#Pipe Beveling Cutting Machine Manufacturer

Explore tagged Tumblr posts

Text

In the dynamic world of fabrication and construction, the efficiency and precision of pipe beveling cutting machines have become indispensable. These machines, designed to prepare pipes for welding by creating clean cuts and angles, are critical for ensuring strong, reliable joints. With various models ranging from basic pipe cutting and beveling machines to advanced stainless steel pipe cutting and beveling machines, the technological advancements in this field have revolutionized how industries approach pipe fabrication. This significance is underscored further by the specialized application of Axxair orbital pipe cutting and beveling machines, which exemplify precision and speed in pipe modification operations.

#Pipe Beveling Cutting Machine#Pipe Beveling Cutting Machine Manufacturer#Pipe Beveling Cutting Machine Exporter#Best Pipe Beveling Cutting Machine#Top Pipe Beveling Cutting Machine#spmequipment

0 notes

Text

SPM epl is an expert in providing precise and effective solutions for a wide range of industrial applications through its modern pipe cutting and lifting equipment. Their modern technologies provide flawless pipeline construction, maintenance, and decommissioning project operations. SPM epl's equipment, which is built for dependability and versatility, provides sturdy solutions for managing a range of pipe materials and diameters, including carbon steel, stainless steel, and unusual alloys.For more info about our product visit website: https://spmepl.com/category/pipe-cutting-equipment/

#Pipe cutting and lifting equipment#manual beveling machine#motorized beveling machine#pipe beveling machine manufacturer

0 notes

Text

Aluminium Alloy 6082 Pipes & Tubes Manufacturers

Introduction :-

Siddhgiri Tubes is a leading manufacturer, supplier, stockist, and exporter of a wide range of 6082 Aluminium Alloy Pipes & Tubes, providing our customers with the most satisfactory value list for Aluminium Alloy. Aluminium alloy 6082 Pipes & Tubes are known for their medium strength and excellent corrosion resistance. Compared to the 6000 series, this alloy offers the highest strength. The addition of manganese controls the grain structure, resulting in a stronger Aluminium composite.

Product details :-

Siddhgiri Tubes is one of the most trusted manufacturers and suppliers of Aluminium Alloy 6082 pipes and tubes. With years of expertise in the field of metal manufacturing, Siddhgiri Tubes offers high-quality aluminium products that meet global standards of performance, durability, and precision. Known for their commitment to excellence, Siddhgiri Tubes ensures that each product is carefully crafted to serve the needs of various industries, including aerospace, construction, automotive, marine, and more.

Aluminium Alloy 6082 is a highly versatile, heat-treatable alloy that offers a perfect balance of strength, corrosion resistance, and workability. As a leading manufacturer, Siddhgiri Tubes provides these products in different sizes, shapes, and finishes to meet specific project requirements. The company’s focus on quality control and rigorous testing ensures that customers receive reliable and high-performance aluminium tubes and pipes.

Product Overview:

Aluminium Alloy 6082 is a high-strength, heat-treatable alloy that offers excellent mechanical properties, making it ideal for structural and high-load applications. Siddhgiri Tubes manufactures these pipes and tubes in a range of shapes such as round, square, and rectangular, offering a variety of solutions for different engineering and construction needs. These products are available in both extruded and welded forms, which can be customized based on specific client requirements.

The 6082 alloy is known for its excellent resistance to corrosion, especially in harsh environments such as marine and coastal areas. It also boasts high tensile strength and good workability, making it suitable for intricate fabrication and complex engineering projects. The alloy can be easily welded, machined, and anodized to provide further customization for applications that require additional protection or aesthetic finishes.

Specification :-

Standards :- ASTM B221, ASTM-B-209M, EN573, EN485, AMS 4003

Grade:- Aluminium Alloy 6082 (UNS A96082)Size1/2" NB - 24" NB

Schedule:-SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Length:- Single Random, Double Random & Cut Length.

End:- Plain End, Beveled End, Treaded

Type:-Seamless / ERW / Welded / Fabricated / LSAW Pipes

Form :- Round, Square, Rectangular, Hydraulic Etc

Advantages :-

High Strength-to-Weight Ratio: Aluminium Alloy 6082 offers an excellent strength-to-weight ratio, making it ideal for lightweight yet strong applications. This is particularly beneficial in industries like aerospace, automotive, and transportation, where reducing weight is essential without compromising structural integrity.

Superior Corrosion Resistance: 6082 alloy's exceptional resistance to corrosion, even in aggressive environments like marine or industrial settings, ensures that the pipes and tubes from Siddhgiri Tubes will maintain their integrity and performance over time. The natural oxide layer that forms on the surface provides effective protection against rust and degradation.

Enhanced Mechanical Properties: The alloy’s high tensile strength and resistance to stress make it suitable for heavy-duty applications where materials are subjected to high loads and pressures. This makes 6082 a top choice for construction, shipbuilding, and other demanding industries.

Excellent Fabricability: Siddhgiri Tubes’ Aluminium 6082 pipes and tubes are easily fabricated, welded, and machined. This makes them a versatile option for various engineering designs, as they can be processed into customized shapes and sizes to meet specific requirements.

Versatility Across Industries: The adaptability of Aluminium 6082 makes it ideal for a wide range of applications, from structural components in buildings to heat exchangers, marine equipment, and more. The wide range of shapes, sizes, and finishes available from Siddhgiri Tubes ensures that the alloy can meet the diverse needs of industries like aerospace, automotive, construction, marine, and more.

Sustainability: Aluminium is a fully recyclable material, and using Aluminium Alloy 6082 from Siddhgiri Tubes contributes to sustainability. The alloy can be recycled without losing its properties, making it an eco-friendly option for industries that prioritize environmental responsibility.

