#Packaged Water Treatment System Market size

Explore tagged Tumblr posts

Text

Middle East & Africa to be Fastest Growing Region for Packaged Water Treatment System Market Through Forecast Period| MarketsandMarkets™

Middle East & Africa to be Fastest Growing Region for Packaged Water Treatment System Market Through Forecast Period| MarketsandMarkets™

The report “Packaged Water Treatment System Market by Technology Type (Extended Aeration, MBR, MBBR, SBR, Reverse Osmosis), Application (Municipal Wastewater, Industrial Wastewater, and Drinking Water) and Region – Global Forecast to 2021”, The global packaged water treatment system market was valued at USD 12.07 Billion in 2015, and is projected to reach USD 21.83 Billion by 2021, at a CAGR of…

View On WordPress

#COVID-19 Impact on Packaged Water Treatment System Market#Global Packaged Water Treatment System Market#package plant wastewater treatment#package wastewater treatment plant#package water treatment plant#packaged sewage treatment plant#packaged waste water treatment plants#packaged wastewater treatment system#Packaged Water Treatment System#Packaged Water Treatment System Demand#Packaged Water Treatment System Market#Packaged Water Treatment System Market Forecast#Packaged Water Treatment System Market Share#Packaged Water Treatment System Market size#small package treatment plant#wastewater package plant

0 notes

Text

Find the best Compact Sewage Treatment Plant(STP) Manufacturer in India ?

With its headquarters located in Greater Noida, Netsol Water is the largest as well as the leading manufacturer of compact sewage treatment plants in India.

Contemporary Compact STP may be put above ground or below ground & is compact in size. Its small & original designs are visually appealing & need very little room to install. Because Compact STP produces no noise & has no smell, you may place it wherever is most convenient for you.

Manufactured & supplied by Netsol Water Gr. Noida, Delhi NCR, India. Netsol Water Compact Sewage Treatment Plants are prefabricated systems that are given to the client ready for plug & play installation.

Small Sewage & Wastewater treatment facilities from Netsol Water, as well as other comparable products, have received international certification according to the highest criteria. The systems are supplied with UV(UltraViolet) tertiary handling units & phosphorous elimination/removal kits. They are packed in cylindrical Poly-Propylene containers/chambers, which are utilized as thermoplastic molding materials.

Essential Elements of a Compact STP(Sewage Treatment Plant):

Complies with all regulatory standards

Does not require an operator i.e., not manually but completely automated.

Re-utilizing treated water for gardening

Up-to-date, packaged STP Underground installation is possible;

Modern Compact STP(Sewage Treatment Plant) saves up to 75% on energy costs;

Sand & charcoal filters are not required

Below Organized are the finest Leading Manufacturers in India for the best Compact STP(Sewage Treatment Plant):

NETSOL WATER

Netsol Water provides solutions for a wide range of sectors, with a focus on water-wastewater, compact STPs(Sewage Treatment Plants), ETPs(Effluent Treatment Processes), separation, & water filtering.

Netsol Water is the best compact sewage treatment plant manufacturer in India.

The greatest waste & Wastewater Treatment solution is offered by NETSOL WATER, a top manufacturer of Compact STPs(Sewage Treatment Plants). One of the most trustworthy waste management partners is Netsol Water.

Engineered design, fabrication, mounting/installation, & maintenance/repairing services are offered by integrated service providers working in Netsol Water.

Their goal is to increase the viability of waste management systems globally in terms of economics, environmental sustainability, & energy efficiency in order to address issues related to population growth, industrialization, & climate change.

Their personalized & project-based approach has helped them carve-out a position in the current waste-management market. This technique enables them to provide comprehensive & efficient solutions to their clients' distinct & dynamic/fluctuating demands .

Netsol Water guarantees/promises complete partner & customer satisfaction by utilizing this comprehensive approach evaluation to provide customized industrial solutions.

COMPACT STP

The firm/company that manufactures Compact STP plants is recognized as the most reliable & well-established supplier partner in the water & wastewater treatment sector.

STP(SEWAGE TREATMENT PLANT) MANUFACTURER

When an individual in India thinks of a high-end most sophisticated WTP(Water Treatment Plant) as well as a consultancy service , their brand name quickly comes to mind .

This is because the world has noticed & acknowledged its looming expertize as the most enthusiastic/passionate business-ignited organization delivering an array or spectrum of superior products-machinery & services involving solutions for water treatment , WasteWater handling/management & treatment , & much more since the year 2012.

URBAN STP Plant

Established in 2012 under the umbrella of Netsol Water, Urban STP Plant focuses as well as concentrates on the engineering design of recreational/swimming pool filtration systems as well as the manufacturing, vending, trading/exporting, & servicing as well as maintenance & repair of WasteWater & Compact STPs(Sewage Treatment Plants). Their motto has always been perfection , so they've created a product collection lined as CETPs(Common Effluent Treatment Plants)(Food & Beverages Industry) , Effluent Treatment Plants(Automotive, Paper & other Industries) , Compact STPs(Sewage Treatment Plants) (Industrial & Commercial Both) , & so on forth , Reverse Osmosis Systems

You can also read : Find The Best Sewage Treatment Plant Manufacturer in India

#netsolwater#commercial ro plant#industrial ro plant manufacturers#industrial ro plant#effluent treatment plant#sewage treatment plant manufacturer#compact stp manufacturer

2 notes

·

View notes

Link

0 notes

Text

Sludge Dewatering Equipment Market

Sludge Dewatering Equipment Market Size, Share, Trends: Alfa Laval Leads

Stringent Environmental Regulations Driving Adoption and Market Growth

Market Overview:

The global sludge dewatering equipment market is set for robust growth, projected to expand at a CAGR of 6.3% from 2024 to 2031. The market is expected to reach a value of USD 7.2 billion by 2031, up from USD 4.4 billion in 2024. The Asia-Pacific region leads the market, holding 42% of the global share in 2024. This dominance is driven by rapid urbanization, significant investments in wastewater treatment infrastructure, and stringent environmental regulations. The market's steady growth is a reflection of the increasing demand for efficient sludge management solutions, heightened awareness about water conservation, and the necessity to comply with environmental regulations.

DOWNLOAD FREE SAMPLE

Market Trends:

One major trend is the growing demand for sustainable packaging solutions. As environmental concerns and consumer preferences shift, the market is moving towards eco-friendly packaging options. Metallized films provide a more sustainable alternative to traditional aluminum foil laminates, requiring less material and being recyclable. This trend drives market players to innovate and develop eco-friendly metallized films, collaborating across the value chain to enhance the recyclability of flexible packaging.

Market Segmentation:

The belt filter press segment dominates the global sludge dewatering equipment market, expected to maintain its lead through the forecast period. Belt filter presses are highly efficient and continuous in operation, capable of handling large volumes of sludge, making them a preferred choice in municipal and industrial sludge dewatering. In 2024, the belt filter press segment accounted for more than YY% of the global market. The demand for cost-effective and reliable sludge dewatering solutions continues to drive this segment's growth.

Belt filter presses typically achieve 25-35% dry solids content in the final dewatered sludge, which is a 2-3% improvement over other technologies like centrifuges. Modern belt filter presses can handle sludge volumes ranging from 5 m³/hour for small units to 180 m³/hour for large industrial applications. They consume approximately 0.5-1.5 kWh of energy per cubic meter of sludge processed, 20-30% less than some alternative technologies. Additionally, the capital cost for a belt filter press system is estimated to be 15-25% lower than comparable centrifuge systems, contributing to their market dominance.

