamalbubbleguard

0 notes

Text

Nilkamalbubbleguard is a trusted manufacturer of high-quality pallets. We offer a wide variety of pallet solutions to meet your specific needs. Explore our durable and cost-effective pallets

#Pallet Manufacturers#Pallets#Wooden Pallets#Plastic Pallets#Industrial Pallets#Material Handling#Shipping Pallets#Nilkamalbubbleguard

0 notes

Text

Comprehensive Commercial Storage Solutions: From Racks to Pallets

Explore our comprehensive range of commercial storage solutions tailored to meet your specific needs. From storage racks and cold storage to storage boxes and warehousing, we provide robust systems to optimize space and enhance efficiency. Our offerings include cable trays in various sizes, ideal for organizing and protecting your wiring infrastructure. As a leading pallet rack manufacturer, we deliver durable pallet racking systems and heavy-duty racks perfect for industrial applications. For retail environments, we offer specialized racks for shops, supermarket racks, and grocery store racks to maximize product display and storage.

Our slotted angle racks and plastic pallets ensure versatile and resilient storage options. Partner with us for top-quality storage products, including industrial pallets and vegetable display racks that cater to diverse warehousing needs. As a supermarket rack manufacturer and display rack for shop provider, we help businesses optimize space and improve customer experience. For cable management, our cable tray manufacturer services offer reliable solutions. Additionally, our warehouse storage solutions and plastic pallets provide robust support for various storage applications.

Website - https://suvidhass.com/ Call more information : +91 9682939624

#Storage Rack#Cold Storage#Storage Box#Warehousing#Cable Tray#Cable Tray Sizes#Pallet Rack Manufacturer#Racks for shop#Super Market Rack#Racks for Storage#Slotted Angel Rack#Plastic Pallets#Racks#Heavy Duty Rack Manufacturer#Storage Products#Pallet Racking System#Supermarket Rack Manufacturer#Display Rack for Shop#Cable Tray Manufacturer#Warehouse Storage#Grocery Store Racks#Industrial Pallet#Vegetable Display Rack#Plastic Pallet

1 note

·

View note

Text

Export Pallets Manufacturers in Delhi excel in producing high-quality pallets for global logistics needs. Companies like Delhi Plastics leverage advanced injection molding technology to create durable plastic pallets that meet international standards for reliability and efficiency in transportation. These pallets are lightweight, resistant to moisture, and ideal for various modes of shipping. Delhi's expertise in export pallet manufacturing ensures compliance with global regulations, facilitating smooth international trade and logistics operations.

Locate Us

Sonipat, Haryana - 131301

+91-8700900663

#syntaxplasticpallets#Plastic Pallets Manufacturers in India#Plastic Pallets Manufacturers in Delhi#Export Pallets Manufacturers in India

0 notes

Text

12 Types of Industrial Plastic Pallets for Supply Chain Management: A Beginner’s Guide

In today’s fast-paced world, supply chain management is crucial to the success of any business. One often overlooked but essential component of efficient supply chain operations is the pallet. Among the various types available, industrial plastic pallets have gained popularity for their durability, hygiene, and versatility. In this guide, we will explore the different types of plastic pallets, their benefits, and how to choose the right plastic pallet manufacturer for your business.

What Are Industrial Plastic Pallets?

Industrial plastic pallets are specialized platforms used to support goods during transportation, storage, and handling. Unlike traditional wooden pallets, plastic pallets are made from high-density polyethylene (HDPE) or polypropylene (PP). This material choice offers several advantages, including resistance to moisture, chemicals, and pests, making them ideal for a wide range of industries.

Plastic pallets are particularly favored in industries where hygiene and cleanliness are paramount, such as food processing, pharmaceuticals, and electronics. Moreover, they are lightweight yet strong, reducing transportation costs and increasing load efficiency.

Benefits of Using Plastic Pallets in Supply Chain Management

When it comes to supply chain management, the choice of pallets can significantly impact the efficiency and cost-effectiveness of operations. Here are some key benefits of using plastic pallets:

Durability and Longevity: Plastic pallets are designed to withstand the rigors of heavy-duty industrial use. Unlike wooden pallets, they do not splinter, crack, or rot, ensuring a longer lifespan. This durability translates into cost savings over time, as plastic pallets require fewer replacements.