Compliance with International Standards: Siddhgiri Tubes’ products meet international standards such as ASTM, ASME, DIN, and others, ensuring high-quality, reliable, and consistent products that can be used worldwide in critical applications.

Conclusion

Siddhgiri Tubes stands out as a leading Aluminium Alloy 6082 pipes and tubes manufacturer, offering top-tier products for a variety of industrial applications. Their pipes and tubes are characterized by high strength, excellent corrosion resistance, and ease of fabrication, making them ideal for use in demanding industries such as aerospace, automotive, marine, and construction.

The 6082 alloy combines the best properties of aluminium, including lightweight, durability, and strength, making it a go-to material for structural and high-performance applications. With a focus on quality, precision, and customer satisfaction, Siddhgiri Tubes ensures that all its products meet the highest industry standards and offer long-lasting performance.

Whether you're looking for customized aluminium pipes and tubes for a specialized project or need reliable solutions for bulk industrial applications, Siddhgiri Tubes provides top-quality Aluminium Alloy 6082 products that guarantee reliability, strength, and sustainability. Choosing Siddhgiri Tubes for your aluminium needs means partnering with a company that values excellence, precision, and quality in every aspect of manufacturing.

0 notes

Text

Proper Installation Techniques for Butt Weld Fittings

Butt weld fittings are essential components in piping systems, providing connections between pipes of the same diameter. Correct installation is crucial to ensure the integrity and safety of the piping system. Here are some key techniques to follow:

1. Preparation:

Cleanliness: Ensure the pipe ends and fitting surfaces are clean and free of dirt, grease, or scale.

Cutting: Use a cutting tool that produces a square, burr-free cut.

Beveling: If necessary, bevel the pipe ends at the appropriate angle for welding.

2. Alignment:

Centering: Align the pipe ends and fitting concentrically to prevent misalignment and ensure a proper weld.

Gap: Maintain a small gap between the pipe ends to allow for weld penetration.

3. Welding:

Welding Process: Choose the appropriate welding process based on the pipe material and application. Common methods include TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding.

Filler Metal: Use a filler metal that matches the base metal of the pipe and fitting to ensure compatibility.

Welding Parameters: Set the welding machine's parameters (voltage, amperage, gas flow rate) according to the specific requirements of the materials and welding process.

Joint Penetration: Ensure proper penetration of the weld into the pipe and fitting.

4. Post-Weld Inspection:

Visual Inspection: Visually inspect the weld for defects such as cracks, porosity, or undercutting.

Non-Destructive Testing (NDT): Use NDT methods like radiographic testing or ultrasonic testing to verify the weld's quality.

5. Heat Treatment:

If required: Depending on the pipe material and application, post-weld heat treatment may be necessary to relieve stresses and prevent cracking.

Platinex Piping Solution is a reputable manufacturer and exporter of stainless steel pipes and fittings, including butt weld fittings. They can provide expert guidance and support for the proper installation of their products.

By following these guidelines and using high-quality fittings from a reliable supplier like Platinex Piping Solution, you can ensure the safe and efficient operation of your piping system.

0 notes

Text

Beveling Laser Pipe Cutting Machine

Introduction In recent years, manufacturing has been revolutionized by technological advances. Laser cutting machines have improved accuracy, efficiency and cost-effectiveness over traditional cutting methods. Bevel laser pipe cutter is one such laser cutter used to cut pipes with unique beveled edges. In this article, we will demonstrate the real-world results of beveled laser pipe cutters for pipe cutting.

Efficiency Bevel laser pipe cutters offer unprecedented cutting efficiency compared to traditional methods. The machine cuts pipes faster using a focused laser beam than traditional sawing or grinding methods. The high precision of the machine saves manufacturers money by reducing material waste. In addition, the machine can cut multiple pipes at the same time, further increasing productivity.

High Accuracy One of the main benefits of the beveling laser pipe cutting machine is its high accuracy. The machine provides high-precision cutting to ensure that pipes fit perfectly when assembled. Unlike traditional methods that can affect the quality of the final product, the bevel laser cutter ensures consistent cutting results. The machine also features automatic edge detection and compensation to ensure cutting accuracy even when cutting challenging shapes and designs.

Versatility The Bevel Laser Pipe Cutter can cut a variety of materials, including metals, plastics and composites. This versatility is made possible by the high power and precision of the laser beam, making it easy to cut a wide range of materials. In addition, the machine can cut pipes of all shapes and sizes, making it suitable for a wide range of industries, including automotive, construction and aerospace.

Safety Laser cutting machines are safe to use with minimal risk of injury to workers. These machines utilize a closed system that prevents the laser beam from shooting out of the machine, thus ensuring the safety of the operators. Additionally, these machines do not generate heat or sparks, thus reducing the risk of fire in the workplace.

Environmental impact Beveling laser pipe cutting machines are an environmentally friendly method of cutting compared to traditional cutting methods. The machine does not produce waste or emit pollutants, thereby reducing the carbon footprint of the manufacturing process. In addition, the machine is energy efficient, consuming less power than traditional cutting methods.

Conclusion In conclusion, the Bevel Laser Pipe Cutter is an efficient, versatile, and accurate method of cutting pipes. The machine offers a number of advantages, including efficiency, precision, versatility, safety, and environmental friendliness.

