#Plastic Cable Glands

Explore tagged Tumblr posts

Text

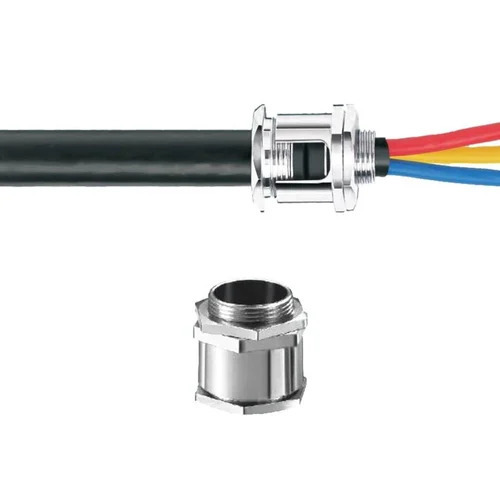

Mastering Cable Glands: Types, Installation, and India's Top Manufacturers

Cable glands play a crucial role in electrical systems by securing cables and preventing hazards caused by environmental factors like moisture, dust, or extreme temperatures. From industrial settings to marine environments, choosing the right cable gland ensures system safety and efficiency. In this guide, we'll cover various cable gland types, the installation process, and highlight top manufacturers in India, such as Atlas Metal Industries.

Understanding Cable Gland Types

Different cable glands are designed for specific needs:

Brass Cable Glands: Ideal for industrial environments due to their durability and conductivity. Plastic Cable Glands: Lightweight and cost-effective for less demanding applications. Waterproof Cable Glands: Essential for marine and outdoor use to prevent water ingress. Armored Cable Glands: Used in heavy-duty environments where additional mechanical protection is needed.

Installation Process: Step-by-Step

Proper installation ensures the gland performs as expected:

Prepare the Cable: Strip the sheath carefully to avoid damage. Insert the Gland: Slide the gland components onto the cable. Tighten the Seal: Use the provided tools to secure the gland without over-tightening. Check the Seal: Ensure it's tight and securely fastened for optimal protection.

Top Cable Gland Manufacturers in India

India is home to leading manufacturers like Atlas Metal Industries, known for producing high-quality industrial cable glands. With decades of expertise, Atlas Metal offers durable, precision-engineered products trusted across industries.

Conclusion

Selecting the right cable gland depends on your specific needs. Whether it’s a waterproof solution for outdoor applications or a brass gland for heavy-duty industrial use, Atlas Metal Industries provides top-tier products that ensure safety and longevity. Looking for reliable cable glands? Contact Atlas Metal Industries for high-quality, durable products. Visit Atlas Metal Industries for more information.

#Atlas Metal Industries#high-quality industrial cable glands#Waterproof Cable Glands#Plastic Cable Glands#Brass Cable Glands

1 note

·

View note

Text

How to Extend the Lifespan of Electrical Equipment in Harsh Environments

Introduction In challenging environments like factories or offshore sites, electrical equipment often faces wear due to exposure to moisture, dust, and vibration. Ensuring that cables are properly secured with the right connectors—such as durable cable gland types—is crucial to extending the life of this equipment. Here are some practical tips for protecting your electrical systems.

Use Appropriate Connectors for Environmental Protection The correct electrical cable gland type and size plays a significant role in protecting cables from dust and moisture. For instance, stainless steel glands are ideal for corrosive environments, while plastic glands provide affordable options for lighter-duty applications. Choosing a gland that aligns with the equipment’s conditions can significantly reduce wear.

Preventing Moisture and Dust Ingress In many environments, electrical failures can be traced back to moisture or dust entering the system. Using the right cable gland types can prevent this, as they create a secure seal around cables and protect them from contaminants, ensuring the equipment’s functionality and extending its lifespan.

Regular Inspection and Maintenance Regularly inspecting connectors and glands is essential to prevent degradation. By ensuring that the electrical cable gland type and size matches the equipment's requirements, you can improve durability and minimize potential hazards.

Conclusion Protecting electrical equipment in harsh environments starts with small details, like choosing the right cable gland types. Proper selection and maintenance of these components can make a noticeable difference in extending equipment lifespan. For a comprehensive guide on cable gland selection, read our blog.-https://qamaralzeyan.com/electrical-cable-gland-types/

0 notes

Text

Connecting the dots the essential role of industrial cable gland connectors

Introduction

Industrial Cable Gland Connectors are vital components in electrical and mechanical systems, designed to securely fasten, seal, and protect cables as they enter electrical enclosures or machinery. These connectors are widely used across a variety of industries, including manufacturing, oil and gas, telecommunications, automation, and construction, where they provide critical protection for cables in harsh environments.

In this blog post, we’ll explore the purpose, types, and benefits of industrial cable gland connectors and why they are essential to the safety and performance of electrical systems.

What Are Industrial Cable Gland Connectors?

Industrial cable gland connectors are mechanical devices that attach and secure electrical cables to equipment, junction boxes, and panels. They provide strain relief to prevent damage to cables, while also protecting against environmental factors such as dust, moisture, and chemicals. Cable glands are typically made from materials like brass, stainless steel, nylon, or plastic, depending on the specific application and environment.

Key Functions of Industrial Cable Gland Connectors

Strain Relief One of the primary functions of cable gland connectors is to provide strain relief, preventing cables from being pulled out of place or damaged due to mechanical stress, tension, or vibrations. This is critical in industrial settings where machinery and equipment are constantly in motion.

Environmental Protection Industrial cable glands create a seal that protects cables from environmental factors such as water, dust, and chemicals. This ensures that electrical systems remain safe and operational, even in harsh or hazardous conditions. In industries like oil and gas or mining, this protection is essential for maintaining the integrity of electrical systems.

Cable Sealing Cable glands provide a watertight and airtight seal around the cable entry points, preventing moisture and contaminants from entering electrical enclosures. This feature is crucial for preventing short circuits, equipment failure, and safety hazards.

Electrical Safety By securely anchoring and sealing cables, industrial cable glands contribute to the overall safety of electrical systems, reducing the risk of fire, electric shock, and equipment malfunctions.

Types of Industrial Cable Gland Connectors

Single Compression Cable Glands These are commonly used for general-purpose industrial applications. They provide effective sealing for standard cables but are typically used in less harsh environments.

Double Compression Cable Glands Designed for more demanding applications, double compression cable glands offer enhanced protection against dust, moisture, and extreme temperatures. They are often used in hazardous areas, such as oil rigs and chemical plants.

EMC Cable Glands These cable glands are designed to prevent electromagnetic interference (EMI), making them ideal for sensitive electrical and communication systems where signal integrity is crucial.

Explosion-Proof Cable Glands Explosion-proof or flameproof cable glands are used in hazardous environments where flammable gases, vapors, or dust are present. These glands prevent sparks or flames from traveling through the cable entry points, ensuring safety in areas prone to explosions.

Benefits of Using Industrial Cable Gland Connectors

Improved System Longevity By protecting cables from environmental damage and strain, cable glands help extend the life of electrical systems and reduce the need for maintenance or replacements.

Enhanced Safety Cable glands reduce the risk of accidents, electrical failures, and fires by providing secure connections and protecting cables from external hazards.

Cost-Effective Investing in high-quality cable glands helps reduce downtime and maintenance costs by protecting electrical systems from damage and wear.

Choosing the Right Cable Gland Connectors for Your Application

When selecting industrial cable gland connectors, consider factors such as the type of cable, environmental conditions, material requirements, and safety regulations. For hazardous environments, it's essential to choose cable glands that are certified for explosion-proof or flameproof applications. Additionally, ensure that the gland material—whether brass, stainless steel, or plastic—matches the demands of the environment to prevent corrosion or degradation over time.