Market Key Players:

Prominent players in the sludge dewatering equipment market include Alfa Laval, Andritz AG, Veolia Water Technologies, SUEZ, Huber SE, and Hitachi Zosen Corporation. These companies are leading the market with their innovative approaches, extensive product portfolios, and global distribution networks, continuously setting industry standards and driving market growth.

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

Mineral Water Plant Machine: The Key to Success in the Mineral Water Business

The demand for clean, safe drinking water has grown exponentially in recent years, making the mineral water business one of the most lucrative ventures in the beverage industry. Setting up a mineral water plant machine is the cornerstone of this thriving industry. From purification to packaging, these machines are designed to handle every aspect of the production process efficiently and effectively.

Understanding Mineral Water Plant Machines

A mineral water plant machine is a comprehensive system used to produce bottled water. It encompasses several processes, including water purification, mineralization, bottling, and packaging. The primary aim is to ensure that the water meets stringent quality standards and is safe for consumption.

These machines are available in various capacities, catering to businesses of all sizes. Whether starting on a small scale or aiming for large-scale production, there is a mineral water plant machine tailored to your needs. The components typically include:

Water Treatment System: Removes impurities, contaminants, and harmful microorganisms.

Mineral Injection Unit: Adds essential minerals to the purified water.

Bottle Washing and Filling Machine: Ensures hygienic filling of water into bottles.

Capping and Sealing Machine: Secures the bottles with tamper-proof caps.

Labeling and Packaging Unit: Prepares the bottles for distribution.

Why Invest in a Mineral Water Plant Machine?

High Demand: The need for clean drinking water is universal, ensuring a steady demand.

Profitability: With low production costs and high market demand, the mineral water business offers attractive profit margins.

Scalability: Mineral water plant machines are versatile and can scale as your business grows.

Regulatory Compliance: Modern machines adhere to strict quality standards, ensuring health and safety regulations compliance.

Steps to Start Your Mineral Water Business

Market Research: Understand the demand, competition, and pricing in your target market.

Business Plan: Outline your goals, investment, and operational strategies.

Licenses and Permits: Obtain necessary permissions from local authorities.

Choose the Right Machine: Invest in a reliable mineral water plant machine that suits your production needs.

Set Up the Plant: Install the machinery, ensuring a clean and hygienic production environment.

Launch and Market: Use effective marketing strategies to promote your brand and reach your audience.

Reliable Mineral Water Plant Machines from Experts

If you are looking for high-quality machines and guidance for your mineral water business, mineralwaterbusiness.com is your go-to resource. They offer a wide range of machines and comprehensive support to help you establish and grow your business. From technical specifications to cost-effective solutions, their expertise ensures that your venture is set up for success.

Contact Details: For more information, expert advice, and product details, visit https://mineralwaterbusiness.com/. Their dedicated team is ready to assist you with every step of the process.

Conclusion

The mineral water business is a promising opportunity in today’s market, and a high-quality mineral water plant machine is integral to success. By investing in the right machinery and leveraging expert guidance from trusted sources like mineralwaterbusiness.com, you can establish a thriving enterprise that meets the growing demand for clean drinking water.

0 notes

Text

The AAC Block Plant Manufacturing Unit

In the quest for sustainable and efficient building materials, Autoclaved Aerated Concrete (AAC) blocks have emerged as a preferred choice across the globe. With their lightweight nature, excellent thermal insulation, and eco-friendly properties, AAC blocks are transforming the construction landscape. At the heart of this revolution are AAC block plant manufacturing units, which play a crucial role in producing these innovative materials. This article explores the significance of AAC block plants, their manufacturing processes, benefits, and their impact on the construction industry.

What Are AAC Blocks?

AAC blocks are precast, lightweight concrete blocks made from a mixture of cement, lime, water, and an expanding agent, usually aluminum powder. This combination undergoes a unique curing process in an autoclave, which gives AAC blocks their distinctive properties, such as superior insulation, fire resistance, and soundproofing. These blocks are ideal for various applications, including residential buildings, commercial complexes, and industrial structures.

The Structure of an AAC Block Plant Manufacturing Unit

An AAC block plant is designed to automate the production of AAC blocks, ensuring efficiency and quality. Key components of an AAC block manufacturing unit include:

Raw Material StorageThe plant begins with storage facilities for essential raw materials, including cement, lime, fly ash, water, and aluminum powder. Proper storage ensures material quality and easy access during production.

Mixing StationIn this phase, the raw materials are carefully measured and mixed to create a homogeneous slurry. The mixing station is critical for achieving the desired properties of the AAC blocks.

Molding SystemThe mixed slurry is poured into molds to shape the blocks. Automated molding systems enhance precision and consistency, producing uniform blocks that meet construction standards.

Cutting EquipmentAfter the blocks are formed, they are cut to specific dimensions using specialized cutting machines. This step ensures that each block is uniform in size, which is crucial for effective construction.

Curing ChamberThe blocks are then placed in an autoclave for high-pressure steam curing. This process not only strengthens the blocks but also enhances their thermal and fire-resistant properties.

Finishing and PackagingOnce cured, the blocks undergo finishing processes, which may include trimming and surface treatment. Finally, the blocks are packaged for transportation, ready to be delivered to construction sites.

Advantages of AAC Block Plant Manufacturing Units

High EfficiencyAutomated processes within AAC block plants significantly increase production capacity, enabling manufacturers to meet the rising demand for AAC blocks in the construction sector.

Quality ControlThe integration of advanced technology ensures that each stage of production adheres to stringent quality standards. Consistency in size, shape, and strength is maintained, which is essential for structural integrity.

Cost-EffectivenessThe lightweight nature of AAC blocks translates to lower transportation costs and reduced labor expenses during installation. Additionally, the energy efficiency of buildings constructed with AAC blocks leads to long-term savings.

Versatile ApplicationsThe versatility of AAC blocks allows them to be used in a variety of applications, from residential homes to commercial buildings and industrial facilities. This adaptability enhances the market potential for AAC block plants.

The Impact on the Construction Industry

As the construction industry in India and worldwide shifts towards sustainable practices, AAC block manufacturing units are becoming increasingly important. Government initiatives promoting green building materials and energy-efficient construction methods are driving the adoption of AAC blocks.

With urbanization on the rise, the demand for efficient building solutions is escalating. AAC block plants are positioned to meet this demand, providing high-quality, eco-friendly materials that align with contemporary construction standards.

Conclusion

The establishment of AAC block plant manufacturing units represents a significant advancement in the construction industry, offering a sustainable, efficient, and high-quality alternative to traditional building materials. As AAC blocks gain traction for their numerous benefits, these manufacturing units are set to play a pivotal role in shaping the future of construction. By harnessing innovative technology and eco-friendly practices, AAC block plants are not just responding to current market demands they are paving the way for a more sustainable and resilient built environment.

0 notes

Text

Portable Water Purifiers Market - Forecast(2024–2030)

Portable Water Purifiers Market Overview

The Portable Water Purifiers Market size is estimated to reach $182.4 million by 2027, growing at a CAGR of 10.1% during the forecast period 2022–2027. Portable water purification devices like portable water purifiers are self-included, effortlessly transported units utilized to purify water from untreated sources (like rivers, lakes and wells) for #drinking purposes. The Portable #water #purifiers frequently remove pathogens, suspended solids and certain toxic compounds. A pitcher filter functions like a water dispensary. A pitcher filter is a device planned to filter drinking water. Water is poured into the filter and cleaner water accumulates in the tank. In the #filtration procedure, impurities and contaminants are eliminated to supply water that is safe and healthy. In addition, filtered water frequently tastes a lot better. Gravity filters weigh less than the #pump filters and therefore are thought to be more portable and usable on travels or camping.

