#Piping Design

Explore tagged Tumblr posts

Text

0 notes

Text

The Role of Pipe Stress Analysis in Piping Design Pipe stress analysis is essential in piping design, ensuring safety and reliability in various industries. By assessing the impact of thermal expansion, pressure fluctuations, and external loads, engineers can prevent failures and leaks. This analysis is crucial for maintaining structural integrity, optimizing performance, and adhering to industry standards. Recent trends emphasize its role in enhancing operational efficiency and minimizing downtime. As industries evolve, integrating advanced simulation tools into pipe stress analysis becomes increasingly vital for sustainable practices. #PipeStressAnalysis #PipingSafety #EngineeringDesign #StructuralIntegrity #OperationalEfficiency For more insights, visit https://inclinedengg.com/

0 notes

Text

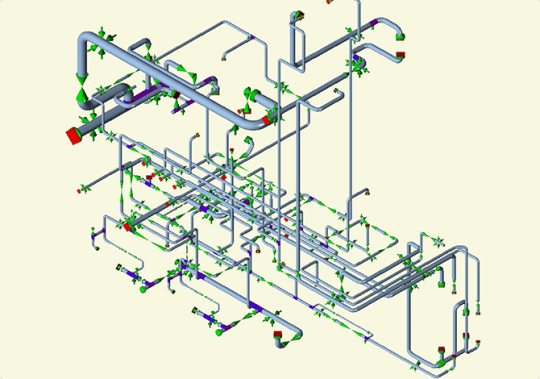

Isometric Drawings for Piping Design.

Isometric drawings in piping design provide a 3D representation of the piping system, illustrating the spatial relationships between pipes, fittings, valves, and other components. These drawings help visualize the design, ensure proper assembly, and facilitate communication among engineers, fabricators, and installers. To read more:

0 notes

Text

Little P.Eng. Engineering for Structural and Piping Design in Hydrogen Pilot Plant for Green Energy

In the race to counteract climate change, green energy solutions are imperative. Hydrogen, known as the universe's most abundant element, offers a promising pathway. Pilot plants are experimental setups designed to understand and optimize large-scale industrial processes. Little P.Eng. Engineering has emerged as a pivotal player in realizing this potential by specializing in the structural and piping design for hydrogen pilot plants.

Hydrogen's Role in Green Energy

Hydrogen is not just another energy source; it's a powerful, clean fuel that, when consumed, emits only water as a byproduct. Green hydrogen, especially, is produced using renewable energy sources, ensuring a low-carbon footprint. As governments and industries realize its potential, pilot plants that can produce, store, and utilize hydrogen efficiently are in demand.

Little P.Eng. Engineering’s Expertise

Little P.Eng. Engineering's team specializes in addressing the unique challenges posed by hydrogen in pilot plants. Their structural and piping designs consider factors such as hydrogen's low density, its propensity to embrittle metals, and the safety requirements necessary when working with the element.

Structural Design Considerations

Hydrogen Embrittlement: Hydrogen can make metals brittle, especially under high-pressure conditions. The structural components must be designed with materials resistant to this phenomenon.

Safety Measures: Hydrogen is flammable. Incorporating explosion-proof structures, safe zones, and preventive measures against accidental leaks is paramount.

Modularity: As pilot plants are often experimental setups, flexibility and modularity in design allow for changes based on the evolving understanding of the process.

Piping Design Considerations

Material Selection: Given hydrogen's small molecule size, it can easily leak through many materials. Piping must be constructed with materials that prevent leakage and are resistant to embrittlement.

Pressure Challenges: Hydrogen storage and transport require high-pressure conditions. The piping system must handle these pressures, ensuring safety and efficiency.

Temperature Factors: Liquid hydrogen storage needs extremely low temperatures. This necessitates designs that can handle thermal stresses and expansion-contraction challenges.

Safety Valves and Monitoring Systems: Real-time monitoring of the hydrogen flow, pressure, and potential leaks are essential. Incorporating advanced monitoring systems and safety valves ensures timely detection and mitigation of any risks.

Applications in Green Energy

Hydrogen pilot plants are not just limited to producing hydrogen. They also focus on:

Storage: Efficiently storing hydrogen is a challenge. Pilot plants explore solutions like high-pressure gas storage or cryogenic liquid storage.

