#Paper plate machine

Explore tagged Tumblr posts

Text

Buy All in One Paper plate machine

All-in-One Paper Plate Machine in Varanasi: A Game Changer for Small Businesses

In recent years, the demand for eco-friendly and disposable products like paper plates has skyrocketed across India. The rise in environmental awareness and the shift away from plastic products have created a new market for sustainable alternatives. Among the most popular products in this category are paper plates, which are used for various occasions, from parties to festivals, and even in daily food service. To meet this growing demand, the All-in-One Paper Plate Machine in Varanasi is becoming a game changer for small businesses and entrepreneurs in the region.

What is an All-in-One Paper Plate Machine?

An All-in-One Paper Plate Machine is an automated system designed to produce paper plates in various sizes and shapes. This machine handles the entire production process, from feeding paper into the machine to shaping, pressing, and trimming the plates. What makes this machine special is its ability to perform all these tasks in a single, continuous operation. It's efficient, cost-effective, and easy to operate, making it an ideal solution for businesses looking to enter the paper plate manufacturing industry.

Why Choose the All-in-One Paper Plate Machine in Varanasi?

Varanasi, a city known for its rich cultural heritage, is also home to a growing market for disposable products. The All-in-One Paper Plate Machine has become highly popular in the region for several reasons:

High Demand for Paper Plates: Varanasi, with its vibrant culture, is known for hosting a variety of festivals, religious events, and community gatherings where paper plates are in high demand. The All-in-One Paper Plate Machine allows businesses to cater to this ever-growing market efficiently.

Cost-Effective and Efficient: Traditional paper plate manufacturing can be time-consuming and labor-intensive. The All-in-One machine automates most of the processes, reducing the need for manual labor. This not only saves time but also cuts down on production costs, making it a more affordable option for small business owners.

Eco-Friendly Solution: As the world shifts towards sustainable alternatives, the demand for eco-friendly products like paper plates is increasing. The All-in-One Paper Plate Machine helps businesses contribute to the environment by offering a biodegradable alternative to plastic plates.

Customization and Variety: With an All-in-One Paper Plate Machine, manufacturers can produce plates of various sizes and designs to cater to different customer needs. Whether it's for small, personal gatherings or large, industrial-sized events, the machine offers versatility and customization options.

Easy to Operate: One of the key features of this machine is its user-friendly design. Even with minimal technical knowledge, operators can easily handle the machine. It requires less maintenance and has a long lifespan, making it a reliable investment for businesses in Varanasi.

Benefits of Owning an All-in-One Paper Plate Machine in Varanasi

Increased Productivity: The automation of the production process significantly boosts productivity. A single machine can produce hundreds or even thousands of paper plates in a day, meeting large-scale demand without compromising on quality.

Low Maintenance: These machines are designed to be low-maintenance and highly durable. Regular cleaning and basic checks are enough to keep the machine running smoothly.

Affordable Investment: The All-in-One Paper Plate Machine is an affordable investment for small to medium-sized businesses. It provides a quick return on investment (ROI) due to its high production capacity and low operational costs.

Versatility: The machine can produce different types of paper plates, such as plain, laminated, or printed, allowing businesses to cater to various customer preferences and expand their product range.

Energy Efficient: With energy-efficient components, the machine helps reduce electricity consumption, further lowering production costs.

Where to Buy the All-in-One Paper Plate Machine in Varanasi?

For entrepreneurs and small businesses looking to purchase the All-in-One Paper Plate Machine in Varanasi, there are several local suppliers and manufacturers who offer this equipment. Many suppliers also provide installation, training, and after-sales support to ensure smooth operation. It's important to choose a trusted and reliable supplier who offers high-quality machines, warranty, and customer service.

Conclusion

The All-in-One Paper Plate Machine in Varanasi is an ideal solution for businesses looking to enter the paper plate manufacturing market. With its efficiency, ease of use, and eco-friendly production process, it has become an essential tool for many entrepreneurs. By investing in this versatile machine, business owners can meet the rising demand for paper plates in Varanasi and beyond, contributing to both business growth and environmental sustainability.

