#Perforated Sheets manufacturer

Text

2023 Future trends in the use of ASTM A240 S32205 Perforated Coil

ASTM A240 S32205 Perforated Coil is a highly durable and corrosion-resistant material used extensively in various industrial applications.

As we move into the future, the demand for this material is expected to increase due to its exceptional properties and versatility.

One of the major trends we can expect to see in the use of ASTM A240 S32205 Perforated Coil is its use in the automotive industry. With the growing emphasis on lightweight and fuel-efficient vehicles, there is a greater need for strong, durable, yet lightweight materials. It fit the bill perfectly, and we can expect to see increased adoption of this material in the automotive industry.

Another trend we can expect is the use of ASTM A240 S32205 Perforated Coil in the construction industry. With the growing demand for sustainable and eco-friendly buildings, there is a greater emphasis on using environmentally friendly materials with a low carbon footprint. ASTM A240 S32205 Perforated Coil is a highly recyclable material that can be reused without losing its properties, making it an ideal choice for sustainable construction.

The Use of ASTM A240 S32205 Perforated Coil is also expected to increase in the marine industry. This is because of its exceptional corrosion resistance properties, making it ideal for use in harsh marine environments. With the growing demand for offshore energy and the increasing use of ships and boats for transportation, there is a greater need for materials that can withstand the harsh marine environment. This Perforated Coil is a perfect fit for this purpose.

Apart from these industries, S32205 Perforated Coil is also expected to increase in the chemical and petrochemical industries. This is because of its exceptional resistance to corrosion and high-temperature environments, making it ideal for use in chemical processing plants and refineries.

In conclusion, the future looks bright for Perforated Coil, which is expected to increase its use in various industrial applications. Its exceptional properties and versatility make it an ideal choice for many industries, and we can expect to see continued adoption of this material in the years to come.

#metal industrial#architecture#stainless steel#construction#buildings#alloy#sheets#stainless steel coil suppliers#perforatedmetal#preforated coils#perforated sheets manufacturer#s32205 perforated coil

7 notes

·

View notes

Text

Why Choose the Best Perforated Sheets Manufacturer?

Cutting-Edge Innovations in Perforation Technology

The best perforated sheet manufacturers in India keep their technology fresh to meet all kinds of customer needs. They create custom designs just right for your projects, helping you get the best results. Choosing a leader in the field means you're working with the best in perforation technology.

Unwavering Commitment to Quality

Quality matters a lot to top manufacturers. They make sure every sheet is excellent. They use the best stuff to make perforated sheets that last long and work well.

Cost-Effective Solutions

Working with top manufacturers means you get great deals on the price of perforated sheets. They offer many designs, like round, square, or special ones, at prices that save you money.

Versatility Across Industries and Works Everywhere

Perforated sheets are super handy in lots of jobs, like building, cars, and making medicines. Top makers understand these needs and make sheets that help with light, air, and looking good.

Dependability and Trusted Worldwide

A trustworthy perforated sheets manufacturer is important, especially if your work goes around the world. The best ones have strong setups and smart shipping that make sure you get your sheets on time, everywhere. Their big networks make buying and selling across borders easy, proving they’re reliable here and abroad.

Specialization in Specific Materials

Some manufacturers focus on things like MS perforated sheets. They’re pros at making sure each material is tough, hard, and can handle the weather. This means you always get the best stuff.

Customer-Centric Approach

The top perforated sheets distributor put their customers first. They're ready to help all day, every day, from helping you pick your sheets to after you buy them. This means you always have help when you need it.

Conclusion

Picking a top perforated sheet manufacturer and supplier means more than just buying something; it’s about teaming up for the best in innovation, quality, smart pricing, and customer care. Make sure your projects get the best and enjoy working with the best.

Source: https://www.linkedin.com/pulse/why-choose-best-perforated-sheets-manufacturer-fine-perforators-rndjc/

#Perforated Sheets manufacturer#best perforated sheet manufacturers in India#price of perforated sheets#perforated sheets manufacturer#top perforated sheet manufacturer and supplier

0 notes

Photo

For more information visit : https://almiqathardware.com/perforated-metal/

#perforated sheets manufacturer#perforatedmetal#metal sheet#metal#oman#sharjah#oman news#perforated pipe

1 note

·

View note

Text

#perforated sheets manufacturer#metal and steel#metal and steel works#metal#steel#perforated sheet#architecture#design

0 notes

Text

How Perforated Sheets Are Redefining Modern Manufacturing

In modern manufacturing, Perforated sheet are transforming product design and functionality. Their versatile designs enhance both performance and aesthetics across industries like construction and aerospace. From improving airflow and noise reduction to offering customizable patterns, perforated sheets are reshaping manufacturing processes. This article explores their significant impact and the role of manufacturers in driving innovation.