Conclusion

Industrial cable gland connectors are indispensable components in maintaining the safety, efficiency, and longevity of electrical systems in demanding environments. Whether you are working in manufacturing, oil and gas, or construction, the right cable gland ensures that your electrical systems remain protected and perform optimally under challenging conditions. Choosing the right type of cable gland for your specific application is a critical step in ensuring the safety and reliability of your entire setup.

0 notes

Text

Sealing Design and IP68 Protection Technology for Metal Pushbutton Switches

In various industrial, automotive, and outdoor applications, metal pushbutton switches are often required to operate reliably in harsh environments, including exposure to water, dust, oil, and other contaminants. Achieving a high level of sealing protection is critical to ensure the durability and functionality of these switches. The IP68 rating, which represents the highest level of protection against dust and water ingress, is a common requirement for metal pushbutton switches used in demanding conditions. This article will explore how to implement IP68 sealing design through the right structure and material selection, analyze the protective performance against contaminants such as oil and dust, and introduce durability testing methods in extreme environments.

1. Achieving IP68 Sealing Design for Metal Pushbutton Switches

1.1 IP68 Definition and Requirements

The IP68 rating is part of the IP (Ingress Protection) standard defined by the International Electrotechnical Commission (IEC). This rating indicates the highest levels of protection:

IP6X: Full protection against dust, meaning no dust particles can enter the switch under any circumstances.

IPX8: Protection against long-term immersion in water, typically under conditions specified by the manufacturer (e.g., depth and duration of immersion).

To achieve this level of protection, metal pushbutton switches must undergo rigorous design considerations, focusing on sealing structures and material choices that prevent the ingress of water and dust, while ensuring reliable operation.

1.2 Sealing Structure Design for IP68 Protection

To meet IP68 requirements, the sealing structure of a metal pushbutton switch must be meticulously designed. The key areas to focus on include:

Sealing Around the Button Actuator: The area between the metal button and the housing must be sealed using high-quality gaskets or O-rings, often made from materials like silicone or rubber. These components maintain their elasticity and sealing capabilities even under compression and frequent operation.

Enclosure Sealing: The enclosure housing the switch’s internal components must be tightly sealed. A double-layer sealing structure can provide extra protection, with one layer guarding against dust and the other against water ingress. For example, in industrial applications, a switch designed with a double silicone gasket was able to pass the IP68 test after being submerged in water at a depth of 1.5 meters for 30 minutes.

Cable Entry Points: The point where the switch's wiring enters the housing is also a vulnerable spot for water and dust ingress. To prevent this, special attention is paid to cable glands, which are designed to maintain a waterproof seal without compromising the integrity of the wiring.

1.3 Material Selection for IP68 Sealing

The materials used in metal pushbutton switches play a critical role in achieving IP68 protection:

Corrosion-Resistant Metals: The metal components of the switch, such as the button and housing, are often made from stainless steel or aluminum alloys, which resist corrosion from water exposure.

High-Density Plastics: For the non-metallic parts, high-density plastics such as polycarbonate or PBT (polybutylene terephthalate) are used to ensure a robust and watertight enclosure.

Elastomers: The gaskets and O-rings used for sealing must be made from elastomeric materials that can withstand both environmental stress and mechanical wear. Silicone and EPDM (ethylene propylene diene monomer) are commonly used for their durability and resistance to environmental factors like UV light and ozone.

2. Protection Against Oil, Dust, and Other Contaminants

2.1 Industrial Applications and Contaminant Exposure

In many industrial settings, metal pushbutton switches are exposed not only to dust and water but also to oil, grease, and other contaminants. These substances can severely affect the performance of the switch if they penetrate the housing, leading to mechanical failures or electrical malfunctions. Therefore, metal pushbutton switches must be designed with robust protective measures to prevent contamination.

2.2 Oil and Dust Resistance

Oil and dust present unique challenges for switch design. Dust can clog the mechanism, leading to improper actuation, while oil can degrade materials or cause electrical shorts. Metal pushbutton switches designed for industrial environments typically employ the following solutions:

Specialized Sealing Materials: Gaskets made from oil-resistant materials, such as fluorosilicone, can effectively prevent oil penetration. In one case study, a switch used in an oil refinery demonstrated long-term reliability after being exposed to a mix of oil and dust, thanks to its use of fluorosilicone seals.

Dust-Proof Design: For dust-prone environments, the switch housing must be completely sealed, ensuring that no particles can enter. This is critical for applications like construction equipment or mining machinery, where metal pushbutton switches are exposed to airborne particles on a daily basis.

2.3 Oil and Dust Performance Testing

To verify the effectiveness of a metal pushbutton switch's sealing against oil and dust, performance testing is conducted under real-world conditions:

Oil Immersion Tests: In these tests, the switch is submerged in oil for an extended period, checking for any material degradation or ingress of oil into the internal components.

Dust Chamber Testing: The switch is placed in a dust chamber, where fine particles are circulated around it. The test is usually conducted for several hours, after which the switch is inspected for any dust ingress.

3. Durability Testing Methods for Extreme Environments

3.1 High-Pressure and High-Humidity Testing

Metal pushbutton switches are often used in extreme environments where they may be subjected to high humidity and pressure. Durability testing methods simulate these conditions to ensure the switch can perform reliably.

Pressure Chamber Tests: These tests expose the switch to high pressure, simulating underwater conditions or the pressure inside industrial machinery. For example, a metal pushbutton switch used in offshore oil platforms successfully passed a test in a pressurized water chamber, maintaining functionality after 24 hours at a depth of 2 meters.

Humidity Testing: High-humidity environments, such as outdoor applications or tropical climates, can cause condensation inside the switch, leading to corrosion or short circuits. Humidity tests place the switch in a high-humidity chamber for extended periods to ensure it remains operational.

3.2 Corrosion Testing

In addition to moisture, certain environments may expose metal pushbutton switches to corrosive chemicals or saltwater. Corrosion testing is essential to evaluate the switch’s resistance to such conditions. One common method is the salt spray test, where the switch is exposed to a saline mist for an extended period, simulating coastal or marine environments. For instance, metal pushbutton switches used in marine applications were tested for 500 hours in a salt spray chamber and showed no signs of corrosion or mechanical degradation.

3.3 Thermal Cycling and Extreme Temperature Testing

Thermal cycling tests expose the switch to rapid changes in temperature, such as transitioning from freezing to high heat. This simulates real-world environments like outdoor installations in regions with extreme seasonal temperature fluctuations. Metal pushbutton switches used in outdoor telecommunications passed thermal cycling tests, remaining operational after being subjected to temperatures ranging from -40°C to +85°C over several cycles.

Conclusion

Achieving IP68 protection in metal pushbutton switches requires a combination of carefully engineered sealing structures, high-quality materials, and rigorous testing protocols. With the right design and materials, metal pushbutton switches can reliably resist the ingress of water, dust, oil, and other contaminants, ensuring long-term functionality in harsh environments. Durability testing, including high-pressure, humidity, corrosion, and thermal cycling tests, verifies that the switch can withstand extreme conditions. These design principles and testing methodologies ensure that metal pushbutton switches meet the highest standards of reliability for demanding industrial, automotive, and outdoor applications.

en.dghongju.com

0 notes

Text

Cable Glands Market — Forecast(2024–2030)

Cable Glands Market Overview:

Cable Glands Market size is estimated to reach $3.9 billion by 2030 growing at a CAGR of 6.5% during the forecast period 2024–2030.

The cable glands market is witnessing a robust surge in demand, driven by the increasing need for secure and efficient cable management solutions across various industries. As businesses expand their infrastructure, the demand for reliable cable glands to ensure proper sealing and protection against environmental factors is on the rise, contributing to the cable glands market growth.