If you're looking to start your own paper plate manufacturing business or upgrade your existing setup, the All-in-One Paper Plate Machine is the perfect investment to help you succeed.

#all in one paper plate machine#all in one paper plate machine in varanasi#laghu udyog india#paper plate machine#disposable plate machine

0 notes

Text

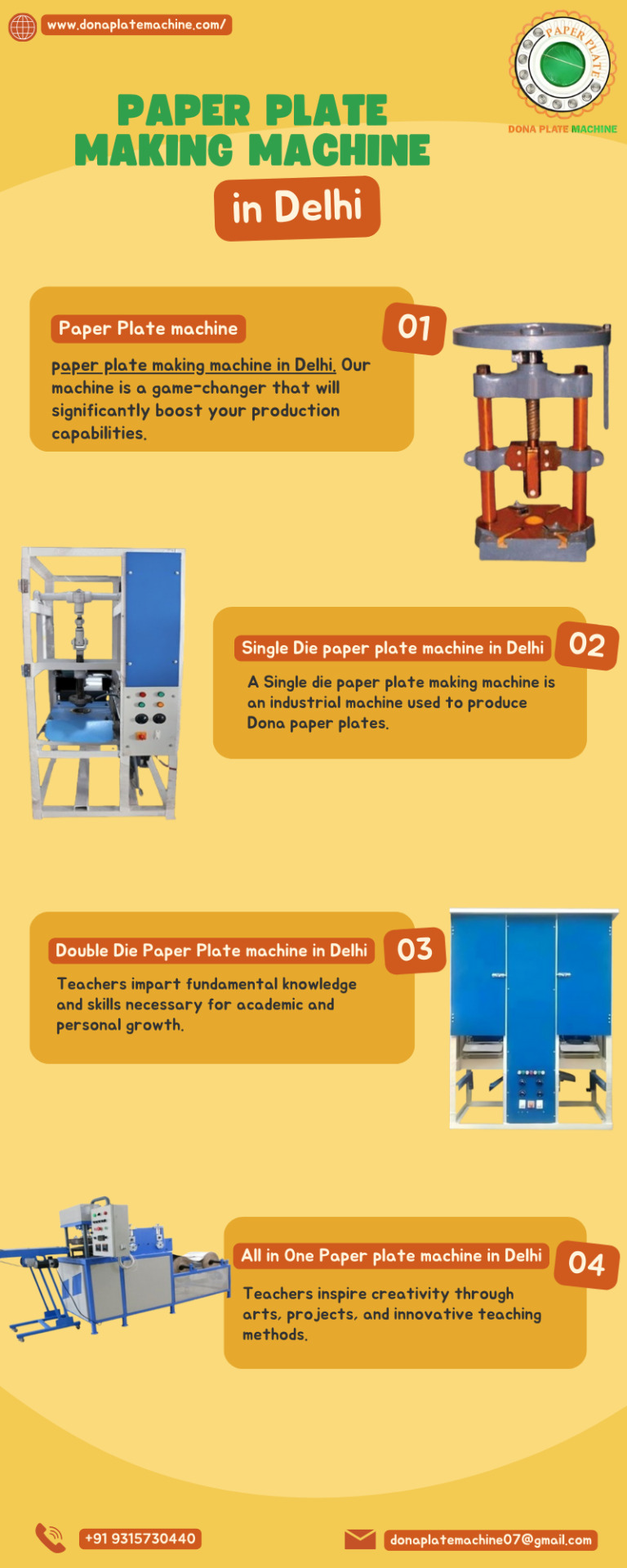

Buy Paper plate making machine in Delhi

Paper Plate Making Machine in Delhi

Introduction

Are you looking for a profitable business opportunity in Delhi? Paper plate manufacturing might just be the perfect choice! With the increasing demand for eco-friendly alternatives, paper plates have become a staple at events, food stalls, and households across the city. Investing in a paper plate making machine can help you start a lucrative business with minimal resources.