In the wild, some dirty water is taken and poured through gravity filters to obtain safe and clean water. Ultraviolet purifiers are considered to provide the most cost-effective method of safeguarding residential drinking water against biological impurities. Numerous makers market ultraviolet purifiers for residential water treatment purposes. Ultraviolet water filters or ultraviolet filters also termed UV water purifiers or UV water sterilizers are efficient systems for destroying bacteria, viruses, cysts and other living organisms that are at times discovered in drinking water. 3M has developed face-mounted filters like the 3M™ Powerflow™ Face-Mounted PAPR Filter: HEPA SP3, 20/Case.

This NIOSH-certified SP3 particulate filter assists in supplying high-efficiency respiratory safeguard in environments including particulates. The soaring application of portable water purifiers in disaster-prone areas and by military personnel, campers, hikers and workers, residing in areas with inadequate drinking water, is set to drive the Portable Water Purifiers Market. The surging inclination towards outdoor activities and the proliferating application of gravity filters while camping is set to propel the growth of the Portable Water Purifiers Industry during the forecast period 2022–2027. This represents the Portable Water Purifiers Industry Outlook.

Portable Water Purifiers Market Report Coverage

The “Portable Water Purifiers Market Report — Forecast (2022–2027)” by Industry ARC, covers an in-depth analysis of the following segments in the Portable Water Purifiers Market.

Sample Report:

by Technology: Gravity Purifier, UV Purifier and RO Purifier. by Distribution Channel: Retail Stores, Direct Sales and Online. by Geography: North America (the US, Canada and Mexico), Europe (Germany, France, the UK, Italy, Spain, Russia and the Rest of Europe), Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand and the Rest of Asia-Pacific), South America (Brazil, Argentina, Chile, Colombia and the Rest of South America) and the Rest of the World (the Middle East and Africa).

Key Takeaways

Geographically, Asia-Pacific (Portable Water Purifiers Market share) accounted for the highest revenue share in 2021 and it is poised to dominate the market over the period 2022–2027, owing to the presence of an enormous population constituting 60% of the global population and the surging application of gravity filters in the Asia-Pacific region.

Portable Water Purifiers Market growth is being driven by the increasing predominance of water-borne ailments and rising awareness regarding the intake of clean drinking water through the application of pitcher filters and gravity filters. However, the surging demand for packaged drinking water is one of the major factors hampering the growth of the Portable Water Purifiers Market.

Portable Water Purifiers Market Detailed Analysis of the Strengths, Weaknesses and Opportunities of the prominent players operating in the market would be provided in the Portable Water Purifiers Market report.

For More Details on This Report — Request for Sample

Portable Water Purifiers Market Segment Analysis — by Technology

The Portable Water Purifiers Market based on technology can be further segmented into Gravity Purifier, UV Purifiers and RO Purifiers. The RO Purifier Segment held the largest Portable Water Purifiers Market share in 2021. This growth is boosted by the increasing application of reverse osmosis for treating hard water. Carbon filtering or carbon filtration is a technique of filtering that utilizes a bed of activated carbon to eliminate contaminants from a liquid applying adsorption. The ability of RO water purifiers to eliminate toxins like lead, mercury, fluoride, arsenic and chlorine is further propelling the growth of the RO Purifier segment.

Inquiry Before:

Furthermore, the RO Purifier segment is estimated to grow with the fastest CAGR of 11.3% during the forecast period 2022–2027. This growth is driven by the amazing advantages of RO Water Purifier like safer drinking water, enhanced shower water, RO water purifier benefits to skin and hair, superior odor and taste of purified water and the affordability and effectiveness of RO Water Purifier.

Portable Water Purifiers Market Segment Analysis — by Distribution Channel

The Portable Water Purifiers Market based on distribution channels can be further segmented into Retail Stores, Direct Sales and Online. The Online Segment held the largest Portable Water Purifiers Market share in 2021. This growth is owing to the burgeoning digital literacy and surging awareness regarding e-commerce amidst the numerous end users. Portable gravity filters, pitcher filters and ultraviolet filters may be available online. The effortless accessibility of portable water purifiers on online websites at discounted rates with home delivery options is further propelling the growth of this segment.

Schedule a Call:

Furthermore, the Direct Sales segment is estimated to grow with the fastest CAGR of 11.8% during the forecast period 2022–2027. This growth is fueled by the surging application of marketing and distribution with a network of representatives or distributors included in the sale of products and services and the soaring inclination of key market players like Kent RO Limited to venture into direct sales.

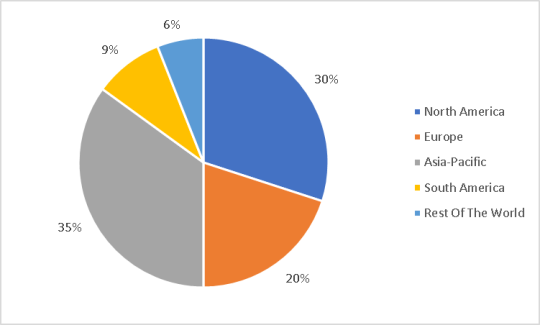

Portable Water Purifiers Market Segment Analysis — by Geography

The Portable Water Purifiers Market based on geography can be further segmented into North America, Europe, Asia-Pacific, South America and the Rest of the World. Asia-Pacific (Portable Water Purifiers Market) held the largest Portable Water Purifiers Market share with 35% of the overall market in 2021. The growth of this region is owing to the surging demand from the urban and rural regions in the Asia-Pacific region. Gravity filters and ultraviolet filters are extensively utilized. The existence of key players like Kent RO Limited in Noida, India is further propelling the growth of the Portable Water Purifiers Industry, thereby contributing to the Portable Water Purifiers Industry Outlook in the Asia-Pacific region.

Furthermore, the North American region is estimated to be the region with the fastest CAGR over the forecast period 2022–2027. This growth is owing to factors like the increasing predominance of waterborne diseases and burgeoning water pollution owing to industrial development in the North American region. The proliferating climate alterations coupled with the increasing application of gravity filters is further fuelling the progress of the Portable Water Purifiers Market in the North American region.

Portable Water Purifiers Market Drivers:

Surging Applications of Portable Water Filters are Projected to Drive the Growth of Portable Water Purifiers Market:

A portable Water Filter is either active charcoal- or an active carbon-based system that removes toxic bacteria and viruses from the water. Their principal application is to clean water observed in nature, allowing one to cook with it and drink it when one is out in the wilderness. They are also used to purify water that one consumes out of the faucets. Gravity filters are typically utilized when the turbidity and color of the influent are too great for pressure filters (turbidity more than 50 NTU and color more than 10 APHA). The mini well gravity water filter is the best portable filter to possess in whatever survival situation one may be in. The filter is effortless to utilize — no pumping or pulling on a straw — and easily eliminates nearly all of the harmful material from dirty water. This gravity filter has soaring filtration performance, is effortless to carry around, maintains healthy minerals in the water and is excellent for groups. An alkaline water filter pitcher, as compared to under-sink or faucet water filters, is a portable filtering device. To filter water prior to it coming out of the faucet, one does not require to link it to the cold-water pipe. Rather, the finest alkaline water filter pitcher filters water directly from the tap, with no installation or setup essential. Water pitchers are a good substitute for people who do not like the flavor of their tap water or wish to drink cleaner, safer water. However, do not wish to tackle the inconvenience of establishing an under-sink or other more complicated system. The surging applications of portable water filters are therefore fuelling the growth of the Portable Water Purifiers Market during the forecast period 2022–2027.