0 notes

Text

With our powder coating services, which provide high-quality finishes for any application, you can elevate your projects. Our knowledgeable staff applies gorgeous, long-lasting coatings that improve both appearance and protection. Our solutions offer a durable, smooth finish and are perfect for use in commercial, industrial, and residential settings. Count on us for excellent powder coating outcomes! Visit us now to know more about Powder Coating Services.

#powder coating services#metal skills in new zealand#sheet metal fabrication#outsourced manufacturing#metal design#metal programming#laser cutting service#best laser cutting services in new zealand#metal skills#steel fabrication#metal fabrication#welding engineering#turret punches#welding services near me#perforated metal sheet#assembly line#hardware insertion

0 notes

Text

Stainless Steel 316L Perforated Plates Stockists

Jaiman Metalloys LLP, a distinguished name in the realm of stainless steel products, proudly presents its high-quality Stainless Steel 316L Perforated Sheets. As leading manufacturers, suppliers, stockists, and exporters, we provide an extensive range of perforated sheets that cater to diverse industrial applications. Our commitment to excellence ensures that every sheet meets the highest standards of durability, performance, and aesthetics.

Stainless Steel 316L Perforated Sheets are renowned for their exceptional properties. The 316L grade, a low-carbon variant of 316 stainless steel, offers enhanced corrosion resistance, making it ideal for harsh environments. The low carbon content minimizes carbide precipitation during welding, ensuring superior weldability and formability. Jaiman Metalloys LLP ensures that our perforated sheets are meticulously crafted to maintain these properties, providing reliable and long-lasting solutions.

Our Stainless Steel 316L Perforated Sheets are incredibly versatile, finding applications across a wide range of industries. From architectural facades, filters, and screens to automotive components and food processing equipment, these sheets serve multiple purposes. As manufacturers and suppliers, Jaiman Metalloys LLP caters to the specific needs of each industry, offering customized perforation patterns and sheet sizes to meet precise requirements.

Stainless Steel 316 Perforated Sheet Specification

Standard : ASTM / ASME A240 / SA240

Size : 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm

Thickness : 0.1mm to 12 mm Thk

Form : Decorative Round Hole, Dimpled, Square Holes, Gold Mirror Round Hole, Round Punch, Etched, Colored Perforated Sheets

Finish : Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)

Hardness : Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc.

#Stainless Steel 316L Perforated Sheets & Plates#Stainless Steel 316L Perforated Sheets & Plates Manufacturers#Stainless Steel 316L Perforated Sheets & Plates Suppliers

0 notes

Text

#ASTM B152 COPPER C14200 PLATES#COPPER C10200 SHEETS#ALLOY C11600 SHEETS#COPPER ALLOY C12000 HOT ROLLED PLATE#UNS C11000 COPPER PLATE#C101 COPPER PLATE MANUFACTURER#THIN COPPER SHEETS EXPORTER#C19400 ROLLS#COPPER PERFORATED SHEET#C12000 CLAD PLATE SUPPLIER INDIA.

0 notes

Text

Innovations in Metal Sheets with Round Holes – Deep Dive with Metart Building Tech

Aesthetic and functional materials have a great importance in architecture and industrial design. Among them, round hole perforated metal sheets stand out for their flexibility, durability, and sheer beauty. A case in point is Metart Building Tech that is known as one of the leading manufacturers of good-quality round hole perforated metal sheets. This comprehensive study on round hole perforated metal sheets examines the excellence of manufacturing in Metart Building Tech and how its products are transforming industries and spaces globally.

Round hole perforated metal sheet manufacturer are celebrated for their unique blend of strength and open area ratio, which make them suitable for diverse applications such as ventilation and filtration to aesthetics or sound attenuation in buildings and structures. The mastery of producing these sheets to cater for various tastes has been achieved by Metart Building Tech which remains steadfast on quality and innovation. To ensure every piece meets the stringiest quality requirements set by this company, machinery precision as well as technology is used throughout the process of making these punched-out sheets. As such, modern tools that equip production facilities of Metart consist a wide range of materials with different thicknesses, drilled holes’ size or patterns tailored specifically to meet its customers’ demands.