0 notes

Text

Choosing a CNC Machine Shop

Choosing a CNC Machine Shop

Machine shops rely on computer numerical control (CNC) to operate their machines. This technology replaced the hand-cranks and levers of old, and enables shop owners to create precise, customized parts with speed and ease. Businesses and product developers need a machine shop with experience handling their specific machining needs. Look for a shop that can sign an NDA before working with you, as it will ensure your designs will remain confidential.

1. Experience

Working with a machine shop that has experience will ensure your product or project is completed quickly and correctly. This will save you

time, money and avoid costly mistakes. Moreover, these shops can help you create prototypes for new products or test them in real-world conditions before they go into production, which will reduce your risk of failure. Most machine shops work business-to-business, making custom products for other businesses to use and sell to their customers. A few are focused on specialty or niche markets and offer additional value-added services. For example, Bates Machine & Mfg. offers consulting to help streamlinethe manufacturing process. When working with a machine shop, look for one that has an extensive range of capabilities and uses modern CNC machines and measuring equipment. Also, check that the machine shop has a good reputation and will sign a non-disclosure agreement (NDA) to protect customer designs.

2. Flexibility

Machine shops are used in the manufacturing process for a wide range of products from car parts to precision electronics. With advanced technology and automated processes, machines are able to cut metal into extremely intricate shapes that cannot be made through traditional methods. This allows for a wider range of products to be produced and makes them more accessible to consumers. In addition, the flexibility of CNC machining can help save time when compared to manual processing. Digital models of products can be processed by the machine and converted into code that a machine then uses to cut the metal. This eliminates the need for a human operator to manually process each design, which can take up to an hour or more. The machine shop must also have the ability to accommodate varying product requirements in terms of tolerances. For example, the shop must be able to prepare pipes that have higher wall thicknesses. They must also be able to use tools that can produce all types of bevels.

3. Customization

A machine shop must be able to work with different materials and deliver results that are perfect for their clients. They must also be flexible enough to take on different size orders. This flexibility is what enables them to provide excellent value for their customers. It is important for a machine shop to be capable of fabricating the various products and parts that go into aerospace equipment. This is why they need to be able to handle stainless steel and aluminium at a high level of quality. The ideal machine shop has previous samples of their work to show their experience and expertise in their industry. They should be able to explain their procedures in detail so that their clients are confident in their abilities. It is also useful for a machine shop to have an online platform through which their clients can track the progress of their order. They should also be able to communicate via phone in case of any queries.

4. Timely Delivery

Whether it's a quick turnaround on a new project or an emergency repair, having a machine shop that is able to deliver on short notice is essential. Look for a CNC machine shop that has the equipment to produce your products quickly, without sacrificing quality. The ability to deliver on time is a direct indicator of a CNC machine shop's efficiency and overall capabilities. A reliable shop will have a high-quality team of expert machinists working alongside state-of-the-art machines to create parts that meet exact custom design specifications. A reputable machine shop will also offer timely communication with its clients. Look for a company that is easily accessible to manage orders through digital mediums and utilizes feedback mechanisms to incite projects' growth. This way, you can stay in contact with your project throughout the process and know exactly what to expect when it's delivered. Additionally, look for shops that can offer ancillary services, such as painting or bead blasting, to shorten the lead time on your order. Read the full article

0 notes

Text

Stainless Steel Pipe and Tube in Andhra Pradesh

Meghmani Metal is the largest Supplier of Stainless Steel Pipe and Tube in Andhra Pradesh, India. Stainless Steel Pipe and Tube are versatile and commonly used in every industry, available in various dimensions and sizes. There are different types of SS Pipe and Tube such as SS ERW Pipe and Tube, SS Welded Pipe and Tube, SS Seamless Pipe and Tube, among others. Custom-sized Stainless Steel Pipe and Tube are supplied to fulfill customers' industrial requirements. These Stainless Steel Pipe and Tube are widely favored for their strong corrosion resistance and weldability, making them highly effective in acidic settings and offering pitting corrosion resistance. Additionally, Meghmani Metal is a leading Copper Sheet Supplier in India. The Stainless Steel Pipe and Tube are manufactured under an experienced team and advanced machining technology. They undergo various quality checks and inspections by our team to ensure the highest standards because our customers are important to us. We provide top-quality Stainless Steel Pipe and Tube at the lowest price in the Steel Market. Specifications: Specifications: ASTM A 312 ASME SA 312 / ASTM A 358 ASME SA 358 Dimensions: ASTM, ASME, and API SS Pipes: 1/2" NB – 16" NB SS ERW Pipes: 1/2" NB – 24" NB SS EFW Pipes: 6" NB – 100" NB Size Range: 1/8" NB TO 30" NB IN Specialization: Large Diameter Sizes Schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS Type: Seamless / ERW / Welded / Fabricated / LSAW Pipes Form: Round, Square, Rectangular, Hydraulic, etc. Length: Single Random, Double Random & Cut Length End: Plain End, Beveled End, Threaded We Provide Stainless Steel Pipe and Tube in Andhra Pradesh Including Adoni, Amaravati, Anantapurm, Chandragiri, Chittoor, Dowlaiswaram, Eluru, Guntur, Kadapa, Kakinada, Kurnool, Machilipatnam, Nagarjunakoṇḍa, Rajahmundry, Srikakulam, Tirupati,Vijayawada, Visakhapatnam, Vizianagaram, Yemmiganur. Read the full article

#Adoni#Amaravati#Anantapurm#AndhraPradesh#Chandragiri#Chittoor#Dowlaiswaram#Eluru#Guntur#India#Kadapa#Kakinada#Kurnool#Machilipatnam#Manufacturer#Nagarjunakonda#Rajahmundry#Srikakulam#SSPipesandTubes#StainlessSteelPipeandTube#StainlessSteelPipeandTubeinAndhraPradesh#StainlessSteelPipeandTubeinIndia#Stockiest#supplier#SupplierofStainlessSteelPipeandTubeinAndhraPradesh#Tirupati#Vijayawada#Visakhapatnam#Vizianagaram#Yemmiganur

0 notes

Text

We manufacture every part of our machines , from the smallest component to the finished product, at our state-of-the-art factory in Poland. Today, we're providing a behind-the-scenes look at our production line , where we build high-quality components for our equipment. In this video, you can see one part being made that will later be used in our welding tractors. Watch the fascinating process for yourself.