Soaring Innovations in Portable Water Purifiers are Expected to Boost the Growth of the Portable Water Purifiers Industry:

Steripen, a Katadyn sub-brand, has developed the Steripen UV technology which makes safe drinking water accessible within seconds. The ultraviolet purifiers for water or ultraviolet filters from Steripen establish the standard for quick, simple and efficient water treatment when traveling, during outdoor activities or readiness for tackling a crisis. Steripen Classic, Ultra, Ultralight, Adventure Opti and Aqua are environmentally friendly substitutes for bottled water. They eradicate viruses, bacteria and protozoa, involving Giardia and Cryptosporidium, in just 48 seconds. Throughout the world, people depend on Steripen’s portable ultraviolet purifiers and acknowledge their effectiveness and dependability. For travelers in developing nations, exposure to unsafe water can be a huge hazard. A handheld device termed the SteriPEN, marketed by a Maine-based firm named Hydro Photon, utilizes ultraviolet light to remove disease-causing microorganisms. The device applies the identical purification technology utilized by bottled-water plants. However, it has been reduced, so that it measures just 6.5 ounces (184 grams) and fits into a backpack. When stuck into a liter of stream or pond water for 90 seconds, it is safe to drink. These portable water purification systems or ultraviolet filters can eradicate bacteria, viruses and protozoa like giardia and cryptosporidium, which can cause sickness. The soaring innovations in portable water purifiers are therefore driving the growth of the Portable Water Purifiers Industry, thereby contributing to the Portable Water Purifiers Industry Outlook during the forecast period 2022–2027.

Portable Water Purifiers Market Challenge:

Limitations of Ultraviolet Filters are Hampering the Growth of the Portable Water Purifiers Market:

The Portable Water Filter bottle is an appropriate alternative for individual use only. It can store up to 20 ounces of water and guarantees hydration on the go. Additionally, it can filter out up to 99.9 percent of impurities. Ultraviolet filters have only one use which is generating microbiologically safe water. In simpler words, there is no impact of chemicals, heavy metals, volatile organic compounds, sediments, hard water issues or any other such problems. A pre-filter is a necessity with these systems. However, most ultraviolet filters (even progressive models like the Luminor Blackcomb 5.0 UV System) appear without any pre- or post-filters. This is principally owing to the fact that consumers have different kinds of filtration requirements and filter cartridges can alter extensively relying on every specific requirement. These issues are thus hampering the growth of the Portable Water Purifiers Market.

Buy Now:

Portable Water Purifiers Industry Outlook

Novel product launches, agreements, mergers and acquisitions, collaborations, partnerships and R&D activities are key strategies adopted by players in the Portable Water Purifiers Market. The top 10 companies in the Portable Water Purifiers market are:

Kent RO limited

GE Corporation

Best Water Technology

Whirlpool Corporation

SteriPEN

General Ecology Inc.

Blue Spring Corporation

Vestergaard

Portable Aqua

Aquasana Inc.

Recent Developments

In April 2022, Bluewater introduced pioneering premium residential and commercial water purifiers. Bluewater recently introduced its market-leading solutions across the UAE and GCC region at an integrated press event and water symposium in the Swedish Pavilion at Expo 2020 Dubai. The event was attended by leading local dignitaries inclusive of Mr. Nasser Mohd Hussain bin Lootah, EVP, Generation (P&W), Dubai Electricity & Water Authority (DEWA), business people from the Horeca industry and a greater count of regional media.

In October 2021, LG Electronics introduced novel 2021 series of water purifiers and Charcoal Microwave Ovens in India. The firm stated that the latest entrants in LG’s health and hygiene portfolio had been thoughtfully planned to assist consumers to live a healthier lifestyle. The novel series of water purifiers were accessible in three models WW184EPB, WW184EPC and WW174NPC, beginning at Rs 28,290.

In September 2020, water heating and treatment leader AO Smith India Water Products Pvt Ltd declared the inclusion of the ‘ProPlanet’ series, the nation’s earliest 5-star-rated water purifiers in terms of water savings, as per the firm in a press release. The ProPlanet water purifiers were outfitted with reverse osmosis (RO) and Silver Charged Membrane Technology (SCMT) that offered 100% RO-purified, baby-safe water, utilizing an 8-stage purification process, it included.

For more Consumer Products and Services Market reports, please click here

0 notes

Text

Calcium Lactate Manufacturing Plant Project Report 2024: Setup and Cost

Introduction

Calcium lactate, a calcium salt of lactic acid, is widely used as a dietary supplement and in various industrial applications. It serves as a vital source of calcium for nutritional products, food fortification, and pharmaceuticals. With increasing awareness about calcium's role in health and nutrition, the demand for calcium lactate is on the rise. The Calcium Lactate Manufacturing Plant Project Report is designed to provide a detailed overview of the steps involved in setting up a manufacturing plant for calcium lactate, including market potential, plant design, technology, and financial considerations. This guide aims to be informative for potential investors, industry professionals, and anyone interested in the manufacturing process of this essential compound.

Market Analysis

Demand and Applications

Calcium lactate is utilized in various sectors:

Nutritional Supplements: It's a common ingredient in dietary supplements aimed at preventing calcium deficiency and promoting bone health.

Food and Beverage Industry: Used as a food additive, it enhances the nutritional content of products and improves texture and stability.

Pharmaceuticals: Employed in certain medications and as a stabilizer in pharmaceutical formulations.

Cosmetics: Acts as a stabilizer and pH regulator in cosmetic products.

The demand for calcium lactate is growing globally, driven by increasing health awareness and the need for dietary supplements. This growth presents a promising opportunity for new manufacturing ventures.

Get a Free Sample Report with Table of Contents @

https://www.expertmarketresearch.com/prefeasibility-reports/calcium-lactate-manufacturing-plant-project-report/requestsample

Competitive Landscape

The market for calcium lactate includes several established players, but it remains open for new entrants. Companies that can offer high-quality products at competitive prices, coupled with efficient production processes, are well-positioned to capture market share. Innovations in production technology and effective marketing strategies are key to gaining a competitive edge.

Plant Design and Technology

Plant Capacity and Layout

A calcium lactate manufacturing plant can be designed to accommodate various production capacities, ranging from small to large-scale operations. The layout typically includes:

Raw Material Storage: Facilities for storing lactic acid and calcium carbonate, the primary raw materials.

Reaction Chamber: Where lactic acid and calcium carbonate react to produce calcium lactate.

Filtration and Crystallization: Processes to purify and crystallize the calcium lactate.

Drying and Packaging: After crystallization, the product is dried and packaged for distribution.

Quality Control: An area dedicated to testing the product to ensure it meets the required standards.

Utility and Support Systems: Includes systems for water treatment, waste management, and other necessary utilities.

Production Technology

The production of calcium lactate involves a straightforward chemical reaction:

Preparation: Lactic acid and calcium carbonate solutions are prepared.

Reaction: These solutions are mixed in a reaction chamber. The reaction produces calcium lactate and carbon dioxide as a by-product.

Filtration: The mixture is filtered to remove any impurities.

Crystallization: Calcium lactate is crystallized from the solution.

Drying: The crystals are dried to obtain the final product.

Packaging: The dried calcium lactate is packaged for shipment.

Modern plants use advanced technologies to enhance efficiency, product quality, and environmental sustainability. Automation and real-time monitoring systems are often employed to ensure consistent production.