For Instance, as per the International Trade Administration, the 14th Five-Year Plan of China places a strong emphasis on new urbanization, energy, water, and transportation infrastructure projects. Estimates indicate that throughout the 14th Five-Year Plan period (2021–2025), total investments in new infrastructure will come to approximately $4.2 trillion. This growth has heightened the demand for essential components, such as cable glands, crucial for secure cable installations. This surge in infrastructure development is likely to drive demand for cable glands, essential components in ensuring secure and efficient cable installations.

Cable Glands Market — Report Coverage:

The “Cable Glands Market Report — Forecast (2024–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Cable Glands Market.

Attribute Segment

By Type

Hazardous Area Cable Glands

Industrial Cable Glands

By Materials

Brass

Stainless Steel

Plastic

Aluminum

Nylon

Nickel

Others

By Cable Type

Armored

Unarmored/Non-Armored

By Application

Control boxes

Skids

Motors

Lighting

Connector for electrical devices

Data Cable

By End-Use

Manufacturing & Processing

Oil & Gas

Mining

Aerospace

Chemicals

Marine

Poer & Utilities

Construction

Automation

Others

By Geography

North America (U.S., Canada and Mexico)

Europe (Germany, France, UK, Italy, Spain, Russia and Rest of Europe),

Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand and Rest of Asia-Pacific),

South America (Brazil, Argentina, Chile, Colombia and Rest of South America)

Rest of the World (Middle East and Africa).

COVID-19 / Ukraine Crisis — Impact Analysis:

The COVID-19 pandemic has had a significant impact on the cable glands market. The global outbreak of the COVID-19 pandemic in 2020 led to a sharp decline in economic activities across various industries. This resulted in a decrease in the demand for cable glands, as many industries were forced to shut down their operations or reduce their production capacity.

The Ukraine crisis is expected to have a significant impact on the cable glands market. The crisis has disrupted supply chains and increased the cost of raw materials. This is expected to lead to higher prices for cable glands. The crisis is also expected to reduce demand for cable glands in some industries, such as construction. This is due to economic uncertainty and the decline in construction activity in some regions.

Sample Request

Key Takeaways:

Fastest Growth of APAC

Geographically, in the global Cable Glands Market share, APAC is analyzed to grow with the highest CAGR of 7.4% during the forecast period 2024–2030. The surging demand for cable glands in the APAC region is intricately tied to robust infrastructure development, notably in China, India, and Southeast Asian nations. Ongoing projects in power generation, telecommunications, and industrial facilities necessitate reliable cable management and protection, driving the need for these essential components. As the region continues its dynamic growth trajectory, the cable gland market is poised to play a pivotal role in supporting and facilitating the expanding infrastructure landscape. For instance, according to the International Energy Agency, China will be accountable for over 45% of the increase in renewable energy output between 2023 and 2025. These developments underscore a pivotal role in shaping the future of renewable energy and the growing market for cable glands in the APAC region.

• Unarmored is Register the Fastest Growth

Unarmored is analyzed to grow with the highest CAGR of 6.8% during the forecast period 2024–2030. The global market for unarmored cable glands, essential components in electrical enclosures, is experiencing steady growth. These glands establish reliable connections between cables and equipment, safeguarding against dust, water, and contaminants. Widely utilized for their protective qualities, unarmored cable glands contribute to the durability and efficiency of electrical systems worldwide. As industries expand and technological advancements continue, the demand for these glands is expected to rise, further propelling the global unarmored cable glands market.

• The Construction Segment is to Register the Highest Market Growth

According to the Cable Glands Market forecast, Construction held the largest market valuation reaching $237.6 million in 2023. The construction industry is experiencing a significant surge worldwide, leading to a higher demand for various construction materials and equipment. One such product in high demand is cable glands, which are essential for securing and protecting cables in construction projects. As the construction industry continues to boom, the cable glands market is expected to witness a steady increase in demand, reflecting the industry’s growth and development. This trend highlights the importance of cable management in ensuring efficient and safe construction practices. Additionally, according to the UK Government, the worldwide construction sector is expected to rise by more than 70% by 2025. As construction projects proliferate worldwide, the demand for reliable and efficient cable management solutions intensifies.

• Growing the demand for Automation Industry

The Cable Glands Market anticipates a rapid surge in the Automation segment, driven by escalating demand for automation within industrial applications. This robust growth trajectory is propelled by the need for efficient and streamlined processes in diverse industries. As automation becomes integral to industrial operations, cable glands play a pivotal role in ensuring secure and organized cable management, further fueling their demand. The market is poised to capitalize on this trend, offering innovative solutions that cater to the evolving automation landscape. This upward trajectory underscores the pivotal role of cable glands in facilitating the seamless integration of automated systems across various industrial sectors. For instance, according to the International Trade Administration, Japan is predicted to have 40% fewer workers overall by 2065. This will lead to a rise in the need for advanced industrial equipment and equipment as well as automated systems. This trend is poised to propel the Automation segment to high growth, particularly in industrial applications.

• Volatility in Raw Material Prices Hampers the Market Growth

Cable glands can be composed of stainless steel, brass, nickel, aluminum, or plastic, depending on the kind of use. Raw material costs are very variable while producing cable glands. Their prices are very dependent on the state of the market because these are essential metals. Cable glands are commonly made from basic materials like brass and aluminum. Fluctuations in material costs impact manufacturing expenses, posing a significant hurdle for market players. This uncertainty complicates pricing strategies and affects profit margins. To navigate these challenges successfully, companies must adopt resilient supply chain practices, explore alternative materials, and implement strategic pricing models. Adapting to the dynamic raw material landscape is essential for sustaining competitiveness in the Cable Glands market.

Inquiry Before Buying

Key Market Players:

Product/Service launches, approvals, patents and events, acquisitions, partnerships and collaborations are key strategies adopted by players in the Cable Glands Market. The top 10 companies in this industry are listed below:

1. Eaton Corporation (TMCX II Armored Glands)

2. Emerson Electric Co (Rosemount™ General Purpose Cable Gland)

3. CMP Products Ltd (CMP Cable Glands)

4. Cortem S.p.A (Cortem NAVB series barrier cable gland)

5. Warom Technology, Inc. (DQM-II Series Explosion-proof Cable Glands)

6. Sealcon LLC (Sealcon Cable glands)

7. Jacob GmbH (Jacob Perfect cable gland)

8. Amphenol Corporation (Amphenol Cable Glands)

9. BARTEC Top Holding GmbH (Bartec Cable glands)

10. ABB Group (ABB RNCG Series Cable gland)

Buy Now

Scope of the Report:

Report Metric Details

Base Year Considered

2023

Forecast Period

2024–2030

CAGR

6.5%

Market Size in 2030

$3.9 billion

Segments Covered

By Type, Materials, Cable Type, Application, End-Use and Region.

Geographies Covered

North America (U.S., Canada and Mexico), Europe (Germany, France, UK, Italy, Spain, Russia and Rest of Europe), Asia-Pacific (China, Japan, South Korea, India, Australia, New Zealand and Rest of Asia-Pacific), South America (Brazil, Argentina, Chile, Colombia and Rest of South America), Rest of the World (Middle East and Africa).