The Growing Demand for Paper Plates in Delhi

Delhi, being a bustling hub of events and street food culture, has seen a surge in the use of disposable plates. With the government promoting sustainable practices, businesses and consumers alike are shifting to biodegradable options like paper plates.

Why Paper Plate Making Machines Are a Smart Investment

Paper plate machines offer efficiency, cost-effectiveness, and scalability. Whether you’re starting small or planning to expand, these machines cater to diverse production needs, ensuring a steady income stream.

Types of Paper Plate Making Machines

Fully Automatic Paper Plate Making Machines

Fully automatic machines handle everything from cutting to molding, requiring minimal supervision. They are ideal for large-scale production.

Semi-Automatic Paper Plate Making Machines

These machines need some manual intervention but are more affordable, making them perfect for small businesses.

Manual Paper Plate Making Machines

Manual machines are cost-effective and suitable for entry-level entrepreneurs. They are simple to use but have lower production capacity.

Features to Look for in a Paper Plate Machine

Production Capacity

Choose a machine that aligns with your production goals. Machines with higher capacity are better for bulk manufacturing.

Durability and Material Quality

Invest in machines made from high-quality materials to ensure longevity and reduce maintenance costs.

Ease of Operation

Opt for user-friendly machines, especially if you’re new to the business. Simpler controls can save time and reduce errors.

Benefits of Using Paper Plate Making Machines

Cost-Effectiveness

These machines reduce labor costs and enhance production efficiency, ensuring better profit margins.

Environmental Benefits

Paper plates are biodegradable and eco-friendly, making them a sustainable choice.

Supporting Local Businesses

By producing paper plates locally, you contribute to Delhi’s economy and create job opportunities.

Leading Suppliers of Paper Plate Machines in Delhi

Reputed Manufacturers and Dealers

Delhi boasts a range of suppliers offering high-quality machines. Look for manufacturers with good reviews and after-sales service.

How to Choose the Right Supplier

Compare prices, features, and warranties before making a purchase. Always opt for suppliers who provide installation and training.

Cost Analysis of Paper Plate Machines in Delhi

Price Range of Different Machine Types

Fully Automatic: ₹1,50,000–₹3,00,000

Semi-Automatic: ₹50,000–₹1,50,000

Manual: ₹20,000–₹50,000

Factors Affecting Pricing

The type of machine, production capacity, and additional features significantly impact the cost.

Setting Up a Paper Plate Business in Delhi

Initial Investment and Budgeting

Your investment will include the cost of the machine, raw materials, and packaging. Plan a detailed budget to avoid overspending.

Licensing and Legal Requirements

Ensure you have the necessary licenses, such as GST registration, to operate legally.

Marketing Strategies for Success

Advertise through social media, local markets, and events to attract clients. Word-of-mouth referrals can also work wonders!

Maintenance Tips for Paper Plate Machines

Regular Cleaning and Upkeep

Clean your machine regularly to prevent blockages and ensure smooth operation.

Troubleshooting Common Issues

Learn to fix minor problems like paper jamming to avoid downtime.

Success Stories of Entrepreneurs in Delhi

Inspiring Examples of Local Businesses

Many small business owners in Delhi have scaled their operations using paper plate machines. Their success highlights the potential of this industry.

Lessons from Their Journeys

Focus on quality, customer satisfaction, and consistent marketing to build a successful business.

Conclusion

Investing in a paper plate making machine in Delhi is a fantastic way to tap into a growing market. With the right strategy, quality equipment, and dedication, you can establish a thriving business while contributing to environmental sustainability.

#paper plate machine in Delhi#paper plate making machine#paper plate machine#dona paper plate machine

0 notes

Text

Emerging Trends in the Paper Plate-Making Machine Industry: A Comprehensive Analysis

Emerging trends in the paper plate-making machine industry are shaping the future of this sector. Here's a comprehensive analysis:

Technological Advancements: The industry is witnessing significant advancements in automation and machine intelligence. Modern paper plate-making machines are equipped with sensors, IoT capabilities, and AI-driven controls, enhancing efficiency, reducing waste, and improving overall productivity.