Financial and Economic Considerations

Investment and Cost Analysis

Setting up a calcium lactate manufacturing plant involves various costs:

Land and Building: Costs vary depending on location and plant size.

Machinery and Equipment: Includes reaction vessels, filtration units, drying equipment, and packaging machines.

Raw Materials: The primary raw materials are lactic acid and calcium carbonate.

Labor: Costs for skilled and unskilled labor.

Utilities: Includes expenses for electricity, water, and waste management.

A detailed financial analysis should also consider ongoing operational costs, market pricing, and potential revenue. With careful management, a calcium lactate plant can achieve profitability within a few years.

Return on Investment (ROI)

ROI for a calcium lactate manufacturing plant depends on several factors, including production efficiency, market demand, and cost management. Effective operational strategies and optimization of production processes can significantly enhance ROI.

Regulatory and Environmental Considerations

Compliance

Manufacturing calcium lactate requires adherence to various regulations:

Health and Safety Regulations: Ensuring safe handling of chemicals and protecting worker health.

Environmental Regulations: Managing waste and emissions to minimize environmental impact.

Product Standards: Complying with quality standards to meet market requirements.

Environmental Impact

Calcium lactate production is relatively environmentally friendly compared to some other chemical processes. However, managing waste and ensuring proper disposal of by-products are essential to minimize environmental impact.

FAQs

What is calcium lactate used for?

Calcium lactate is used primarily as a dietary supplement to prevent calcium deficiency. It is also employed in the food and beverage industry, pharmaceuticals, and cosmetics for its stabilizing and fortifying properties.

How is calcium lactate manufactured?

Calcium lactate is manufactured by reacting lactic acid with calcium carbonate. The reaction produces calcium lactate and carbon dioxide. The mixture is then filtered, crystallized, dried, and packaged.

What are the key considerations when setting up a calcium lactate manufacturing plant?

Key considerations include market demand, plant capacity, production technology, investment costs, regulatory compliance, and environmental impact. Effective planning and management are crucial for success.

What are the environmental impacts of calcium lactate production?

Calcium lactate production is relatively low-impact, but managing waste and emissions is still necessary to minimize environmental effects. The process produces carbon dioxide as a by-product, which should be managed appropriately.

How profitable is a calcium lactate manufacturing plant?

Profitability depends on factors such as production efficiency, market demand, and cost management. With the right strategies and efficient operations, a calcium lactate plant can achieve favorable returns on investment.

Media Contact:

Company Name: Claight Corporation Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A. Email: [email protected] Toll Free Number: +1–415–325–5166 | +44–702–402–5790 Address: 30 North Gould Street, Sheridan, WY 82801, USA Website: www.expertmarketresearch.com Aus Site: https://www.expertmarketresearch.com.au

0 notes

Text

The Molecular Sieve Market is projected to grow from USD 3,902.49 million in 2023 to an estimated USD 5,705.07 million by 2032, with a compound annual growth rate (CAGR) of 4.25% from 2024 to 2032.The molecular sieve market has witnessed significant growth in recent years, driven by the increasing demand for efficient separation and purification technologies across various industries. Molecular sieves, which are porous materials with uniform pore sizes, are used extensively for applications such as gas and liquid separation, dehydration, and catalytic processes. This article explores the current state of the molecular sieve market, its trends, opportunities, and the challenges it faces.

Browse the full report at https://www.credenceresearch.com/report/molecular-sieve-market

Market Overview

The molecular sieve market is segmented based on type, application, and region. Key types of molecular sieves include zeolites, silica gels, alumina, and others. Zeolites dominate the market due to their extensive use in gas adsorption, catalytic cracking, and drying processes. Silica gels are also popular for their use in moisture control and packaging applications.

Market Trends

1. Growing Industrial Applications: Molecular sieves are crucial in various industrial processes, including petrochemicals, automotive, and pharmaceuticals. The rise in industrial activities, especially in developing economies, is driving the demand for molecular sieves. Their role in enhancing the efficiency of chemical reactions and improving product purity makes them indispensable in modern industrial operations.

2. Technological Advancements: Advances in material science and nanotechnology are leading to the development of more efficient and specialized molecular sieves. Innovations such as high-performance zeolites and tailor-made silica gels are expanding the range of applications and improving the performance of these materials. These advancements are opening new opportunities for market players and contributing to market growth.

3. Environmental Concerns: With increasing awareness of environmental issues, there is a growing demand for environmentally friendly and sustainable technologies. Molecular sieves play a significant role in reducing emissions and improving the efficiency of various processes. For instance, they are used in CO2 capture and air purification systems, aligning with global efforts to combat climate change.

4. Expansion of End-Use Industries: The molecular sieve market is benefiting from the expansion of end-use industries such as oil and gas, automotive, and healthcare. The oil and gas sector uses molecular sieves for natural gas purification and petrochemical processing. In the automotive industry, they are employed in fuel cell technologies and exhaust gas treatment. The healthcare sector uses them in drug manufacturing and water purification.

Opportunities

1. Emerging Markets: Developing regions such as Asia-Pacific, Latin America, and the Middle East are witnessing rapid industrialization and infrastructure development. This growth is driving the demand for molecular sieves in various applications. Companies that expand their presence in these emerging markets stand to benefit from increased opportunities and market potential.

2. Innovation and Product Development: Investment in research and development to create advanced molecular sieve products presents a significant opportunity for market players. Developing new types of molecular sieves with enhanced performance characteristics can lead to a competitive advantage and open up new markets.

3. Strategic Partnerships and Collaborations: Forming strategic partnerships and collaborations with other industry players can help companies expand their product offerings and reach new markets. Collaborations with research institutions and technology providers can also lead to the development of cutting-edge solutions and technologies.

Challenges

1. Raw Material Costs: The cost of raw materials used in the production of molecular sieves, such as alumina and silica, can be volatile. Fluctuations in raw material prices can impact the overall cost of production and affect profit margins. Companies need to adopt effective cost management strategies to mitigate this challenge.

2. Regulatory Compliance: Molecular sieve manufacturers must comply with various regulatory requirements and standards, which can vary by region. Ensuring compliance with environmental and safety regulations requires investment in quality control and regulatory expertise.

3. Competition: The molecular sieve market is highly competitive, with numerous players vying for market share. Companies need to continuously innovate and differentiate their products to stay ahead of competitors. Pricing pressures and market saturation can also pose challenges for new entrants.

Key players

Arkema

Axens

BASF SE

CarboTech

Clariant

Desicca Chemical Pvt. Ltd.

Hengye Inc.

Honeywell International Inc.

JIUZHOU CHEMICALS

KNT Group

Kuraray Co. Ltd

Merck KGaA

OMRON Healthcare Inc.

Palmer Holland

Resonac Holdings Corporation

Sorbead India

Tosoh Corporation

R. Grace & Co.-Conn.

Zeochem AG

Zeolyst International

Segments

Based on Shape

Pelleted

Beaded

Powdered

Based on Size

Microporous

Mesoporous

Macroporous

Based on End-User

Automotive

Cosmetics and Detergent

Oil and Gas

Pharmaceutical

Other End-User Industries

Based on Product Type

Carbon

Clay

Porous Glass

Silica Gel

Zeolite

Based on Region

North America

US

Canada

Mexico

Europe

Germany

Uk

France

Italy

Spain

Russia

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

Australia

Rest of Asia Pacific

South America

Brazil

Argentina

Rest of South America

Middle East & Africa

UAE

Saudi Arabia

Qatar

South Africa

Rest of the Middle East & Africa

Browse the full report at https://www.credenceresearch.com/report/molecular-sieve-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Building a perfect Organic Fertilizer Production Line is an effective way to realize the rapid decomposition and high-quality transformation of cattle manure. The production line integrates raw material pretreatment, mixing ratio, high temperature fermentation, granulation molding, drying and cooling, screening and packaging and other links, forming a closed-loop circular economy system. In this system, cow manure is scientifically proportionally mixed with carbon-rich organic materials such as straw, leaves, and vegetable residues to create optimal conditions for microbial activity by precisely controlling the C/N ratio.