#PromotechIndia#TopQuality#PolishProduction#BehindTheScenes#Manufacturing#FactoryLife#WorkDay#Promotech

0 notes

Text

The Manufacturing Process Of A 45-Degree Elbow In India

Petromet Flange Inc is among the foremost Pipe Fittings 45 Degree Elbow Manufacturer in India. Manufacturing a 45-degree elbow in India involves several steps, and it typically requires the use of specialized equipment and materials. 45-degree elbows are commonly used in piping systems to change the direction of flow at a 45-degree angle.

Here's A General Overview Of The Manufacturing Process For A Welded 45-Degree Elbow In India

Material Selection:

The first step is to select the appropriate material for the 45-degree elbow based on the specific requirements of the application. Common materials for elbow manufacturing include carbon steel, stainless steel, alloy steel, and various other materials.

Cutting and Forming:

The selected material is cut into suitable lengths. The ends of the cut pieces are then prepared for welding by beveling or machining to create a smooth and precise edge.

Bending:

To create the 45-degree angle, the prepared pipe sections are bent using a hydraulic or mechanical press. Precision is crucial to ensure the angle is accurate.

Welding:

The two pipe sections that have been bent are aligned and welded together using appropriate welding techniques. Common methods include TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), or SMAW (Shielded Metal Arc Welding). The welding process ensures a strong and leak-proof joint.

Inspection and Testing:

The welded 45-degree elbow undergoes various quality checks, including visual inspections, non-destructive testing (NDT), and pressure tests to ensure it meets the required standards and specifications.

Surface Finish:

After welding and testing, the elbow's surface may be cleaned, ground, or polished to achieve the desired finish and remove any imperfections.

Coating and Painting (optional):

Depending on the application and the material used, the elbow may be coated or painted to protect it from corrosion or other environmental factors.

Packaging and Shipment:

Once the 45-degree elbow has passed all quality control checks and meets the necessary standards, it is packaged for shipment to customers or distributors.

Pipe Fittings 45 Degree Elbow Manufacturer in India

Petromet Flange Inc is one of the leading Pipe Fittings 45 Degree Elbow Manufacturer in India. We offer a wide range of Pipe Fittings 45 Degree Elbow in different dimensions, specifications & shapes to meet the needs of our clients. Additionally, we may modify 45 Degree Elbow to meet customer specifications. Our pipe fittings undergo rigorous testing to ensure their precision, accuracy, and longevity.

Petromet Flange Inc specialises in the distribution and sale of Pipe Fittings 45 Degree Elbow to various industries. Are you in search of reliable and quality-oriented 45 degree elbow manufacturers in India? Look no further. Petromet Flange INC is reputed across the globe for its High quality Pipe Fittings 45 Degree Elbow.

We treat our clients by giving them the best products and services. Our Pipe Fittings 45 Degree Elbows are used in various applications.

Manufacturing processes can vary among different manufacturers and may involve additional steps or specific quality control measures. It's important to adhere to industry standards and specifications, such as ASME, ASTM, or API, when producing pipe fittings like 45-degree elbows to ensure their reliability and performance in various applications. Additionally, consider environmental and safety regulations in the manufacturing process to promote sustainable and safe practices.

Website: petrometfitting.com

Product: 45 degree elbow manufacturers

Other Product: Pipe Fittings Suppliers in Saudi Arabia.

0 notes

Text

Benefits of Investing in CNC Plasma Cutting Machine?

Why would you invest in a CNC plasma cutting machine as opposed to a laser or waterjet is a question we are frequently asked.

Each form of profiling machine has advantages and disadvantages; in this article, I’ll try to elaborate on some of the factors that convince many businesses to purchase a CNC plasma cutter:

RELATIVELY LOW PURCHASE COST

The price of plasma cutters can vary significantly depending on the features needed, just like the price of most CNC machines. However, they are typically the most affordable choice when purchasing a profile cutting machine. The most expensive alternative is using a laser cutting machine, with waterjets falling somewhere in the between.

ECONOMICAL OPERATING COSTS

A further achievement for plasma cutting technology. When making your comparison, much like with any machinery purchase, you must take power usage, consumables, gases & compressed air, and routine maintenance into account. Running a plasma cutter typically costs around 25% less than running a laser cutter and 50% less than running a waterjet.

PRODUCTION RATES

Without comparing production rates, no cost comparison could be deemed complete. While CNC plasma cutters really shine when processing thicker plates, with typical cutting rates being significantly greater than with other techniques, laser cutting is by far the fastest way to cut thin sheet material. On comparable materials, waterjet is substantially slower than laser and plasma.

Less complex adjustments are needed when using CNC plasma cutting machine. Because of technological advancements, smaller setups can now benefit from faster cutting and increased production.

CUT QUALITY

High Definition plasma has made it possible to work more quickly and precisely than with earlier plasma technology. The latest plasma machines now offer exceptional cut quality with very little bevel and a virtually dross-free finish, all while maintaining production feed rates. While laser and waterjet still have the advantage in terms of edge squareness, the latter technology also has the benefit when it comes to edge quality. The quality of a plasma cut part is typically more than enough for a fabrication setting.