The applications of round-hole-perforated-metal-sheets cut-across several industries including construction, automotive industry aerospace electronics among others. In constructions these are used for facades, cladding balustrade works amongst other architectural elements providing not only an eye’s attractive scene but also performing functions like light scattering and ventilation purposes. Architects can stretch their creativity through these craft able metal sheets made by Metart Building Tech. For instance, during manufacturing processes it emphasizes recycling thus minimizing environmental impact hence making it a choice material where there exist environmentally sensitive clients.

This dedication to bespoke solutions along with customer satisfaction makes Metart Building Tech unique among its peers. The custom fabrication services is what distinguishes Metart Building Tech from other competitors since we know that every project comes with its unique challenges and requirements. Clients are therefore provided with the flexibility of receiving outputs that perfectly match their specifications whether it is a matter of special hole patterns, sizes or material properties. Besides fabrication, the company also provides extensive support services such as design consultancy, technical assistance, and after sales care which guarantees a seamless journey from concept to completion.

Apart from excellent products, Metart Building Tech is recognized for being a trailblazer in embracing and promoting digital transformation within its industry. The company has benefited immensely by using advanced digital tools and technologies to streamline all aspects of operation ranging from order processing to product delivery thus ensuring efficiency as well as transparency. In this manner the company’s customer experience will be enriched besides positioning Metart Building Tech as an innovative player in the manufacturing sector.

As we prepare for the years ahead, there remains an endless potential of the round hole perforated metal sheets to shape contemporary architecture and industrial applications. Metart Building Tech is continuously carrying out research and development to find new materials, patterns and ways of making that can expand the uses of perforated metals. Being innovative, sustainable and quality-orientated company has developed trust with customers in all parts of the world making it an essential player in the changing directions of application for perorated metals that are exciting as well as sustainable.

In conclusion, Metart Building Tech is a combination of old and new generation; thus it represents the highest standards ever reached by a company involved in manufacture of round hole perforated metal sheets. Through its commitment to quality service delivery, customer-focused approach, eco-friendly products, etc., this corporation does not only satisfy but surpasses consumer expectations. With advancing industries demanding more creative and environmentally friendly products, Metart Building Tech stands at a unique position to spearhead construction industry’s future developments including design among others. At this points during which every sheet produced by Metart building tech is not just manufacturing but rather visionary redefining open spaces into something else.

1 note

·

View note

Text

One of the Leading producers of Aluminium Bronze Round Bar Manufacturer in India By Rajkrupa Metal Industries

Website: https://rajkrupametal.com/

Product: https://rajkrupametal.com/aluminium-bronze-round-bar-manufacturer-india/

Aluminium Bronze CUAL10NI5FE4 Round Bar: https://rajkrupametal.com/aluminium-bronze-cual10ni5fe4-round-bar-manufacturer-supplier-stockist-india/

Round Bars Manufacturer in India- https://rajkrupametal.com/round-bars-manufacturer-supplier-india/

#Aluminium Bronze Round Bar#Aluminium Bronze Round Bar Manufacturer#Bronze CUAL10NI5FE4 Round Bar#Perforated Sheet

0 notes

Text

Why Opt for Top Perforated Sheets Manufacturers?

Selecting a leading perforated sheets manufacturer is crucial when securing high-quality perforated sheets. These top-tier manufacturers are celebrated for their commitment to innovation, superior quality, and customer satisfaction. Here's why choosing a renowned manufacturer is pivotal for your perforation needs.

Innovations in Perforation Technology

Top-tier producers in the perforated sheet manufacturers in India category consistently advance their technology and infrastructure to cater to diverse client demands. This includes offering tailor-made perforation designs ideal for specific applications, ensuring you receive the most effective solution for your projects. Opting for an industry leader means choosing a partner at the cutting edge of perforation technology.

Commitment to Quality

Quality is paramount; top manufacturers uphold rigorous standards to ensure every product meets and exceeds expectations. This commitment extends to employing world-class facilities and materials and producing perforated sheets that excel in strength, durability, and performance.

Cost-Effective Solutions

One of the significant advantages of working with a top manufacturer is the value of the perforated sheet price. These manufacturers offer competitively priced products without compromising quality. They utilize their extensive experience and capabilities to produce various perforations—round, square, slotted, or custom—at prices that deliver excellent value for your investment.

Wide Range of Applications

Perforated sheets are versatile, finding applications across many industries, such as architecture, automotive, and pharmaceuticals. Leading manufacturers possess the expertise to cater to all these sectors by providing sheets that enhance natural lighting, ventilation, and the aesthetic appeal of structures.