As one of the core equipment in the organic fertilizer production line, the Fertilizer Granules Compaction Machine has a unique double-roll extrusion technology that can uniformly squeeze the mixed compost materials into granules. This process not only improves the appearance quality and market value of the product, but also promotes the further activity of internal microorganisms and accelerates the decomposition and stabilization process of organic matter. Through the Fertilizer Granules Compaction Machine treatment of organic fertilizer particles, uniform size, moderate density, easy to store, transport and use.

Composting Composting is an effective way to decompose cow dung rapidly. Create a compost pile in a well-ventilated area. Mix the cow dung with other organic materials like straw, leaves, or vegetable scraps. Turn the pile regularly to aerate it and maintain moisture levels. The composting process generates heat, which speeds up decomposition.

Balancing carbon-to-nitrogen ratio Cow dung is rich in nitrogen but lacks carbon. To facilitate faster decomposition, balance the carbon-to-nitrogen ratio in the compost pile. Add carbon-rich materials like dried leaves, sawdust, or shredded newspaper to create a balanced environment for microbial activity.

Moisture management Microorganisms responsible for decomposition require moisture to thrive. Ensure that the compost pile remains moist but not overly saturated. If the pile is too dry, add water periodically. Conversely, if it becomes too wet, mix in dry materials to improve drainage.

Temperature optimization Decomposition occurs more rapidly at higher temperatures. Aim to maintain the compost pile between 49°C to 71°C to encourage microbial activity. Insulating the pile with a layer of straw or covering it with a tarp can help retain heat.

Turning the pile Regularly turning the compost pile helps aerate it, providing oxygen to the microorganisms. Use a Compost Turning Machine to mix the materials thoroughly. Turning the pile every few days or weeks, depending on its size, will help speed up the decomposition process.

In the stage of compost fermentation, the Windrow Compost Turning Machine��plays an irreplaceable role. It can go deep into the inside of the reactor body and carry out all-round and uniform turning of the mixture of cow manure and organic materials, which effectively solves the problems of low efficiency and high labor intensity of traditional manual turning. Regular churning not only promotes the aeration inside the pile, providing sufficient oxygen for microorganisms, but also ensures the uniform distribution and stable increase of compost temperature. In the suitable temperature range (49°C to 71°C), the microbial activity was stimulated to the maximum, thus accelerating the decomposition process of cow manure.

Adding compost activators Compost activators contain beneficial microorganisms that accelerate decomposition. You can find these products at garden centers or online. Follow the instructions on the package to determine the appropriate amount to add to your compost pile.

#Organic fertilizer production line#Fertilizer Granules Compaction Machine,Windrow Compost Turning Machine

0 notes

Text

Caustic Soda Procurement Intelligence: A Deep Dive

The caustic soda category is anticipated to grow at a CAGR of 5.1% from 2023 to 2030. In 2022, the category size was estimated to be valued at USD 40.6 billion with the Asia-Pacific region's dominance as a result of a rise in raw material industrial demand for textiles, paper, and other materials as well as manufacturing hubs. The category is escalated globally, owing prominently to its intense abilities and importance across both the residential sector & industries. It is a versatile compound that finds numerous applications across different industries from primary usage in detergents, packaging, and treatment to food, chemical, and automobile. Another factor fueling the category growth is its use in processes such as, making drugs and bauxite purification. Being a primary product for many industries, demand for it remains high, whether it is for parts of EV in cars or the water treatment business. The category is also widely utilized in the extraction of bauxite, and demand for it will rise parallelly as the region's production of aluminum rises.

An increase in innovation and development in production techniques would present potential sustainable growth opportunities for the category. When compared to caustic soda generated conventionally, Vynova renewable caustic soda has a much smaller carbon footprint, as it is manufactured using renewable electricity. It makes it possible for clients in a variety of industries to produce more environmentally friendly goods. Westlake's low-carbon caustic soda, sold under the trade name GreenVin, has a lower carbon footprint by more than 30% than standard Westlake Vinnolit caustic soda. Hamwha, a leading chemical company, increases the amount of caustic soda it produces for advancing and developing the usage of elements in sustainable transportation - specifically EV production.

With numerous suppliers and producers, from large multinational chemical firms to smaller regional or local businesses, the category is highly fragmented. Due to the variety of applications in the category, there are numerous niche markets created. Each industry has its own manufacturing capacity, distribution system, and consumer. The distribution of the categories is influenced by industry demand, economic situations, legal and regulatory frameworks, and technological development. In 2022, Asia Pacific accounted for a large portion of the market. China dominates both production and demand for caustic soda, as it does with so many other chemical products. It holds around half of the world's caustic soda manufacturing capacity. Shale gas output in the US has significantly increased recently, rising category demand.

Order your copy of the Caustic Soda Procurement Intelligence Report, 2023 - 2030, published by Grand View Research, to get more details regarding day one, quick wins, portfolio analysis, key negotiation strategies of key suppliers, and low-cost/best-cost sourcing analysis

Approximately 99.5% of caustic soda consumed worldwide is produced through the conventional chlor-alkali process. Raw materials, production volume, machinery, etc. are the cost components of the category. Energy usage also accounts for a sizable amount of variable costs. Prices for caustic soda increased globally, averaging USD 769/MT in the first quarter of 2023 compared to last year’s average USD 719/MT due to factors such as supply chain disruption and rising energy costs. Sales of caustic soda increased by 17% in Q1FY23 to 278,000 tonnes, with a utilization rate of 89%. Following Russia's invasion of Ukraine, China took over the role of Russia and Ukraine as suppliers of chlor-alkali products to Europe, which resulted in shortages in the Asian domestic market and an increase in local pricing. Due to the oversaturation of the market in Europe brought on by cheap imports from China, the prices remained lower in the region.

The category can be sourced from various methods, primarily through the domestic market. Due to the simple accessibility of production's raw materials, many nations have domestic manufacturing facilities. It provides advantages like lower shipping costs, shorter lead times, and support for the local economy. As per the industry specification quality testing should be done to meet standards and requirements. Suppliers that demonstrate sustainable practices is another factor influencing sourcing intelligence.

Browse through Grand View Research’s collection of procurement intelligence studies:

Chemical Management Services Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

Plasticizers Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

Caustic Soda Procurement Intelligence Report Scope

Caustic Soda Category Growth Rate: CAGR 5.1% from 2023 to 2030

Pricing growth Outlook: 2% - 3% (annual)

Pricing Models: Spot pricing, Production and processing pricing, Quality standards pricing, Competition based pricing

Supplier Selection Scope: Cost and pricing, Past engagements, Production capacity, Supply chain and Logistics

Supplier selection criteria: Quality standards, production capacity, pricing, supply chain transparency, transportation and handling, technical specifications, operational capabilities, regulatory standards and mandates, category innovations, and others.