CNC CONTROL

The “brain” of the entire system is the CNC control of the plasma cutting machine of your choice. The majority of contemporary CNC controls can operate with various toolpath files. In order to reduce waste, some additionally incorporate CAM nesting and optimisation tools. Others also include CAD drawing software. The filtration equipment and other auxiliary devices will be operated under the guidance of the CNC control.

A CNC flame cutting machine, also known as a CNC oxy-fuel cutting machine, is a type of industrial cutting tool used for cutting through thick metal plates or sheets. It utilizes a combination of fuel gases and oxygen to create a controlled flame that melts and removes the metal in the cutting path.This machine is used for facilitating the process of plasma cutting, which uses an accelerated jet of hot plasma to cut through electrically conducting materials. Furthermore, it is a well-liked option for applications in both large-scale enterprises and tiny hobbyist shops due to its fast speed and accuracy cut.

Additionally, it is put through a variety of quality tests with expert supervision. Additionally, a variety of metals are cut using a CNC plasma cutting machine of the gantry type. Computers run plasma CNC machines, which use programmed instructions to make materials that adhere to exact requirements. The cutting torch is the standard tool used in plasma cutting machines to cut metal plates, sheets, bolts, pipes, etc.CNC plasma cutter machines have a system that can move the path of plasma torch by computer. Pusaan Automation PVT LTD is the best gantry type CNC Plasma cutting machine manufacturer in India. In the industrial world, our plasma cutting machine is highly regarded. Compared to a fibre laser cutting machine, a plasma cutter can easily cut materials that are the same thickness or thicker. When compared to other dealers and manufacturers, the price of the Gantry type CNC plasma cutting machine is reasonable. For more information about the Bench type machine and Portable CNC plasma cutting machine.

Here's an overview of how a CNC flame cutting machine typically operates:

Material Preparation: The metal sheet or plate to be cut is placed on a cutting table or platform. It is securely clamped or held in place to ensure stability during the cutting process.

Gas Supply: The machine has gas supply systems to provide the necessary fuel gases, typically acetylene or propane, and oxygen. These gases are mixed in precise ratios to create a combustible flame.

Ignition and Preheating: The CNC flame cutting machine has torches or burners that ignite the fuel gas and oxygen mixture. The torches are positioned above the material, and the preheating process begins. The preheating flame raises the temperature of the metal along the cutting path.

CNC Control: The machine is equipped with a computer numerical control (CNC) system that controls the movement of the cutting torch. The operator programs the desired cutting path into the CNC system or imports a pre-designed cutting pattern.

At Pusaan India, all our plasma cutting systems are full turnkey setups with a range of add-on accessories. Regardless of your application, you must ensure that the CNC plasma cutting machine you purchase satisfies your needs before making an investment. If you need assistance choosing the best course of action for your company, don’t be afraid to contact our Support Team.

#CNC PLASMA#CNC PLASMA CUTTER#CNC PLASMA CUTTING#CNC PLASMA CUTTING MACHINE#CNC flame cutting machine

0 notes

Text

The Pipe Beveling Cutting Machine is a revolutionary equipment for your welding business. Precision cutting, smooth and accurate beveling, these are the benefits that you can get if you use this machine for your various thickness pipes. The machine can cut and bevel pipes made of carbon steel, stainless steel, aluminum and other metal materials. It is also suitable to be installed and used in different industrial settings for increased efficiency and safety. Eliminate the hassle of manual beveling and start achieving consistent and accurate results with the Pipe Beveling Cutting Machine. Industrial Pipe Beveling Cutter

#Pipe Beveling Cutting Machine#Pipe Beveling Cutting Machine Manufacturer#spmequipment#Pipe Beveling Cutting Machine Supplier

0 notes

Text

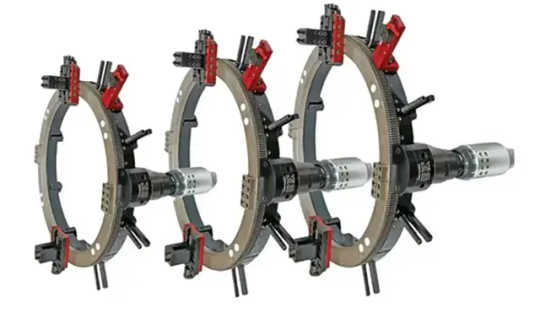

The Pipe Cutting & Bevelling Machine That You Can Depend On

Pipe-cutting and bevelling machines have become indispensable tools in various industries, offering a multitude of benefits that streamline operations and enhance productivity. From critical applications in diverse sectors to their ability to cut weld material and work in constricted spaces, these machines have revolutionized the way professionals approach pipe fabrication. In this article, we will explore the exceptional advantages of having a pipe-cutting and bevelling machine, with a specific focus on Tritorc's innovative solutions.

I. Critical Applications in Various Industries

Pipe cutting and bevelling machines have extensive use in critical applications across various industries. From oil and gas to petrochemicals, power generation, and beyond, these machines are instrumental in projects involving pipeline installation, maintenance, and modification. In the oil and gas sector, for instance, these machines play a vital role in pipeline repair, ensuring efficient operations and minimizing downtime. Their application extends to the HVAC, construction, and shipbuilding industries, where precision cutting and bevelling are essential for optimal performance.

II. Machine Applications

From Steam Turbine Breech Nut Cutting to Weld Material Removal: One notable application of pipe cutting and bevelling machines is in the field of steam turbine maintenance, particularly in the cutting of steam turbine breech nuts. Tritorc's pipe-cutting machines have earned a reputation for their exceptional performance in this regard, providing accurate and efficient cuts to facilitate repairs and replacements.