Key Market Players

1. Eaton Corporation

2. Emerson Electric Co

3. CMP Products Ltd

4. Cortem S.p.A

5. Warom Technology, Inc.

6. Sealcon LLC

7. Jacob GmbH

8. Amphenol Corporation

9. BARTEC Top Holding GmbH

10. ABB Group

For more Information and Communications Technology Market reports, please click here

0 notes

Text

Glands Market Size, Type, segmentation, growth and forecast 2023-2030

Cable Glands Market Scenario and Scope

Cable glands are crucial components used for sealing and securing the ends of electrical cables as they pass through enclosures, such as junction boxes. These devices are vital in various industries for ensuring cable protection and management, enhancing safety, and maintaining the integrity of electrical systems. The global Cable Glands Market was valued at USD 2.20 billion in 2022 and is projected to reach USD 3.80 billion by 2030, registering a CAGR of 8.20% during the forecast period. The market's growth is driven by the increasing demand for cable protection and management systems, particularly in industries such as oil and gas, telecommunications, and construction.

Get a Sample PDF of the Report: https://www.reportprime.com/enquiry/sample-report/368

Market Trends Influencing the Cable Glands Market

Rising Demand for Cable Protection Systems: The need for effective cable protection in industries such as oil and gas, telecommunications, and construction is a significant driver of the Cable Glands Market.

Growth in Industrial Development: Established infrastructure in North America and Europe makes these regions the largest markets for cable glands. However, the Asia Pacific region is expected to experience the highest growth rate, driven by rapid industrialization in developing countries like China and India.

Technological Advancements: Innovations in materials and design are leading to more durable and efficient cable glands, further boosting market demand.

Focus on Safety and Compliance: The market is also driven by stringent safety regulations and the need for compliance with international standards, particularly in hazardous environments.

Request a Free Sample PDF Brochure of Cable Glands Market: https://www.reportprime.com/enquiry/sample-report/368

Cable Glands Segment Analysis

Cable Glands Market, by Type:

Plastic and Polymer Glands

Metal Glands

Plastic and polymer glands are widely used in various applications due to their cost-effectiveness and resistance to corrosion. However, metal glands are preferred in environments requiring higher durability and strength, such as in the oil and gas industry.

Inquire or Share Your Questions If Any Before Purchasing This Report: https://www.reportprime.com/enquiry/pre-order/368

Cable Glands Market, by Application:

Oil and Gas

Mining

Construction

Railway

Chemical

Aerospace

Power and Energy

Others

The oil and gas industry is a significant segment within the Cable Glands Market, due to the need for secure and durable cable management solutions in challenging environments. The construction and telecommunications sectors also represent substantial market segments, driven by ongoing infrastructure projects and the expansion of communication networks.

Cable Glands Competitive Analysis

Amphenol

Emerson

ABB

TE Connectivity

Eaton

Hubbell Incorporated

Axis Communications

PFLITSCH GmbH

CMP Products

Lapp Group

Hummel AG

WISKA

Weidmüller Interface

BARTEC Group

R.Stahl AG

Warom Group

Bimed Teknik

El Sewedy Electric

CCG Cable Terminations

Beisit Electric Tech

Jacob GmbH

Cortem

Metal Craft Industries

Caledonian Cables

Sealcon

The competitive landscape of the Cable Glands Market is marked by the presence of key players such as Amphenol, Emerson, and ABB, who are focusing on expanding their product portfolios and investing in research and development to enhance product performance. The Asia Pacific region is a critical area of focus for these companies, due to the rapidly growing demand for cable management solutions in developing economies.

Regulatory and Legal Factors

Regulatory and legal factors play a vital role in the Cable Glands Market, especially concerning safety regulations and standards. Key regulations include:

ATEX Directive: This European directive lays down requirements for equipment and protective systems intended for use in potentially explosive atmospheres. Compliance with ATEX is essential for cable glands used in hazardous environments, such as oil and gas facilities.

IECEx Certification: This international certification ensures that electrical equipment, including cable glands, is safe for use in explosive atmospheres.

RoHS Compliance: The Restriction of Hazardous Substances (RoHS) directive restricts the use of specific hazardous materials in electrical and electronic products, impacting the materials used in cable glands.

ISO Certifications: Adherence to ISO standards ensures that cable glands meet global quality and safety requirements, which is crucial for market acceptance.

Ensuring compliance with these regulations is essential for companies operating in the Cable Glands Market to avoid legal challenges, enhance product safety, and maintain a competitive edge.

Buy now: https://www.reportprime.com/checkout?id=368&price=3590

0 notes

Text

Cable Glands: Essential Components for Secure Electrical Installations - A Guide by Trans Light Electricals LLC

In the world of electrical installations, safety and security are paramount. One crucial component that ensures the integrity of electrical systems is the cable gland. At Trans Light Electricals LLC, we specialize in providing high-quality cable glands designed to meet the demands of various industrial and commercial applications. In this post, we’ll explore what cable glands are, their importance, and how to select the right ones for your projects.

What Are Cable Glands?

Cable glands, often referred to as cable connectors or fittings, are devices that attach and secure the end of an electrical cable to equipment. Their primary purpose is to ensure that the electrical connections are safe, secure, and protected from external elements like moisture, dust, and mechanical stress. They are essential for maintaining the performance and longevity of electrical systems.

Why Are Cable Glands Important?

Sealing and Retention: Cable glands provide a secure seal, preventing environmental contaminants from entering sensitive electrical equipment. This is crucial in outdoor and industrial environments where dust, moisture, or chemicals could damage the system.

Strain Relief: Cable glands relieve mechanical stress on cables, preventing them from being pulled out or damaged due to tension or vibration. This ensures the longevity and safety of the connection.

Cable Protection: By providing a protective barrier, cable glands shield cables from sharp edges or abrasion, reducing the risk of wear and tear over time.

Compliance and Safety: High-quality cable glands help ensure that installations comply with industry standards and regulations, promoting safety and reliability.

Types of Cable Glands

At Trans Light Electricals LLC, we offer a wide range of cable glands to suit various applications. Some of the most common types include:

Metallic Cable Glands: Ideal for heavy-duty applications, metallic cable glands offer excellent durability and protection in harsh environments.

Non-Metallic Cable Glands: Made from plastic or other materials, these glands are lightweight, corrosion-resistant, and suitable for less demanding environments.

EMC Cable Glands: These are designed to provide electromagnetic compatibility, ensuring that the cable does not emit or absorb electromagnetic interference.

Flameproof Cable Glands: Specifically engineered for hazardous environments, these glands prevent the ignition of flammable gases or dust.

How to Choose the Right Cable Gland

Selecting the correct cable gland depends on several factors, including:

Cable Type and Diameter: Ensure the gland fits the cable size correctly for a secure seal.

Operating Environment: Consider the conditions in which the gland will be used, such as exposure to chemicals, extreme temperatures, or water.

Material: Choose the material based on the application’s needs, whether metallic for strength or non-metallic for resistance to corrosion.

Certification: For installations in hazardous areas, it’s vital to select cable glands that meet the necessary safety standards.

Why Choose Trans Light Electricals LLC?

At Trans Light Electricals LLC, we pride ourselves on being a leading cable gland supplier in the industry. Our products are sourced from reputable manufacturers and are designed to meet the highest standards of quality and safety. Whether you need cable glands for industrial, commercial, or residential applications, we have the solutions to ensure your installations are secure and reliable.

Trans Light Electricals LLC

Ras Al Khor Industrial Area – Ras Al Khor Industrial Area 2 – Dubai – United Arab Emirates

+97143399627

0 notes

Text

Best Overview of Cable Entry Systems & Accessories

Cable entry systems and accessories are integral components in the management and protection of cables in various electrical, electronic, and industrial applications. These systems are designed to facilitate the organized routing of cables through enclosures, walls, panels, or machinery, while also providing protection against environmental and mechanical stresses. The use of cable entry systems is critical in ensuring the safety, reliability, and efficiency of electrical installations across a wide range of industries.

What Are Cable Entry Systems?