Hygiene and Ease of Cleaning: In industries where sanitation is critical, such as food and pharmaceuticals, plastic pallets offer a significant advantage. They are easy to clean and sanitize, reducing the risk of contamination. Additionally, plastic pallets are resistant to moisture, making them ideal for environments where hygiene is a top priority.

Environmental Sustainability: Many plastic pallets are made from recyclable materials, contributing to a more sustainable supply chain. At the end of their life cycle, recyclable plastic pallets can be processed into new products, reducing waste and minimizing the environmental impact.

Safety: Plastic pallets are free from nails, splinters, and sharp edges, making them safer for workers to handle. Their lightweight design also reduces the risk of injuries during manual handling, improving overall workplace safety.

Customization and Versatility: Plastic pallets come in various designs and sizes to suit specific industry needs. Whether you require pallets for export, storage, or specialized applications, plastic pallets can be customized to meet your requirements. This versatility ensures that your supply chain operates efficiently and effectively.

12 Types of Industrial Plastic Pallets

Now that we understand the benefits of using plastic pallets, let’s explore the 12 different types of industrial plastic pallets available for supply chain management. Each type has unique features and is suited to specific applications.

Nestable Plastic Pallets

Description: Nestable plastic pallets are designed to fit into each other when empty, reducing the amount of space required for storage.

Uses: These pallets are ideal for businesses that need to save space when pallets are not in use. They are commonly used in retail and distribution centers.

Benefits: Space-saving, cost-effective, and easy to handle.

Stackable Plastic Pallets

Description: Stackable plastic pallets feature a solid base that allows them to be securely stacked on top of each other, even when loaded with goods.

Uses: These pallets are perfect for warehouse storage and transportation, where vertical space utilization is essential.

Benefits: Maximizes storage capacity, provides stability during transport.

Rackable Plastic Pallets

Description: Rackable plastic pallets are designed to be used with racking systems in warehouses. They have reinforced edges that provide extra support when placed on racks.

Uses: Ideal for heavy-duty applications where goods need to be stored on racks for long periods.

Benefits: Provides excellent load-bearing capacity, enhances storage organization.

Export Plastic Pallets

Description: Export plastic pallets are lightweight pallets designed for international shipping. They are often made to meet specific international regulations.

Uses: Best suited for one-way shipping, where the pallet is not expected to be returned.

Benefits: Cost-effective, compliant with international shipping standards.

Hygienic Plastic Pallets

Description: Hygienic plastic pallets are smooth and easy to clean, with no crevices where dirt or bacteria can accumulate.

Uses: Commonly used in industries that require high levels of cleanliness, such as food processing and pharmaceuticals.

Benefits: Promotes sanitation, reduces contamination risks.

Spill Control Plastic Pallets

Description: Spill control plastic pallets feature built-in containment trays to catch and contain spills of liquids, such as chemicals or oils.

Uses: Essential for industries that handle hazardous materials, such as chemicals and oil.

Benefits: Prevents environmental contamination, ensures compliance with safety regulations.

Drum Plastic Pallets

Description: Drum plastic pallets are specifically designed to hold drums securely in place, preventing them from rolling or tipping over.

Uses: Ideal for storing and transporting barrels and drums in industries like oil, chemicals, and beverages.

Benefits: Provides stability for cylindrical containers, enhances safety during transport.

Heavy-Duty Plastic Pallets

Description: Heavy-duty plastic pallets are built to handle large, bulky loads. They are reinforced to support substantial weight without deforming.

Uses: Best suited for industries that require the transport of heavy goods, such as construction and manufacturing.

Benefits: High load capacity, long-lasting durability.

ESD Plastic Pallets

Description: ESD (Electrostatic Discharge) plastic pallets are designed to protect sensitive electronic components from static electricity.

Uses: Commonly used in electronics manufacturing and assembly.

Benefits: Protects electronic goods from damage, ensures compliance with ESD safety standards.

Freezer Spacer Pallets

Description: Freezer spacer pallets are designed for use in cold storage environments. They allow air circulation around products to maintain consistent temperatures.

Uses: Essential for food and pharmaceutical industries that require cold storage.

Benefits: Improves cold storage efficiency, prevents product spoilage.

Custom Plastic Pallets

Description: Custom plastic pallets are tailored to meet specific needs, including size, shape, and load capacity.

Uses: Ideal for businesses with unique pallet requirements that standard sizes cannot accommodate.