Global Reach and Reliability

The reliability of a manufacturer is crucial, significantly when your needs extend across global markets. Top suppliers maintain robust production capabilities and efficient logistics and export facilities to ensure timely delivery worldwide. Their extensive network and strategic partnerships aid in streamlining the export and import processes, making them a reliable choice for local and international demands.

Focus on Specific Materials

Manufacturers like those specializing in MS perforated sheet production ensure that each material meets specific industry standards for strength, hardness, and resistance to environmental impacts. This specialization guarantees that your material requirements are met with the utmost precision and quality.

Customer-Centric Approach

Finally, the best manufacturers prioritize customer satisfaction above everything. They are equipped to offer 24x7 support, with expert teams ready to assist at every stage—from selection and customization to post-purchase service. This customer-centric approach ensures a seamless experience and support whenever needed.

Conclusion

Choosing a leading Best perforated sheets manufacturer for your perforated sheets means more than purchasing a product. It's about entering a partnership that promises and delivers excellence in innovation, quality, cost efficiency, and customer service. Ensure your projects benefit from the best in the business and experience a partnership beyond the transaction.

Source: https://602b65761ca07.site123.me/articles/why-opt-for-top-perforated-sheets-manufacturers

#perforated sheets manufacturer#perforated sheet manufacturers in India#perforated sheets#perforated sheet price#Best perforated sheets manufacturer

0 notes

Text

We manufacture perforated metal screens and allied products. Metals with perforations offer many benefits, including strength, rigidity, adjustability, lightness, small thickness, decorative attractiveness, etc. Perforated metal screens are manufactured with great precision & quality by our team with over three decades experience. India and worldwide are among the industries we supply. Visit: https://www.diamondscreens.com/

#Industrial Perforated Metal Screens#Perforated Metal Mesh Manufacturers#Perforated Metal Sheet Suppliers India#Metal perforated Cable manufacture India#Perforated Metal for Furniture in India

0 notes

Text

Premium Quality Perforated Sheet Manufacturers in India

Sagar Steel Corporation is one of the leading Perforated Sheet Manufacturers in India. We specialize in providing a wide range of top-quality Perforated Sheets that are manufactured using high-grade raw materials. As a Perforated Sheet Manufacturers in Bangalore, Our products are highly durable, reliable and corrosion-resistant. We also provide Alloyvi 20 Pipe that has excellent strength and durability and is used in many different industries. Maximum client satisfaction is ensured by the highest levels of quality and dependability in our products. We work hard to offer our clients the highest-quality items at affordable pricing, making us one of the most dependable companies around. Perforated Sheet Manufacturers in Pune and Perforated Sheet Manufacturers in Delhi.

0 notes

Text

Conveyor Belt Mechanics: Understanding the Inner Workings

In today’s world, conveyor belts act as silent yet essential helpers, ensuring smooth operations across various industries. Comprising key components like belts, pulleys, and motors, these systems are tailored to specific tasks by Conveyor Belt Manufacturers. They not only design and customize belts but also innovate to address issues like wear and contamination. As technology evolves, conveyor belts, including durable rubber conveyor belts, will advance, bringing greater efficiency and innovation to global industries.

Read More:https://fyberly.com/conveyor-belt-mechanics-understanding-the-inner-workings/

0 notes

Text

Sunday Steve - Day Eleven

Things that would be new or unfamiliar to Steve in the 21st century, either due to the time period he grew up in, or his social-economic status and other such factors.

Day Eleven: Toilet Paper

People used many things as toilet paper before commercial toilet paper was available. As indoor plumbing became more common toilet paper became more necessary because pipes were not designed for almanac pages or newspapers.

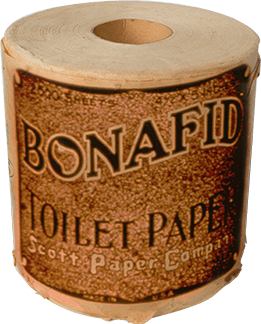

In the late 1800s toilet paper was still a luxury but it was being developed. "In 1890, toilet paper started to look a lot more like stuff we’re used to seeing today. It came on a roll in perforated sheets. It was a tough sell though because no one wanted to admit to buying it. In Germany, a company called ‘ Hakle’ overcame the problem with the slogan “ask for a roll of Hakle if you don’t want to say toilet paper.” (Link)

Late 1800s toilet paper. 2500 sheets.