Focus on Sustainability: With growing environmental concerns, there is a shift towards sustainable practices. Manufacturers are developing eco-friendly machines that use biodegradable materials and consume less energy. This trend aligns with the global movement towards reducing plastic usage.

0 notes

Text

youtube

#business#incense business#profitable business#agarbatti#paper plate#paper plate business#paper plate machine#paper plate machine manufacturer#Youtube

0 notes

Text

going to ebisu if im not back in three hours assume i got lost looking at sanrio items

#snap chats#i have to announce this in the event i really am gone for hours and stream's late LMAOOOO#i tried to glue my plate back together but the internet is saying Dont Ingest Gorilla Glue Are You Fucking Stupid#so im getting a new plate. i was planning on having tamago and rice for breakfast and i already have the rice soaking so.....#anyway ill be back. we hope it's soon but I'll Be Back.#i prob wont get a kirby gacha while im out since im already nearing budget on this week so BIG rip#on the bright side i'll save up for next week... maybe.. if they swap out the machine next week...#ok bye i have to go out and get this stupid plate. and origami paper. probably something else too since i have no impulse control

19 notes

·

View notes

Text

Paper Plate Making Machine in Patna | Arya Industries

Arya Industries is one of the Paper Plate Making Machine in Patna! designed to deliver high efficiency and durability. Our machines are easy to operate, energy-efficient, and capable of producing a wide range of paper plates in various sizes and designs. With a focus on quality and affordability, Arya Industries provides machines that ensure smooth operation, low maintenance costs, and high production output, For detailed pricing and to learn how our machines can help you enter the thriving paper plate industry, contact us today. With Arya Industries, you’re guaranteed a high-quality product at the best possible price.

Our machines are designed for efficiency, durability, and ease of use, ensuring a smooth production process with minimal maintenance. Whether you’re producing standard paper plates or specialty designs, our machines can handle various sizes and shapes, delivering consistent results with high output.

we prioritize both performance and cost-effectiveness. Our paper plate making machines are energy-efficient, reducing operational costs while maximizing production. With advanced technology, the machines are capable of fast production cycles, making them ideal for large-scale manufacturing needs.

Our arya industries is your trusted partner for reliable, affordable, and high-quality machines. Contact us today for more details on pricing and machine specifications, and let us help you take your business to the next level!

Address : Deoghar, Jharkhand, India,

Contact us : +91 88004 30824

Visit us : www.aryaindustries.co

#aryaindustries#boostproductivity#paperplatesmachinesinpatna#affordablequalitymachinery#bestmachinemanufacturingcompany#choosearyaindustries#paper plate making machines

0 notes

Text

A good paper plate-making machine boosts productivity through increased efficiency. Contact reliable paper plate making machine manufacturers for the best equipment.

1 note

·

View note

Text

Top 10 Profitable Paper Products Manufacturing Business Ideas

Unlock the potential of the paper industry with these 10 profitable paper products manufacturing business ideas. Learn how to start and succeed in this sustainable sector.#BusinessIdeas #PaperBusiness #Entrepreneurship #SmallBusiness #Startup #EcoFriendly

The paper business is the most rapidly expanding sector of all time. Paper may be used to make a variety of products, as well as to start small businesses. These ideas not only meet the growing demand for environmentally friendly products but also provide tremendous chances for creativity and success. Today, every business is seeking greenways to be environmentally conscious and socially…

#business tips#Eco-Friendly Business#entrepreneurship#Lucrative Business Ideas#paper and pulp business ideas#paper box business ideas#Paper Business Ideas#paper crafts business ideas#paper plate making machine#Paper Products#Paper Products Manufacturing#Paper Products Manufacturing Business#Paper-Based Business#small business ideas#startup ideas

0 notes

Text

Buy Paper Plate Making Machine | FoodmartAgro

#Paper Plate Making Machine#Paper Plate Making Machine in Ranchi#foodmartagro#single die paper plate machine

0 notes

Text

Buy Manual Paper Plate Machine.

Our Company Laghu Udyog India provides Best Quality paper plate machine in Varanasi.