Benefits: Provides a perfect fit for specialized applications, enhances operational efficiency.

Recyclable Plastic Pallets

Description: Recyclable plastic pallets are made from materials that can be easily recycled at the end of their life cycle.

Uses: Suitable for environmentally conscious companies looking to reduce their carbon footprint.

Benefits: Promotes sustainability, reduces waste.

How to Choose the Right Plastic Pallet Manufacturer

Selecting the right plastic pallet manufacturer is crucial to ensuring that you receive high-quality, durable pallets that meet your specific needs. Here are some key factors to consider when choosing a supplier:

Experience and Expertise: Look for a manufacturer with a proven track record in producing high-quality plastic pallets. Experience often translates into better product quality and customer service.

Quality and Certifications: Ensure that the manufacturer adheres to industry standards and certifications. This is particularly important if you require pallets for specialized applications, such as food-grade or ESD pallets.

Customization Options: A good manufacturer should offer customization options to meet your unique needs. Whether you need custom sizes, colors, or features, the ability to tailor products is a significant advantage.

Environmental Responsibility: Consider a manufacturer that prioritizes sustainability by offering recyclable plastic pallets and environmentally friendly production processes. This aligns with growing consumer and regulatory demands for greener practices.

Ongoing Support: Choose a manufacturer that provides ongoing support, including product advice, maintenance tips, and responsive customer service. This ensures a smooth and hassle-free experience.

By carefully selecting a reliable plastic pallet manufacturer, you can enhance the efficiency and effectiveness of your supply chain operations.

Conclusion

In summary, industrial plastic pallets are a vital component of modern supply chain management, offering numerous benefits such as durability, hygiene, and environmental sustainability. By understanding the different types of plastic pallets available, you can make informed decisions that improve your supply chain’s efficiency and cost-effectiveness.When selecting a plastic pallet manufacturer, prioritize experience, quality, and customization options to ensure you receive the best products for your specific needs. By doing so, you’ll be well on your way to optimizing your supply chain with the right plastic pallets.

0 notes

Text

Polycon UAE: Comprehensive Solutions for Water Storage, Safety, and More

Polycon UAE stands as a leader in delivering premium-quality water tanks, road barriers, portable restrooms, and other essential products for diverse applications. Whether you are seeking municipality-approved tanks in Al Ain, plastic road barriers in UAE, or portable toilets in Abu Dhabi, we have a solution tailored to your needs.

Unmatched Water Storage Solutions

Polycon UAE’s water storage tanks are engineered to meet the highest standards of quality, safety, and reliability. As one of the best water tank manufacturers in UAE, we offer a broad range of options:

Polycon Water Tanks: Renowned for durability and UV resistance, ideal for residential and industrial use.

Underground Tanks in Abu Dhabi: Space-efficient and robust for long-term water storage.

Horizontal Tank Suppliers in Al Ain: Perfect for areas with limited space, offering optimal capacity.

Conical Tanks in Al Ain: Ideal for specialized storage applications requiring easy discharge.

PVC or Plastic Polyethylene Tanks in Abu Dhabi: Lightweight, non-corrosive, and cost-effective.

Slim Tanks: Designed for compact spaces without compromising on capacity.

Best Plastic Tank Manufacturers in UAE: Our tanks are recognized for their strength, durability, and compliance with safety regulations.

We also cater to pricing inquiries with affordable options for 1000-liter water tanks in UAE and 5000-gallon water tanks in UAE, ensuring you find the perfect fit for your budget.

Road Barriers and Safety Solutions

Road safety is paramount, and Polycon UAE specializes in manufacturing and supplying durable road barriers and safety barriers across the UAE. Our range includes:

Road Barriers in UAE: High-quality plastic barriers for highways and construction zones.

Track Barriers in Abu Dhabi: Designed for sports tracks and high-speed safety requirements.

Plastic Road Barriers Suppliers in UAE: Lightweight yet durable for easy deployment and transportation.

Safety Barrier Suppliers in Al Ain: Engineered for maximum visibility and impact resistance.

Road Barrier Manufacturers in UAE: Trusted by contractors and government agencies alike for reliable solutions.

Our road safety barriers in UAE are built with a focus on sustainability, ensuring they withstand the harshest weather conditions while maintaining optimal performance.