Charmin began marketing its toilet paper around its softness in 1928, as well as selling economy-sized packs of four rolls in 1932 (Link).

There were two types of toilet paper. Soft and hard. "The hard paper was more affordable and was very shiny on one side of it" (Link). Hard paper often had printed text on it (most of the examples I've found are British).

Every source I've found says that toilet paper began to be advertised as "splinter free" in the 1935. Most casual articles don't dig into what this actually means, but I found some ads for the infamous splinter free toilet paper.

Splinters resulted from the manufacturing process, and as you can see in the below images the splinters were usually very small. I haven't been able to find out how genuinely inconvenient this splinters were.

1930s toilet paper ad (Link) (Link)

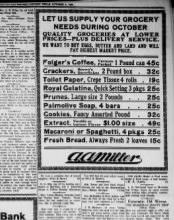

You can see the various marketing methods for soft toilet paper, treating it like a medical issue and appealing to women.

You can also see 3 rolls being sold for 20-25 cents. I think that is very expensive for toilet paper in the 30s. I've found a source showing 2 rolls of Clifton toilet paper being sold for 9 cents in 1932. (Link) And this link shows 4 rolls of crepe toilet paper being sold for 19 cents in 1930 (Link is behind a pay wall but I managed to download the price list). I'm guessing the rolls in the splinter-free ads are soft toilet paper, and the cheaper examples I found are hard toilet paper.

1930 grocery price list. Toilet paper is the third item, listing four crepe rolls for 19 cents.

In 1940 one roll is being sold for 15 cents (Link), but it's not clear if this is soft or hard toilet paper. I'm guessing soft since it's almost the price of four rolls in 1930.

My guess is Steve paid around 9 cents for 2 (19 cents for 4) rolls of hard toilet paper. I doubt he bought soft toilet paper since it cost about 20-25 cents for 2-3 rolls. But I can't know the prices for sure.

One thing for sure is modern toilet paper is softer than the paper Steve would have bought. Britain didn't even start manufacturing 2-ply toilet paper until 1942. Over the years soft toilet paper become the norm (although institutions like schools often have thinner, harder paper).

Given this information, Steve would probably be used to buying harder, cheaper toilet paper for about 9 cents for 2 rolls/19 cents for 4 rolls. Soft 'expensive' toilet paper would be surprising as the norm, and I think he'd find our massive packs of toilet paper shocking. Although as we'll see, soldiers were provided Waldorf paper, which seems to be a more softer, expensive brand.

Army Toilet Paper

Soldiers were provided toilet paper with K-rations and later with C-rations. A soldier would get one accessory packet a day with either ration and it came with twelve sheets of Waldorf toilet paper.

(Link) Accessory packet with Waldorf toilet paper.

You may have seen the factoid that British soldiers were rationed 3 sheets of toilet paper per day compared to American soldiers having 22 sheets. I believe this is a misinterpretation of this book discussing the resources available to American soldiers on base in Britain (pg. 288). But after further research I think the actual number of sheets British soldiers got a day on the front was 4 sheets. (Link) American soldiers got 12 sheets included in their K-ration. (Link)

If a soldier ran out of toilet paper they most likely had to make do. I've seen stories of pages from books being used, or even paper bills. (Link)

Bonus

First paper towels sold 1931 (Link).

1936 paper towel ad

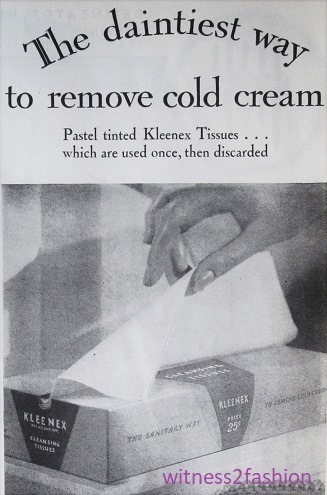

Facial tissue paper originated from gas mask filters in World War One. Kleenex were marketed as a cold cream and makeup remover in the 20s and began being marketed for colds in the 30s. (Link)

1930 ad for Kleenex for 25 cents.

Personally, I don't think Steve would have spent money on either of these things, but they did exist.

#sunday steve#steve rogers#toilet paper#crepe paper#history#american history#20th century#20th century history#steve rogers meta#meta#kleenex#paper towel#1900s#splinter free toilet paper#1930s#world war two#rations#army rations#early 20th century

14 notes

·

View notes