Power Generation: Pilot plants test fuel cells and other means to convert hydrogen back into electricity.

Integration with Other Renewable Sources: Connecting hydrogen production with wind, solar, and hydroelectric power sources ensures a continuous energy supply, even when these sources aren't generating power.

Green Mobility: Hydrogen fuel cell vehicles (FCVs) are on the rise. Pilot plants play a pivotal role in researching and optimizing hydrogen production, storage, and refueling stations for these vehicles.

Advancing the Future

Little P.Eng. Engineering's commitment to green energy is evident in its consistent research and innovation in structural and piping designs. By regularly updating their designs based on feedback from pilot plants, they ensure safety, efficiency, and scalability for large-scale hydrogen production.

The company also collaborates with universities, research institutions, and industries to stay at the forefront of technology. Such partnerships help in the exchange of ideas and the rapid adoption of best practices.

Challenges and Opportunities Ahead

While the potential of hydrogen as a green energy source is immense, there are challenges:

Economic Feasibility: Bringing down the costs associated with hydrogen production, storage, and usage is essential for its mainstream adoption.

Scalability: While pilot plants offer invaluable insights, scaling these solutions to meet global energy demands requires further research and innovations.

Public Awareness and Acceptance: For hydrogen to be widely adopted, both as an energy storage medium and a fuel, public understanding and acceptance of its benefits and safety are crucial.

Little P.Eng. Engineering, with its expertise and dedication, is poised to address these challenges, turning them into opportunities for a greener future.

Conclusion

As we grapple with the urgency of transitioning to green energy solutions, hydrogen emerges as a beacon of hope. With its abundant availability and potential for clean energy generation, it can revolutionize the energy landscape. Companies like Little P.Eng. Engineering, through their specialized structural and piping designs, play a pivotal role in this transition. As the world moves towards a sustainable future, the role of such innovators becomes even more significant.

Tags:

Meena Rezkallah

Little P.Eng. Engineering

Structural design

Energy efficiency

Engineering expertise

Hydrogen pilot plant

Green energy

Piping design

Sustainable energy sources

Hydrogen storage

Hydrogen transportation

Structural stability

Pressure-relief systems

Safety mechanisms

Hydrogen production

Electrolysis

Advanced simulations

Material embrittlement

Leak prevention

Optimal hydrogen flow

Seismic resilience

Weather-resistant structures

Modular designs

Renewable energy

Zero carbon emissions

Advanced safety

North American energy transition

Environmental consciousness

Hydrogen infrastructure

Hydrogen diffusivity

Hydrogen Production Plant Design

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Meena Rezkallah#Little P.Eng. Engineering#Structural design#Energy efficiency#Engineering expertise#Hydrogen pilot plant#Green energy#Piping design#Sustainable energy sources#Hydrogen storage#Hydrogen transportation#Structural stability#Pressure-relief systems#Safety mechanisms#Hydrogen production#Electrolysis#Advanced simulations#Material embrittlement#Leak prevention#Optimal hydrogen flow#Seismic resilience#Weather-resistant structures#Modular designs#Renewable energy#Zero carbon emissions#Advanced safety#North American energy transition#Environmental consciousness#Hydrogen infrastructure#Hydrogen diffusivity

0 notes

Text

Piping engineering is a branch of mechanical engineering that oversees the design of piping as well as the layout of equipment and process units. It is concerned with the management of equipment and process units in chemical, petrochemical, or hydrocarbon plants. To learn more about it, go to Piping Design Online Training and begin a career in this field.

0 notes

Text

Piping Design

MECS Engineering Inc. is a licensed professional engineers (P.Eng./P.E.) team to support companies worldwide SPECIALIZE in Piping Engineering, Stress Analysis, Pressure Vessels, equipment Design etc..