Cable entry systems refer to assemblies or devices that allow cables to pass through barriers such as enclosures or walls while maintaining the integrity and safety of the installation. These systems include various components like entry frames, grommets, seals, cable glands, and strain relief devices. Each component plays a specific role in securing and protecting the cables, ensuring they are properly organized and shielded from potential hazards.

The primary purpose of cable entry systems is to create a secure and sealed entry point for cables. This prevents the ingress of dust, moisture, chemicals, and other contaminants that could damage the cables or interfere with their operation. Additionally, these systems provide mechanical protection by preventing cables from being pulled, bent, or subjected to vibrations that could lead to wear and tear over time.

Key Components of Cable Entry Systems

Cable entry systems are composed of several key components, each of which serves a specific function in ensuring the effective management and protection of cables. These components include:

Cable Glands:

Cable glands are devices that secure cables as they enter an enclosure, providing both mechanical retention and environmental sealing. They are designed to prevent the ingress of dust, moisture, and other contaminants while also providing strain relief to protect cables from mechanical stress. Cable glands are available in various materials, such as plastic, brass, and stainless steel, to suit different environmental conditions and cable types.

Entry Frames and Plates:

Entry frames and plates are modular components that allow multiple cables to be routed through a single entry point. They are typically installed into pre-cut openings in panels or enclosures, providing an organized and secure passage for cables. Entry frames often include grommets or seals that further enhance environmental protection and strain relief.

Grommets and Seals:

Grommets and seals are essential for creating a tight and secure fit around cables as they pass through entry frames or plates. Grommets are flexible rings that protect cables from sharp edges and prevent chafing, while seals ensure that no dust, moisture, or other contaminants can enter the enclosure. These components are particularly important in maintaining the integrity of installations in harsh environments.

Strain Relief Devices:

Strain relief devices are designed to prevent mechanical stress on cables, which can occur due to pulling, bending, or vibration. These devices secure the cable in place, preventing movement that could lead to damage. Strain relief is especially important in applications where cables are subject to frequent movement or need to maintain a fixed position relative to the enclosure or machinery.

Blind Plugs and Blanking Plates:

Blind plugs and blanking plates are used to seal off unused entry points in modular cable entry systems. This helps maintain the system's environmental protection by preventing dust, moisture, or other contaminants from entering the enclosure. These components also provide flexibility in system design, allowing for future expansion without compromising the current installation.

Types of Cable Entry Systems

Cable entry systems come in various types, each designed to meet specific application requirements. Some of the most common types include:

Split Cable Entry Systems:

Split cable entry systems are designed to allow cables with pre-terminated connectors to pass through an entry point without the need to remove the connectors. The system can be opened, the cable inserted, and then closed around the cable, making it ideal for retrofitting or adding new cables to an existing installation.

Brush Cable Entry Systems:

Brush cable entry systems use brush-like materials to allow cables to pass through while minimizing the ingress of dust and debris. These systems are commonly used in data centers or server rooms where it is important to maintain airflow and cooling efficiency while managing a large number of cables.

Membrane Cable Entry Systems:

Membrane cable entry systems feature flexible membranes that self-seal around cables when they are pushed through. These systems are ideal for applications where cables frequently need to be added or removed, as the membrane adapts to different cable sizes and configurations.

Multi-Entry Cable Glands:

Multi-entry cable glands are designed to accommodate multiple cables through a single entry point, offering sealing and strain relief for each individual cable. These glands are particularly useful in compact installations where space is limited.

Applications of Cable Entry Systems

Cable entry systems are used in a wide range of industries and applications, including:

Industrial Automation:

In industrial environments, cable entry systems protect cables from harsh conditions such as dust, moisture, and chemical exposure. They are essential for ensuring the reliability and safety of machinery and control systems.

Telecommunications and Data Centers:

In telecommunications and data centers, cable entry systems help manage large volumes of data and power cables. They prevent signal interference, ensure proper airflow, and protect cables from physical damage.

Transportation and Automotive:

In the automotive and transportation industries, cable entry systems protect wiring harnesses as they pass through vehicle bodywork, shielding them from mechanical damage, moisture, and other environmental factors.

Construction and Building Services:

In construction, cable entry systems are used to route electrical, data, and communication cables through walls, floors, and ceilings. They help maintain the integrity of fire-rated barriers and ensure compliance with building codes.

Marine and Offshore:

In marine environments, cable entry systems protect cables from saltwater, extreme temperatures, and mechanical stress. They are used on ships, offshore platforms, and other maritime structures.

Energy and Utilities:

Cable entry systems are used in power generation and distribution, including renewable energy installations. They protect cables from environmental conditions and ensure reliable operation of electrical systems.

Benefits of Cable Entry Systems & Accessories

The use of cable entry systems and accessories offers several key benefits:

Enhanced Safety:

Cable entry systems reduce the risk of electrical hazards by securely routing and protecting cables, preventing short circuits, fires, and electric shocks.

Improved Organization:

These systems help organize cables, reducing clutter and making maintenance and troubleshooting easier. This is particularly important in complex installations with numerous cables.

Environmental Protection:

Cable entry systems provide robust protection against environmental factors, extending the lifespan of cables and reducing the likelihood of damage.

Compliance with Standards:

Properly designed and installed cable entry systems help ensure compliance with industry standards and regulations, which is crucial for safety and reliability.

Cost Savings:

By preventing cable damage and reducing maintenance needs, cable entry systems can lead to significant cost savings over the life of an installation.

Conclusion

Cable entry systems and accessories are vital for the safe, organized, and efficient management of cables in various industrial and commercial applications. These systems protect cables from environmental and mechanical hazards, ensuring the reliability and longevity of electrical installations. Whether in industrial automation, telecommunications, transportation, or construction, cable entry systems play a crucial role in maintaining the integrity and performance of modern electrical systems.

0 notes

Text

Novoflex - Engineered Plastic Component Manufacturer

Novoflex is an Indian pioneer and leading manufacturer of engineered plastic components catering to a wide variety of industries, supplying high precision, high performance Cable Ties, Cable Glands and various other wiring accessories to OEM’S for 4 decades.

Novoflex is widely known for its:

Intricate engineered parts manufacturing expertise.

Continuous innovation in product design.

Internationally approved stringent Quality Control procedures.

Cost effective solutions for all industries.

Prompt and timely deliveries.

Customer centric approach.

0 notes

Text

Ensuring Secure and Reliable Electrical Installations with Industrial Cable Glands

In the realm of industrial applications, the importance of secure and reliable electrical installations cannot be overstated. Cable glands play a crucial role in achieving this goal by providing essential protection and ensuring optimal connectivity for cables. As a renowned manufacturer in the metal industry, Atlas Metal recognizes the significance of quality cable glands and offers a comprehensive range of solutions to meet diverse industrial needs.

The Importance of Industrial Cable Glands

Industrial cable glands are designed to withstand harsh environments and demanding applications, ensuring the safety and longevity of electrical installations. These vital components are widely used in industries such as railways, oil and gas, mining, and more, where reliable connectivity and protection against environmental factors are paramount.

Types of Industrial Cable Glands

The versatility of industrial cable glands is evident in the various types available, each tailored to specific requirements.

Armoured Cable Glands

Armoured cable glands are engineered to provide secure connections and enhanced protection against mechanical strain, ensuring the integrity of armoured cables in demanding environments.

Metal Cable Glands

Constructed from durable materials like brass or aluminium, metal cable glands offer exceptional robustness and longevity, making them suitable for a wide range of industrial applications.

Stainless Steel Cable Glands

For harsh and corrosive environments, stainless steel ss cable glands are the ideal choice. Their exceptional resistance to corrosion ensures durability and reliable performance, making them indispensable in industries such as marine, oil and gas, and chemical processing.

Brass Cable Glands

Known for their excellent electrical conductivity and corrosion resistance, brass cable glands are widely used in various industrial settings, providing reliable sealing and secure connections.