#manual paper plate machine#paper plate machine in varanasi#paper plate making machine#laghu udyog india#Laghu Udyog

0 notes

Text

Paper Plate making machine in Delhi

#paper plate machine#paper plate making machine#automatic paper plate making machine#dona plate making machine#paper plate making machine in delhi#dona paper plate machine#paper plate machine in delhi#dona plate machine

0 notes

Text

Notebook making machine

0 notes

Text

Walgreens: Plan B for When Plan A is Live Streaming

Walgreens: Plan B for When Plan A is Live Streaming On Saturday, August 31st, I clocked out of Walgreens for the final time, closing a chapter that started in April 2018. For 6.5 years, Walgreens was there—my safety net, my “Plan B for Plan B”—whenever the demands of streaming, creative projects, and on-screen time got too hectic. It wasn’t just a job; it became part of my rhythm. But let me be…

#banana detective#banana incident#california#cashier#corporate chaos#couponers#coworker bond#curbside chaos#curbside pickup#customer diplomacy#Customer Interaction#customer service#eGirl#emotional customer moments#impromptu lunch#Jade Ann Byrne#Karen#lanyards#late-night shifts#locker essentials#nostalgia#paper plates#photo department#photo machine breakdowns#Plan B#quirky customers#retail grind#retail humor#retail life#retail memories

0 notes

Text

An introduction to the Satish Institute of International Metal Machine Tool Engineering; a world leading innovative equipment solutions provider

Take a look at Kesya International Machine Manufacturing as it Albanize the machinery industry through cutting-edge technology and sustainable practices. Established with the aim of increasing production efficiency, Kesya International has a wide variety of high-quality machinery meant for different areas such as food processing, packaging, textiles or automotive industries. This is reflected in our commitment to innovation via our advanced automation systems and smart technology that enable companies to optimize their processes while minimizing environmental effects.

Kesya International is a company that has been able to create specialized machine tools and machinery due to the fact that we emphasize customer satisfaction above everything else helping each of our clients personally. We therefore become an integral part of their operations along with them as they grow. In that way, we are able to learn from their difficulties when they come up with certain jobs for them thus providing custom machinery aimed at improving their production rate. Quality control is basically our main focus in the production process; hence each machine would undergo intense tests which are internationally accepted so as to confirm reliability and efficiency.

As a global player in the machinery sector, Kesya International is committed to sustainability, designing machines that consume less energy and produce minimal waste. Our eco-friendly solutions not only help businesses meet their production goals but also align with the growing demand for environmentally responsible practices.

As we strengthen our technological advances in the manufacturing of paper plates among others, join us as we continue to think outside the box. Kesya International Machine Manufacturing is dedicated to leading our industry towards a better tomorrow by implementing strategies that are all about improving continuously. See what kind of machines we have today that can help your business be successful in the middle of many competitors. Whatever you need; whether it be packaging machines or processing equipment or customized types of machine that meet your specifications, behind each product is a group of people who care about you and your business. This is where success thrives within quality products with innovative approaches that keep customers satisfied – welcome aboard at Kesya International.

0 notes

Text

Techpulp, founded in 2019, has quickly established itself as a main leading within the Moulded Fibre machinery industry, known for its dedication to sustainability and advanced technology. We're proud of our careful planning and commitment to delivering excellent machinery.

At Techpulp, we mixture innovation with practicality. Our equipment is regionally designed and manufactured, making sure advanced functionality and high productiveness. We work closely with international companions to ensure smooth get admission to spare parts and extremely good assist, ensuring the seamless operation of our clients' businesses. Sustainability is essential to us—it is woven into each a part of our organisation. We’re putting new requirements in our industry with eco-friendly system that demonstrates our commitment to the surroundings. Whether or not through product format or how we operate, we purpose to lead with the aid of instance. We at Techpulp consider ourselves to be leaders in our area. We are really concerned approximately using environmentally friendly era. We constantly improve our device to satisfy the wishes of our customers. Every pulp moulding machine demonstrates our dedication to growing excessive-acting, energy-green, environmentally friendly machinery inside the effort to create a better future. Innovation drives us ahead. We’re not simply promoting machines; we are fostering a tradition of excellence. Our intention is to empower corporations to gain their production aspirations even as minimizing their environmental footprint. Whether or not you're looking for an edge trimming machine or other contemporary solutions, be part of us at Techpulp as we forge ahead in the direction of a sustainable destiny with our today's system. Allows collaborate to construct an international in which era complements productiveness and champions environmental obligation. Find out how Techpulp can remodel your commercial enterprise and lead your enterprise toward a greater sustainable and prosperous day after today.