Portable Restrooms and Spill Containment Solutions

Polycon UAE provides modern and hygienic portable bathrooms, portable restrooms, and porta cabins for a variety of applications, including events, construction sites, and remote locations.

Portable Toilets in UAE: Designed for convenience, durability, and comfort.

Portable Restrooms in Abu Dhabi: Ideal for temporary setups, ensuring sanitation and ease of use.

Best Porta Cabin Manufacturer in UAE: Custom-designed porta cabins for versatile applications.

For industrial safety, our spill containment pallets in UAE and dual-face pallets provide superior containment and handling solutions for hazardous materials.

Superior Plastic Tanks and Pallets

As a leading plastic tank supplier, Polycon UAE offers a comprehensive selection of plastic water tanks and polyethylene tanks in Al Ain. Our products include:

Water Tanks in Abu Dhabi, Dubai, and Sharjah: Tailored for diverse storage needs.

Plastic Pallets in Al Ain: Durable and lightweight for industrial use.

With a focus on innovation, we are the best tank manufacturer in Abu Dhabi, providing solutions for residential, commercial, and industrial water storage.

Why Choose Polycon UAE?

Government-Approved Water Tanks in Abu Dhabi: Compliance with all safety and quality standards.

Biggest Water Tank Manufacturers: Extensive capacity to cater to projects of any scale.

Top Water Tanker Suppliers in UAE: Trusted for timely delivery and exceptional product quality.

Custom Solutions: Tailored products for specific needs, from storage tanks in Abu Dhabi to portable bathrooms in UAE.

At Polycon UAE, our commitment to quality and customer satisfaction ensures that you receive only the best water tank suppliers in UAE and related products.

Contact us today to learn more about our extensive product offerings and services, and experience why we are the trusted choice for plastic tanks, road barriers, and portable restrooms across the UAE!

#inspection chambers in uae#road barriers and safety barriers in abudhabi#polycon water tank#Track Barrier in uae#rotolining price in uae#sports track barriers in abudhabi#Dual Face Pallets in UAE#Track Barriers#underground tank in abudhabi#Conical Tank suppliers in AL AIN#water storage tank#Road Safety Barrier in UAE#road barriers in uae#Road Barrier Manufacturers UAE#horizontal tank suppliers in Al AIN#Road Barrier suppliers in AL AIN#plastic road barriers suppliers in uae#Road Barriers Suppliers in UAE#plastic road barrier in uae#Safety Barrier suppliers in AL AIN#safety barrier supplier in uae#plastic road barrier#Polyethylene tanks in AL AIN#road barriers#Spill Containment Pallets in UAE#portable toilets uae#water storage tanks#Portable Restroom uae#Plastic tanks in UAE#portable bathroom uae

0 notes

Text

Star Corporation: Leading the Way as a Top Plastic Pallet Manufacturer

In today’s fast-paced logistics and supply chain industry, durability, efficiency, and sustainability are key factors when selecting the right pallet solutions. Star Corporation, a trusted name in the industry, stands out as a leader in providing high-quality, cost-effective, and eco-friendly plastic pallets to businesses worldwide.

As a leading Plastic Pallet Manufacturer, we understand the growing demand for durable and sustainable pallet solutions. Our plastic pallets are designed to meet the highest industry standards, offering superior strength, hygiene, and reusability compared to traditional wooden pallets. With a commitment to innovation and quality, Star Corporation continues to revolutionize the pallet manufacturing industry.

Why Choose Plastic Pallets?

Plastic pallets have become the preferred choice for many industries, including pharmaceuticals, food and beverage, retail, and manufacturing. Unlike traditional wooden pallets, plastic pallets offer numerous benefits:

Durability – Plastic pallets are resistant to moisture, chemicals, and harsh weather conditions, making them ideal for long-term use. Hygiene – Unlike wooden pallets that may harbor bacteria or pests, plastic pallets are easy to clean and sanitize, ensuring compliance with industry standards. Lightweight & Strong – Despite being lighter than wood, plastic pallets have a high load-bearing capacity, making them a superior choice for shipping and storage. Eco-Friendly – Many plastic pallets are made from recycled materials and are 100% recyclable, supporting sustainable business practices. Cost-Effective – With a longer lifespan and lower maintenance costs, plastic pallets provide better long-term value.

Star Corporation: The Trusted Plastic Pallet Manufacturer

At Star Corporation, we take pride in our state-of-the-art manufacturing process, producing a wide range of plastic pallets tailored to different industry needs. Our commitment to innovation and quality ensures that businesses receive durable and efficient pallet solutions.