Report Coverage: Revenue forecast, supplier ranking, supplier matrix, emerging technology, pricing models, cost structure, competitive landscape, growth factors, trends, engagement, and operating model

Key companies

Dow Chemical Company

PPG Industries

Hanwha Chemical Corporation

INEOS Group

Solvay SA

BASF SE

FMC Corporation

Occidental Petroleum Corporation

Formosa Plastics Group

Tosoh Corporation

Brief about Pipeline by Grand View Research:

A smart and effective supply chain is essential for growth in any organization. Pipeline division at Grand View Research provides detailed insights on every aspect of supply chain, which helps in efficient procurement decisions.

Our services include (not limited to):

• Market Intelligence involving – market size and forecast, growth factors, and driving trends

• Price and Cost Intelligence – pricing models adopted for the category, total cost of ownerships

• Supplier Intelligence – rich insight on supplier landscape, and identifies suppliers who are dominating, emerging, lounging, and specializing

• Sourcing / Procurement Intelligence – best practices followed in the industry, identifying standard KPIs and SLAs, peer analysis, negotiation strategies to be utilized with the suppliers, and best suited countries for sourcing to minimize supply chain disruptions

0 notes

Text

Find The Best Commercial RO Plant Manufacturer In Faridabad ?

A particular membrane has been employed to filter contaminants whether chemical substances or any other solid materials out of water. This eliminates the salts, small particles, & additional contaminants while purging them from the water. Large commercial RO units for various commercial businesses & industries In Faridabad complete this task. We'll go further into elaborate discussion along with inspecting the commercial RO plant manufacturer In Faridabad's exact specifications.

Netsol Water is an esteemed & reputable Commercial RO Plant Manufacturer In Faridabad in this water treatment plant.

The RO Plant units that Netsol Water designs & manufactures for the commercial business market are something it is extremely confident of. The water issues in the area can be handled by our staff very easily. Groundwater often contains abnormally high levels of iron, fluoride, & sometimes arsenic. As a result, drinking the water is dangerous and may be detrimental to your health if you do it often. This is where Netsol Water's efficiently made commercial RO Plant facilities proves to be significant.

Because Netsol Water & its partner branch companies have been in this company for a long time, they have delighted & satisfied customers throughout the region. Our knowledgeable staff designs, assembles, & installs customized RO plants to meet the specific needs of our clients. Our facilities consistently utilize world-class modern, contemporary technology & its parts to offer clean, safe water.

Why Do Companies Require Commercial RO Plants?

Longer-lasting factory machinery;

Clean, safe water for cooking & drinking;

Better-tasting food & beverage items;

Complying with government regulations on water quality

Netsol Water is very talented in designing & manufacture commercial RO plants in various sizes as well types to satisfy the needs accordingly of each client:

Little plants for hotels & restaurants

Those that are medium-sized for little factories

Big systems for municipalities & huge industries

How Are RO Plants Manufactured by the Commercial RO Plant Manufacturer In Faridabad?

We employ long-lasting, high-quality materials;

Our designs conserve water as well as electricity.

Every component incorporated in the RO Plants are verified to ensure optimal best performance.

Utilization of Our Industrial RO Systems

Commercial RO Manufacturing units are flexible & fit for a variety of applications. Here are some examples of common applications of a Commercial RO Plant:

Ensuring that hotels & restaurants situated here should have clean water for cleaning, cooking, as well as drinking.

All Hospitals In Faridabad must be provided potable water for medical procedures including patient care in OPDs.

Clean drinking water should be provided to instructors & students at educational institutions.

Agriculture Fields of Faridabad is Provided by RO Plants irrigational plus clean water for animals.

The manufacturing industries for various items supply purified water for consumption in various residential as well as commercial activities.

Providing pure water in apartment buildings which belong to several residences.

Bottled water plants are those that generate high-quality packaged bottled water for sale to retailers.

Post-Sale Assistance

Just Buying a Commercial RO plant & installing is not the only benefit you can get out of it. Netsol Water also offers the following advantage through their manufactured Commercial RO Plant:

To take full advantage out of Commercial RO plant at any site, professionals at Netsol Water always available to assist you;

Experts who are trained regularly working with this firm will go through routine check-ups;

Professionals as a team working together will teach clients’ part to operate the plant;

What Makes Netsol Water the Best Option?

The integration of high-quality components in place of expansive parts lowers costs;

Netsol Water offers reasonable pricing;

The company is primarily local & knowledgeable about all types of water specific to the area;

And Netsol Water will arrive and react promptly when you require us for any assistance.

Conclusion

By offering an effective & reasonably priced solution, Commercial RO Plant Manufacturer In Faridabad is meeting the growing need for premium purified water. These commercial RO manufacturers apply these RO plant components in a variety of residential as well as commercial applications.

The manufacturer of commercial RO Plant systems promises years of reliable & efficient water filtration with the correct maintenance, upkeep, & repairs. The cost of these Commercial RO treatment plants is also reasonably & relatively affordable. One of the top producers of commercial RO plants in the country, Netsol Water helps to provide the best discounts if you're searching to get the best commercial RO plants at the lowest possible cost.

#commercial ro plant#commercial ro plant manufacturer in faridabad#water is life#water treatment plant#save water save life

0 notes

Link

0 notes

Text

Advanced Ceramics Market Developments, Trends & Opportunities till 2032

Advanced Ceramics Market provides in-depth analysis of the market state of Advanced Ceramics manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Advanced Ceramics in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Advanced Ceramics Market Report:

The report offers a comprehensive and broad perspective on the global Advanced Ceramics Market.

The market statistics represented in different Advanced Ceramics segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Advanced Ceramics are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Advanced Ceramics.

Major stakeholders, key companies Advanced Ceramics, investment feasibility and new market entrants study is offered.

Development scope of Advanced Ceramics in each market segment is covered in this report. The macro and micro-economic factors affecting the Advanced Ceramics Market

Advancement is elaborated in this report. The upstream and downstream components of Advanced Ceramics and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/advanced-ceramics-market-100587

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Hydrogenated Bisphenol A MarketMarket Share

Analgesics MarketMarket Growth Rate

Water Free Urinals MarketMarket Forecast

Global Microbial Air Samplers MarketMarket Size

Nausea And Vomiting Treatment MarketMarket Growth

Electronic Document Management System MarketMarket Analysis

Pharmaceutical Grade Phycocyanin MarketMarket Size

Global Carbon Management Software MarketMarket Share

Global Irreversible Electroporation Ablators MarketMarket Growth

Drainage Catheter MarketMarket

Artificial Intelligence Software MarketMarket Share

Frozen Pizza MarketMarket Growth Rate

Environment Management, Compliance and Due Diligence MarketMarket Forecast

Global Smart Wireless Propane Tank Meter MarketMarket Size

Hospitality MarketMarket Growth

Music Streaming Subscription Service MarketMarket Analysis

Paper Cushion System MarketMarket Size

Global Payment Orchestration MarketMarket Share

Global App Store Optimization ASO Tools MarketMarket Growth

Geographic Information System (GIS) Software MarketMarket

Vanadium MarketMarket Share

Ceramic Packages MarketMarket Growth Rate

EV Motor Controller MarketMarket Forecast

Global Machine Vision and Vision Guided Robotics MarketMarket Size

PolyDADMAC MarketMarket Growth

Plastic Foldable Chair MarketMarket Analysis

Healthcare Provider Network Management MarketMarket Size

Global Formwork Panels MarketMarket Share

Global Stabilizers Used in Antibody Drugs and Vaccines MarketMarket Growth

Intelligent Flow Meter MarketMarket

Orthopedic Orthotics MarketMarket Share

Aquarium MarketMarket Growth Rate

Dextranase MarketMarket Forecast

Global Vehicle Retarder MarketMarket Size

Laminate Wood Flooring MarketMarket Growth

Sintering Furnace Powder Metallurgy marketMarket Analysis

Condensate Polishing Device MarketMarket Size

Global High Voltage Divider MarketMarket Share

Global Professional Makeup Cases MarketMarket Growth

Membrane Chromatography MarketMarket

0 notes

Text

The Essential Guide to Mineral Water Machinery and Mineral Water Plants

The demand for clean and safe drinking water has skyrocketed in today's fast-paced world. This has led to a significant increase in the production and consumption of packaged mineral water. To meet this demand, businesses rely heavily on advanced mineral water machinery and the establishment of efficient mineral water plants. These components are pivotal in ensuring consumers' consistent supply of high-quality mineral water.