Piping Design

0 notes

Text

0 notes

Text

Wild Life Gem & Joel

#geminitay#geminitay fanart#smallishbeans#wild life smp#trafficblr#amararala art#going for mechanic core with their designs so far#when i googled torreto it showed him holding a pipe so there you go joel

427 notes

·

View notes

Text

ahem. aheem

(i hope it's obvious but if not: jack is Not trying to hit dave here he's just swanging that crank around)

#pinixy's art#dsaf#dayshift at freddy's#dsaf jack#dsaf dave#dsaf art#dsaf fanart#do hand cranks have a canon design. i hope not#i kinda always pictured them as metal pipe type things. i doubt fazbenders would be willing to give their employees nicer ones#anyway. dabey 💔💔💔💔💔💔💔💔💔💔💔#also uhhhhh if anyone's interested i could pick apart a couple choices i made w/color and stuff in this if you want. shrugs#the yellow at the end has a meaning i can get into

292 notes

·

View notes

Text

you better not be freeing your mind at night

#my art#furry#fursona#anthro#oc#a critter#a creature#tenatively calling it#oc: meadow#this is a combination of all my main sonas (tilly milo and cow) and its just kinda a dragon creature thing#gonna have fun with its design and make it SUPER fluid like#what if i ACTUALLY leaned fully into the shapeshifter thing for once#:3#anyways#a doodlie#im doing commissions today and almost forgot to post this in the throughs (throwes? ?) of puppy dog drawings#weed#smoking#pipe

1K notes

·

View notes

Text

they were boys together !!!

#every time i think about these two sat on the bus in their little school uniforms i start sobbing uncontrollably#paul mccartney#george harrison#beatles#beatles fanart#p + g#i think about them meeting as like little tiny 11/12 year olds or whatever and then growing up together and being beatles and falling out#and then coming back together but never fully going back to how it once was and i just go insane#mcharrison is the secret even more tragic yaoi in the beatles you lot are just not ready to hear it#as someone who is a george in one friend group (continually babied and underestimated bc im the youngest) i get him#but as an actual oldest sibling and also generally a paul coded person i also get pauls perspective like pipe down pipsqueak 🗣️#as a designated baby friend sometimes u just have to accept the abuse unfortunately for george and how can he not when he was SO SO tiny#bro was never gonna live down that 9 month age gap i fear#he is 3 apples tall !! u just KNOW he was so pissed off when he finally got the growth spurt and was still shorter than paul by an inch#anyway stream inspite of all the danger (mccartney harrison) :3

161 notes

·

View notes

Note

this feels like the sort of thing you'd know, or at least be able to track down in shorter order than I could: where did the "rotate pipes to complete a pathway across a grid" game first appear?

Assuming you're talking about video games, the earliest example of the type that I'm aware of is Pipe Mania (1989). There are earlier games of this general class (i.e., path-building games where the player needs to complete a connection between two points given limited resources), of course, but to the best of my knowledge Pipe Mania is the first one which both incorporates a race-against-the-clock element and uses plumbing as a framing device.

196 notes

·

View notes

Text

quick magnus protocol character designs because babygirl i am ready to go FERAL again. in order: alice, lena, sam, colin and gwen

#the magnus protocol#the magnus archives#tmagp#tma#making my gwen as Friend as possible so it’s even more fun when she inevitably pipe murders someone#alice dyer#lena kelley#samama khalid#colin becher#gwendolyn bouchard#tmagp fanart#my art#the magnus protocol art#character designs#illustration#radarpls

450 notes

·

View notes

Text

Chara sheet for Galatea

#winx club#winx galatea#winx club galatea#magical girls#fairy transformations#winx club minor fairies#locally sourced art#enchantix#onyrix#one thing I really enjoy about the og onyric design is the neon pipes so shout out to them

172 notes

·

View notes

Text

Leading the Future with Structural and Piping Design for Hydrogen Pilot Plants in the Green Energy

As the world gradually transitions towards sustainable energy sources, hydrogen stands out as a beacon of hope in the quest for green energy. The intricacies involved in harnessing hydrogen's power necessitate advanced pilot plants equipped with state-of-the-art designs. Enter Little P.Eng. Engineering, the torchbearer of structural and piping design for hydrogen pilot plants, pushing the boundaries of innovation and safety in North America.

The Growing Importance of Hydrogen in Green Energy

With zero carbon emissions when burned, hydrogen promises a cleaner future, especially when produced through green methods like electrolysis of water using renewable energy. The challenge lies in efficiently storing and transporting hydrogen, which requires meticulously designed infrastructure. This is where pilot plants come into play, acting as the testing grounds for groundbreaking technologies and methodologies.

Understanding the Role of Structural and Piping Design

In any hydrogen pilot plant, the importance of structural and piping design cannot be overstated:

Structural Design: Ensures the physical stability and safety of the plant. With hydrogen's volatile nature, the infrastructure must be robust enough to withstand pressures, prevent leaks, and guarantee longevity.