Additionally, these machines are well-suited for cutting and removing weld material, allowing for the precise modification of pipelines and structural components. Their versatility makes them indispensable in a variety of projects, ensuring high-quality results and efficient workflow.

III. References to Tritorc and Its Machines

Tritorc, a leading manufacturer of pipe-cutting and bevelling machines in India, has been at the forefront of innovation in this field. Their dedication to providing cutting-edge solutions has earned them a reputable status in the business. Tritorc's machines offer unparalleled precision, durability, and versatility, catering to the diverse needs of professionals across different sectors.

IV. Operating in Constricted Spaces

Overcoming Limitations: One of the significant advantages of pipe-cutting and bevelling machines is their ability to operate effectively in constricted spaces. Traditional cutting methods often struggle with limited accessibility, hindering project execution. However, Tritorc's machines are specifically designed to address these challenges, providing compact and portable solutions that excel in tight spaces. This enables professionals to carry out precise cutting and bevelling operations with ease, even in the most challenging environments.

V. The Leading Pipe Beveling Machine Manufacturers in India

In India, Tritorc stands out as one of the leading manufacturers of pipe beveling machines. With their commitment to quality, innovation, and customer satisfaction, Tritorc has gained the trust of industry professionals. Their comprehensive range of pipe beveling machines caters to various pipe diameters and beveling requirements, ensuring that customers can find the ideal solution for their specific applications.

Conclusion

The advent of pipe-cutting and bevelling machines has transformed the industrial landscape, enabling professionals to streamline operations, improve efficiency, and achieve superior results. Tritorc, as a renowned manufacturer of these machines in India, has played a pivotal role in driving innovation in the field. With their exceptional performance in critical applications, ability to cut weld material, and adaptability in constricted spaces, Tritorc's machines have become essential assets for professionals across industries. By embracing these cutting-edge solutions, companies can elevate their pipe fabrication processes, minimize downtime, and enhance overall productivity, leading to long-term success in their respective sectors.

0 notes

Text

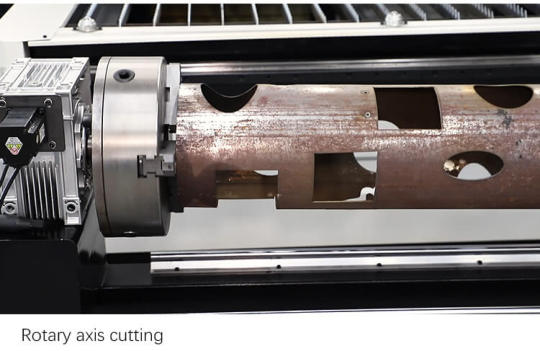

Professional Tube Laser Cutter Machine for Precise Cutting

In industries that require precise and efficient tube cutting, having the right equipment is essential. LXCuttingMachine.com proudly presents the Tube Laser Cutter Machine, a cutting-edge solution to revolutionize tube-cutting processes.

State-of-the-Art Laser Cutting Technology:

The Tube Laser Cutter Machine offered by LXCuttingMachine.com harnesses the power of advanced laser cutting technology to deliver exceptional cutting performance. Our machine utilizes a high-powered laser beam to accurately and cleanly cut through a wide range of tubes and pipes, including round, square, rectangular, and oval shapes. The laser beam provides precise cuts with minimal deviation, resulting in superior quality and eliminating the need for additional finishing processes. With our Tube Laser Cutter Machine, you can achieve precise cuts with remarkable speed and efficiency.

Unmatched Precision and Accuracy:

Precision is paramount in tube cutting, and our Tube Laser Cutting Machine offers precise results, and because it has a computer-controlled system and a high-precision cutting head, our equipment guarantees little errors and keeps tight tolerances throughout the cutting process. You may obtain the specified specifications with extraordinary accuracy thanks to the innovative technology, which ensures exact cuts, beveled edges, and intricate curves. You may be sure that every cut made using our tube laser cutter machine satisfies your exact specifications.

Versatile and Flexible Applications:

The Tube Laser Cutter Machine by LXCuttingMachine.com is highly versatile, making it suitable for various industries and applications. Whether you are in the automotive, construction, furniture, or manufacturing industry, our machine can efficiently handle various materials, including steel, stainless steel, aluminum, copper, and more. It is ideal for fabricating components, creating architectural structures, producing frames, and manufacturing intricate parts. Our Tube Laser Cutter Machine's versatility empowers you to meet your industry's diverse cutting needs with ease.

Enhanced Efficiency and Productivity:

Our Tube Laser Cutter Machine is designed to enhance efficiency and productivity in tube cutting processes significantly. The machine's advanced features, such as high cutting speeds and rapid positioning capabilities, enable quick and efficient processing, saving valuable time and increasing production throughput. The computer-controlled system eliminates manual adjustments, ensuring consistent and precise cuts while minimizing material waste. By optimizing your tube-cutting operations with our Tube Laser Cutter Machine, you can achieve higher efficiency, meet tight deadlines, and maximize your productivity.

User-Friendly Interface and Support:

At LXCuttingMachine.com, we prioritize user-friendliness and customer support. Our Tube Laser Cutter Machine features an intuitive interface and user-friendly software that simplifies programming and operation. Operators can easily set cutting parameters, import design files, and confidently monitor the cutting process. Additionally, we provide comprehensive technical support and training to ensure a smooth integration of our Tube Laser Cutter Machine into your workflow. Our dedicated team is committed to assisting you every step of the way, from installation to maintenance and beyond.