What Is Mineral Water Machinery?

Mineral water machinery refers to the specialized equipment used in purifying, bottling, and packaging mineral water. This machinery is designed to handle a variety of processes, from water purification to filling and labeling bottles. It plays a critical role in maintaining the purity and hygiene of the water, ensuring it meets regulatory standards.

Key Components of Mineral Water Machinery:

Water Treatment SystemsThese systems remove impurities and contaminants from raw water. They include filtration units, reverse osmosis (RO) systems, and UV sterilizers to ensure the water is safe for consumption.

Bottling MachinesBottling machines are used to fill purified water into bottles of various sizes. These machines operate at high speeds and are equipped with features to prevent contamination during the bottling process.

Labeling and Packaging EquipmentAfter the water is bottled, labeling and packaging machinery ensure the bottles are ready for distribution. Labels typically include brand details, nutritional information, and manufacturing dates.

Quality Control SystemsAdvanced mineral water machinery often includes automated quality control systems. These systems check for any inconsistencies in the production process, ensuring that only the best quality water reaches consumers.

What Is a Mineral Water Plant?

A mineral water plant is a facility where mineral water is processed, bottled, and packaged. It integrates various types of mineral water machinery to create a seamless production line. The primary objective of a mineral water business is to ensure a consistent supply of high-quality mineral water that adheres to strict hygiene and safety standards.

Setting Up a Mineral Water Plant:

Site Selection and Layout PlanningThe first step is choosing a suitable location for the plant, considering factors like water source availability, transportation accessibility, and compliance with local regulations.

Procurement of Mineral Water MachineryThe selection of machinery depends on the production capacity and specific requirements of the plant. High-quality machinery ensures efficient operations and reduces maintenance costs.

Water Source and Quality TestingThe plant must have access to a reliable water source. Comprehensive testing is conducted to determine the treatment processes required to meet quality standards.

Installation and CommissioningAfter the machinery is procured, it is installed and tested to ensure smooth operations. This phase also includes staff training on the use and maintenance of the equipment.

Regulatory ComplianceThe plant must comply with local and international standards for water quality, hygiene, and safety. Certifications from regulatory bodies are essential for the legal operation of the plant.

Benefits of Investing in Mineral Water Machinery and Plants:

Ensured Water QualityAdvanced machinery guarantees that the water is free from contaminants, making it safe and healthy for consumption.

Cost-Effective ProductionAutomated processes reduce labor costs and increase production efficiency, resulting in cost savings for the business.

ScalabilityMineral water plants can be designed to meet varying production capacities, allowing businesses to scale operations as demand grows.

Brand ReputationConsistently delivering high-quality products helps businesses build trust and a strong reputation in the market.

Conclusion

The increasing demand for packaged mineral water presents a lucrative opportunity for businesses in the beverage industry. Investing in state-of-the-art mineral water machinery and setting up a well-designed mineral water plant is essential for meeting consumer expectations and maintaining competitiveness in the market. By prioritizing quality, efficiency, and compliance, businesses can achieve long-term success in this thriving industry.

0 notes

Text

Top Water Brands in India: A Comprehensive Guide

Life depends on water, and as worries about water quality grow, many households and travelers in India rely on packaged drinking water. Clean and safe drinking water is vital for daily use, travel, and special events. This article explores the leading water brands in India, highlighting their distinct products and explaining why they excel in the competitive market.

Bisleri: The Pioneer of Packaged Drinking Water

Bisleri is frequently the initial brand that comes to mind when considering packaged drinking water brands in India. Established in 1969, Bisleri has become a symbol of reliability and purity. Stringent quality control measures are in place to ensure the safety of every bottle of Bisleri water. Bisleri is available in various sizes, ranging from small 250ml bottles to large 20-liter jars, to meet every requirement. The brand's dedication to delivering clean water has made it a well-known name throughout the country.

Aquafina: Purity Guaranteed

PepsiCo owns Aquafina, which is a top mineral water brand in India. Aquafina is famous for its refreshing taste and thorough purification process, guaranteeing that every drop is impurities-free. The water undergoes a seven-step purification process, which includes reverse osmosis and ozonation, ensuring its high safety standards. Aquafina's widespread availability and unwavering quality have made it a favored option for consumers.

Kinley: Trustworthy and Reliable

Kinley, a prominent contender in the Indian packaged drinking water industry, is a significant part of Coca-Cola. With its slogan "Boond Boond Mein Vishwas," meaning "Trust in every drop," Kinley highlights its dedication to purity. The brand utilizes a thorough purification method involving reverse osmosis, UV filtration, and ozonization. Kinley's well-balanced mineral content guarantees a delightful flavor, establishing it as a popular option for numerous consumers.

Himalaya: Natural Mineral Water

Himalaya is a great option for individuals who favor natural mineral water. It originates from the pure Himalayan springs and undergoes natural filtration through rock layers, resulting in a special mineral composition. The water contains important minerals such as calcium and magnesium, which are responsible for its unique flavor and health advantages. For those looking for a high-quality and natural way to stay hydrated, Himalaya mineral water is an excellent selection.

Bailley: Purity and Affordability

Bailley, produced by Parle Agro, blends purity with cost-effectiveness. With a strong distribution system, Bailley water is easily accessible even in the most remote areas of India. The water goes through a rigorous purification process to meet global standards, establishing it as a dependable option for daily use. Bailley’s accessibility and cost-effectiveness have made it popular among budget-conscious consumers.

Clear Premium Water: The Rising Star

Clear Premium Water is rapidly becoming well-liked due to its exceptional quality and delightful taste. The brand is dedicated to providing its consumers with pure, fresh, and mineral-enriched water. Clear Premium Water undergoes rigorous purification processes, such as microfiltration and UV treatment, to ensure it adheres to the most stringent safety standards. Its elegant packaging and top-notch quality make it the preferred choice for individuals who refuse to compromise on the quality of their water.

Clear Pani prioritises offering affordable, safe, and clean drinking water, particularly targeting rural and semi-urban areas to ensure access to safe drinking water for everyone. The advanced filtration technologies used in Clear Pani's thorough purification process guarantee the removal of harmful contaminants from the water. Clear Pani has built a loyal customer base due to its commitment to making safe water accessible to all.

Conclusion

The demand for safe and clean drinking water continues to rise in a country as diverse as India. From established giants like Bisleri and Aquafina to emerging brands like Clear Premium Water, the market offers a variety of choices to suit different needs and preferences. Whether you’re looking for the trusted quality of Kinley, the natural purity of Himalaya, or the affordability of Bailey, there's a brand to match every requirement. Ensuring access to safe drinking water is crucial, and these top water brands in India are dedicated to meeting this essential need.

0 notes