Piping Design: Deals with the intricate network of tubes and pipes that transport hydrogen and other fluids within the plant. An optimized piping system reduces losses, increases efficiency, and ensures the safe transportation of hydrogen.

Little P.Eng. Engineering's Expertise in Action

1. Customization: Every pilot plant has unique needs. Little P.Eng. Engineering’s team initiates a thorough groundwork phase, understanding the plant's specific requirements, and then tailoring designs to fit those needs perfectly.

2. Advanced Simulations: Before any design is finalized, it undergoes rigorous simulations to test its viability, strength, and efficiency. This ensures that any potential issues are addressed long before implementation.

3. Safety Above All: Given hydrogen's highly flammable nature, safety is paramount. Designs incorporate advanced safety mechanisms, pressure-relief systems, and fail-safes, ensuring the utmost protection for both the workers and the environment.

4. Seamless Integration: Little P.Eng. Engineering’s designs aren’t just about functionality – they're about integration. The designs ensure that all components of the pilot plant work in harmony, enhancing the overall operational efficiency.

A Look at Piping in Detail

Hydrogen, with its low viscosity and high diffusivity, poses unique challenges:

Material Selection: Hydrogen can lead to material embrittlement. Little P.Eng. chooses materials that resist this phenomenon, ensuring the pipes remain durable even under intense hydrogen flow.

Leak Prevention: With advanced sealing technologies and meticulous design, the piping systems are virtually leak-proof, preventing hydrogen wastage and potential hazards.

Optimal Flow: The piping designs ensure that hydrogen flows at optimal rates, reducing energy consumption and maximizing efficiency.

The Structural Marvels of Little P.Eng. Engineering

When it comes to structural design, it's a balance of strength, flexibility, and longevity:

Earthquake Resilience: Many areas in North America are prone to seismic activities. Designs from Little P.Eng. factor in these challenges, ensuring that structures can withstand tremors without sustaining damage.

Weather Resistance: Whether it's the freezing Canadian winters or the blistering heat of the southern USA, the structures are built to weather it all, quite literally.

Modularity: As the hydrogen industry evolves, pilot plants might need upgrades. Little P.Eng.'s modular designs ensure that expansions and modifications can be made without major overhauls.

Conclusion

The green energy revolution is upon us, and hydrogen is at its forefront. As pilot plants become the crucibles of innovation in this sector, having the right structural and piping design is crucial. Little P.Eng. Engineering, with its blend of expertise, innovation, and commitment to sustainability, is not just a participant but a leader in this transition towards a cleaner future. Their designs for hydrogen pilot plants stand as testaments to what is possible when engineering prowess meets environmental consciousness.

Tags:

Little P.Eng. Engineering

Structural design

Energy efficiency

Engineering expertise

Hydrogen pilot plant

Green energy

Piping design

Sustainable energy sources

Hydrogen storage

Hydrogen transportation

Structural stability

Pressure-relief systems

Safety mechanisms

Hydrogen production

Electrolysis

Advanced simulations

Material embrittlement

Leak prevention

Optimal hydrogen flow

Seismic resilience

Weather-resistant structures

Modular designs

Renewable energy

Zero carbon emissions

Advanced safety

North American energy transition

Environmental consciousness

Hydrogen infrastructure

Hydrogen diffusivity

Cleaner future

Hydrogen Production Plant Design

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng. Engineering#Structural design#Energy efficiency#Engineering expertise#Hydrogen pilot plant#Green energy#Piping design#Sustainable energy sources#Hydrogen storage#Hydrogen transportation#Structural stability#Pressure-relief systems#Safety mechanisms#Hydrogen production#Electrolysis#Advanced simulations#Material embrittlement#Leak prevention#Optimal hydrogen flow#Seismic resilience#Weather-resistant structures#Modular designs#Renewable energy#Zero carbon emissions#Advanced safety#North American energy transition#Environmental consciousness#Hydrogen infrastructure#Hydrogen diffusivity#Cleaner future

0 notes

Text

Understanding pipe production and joining techniques will be aided by the piping designing course. One can enroll in any of the numerous Delhi-based institutions offering the Piping Design Course to begin a career in this field.

#Piping Design#Piping Design Training#Piping Design Certification#Piping Design Course#software testing certification

0 notes