Our Plastic Pallet Solutions

We offer a variety of plastic pallets, including:

Heavy-Duty Plastic Pallets – Ideal for industrial applications requiring high weight capacity and durability. Hygienic Plastic Pallets – Specially designed for food, pharmaceutical, and cleanroom environments. Nestable & Stackable Pallets – Space-saving designs that optimize warehouse storage. Export Pallets – Lightweight and compliant with international shipping regulations.

Why Star Corporation Stands Out?

✔ Advanced Manufacturing – We utilize cutting-edge technology and high-quality raw materials to produce durable plastic pallets. ✔ Customization Options – Tailored pallet solutions to meet specific business needs, including color, size, and load capacity. ✔ Eco-Friendly Commitment – Our products are designed with sustainability in mind, reducing environmental impact. ✔ Global Reach – Supplying top-quality plastic pallets to businesses across different industries worldwide.

Conclusion

As a leading plastic pallet manufacturer, Star Corporation is committed to providing superior, long-lasting, and eco-friendly pallet solutions for businesses worldwide. Whether you need plastic pallets for storage, shipping, or export, we have the right solution for you.

Choose Star Corporation for reliability, innovation, and sustainability. Contact us today to explore our wide range of plastic pallets and find the perfect fit for your business needs.

0 notes

Text

Eco-Friendly and Efficient: The Future of Plastic Pallets in Industry

In today’s evolving world, which prioritizes sustainability and environmental awareness, companies are increasingly seeking eco-friendly options that not only enhance efficiency but also positively impact the environment. An example of such a solution that is gaining popularity is the adoption of plastic pallets.

These versatile instruments signify a move, towards embracing eco methods, in the logistics and supply chain sectors.

The Benefits of Plastic Pallets

Sustainability: Plastic pallets are designed to be used and reused throughout their lifetime and are made of recyclable materials. They provide a more sustainable choice compared to other materials, aligning with eco-friendly business practices.

Durability and Longevity: Plastic pallets endure harsh conditions and heavy loads without splintering or warping over time, unlike traditional pallets. They are a choice as they last longer and reduce the amount of waste going to landfills.

Hygiene and Safety: In sectors, like the food and pharmaceutical industries cleanliness is crucial Plastic pallets boast porous surfaces that are simple to sanitize preventing contamination and meeting safety standards The absence of edges or splinters adds a layer of safety, for employees when handling and moving them

Cost-Effectiveness: Although plastic pallets may require an investment compared to alternative choices initially; their durability and minimal maintenance requirements can ultimately lead to cost savings in the long run. Moreover plastic pallets lighter weight can contribute to reduced transportation expenses and better fuel efficiency.

The Future of Plastic Pallets in Industry

The rising emphasis, on sustainability in industries is driving a growing need for friendly items such, as plastic pallets. Several trends indicate that plastic pallets will play a crucial role in the future of logistics and supply chain management:

Increased Recycling Initiatives: Many businesses are adopting closed loop systems to recycle plastic pallets once they have served their purpose aiming to minimize impact and promote an economy.

Technological Advancements: Advancements in manufacturing have led to the development of more effective plastic pallets with upgraded designs and materials, enhancing their capabilities across various uses.

Global Standards and Certifications: As companies prioritize sustainability as a measure of success, in the business landscape they will increasingly pursue certifications for their packaging and materials. In this context, plastic pallets that adhere to eco criteria are poised to emerge as the top choice, for businesses aiming to demonstrate their dedication to environmental responsibility.

E-commerce Growth: The rise of online shopping has led to an increased demand, for logistics services like never before Plastic pallets offer an lightweight solution that can improve effectiveness and reduce shipping costs making them an ideal option, for the e commerce sector.

Conclusion

It’s clear that there is a shift, towards logistics solutions lately. Plastic pallets are leading the way by providing eco friendly options that enable businesses to boost efficiency and lessen their environmental impact.

At Swift Technoplast, we provide innovative plastic pallet solutions that meet the demands of modern industries, helping you optimize your supply chain and promote sustainability.

#heavy duty plastic pallets#plastic pallets near me#pallet plastic#plastic pallets manufacturer#plastic pallets supplier#hdpe pallet#pvc pallets#shipping pallet

0 notes