Plastic Cable Glands

Plastic cable glands offer cost-effective solutions for non-corrosive environments. Made from high-quality engineering plastics, these glands are lightweight, easy to install, and provide good sealing properties, making them suitable for a range of industrial and commercial applications.

Selection Criteria for Industrial Cable Glands

The selection of industrial cable glands is a critical process, and Atlas Metal emphasizes the importance of considering key criteria to ensure optimal performance, safety, and longevity. Factors such as cable diameter and type, operating temperature and pressure, environmental conditions, and the systematic classification of hazardous areas must be carefully evaluated.

Proper Installation and Maintenance

Installation Procedures

Proper installation of cable glands is crucial for ensuring secure connections and reliable performance. Atlas Metal provides step-by-step installation procedures, ensuring that cable glands are correctly positioned, tightened, and secured, minimizing the risk of moisture ingress, cable slippage, or improper fitting.

Regular Inspection and Cleaning

Regular inspection and cleaning are essential for maintaining the integrity of cable glands over time. Atlas Metal recommends routine inspections to identify any signs of wear, corrosion, or damage, and suggests periodic cleaning to remove dust, debris, or contaminants that may hinder performance.

Cable Gland Manufacturers in india - Atlas Metal

With over two decades of experience, Atlas Metal has established itself as a trusted leader in the metal industry, specializing in manufacturing high-quality electrical and lightning safety solutions, including cable glands and cable gland accessories. The company's commitment to excellence and relentless pursuit of innovation ensure the manufacturing of premium quality products that prioritize safety and superior performance.

Conclusion

Industrial cable glands are vital components for secure and reliable electrical installations in demanding environments. By understanding the different types, materials, and selection criteria, and following proper installation and maintenance procedures, industries can achieve optimal performance, safety, and longevity in their electrical installations.

#cable lugs manufacturers in india#brass conduit fittings in india#lugs manufacturers in india#copper lugs manufacturers in india#brass fitting manufacturers in india#pipe fittings manufacturers in india#cable gland manufacturers in jamnagar

0 notes

Text

Fiber Optic Terminal box # OTB-P030

Features:

ABS plastic material

White or black color

Mechanical sealing structure

Waterproof, IP65

Cable port: 4pcs cable gland PG16 suitable for Φ10-14mm cable entry, and 2pc Φ20mm reserved hole.

With 2pc OST-048 splice tray, max. 48 fibers

Can load 4pcs 1x8 or 2pc 1x16 splitter cassette or 1pc 48 SC simplex adapter plate

Outdoor wall mounted application

0 notes

Text

Stay Confident All Day: Fearless Tape Double-Sided Tape

Fearless Tape is a brand that specializes in adhesive tapes designed to provide a secure and discreet solution for various wardrobe malfunctions and garment adjustments.

Hot Product

Fearless Tape – Double Sided Tape

Double Sided Tape

Made in the USA

Instructions: Remove from backing and press firmly to either fabric or skin that’s clean, dry, and oil free. Remove remaining backing and apply item to be secured. Remove tape before washing, cleaning, or ironing garments. Pretest fabric.

A Review Of Fearless Tape

Bought these for a wedding. My bridesmaid dress sat on the edge of my shoulders and even with alterations and being so tight I could barely move, it still would not stay on my shoulders. In comes this tape. I taped my shoulders and bust all the way around, front to back. Could I move? No. Did my dress move? Also No. This tape did a wonderful job of keeping my dress on me. I would have been miserable without it. I was able to dance and move and do what I needed to – although restricted because tight dress. The tape did pull a bit but it stayed stuck to my skin and the dress. I had to have help being taped in. So if you are going to use this, seek help. I think the value of this is great. You get a ton of strips and get your moneys worth. All the other bridesmaids were coming and getting tape from me. I had plenty for myself, four other bridesmaids who had to be taped in completely and the bride. The only complaint I have with this stuff is it puts your skin thru the wringer. I spot tested this out as I have sensitive skin and it gave me hives where I pulled the tape off. Also you have to be very careful pulling this off as it will rip your skin. Just be very careful and if you have sensitive skin I would recommend spot testing first. Overall I like this product and would purchase again and would/have recommend to others.

I use this to adhere the front of my dress to my chest so I don’t get the dreaded gap or bra slip and have to deal with constantly adjusting my lower dresses to feel comfortable. It stays in place for hours and is easy to use. It does hurt pretty bad to take off so my advice is rip it quick. The adhesive may cause some irritation if your skin is very sensitive like mine.

Customer Q&As

Q: what color is this?

A: White, but it’s a little bit complicated to peel the paper off, not the best product

Q: How thick height wise is it?

A: Very thin. about the same as scotch tape.

Q: Will this keep sanity jewelry in place?

A: It might, but probably not all day long!

Value Pack: Get the most bang for your buck with the eBoot Plastic Waterproof Adjustable Cable Glands Joints, available in a convenient value pack. With multiple glands included in each pack, you can tackle multiple projects or have spares on hand for future use.

Secure Your Cables with Confidence: Protect and organize your cables with the eBoot Plastic Waterproof Adjustable Cable Glands Joints. With their versatile design, waterproof protection, and durable construction, these cable glands offer a reliable solution for all your cable management needs, ensuring safety, efficiency, and peace of mind.

0 notes

Text

Outdoor fiber optic box can load 24pcs SC simplex adapters or 1pc 1X16 cassette splitter for cable distribution and connection.

OTB-P068

Features:

ABS plastic material

Waterproof IP65

Cable port: 1 oval port with 2 holes φ13.5mm for cable entry without cutting; 1 M20 PG cable gland port;

24 drop cable ports (each port with 2 hole for 2*3mm flat cable entry)

Capacity: max. 48 fibers

Can load 1pc adapter plate with 24 SC simplex adapter ports or 1pc 1x16 cassette splitter

Can load 3pcs 1x8 steel tube splitter & 1pc 1x16 steel tube splitter

Outdoor wall mounted or pole mounted application

#wallmount#facebook#napbox#fiberoptic#network#5G#fiberopticterminalbox#fibersplicebox#fiberbox#splicebox#pigtial#cable#fibercable #2024 #indonesia#hello#world#news#telecom#construction#contractor#wholesaler#factory#alibaba#madeinchina#OEM#ODM#patchcord#adapter#highquality#produce #product #telco #internet #fibernet #5G #cctv #catv #best #monday #friday #summer #spring #hotsale #business

0 notes

Text

Maximizing Efficiency with Cable Entry Systems and Accessories

Cable Entry Systems & Accessories: Streamlining Electrical Installations

Efficient cable management is essential in any electrical or industrial setup, where multiple cables need to be securely organized, protected, and routed. This is where Cable Entry Systems and Accessories come into play. These systems allow cables to pass through enclosures, panels, and machines while maintaining a high level of protection against environmental factors like dust, moisture, and mechanical stress.

In this post, we’ll explore the importance of cable entry systems, the available types, and the various accessories that enhance their functionality.

What are Cable Entry Systems?

Cable entry systems are designed to provide organized and secure entry points for cables into electrical enclosures, control panels, or equipment housings. They ensure that cables are not only neatly routed but also protected from external damage and strain. These systems are essential in maintaining the integrity of electrical installations in industries such as manufacturing, telecommunications, and energy.

Key Benefits of Cable Entry Systems

Protection: Cable entry systems provide protection against dust, water, and other environmental hazards. Many of these systems have high IP (Ingress Protection) ratings to ensure they can withstand harsh conditions.

Ease of Installation: These systems are designed to make installation quick and easy. They often feature pre-configured seals or modular designs, allowing for flexible cable routing and adjustments.