#Pulp Moulding Machine#Pulp Molding Machine#Paper Pulp Molding Machine#Paper Pulp Molding Machine price#Pulp Moulding Machinery#Bagasse Tableware Making Machine#Bagasse tableware machine Manufacturer#Bagasse Plate Making Machine

0 notes

Text

Paper Plate Making Machines: Arya Industries

In today’s world, where eco-friendly products are gaining momentum, paper plates stand out as a practical alternative to plastic disposables. Whether for small businesses or large-scale manufacturers, investing in a high-quality paper plate making machine is crucial. Arya Industries, a renowned name in the machinery sector, offers the best solutions for this demand with its range of reliable and efficient paper plate-making machines.

Why Choose Arya Industries for Paper Plate Making Machines?

1. High-Quality Machines

Arya Industries specializes in manufacturing premium paper plate-making machines that ensure durability and excellent performance. These machines are designed using advanced technology to meet the highest quality standards, ensuring long-lasting performance with minimal maintenance.

2. Versatile Options

Arya Industries provides a variety of machines tailored to different needs, from manual to fully automatic paper plate making machines. Whether you’re a startup or an established business, Arya Industries has machines suitable for every scale of production.

3. User-Friendly Operation

The machines offered by Arya Industries are user-friendly, with easy-to-operate features that do not require advanced technical skills. Even if you are new to this business, these machines are designed to provide a smooth experience with efficient production.

4. Cost-Effective Solutions

Arya Industries provides paper plate-making machines at competitive prices. The machines are designed to deliver high output with low power consumption, making them a cost-effective choice for businesses looking to maximize profits.

5. Customization and Flexibility

The machines are available in various configurations to produce different plate sizes and designs, offering flexibility according to market demands. Arya Industries can also customize machines to meet specific requirements, helping businesses stay ahead of the competition.

Types of Paper Plate Making Machines Offered by Arya Industries

Single Die Paper Plate Machine: Ideal for small-scale production, this machine is perfect for businesses that are just starting out.

Double Die Paper Plate Machine: Designed for higher production, this machine allows the simultaneous creation of two plates, doubling your output.

Automatic Paper Plate Making Machine: For businesses looking for fully automated solutions, this machine reduces manual intervention and enhances production efficiency.

Hydraulic Paper Plate Making Machine: With robust hydraulic power, this machine is engineered for heavy-duty operations, making it ideal for large-scale production.

Why Invest in a Paper Plate Making Business?

With the growing awareness of the environmental impact of plastic products, the demand for paper plates is increasing rapidly. As a result, starting a paper plate manufacturing business has become a lucrative opportunity. By choosing Arya Industries as your machinery provider, you can ensure that your business is equipped with the most reliable and efficient machines available in the market.

Support and Services

Arya Industries is not just about selling machines; they provide complete support, from installation and training to after-sales service. Their expert team is always available to offer guidance and troubleshooting, ensuring that your production process runs smoothly without any disruptions.

Conclusion

If you’re planning to start or expand your paper plate-making business, Arya Industries is your go-to partner. With a range of high-quality, efficient, and affordable paper plate-making machines, you can trust Arya Industries to deliver the best results. Invest in the future of sustainable disposable products with Arya Industries and take your business to new heights

Visit: https://www.aryaindustries.co/

#affordablequalitymachinery#boostproductivity#nonwovenbagmakingmachineinpatna#bestmachinemanufacturingcompany#bestindustrialmachineprovider#Paper Plate Making Machines#Paper Plate Making Machines in patna

0 notes