Conclusion:

LXCuttingMachine.com Tube Laser Cutter Machine is a cutting-edge solution that offers unmatched precision, efficiency, and versatility in tube-cutting applications. Our Tube Laser Cutter Machine empowers industries to achieve superior results and optimize their tube-cutting processes with its advanced laser-cutting technology, high precision, flexibility, and enhanced productivity.

0 notes

Text

How are Buttweld fittings made?

Buttweld Pipe fittings are essential components in various industries, ensuring the seamless flow of liquids and gases. These fittings are crucial for industries such as oil and gas, petrochemicals, power plants, and many others. As one of India's leading Buttweld Pipe Fittings manufacturers, suppliers, stockists, and exporters in India, we pride ourselves on offering an extensive range of products in various grades, sizes, standards, and materials.

In this blog post, we will take you through a comprehensive guide on how buttweld fittings are made, shedding light on their manufacturing process and highlighting the benefits they bring to various industries.

The Importance of Butt Weld Fittings:

Butt weld fittings play a crucial role in various industries. They are specifically designed to create strong, leak-proof connections between pipes, ensuring the integrity of the overall system. These fittings are widely used in applications where reliable and durable connections are essential. Their robust construction and resistance to extreme conditions make them suitable for industries such as oil and gas, chemical, pharmaceutical, food processing, power plants, and so on.

Butt Weld Fittings Manufacturing Process

The manufacturing process of butt weld fittings involves several steps to ensure their integrity and reliability.

Raw Material Selection

The manufacturing process of buttweld fittings begins with the selection of high-quality raw materials. Commonly used materials include Stainless Steel, Hastelloy, Carbon Steel, Nickel Alloy Steel, Duplex Steel, Alloys Steel, Super Duplex Steel, Titanium Alloys, Aluminium, Monel, Alloy 20 Steel, SMO 254, Inconel, and Incoloy. The choice of material depends on the specific application and the operating conditions of the piping system.

Cutting and Beveling

Once the raw material is selected, it is cut into the desired length, and the ends are beveled. Beveling is necessary to ensure a smooth transition and proper alignment during the welding process. The bevel angle and shape are carefully determined to meet the welding requirements.

Forming

The next step is forming, where the beveled ends of the fittings are shaped into the desired form. This is typically done through hot or cold forming processes such as pressing, hammering, or extrusion. The forming process ensures that the fittings have the required dimensions and shape.

Heat Treatment

After forming, the fittings undergo heat treatment to enhance their mechanical properties. Heat treatment involves heating the fittings to a specific temperature and then cooling them in a controlled manner. This process helps improve the strength, hardness, and resistance to corrosion of the fittings.

Machining

In the machining stage, any excess material or rough edges are removed from the fittings. Machining operations such as turning, milling, drilling, and grinding are performed to achieve the desired dimensions and surface finish. This ensures that the fittings are precise and meet the required specifications.

Welding

Welding is a critical step in the manufacturing of buttweld fittings. The beveled ends of the fittings are joined together using various welding techniques such as TIG (Tungsten Inert Gas) welding or MIG (Metal Inert Gas) welding. The welding process creates a strong and permanent bond between the fitting ends, ensuring a leak-proof connection.

Inspection and Testing

After welding, the fittings undergo thorough inspection and testing to ensure their quality and integrity. Non-destructive testing methods such as ultrasonic testing, radiography, and dye penetrant inspection are performed to detect any defects or imperfections. This step ensures that only fittings of the highest quality are released for use.

Surface Treatment

The final step in the manufacturing process is surface treatment. The fittings are cleaned, deburred, and then coated with a protective layer to enhance their resistance to corrosion. Surface treatment methods may include pickling, passivation, electroplating, or painting, depending on the material and application requirements.

0 notes

Text

Table Type CNC Plasma Cutting Machine

iGP plasma cutting machine is used for cutting thick metals. The Hypertherm cutting head is a reliable and robust plasma source. Together with the CNC control unit and power source provides precise and high-quality cutting. P-Series plasma cutting machine is designed for precision cutting, High Performance, and High Speed. It can be equipped with Pipe cutting, a 5-Axis beveling head, multi-plasma heads, and Oxy cutting heads.

CNC plasma table machine, including flat plasma cutting machine, plate and tube integrated plasma cutting machine, square tube plasma cutting machine. The reinforced bed makes the equipment more stable during operation, compared with portable plasma cutting machine and gantry plasma cutting machine, desktop plasma cutting machine has the advantages of fast speed and high precision, and is more suitable for batch processing of medium and thin plates.

The CNC plasma cutter machine can not only meet 80% of the needs of large-scale flat cutting, but also 20% of the needs of tube cutting. It is equipped with an advanced tube-sheet dual-use CNC cutting system and a tube-sheet dual-use CNC cutting system.The software realizes the efficient and convenient interchange of cutting methods while cutting the tube and sheet material, which can not only meet the needs of users for cutting round and square tubes but also meet the special-shaped processing of steel plates.

CNC plasma and pipe cutting machine is a precision mechanical transmission device with thermal cutting technology combined with a high efficiency, high precision, high reliability. With inimitable man-machine interface, operation is simple and easy , can cut out various shapes of complex sheet metal quickly and accurately, especially suitable for automatically, thin steel non-ferrous metals, stainless steel and carbon steel plate cutting. It adopts an integrated modular design, quick installation, convenient movement.

Table Type CNC Plasma Cutting Machine Features:

The beam uses light structural design,with good rigidity structure, light deadweight .

The gantry structure, Y axis used dual-motor dual-driven system,X,Y,Z axis all use dual-straight rail that make the machine driving smoothly with high-precision.