Safety: By securely holding cables in place and offering strain relief, cable entry systems help prevent electrical faults, wear, and potential accidents.

Efficiency: Proper cable management through these systems enhances the efficiency of electrical installations, reducing the need for costly repairs and downtime due to cable damage or mismanagement.

Types of Cable Entry Systems

Cable Glands: As part of a cable entry system, cable glands secure individual cables as they enter enclosures. They provide strain relief and environmental sealing, protecting the internal components from moisture, dust, or other contaminants.

Cable Entry Frames: These are modular systems that allow multiple cables to pass through a single entry point. Entry frames are ideal for applications where numerous cables need to be routed in an organized manner.

Brush Strips: Brush strips are used for low-density cable entry points, providing a flexible barrier for cables while offering a level of protection against dust and other particles. They are often used in server cabinets and IT installations.

Split Cable Entry Systems: These systems allow pre-terminated cables (cables with connectors already attached) to pass through enclosures without needing to cut and re-terminate them. The split design ensures ease of installation while maintaining a secure seal.

Cable Entry Accessories

In addition to cable entry systems, various accessories help to optimize the performance and functionality of the setup. Some common cable entry accessories include:

Strain Relief Clamps: These clamps provide additional strain relief to cables, ensuring that the cable does not experience excessive stress at the entry point. This reduces the risk of electrical failure and cable damage over time.

Sealing Plugs: Sealing plugs are used to fill unused entry points in a cable entry frame or panel, maintaining the integrity of the enclosure’s environmental protection.

Cable Ties and Holders: Cable ties and holders help organize cables inside enclosures, preventing them from becoming tangled or creating clutter. They contribute to both aesthetic neatness and operational efficiency.

Grommets: Cable grommets are rubber or plastic fittings that protect cables from sharp edges as they pass through holes or openings. They provide both a seal and mechanical protection, reducing wear and tear on cables.

Blind Plates: These are used to cover unused cable entry openings, maintaining the enclosure's IP rating and protecting against environmental hazards.

Applications of Cable Entry Systems

Manufacturing Plants: Cable entry systems are vital in large-scale industrial plants where machines and control panels require complex cabling.

Telecommunications: Telecom infrastructure, including data centers, uses cable entry systems to manage large volumes of cables efficiently.

Energy Sector: In renewable energy, oil, and gas sectors, cable entry systems ensure secure and protected installations in harsh environments.

Automotive Industry: Cable entry systems are employed in vehicles to manage electrical wiring securely.

Conclusion

Cable entry systems and accessories are indispensable in creating organized, safe, and efficient electrical installations. Whether you're managing a few cables or hundreds, selecting the right system and accessories ensures longevity and optimal performance in any environment. By securing and protecting cables, these systems prevent costly damage and maintain high standards of safety and performance.

0 notes

Text

Exploring the Functionality of Key Cable Gland Components?

Introduction

Cable glands play a crucial role in ensuring the proper installation and functionality of electrical and data cables in various industries and applications. These glands not only provide a secure and waterproof seal around cables but also protect them from environmental factors such as dust, moisture, and chemicals. Understanding the components of cable glands is essential for ensuring their effectiveness and reliability in different settings. In this blog post, we will explore the functionality of key Cable gland components and their importance in cable management systems.

Body:

1.1. Cable Gland Basics:

Before delving into the components of cable glands, it's important to understand their basic structure and function. A cable gland, also known as a cable connector or fitting, is a device designed to attach and secure the end of a cable to an electrical or mechanical enclosure. It typically consists of a threaded body, a sealing element, and various other components that ensure a tight seal and provide strain relief for the cable.

1.2. Threaded Body:

The threaded body of a cable gland serves as the main housing for the gland assembly. It is usually made of metal, such as brass, stainless steel, or aluminum, although plastic versions are also available for less demanding applications. The threaded body is designed to screw into a corresponding threaded hole in the enclosure, providing a secure connection that prevents the gland from coming loose under vibration or tension.

1.3. Sealing Element:

The sealing element is perhaps the most critical component of a cable gland, as it is responsible for creating a watertight and dustproof seal around the cable. Common sealing materials include neoprene, silicone, rubber, and thermoplastic elastomers (TPE). The choice of sealing material depends on factors such as the application environment, temperature range, and chemical resistance requirements.

1.4. Compression Nut:

The compression nut is used to compress the sealing element against the cable and the threaded body, forming a tight seal that prevents moisture and contaminants from entering the enclosure. It is typically made of metal and features internal threads that match those on the threaded body. By tightening the compression nut, installers can adjust the compression force applied to the sealing element, ensuring a secure and reliable seal without damaging the cable insulation.

1.5. Clamping Device:

Some cable glands feature a clamping device or mechanism designed to provide strain relief for the cable, preventing it from being pulled out of the gland or becoming damaged due to excessive bending or tension. This is especially important in dynamic applications where cables are subject to movement or vibration. Common types of clamping devices include rubber grommets, spiral cable glands, and adjustable clamps.

1.6. O-Ring or Washer:

In addition to the main sealing element, many cable glands incorporate an O-ring or washer at the interface between the gland and the enclosure. This secondary seal helps to further enhance the waterproof and dustproof properties of the gland assembly, especially in outdoor or harsh environments where moisture ingress is a concern. The O-ring or washer is typically made of rubber or silicone and is compressed between the gland and the mounting surface when the gland is installed.

Importance of Cable Gland Components:

2.1. Environmental Protection:

One of the primary functions of cable glands is to provide environmental protection for cables and electrical connections. By sealing the entry point of the cable into the enclosure, cable glands help to prevent moisture, dust, dirt, and other contaminants from entering sensitive equipment and causing damage or malfunction. This is particularly important in outdoor or industrial settings where cables are exposed to harsh conditions.

2.2. Safety and Reliability:

Proper cable gland installation ensures the safety and reliability of electrical and data systems by minimizing the risk of short circuits, electrical arcing, and equipment failure. By creating a secure and watertight seal around cables, cable glands help to prevent accidental contact with live conductors, reducing the risk of electrical hazards and fire.

2.3. Compliance with Regulations:

In many industries, compliance with regulatory standards and codes is mandatory to ensure the safety and integrity of electrical installations. Cable glands that are properly designed and installed according to industry standards help companies meet these requirements and avoid potential fines or legal liabilities. Common standards governing cable gland design and installation include the National Electrical Code (NEC), the International Electrotechnical Commission (IEC), and the European Union's Restriction of Hazardous Substances (RoHS) directive.

2.4. Long-Term Performance:

The quality and durability of cable gland components directly impact the long-term performance and reliability of cable management systems. High-quality materials, precision engineering, and rigorous testing ensure that cable glands can withstand the rigors of daily use and continue to provide effective sealing and strain relief over their operational lifespan. Investing in premium Cable gland components upfront can save time and money on maintenance and replacement costs down the line.

Conclusion:

Cable glands are essential components of electrical and data cable installations, providing protection, safety, and reliability in a wide range of applications. By understanding the functionality of key cable gland components such as the threaded body, sealing element, compression nut, clamping device, and O-ring or washer, installers can ensure the proper selection, installation, and maintenance of cable glands for optimal performance and compliance with industry standards. Whether in industrial, commercial, or residential settings, cable glands play a critical role in safeguarding equipment, infrastructure, and personnel against the hazards of environmental exposure and electrical faults.

0 notes

Text

Emerging Trends and Opportunities: Cable Glands Market Insights 2023-2032

Allied Market Research published a report on the Cable Glands Market by Type (Industrial, Hazardous), by End User (Oil and Gas, Mining, Aerospace and Defense, Manufacturing and Processing, Chemical, Others), by Cable Type (Armored, Unarmored), by Material (Brass, Stainless Steel, Plastic/Nylon, Others), by Sealing Technique (Inner Seal, Outer Seal, No Seal): Global Opportunity Analysis and Industry Forecast, 2023-2032.