Aiming at cutting three dimension LED character, trough metal panels and floor cutting, the accuracy can reach good indicators.If it equipped with United States HYPERTHERM plasma source the machine can reach threshold.

Equipped with other advertise equipment (blister/engraving machine) . Improve the efficiency of several times.

Cutting mouth is small, tidy,and avoid a second dressing processing.

It can apply to iron sheet, the aluminium sheet, the galvanized sheet, hundred steel plates , metal plates.

The numerical control system disposes high, the automatic striking arc, the performance is stable.

Support Wentai, Astronautics Haire, ARTCAM softwares, Type3 produce standard G code way document,also can change software to read AUTO CAD softwares produce DXF form documents.

igoldencnc is professional on CNC cutting machine powered by plasma and oxy-fuel. From basic plate cutting machine, Gantry cnc plasma cutting machine, table cnc plasma cutting machine and portable cnc plasma cutting machine, igoldencnc is also Leading manufacturer in pipe and profile cutting machine, from pipe cutting and beveling, tube cutting and beveling, beam/angle steel/ channel steel/flat buld processing. By developing our own system and software in 3D profiling, igoldencnc become the top brand in metal cutting with competitive price and professional products.We have a comprehensive, made in the USA product line and the engineering expertise to customize our software and controls for your unique application needs. Our CNC plasma tables offer state-of-the-art technology and high-quality components you’d expect to find in machines that cost two to three times as much or sometimes more.

1 note

·

View note

Text

Equipment for cleaning pipes Machines for cutting pipes in Singapore

Pipe Cutting Machines Pipe Cutting Machines are becoming increasingly popular in Singapore due to their ability to quickly and accurately cut pipes of any size. With the right machine, one can easily and safely cut even the toughest of materials with ease. This is especially beneficial for heavy industrial applications such as mechanical engineering, plumbing, and construction works. It is also suitable for smaller tasks such as cutting PVC pipes for aquariums or other DIY projects. With a wide variety of machines available on the market, it can be difficult to decide which one is best for your needs. Our guide will help you choose the right machine that fits your work requirements.

Pipe-cutting machines are an essential tool for those working in metalwork and engineering. They provide a fast and accurate way to cut, bevel, miter, and groove pipes of various sizes and shapes. With the right pipe-cutting machine, you can save time and money while ensuring that your projects are completed with ease. These machines can be used to reduce wastage, improve efficiency in the workplace and make sure that each cut is precise.

A pipe-cutting machine is a specialized tool that is used to cut pipes accurately and efficiently. Pipe-cutting machines can be used to cut a variety of pipes, including steel, copper, aluminum, and PVC pipes.

There are several types of pipe-cutting machines, including:

Manual pipe cutting machines - These machines are operated by hand and are suitable for cutting small-diameter pipes.

Semi-automatic pipe-cutting machines - These machines are partially automated and require some human intervention. They are suitable for cutting pipes of various diameters.

Fully automatic pipe-cutting machines - These machines are fully automated and require minimal human intervention. They are suitable for cutting pipes of various diameters quickly and accurately.

Pipe-cutting machines can be used in a variety of industries, including plumbing, construction, and manufacturing. They are designed to be efficient, accurate, and safe to use. Some of the features of pipe-cutting machines include adjustable cutting speed, automatic feed, and precision cutting angles.

When choosing a pipe-cutting machine, it's important to consider factors such as the type of pipe being cut, the size of the pipe, the thickness of the pipe, and the required accuracy of the cut. Additionally, it's important to consider the cost of the machine and the maintenance requirements.

Pipe Cleaning Machine Pipe cleaning machines are specialized tools that are used to clean pipes and remove blockages or debris from the inside of pipes. They are used in a variety of industries, including plumbing, construction, and manufacturing.

There are several types of pipe-cleaning machines, including:

High-pressure water jet machines - These machines use a high-pressure water jet to clean the inside of pipes. They are effective in removing blockages, rust, and other debris from the pipes.

Rotary pipe cleaning machines - These machines use rotating brushes or blades to clean the inside of pipes. They are effective in removing grease, dirt, and other debris from the pipes.

Chemical cleaning machines - These machines use chemicals to clean the inside of pipes. They are effective in removing mineral deposits and other hard-to-remove substances from the pipes.

When choosing a pipe cleaning machine, it's important to consider factors such as the type and size of the pipe being cleaned, the severity of the blockage or debris buildup, and the required level of cleaning. Additionally, it's important to consider the cost of the machine, the maintenance requirements, and the safety features of the machine.

Some of the benefits of using a pipe cleaning machine include improved pipe performance, reduced risk of blockages and backups, and increased efficiency of pipe-related operations. Pipe Cleaning Machines have become an increasingly important tool in the maintenance of plumbing systems. As pipes are being used more and more in modern buildings, they require regular cleaning to ensure they remain free from blockages, dirt, and debris. This is where Pipe Cleaning Machines come in. With their powerful rotating brushes, they can quickly remove any buildup inside a pipe with minimal effort, allowing for efficient cleaning and maintenance of your plumbing system…BUY ON AARON Accessories Pte Ltd Pros: Quickly and powerfully clean your pipes, with minimal effort by rotating brushes that spread out bristles to effectively remove any buildup or debris in your pipe. They are also lightweight. You can use them in both cold and hot water, while they are rated for a maximum of 50 degrees Celsius. They come with a mounting tool and a 2-in-1 brush head that allows you to switch between the two modes when needed. They have a suction base that is quieter than traditional plungers, so it won’t disturb you or anyone else around.

1 note

·

View note