The cable glands market was valued at $2.4 billion in 2022 and is estimated to reach $4.5 billion by 2032, growing at a CAGR of 6.8% from 2023 to 2032.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐑𝐞𝐩𝐨𝐫𝐭 𝐒𝐚𝐦𝐩𝐥𝐞 & 𝐓𝐎𝐂: https://www.alliedmarketresearch.com/request-sample/3321

A cable gland also known as a cord grip, strain relief, cable connector or fitting is intended to attach and secure the end of an electrical cable to the equipment. The major factors that favor market growth include an increase in government initiatives to improve connectivity within regions, growth in construction industry worldwide, and rise in energy demand levels globally coupled with the surge in population. However, the volatile raw material prices are expected to hinder market growth in the near future.

Cable glands, also known as cable connectors or cable fittings, are devices used to securely attach and seal cables to equipment, enclosures, or surfaces while providing protection against environmental factors such as dust, moisture, and other contaminants which is expected to drive the cable glands market share. They are commonly used in various industries including electrical, telecommunications, manufacturing, and construction. The primary purpose of cable glands is to create a tight and secure connection between a cable and the equipment or enclosure it is being connected to. Rise in the adoption of cable grands in oil and gas, mining is expected to boost the cable glands market growth in the near future.

This helps prevent the cable from being pulled or twisted, which can damage the cable itself or the connections within. In addition, cable glands help maintain the integrity of the enclosure or equipment by sealing out moisture, dust, and other potentially harmful substances. Cable glands are available in various materials such as metal, plastic, or rubber, depending on the specific application and environmental conditions. Furthermore, Cable glands ensure safety by containing any potential electrical hazards which boosts the cable glands market size in the near future.

𝐆𝐞𝐭 𝐂𝐮𝐬𝐭𝐨𝐦𝐢𝐳𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬 𝐰𝐢𝐭𝐡 𝐲𝐨𝐮’𝐫𝐞 𝐑𝐞𝐪𝐮𝐢𝐫𝐞𝐦𝐞𝐧𝐭𝐬: https://www.alliedmarketresearch.com/request-for-customization/3321

As per cable glands market forecast, the future of cable glands looks promising as the product is expected to play a dominant role in the oil and gas and power sector. Several developments have been undertaken by numerous government organizations to improve the network infrastructure of their regions, thereby increasing the demand for data transmission cables and accessories which boosts the cable glands market trends in forecast period. New data centers have been set up worldwide owing to rapid growth of the IT sector which requires cables and cable glands in bulk quantities and expected to create global cable glands market opportunities.

𝐂𝐨𝐦𝐩𝐞𝐭𝐢𝐭𝐢𝐯𝐞 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬:

The Cable Glands industry's key market players adopt various strategies such as product launches, product development, collaboration, partnership, and agreements to influence the market. It includes details about the key players in the market's strengths, product portfolio, market size and share analysis, operational results, and market positioning.

𝐒𝐨𝐦𝐞 𝐨𝐟 𝐭𝐡𝐞 𝐦𝐚𝐣𝐨𝐫 𝐤𝐞𝐲 𝐩𝐥𝐚𝐲𝐞𝐫𝐬 𝐢𝐧 𝐭𝐡𝐞 𝐠𝐥𝐨𝐛𝐚𝐥 𝐂𝐚𝐛𝐥𝐞 𝐆𝐥𝐚𝐧𝐝𝐬 𝐦𝐚𝐫𝐤𝐞𝐭 𝐢𝐧𝐜𝐥𝐮𝐝𝐞,

Emerson Electric Co. 3M ABB Ltd. Hubbell Incorporated Amphenol Corporation Jacob Gmb Elektrotechnische Fabrik CMP Products Ltd Cortem S.P.A Eaton Corporation plc BARTEC Top Holding GmbH

Cable glands consist of several components, including a gland body, a locknut or fixing nut, a sealing ring or gasket, and in some cases, additional accessories like a strain relief component. Cable glands come in various sizes and types to accommodate different cable diameters, types of cables (such as armored cables or non-armored cables), and levels of protection required. Proper selection of the appropriate cable gland for a given application is crucial to ensure the safety, functionality, and longevity of the connected equipment and cables.

Cable glands market is segmented into type, end user, cable type, material, sealing technique, and region. On the basis of type, the market is categorized into industrial and hazardous. By hazardous type, the market is further divided into increased safety, flameproof, EMC and others. On the basis of end user, it is divided into oil & gas, mining, aerospace and defense, manufacturing & processing, chemicals and others. On the basis of cable type, it is classified into armored and unarmored. On the basis of material, it is classified into brass, stainless steel, plastic & nylon and others. On the basis of sealing technique, it is classified into no seal, inner seal and outer seal. Region-wise, it is analyzed across North America, Europe, Asia-Pacific and LAMEA.

𝐈𝐧𝐪𝐮𝐢𝐫𝐲 𝐛𝐞𝐟𝐨𝐫𝐞 𝐁𝐮𝐲𝐢𝐧𝐠: https://www.alliedmarketresearch.com/purchase-enquiry/3321

𝐊𝐞𝐲 𝐅𝐢𝐧𝐝𝐢𝐧𝐠𝐬 𝐎𝐟 𝐓𝐡𝐞 𝐒𝐭𝐮𝐝𝐲:

- On the basis of type, the hazardous segment growing with the highest CAGR of 7.0% in the forecast period - On the basis of end user, the oil and gas segment held the market share of more than 25% in 2022 in terms of revenue - On the basis of cable type, the armored segment held the market share above 70% in 2022 in terms of revenue - On the basis of material, the plastic /nylon segment grew with the highest CAGR of 7.3% in the forecast period - On the basis of sealing technique, the brass segment held the market share above 50% in 2022 in terms of revenue - On the basis of region, the Asia-Pacific region growing with the highest CAGR of 7.1% in 2023-2032

𝐓𝐫𝐞𝐧𝐝𝐢𝐧𝐠 𝐑𝐞𝐩𝐨𝐫𝐭𝐬 𝐢𝐧 𝐭𝐡𝐞 𝐄𝐧𝐞𝐫𝐠𝐲 𝐚𝐧𝐝 𝐏𝐨𝐰𝐞𝐫 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲:

𝟏. 𝐅𝐢𝐫𝐞 𝐑𝐞𝐬𝐢𝐬𝐭𝐚𝐧𝐜𝐞 𝐂𝐚𝐛𝐥𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 - https://www.globenewswire.com/news-release/2021/12/15/2352371/0/en/Fire-Resistance-Cable-Market-Is-Expected-to-Reach-2-5-Billion-by-2030-Says-AMR.html

𝟐. 𝐇𝐢𝐠𝐡 𝐕𝐨𝐥𝐭𝐚𝐠𝐞 𝐂𝐚𝐛𝐥𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 - https://www.globenewswire.com/news-release/2020/05/13/2032806/0/en/High-Voltage-Cables-Market-to-Reach-23-4-Billion-by-2027-AMR.html

𝐀𝐛𝐨𝐮𝐭 𝐔𝐬:

Allied Market Research is a top provider of market intelligence that offers reports from leading technology publishers. Our in-depth market assessments in our research reports take into account significant technological advancements in the sector. In addition to other areas of expertise, AMR focuses on the analysis of high-tech systems and advanced production systems. We have a team of experts who compile thorough research reports and actively advise leading businesses to enhance their current procedures. Our experts have a wealth of knowledge on the topics they cover. Also, they use a variety of tools and techniques when gathering and analyzing data, including patented data sources.

0 notes